#cone pieces australia

Explore tagged Tumblr posts

Text

Shop The Luxurious And Premium Bongs Online Australia

Bongs are water pipes used cool and filter the Smoke produced by a heated mixture of herbs and tobacco. They are getting ready with a simple design: a bowl where the herb is placed, attached to a stem that leads to an air chamber equipped with a mouthpiece or port. The bottom of the section fills with water, so when you take a hit from your bong, you inhale the Smoke that filters by the water. The water cools the Smoke and filters out any lingering particles. The shape of the bong also makes it easier to inhale more extensive amounts of Smoke with each hit because there is more room for it in your lungs.

People use bongs for water filtration or to cool Smoke. Various styles exist, from cheap and simple homemade wooden pipe to large, elaborate glass pieces that require ice cubes. Some people will prefer different types of bongs depending on the materials they want on their bodies, while others want a specific, straightforward device with no fancy parts. You can also find Bongs Online Australia at very reasonable prices.

There are many different types of bongs, but the main ones are:

-Basic Bong: This type is the most common and comes in many sizes. It is a straight glass pipe with a bowl at one end and a mouthpiece at the other. The Smoke travels through water and gets cooled as it goes.

-Double Chamber Bong: This type has two chambers separated by either a cube of ice not or a percolator.

-Beaker Bong: This type has a large base that looks like a beaker and gets ready with glass or acrylic. It is often colour-coded so that you can tell how much water to add depending on your smoking preference.

-Waterfall Bong: This type is similar to the basic bong, but it has an extra chamber above the main one where Smoke can get filtered through more water before inhaling.

Get ready to experience the ultimate smoking pleasure with Creative Smoke! Their collection includes a variety of sizes and shapes so you can find the best fit for your needs. Plus, their products are all made from high-grade materials, ensuring durability and reliability. They understand that bongs are one of the best ways to enjoy your smoking experience. With the advent of technology and the ever-changing lifestyle, modern smokers like you have a great choice of bongs. Check out their collection today and enjoy the best Bongs Australia.

#online smoke shop australia#buy cone piece#flavoured rolling papers near me#ceramic bongs australia#cone pieces australia#bong shop australia#glass bongs australia#liquid nicotine australia#buy vapes online australia#buy vapes online#cheap bongs online#vape starter kit#glass bongs online

1 note

·

View note

Text

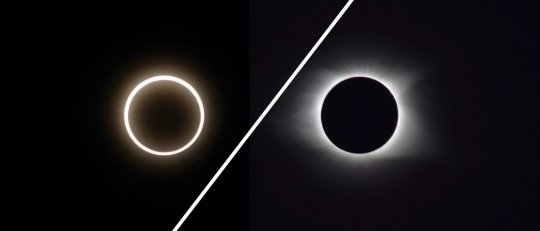

Get Ready for a Hybrid Solar Eclipse (total and annular combined)

On April 20, parts of the Pacific and Indian Ocean regions will experience a rare type of event called a hybrid solar eclipse.

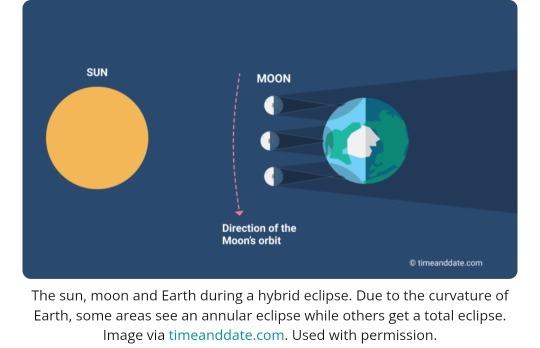

Hybrid solar eclipses shift from total to annular as the moon's shadow races over Earth; in some places, the moon completely blots out the sun, whereas in others a ring of light is visible around the edge of our natural satellite. These eclipses are quite rare, occurring just a few times every century — and one will grace our planet's skies less than two weeks from now.

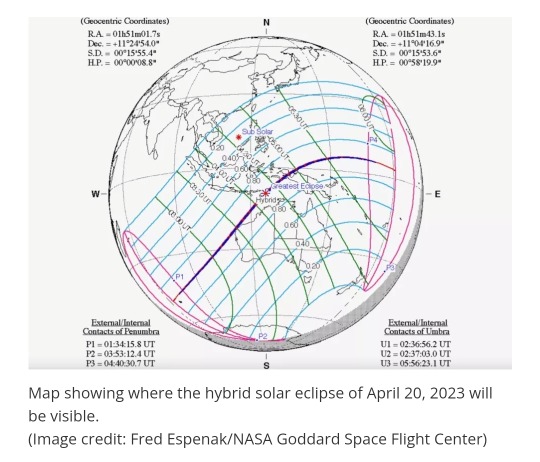

While not observable from the U.S., the hybrid eclipse will be visible from western Australia, East Timor, and eastern Indonesia beginning at 21:36 EDT on April 19 (0136 GMT on April 20) and ending at 2:59 a.m. EDT (0659 GMT) on the following day, according to In the Sky. (It will be April 20 in those regions where the eclipse is visible.)

Some skywatchers in this region will be treated to a total solar eclipse, whereas others will see a "ring of fire" annular eclipse. Still, others will witness a partial solar eclipse, with the moon taking a bite out of a portion of the sun.

There are two points on Earth where the eclipse will transition from annular to total to annular again. However, those two spots are remote locales in the middle of the ocean, Space.com’s Jamie Carter pointed out in an explainer about the April 20 hybrid eclipse.

This hybrid eclipse will appear as a total or annular solar eclipse when viewed from Western Australia from 10:29 p.m. to 10:35 p.m. EDT on April 19 (0229 to 0235 GMT on April 20), in East Timor from 11:19 p.m. to 11:22 p.m. EDT (0319 to 0322 GMT) and in Indonesia from 11:23 p.m. to 11:58 p.m. EDT (0323 to 0358 GMT).

The celestial event will appear as a partial eclipse from many more countries, including the French Southern Territories, where 93% of the sun will be eclipsed; Papua New Guinea, where 87% of the sun will be blocked; and the Marshall Islands, where 95% of the sun’s disk will be covered by the moon, according to In the Sky.

Hybrid eclipses happen due to the fact that Earth is curved and the moon’s shadow has different regions, particularly a darker central region known as the umbra and a lighter outer region, the penumbra. Hybrid eclipses occur when the moon is as far away from Earth as it can be in its elliptical orbit, while still having the umbra meet the surface of our planet.

"The moon is just at the right distance from Earth for the apex of its cone-shaped shadow to be slightly above the Earth's surface at the beginning and end of the eclipse path, causing the moon's antumbral shadow to move across Earth, causing an annular solar eclipse," Carter wrote in his explainer piece. "However, in the middle of the eclipse path, the apex of the moon's umbral shadow strikes Earth's surface because that part of the planet is slightly closer to the moon."

The last eclipse of this type occurred almost 10 years ago, on Nov. 3, 2013. The next hybrid solar eclipse after this month's will occur in November 2031 and will be visible from some parts of the contiguous United States. After this, the next time skywatchers will get to see a hybrid eclipse is on March 23, 2164. 😳

9 notes

·

View notes

Link

$1,477.25 $649.99 SOGA Ice Shaver Commercial Electric Stainless Steel Ice Crusher Slicer Machine 120KG/h - Specialty Appliances - CommercialElectricIceShaver168 https://nzdepot.co.nz/product/soga-ice-shaver-commercial-electric-stainless-steel-ice-crusher-slicer-machine-120kg-h-specialty-appliances-commercialelectriciceshaver168/?feed_id=173571&_unique_id=66ecbb281f3ea Our very own branded economy ice shaver designed to produce a coarser consistency of shave ice ideal for our Snow-Cone brand and capable of producing up to an incredible 1.2 kg of shave ice per hour. Features: Durable Stainless Steel Construction Professional grade high-speed 250W motor High production rate of 1.2 kg of shave ice per hour Ice Hopper Capacity: 80 Pieces (3cm cubes) Warranty: 12 Months Parts & Labour Low Energy Consumption Easy to Clean Longer Durability Competitive Price Around Australia Market Specifications: Power: 250W Capacity: 120kg/hr Speed: 320/min Voltage: 220-240V Height: 542mm Length: 286mm Width: 379mm Weight: 15Kgs […] #

0 notes

Text

Thursday, August 8 - Vansittart Bay

We had another beautiful day, with lots of sun and not too hot temperatures. We anchored in Vansittart Bay, which provided us with the opportunity for two entirely different types of excursions. First up was a short ride to a beach where we climbed over a sand dune to discover a mud flat with rock formations and the forest beyond. In 1942, during the evacuations of Darwin and other areas after the bombing by the Japanese, a DC3 aircraft (in a C53 configuration as a personnel carrier) took off from Perth to Darwin at night, planning to stop in Broome. A navigation error of one number caused the pilot and crew (no real passenger transport on this flight) to miss Broome by a wide margin inland, and by the time the error was discovered, they headed out towards the coast, hoping to ditch on the water as they were running low on fuel. In a flash of lightning, they discovered the mud flats we crossed, thought to land there, saw the rocks and bounced up and over them and came to rest in the forest just beyond. Miraculously, no one died, and eventually all were rescued after a couple of hungry days.

The plane is still where it "crashed" in February 1942, and despite cyclones, fires, and the climate, it is in remarkably good condition. The plane's pieces were made in the USA, but the plane itself was assembled by Australian women since the men were already at war (maybe that's why it's still in great condition). We were able to walk around it and view from all angles - there are still wires inside! Surrounding the plane is more recent vegetation and lots of small delicate flowers - a contrast to all that metal.

After viewing the plane we took our time heading back across the mud flats - it was filled with small fiddler crabs, the occasional hermit crab and these good-looking cone snails. Although they look interesting, I only found out later that they are some of the most venomous creatures in Australia, with one of the most potent neurotoxins known to man. We watched a couple having a "race", leaving behind meandering tracks. We also saw one sandpiper, looking a little out of place.

After lunch the ship was repositioned slightly for a visit to Jar Island, which has several sites of Gwion Gwion rock art. This is completely different than the more recent art that the aboriginals still consider part of their story, and this earlier art is quite sophisticated in many ways. Many of the figures are anthropomorphic, with decorations such as tassels, sashes, and headdresses as part of the figures. This art is so old that there is no longer pigment, but rather has been mineralized with the rock, so carbon dating is nearly impossible. However, one was dated to 17,000 years ago, although pictures like the echidna (top photo) suggest they are much older, since the echidna has been extinct in the Kimberley for probably 40,000 years. It is also telling that this island was part of the mainland around that time, too. The detail work on the humanoid figures is extremely fine - truly wonderful. We visited two sites, but are sure there are many more, both here on this small island and on the mainland.

We spent a little more time by some rock formations watching Tree Martins cavort in the wind, while a White-bellied Eagle passed overhead. We caught one of the last Zodiacs back to the ship, and cleaned up for another event - champagne and caviar on the patio deck along with music before heading to the "Indian Market" buffet - a real treat since our executive chef is from India.

Tomorrow is the last excursion day for this leg of our journey when we will head up the King George River to a couple of waterfalls, or what remains of them at this point in the dry season. We're looking forward to seeing more of the geology from the Zodiacs.

0 notes

Text

17th June 2024

Roman reset day…

Not the biggest day. Roman is a menance at night. Not sure if it’s developmental or just the trip taking its toll or the fact he hasn’t used nearly as much energy as he has on every other day of the trip. But we’ve got one very sookie boy during the day who has also decided to start meowing. He meows as soon as he wakes up and then juts meows at us throughout the day. No idea where he learnt that from but it is adorable. What isn’t adorable is having to carry him everywhere! He is a little off and insisting I carry him and not Ash. Thinking a playground might encourage him to run around and lose some energy we headed back to the playground we discovered on our first ever day in Rome. We kind of got Roman to move but not much. So we strolled through the park, me carrying him mostly. It was starting to heat up so we didn’t venture too far. Maybe a bit of a reset day would help Roman, so we headed back for a nap and grabbed a heap of fruit along the way which he has not been eating much of lately! He devoured it in front of paw patrol before another long battle for a nap. A short nap.

So that afternoon we decided to continue to try and tire him out AND give him a reset day. Cos that makes sense. We went to a cute little toy shop which had a train table he was obsessed with. We picked a few lil surprise toys for the plane home while he played with the trains. But we could not tear that kid out of there! The only thing that would move him was the promise of ice cream. What a mistake. We were asked every 5 minutes for the next hour or so “ice cream?”. But we got him to a little park at the end of the street that was green and leafy and shady. It had a massive old Roman ruin in the middle of it, a beautiful fountain, and a stinking hot playground. Every piece of equipment was boiling hot from being out in the hot sun. All except the metal slide! Which unlike in Australia was in the shade! And this is where Roman played, over and over and over. Often sitting at the top or bottom just pondering life.

It was another battle to leave the playground. This kid has caught attitude, no idea where his stubbornness comes from because I am definitely not stubborn! 🙃 Using the ice cream card we managed to lure him out and yes, this time we found ice cream! And we got a cone to share and wandered back through the streets to home.

We made pasta at home for dinner and just had a chill night in. When Roman went to bed, again another battle 🫠, we watched the new house of the dragon. So all in all another great day.

0 notes

Text

Mobile Crushers Market Insights: Comprehensive Global Forecast (2023-2032)

The Global Mobile Crushers Market is projected to witness significant growth, with its value expected to surge from USD 2,789.41 million in 2023 to USD 4,271.97 million by 2032, reflecting a compound annual growth rate of 4.85%.

The mobile crushers market is experiencing significant growth, driven by the increasing demand for efficient, mobile, and flexible crushing solutions in the mining and construction industries. This market expansion is influenced by several factors, including urbanization, the expansion of infrastructure projects, and the need for resource-efficient technologies. As urban areas expand, the demand for raw materials like aggregates for construction increases, pushing the need for equipment that can process these materials directly at the source to minimize transportation costs and environmental impact.

Mobile crushers are favored in settings where fixed installations are impractical or uneconomical, such as remote mining locations or large-scale construction projects that require the frequent relocating of crushing equipment. The versatility and mobility of these crushers allow operators to quickly adapt to changing project needs and site conditions. Technological advancements have also played a crucial role in market growth, with manufacturers integrating features like automation, remote monitoring, and advanced diagnostics into their machines, enhancing both performance and user safety.

Mobile crushers are highly versatile pieces of machinery that are used in the mining and construction industries to break down large rocks, stones, and other materials into smaller, more manageable sizes. Unlike stationary crushing equipment, which remains fixed in one location, mobile crushers can be transported to various sites, making them particularly valuable for projects that require mobility and flexibility. These machines come in various configurations, including jaw crushers, impact crushers, cone crushers, and gyratory crushers, each designed for specific types of materials and crushing processes.

The operation of a mobile crusher involves several stages. Raw materials are first fed into the crusher's hopper, and then moved by a conveyor belt to the crushing mechanism. Depending on the model, the crushing process may involve a single stage or multiple stages, where the materials are reduced to the required sizes through compression, impact, or shear forces. The crushed material is then either directly used on site, transported to another location for further processing, or stockpiled for future use.

More About Report- https://www.credenceresearch.com/report/mobile-crushers-market

Key Player Analysis:

Astec Industries

Thyssenkrupp AG

Terex Corporation

Metso Corporation

Sandvik AB

McCloskey International

Kleemann GmbH

SBM Mineral Processing GmbH

Striker Australia Pty Ltd

Growth Factors:

Urbanization and Infrastructure Development: As global urbanization accelerates, there is a corresponding rise in infrastructure projects, including roads, buildings, and public utilities. Mobile crushers play a crucial role in these projects by providing the necessary raw materials, such as crushed stone and aggregates, directly at the construction sites.

Flexibility and Efficiency: Mobile crushers offer significant flexibility and efficiency advantages over stationary crushers. They can be easily moved between sites, which is particularly valuable in large-scale or remote projects. This mobility reduces material transportation costs and allows for rapid setup and dismantling, aligning well with the variable demands of construction timelines and site locations.

Technological Advancements: Innovations in mobile crusher technology, such as automation, real-time data monitoring, and GPS tracking, have enhanced operational efficiencies, reduced labor costs, and improved safety profiles. These technological enhancements also allow for better resource management and compliance with environmental standards.

Environmental and Regulatory Pressures: Increasing environmental awareness and stricter regulations regarding construction and mining operations have led to greater demand for mobile crushers that are environmentally friendly. These machines often feature reduced emissions, lower noise levels, and better fuel efficiency, making them more acceptable under new environmental standards.

Economic Shifts in Developing Countries: Rapid economic development in countries like China, India, and Brazil has spurred extensive mining activities and construction projects, driving the demand for mobile crushing equipment. The shift towards constructing more infrastructure to support economic growth in these regions continues to boost market prospects.

Replacement of Older Equipment: The need to replace or upgrade older crushing equipment with more efficient and environmentally friendly models also contributes to market growth. This replacement cycle is a significant factor, especially in developed markets with strict environmental laws and high labor costs.

Adaptability to Multiple Applications: Mobile crushers are adaptable to a variety of applications, from stone quarries and mining sites to demolition sites and recycling plants. This versatility makes them invaluable across different sectors, enhancing their market demand.

Segments:

Based on Type

Jaw crushers

Impact Crushers

Others

Based on Application

Mining & Quarry

Construction Aggregates

Material Recycling

Others

Market Challenges:

High Initial Investment Costs: Mobile crushers require a substantial initial investment, which can be a barrier for small to medium enterprises (SMEs) and startups. The cost of purchasing and maintaining these machines can deter potential buyers who might otherwise benefit from their use.

Operational Complexity: Operating mobile crushers involves dealing with several complex mechanisms. Proper training and skilled personnel are necessary to ensure efficient and safe operations. This need for specialized labor can increase operational costs and complexity.

Logistical and Transport Issues: Despite their mobility, transporting mobile crushers between sites over large distances can be challenging and costly, especially in regions with inadequate transport infrastructure. The logistical complexity can also involve regulatory compliance regarding oversized loads on public roads.

Maintenance Challenges: Mobile crushers are subjected to extreme wear and tear, especially when used in harsh environments typical of mining and construction sites. Frequent breakdowns and the need for regular maintenance can lead to downtime, affecting productivity and operational costs.

Environmental and Regulatory Compliance: Adhering to stringent environmental regulations is a significant challenge. Mobile crushers must comply with emission standards, noise regulations, and other environmental requirements, which can vary widely by region and over time as policies become stricter.

Browse the full report – https://www.credenceresearch.com/report/mobile-crushers-market

Browse Our Blog : https://www.linkedin.com/pulse/mobile-crushers-market-forecast-analysis-lumef

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Enhancing Safety: The Crucial Role of Traffic Cones in Construction Zones

Welcome, readers, to a discussion on a topic that is of utmost importance in the construction industry - safety. As we delve into the world of construction zones, it is crucial to emphasize the significance of maintaining a safe environment for both workers and the public. In this blog post, we will explore the pivotal role of traffic cones in ensuring safety within construction zones, shedding light on their indispensable function in mitigating potential hazards.

The responsibility of guaranteeing safety in construction zones extends beyond mere compliance with regulations; it encompasses the implementation of effective safety measures, one of which involves the strategic use of construction cone in Australia. These simple yet highly effective devices play a vital role in guiding traffic, marking hazards, and delineating work areas, thereby minimizing the risk of accidents and ensuring a secure environment for all involved.

Section 1: Understanding the Purpose of Traffic Cones

The primary purpose of traffic cones in construction zones is multi-faceted, encompassing various essential functions that contribute to overall safety. These bright orange beacons serve as visual cues, guiding both vehicular and pedestrian traffic around construction sites, redirecting flow, and ensuring that individuals stay clear of potential hazards. Moreover, they play a pivotal role in marking off specific areas, delineating boundaries, and alerting individuals to potential dangers, thus serving as a crucial line of defense against accidents.

The distinctive conical shape of these devices, coupled with their vibrant color, makes them easily noticeable, even from a distance. As a result, they effectively communicate warnings and directives to individuals navigating the construction zone, enhancing overall safety and minimizing the likelihood of mishaps.

Section 2: Compliance with Safety Regulations

In the realm of construction safety, adherence to regulatory standards is non-negotiable. The use of traffic cones in construction zones is not merely a matter of preference; it is a legal requirement aimed at safeguarding the well-being of workers and the public. These regulations, set forth by relevant authorities, mandate the use of traffic cones to demarcate work areas, mark hazards, and ensure a safe flow of traffic around construction sites.

By complying with these safety regulations, construction companies and contractors demonstrate their commitment to providing a secure working environment. Moreover, adherence to these standards significantly reduces the likelihood of accidents, protects against potential liability, and contributes to the overall professionalism and credibility of the construction operation.

Section 3: Types and Characteristics of Traffic Cones

Traffic cones are available in a variety of types, each designed to cater to specific requirements and conditions prevalent in construction zones. From traditional, single-piece cones to collapsible, space-saving models, the market offers a diverse array of options to suit various needs. Additionally, the incorporation of reflective strips enhances visibility, particularly during low-light conditions or at night, ensuring that the cones remain conspicuous and effective in all situations.

Durability is a key characteristic of high-quality traffic cones, as they are often subjected to harsh environmental elements and the wear and tear of daily use. Furthermore, their ability to withstand impact and resiliently maintain their shape is integral to their functionality in effectively delineating work areas and hazards.

Section 4: Placement and Maintenance Best Practices

The strategic placement of traffic cones is paramount to their effectiveness in ensuring safety within construction zones. Proper positioning, in accordance with established guidelines, maximizes their visibility and impact, effectively guiding traffic and delineating potential hazards. Additionally, routine maintenance practices, such as cleaning, inspection for damage, and replacement of worn or damaged cones, are imperative in ensuring their longevity and functionality.

By adhering to best practices in both placement and maintenance, construction companies and contractors can optimize the effectiveness of traffic cones, contributing to a safer and more organized construction environment.

Section 5: Benefits of Using Traffic Cones

The utilization of traffic cones yields an array of benefits for both workers and motorists navigating construction zones. For workers, these cones serve as a protective barrier, marking off work areas and potential hazards, thus reducing the risk of accidents and injuries. Furthermore, they contribute to the efficient flow of traffic, minimizing disruptions and ensuring that construction activities proceed smoothly.

For motorists, the presence of traffic cones serves as a visual guide, alerting them to changes in traffic patterns, potential hazards, and areas to avoid. By providing clear directives and warnings, these cones contribute to accident prevention, safeguarding the well-being of both motorists and construction workers.

Conclusion

The importance of traffic cones in construction zone safety cannot be overstated. By serving as beacons of guidance, warning, and delineation, these simple yet vital devices play a pivotal role in maintaining a secure environment within construction zones. Compliance with safety regulations, coupled with the strategic use and diligent maintenance of traffic cones, contributes to accident prevention and the overall well-being of workers and the public.

As we navigate the realm of construction safety, it is imperative to recognize the instrumental role of traffic cones and prioritize their effective utilization. By doing so, we not only uphold regulatory standards but also demonstrate our unwavering commitment to safety within the construction industry. Let us collectively strive to enhance safety in construction zones, one traffic cone at a time.

0 notes

Text

Mobile Crushers Market Insights: Comprehensive Global Forecast (2023-2032)

The Global Mobile Crushers Market is projected to witness significant growth, with its value expected to surge from USD 2,789.41 million in 2023 to USD 4,271.97 million by 2032, reflecting a compound annual growth rate of 4.85%.

The mobile crushers market is experiencing significant growth, driven by the increasing demand for efficient, mobile, and flexible crushing solutions in the mining and construction industries. This market expansion is influenced by several factors, including urbanization, the expansion of infrastructure projects, and the need for resource-efficient technologies. As urban areas expand, the demand for raw materials like aggregates for construction increases, pushing the need for equipment that can process these materials directly at the source to minimize transportation costs and environmental impact.

Mobile crushers are favored in settings where fixed installations are impractical or uneconomical, such as remote mining locations or large-scale construction projects that require the frequent relocating of crushing equipment. The versatility and mobility of these crushers allow operators to quickly adapt to changing project needs and site conditions. Technological advancements have also played a crucial role in market growth, with manufacturers integrating features like automation, remote monitoring, and advanced diagnostics into their machines, enhancing both performance and user safety.

Mobile crushers are highly versatile pieces of machinery that are used in the mining and construction industries to break down large rocks, stones, and other materials into smaller, more manageable sizes. Unlike stationary crushing equipment, which remains fixed in one location, mobile crushers can be transported to various sites, making them particularly valuable for projects that require mobility and flexibility. These machines come in various configurations, including jaw crushers, impact crushers, cone crushers, and gyratory crushers, each designed for specific types of materials and crushing processes.

The operation of a mobile crusher involves several stages. Raw materials are first fed into the crusher's hopper, and then moved by a conveyor belt to the crushing mechanism. Depending on the model, the crushing process may involve a single stage or multiple stages, where the materials are reduced to the required sizes through compression, impact, or shear forces. The crushed material is then either directly used on site, transported to another location for further processing, or stockpiled for future use.

More About Report- https://www.credenceresearch.com/report/mobile-crushers-market

Key Player Analysis:

Astec Industries

Thyssenkrupp AG

Terex Corporation

Metso Corporation

Sandvik AB

McCloskey International

Kleemann GmbH

SBM Mineral Processing GmbH

Striker Australia Pty Ltd

Growth Factors:

Urbanization and Infrastructure Development: As global urbanization accelerates, there is a corresponding rise in infrastructure projects, including roads, buildings, and public utilities. Mobile crushers play a crucial role in these projects by providing the necessary raw materials, such as crushed stone and aggregates, directly at the construction sites.

Flexibility and Efficiency: Mobile crushers offer significant flexibility and efficiency advantages over stationary crushers. They can be easily moved between sites, which is particularly valuable in large-scale or remote projects. This mobility reduces material transportation costs and allows for rapid setup and dismantling, aligning well with the variable demands of construction timelines and site locations.

Technological Advancements: Innovations in mobile crusher technology, such as automation, real-time data monitoring, and GPS tracking, have enhanced operational efficiencies, reduced labor costs, and improved safety profiles. These technological enhancements also allow for better resource management and compliance with environmental standards.

Environmental and Regulatory Pressures: Increasing environmental awareness and stricter regulations regarding construction and mining operations have led to greater demand for mobile crushers that are environmentally friendly. These machines often feature reduced emissions, lower noise levels, and better fuel efficiency, making them more acceptable under new environmental standards.

Economic Shifts in Developing Countries: Rapid economic development in countries like China, India, and Brazil has spurred extensive mining activities and construction projects, driving the demand for mobile crushing equipment. The shift towards constructing more infrastructure to support economic growth in these regions continues to boost market prospects.

Replacement of Older Equipment: The need to replace or upgrade older crushing equipment with more efficient and environmentally friendly models also contributes to market growth. This replacement cycle is a significant factor, especially in developed markets with strict environmental laws and high labor costs.

Adaptability to Multiple Applications: Mobile crushers are adaptable to a variety of applications, from stone quarries and mining sites to demolition sites and recycling plants. This versatility makes them invaluable across different sectors, enhancing their market demand.

Segments:

Based on Type

Jaw crushers

Impact Crushers

Others

Based on Application

Mining & Quarry

Construction Aggregates

Material Recycling

Others

Market Challenges:

High Initial Investment Costs: Mobile crushers require a substantial initial investment, which can be a barrier for small to medium enterprises (SMEs) and startups. The cost of purchasing and maintaining these machines can deter potential buyers who might otherwise benefit from their use.

Operational Complexity: Operating mobile crushers involves dealing with several complex mechanisms. Proper training and skilled personnel are necessary to ensure efficient and safe operations. This need for specialized labor can increase operational costs and complexity.

Logistical and Transport Issues: Despite their mobility, transporting mobile crushers between sites over large distances can be challenging and costly, especially in regions with inadequate transport infrastructure. The logistical complexity can also involve regulatory compliance regarding oversized loads on public roads.

Maintenance Challenges: Mobile crushers are subjected to extreme wear and tear, especially when used in harsh environments typical of mining and construction sites. Frequent breakdowns and the need for regular maintenance can lead to downtime, affecting productivity and operational costs.

Environmental and Regulatory Compliance: Adhering to stringent environmental regulations is a significant challenge. Mobile crushers must comply with emission standards, noise regulations, and other environmental requirements, which can vary widely by region and over time as policies become stricter.

Browse the full report – https://www.credenceresearch.com/report/mobile-crushers-market

Browse Our Blog : https://www.linkedin.com/pulse/mobile-crushers-market-forecast-analysis-lumef

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes