#computerized tensile testing machine specification

Explore tagged Tumblr posts

Text

Computerized Tensile Testing Machine -M-SERIES

Computerized tensile testing machine can perform a wide range of mechanical tests including tensile, compression, bend, peel, tear, friction, and shear testing. These systems are designed to test materials, components, and products in accordance with ASTM, ISO, and other industry standards. Compatible with hundreds of accessories for a wide range of applications, these universal testing systems are available in a multiple sizes and configurations for R&D, QC, and other mechanical testing up to 100 kN force. Computerized system records and collects data from various sensors, including the load cell and extensometer, during the test. It displays real-time data such as force, displacement, and strain. After the test, the collected data can be analyzed to determine material properties like tensile strength, yield strength, modulus of elasticity, and other relevant parameters. The control system of a computerized tensile testing system is responsible for applying the force and controlling the test parameters. It typically includes a computer or microprocessor, software, and an interface to communicate with the machine. The software allows users to input testing parameters, monitor the test progress, and collect and analyze data.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#testing#tensile testing machine#tensile testing#computerized tensile testing machine#computerized tensile testing system#universal testing machine#universal testing system#material testing machine#computerized tensile testing machine supplier#computerized tensile testing machine manufacture#computerized tensile testing machine specification#computerized tensile testing machine price#computerized tensile testing machine cost#computerized tensile testing machine in ghazibad#computerized tensile testing machine in delhi#computerized tensile testing machine in uttar pradesh#computerized tensile testing machine supplier in delhi#computerized tensile testing machine supplier in ghaziabad#computerized tensile testing machine supplier in india#computerized tensile testing machine manufacture in india#computerized tensile testing machine manufacture in delhi#computerized tensile testing machine manufacture in uttar pradesh#computerized tensile testing machine manufacture in ghaziabad

1 note

·

View note

Text

Exploring Suzuki Instruments’ Computerized Touch Screen Universal Testing Machines

Universal Testing Machines (UTMs) are essential in determining the mechanical properties of materials, including tensile strength, compression strength, and other key performance metrics. Suzuki Instruments provides a range of Computerized Touch Screen Universal Testing Machines designed to meet the specific needs of a variety of industries, offering precision, user-friendly interfaces, and robust functionality. In this blog, we will delve into the features and benefits of four different models of Suzuki Instruments’ UTMs, helping you understand which machine would be best suited to your testing needs.

1. UTE-TS — Versatility and Performance

The UTE-TS model is an ideal choice for laboratories and industries requiring flexible and precise testing. This machine is designed to offer reliable results for a wide variety of materials, including metals, plastics, composites, and elastomers. The computerized touch screen interface allows for easy operation, simplifying the testing process even for users with minimal technical expertise.

KNOW MORE

2. UTE-HGFL-TS — For High-Grade Load Testing

The UTE-HGFL-TS model is designed for handling higher loads and is equipped to perform testing on materials that experience high stress and strain. This machine is built to measure the behavior of materials under extreme forces, making it ideal for industries such as construction, automotive, aerospace, and metalworking.

KNOW MORE

3. UTES-HGFL-TS — Advanced Flexural Testing

The UTES-HGFL-TS model is tailored for flexural (bending) testing, a key procedure for evaluating the strength and flexibility of materials. Materials such as plastics, ceramics, and metal alloys used in industries like automotive, aerospace, and manufacturing rely heavily on flexural testing to ensure safety, durability, and compliance with standards.

KNOW MORE

4. UTES-TS — Compact yet Powerful

For organizations with limited space but still requiring reliable and accurate testing, the UTES-TS model offers a compact and efficient solution. While smaller in size, this machine does not compromise on performance. It is well-suited for smaller laboratories, educational institutions, or businesses with limited floor space.

KNOW MORE

Why Choose Suzuki Instruments’ Universal Testing Machines?

Suzuki Instruments has built a strong reputation for producing high-quality, reliable testing equipment. Their range of computerized touch screen Universal Testing Machines offers several key advantages, including:

User-Friendly Touch Screen Interface: Simplifies the setup and operation of tests, allowing both experienced and novice operators to easily navigate the system.

Advanced Software: The built-in software offers detailed analysis, data storage, and easy reporting, ensuring that test results are accurate and readily accessible.

Versatility: Suzuki Instruments’ UTMs can perform a wide variety of tests, making them suitable for a wide range of industries, including automotive, aerospace, construction, and research laboratories.

Precision and Accuracy: The machines are designed to deliver consistent, reliable results, crucial for high-stakes testing environments where accuracy is paramount.

Suzuki Instruments’ Computerized Touch Screen Universal Testing Machines provide an effective and versatile solution for material testing. Whether you choose the UTE-TS for general-purpose testing, the UTE-HGFL-TS for high-load applications, the UTES-HGFL-TS for advanced flexural testing, or the compact UTES-TS, you can trust that each model offers the precision, ease of use, and advanced features necessary for obtaining reliable and accurate test results.

In any industry where material strength and reliability are of utmost importance, investing in a Suzuki Instruments UTM is a step toward ensuring your products meet the highest standards. With these testing machines, you gain not only the confidence that your materials are performing as expected but also the peace of mind that you are using some of the most advanced equipment available in the industry.

0 notes

Text

Supplier of Stainless Steel Wire Rod in Jharkhand

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Wire Rod in Jharkhand. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel. Stainless Steel Wire rod is a semi-finished product made from stainless steel. Our wire rods are produced in various diameters and grades to meet the specific needs of different industries. Key Properties: Corrosion Resistance: Resists oxidation and corrosion, making it suitable for various environments. Strength: Offers excellent mechanical strength and durability. Aesthetic Appeal: Maintains a polished and attractive appearance. Specification: Stainless steel Wire Rod Grades: ASTM: 201, 202, 204Cu, 301, 302, 303, 304, 304Cu, 304HC, 304L, 304H, 310, 310S, 312, 314, 316, d16L, 316LN, 316TI, 316LCu, 321, 410, 420, 430, 430L, 904L DIN/EN: 1.4301, 1.4306, 1.4307, 1.4310, 1.4401, 1.4404, 1.4567, 1.4841, 1.4842, 1.4541, 1.4845, 1.4570, 1.4571, 1.4578, 1.4597, 1.4362, 1.4370 and 1.4016 Size: 0.03mm to 16mm Heat Treatment: Solution Annealing for Austenitic Grades Normal Annealing for Martensitic Grades Finish: Black, Bright, Matte Finish, Soap Coated, Electro Polish Quality Other Special Grade: Electrode Grades: ER304, ER304L, ER307, ER307SI, ER308, ER308L, ER308LSI, ER310, ER316, ER316L, ER316LSI, ER347, ER347SI, ER309L, ER430 And ER420 Condition: Soft, 1/4 Hard, 1/2 Hard, Full Hard, HRP & Solution Annealed Packing: Simple 4-steel Strip Packing for Coil Poly Packing with Plastic Strip for HRP and HRAP Wrapping with Plastic Strip As Per Customer Requirements Testing: Computerized Tensile Testing Machine Bend Testing Wrap Testing Torsion Testing Machine Hardness Testing Machine IGC Testing Facilities Cold Upset Test Facility PMI Tester Chemical Composition Analyses Radioactive Contamination Testing Application: Construction and Architecture Automotive Industry Oil and Gas Industry Power Generation Arisa Impex is a Supplier of Stainless Steel Wire Rod in Jharkhand including locations like Ranchi, Bokaro, Jamshedpur, Dhanbad, Giridih, Hazaribagh, Ramgarh, Hazaribagh, Chirkunda, Mango, Chaibasa, Koderma, Sahibganj, Jhumri Telaiya, Jamtara, Dumka, Gumia, Madhupur, Phusro, Chakradharpur. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

0 notes

Text

Guide To choose the Right Tensile/Compression Strength Testing Machine

Despite the fact that Tensile/Compression strength testing machines are and utilized pretty much in every industry there is still absence of information with regards to buying the right machine. Given the scope of items, the features and the variations in cost getting one can be a bit overwhelming and this becomes especially true for non -standard applications.

One of the inquiries we get posed to by our clients is whether to pick a manually operated machine or motorized one and if motorized is chosen, would it be a good idea for us we pick a machine with Computer Control and inclusive of data acquisition. So, we should check out at this according to a point of view of a spring manufacturer.

There are two elements which go with this choice simpler. The first and most clear one is the price. Manually operated machines are less expensive obviously, then motorized lastly computerized. In any case, in the event that you are taking a heavier spring which are utilized in train bogies or airplanes, then, at that point, motorized ones must be utilized no matter what the budget. Imaging putting a pressure power of 5000 kg on a spring, (for example, the ones utilized under the train bogies) with a hand wheel. Indeed, even with utilization of a geared 3 train it's diligent effort.

Whenever that is chosen, the other element which is significant is the volume of testing. A spring manufacturer can let out a huge number of springs a day. The question then is whether to do batch testing or 100% testing. Batch testing is where you pick a couple of tests from the batch, test them and assuming all are good you say that the entire batch is good. In such cases a manual machine would be satisfactory. However, if one wants to test several thousand springs a day it's smarter to go for a motorized machine and reduce the burden of manual labour on the machine operator.

So, we decided on a manual or motorized machine. Subsequent stage in the development is whether to get a computer-controlled machine. These are machines operated straightforwardly from the computer and give the testing output as a force versus displacement chart. This imagines the way of behaving of the spring constantly. Regularly these software’s also provide a statistical report for all the tests, so min, max, standard deviation etc. and so forth. Are accessible as reports. Any large organizations where the report should be imparted to the higher ups who just need an outline of the production quality, these machines are a good decision. Any new product requiring data for approval must be tested on such machines. In many cases the client request that the manufacturer present the report online or in pdf format to avoid any possibility of manipulation. The best way to avoid from this is to utilize a computerized machine.

In specific cases the product you manufacture dictates the type of machine, there are ASTM, IS norms which settle on the decision for you. Be that as it may, for situations where it’s a non-standard product, we trust this article assists you with choosing what's best for you.

#utm#tensile#compressiontesting#stm#spring#universal testing machine manufacturers#mechanical engineering#manufacturer#springtesting#tensile testing machines

0 notes

Text

Create high tensile forces for testing materials with a tensile strength tester

The most significant and widely used type of mechanical test that will be conducted on the material is the tensile test or tension test. The force or tension is applied to the material until it fails or breaks and its response to the stress is measured. This quality test is considered to be one of the important tests that will measure the tensile force to stretch or break the material with ease. You can easily conduct a quality test on the material with the help of the Presto tensile strength tester.

Presto tensile testing machine is one of the advanced testing equipment that is used to measure the tensile strength of materials and provide you with accurate and precise analysis. This lab testing equipment is widely used in several industries including the plastic industry, for the purpose of studying the tensile properties of materials. Here in this blog, we are going to provide you the information about how you can easily create high tensile forces on materials with the use of the Presto tensile strength tester.

Measure the tensile force required to break a sample with Presto tensile strength tester

Tensile testing is a vital process for understanding the behavior of materials under tension. By applying a pulling force to a material, it is possible to see how the material responds to stress and identify any potential weaknesses. Additionally, tensile testing can be used to determine the strength of a material, as well as its flexibility and elongation properties.

As such, this type of testing is essential for quality control in a wide range of industries. In recent years, there have been significant advances in tensile testing technology, making it easier than ever to obtain accurate and reliable results. We at Presto is India’s top leading manufacturer of tensile strength tester and provide you with different models of this lab testing instrument.

From tensile tester digital cum computerized model to computerized tensile testing machine with COF, you will get several models of tensile testers available at the best and most affordable prices.

Below we have listed the features and technical specifications of the tensile tester digital model.

Features and technical specifications of Presto digital tensile strength tester

The elongation tester or tensile strength tester is one of the important laboratory testing instruments that come with the ability to test the tensile properties of materials with ease. This testing instrument will help you to measure the effectiveness and behavior of materials when tensile force is applied to them.

Presto universal tensile strength tester can be used in industries where compression, bending and shear methods are used to determine the tensile properties of materials.

Let us find out the features and technical specifications of this tensile strength tester.

High testing range

Vice-type clamping grips for firm gripping of the test specimen.

Advanced peak load indicator for accurate readout and storage of test results.

Limit switches protection for the protection of grips and the machine.

Strong load frame.

Safety limit switches are incorporated for both the upward and the downward directions.

Completely hardened and nickel-plated center load bearing screw provided for longer, rugged life.

Technical Specifications of tensile strength tester

READ MORE…………………

0 notes

Text

What Are The Purpose Of Plastic Film Testing?

The basic qualities and performance of plastic film testing are governed by a number of ASTM standards. These specifications cover everything from single-material films to multi-material, anisotropic structures, and they help to define qualities like tensile strength, tearing resistance, and piercing energy. Our materials engineers have a wide range of experience that provides accurate, consistent, and timely results, all of which are backed up by our ISO 17025 certification.

Quite possibly the most rudimentary test that can be performed on an item is the pliable test to really take a look at the breaking opposition of an item. A test example is held under pressure to work on contradicting powers following up on inverse countenances both situated on the very pivot that endeavors to pull the example separated. These tests are easy to set and finish and uncover numerous qualities of the items that are tried. These tests are estimated to be essentially the converse of a pressure test.

The purpose behind this test Typically, this test is intended to run until the example breaks or comes up short under the particular burden. The qualities that are determined from this kind of test can shift yet are not restricted to rigidity, extension, extreme strength, modulus of power, yield strength, and strain solidifying. The estimations are taken during the test to uncover the qualities of a material while it is under a ductile burden.

Maeon Laboratory is one of the best Film Testing Laboratory in Chennai, India. The lab is equipped to determine film properties and collect data on film performance for a variety of stretch film grades using a variety of film stretching conditions. Our goal is to match a customer`s application with the proper product or wrap design.

Pliable Testing for Plastics Composites and Plastic are polymers with substances added to work on the presentation or diminish costs. Plastic might be squeezed or projected or expelled into sheet, film, or fiber-supported plates, glass, tubes, fiber, bottles, and boxes. Thermo Hardening or thermosetting plastics can be weak or hard and temperature safe. Thermosets incorporate polyester pitches, epoxy tars, polyurethane, phenolic saps, non-meltable, non-deformable, and polyurethane. Polymer film testing and plastics can be tried to quantify item quality. The tests measure the weight needed to part or break a plastic test material and test extension or stretch to that breaking load. The subsequent information helps to recognize item quality and quality control checks for materials.

Plastic testing instruments, general test machines give a steady pace of augmentation since plastic pliable test conduct is subject to the speed of the test machine. The examples stacked on the machines are set according to ASTM, DIN, ISO elastic test example measurements. The Plastic analyzer machine ought to consistently depend on standard agreements. According to ASTM D638, Plastic malleable test guidelines help to quantify strain under 20% augmentation esteems. High strain can be estimated by the machine, computerized peruser. Plastic film testing is done according to the standard ASTM D882.

A great testing machine is intended to gauge the strength of a particular item, test technique, and item type. A decent instrument can be the main arrangement needed for your quality confirmation and a more regrettable decision can make you go in misfortune as well. So pick the instrument intelligently.

Visit our Plastic material testing laboratory

0 notes

Text

Advantages of Portable Hardness Testers

Hardness testers are devices that are used primarily for testing the hardness of workpieces by applying rapid shock loading. These instruments are designed to measure the force required to penetrate a material, either with a calibrated steel probe or a diamond tip. Hardness testers are used to determine the hardness of steel, aluminum, brass, and other materials.

Hardness testers have taken on a variety of forms over the decades since their invention. Most manufacturers now produce a wide variety of models to suit various applications and needs of users. In general, hardness testers are classified as either impact testers or penetration testers. Impact testers use an impact hammer to generate shock loads while penetration testers must penetrate a workpiece in order for the resulting force to be measured. Both types serve identical functions and have the same basic design components.

Portable Rockwell hardness tester: Portable Rockwell hardness tester is the commonly used hardness testing equipment in the industries. The machine is a handy piece of equipment. It can be moved around easily and used by a single person. The portable hardness testers are available in different types and specifications, and they can be utilized in various industries, such as engineering, construction, automotive industry, etc.

The portable hardness tester is also available with a computerized digital display with auto-ranging feature and data evaluation system at reasonable price. Most engineers prefer this machine as they do not need to use an external computer for data analysis or saving/recording of test results etc.

Metal Hardness & Ultrasonic Testing: A manual hardness tester using a ball-peen hammer would not be suitable for daily use. It can be used just to confirm if the material is really harder or softer than the supplier's specification. A portable Rockwell hardness tester is much more convenient and can measure the hardness in different areas of a workpiece simultaneously.

Unlike manual devices, it will provide digital reading directly for comparative purposes, which can be easily recorded into a computer or printed out for future reference. The portable metal hardness tester comes with a printout, which is mainly used for recording data automatically if the device is connected to a computer rather than manually writing it down on paper. However, the printed record can be stored for a long time and is easier to read than making notes during the testing process. A portable hardness tester can also conduct a variety of other testing methods including indentation test, micro-hardness test, splitting tensile test and for rough hardness. Its measuring range can cover a few grains (HRA) to hundreds of Rockwell C (HRc), which reflects different hardness levels. When you are searching for a portable Rockwell Hardness Tester online check out the following tips for finding a good deal. Portable hardness testers have taken on various forms over the decades since their invention. Most manufacturers now produce a wide variety of models to suit various applications and the needs of users.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, paint meter, portable rockwell hardness tester, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards. For more information, visit https://www.testcoat-usa.com/ Original Source: https://bit.ly/3DxN3pb

0 notes

Text

The Fact About Strapping Machine In Delhi That No One Is Suggesting

Major duty knurled roller conveyor, velocity adjustable· • HMI touch display screen control panel, consumer helpful· As an acclaimed entity, we are providing a premium excellent assortment of Strapping Machine to our valued shoppers. We're supplying this product or service in different dimensions. Get in touch with the manufacturer to obtain a estimate or possibly a value Dynaric is a number one supplier of plastic strapping machines and personalized methods including primary semi-computerized table prime machines, via substantial velocity arch kind units, culminating with thoroughly computerized, large pace, operator- fewer tools and entire techniques. Write-up provides a reserve price A reserve rate was stored for this article. If this selling price just isn't met throughout the auction, bids are acknowledged less than reservation. Dynaric operates considered one of the largest plastic strapping production facilities in The us, located in Virginia Seashore, VA. There we manufacture a complete line of plastic strapping merchandise including machine grade, managed elongation and higher tensile. Packaging has grown to be significant as a consequence of commerce. What used to be performed by hand is at the moment carried out by packaging, specially designed for precise employs. This is often why this sector turned so essential. Revolutionary packaging technologies shield the products all through transportation and storage. Moreover, the packaging ought to act as a kind of ad to the product and assist boost income. Providing you a whole alternative of goods which incorporate stainless-steel box strapping machines, semi automated box strapping machine, box strapping machines, pneumatic strapping machine, semi automatic strapping machine and semi automatic low height strapping machine. Make contact with MWES to find out about our devices And exactly how they're able to increase your manufacturing program’s effectiveness. Our supplied vary is top quality tested and continues to be passed on many parameters. The machine with really low desk is suited to the packages that are extremely large or heavy such as Vehicle industries. Our strapping answers combine much more than a hundred several years previous cyclop good quality with our industrial encounter. Combining the know-how on numberless sorts of solutions to become packaged, we are particularly capable to deliver Resolution ... The infrastructure of the company is effectively developed with each of the amenities which can be needed with the producing of the strapping machine. Scroll Signup Productive! :We now have sent your login specifics on e mail. A verification e-mail has also been despatched in your electronic mail deal with. was Established in 1991 with 1 theory in your mind: to provide the highest top quality products and repair to our consumers. Solar Packaging is an 'A' amount packaging distributor. Contact us currently or go to our Internet site To learn more about our items!Strapping Machine Suppliers

0 notes

Text

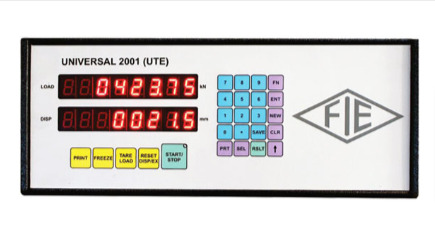

Computerized Universal Testing Machine

Computerized universal testing machine is an advanced testing instrument used to evaluate the mechanical properties of materials. It is equipped with computerized control and data acquisition systems, offering precise control over testing parameters and accurate measurement of test results. Look for a machine with a computerized control system that allows for precise and intuitive operation. The control system should provide the ability to set and adjust testing parameters such as load, displacement, and strain rate. It should offer a user-friendly interface for easy test setup and control.

Universal testing machines typically offer a wide range of test modes, including tensile, compression, bending, shear, and more. Ensure that the machine supports the specific test modes and standards relevant to your application. Common standards include ASTM, ISO, DIN, and EN. A reliable testing machine should be calibrated and provide accurate results. Regular calibration and maintenance are essential to ensure the accuracy and reliability of the test results. Look for machines that are calibrated to recognized standards and have a high level of accuracy.

Check for the availability of a wide range of grips, fixtures, and accessories compatible with the machine. These accessories allow for testing various types of specimens and expand the capabilities of the machine.

testing machine, universal testing machine, advance testing machine, computerized universal testing machine, utm, computerized control system,

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#testing#testing machine#universal testing machine#computerized testing machine#computerized universal testing machine#advance testing machine#computerized control system

1 note

·

View note

Text

Suzuki Instruments: Leading Manufacturer of Universal Testing Machines in India

Suzuki Instruments, a prominent name in the field of material testing equipment, has been serving industries with high-quality universal testing machines (UTMs) for decades. Based in India, Suzuki Instruments specializes in a wide range of UTMs, including Analogue Universal Testing Machines, Electronic Universal Testing Machines, and Computerized Universal Testing Machines. These machines are indispensable in various industries like automotive, aerospace, construction, research, and education, where precise and reliable mechanical testing is essential.

In this blog, we will focus on the different Analogue Universal Testing Machines (UTMs) offered by Suzuki Instruments, covering their models and applications. These machines are designed to measure a variety of mechanical properties, such as tensile strength, compression strength, elongation, and more. Let’s explore some of the models that make Suzuki Instruments a trusted choice for manufacturers and educational institutions.

Key Models of Suzuki Instruments’ Analogue Universal Testing Machines

1. UTN Model

The UTN model is one of the most popular analogue universal testing machines offered by Suzuki Instruments. It is a versatile machine used for both tensile and compressive testing of a wide range of materials, including metals, plastics, and rubber. This model features an analog control system that provides accurate and clear readings of force and elongation.

KNOW MORE

2. UTN-HGFL Model

The UTN-HGFL model is an advanced version of the UTN model, designed for high-grade material testing. This machine offers enhanced precision and durability, making it ideal for more demanding industrial applications. It is equipped with a high-force load cell and a more robust frame, allowing it to handle a higher load capacity.

KNOW MORE

3. UTN/E Model

The UTN/E model is another offering from Suzuki Instruments, designed specifically for educational institutions and research labs. This model is often used in academic settings where students and researchers need to conduct basic tensile and compression tests to understand material properties.

KNOW MORE

4. UTE Model

The UTE model is Suzuki Instruments’ next step in the analogue testing machine lineup. It is built for heavier applications and provides a wider range of testing capabilities compared to the basic UTN model. The UTE model is equipped with a larger testing chamber and is capable of handling materials that require higher tensile and compressive forces.

KNOW MORE

5. UTE HGFL Model

Building upon the UTE model, the UTE HGFL model is designed for high-force testing applications. It is built with high-strength components, allowing it to test materials under extreme conditions. This model features an upgraded analog display system and is equipped with high-grade load cells to ensure accurate force measurement, even under the most demanding tests.

KNOW MORE

6. UTES Model

The UTES model is a more specialized analogue universal testing machine, designed for testing specific materials like polymers, elastomers, and textiles. It is used in industries that require precise control over the tensile and compression testing process, such as in the automotive or textile industries.

KNOW MORE

7. UTES-HGFT Model

The UTES-HGFT model is a high-performance version of the UTES model, designed for materials that require even higher force testing. It is equipped with enhanced features such as high-grade sensors and stronger frames, making it capable of handling extreme load capacities.

KNOW MORE

Applications of Suzuki Instruments’ Analogue Universal Testing Machines

Suzuki Instruments’ UTMs find widespread applications across various industries:

Automotive Industry: Testing the strength of parts like engine components, suspension systems, and tires.

Aerospace Industry: Ensuring materials meet rigorous standards for durability and reliability.

Construction and Engineering: Verifying the strength of building materials such as concrete, steel, and composites.

Textile and Polymer Industries: Testing the tensile strength and elasticity of fabrics and polymer materials.

Research and Education: Teaching material science concepts and testing new materials.

Suzuki Instruments has firmly established itself as a leader in the field of material testing equipment, offering a diverse range of universal testing machines to meet the varying needs of industries and research institutions. From the UTN to the UTES-HGFT model, Suzuki Instruments’ analogue UTMs are reliable, durable, and capable of providing accurate results for a wide array of materials. Whether you’re looking to test metals, polymers, composites, or any other material, Suzuki Instruments has a solution tailored to your needs.

By investing in one of Suzuki Instruments’ universal testing machines, you are ensuring the quality and reliability of your material testing processes, which is crucial for maintaining the integrity and performance of your products. For more details or inquiries, feel free to contact authorized Suzuki Instruments dealers or visit their official website.

1 note

·

View note

Photo

Universal Testing Machine Manufacturers and Suppliers by International Equipments

Computerized Twin screw Universal Testing Machine to determine properties of Tensile & Elongation as per ASTM D 638 & ISO 527, Compression as per ASTM D 695 & Flexural (three point bending), as per ASTM D 790 with auto stop, auto reverse facility & direct display of result through 32 bit micro controller having 4 lines and 20 character display. Suitable for checking all types of polymers, compounds, composite materials, fibre reinforced plastics (FRP) and polymeric materials.

Universal Testing Machine (BOTH OPTIONS SERVO & VFD)

Specification:

• Load capacity : Various different capacities can be offered up to 5000 kg.*

• No. of load cell : Optional One or Two. • Cross Travel : up to 1000 mm • Facility of full scale elongation as well as Extensometer gauge length elongation (OPTIONAL) • Horizontal day light : 450mm • Speed: Variable between 0.5mm/minute to 800mm/minute depending on model. • Paint: Powder coated. • Power : 230 Volts, 50Hz, single phase.* Equipment with other capacities could also be supplied as per the requirement.All results such as Peak load, Elongation at Peak load, Break load, Elongation at break load, % elongation at Peak, % elongation at Break, Tensile strength at Peak, Tensile strength at Break, Flexural stress, Compression Strength, Secant Modulus, Tangent Modulus & Flexural Modulus are directly displayedn Microcontroller as well as through PC software.

0 notes

Text

Computerized Universal Testing Machine Front Open with Hydraulic Grip & Servo System

Computerized universal testing machine with a front-open design, hydraulic grip, and servo system is an advanced testing instrument used for evaluating the mechanical properties of materials. The combination of a front-open design, hydraulic grip, and servo system offers precise control, reliable gripping, and accurate testing results. Look for a machine equipped with computerized control and data acquisition system. This allows for precise control of testing parameters, real-time data monitoring, recording, and analysis. The software should have a user-friendly interface and provide comprehensive data analysis tools. Universal testing machines typically offer a range of test modes, including tensile, compression, bending, and shear tests. Ensure that the machine supports the specific test modes and standards relevant to your application. Common standards include ASTM, ISO, DIN, and EN.

Computerized universal testing machine with a front-open design is hydraulically controlled servo Universal Testing Machine. The main advantage of this servo system is a test can be conducted by giving a specific load rate or elongation rate. The oil flow is controlled by the close loop feedback from the load elongation system. Test with specific load steps can also be conducted.

testing machine, universal testing machine, universal testing machine with servo system, universal testing machine with hydraulic, computerized universal testing machine with hydraulic servo system, computerized universal testing machine with front open, computerized universal testing machine with front open hydraulic servo system

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#testing#testing machine#universal testing machine#computerized universal testing machine#computerized universal testing machine with servo system#computerized universal testing machine with hydralic grip

1 note

·

View note

Text

Computerized Tensile Testing Machine -C SERIES

Computerized tensile testing machine provide precise and repeatable results, allowing for accurate characterization of material properties. They are commonly used in industries such as manufacturing, construction, research and development, and quality control to ensure material compliance, assess product quality, and aid in material selection and design.

These models are suitable for testing metals and iron, Plastics, Rubber, Ceramics, Fabrics, Composites, Cables and wires. Load is measured through a strain gauge based Load Cell and elongation is through rotary encoder. Depending upon the customers requirement a suitable type of grips are available. Extra Load cell can be offered suitable for low load samples.

Tensile testing machines include safety features to protect operators and prevent damage to the machine. These features may include emergency stop buttons, overload protection, and software-controlled limits for maximum force or displacement.

tensile testing machine, computerized tensile testing machine, universal testing system, computerized tensile testing machine supplier, computerized tensile testing machine manufacture, computerized tensile testing machine specification, computerized tensile testing machine best price, computerized tensile testing machine near by supplier, computerized tensile testing machine cost

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#tensile testing#tensile testing machine#computerized tensile testing#computerized tensile testing machine#computerized tensile testing machine supplier#computerized tensile testing machine manufacturer#computerized tensile testing machine price#computerized tensile testing machine best price#computerized tensile testing machine near by#computerized tensile testing machine exporter#computerized tensile testing machine dealer

1 note

·

View note