#co2lasercuttingmachines

Explore tagged Tumblr posts

Text

CO2 Laser Cutting CNC Machines

Introduction:

In the realm of modern manufacturing, precision and efficiency reign supreme. From intricate designs to mass production, industries seek technologies that can deliver both accuracy and speed. Among the array of tools available, CO2 laser cutting CNC machines stand out as pioneers in the field. These machines harness the power of laser technology coupled with computer numerical control (CNC) to achieve remarkable precision in cutting a variety of materials. Let’s delve into the intricacies of CO2 laser cutting CNC machines and explore their applications, benefits, and future prospects.

Understanding CO2 Laser Cutting CNC Machines:

CO2 laser cutting CNC machines operate on the principle of using a high-powered laser beam to cut through materials with unparalleled accuracy. The core component of these machines is the CO2 laser tube, which generates the laser beam through the excitation of carbon dioxide gas. This laser beam is then directed by mirrors onto the surface of the material, where it melts, burns, or vaporizes the material along the desired cutting path.

The CNC aspect of these machines refers to computer numerical control, which enables precise control over the movement of the laser beam. Through sophisticated software programs, users can create intricate designs and patterns, which are then translated into precise instructions for the CNC system to follow. This level of automation not only enhances accuracy but also allows for rapid prototyping and customization.

Applications of CO2 Laser Cutting CNC Machines:

The versatility of CO2 laser cutting CNC machines makes them indispensable across various industries. Some common applications include:

Metal Fabrication: CO2 laser cutting CNC machines excel in cutting a wide range of metals, including steel, aluminum, and titanium. They are utilized in industries such as automotive, aerospace, and electronics for cutting intricate components with tight tolerances.

Woodworking: From furniture manufacturing to architectural modeling, CO2 laser cutting CNC machines offer precise cutting of wood and plywood. They enable intricate designs, delicate engraving, and efficient production of customized wooden products.

Acrylic and Plastic Cutting: CO2 lasers are highly effective in cutting acrylics, plastics, and polymers. They are widely used in signage, displays, and packaging industries for creating precise cuts and intricate shapes.

Textile and Leather Processing: In the fashion and textile industry, CO2 laser cutting CNC machines are employed for precise cutting and engraving of fabrics, leather, and synthetic materials. They enable intricate designs, patterns, and precise finishing touches.

Benefits of CO2 Laser Cutting CNC Machines:

The adoption of CO2 laser cutting CNC machines offers numerous benefits for manufacturers:

Precision: With laser technology and CNC control, these machines offer unparalleled precision, allowing for intricate designs and tight tolerances.

Versatility: CO2 laser cutting CNC machines can cut a wide range of materials, including metals, wood, plastics, textiles, and more, making them versatile tools for diverse applications.

Speed and Efficiency: The combination of laser cutting and CNC automation enables rapid prototyping, quick production runs, and efficient material utilization, leading to shorter lead times and increased productivity.

Minimal Material Waste: Laser cutting produces minimal material waste compared to traditional cutting methods, leading to cost savings and environmental benefits.

Future Prospects:

As technology continues to advance, the capabilities of CO2 laser cutting CNC machines are expected to evolve further. Integration with artificial intelligence (AI) and machine learning algorithms may enhance automation, optimize cutting parameters, and improve overall efficiency. Moreover, advancements in laser sources and optics may lead to higher cutting speeds, increased power, and improved cutting quality, expanding the application range of these machines.

Conclusion:

CO2 laser cutting CNC machines represent the epitome of precision and efficiency in modern manufacturing. With their ability to cut a wide range of materials with unparalleled accuracy, these machines have become indispensable tools across various industries. As technology continues to advance, the future holds even greater promise for CO2 laser cutting CNC machines, paving the way for innovative applications and enhanced productivity in manufacturing processes.

0 notes

Text

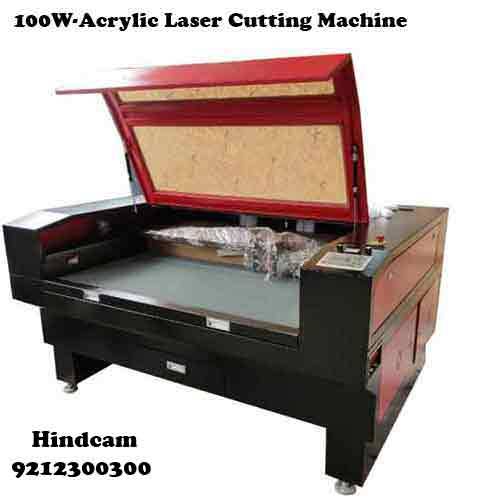

Hindcam is manufacturing the high-powered 100W CO2 laser cutting machine that stands at the forefront of this technological advancement. It offers unparalleled capabilities in cutting various materials with precision and speed. Our CO2 laser machine represents a pinnacle of versatility and reliability in the realm of cutting and engraving.

#co2laser#Co2LaserCuttingMachine#co2laserresurfacing#laserengraving#lasercuttingequipments#lasercuttingmachineforsale#lasercuttingandengraving#hindcam

1 note

·

View note

Video

tumblr

warning! vinyl cutting plotter revealed: here's what you NEED to know #co2lasercuttingmachine

0 notes

Photo

So time for a Co2 laser controller upgrade after my machine caught fire while I had left it alone. Almost repaired at last. . . #ruidasilvateam #ruidazonacional #co2lasercuttingmachinefornonmetal #co2lasercutter #co2lasercuttingmachineforinjectionnozzle #ruida #lasercutter #ruidazo #co2lasermachine #co2lasercuttingmachinesamples #co2lasercuttingmachines #co2lasercuttingmachineforacrylic #ruidacruz #ruidanthair1892 #co2laserresurfacing #co2lasercuttingmachineforfabric #co2lasertreatment #co2laserengraving #co2lasercuttingmachineandparts #lasercuttergr #co2lasercuttingmachine #fiberlasercutter #ruidasilva #co2lasercuttingmachineforhelmet #co2lasercuttingmachinepriceinindia #co2laser #ruidacostasoares #ruidas #lasercutters #intags https://www.instagram.com/p/CdbYkSejWGj/?igshid=NGJjMDIxMWI=

#ruidasilvateam#ruidazonacional#co2lasercuttingmachinefornonmetal#co2lasercutter#co2lasercuttingmachineforinjectionnozzle#ruida#lasercutter#ruidazo#co2lasermachine#co2lasercuttingmachinesamples#co2lasercuttingmachines#co2lasercuttingmachineforacrylic#ruidacruz#ruidanthair1892#co2laserresurfacing#co2lasercuttingmachineforfabric#co2lasertreatment#co2laserengraving#co2lasercuttingmachineandparts#lasercuttergr#co2lasercuttingmachine#fiberlasercutter#ruidasilva#co2lasercuttingmachineforhelmet#co2lasercuttingmachinepriceinindia#co2laser#ruidacostasoares#ruidas#lasercutters#intags

0 notes

Photo

Benefits of Using Laser Technology on Leather. https://www.lasercuttingmachines.co.in/

#CO2LaserCuttingMachines#SingleHeadLaserCuttingMachines#AcrylicLaserCuttingMachines#MDFLaserCuttingMachines#DoubleHeadLaserCuttingMachines#PaperLaserCuttingMachines#LeatherLaserCuttingMachines

0 notes

Text

“Committed To Make A Difference By Delivering More Than Expectations"

Valor5 is the brand who helps you in Signage Industry with entire Solution of Finishing Equipment like Co2 laser Cutting Machine , Fiber Laser Cutting Machine, CNC Router, Digital Cutting Creasing and Routing, Channel Letter Bender, Clincher, Spot Welder, Waterjet etc. To know more please call on 7030567766 / 7798082822

1 note

·

View note

Link

As one of the most professional 5x10 ft 1530 co2 laser cutting machine for acrylic plywood manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to buy 5x10 ft 1530 co2 laser cutting machine for acrylic plywood at competitive price from our factory.

0 notes

Text

4 Ways A Co2 Laser Cutting Machine Can Benefit Your Business

Co2 lasers were developed by Kumar Patel in 1964 and are still one of the most useful lasers in use today. A Co2 laser is great for applications requiring precision, mass production, and most importantly, personalization. With Co2 Laser Cutting Machine, you can create designs, decorations, and the like on almost any material, including wood, plastic, metal, and paper.

Reduce Material Waste & Expedite Production!

With a Co2 Laser Cutting Machine, productivity can be increased substantially because the material is cut faster than with other methods. The machine also helps in avoiding environmental hazards associated with manual cutting, such as overworking of workers and accidents. Also, reduced material waste leads to a lower budget need for disposal and reduces the expenditures on new materials.

Reduce Manufacturing Time.

By taking advantage of the precise cutting ability of a Co2 laser beam and BOFA Filter Replacement, delayed or unwanted product parts can be eliminated, and manufacturing time can be significantly shortened. This was recently used in the automotive industry where chips and wiring harnesses are now being produced using this technology at high speeds without compromising quality or function.

Enhanced Or Functional Parts.

Functional parts that need to be precision-cut often require multiple manufacturing steps that add extra cost, time, or both. A Co2 laser cutter can eliminate these steps and produce parts right up to a very high degree of accuracy – even down to the finest details – without any additional tooling or fixtures needed on-site. As a result, parts produced by a Co2 laser cutter often have more functionality than their traditional counterparts and require less setup time during assembly or manufacture.

Reduced Environmental Impact & Reduced Energy Consumption.

Compared to other manufacturing processes, co2 laser cutting machine tends to have a low environmental impact due “cutting” does not create dust particles like blades do which tend to significantly increase air pollution levels in areas adjacent to factories, etc., what is more, is that with modern CMMS & CAD grade software there is very little noise made while the machine is working which means it does not disturb people working nearby either.

0 notes

Text

CO2 Laser Cutting Machine (RUIDA) For Cutting & Engraving At MDF Sheet, Acrylic Sheet for Making Lamp Or Other Gift Item Or KeyChains & Many more For More Information

Company Details:--------------

Name - Ambition Gifts

Contact no: 011 4156 3389

youtube

#Co2LaserCuttingMachine#MDFCuttingMachine#acryliccuttingmachine#lampmakingmachine#delhi#india#facebookpost#sublimationindustry#Youtube

1 note

·

View note

Photo

VALOR5 Finishing Equipments for Signage Industry

Finishing Equipments like Co2 laser Cutting Machine, CNC Router, Fiber Laser available with service support. To know more please contact us on 7798082822 or visit us at https://www.global5tech.com

0 notes

Text

🔛 160100 CO2 Laser Cutter with Conveyor System, Roll Feeder and Collecting Table ✨💯

0 notes

Video

youtube

With CCD camera co2 laser follow cutting 20mm acrylic --- cut "CAR sheet"

Email: iris@leapion.com WhatsApp/ WeChat: +86 15314120680

0 notes

Photo

Shop for inexpensive laser cutting machines with high-speed, high precision and high efficiency from Prakash Laser. Get a free quote now and get guaranteed the best quality and deal with your purchase with us https://bit.ly/2MmF3vg

0 notes

Video

tumblr

Leather is an exceptionally popular material to laser engrave and cut for a variety of reasons.

Raw leather sheets and premade leather products are relatively affordable, extremely durable, and have a high perceived value, especially when they are personalized for a customer with a laser. Combining an RECI Laser and this versatile substrate can open the door to many profitable applications and opportunities, from fashion accessories to promotional products and everything in between.

#laser#engravingmachine#engraver#laserengraver#co2laser#co2laserengraving#co2lasercuttingmachine#laserengravingmachine

0 notes

Photo

#co2lasercutter #co2laser #lasermachine #lasercutting #lasercutter #cncmachine #cncmachining #co2lasercuttingmachine(在 Jinan, Shandong Province China) https://www.instagram.com/p/CAu51Yplk-j/?igshid=1bbd4egq84ln2

#co2lasercutter#co2laser#lasermachine#lasercutting#lasercutter#cncmachine#cncmachining#co2lasercuttingmachine

0 notes