#cnc milling machine price

Explore tagged Tumblr posts

Text

Looking for CNC Lathe Machine Manufacturer & Supplier Pune? Leymonn Enterprice is prominent CNC lathe machinery manufacturer & supplier in competitive price. Traditionally, human-operated lathe machines were used for part manufacturing. However, today, CNC lathe has become a popular adoption for parts production.

#cnc lathe machine Pune#cnc lathe machine price#cnc lathe machine supplier#CNC Milling Machine#cnc milling machine price#cnc mini lathe machine#Pune

1 note

·

View note

Text

India's largest CNC machine tools group, Sahil Machines. Leading CNC machine manufacturers offering comprehensive machining centers both in India and overseas.

Established in 1968, Sahil Alloys & Machine Tools is a CNC machine manufacturer in India that has been innovating the manufacturing and CNC sectors since day one through our brand Suraj. By driving innovation, we strive to contribute to society and bring a positive impact on the global manufacturing and CNC industries.

#cnc machine#cnc machine operator#cnc router machine#cnc machine price#cnc machine price in india#cnc milling machine#cnc router machine price

1 note

·

View note

Text

Cosmos Impex: Leading CNC Machine Tools Manufacturer & Supplier in India

Established in 1987, Cosmos Impex excels in Leading CNC Machine Tools Manufacturer & Supplier in India. We offer cutting-edge machining centers, including vertical and horizontal turning centers, 5-axis and die-mould machining centers, and imported machines from Taiwan and Japan. Our commitment to innovation, quality, and customer service ensures top performance and reliability for manufacturers across India.

#cnc machine manufacturer india#cnc machine suppliers in india#cnc machine manufacturers in vadodara#cnc machine cost in india#cnc machine manufacturer in gujarat#cnc vertical machining centers#best vmc machine in india#vertical milling machine cnc#cnc drilling tapping machine#cnc turning machine manufacturers in india#cnc vertical turning lathe#vertical turning lathe#Digital factory solution iot cnc#surface grinder machine manufacturer#surface grinding machine price#cnc lathe machine manufacturer in india#cosmos vmc#cosmos vmc 1160#cosmos vmc 800#cosmos cvm 1370 price in india#cosmos cvm 1160 price#cosmos cvm 640 price in india#cosmos cvm 800 specifications#cosmos cvm 1370#cosmos cvm 1160

0 notes

Text

I was tagged by @sleightlyoffhand to list 5 topics I can talk on for an hour without preparing any material. You asked for it.

3D printing. This one was too easy. I could talk specifics of FDM machines and materials, or vaguely about other types. These range from SLS to DLP, to more niche high price models I'll never see irl except once. Like anything from Stratasys. Who I used to hecking idolize for having one of the first patents for 3D printing, other than the guy who came up with SLA.

CNC machines. This is probably an extension of 3D printing, as most FDM machines work pretty similar to most CNC mills, engravers etc. The code is the same (gcode). It can be easily written for simple processes like cutting, facing, and drilling. But, just as a slicer program converts 3D models to gcode, there are programs out there for turning 3D information into CNC gcode. It's just a subtractive process instead of an additive one.

The consequences of technology. Especially AI. It may be the best and worst thing to happen to humanity. I could rant about all the wonderful and horrible things that could arise, but it is probably better for both of us if I don't.

Minecraft. Maybe I quit lately, but I could still talk about the history from beta onwards. At least up until whatever update added the chat moderation. I really like pistons (old update) and I really like the bees (is that still considered new?). I love automatic farms, but they are more fun when you have a team that can use them. Don't get me started on redstone, or it will turn into a ramble about electronics and logic gates.

Crash Bandicoot. This place is not a place of honor. No highly esteemed deed is commemorated here. Nothing of value is here. What is here was dangerous and repulsive to us.

Tagging: @wigglerhope @ravenekrops @moth-unit-00

7 notes

·

View notes

Text

CNC Machining - Everything You Need to Know

CNC machining is a very broad category of possible operations and processes. Among CNC machining operations, drilling, milling, and turning are the most common.

DRILLING

Drilling processes use bits with a diameter the same size as the diameter of the desired hole. The machining equipment inserts the spinning drill bit perpendicularly into the workpiece until it drills a hole of a predetermined length. More complex equipment can produce angular holes, and drilling tools can provide capabilities such as:

MILLING

The milling process removes cuts of material from the workpiece by moving the material against a spinning cutting edge. The tools have multiple cutting points, and each tool spins to provide a sharp cutting surface with a different length and shape. When the workpiece is pressed against milling tools, thin strips or cuts of material are removed from the existing edge. This can create shallow cuts, wide cuts, or flat-bottom cavities to shape the part. Peripheral milling processes may cut deeper to create slots or threads into the piece’s general shape.

TURNING

Turning processes turn the workpiece instead of the cutting tool. They include cutting processes such as boring, grooving, and facing. They cut excess material off of a workpiece by using single-point cutting tools precisely applied to the rotating workpiece. Turning creates cylindrical parts that have a specified diameter. Turning can create linear features both inside and on the exterior edge of the parts. These features include:

ADVANTAGES OF CNC MACHINING

Many manufacturers prefer machining processes because they create parts or components from a single workpiece. CNC machining has several additional advantages. These include:

Increased productivity. Facilities with CNC machining can produce parts 24/7. The machines may run continuously with little-to-no human intervention. The machines also require less space than workstations or manual machining setups, so a facility with a set square footage can have more machines running simultaneously.

A high degree of accuracy. CNC machining uses highly detailed programming operations. The machines follow these instructions without allowing any unwanted variation or human error. The parts will be high-quality, precise, and identical. CNC machining can also produce parts with intricate, complex designs.

Faster project completion. Every CNC machining process starts with a CAD design, so the prototyping process will be much faster. The software catches or prevents many possible design flaws or potential risks with different materials. When the prototyping and testing processes are shortened, products can go from design into production faster. CNC machining instructions can also be modified or replaced quickly, so there is little delay between changes in production runs.

Cost-effectiveness. CAD file designs and reduced risks of manufacturing errors reduce the per-unit cost of production. CNC machining also requires less human labor, which further reduces the price of manufacturing the products.

For customers seeking a complete manufacturing solution, Pro-Type Industries, Incorporated offers a level of value and process flexibility that is unmatched in the industry. We operate a state-of-the-art facility that is equipped with some of the most advanced CNC machining systems available.

With our experienced skillful engineers team, we providing high quality custom CNC metal and plastic parts to world wide clients in many industries field. We are always appreciated by high tolerance quality and one-stop service of multiple processes. We are now working for clients partners from USA, Euro, Mid-East, Asian, supporting clients’ projects by excellent quality, bottom cost and quick lead-time.

3 notes

·

View notes

Text

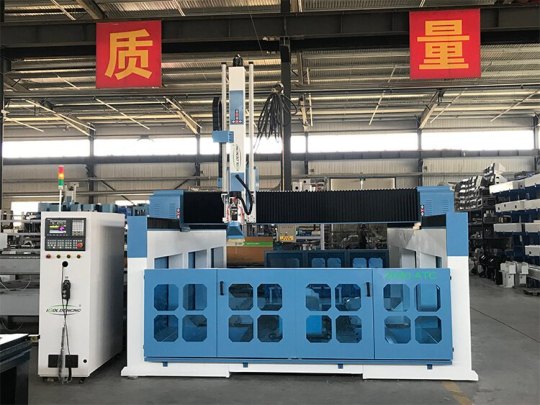

Automatic Tool Change Foam Router EPS CNC Carving Machine

CNC Router Foam Cutting Machine

Automatic Tool Change Foam Router, also known as an EPS CNC Carving Machine with Automatic Tool Change, is a specialized computer-controlled machine designed for cutting, carving, and shaping Expanded Polystyrene (EPS) foam materials. These machines are equipped with an automatic tool change system that allows for the seamless swapping of cutting tools during the CNC routing process.The 3d CNC router milling machine can be seamlessly spliced, suitable for various shapes.This CNC router foam machine also can be used in embossing, lettering, hollowing, cutting, vertical carving, round carving, etc.

This 4 axis cnc foam router is a little special when compared with the ordinary four axis machine. The conventional 4-axis construction has two types: one is that the spindle can swing ±90 degrees; the other refers to the rotary axis. Either of the two can be called the ordinary 4-axis cnc machine. What makes this machine special is that it is actually a 2 in 1 cnc foam router as it has the two types 4 axis construction stated above. Based on this design, there is no doubt that it has more possibilities than a normal 4-axis machine. The 4 axis cnc foam router here is perfect for 3D polystyrene shapes making.

4 Axis 3d CNC Router Milling Machine

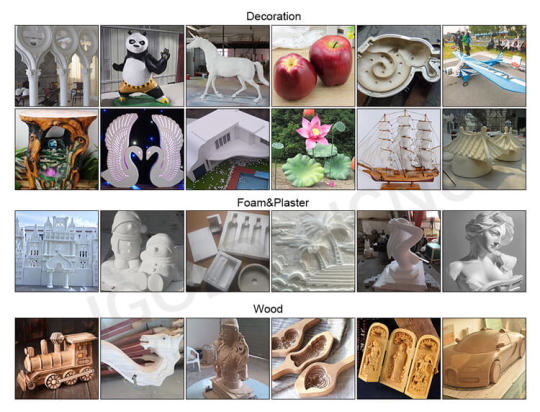

EPS/foam CNC router usually comes with a big working dimension for carving and cutting large-size workpieces of wood, aluminum, and styrofoam. It can also be equipped with an ATC spindle and a rotary device for complex, heavy-duty, and long-term work. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

Automatic Tool Change Foam Routers are specifically designed to work with EPS foam materials. EPS foam is commonly used in various industries for insulation, packaging, and creative applications due to its lightweight and easy-to-cut properties.Like other CNC machines, EPS CNC carving machines with automatic tool change offer high precision and accuracy. The CNC technology ensures that complex designs, intricate patterns, and 3D shapes can be executed with precision.

Foam Router EPS CNC Carving Machine

Packaging: Creating custom foam inserts for protecting fragile items during shipping.

Sculpture and Art: Carving intricate sculptures and art pieces from EPS foam.

Architectural Design: Crafting decorative elements and architectural details.

Set Design: Producing props and scenery for theater, film, and events.

Sign Making: Crafting 3D signs, logos, and lettering.

This cnc router foam cutter is designed especially for custom EPS expanded polystyrene foam moldings. The molded foam is usually used for casting & founding. Three-axis construction with 1500x3000mm machining size (5×10 in English); (need 4th rotary? please check out foam milling machine with rotary axis) Dirt guard is designed on X Y Z axes particular for cnc foam machining, which keeps the precise transmission parts away from the machining debris. The table is made of aluminum profiles. It is ideal for EPS EVA foam machining as well as wood machining. CNC router foam cutter for custom EPS EVA molding for sale at a reasonable price now!

Application Scope

How Many Kinds of CNC Foam Router Are There?

Well, this need to see from which perspective. From a motion axis quantity perspective, there are 3 axis, 4 axis and 5 axis cnc foam router; from application point of view, there are cnc foam router for polystyrene, for woods and for aluminum.

0 notes

Text

If you're in the market for used CNC machines, look no further than The Equipment Hub. We offer a comprehensive selection of high-quality, pre-owned CNC equipment perfect for a variety of manufacturing applications. Our used machines undergo rigorous inspections to ensure they meet our high standards for performance and reliability. With options suitable for milling, drilling, and cutting, you can find the right fit for your production needs at competitive prices. Our knowledgeable team is ready to assist you in making the best choice for your business.

1 note

·

View note

Text

How to Spot Quality Equipment at Machine Shop Auctions

When browsing machine shop equipment auctions, it’s crucial to know how to spot quality items. Auctions are excellent for finding well-priced machinery and tools, but without careful evaluation, there’s a risk of buying faulty or worn-out equipment. Here’s a guide to help you identify quality equipment at these auctions.

1. Research the Equipment Types in Demand

Before attending a machine shop equipment auction, do some research on the equipment types you’re interested in. Each category, from milling machines to CNC lathes, has its quality benchmarks. Knowing the specifications and expected lifespan of the tools you need can help you quickly filter out poor-quality items. Review online forums, and machinery sales websites, or consult with industry experts to understand the market standards for each piece.

2. Examine Visual Condition Closely

A good inspection begins with a detailed visual assessment. Check for obvious signs of wear and tear that might indicate excessive use or lack of maintenance. Look for:

- Rust: Rust can compromise the structural integrity of metal equipment. Minor surface rust may not be a dealbreaker, but extensive rust, especially on critical components, suggests neglect.

- Welding or Repairs: Signs of past repairs or welding work may indicate previous damage. This isn’t necessarily a dealbreaker, but it’s best to understand the nature of the repairs and how they impact functionality.

- Cleanliness: While auctioned equipment often shows signs of use, machinery that appears clean and well-kept may have been better maintained.

3. Assess Operational Readiness

Many machine shop equipment auctions allow potential buyers to inspect machinery while in operation. If possible, test the equipment to ensure that all moving parts work smoothly and without unusual noise. Equipment that operates without stalling, rattling, or struggling under pressure is a good sign. Take note of any resistance or roughness in moving parts, as these can indicate wear on the gears or bearings.

4. Check the Maintenance Records

Some sellers may provide maintenance records, especially for high-value machinery like CNC machines or larger lathes. A consistent record of servicing, calibration, and part replacements shows that the equipment was cared for and maintained at a professional level. When possible, ask the auction manager or the equipment owner for these records to get a better sense of the equipment's history.

5. Inspect Tooling and Accessories

Tooling and accessories that come with machine shop equipment are often valuable on their own. Look for any extras like cutting tools, holders, clamps, and adapters, that can add significant value to your purchase. Assess the condition of these accessories—worn-out or broken tools might indicate heavy use. Conversely, if the equipment comes with well-kept accessories, it suggests that the previous owner maintained the machinery carefully.

6. Pay Attention to Brand Reputation

Certain brands have a reputation for quality and longevity in the machine shop industry. Research the brands available at the auction and prioritize those known for reliability, such as Haas for CNC machinery or Bridgeport for milling machines. Lesser-known brands might be tempting for their lower prices, but it’s essential to research their track record in terms of durability and parts availability.

7. Look for Signs of Obsolescence

When investing in machine shop equipment, ensure it isn’t outdated or difficult to repair. Older machines can sometimes be cost-effective, but they might lack modern functionality and safety features. Additionally, sourcing parts for older equipment can be a challenge. Look up the model and confirm that parts and support are still available from the manufacturer or aftermarket suppliers.

8. Estimate Repair Costs and Factor Them In

Some auctioned equipment may have minor issues that require repair or maintenance. If you spot an item with small mechanical issues but the potential for longevity, estimate the repair costs. Simple repairs, like replacing belts or bearings, are often affordable and can justify purchasing a machine at a lower price. However, costly or complex repairs (e.g., motor replacement on CNC machinery) may not be worth the investment.

9. Be Cautious of “As-Is” Terms

Most machine shop equipment auctions sell items on an “as-is” basis, meaning there are no guarantees on condition. While this is common, it places more responsibility on the buyer to assess quality carefully. Be extra cautious and scrutinize each piece thoroughly, as the “as-is” condition often means you won’t have recourse if the equipment turns out to be faulty.

10. Consult with a Specialist When in Doubt

If you’re new to purchasing at machine shop equipment auctions or if you’re planning to buy high-value equipment, consider bringing a specialist or technician. A knowledgeable person can spot potential issues and help you avoid costly mistakes. Their insights can be invaluable, especially for evaluating intricate machinery like CNC mills or lathes.

Final Thoughts

Machine shop equipment auctions offer great opportunities to acquire quality machinery at reduced prices. However, evaluating each piece’s quality before bidding is essential to ensure you’re making a wise investment. With these tips, you’ll be better prepared to navigate machine shop equipment auctions, identify quality machinery, and find the right equipment for your workshop needs.

0 notes

Text

Mucision integrates seamlessly with over 10,000 qualified manufacturing partners, including ITAR qualified and AS9100D registered CNC milling facilities. That massive network means that whatever your part, we have a shop and a machine that can make it. We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes. We offer instant pricing, on-demand lead times, and design-for-manufacturability feedback on materials and manufacturing processes for your custom CNC milled parts, no matter your industry.

0 notes

Text

Benefits of a CNC Machine Shop

Benefits of a CNC Machine Shop

A CNC machine shop can produce products and parts more quickly and accurately than traditional manufacturing methods. This can help businesses reduce lead times and meet customer demands more quickly. They also can save money by working with a third-party shop that will not require them to invest in expensive tools and equipment. This helps them avoid unnecessary wear and tear on their own machines.

Speed

When it comes to manufacturing, speed is key. Customers appreciate a business that can produce products quickly and easily. This translates to faster shipping times and reduced overhead costs. Speed also increases customer satisfaction, which can lead to a more loyal and engaged customer base. A satisfied customer will not only remain loyal to the brand, but will also act as an unofficial brand ambassador within their spheres of influence. When choosing a CNC machine shop, look for one that has a range of capabilities and uses modern machinery. This will ensure that the machine shop can deliver quality parts. In addition, make sure the shop is honest about its capabilities and doesn’t attempt to deliver services that are beyond its scope. To avoid this, always have the shop sign an NDA before starting work. This will protect your intellectual property from being passed on to a third party. This is especially important if you are using a third-party machine shop to manufacture prototypes for your business.

Accuracy

A CNC machine shop with an experienced staff and modern equipment can provide you with high-quality results. The shop should be capable of producing a wide range of parts and can accommodate different sizes. They should also use standard measuring equipment to ensure that the finished products meet dimensional specifications. A quality CNC machine shop will use a 3D scanner to measure the geometry of the workpiece and provide a model. This allows the machinist to accurately determine the tolerances and other parameters of the part before machining. This tool saves time and money by ensuring that the finished product meets your specifications. It is important to consider the long-term value of a machine shop when choosing one for your production needs. The best shop will have the most updated equipment and can produce your parts quickly and efficiently. They will avoid expensive mistakes and delays that can cause your business to lose money. They will also ensure the safety of employees and customers by following strict health and safety guidelines.

Flexibility

Flexibility is the ability to move a joint through its full normal range of motion (ROM). It also helps improve performance, posture, and movement, prevents muscle imbalance, and decreases injury risk. It is a key component of good health and can be influenced by age, injury, and lifestyle. In addition to speed and accuracy, flexibility increases production time by decreasing machine downtime. In addition, flexibility enables machinists to quickly change tooling when a part breaks or malfunctions. This type of flexibility is vital for any manufacturing business to thrive. When evaluating CNC shops, look for long-term value rather than just the lowest price per part. The best shop will have equipment that produces quality results without delays or costly mistakes. Choose a shop that can mill, turn, and lathe, and has two to five-axis shaping capabilities for the most precise work. You should also consider whether they have the capability to deliver finished parts in a timely manner.

Cost

A CNC machine shop’s costs depend on its size, experience, and technology. Its rates should be fair and competitive with those of other machine shops. However, it is important to consider that low prices may result in substandard machined parts and long delays. You can avoid this by choosing a CNC machine shop with updated equipment and a large customer base. This way, you can ensure that the shop will work quickly and accurately on your project. In addition to being able to handle complex projects, you should also make sure the machine shop has a wide range of machines for turning, milling, and lathes. This will allow them to work on a broad range of shapes and sizes. Moreover, a quality CNC workshop will always respect your confidentiality and will never disclose your designs to third parties. You can ask the workshop to sign a Non-Disclosure Agreement (NDA). This will safeguard your designs from unauthorized use. Read the full article

0 notes

Video

youtube

At KD Hardware, we specialize in delivering high-precision CNC turning services to customers around the globe. Equipped with a skilled engineering team and state-of-the-art technology, we handle a wide range of machining needs—from automatic CNC lathes to turn-mill centers and Swiss-type lathes.

Whether you require simple components or complex structures, we bring your designs to life with precision and efficiency.

With a fleet of over 30 CNC lathes, including the CK-32, CK-40, and CK-50 models, we provide fast and comprehensive CNC turning solutions. Our goal is to help you shorten product development cycles while offering competitive pricing and on-time, accurate delivery.

We work with a variety of materials, such as stainless steel, aluminum alloys, copper, and plastics, ensuring high-performance and cost-effective machining solutions tailored to meet the demanding standards of various industries.

No matter your sector, KD Hardware is your trusted partner for all CNC machining needs. For more information about our turn-mill technology or to explore collaboration opportunities, don't hesitate to contact us!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#turningmachining#cncturning#cnclatheservice#cncgrindingservices#cncturningcompany#cncprecisionturning#largecncturning#customcncturning#turninginmachining#largecncturningservices#latheturningservices

0 notes

Text

Used Cnc Machines

Explore our range of high-quality used CNC machines at The Equipment Hub. We offer a comprehensive selection of used CNC machines, including mills, lathes, and routers, all rigorously tested to ensure they meet our high standards for performance and reliability. Whether you’re looking to expand your workshop or replace old equipment, our used CNC machines provide exceptional value and efficiency. Visit The Equipment Hub to view our inventory and find the perfect CNC machine to suit your needs. Enhance your operations with our trusted, pre-owned machinery and achieve outstanding results at a great price.

0 notes

Text

Accelerate Your Innovations with Influx Labs: Experts in Prototype CNC Machining

Introduction

In the fast-paced world of product development and manufacturing, having a reliable partner for prototype CNC machining and quick lead time parts is crucial. At Influx Labs, we specialize in providing high-quality CNC milling services that streamline the prototyping process and expedite the production of your innovative designs. Our commitment to precision, speed, and efficiency ensures that your projects move forward seamlessly from concept to completion.

Why Choose Influx Labs for Prototype CNC Machining?

Expertise in Precision Engineering

At Influx Labs, our team of skilled engineers and machinists brings extensive expertise in prototype CNC machining. Our advanced CNC milling equipment and rigorous quality control processes guarantee the precision and accuracy required for complex prototypes. Whether you need intricate components or large-scale prototypes, we have the capabilities to meet your exact specifications.

Rapid Turnaround for Quick Lead Time Parts

In today’s competitive market, time is of the essence. That’s why we prioritize quick lead time parts to help you accelerate your product development cycle. Our efficient workflow and state-of-the-art machinery enable us to deliver high-quality parts within tight deadlines, ensuring that your project stays on track and meets its launch goals.

Custom CNC Milling Solutions

Every project is unique, and at Influx Labs, we understand that one size does not fit all. Our custom CNC milling solutions are designed to cater to your specific needs, whether you require prototype components with complex geometries or parts with tight tolerances. We work closely with you to understand your requirements and provide tailored solutions that enhance your product’s performance and functionality.

Commitment to Quality and Precision

Quality and precision are at the core of what we do. At Influx Labs, we employ rigorous quality control measures to ensure that every part meets the highest standards. Our CNC milling process is designed to minimize errors and maximize accuracy, resulting in prototypes that accurately reflect your design intent and meet your functional requirements.

The Benefits of Prototype CNC Machining

Prototype CNC machining offers several advantages for product development and manufacturing. Here’s how partnering with Influx Labs for your prototyping needs can benefit your projects:

Enhanced Design Verification

Prototype CNC machining allows you to create physical models of your designs, providing a tangible representation of your concepts. This enables you to verify the design, test functionality, and identify potential issues before moving into full-scale production. Our precision machining ensures that your prototypes accurately reflect your design specifications, facilitating effective evaluation and refinement.

Accelerated Development Cycle

With quick lead time parts and efficient CNC milling, you can significantly shorten your product development cycle. Rapid prototyping allows you to iterate on your designs quickly, make necessary adjustments, and move forward with confidence. Influx Labs’ streamlined processes and advanced technology help you stay ahead of the competition and bring your products to market faster.

Cost-Effective Solutions

Prototype CNC machining offers cost-effective solutions for developing and refining your products. By identifying and addressing design issues early in the process, you can reduce the risk of costly changes during production. Influx Labs’ competitive pricing and efficient machining processes ensure that you receive high-quality prototypes without exceeding your budget.

Flexibility and Adaptability

Our CNC milling services provide the flexibility and adaptability needed to accommodate a wide range of prototype requirements. Whether you need single prototypes or small production runs, Influx Labs can scale our services to meet your needs. Our ability to work with various materials and machining techniques ensures that we can handle diverse project demands.

The CNC Milling Process at Influx Labs

Understanding the CNC milling process can help you appreciate the precision and efficiency involved in creating high-quality prototypes. Here’s an overview of how our CNC milling services work:

Design and Preparation

The process begins with the creation of a detailed design for your prototype. We work with you to finalize the design and prepare it for CNC milling. This involves generating a 3D model and developing a machining plan that outlines the specific operations required to achieve the desired results.

Material Selection

Choosing the right material for your prototype is crucial for achieving the desired performance and functionality. Influx Labs offers a wide range of material options, including metals, plastics, and composites. Our team can recommend the best material for your application based on your design requirements and performance criteria.

CNC Milling Operations

Once the design and material are finalized, we proceed with the CNC milling operations. Our advanced CNC machines use computer-controlled tools to precisely cut and shape the material according to the design specifications. This process ensures high accuracy and repeatability, producing prototypes that closely match your design intent.

Quality Control and Testing

After machining, each prototype undergoes thorough quality control and testing to ensure it meets the required standards. We inspect dimensions, tolerances, and overall quality to verify that the prototype performs as intended. Any necessary adjustments are made to ensure the final product meets your expectations.

Delivery and Support

Once the prototypes are complete and approved, we deliver them to you promptly. Influx Labs is committed to providing ongoing support throughout the prototyping process. If you have any questions or require additional modifications, our team is available to assist you and ensure your project’s success.

Why Quick Lead Time Matters

In the world of product development, quick lead time parts are essential for staying competitive and meeting market demands. Here’s why having a partner like Influx Labs with a focus on rapid prototyping is advantageous:

Faster Time-to-Market

Quick lead times enable you to bring your products to market faster, giving you a competitive edge. By accelerating the prototyping phase, you can move more swiftly through design iterations and start production sooner. Influx Labs’ commitment to quick turnaround times ensures that you can meet your project deadlines and capitalize on market opportunities.

Efficient Iteration and Testing

Rapid prototyping allows for efficient iteration and testing of your designs. With quick lead times, you can make adjustments based on test results and refine your prototypes more effectively. This iterative process helps you achieve a final product that meets your performance and quality standards.

Reduced Development Costs

Faster prototyping can lead to reduced development costs by minimizing delays and optimizing resource allocation. By addressing design issues early and efficiently, you can avoid costly rework and production setbacks. Influx Labs’ quick lead time parts contribute to cost-effective development and streamlined project management.

Get Started with Influx Labs

Ready to take your prototypes to the next level with expert CNC machining and quick lead time parts? Contact Influx Labs today to discuss your project requirements and discover how our CNC milling services can support your innovation journey. Our team is dedicated to providing high-quality solutions that drive your success and help you achieve your goals.

Conclusion

Influx Labs is your trusted partner for prototype CNC machining, quick lead time parts, and custom CNC milling solutions. With our expertise, advanced technology, and commitment to quality, we make it easy to bring your designs to life and accelerate your product development. Choose Influx Labs for your next project and experience the benefits of working with a dedicated, professional team that prioritizes your success.

0 notes

Text

CNC Milling Machines UAE | Cutting-Edge Technology, Unmatched Accuracy

Invest in high-quality CNC milling machines from our Dubai supplier. We offer a wide range of models to suit your specific needs, ensuring optimal performance and efficiency. Our competitive pricing and exceptional customer service make us your trusted partner.

https://middleeastcnc.com/cnc-milling/

0 notes

Text

High-Quality CNC Milling Manufacturers India - Deccanew.

Discover the leading CNC Milling Manufacturers in India with Deccanew. Offering precision engineering and high-quality CNC milling solutions, Deccanew is your trusted partner for all CNC milling needs. Contact us at 9657039991 for more information.

CNC (Computer Numerical Control) milling has revolutionized the manufacturing industry, especially in India, where precision, efficiency, and scalability are key factors. As the demand for high-quality components grows across various sectors, finding the right CNC Milling Manufacturers becomes crucial. At Deccanew, we pride ourselves on being a leader in this space, offering top-notch CNC milling services that meet the diverse needs of our clients.

Why Choose CNC Milling?

CNC milling india offers unparalleled precision and repeatability, making it the preferred choice for manufacturing complex parts and components. Whether it's the automotive, aerospace, or electronics industry, CNC milling ensures that every piece produced meets exact specifications. Here are a few reasons why CNC milling is the go-to process for manufacturers:

Precision Engineering: CNC machines can operate with micrometer precision, ensuring that each component is identical to the design specifications.

High Efficiency: Once programmed, CNC machines can run continuously, producing parts quickly and efficiently without the need for constant supervision.

Versatility: CNC milling can work with a wide range of materials, including metals, plastics, and composites, making it suitable for various industries.

Scalability: Whether you need a single prototype or mass production, CNC milling can handle varying production volumes with ease.

Deccanew: Your Trusted CNC Milling Manufacturer in India

At Deccanew, we understand the importance of precision and quality in CNC milling. Our state-of-the-art facilities and experienced team ensure that we deliver top-notch milling services that cater to the specific needs of our clients. Here’s why Deccanew stands out among CNC Milling Manufacturers in India:

Advanced Technology: We utilize the latest CNC milling machines equipped with advanced software to ensure precision and efficiency in every project.

Skilled Workforce: Our team of engineers and technicians are experts in CNC milling, with years of experience in delivering high-quality products.

Customization: We offer customized CNC milling solutions tailored to meet the unique requirements of our clients, ensuring that we deliver exactly what you need.

Quality Assurance: Quality is at the forefront of everything we do. We adhere to stringent quality control measures to ensure that every product meets the highest standards.

Competitive Pricing: Despite offering top-tier services, we ensure that our pricing is competitive, providing value for money to our clients.

Applications of CNC Milling

CNC milling is used across various industries to produce a wide range of products. Some of the key applications include:

Automotive Industry: Production of engine components, transmission parts, and other critical automotive components.

Aerospace Industry: Manufacturing of complex parts for aircraft, including turbine blades and structural components.

Medical Devices: Precision milling of surgical instruments, implants, and other medical devices.

Electronics: Production of enclosures, connectors, and other electronic components that require high precision.

Consumer Goods: Manufacturing of parts for appliances, tools, and other consumer products.

Why Deccanew is the Best Choice for CNC Milling in India

When it comes to CNC milling in India, Deccanew is a name you can trust. Our commitment to quality, precision, and customer satisfaction sets us apart from other CNC Milling Manufacturers. We understand that every project is unique, and we work closely with our clients to ensure that we deliver products that meet their exact requirements. Here’s what you can expect when you choose Deccanew:

Timely Delivery: We understand the importance of deadlines, and we strive to deliver all projects on time, without compromising on quality.

Customer Support: Our team is always available to assist you with any queries or concerns, ensuring a smooth and hassle-free experience.

Sustainable Practices: We are committed to sustainable manufacturing practices, minimizing waste, and reducing our environmental footprint.

CNC milling is a critical process in modern manufacturing, and choosing the right partner can make all the difference. Deccanew is proud to be a leading CNC Milling Manufacturer in India, offering high-quality, precision-engineered products that meet the needs of our clients across various industries. Contact us today at 9657039991 to learn more about our CNC milling services and how we can help you with your next project.

Visit:-https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.php

Contact: 9657039991

0 notes

Text

Affordable CNC Milling Machine Wood and Metal

In the realm of modern manufacturing, the CNC milling machine stands as a cornerstone of precision and efficiency. These machines have revolutionized the way we approach machining processes, offering unparalleled accuracy and the ability to produce complex parts with ease. Whether you’re a seasoned machinist or a newcomer to the field, understanding the intricacies of CNC milling machines can significantly enhance your manufacturing capabilities.

Affordable CNC Milling Machine

A CNC (Computer Numerical Control) milling machine is a sophisticated and highly precise tool used to shape and cut materials like metal, wood, and plastic. These machines are widely used in manufacturing and prototyping due to their ability to produce complex shapes and high-quality finishes.

Equipment that uses computerized controls to operate and manipulate cutting tools to shape materials into desired forms. These machines are capable of performing a wide range of operations, including drilling, cutting, and milling, with high precision and repeatability.

Small CNC milling machines are compact, desktop-sized machines that offer a range of advanced milling capabilities in a space-efficient package. These machines are well-suited for prototyping, small-scale production, and educational/hobbyist use.

Key Features of Small CNC Milling Machines

Compact Size

Small CNC mills have a small footprint, often fitting on a desktop or workbench. This makes them ideal for use in limited workshop or studio spaces. Typical work envelopes range from around 8″ x 6″ x 3″ up to 15″ x 12″ x 5″.

High Precision

Despite their small size, these machines are capable of producing parts with tight tolerances and smooth surface finishes. They utilize high-quality components like ball screws, linear guides, and rigid frames to achieve this precision.

Versatile Machining

Small CNC mills can handle a variety of materials including wood, plastics, aluminum, and other soft metals. This versatility allows them to be used for prototyping, model making, and small-scale production across many industries.

User-Friendly Operation

Many small CNC mills are designed with ease of use in mind. They often feature intuitive control interfaces, automated tool changers, and integrated CAM software to simplify the machining process. This makes them accessible for hobbyists and small businesses.

Affordable Pricing

Compared to larger industrial CNC machines, small desktop models are much more affordable, making them accessible for individual users and small shops. Prices can range from a few thousand dollars up to around $10,000 for a well-equipped model.

Types of CNC Milling Machines

There are several types of CNC milling machines, each designed for specific applications and capabilities. Here are some of the most common types:

Vertical CNC Milling Machines

Vertical CNC milling machines have a vertically oriented spindle that holds the cutting tool. These machines are versatile and commonly used for a wide range of applications, from prototyping to production.

Horizontal CNC Milling Machines

Horizontal CNC milling machines have a horizontally oriented spindle. These machines are ideal for machining heavy and large parts, as they offer greater stability and support.

5-Axis CNC Milling Machine

5-axis CNC milling machines are capable of moving the cutting tool along five different axes simultaneously. This allows for the creation of highly complex and intricate parts, making these machines ideal for aerospace, automotive, and medical industries.

How Does a CNC Milling Machine Work?

The operation of a CNC milling machine involves several key steps:

Design Creation: The first step is to create a digital design of the part using CAD (Computer-Aided Design) software. This design is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software.

Material Loading: The raw material, often referred to as the workpiece, is securely clamped onto the machine’s worktable.

Tool Selection: The appropriate cutting tools are selected and loaded into the machine’s tool holder.

Machining: The CNC program is executed, and the machine’s cutting tools follow the programmed path to shape the material into the desired form.

Finishing: After machining, the part may undergo additional processes such as deburring, polishing, or coating to achieve the final finish.

Types of Materials

Desktop CNC machines are versatile and can process a wide range of materials, including:

Wood: Commonly used in woodworking and carpentry.

Plastics: Utilized in prototyping and product design.

Metals: Employed in jewelry making, metalworking, and small-scale manufacturing.

Composites: Applied in automotive, aerospace, and consumer goods.

Foam: Used in packaging, modeling, and crafts.

Applications of CNC Milling Machines

Prototyping and Product Development

In the fields of prototyping and product development, desktop CNC machines are invaluable tools. Applications include:

Rapid Prototyping: Creating functional prototypes quickly and accurately.

Custom Parts: Producing custom components for various projects.

Product Design: Testing and refining product designs before mass production.

Education and Training

Desktop CNC machines are widely used in educational institutions for teaching and training purposes. Applications include:

Engineering Education: Providing hands-on experience with CNC technology.

Vocational Training: Preparing students for careers in manufacturing and machining.

STEM Programs: Enhancing science, technology, engineering, and mathematics education.

Choosing the Right CNC Milling Machine

When selecting a CNC milling machine, there are several factors to consider:

Machine Size

The size of the machine determines the maximum dimensions of the workpiece you can machine. Consider the types of projects you plan to work on and choose a machine with an appropriate work envelope.

Spindle Speed

The spindle speed affects the cutting performance and surface finish of the machined part. Machines with adjustable spindle speeds allow you to optimize the cutting conditions for different materials.

Tool Capacity

The tool capacity refers to the number of tools the machine can hold and automatically change during the machining process. A larger tool capacity allows for greater flexibility and efficiency in machining complex parts.

Software Compatibility

Ensure that the CNC milling machine is compatible with the CAD/CAM software you plan to use. Some machines come with proprietary software, while others are compatible with popular design programs like SolidWorks and Mastercam.

Ease of Use

If you’re new to CNC machining, look for a machine that is user-friendly and comes with comprehensive instructions and support. Many manufacturers offer online tutorials and customer support to help you get started.

Frequently Asked Questions (FAQ)

What materials can a CNC milling machine work with?

CNC milling machines can work with a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and wood.

How do I create a CNC program for my design?

CNC programs are created using CAM software, which converts the digital design from CAD software into machine-readable code. This code is then uploaded to the CNC milling machine for execution.

Can I use a CNC milling machine for prototyping?

Yes, CNC milling machines are commonly used for prototyping due to their ability to quickly and accurately produce parts with complex geometries.

How do I maintain my CNC milling machine?

Regular maintenance includes cleaning the machine, checking and replacing cutting tools, calibrating the machine, and ensuring the software is up to date. Refer to the manufacturer’s instructions for specific maintenance guidelines.

What is the difference between a vertical and a horizontal CNC milling machine?

Vertical CNC milling machines have a vertically oriented spindle, making them versatile and suitable for a wide range of applications. Horizontal CNC milling machines have a horizontally oriented spindle, offering greater stability and support for machining heavy and large parts.

0 notes