#chemical oxygen demand cod

Explore tagged Tumblr posts

Text

Chemical Oxygen Demand and Total Organic Carbon Analysis

Chemical Oxygen Demand (COD) and Total Organic Carbon (TOC) are widely used analysis methods in water treatment plants, petrochemicals and drinking water treatment. In this blog, let me walk you through the analysis of Chemical Oxygen Demand, Total Organic Carbon and its applications. Let’s get started with Chemical Oxygen Demand. What is Chemical Oxygen Demand?Why COD and TOC are…

View On WordPress

#biochemical oxygen demand class 12#biochemical oxygen demand kya hai#biochemical oxygen demand upsc#chemical oxygen demand cod#chemical oxygen demand definition#chemical oxygen demand water#what is chemical oxygen demand?#what is cod chemical oxygen demand

0 notes

Text

Chemical Oxygen Demand Sensor & Analyzer | Wizse Nsor Inc.

Wizse Nsor Inc. specializes in providing state-of-the-art Chemical Oxygen Demand (COD) sensors and analyzers that offer accurate, real-time monitoring for water quality management. Our COD sensors are designed to efficiently measure the amount of oxygen required to break down organic pollutants in water, making them ideal for wastewater treatment, environmental monitoring, and industrial applications.

Our COD analyzers use advanced optical and electrochemical technologies to deliver precise and reliable results, ensuring compliance with environmental standards and regulatory requirements. Whether you're in the field of water treatment, industrial processing, or environmental research, our COD sensor solutions are built to meet the rigorous demands of various applications.

The high sensitivity and durability of our COD sensors make them perfect for continuous monitoring in challenging environments. With easy integration, low maintenance, and real-time data collection, Wizse Nsor Inc. ensures that users receive consistent, accurate measurements for better decision-making.

Wizsensor Inc. is committed to innovation and customer satisfaction. We combine cutting-edge sensor technology with industry expertise to provide reliable and efficient COD monitoring solutions. Choose Wizse Nsor Inc. for the best in chemical oxygen demand sensor technology.

Water Conductivity Meter: Essential Guide by WizSensor

Water Conductivity Meter: Ultimate Guide

Ammonium Sensor & Ammonia Nitrogen Sensor Guide

Understanding Chemical Oxygen Demand (COD) Sensors

#Ammonium sensor#Ammonia nitrogen sensor#Water quality ammonium sensor#chemical oxygen demand sensor#chemical oxygen demand analyzer#cod sensor#dissolve oxygen sensor#dissolved oxygen probe#portable dissolved oxygen meter#optical dissolved oxygen sensor#do sensor

0 notes

Link

.

#Biological oxygen demand (BOD)#Chemical oxygen demand (COD)#Landfill leachate#Organic matter (or organic material)

1 note

·

View note

Text

Concept of chemical oxygen demand (COD), meaning, practical applications, and effective strategies for controlling and measuring COD levels

0 notes

Text

I dont understand how people can't love him. "he's boring" i feel like that's literally the point. hes talking about cod (chemical oxygen demand) to a cute girl who wants to kiss him

48 notes

·

View notes

Text

COD Thermoreactor

A COD (Chemical Oxygen Demand) thermoreactor is a specialized instrument used in environmental and water quality laboratories for the determination of COD levels in water samples. It facilitates the digestion of organic matter in the samples through a chemical reaction under controlled temperature conditions. The thermoreactor typically consists of a heating block or chamber with multiple sample positions, each capable of holding sample vials or tubes. The temperature is precisely controlled to accelerate the chemical reactions involved in COD analysis, ensuring efficient digestion of organic compounds. After digestion, the samples are typically cooled and then analyzed using colorimetric methods to determine the COD concentration.

#COD Thermoreactor suppliers in france#cod thermoreactor manufacturer in Indianapolis#cod thermoreactor suppliers in wisconsin.

4 notes

·

View notes

Text

0 notes

Text

Water testing Chennai - Falcon Industrial Testing Laboratory

Water is one of the most essential resources for life, and its quality directly impacts health, agriculture, construction, and industrial processes. In Chennai, where water scarcity and pollution are growing concerns, water testing plays a crucial role in ensuring safe and clean water for drinking, construction, and environmental compliance.

Whether you are a homeowner, builder, or industrial facility, professional water testing in Chennai helps detect contaminants, assess water purity, and comply with safety standards. This blog explores the importance of water testing, the different types available, and why Chennai residents and businesses should prioritize regular testing.

Why is Water Testing Important in Chennai?

Chennai faces multiple water-related challenges, including groundwater depletion, industrial pollution, and seawater intrusion. Contaminated water can lead to severe health issues, structural damage in construction, and environmental hazards. Here’s why water testing is essential:

Health & Safety – Drinking water contaminated with heavy metals, bacteria, or chemicals can cause diseases. Regular testing ensures compliance with WHO and BIS standards.

Infrastructure and construction: Poor water quality can corrode steel and weaken concrete.Construction materials testing in Chennai often includes water analysis to ensure durability.

Environmental Compliance – Industries must test wastewater before discharge to avoid pollution. Wastewater testing in Chennai helps industries adhere to CPCB and TNPCB norms.

Agricultural Use – Salinity and chemical levels in irrigation water affect crop yield. Testing ensures optimal water quality for farming.

Types of Water Testing Services in Chennai

1. Drinking Water Testing

Ensuring safe drinking water is critical. Tests check for:

Microbial contamination (E. coli, coliform)

Heavy metals (lead, arsenic, mercury)

Chemical pollutants (fluoride, nitrate, chlorine)

pH levels and turbidity

2. Construction Water Testing

Water used in concrete mixing must be free from impurities. Construction materials testing in Chennai includes:

Chloride and sulfate content analysis

pH and alkalinity tests

Organic and inorganic impurities

3. Wastewater & Effluent Testing

Industries must treat wastewater before disposal. Wastewater testing in Chennai examines:

Both chemical and biological oxygen demands (BOD and COD)

Oil & grease content

Heavy metals and toxic chemicals

4. Environmental Water Testing

Lakes, rivers, and groundwater sources are tested for pollution. Environmental testing in Chennai includes:

Surface and groundwater quality analysis

Detection of industrial pollutants

Microplastics and pesticide residues

5. Swimming Pool & Recreational Water Testing

Ensures water is free from harmful bacteria and chemicals like chlorine to prevent infections.

Other Essential Testing Services in Chennai

While water testing is crucial, Chennai also requires other quality checks for safety and compliance:

Soil Testing Chennai – Determines soil strength and composition for construction.

Geotechnical Investigation Chennai – Assesses soil stability for foundations.

Air Testing Chennai – Measures indoor and outdoor air pollution levels.

Steel Testing Chennai – Ensures the quality of steel used in construction.

Food Quality Testing Chennai – Checks for contaminants in food products.

Pollution Testing Chennai – Monitors air, water, and soil pollution.

Standard Penetration Test Chennai – Evaluates soil density for construction projects.

Earth Resistivity Test Chennai – Measures ground resistance for electrical safety.

Non-Destructive Testing Chennai: Examines materials without causing any harm (radiography, ultrasonic).

How is Water Testing Conducted?

Professional labs in Chennai follow standardized methods:

Sample Collection: Water samples are taken in sterile containers.

Lab Analysis – Advanced equipment like spectrophotometers and chromatographs detect contaminants.

Reporting – Detailed reports with recommendations for treatment (if needed).

Choosing the Right Water Testing Lab in Chennai

When selecting a testing service, consider:

NABL Accreditation – Ensures accuracy and reliability.

Advanced Equipment – Labs should use modern technology

Fast Turnaround – Quick results for timely decisions.

Expertise – Experienced technicians for precise analysis.

With increasing pollution and depleting water resources, water testing in Chennai is no longer optional���it’s a necessity. Whether for drinking, construction, or industrial use, regular testing ensures safety, compliance, and sustainability.

If you need water testing, soil testing, geotechnical investigation, or environmental testing in Chennai, always rely on certified labs for accurate results. Protect your health, infrastructure, and environment by prioritizing quality testing today!

Contact us

Phone Number : +918056159517

Website: https://fitpl.in/water-testing-in-chennai.php

#watertestingchennai#building materials testing chennai#materialtestinglabinchennai#falconlab#soil testing

0 notes

Text

Who Is The Best Sewage Treatment Plant Manufacturer In Gurgaon ?

Cities in India are significantly expanding towards urban as well as growing industrial metropolitan region of Gurgaon. Industries like Pulp & paper mills, chemical plants, & textile mills are some of the major heavy industries present in almost every state & cities, in addition to various medium & small-sized businesses that produce plastic goods, soaps, & other items which eventually requires treated good quality of water from a good sewage treatment plant manufacturer in Gurgaon for their specific manufacturing such as Commercial RO Plant.

The natural drains & waterways surrounding any areas near Gurgaon have been severely contaminated nowadays for decades by the untreated effluent water & sewage wastes discharge from these companies & houses. Study Evidences indicates that the water in these bodies of water contains hazardously high concentrations of pollutants, including color, total solids dissolved, chloride compounds, sulfur compounds, as well as bio-chemical oxygen demand, making it unsafe for human consumption. Such a circumstance clearly shows that the most innovative & growing sewage treatment plant manufacturer in Gurgaon must be founded & developed as soon as possible.

STP Plants for Every Possible location of Gurgaon for Severe Contamination of Water or Air Pollution

According to current estimates, the capacity & efficacy of STP treatment sets or setups are not sufficient to fulfill or surpass the mandatory limitations on discharge for treating significant amounts of complex wastewater, such as sewage or effluent.

There is a low degree of sewage network connectivity in this city, as only a small percentage of residential areas are connected to sewer lines. Groundwater becomes contaminated when residual raw sewage is dumped in landfills alongside adjacent bodies of water.

Putting into practice scientifically planned STP Plants is the most important action authorities can take right now to reduce its excessive water pollution & maintain both industrial & residential expansion in the years to come.

The significance of the role that Commercial RO Plant plays as a Sewage treatment plant manufacturer in Gurgaon

Commercial RO Plant are among the most rapidly emerging firm in Central India that manufactures bespoke Sewage Treating Plants, has the potential to significantly contribute to the provision of practical & effective wastewater treatment solutions & its Complete functioning to municipality & industry sectors.

Through the application of cutting-edge world-class & innovative technology, Commercial RO Plant concentrates & excels in creating compact, decentralized STP plants that can get around the limitations caused by a lack of drainage infrastructure, fluctuating incoming sewage waste quality, as well as flow rates.

Plans for Implementation in the Affected Area of Severe Water or relying air Contamination

With the utilization of population & industrial growth estimates, the following Sewage Treatment Plant Manufacturer In Gurgaon may integrate diverse plans to developed STP Plants especially for Gurgaon:

1) Common STP based on cluster habitats: On the outer border side of cities or towns, related small & medium-sized enterprises such as textile, dying, & plastic products manufacture can establish industrial parks or group clusters.

With a collecting tank & an underground sewage network, Commercial RO Plant may set up Centralized &Common Sewage Treatment Plant Manufacturer In Gurgaon with units producing several capacities. These plants would transport wastewater from each factory to the STP for treatment prior to ultimate discharge following pollution board regulations. This saves infrastructure costs for individual STP units.

Consecutive Wastewater or Sewage Treatment: Larger chemical, pulp & paper factories must implement the idea of sequential sewage treatment, which divides the plant's sewage waste streams into ports with high & low COD-BOD levels.

The high COD-BOD fraction is subjected to primary as well as secondary biological treatments in order to remove organics along with recycle treated water for application in subsequent diverse operations. The excess Low COD-BOD sewage waste is processed using a tertiary process such RO or ultra-filtration to remove solids, salts, along with trace levels of hazardous substances before being released in accordance with all requirements.

Upgrading Existing Sewage treating Plants: A considerable number of older, underperforming residential or industrial STPs may be either fully reconstructed with a bigger treatment capacity by the technical team under Commercial RO Plant to match the increasing sewage liquid waste flow rates & characteristics, or retrofitted with new equipment.

When ZLDP (Zero Liquid Discharge Plants) modules with Multiple Effect Evaporators & Agitated Thin Film Dryers are added, it becomes possible to recover dry soluble salts & high-quality distilled water from sewage water that are challenging to handle.

Decentralized Systems of STP Plants for residential apartments & colonies are necessary due to mounting urban population. These plants need to be placed in close proximity to the sewage generation source. Commercial RO Plant provides small, skid support & mounted STP systems powered by SBR & MBBR technologies.

Rather of relying on extensive sewer networks to treat sewage, these ready-to-install STPs may be installed close to big residential flats, housing societies, & urban villages.

Tertiary Treatment for Reuse: To produce permeate quality that satisfies recycled water quality standards for utilizations like horticulture, agriculture, construction, etc., the secondary treated sewage from STP Plants can be further polished using tertiary membrane filters like Ultra-filtration.

O&M(Operation & Maintenance): Commercial RO Plant provides full operation & maintenance responsibility for the STP Plants they installed at every point of Gurgaon. This includes providing process chemicals, yearly maintenance contracts, equipment health checks, periodic plant audits, laboratory testing, & operator training.

Conclusion

Every City & town for example like Gurgaon needs an integrated strategy that combines public involvement, sustainable engineering solutions, & legislative interventions to handle the environmental disaster brought on by its unchecked development.

Commercial RO Plant, privately owned, modern facilities for Sewage Treatment Plant manufacturer In Gurgaon, provides complete, turnkey solutions for setting up specialized STP plant manufacturing in every region belonging to Gurgaon in accordance with site-specific requirements & legal requirements.

#sewage treatment plant#sewage treatment plant manufactruer#sewage treatment plant manufacturer in gurgaon#gurgaon#water treatment plant#netsol water#save water

0 notes

Text

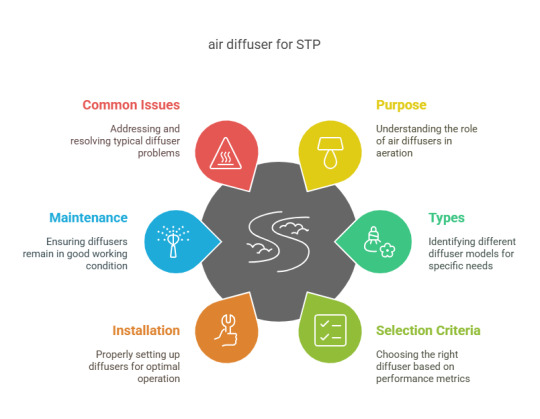

Unlocking Efficient Sewage Treatment: The Role of Air Diffuser for STP by Titan Aeration

In today’s world, efficient wastewater treatment is a necessity — not just for compliance with environmental regulations but for protecting public health and preserving water resources. One of the most vital components of any Sewage Treatment Plant (STP) is the air diffuser. An air diffuser for STP plays a critical role in ensuring that the biological treatment processes are effective and energy-efficient.

At Titan Aeration, we specialize in providing high-performance air diffusers for STP, tailored to meet the demands of modern wastewater treatment plants. In this blog, we will explore what an air diffuser is, how it works, its types, its benefits, and why it’s indispensable in sewage treatment plants.

What is an Air Diffuser for STP?

An air diffuser for STP is a mechanical device used in sewage treatment plants to distribute air uniformly into the wastewater. The main purpose of this process, known as aeration, is to supply oxygen to aerobic microorganisms, which break down organic matter in the sewage.

How Does an Air Diffuser Work in STPs?

1. Oxygen Transfer

The diffuser releases compressed air into the sewage in the form of bubbles. These bubbles help increase the dissolved oxygen (DO) levels in the water, which is crucial for microbial activity.

2. Mixing of Wastewater

Apart from oxygenation, the air bubbles also ensure uniform mixing of wastewater. This prevents the settling of solids and enhances the overall treatment efficiency.

3. Support for Biological Treatment

Bacteria and other microorganisms require oxygen to digest the organic matter present in sewage. The air diffuser for STP supports this biological activity, ensuring complete and efficient decomposition.

Types of Air Diffusers Used in STP

1. Fine Bubble Diffuser

These diffusers release small bubbles that offer a higher surface area, resulting in better oxygen transfer. They are energy-efficient and are widely used in municipal and industrial STPs.

2. Coarse Bubble Diffuser

Coarse bubble diffusers emit larger bubbles and are used where clogging is a concern. They offer better mixing but less oxygen transfer efficiency than fine bubble types.

3. Tube Diffuser

Tube diffusers are cylindrical and used for their high performance and resistance to fouling. They are a great option for continuous operation systems.

4. Disc Diffuser

Disc diffusers are flat and circular, commonly made from EPDM or silicone. They are known for high oxygen transfer efficiency and easy maintenance.

Why Choose Titan Aeration’s Air Diffuser for STP?

At Titan Aeration, we understand the importance of robust and efficient aeration systems in sewage treatment. Our air diffusers for STP are:

· Made with High-Quality Materials: We use durable and non-corrosive materials like EPDM and silicone.

· Energy-Efficient: Designed to minimize power consumption while maximizing oxygen transfer.

· Low Maintenance: Our diffusers are easy to install, operate, and maintain.

· Customizable: We provide tailored solutions depending on tank size, air flow rate, and treatment load.

Key Benefits of Using an Air Diffuser for STP

1. Enhanced Oxygen Transfer

Fine and uniformly dispersed bubbles ensure a higher oxygen transfer rate, improving biological treatment efficiency.

2. Cost-Effective Operation

Efficient oxygen distribution reduces energy usage, which is one of the highest operational costs in STPs.

3. Improved Water Quality

Better aeration ensures the removal of BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), and other pollutants.

4. Reduced Odors

Efficient treatment reduces the formation of anaerobic zones that cause foul odors.

5. Long Lifespan

High-quality air diffusers from Titan Aeration are built to last, even under challenging operating conditions.

Applications of Air Diffuser for STP

· Municipal Wastewater Treatment Plants

· Industrial Sewage Treatment

· Housing Societies and Residential Complexes

· Hospitals and Educational Institutions

· Hotels and Commercial Buildings

Factors to Consider While Choosing an Air Diffuser for STP

1. Oxygen Requirement

Evaluate the oxygen demand of your plant to determine the type and number of diffusers required.

2. Tank Design

The shape and size of the aeration tank influence the choice of diffuser (disc or tube).

3. Air Flow Rate

Choose diffusers that can handle your plant’s air supply without clogging or over-pressuring.

4. Maintenance and Durability

Opt for low-maintenance diffusers with resistance to fouling, tearing, and chemical damage.

Maintenance Tips for Air Diffuser for STP

· Regular Cleaning: Prevent clogging and biofilm buildup by cleaning periodically.

· Air Filter Maintenance: Ensure that the air supply is clean to prevent dust or oil damage to the diffuser.

· Backflushing: Occasionally reverse air flow to clear out obstructions in fine bubble diffusers.

· Periodic Inspection: Check for cracks, hardening, or fouling of membranes to replace on time.

Why Air Diffuser Efficiency Matters in STP

A poorly functioning air diffuser for STP can lead to insufficient oxygen levels, poor microbial activity, and incomplete treatment. This can result in untreated or partially treated wastewater being discharged, violating environmental norms and causing harm to aquatic ecosystems.

With increasing urbanization and tighter pollution control regulations, optimizing your STP’s aeration system is more crucial than ever. At Titan Aeration, we help you achieve this with our reliable and efficient range of air diffusers.

Conclusion

The air diffuser for STP is not just a component — it’s the heart of the aeration process in sewage treatment. By ensuring proper oxygen supply, it enables effective microbial digestion, energy efficiency, and regulatory compliance. Whether you’re upgrading an existing system or setting up a new one, choosing the right air diffuser is critical.

Titan Aeration is committed to offering top-quality air diffusers that enhance the performance of your STP, reduce operational costs, and support sustainable wastewater management. Get in touch with us today for a customized solution that fits your treatment plant’s needs.

Frequently Asked Questions (FAQs)

Q1. What is the purpose of an air diffuser in an STP?

An air diffuser introduces air into the sewage to increase dissolved oxygen levels, supporting the biological breakdown of organic matter by microorganisms.

Q2. How often should air diffusers in STPs be maintained?

It depends on the type of diffuser and wastewater characteristics. However, regular inspection and cleaning every 6 to 12 months are generally recommended.

Q3. Which is better for STPs — fine bubble or coarse bubble diffuser?

Fine bubble diffusers offer better oxygen transfer efficiency, making them ideal for most STPs. Coarse bubble diffusers are used where clogging is a concern.

Q4. Can Titan Aeration provide custom solutions for different STP sizes?

Yes, Titan Aeration offers customized air diffuser for STP solutions based on plant size, treatment capacity, and client requirements.

Q5. What is the lifespan of an air diffuser for STP?

With proper maintenance, Titan Aeration’s diffusers can last anywhere between 5 to 8 years or more, depending on operational conditions.

Visit here for more details: https://titanaeration.com/magnum-membrane-air-tube-diffusers.html Website: www.titanaeration.com Contact us: +91 20 6640 1400 Email id: [email protected]

0 notes

Text

Ammonium Sensor: Guide to Ammonia Nitrogen Detection

Ammonium sensors and ammonia nitrogen sensors are critical for monitoring water quality and industrial processes. These devices detect harmful ammonia levels, ensuring environmental safety. WizSensor specializes in high-precision sensors for diverse applications.

Ammonium Sensor: Guide to Ammonia Nitrogen Detection

Chemical Oxygen Demand Sensors

Ammonium Sensor & Ammonia Nitrogen Sensor

#dissolve oxygen sensor#do sensor#chemical oxygen demand sensor#cod sensor#Ammonium sensor#Ammonia nitrogen sensor

0 notes

Text

Comprehensive Water Testing Services in India for Safe Water

Comprehensive Water Testing Services in India for Safe Water

Water is the essence of life, but its quality can significantly impact health, safety, and business operations. At The Fair Labs, we provide top-tier water testing services in India to ensure your water is safe, clean, and compliant with regulatory standards. Whether you’re a homeowner, business owner, or industrial operator, our advanced water testing solutions deliver accurate results to protect your health and environment.

Why Water Testing Services in India Are Essential

Water contamination is a growing concern across India due to industrial runoff, agricultural activities, and aging infrastructure. Unsafe water can lead to health issues, operational inefficiencies, and legal challenges. Our water testing services in India help identify contaminants like bacteria, heavy metals, pesticides, and chemicals, ensuring your water meets safety standards set by the Bureau of Indian Standards (BIS) and the World Health Organization (WHO).

Regular water testing is critical for:

Health Protection: Detects harmful pathogens and chemicals that can cause illnesses.

Regulatory Compliance: Meet government and industry standards for water quality.

Environmental Safety: Ensure wastewater does not harm the ecosystem.

Operational Efficiency: Maintain water quality for industrial processes and equipment longevity.

What We Offer: Comprehensive Water Testing Solutions

At The Fair Labs, our water testing services in India are designed to cater to diverse needs, from residential to industrial applications. We use state-of-the-art equipment and accredited methodologies to deliver precise and reliable results. Our services include:

1. Drinking Water Testing

Ensure your drinking water is safe with our thorough testing for microbial contaminants, pH levels, turbidity, and chemical impurities. We analyze parameters like E. coli, coliform bacteria, nitrates, and heavy metals to guarantee compliance with IS 10500:2012 standards.

2. Industrial Water Testing

Industries rely on high-quality water for manufacturing, cooling, and other processes. Our water testing services in India assess water for hardness, dissolved solids, and chemical composition to optimize industrial operations and prevent equipment damage.

3. Wastewater Testing

Proper wastewater management is crucial for environmental compliance. We test wastewater for pollutants, biochemical oxygen demand (BOD), chemical oxygen demand (COD), and other parameters to ensure safe disposal and adherence to regulations.

4. Groundwater and Surface Water Testing

Groundwater and surface water sources are vital for agriculture and community use. Our testing services detect contaminants like pesticides, fertilizers, and heavy metals, helping you maintain safe water sources.

5. Specialized Testing for Specific Needs

We offer customized testing for swimming pools, aquaculture, and construction water, ensuring safety and quality for specialized applications.

Why Choose The Fair Labs for Water Testing Services in India?

With years of experience and a commitment to excellence, The Fair Labs stands out as a trusted provider of water testing services in India. Here’s why clients across the country choose us:

Accredited Laboratories: Our labs are NABL-accredited, ensuring reliable and standardized testing.

Expert Team: Our scientists and technicians are highly trained in water quality analysis.

Advanced Technology: We use cutting-edge equipment for precise and timely results.

Nationwide Reach: We serve clients across India, from urban centers to rural areas.

Customer-Centric Approach: We provide detailed reports and actionable recommendations tailored to your needs.

Visit The Fair Labs to learn more about our services and how we can help you ensure water safety.

The Process of Our Water Testing Services

Our water testing services in India follow a streamlined process to deliver accurate results:

Sample Collection: We collect water samples using sterile, standardized methods to avoid contamination.

Laboratory Analysis: Samples are tested in our advanced labs for physical, chemical, and microbiological parameters.

Detailed Reporting: We provide comprehensive reports with clear insights and recommendations.

Consultation: Our experts guide you on corrective actions if issues are detected.

Common Contaminants We Test For

Water quality can be compromised by various contaminants. Our water testing services in India cover:

Microbiological Contaminants: Bacteria (E. coli, coliform), viruses, and pathogens.

Chemical Contaminants: Heavy metals (lead, arsenic, mercury), pesticides, and nitrates.

Physical Parameters: pH, turbidity, color, and odor.

Organic Pollutants: Volatile organic compounds (VOCs) and industrial chemicals.

Who Needs Water Testing Services in India?

Our services cater to a wide range of clients, including:

Homeowners: Ensure safe drinking water for your family.

Businesses: Maintain water quality for commercial operations, such as restaurants and hotels.

Industries: Comply with regulations and optimize water-dependent processes.

Municipalities: Monitor public water supplies for community safety.

Farmers: Test irrigation water to protect crops and soil health.

The Importance of Regular Water Testing

Water quality can change due to environmental factors, seasonal variations, or infrastructure issues. Regular testing ensures ongoing safety and compliance. By partnering with The Fair Labs for water testing services in India, you can proactively address water quality issues before they become costly problems.

How to Get Started with The Fair Labs

Ensuring safe water is just a click away. Our team will guide you through the process, from sample collection to result interpretation, ensuring you have the information you need to make informed decisions.

Conclusion

Safe water is non-negotiable for health, business, and environmental sustainability. With water testing services in India from The Fair Labs, you can trust that your water is safe, clean, and compliant. Our NABL-accredited labs, expert team, and advanced technology make us the go-to choice for water quality testing across India. Don’t compromise on water safety—contact The Fair Labs today at our website to schedule your water test and take the first step toward a safer, healthier future.

0 notes

Text

How Chemical Testing Labs in Abu Dhabi Ensure Compliance with Environmental Regulations? | +971 554747210

In today’s rapidly evolving industrial landscape, environmental sustainability is no longer optional — it’s a legal and ethical imperative. Abu Dhabi, as a major industrial and economic hub of the UAE, faces growing pressure to meet stringent environmental regulations aimed at reducing pollution, safeguarding public health, and preserving natural resources. To meet these challenges, chemical testing labs in Abu Dhabi play a crucial role in ensuring businesses and industries comply with environmental standards set by government authorities.

This article explores how chemical testing lab in Abu Dhabi contribute to environmental regulatory compliance and why partnering with an accredited lab is essential for industries aiming to operate responsibly and sustainably.

Understanding Environmental Regulations in Abu Dhabi

Abu Dhabi’s environmental framework is designed to protect air, water, and soil quality while promoting sustainable development. Key regulations include:

The Environmental Protection Law by the Environment Agency – Abu Dhabi (EAD), focusing on pollution control and waste management.

Air Quality Standards enforcing limits on emissions from factories and vehicles.

Water Quality Regulations ensuring safe discharge and reuse of industrial wastewater.

Hazardous Waste Management Rules governing the handling, treatment, and disposal of chemical waste.

Compliance with these regulations requires ongoing monitoring, testing, and reporting of chemical substances released into the environment.

The Role of Chemical Testing Labs in Environmental Compliance

Chemical testing labs serve as the backbone for verifying that industrial processes and products meet environmental laws. Here’s how:

1. Precise Analysis of Pollutants

Chemical labs use advanced instrumentation to detect and quantify pollutants in air, water, and soil samples. Common tests include:

Heavy metal testing: Detecting lead, mercury, cadmium, and arsenic which are toxic to ecosystems and humans.

Volatile Organic Compounds (VOCs): Measuring emissions that contribute to air pollution and health hazards.

Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD): Assessing water pollution levels to determine organic contaminant loads.

pH and salinity testing: Monitoring water acidity and salt concentrations affecting aquatic life.

Accurate analysis enables businesses to identify pollutants and take corrective actions before exceeding regulatory limits.

2. Wastewater Testing and Treatment Verification

Industries in Abu Dhabi often generate large volumes of wastewater containing harmful chemicals. Chemical testing labs analyze wastewater samples to:

Verify that treatment processes effectively remove contaminants.

Ensure discharge water meets EAD and international standards for safe release or reuse.

Monitor parameters such as heavy metals, suspended solids, nutrient levels, and toxic substances.

Regular testing ensures compliance and prevents environmental damage caused by untreated or poorly treated wastewater.

3. Soil Contamination Assessment

Chemical labs evaluate soil samples from industrial sites to detect contamination from chemical spills, improper waste disposal, or atmospheric deposition. Testing includes:

Analysis of heavy metals and persistent organic pollutants.

Detection of hydrocarbons and petroleum derivatives.

Assessment of soil pH and nutrient balance.

Identifying soil contamination early helps industries implement remediation strategies and avoid penalties from environmental authorities.

4. Air Quality Monitoring

Chemical testing labs conduct ambient air and emissions testing using specialized equipment. This includes:

Monitoring particulate matter (PM2.5 and PM10) concentrations.

Measuring sulfur dioxide (SO2), nitrogen oxides (NOx), and carbon monoxide (CO) levels.

Detecting hazardous gases and VOCs emitted during manufacturing.

Data from labs support regulatory reporting and help industries adopt cleaner technologies.

5. Hazardous Waste Characterization

Proper classification and handling of hazardous waste are vital for compliance. Chemical labs analyze waste streams to:

Identify toxic and reactive components.

Determine appropriate treatment and disposal methods.

Support the development of waste management plans adhering to Abu Dhabi’s regulations.

This minimizes environmental risks and ensures legal handling of hazardous materials.

Why Choose Accredited Chemical Testing Labs in Abu Dhabi?

Accreditation is a mark of quality, reliability, and international recognition. In Abu Dhabi, choosing an ISO/IEC 17025 accredited chemical testing lab ensures:

Accuracy and consistency of test results.

Use of validated test methods and calibrated instruments.

Qualified experts conducting testing and interpretation.

Transparent reporting compliant with regulatory requirements.

Accredited labs also provide traceability and accountability, critical for regulatory inspections and audits.

Benefits of Partnering with Local Chemical Testing Labs

Working with chemical testing labs based in Abu Dhabi offers distinct advantages:

Faster turnaround times: Proximity reduces sample transport delays, enabling quicker decision-making.

Regulatory expertise: Local labs understand Abu Dhabi’s environmental laws and reporting formats.

Customized testing solutions: Labs tailor tests to specific industrial sectors such as oil and gas, manufacturing, or construction.

Ongoing support: Beyond testing, labs provide consultancy on environmental compliance and pollution control strategies.

Case Study: Industrial Facility Achieves Compliance Through Chemical Testing

An Abu Dhabi-based manufacturing plant faced challenges with wastewater discharge limits due to high heavy metal content. Partnering with a local chemical testing lab, the facility:

Conducted comprehensive wastewater and soil testing.

Identified contamination sources within production lines.

Implemented targeted treatment upgrades.

Used lab data to demonstrate compliance during EAD inspections.

This collaboration avoided costly fines, enhanced environmental stewardship, and improved community relations.

Emerging Trends in Environmental Chemical Testing

Chemical testing labs in Abu Dhabi are adopting innovative technologies to enhance environmental monitoring, such as:

Real-time sensors for continuous emissions monitoring.

Portable field testing kits for rapid onsite assessments.

Advanced chromatographic and spectrometric techniques for detecting emerging contaminants like microplastics and pharmaceuticals.

Data integration platforms that streamline regulatory reporting and compliance tracking.

These advancements enable more proactive environmental management and support Abu Dhabi’s sustainability goals.

Conclusion

Environmental compliance is a critical challenge for industries operating in Abu Dhabi. Accredited chemical testing labs provide the essential analytical backbone to monitor pollutants, verify treatment efficacy, and ensure adherence to stringent regulations. Their expertise and advanced testing services enable businesses to safeguard the environment, avoid penalties, and support the emirate’s vision for sustainable industrial growth.

#chemical testing lab#chemical testing#testing lab near me#testing lab uae#chemical testing services

0 notes

Text

New Chemical Projects in Gujarat – Quanta Leads with Innovation

Gujarat is one of India’s fastest-growing hubs for the chemical industry. The state is witnessing a surge in new chemical projects thanks to its strong industrial base, excellent port connectivity, and supportive government policies. One of the leading companies driving this growth is Quanta Process & Project Services, an engineering consultant based in Vadodara.

Key Chemical Projects Delivered by Quanta in Gujarat Quanta has worked on several important chemical projects across Gujarat. Some of their recent projects include:

Specialty Chemical Plant, Dahej – Designed and delivered a facility for EV battery chemicals, including core process units, utility systems, and storage tanks.

Fluorine Chemistry Projects – Completed multiple plants for fluorine-based chemicals in Jolva, Dahej, and Ranjitnagar, covering both process and support infrastructure.

Agrochemical Expansion, Jhagadia – Supported plant expansion with process upgrades, utility integration, and a COD (chemical oxygen demand) reduction unit.

Metal Recycling Plant, Halol – Provided engineering, procurement, and construction support for a recycling unit with utility blocks, warehouses, and raw material storage.

Why Gujarat is Ideal for Chemical Projects Gujarat offers several advantages for chemical industries:

Strategic Location: Proximity to ports and industrial corridors.

Skilled Workforce: Availability of trained professionals in engineering and manufacturing.

Supportive Policies: Government initiatives that encourage industrial investment.

Robust Infrastructure: Well-developed industrial zones and facilities.

Conclusion The chemical industry in Gujarat is growing rapidly, with new projects enhancing the state's industrial landscape. Companies like Quanta Process & Project Services play a vital role by providing expert engineering services, ensuring these projects are completed efficiently and effectively.

#chemical plant consultant#chemical industry#engineering consultant#project management consultancy#epcm services#detailed engineering

0 notes

Text

The Importance of Regular Waste Water Testing for Industrial Facilities

In today’s industrial landscape, sustainability, environmental compliance, and operational efficiency are more critical than ever. One key element that intersects all three is wastewater management. Industrial operations—from manufacturing plants to processing units—generate wastewater that may contain harmful chemicals, toxins, or biological contaminants. Proper management of this waste isn’t just a regulatory requirement—it’s an environmental and business necessity.

That’s where the role of a Waste Water Testing Lab becomes vital. These specialized laboratories provide analytical testing services that help industries understand, manage, and improve the quality of their wastewater. Regular testing through an accredited waste water testing lab ensures regulatory compliance, minimizes environmental impact, and enhances operational safety.

In this blog, we explore the importance of regular waste water testing for industrial facilities, what it entails, and why working with a certified waste water testing lab can save time, money, and legal trouble.

Why Waste Water Testing Matters for Industries

Industries use large volumes of water for processes such as cooling, cleaning, dyeing, and chemical mixing. After use, the discharged wastewater often contains:

Heavy metals like lead, cadmium, or mercury

Organic pollutants like oils, greases, and solvents

Pathogenic microorganisms

High Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD)

Suspended solids, nutrients like nitrogen and phosphorus

If not treated and tested properly, these pollutants can contaminate natural water bodies, groundwater, and agricultural land. The environmental consequences are severe—and so are the penalties.

Regular testing through a waste water testing lab ensures that the effluent released meets national and local environmental standards.

What Does a Waste Water Testing Lab Do?

A waste water testing lab is a dedicated facility equipped with advanced tools to analyze and quantify the composition of wastewater. These labs provide:

Sampling services at the point of discharge

Chemical, physical, and biological analysis of wastewater

Compliance reporting as required by local pollution control boards

Expert interpretation and recommendation of corrective actions

Common parameters tested include:

pH level

Total Suspended Solids (TSS)

Biochemical Oxygen Demand (BOD)

Chemical Oxygen Demand (COD)

Oil & grease

Toxic metals (lead, arsenic, chromium)

Coliform bacteria

Ammonia & nitrates

Regular engagement with a waste water testing lab enables industrial units to continuously monitor the effectiveness of their Effluent Treatment Plant (ETP) and maintain environmental compliance.

Legal and Regulatory Compliance

One of the primary reasons for regular wastewater testing is to comply with regulations set by environmental authorities. In most countries, including India, compliance with pollution control norms is mandatory under laws such as:

The Water (Prevention and Control of Pollution) Act, 1974

The Environment (Protection) Act, 1986

Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) guidelines

Failure to comply can result in:

Hefty fines

Legal action or imprisonment

Suspension or cancellation of operational licenses

Reputational damage

A waste water testing lab plays a crucial role in helping facilities produce certified reports required for applying and renewing Consents to Operate (CTO) or Establish (CTE).

The Environmental Impact of Untested Wastewater

Regular testing isn’t just about satisfying regulations—it’s also about protecting the environment. Discharging untreated or inadequately treated wastewater can:

Contaminate local rivers, lakes, and groundwater

Harm aquatic life by altering the pH and oxygen levels

Disrupt agricultural productivity through heavy metal accumulation

Pose serious health risks to surrounding communities

By partnering with a waste water testing lab, industries can ensure that their effluent is treated effectively and safely before it is discharged or reused.

How Regular Testing Enhances Operational Efficiency

Regular testing provides valuable insights that help facilities:

Optimize treatment plant performance

Identify inefficiencies in water usage and treatment processes

Reduce operational costs by avoiding overdosing of treatment chemicals

Predict maintenance needs for ETPs and equipment

Improve water reuse strategies for internal cleaning, cooling, or irrigation

A reputable waste water testing lab provides trend data over time, helping managers make data-driven decisions to enhance efficiency and cut costs.

Supporting Sustainability Goals

Industries worldwide are under pressure to adopt sustainable practices and meet Environmental, Social, and Governance (ESG) targets. Wastewater management plays a significant role in these goals.

By using a waste water testing lab, companies can:

Measure and reduce their water footprint

Document compliance for sustainability audits

Report environmental performance to stakeholders

Achieve green certifications such as ISO 14001

Regular testing enables industries to track improvements and demonstrate accountability in environmental stewardship.

Frequency of Waste Water Testing

The frequency of testing depends on:

The industry type (e.g., textiles, pharmaceuticals, food processing)

Volume and nature of wastewater generated

Local regulatory mandates

Risk factors associated with the effluent

In general, monthly or quarterly testing is recommended for most industries. However, high-risk facilities may require weekly or even daily sampling, especially when effluent characteristics vary with production shifts.

Consulting with an experienced waste water testing lab will help you design a suitable monitoring plan.

Choosing the Right Waste Water Testing Lab

To ensure accuracy and regulatory acceptance, industries should select a lab that is:

✅ Accredited by NABL or an equivalent body ✅ Equipped with state-of-the-art instruments ✅ Staffed by qualified chemists and microbiologists ✅ Experienced with your industry-specific effluent ✅ Capable of on-site sampling and prompt reporting

Some leading labs also offer advisory services, helping industries upgrade their ETPs or achieve Zero Liquid Discharge (ZLD).

Final Thoughts

In the era of environmental accountability, regular wastewater testing is no longer a luxury—it’s a necessity. With stricter pollution norms, greater public awareness, and the growing impact of climate change, industries must act responsibly in how they manage their effluent.

Partnering with a trusted waste water testing lab provides the clarity, data, and confidence needed to stay compliant and sustainable. It not only protects the environment but also boosts your operational integrity, brand image, and bottom line.

#waste water testing lab#waste water testing#water testing#water testing lab#testing lab near me#testing lab in delhi

0 notes

Text

Top Things to Consider Before Installing an Industrial Effluent Treatment Plant (ETP)

As industries grow, so does the volume and complexity of their wastewater. For manufacturers, chemical units, and other industrial establishments, installing an Effluent Treatment Plant (ETP) is not just a regulatory requirement—it’s an environmental and operational necessity. But setting up an ETP isn’t a one-size-fits-all process. It requires thoughtful planning and careful evaluation.

In this article, we’ll cover the top things to consider before installing an industrial ETP, helping you make a compliant, cost-effective, and sustainable decision for your facility.

✅ 1. Understand the Nature of Your Effluent

Before choosing any ETP system, it’s essential to analyze the quality and quantity of your wastewater. Key parameters to consider include:

BOD (Biochemical Oxygen Demand)

COD (Chemical Oxygen Demand)

pH levels

Total Suspended Solids (TSS)

Presence of heavy metals, oil & grease, or hazardous chemicals

A detailed effluent analysis report helps in designing a plant that meets both your operational and compliance needs.

✅ 2. Compliance with Local Environmental Regulations

Every state and country has strict pollution control norms. In India, industries must meet guidelines set by the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs).

Ensure the ETP you install:

Meets effluent discharge standards

Includes provision for treated water testing and recordkeeping

Is compliant with zoning, safety, and waste disposal laws

Failure to comply can result in heavy penalties or even shutdown notices.

✅ 3. Choosing the Right ETP Technology

ETP systems use various treatment technologies, such as:

Activated Sludge Process (ASP)

Sequential Batch Reactor (SBR)

Moving Bed Biofilm Reactor (MBBR)

Reverse Osmosis (RO) for tertiary treatment

The choice depends on your wastewater composition, land availability, and budget. Consult with an experienced ETP manufacturer to select a system that balances efficiency, space, and cost.

✅ 4. Space and Infrastructure Availability

ETPs can take up significant space, especially for larger facilities. Before installing, assess:

Available land for the plant setup

Drainage and piping layout

Ease of access for maintenance and monitoring

In cases of space constraints, compact or modular ETP designs can be considered.

✅ 5. Capital and Operational Costs

While the initial setup cost is a concern, ongoing operation and maintenance (O&M) costs must also be factored in:

Power and chemical consumption

Skilled labor or operator cost

AMC and spare parts

Sludge disposal charges

A lower-cost plant may lead to higher operational expenses or compliance issues in the long run. So, consider the Total Cost of Ownership (TCO) when evaluating ETP systems.

✅ 6. Automation and Monitoring Features

Modern ETPs come equipped with automation and remote monitoring systems to track:

Flow rate

pH and DO levels

Power usage

Equipment status

This not only improves efficiency but also ensures real-time compliance reporting. For industries looking for long-term scalability, automation is a smart investment.

✅ 7. Expertise and Service Support

Choose an ETP vendor or consultant with:

Proven track record in your industry type

Turnkey solution capability (design, build, install, train)

Strong after-sales support, including AMC services

Readiness for on-site staff training and documentation

A reliable vendor ensures smooth installation and reduces post-commissioning issues.

✅ 8. Plan for Treated Water Reuse

Instead of discharging treated effluent, industries in Pune, Mumbai, and other cities are increasingly reusing treated water for:

Cooling towers

Gardening

Floor cleaning

Flushing

Incorporating reuse options early in the design helps cut water costs and supports sustainability goals.

Conclusion

Installing an industrial effluent treatment plant is a critical decision that affects your operational efficiency, legal compliance, and environmental impact. By considering the factors above—effluent quality, space, technology, costs, and compliance—you can implement a treatment solution that not only meets norms but also strengthens your corporate responsibility and brand image.

0 notes