#ceramic membrane applications

Explore tagged Tumblr posts

Text

Ceramic Membrane Filtration: A Breakthrough in Water Treatment

Discover the power of ceramic membrane filtration in purifying water. Explore its applications in wastewater treatment, industrial processes, and more. Learn how ceramic membranes provide sustainable and efficient solutions with IPNR Endura.

#ceramic membrane filtration#ceramic water treatment#water purification technology#sustainable water filtration#ceramic membrane applications

0 notes

Text

Wet Beast Wednesday: abalone

This is a Wet Beast Wednesday post, but it would also be applicable for Mollusk Monday and maybe even Flat Fuck Friday. Today I'll be introducing you to the abalone. The squat snails have some strange features that set them apart from their fellows in the shell squad. Unfortunately, over harvesting of abalone for their meat and shells have put many abalone species in danger.

(Image: an abalone attached to a rock. It is a snail with a large, broad, and flat brown shell. A muscular foot attaches the animal to the rock. Around the body is a membrane covered in tentacles that reach out around the body. End ID)

Abalone are marine snails of the genus Haliotis (not to be confused with halitosis) that can range in shell diameter from 20 mm (0.8 in) to 300 mm (12 in). The number of species is a matter of some debate. There's a lot of variation in morphology within species which led to many species being incorrectly classified as multiple species. The most accepted number appears to be 56 species and 18 subspecies. Abalone shells are highly flattened and the spiral can be hard to see, making them look like large limpets. They have no operculum and cannot withdraw into their shells like other snails can. Instead, when threatened they suction as hard as possible to an object. The shells have holes in them on one side which are used for respiration, waste disposal, and release of gametes. As abalone grow, the number of holes will change with some being filled in and new ones forming. The interior of the shell is covered in nacre. This substance, also called mother-of-pearl is valuable for its polished, iridescent appearance. Abalone use the nacre to make claw-shaped pearls. The shell is composed of microscopic bricks of calcium carbonate glued together by a protein structure. When pressure is applied to the structure, the bricks slide against each other and the protein glue stretches. This helps absorb the energy of blows and makes the shells very resistant to cracking. The shell structure of abalone has been studied to make sturdier body armor and ceramics.

(Image: an empty and polished abalone shell, seen from below. The shell is lined with shiny and iridescent nacre. The nacre color varies with species, but in this case is blue-green. A line of holes are on one side of the shell. End ID)

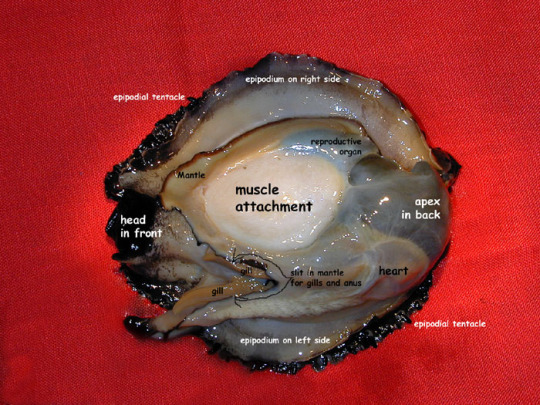

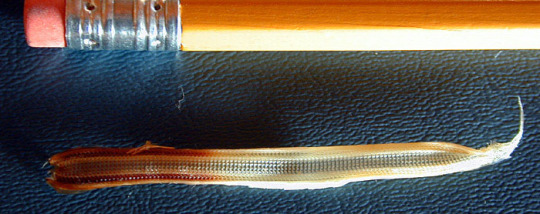

The majority of the shell's interior is filled with the muscular foot, which the abalone uses for locomotion. The foot is attached to the shell in the center. Around the edge of the foot is a structure called the epipodium. This is a frilled membrane lined with sensory tentacles. When an abalone is relaxed, it will extend the tentacles to examine its surrounding. When threatened, the tentacles retract for safety. Along the edge of the shell is the mantle, which produced the material for the shell. Abalone will grow larger throughout their lives, with the mantle continuously making new shell. At the front is the head, which has sensory tentacles and a mouth that contains a pair of oral tentacles use for finding food and the radula. The radula is a tongue-like structure lines with sharp teeth. The teeth scrape algae off of rocks and into the mouth. The teeth are arranged in rows that move forward like a conveyor belt, allowing worn out teeth to fall out and be replaced by fresh ones. The head is near the newest-formed hole and the anus is next to the rearmost hole.

(Image: an abalone seen from below, with the foor removed and anatomy labeled. The organs circle around a central muscle that the foot attaches to. A small head is in the front while the epipodium rings the body. Source. End ID)

(Image: an abalone's radula, removed and next to a pencil for scale. It is a long, thin structure lined with rows of tiny teeth. The front end is stained brown with algae. End ID)

Abalone live on coasts worldwide, with the exception of the North American Atlantic coast, South American Pacific Coast, and the poles. Most species live in cold water, but tropical species are known. They spend their times feeding on algae. Abalone shells are usually covered with life, including algae and sessile animals like tunicates, sponges, and tube worms. The hitchhikers combined with the upper shell's dull appearances serves as effective camouflage. During mating season, males and females release gametes into the water. The number of eggs a female can produce increases with size and can be up to 11 million per season. The larvae start out in a swimming form before metamorphosing into non-swimming juveniles called spat. Abalone reach sexual maturity young and at a small size.

(Iamge: dozens of abalone spat in a tank. They are miniature versions of the adults, but have nacre on the outside of the shell as well, giving them a shiny turquoise color. End ID)

Abalone have been hunted by huamns for millennia, with the oldest evidence of use being a 100,000 year old "workshop" found in Blombos Cave, South Africa, where abalone shells were used as storage for ochre mixtures. Throughout their native ranges, abalone have been harvested for their meat, nacre, and pearls. The shells are often used for jewelry, as decorative inlay, and, in some cultures, as currency. The foot is edible and considered a delicacy in some cultures and a staple in others. The value of abalone has led to worldwide overfishing, resulting in many species being endangered. Captive farming has become a major industry in many places to meet the abalone demands. Farming began in China and Japan in the 1950s and 60s and the majority of abalone farms are still in east Asia. Because of overfishing, the majority of the world's abalone supply now comes from farms. Sport fishing is legal in many parts of the world, with 25% of the wild harvest coming from Tasmania. Many places require permits and have catch limits, but poaching remains a major industry. Collection of abalone is usually done with a blunt scoop called an abalone iron that can pop the animal off of rocks. It has to be blunt because abalone blood does not clot and any cut will lead to the animal bleeding to death. Overharvesting and increasing ocean acidification are the largest threats to abalone. Places where abalone are reintroduced to the wild have seen increased biodiversity and environmental health.

(Image: a carving made by the Haida people of British Columbia, Canada. It reselbles a face with a tall hat or head with a small body carved on it. Abalone shells are used for inlay,, cut into rectangles with the nacre facing out. End ID)

#wet beast wednesday#abalone#snail#snails#sea snail#mollusk#molluscs#marine biology#marine life#biology#ecology#zoology#animal facts#informative#educational#image described

159 notes

·

View notes

Link

0 notes

Text

Tubular Membranes Market

Tubular Membranes Market Size, Share, Trends: Pentair plc Leads

Growing Adoption of Ceramic Tubular Membranes

Market Overview:

The global Tubular Membranes market is projected to grow at a CAGR of 7.2% from 2024 to 2031. The market size is expected to increase significantly during this period. Asia-Pacific currently dominates the market, followed closely by North America and Europe. Key metrics include increasing adoption across various industries, rising demand for water and wastewater treatment solutions, and growing emphasis on sustainable industrial processes.

The Tubular Membranes market is steadily expanding, driven by rising demand for effective separation and filtration technologies across a wide range of sectors. Tubular membranes are rapidly being used in a variety of applications due to their adaptability, durability, and ability to withstand high solid content streams.

DOWNLOAD FREE SAMPLE

Market Trends:

The use of ceramic tubular membranes is rapidly expanding across industries. These membranes are more chemically, thermally, and mechanically resistant than polymeric counterparts, making them excellent for harsh operating environments. Ceramic tubular membranes are increasingly being utilised in the food and beverage industry to clarify and concentrate products, hence improving product quality and extending working life. The water treatment industry is also embracing ceramic membranes due to their capacity to handle difficult feed streams and resistance to fouling. This trend is projected to continue as businesses look for more robust and efficient filtering systems to meet strict quality and environmental requirements.

Market Segmentation:

Ceramic tubular membranes have acquired popularity in a variety of industries due to their high durability, chemical resistance, and ability to work under extreme temperatures. This segment's dominance can be ascribed to rising demand for high-performance filtering solutions in demanding applications, particularly in the chemical processing, food and beverage, and water treatment sectors.

Recent advances in ceramic membrane technology have increased its desirability. For example, the discovery of nanoporous ceramic membranes has led to groundbreaking applications in gas separation and molecular sieving. Leading manufacturers reported a 35% increase in ceramic tubular membrane sales over the previous year, with significant growth in the pharmaceutical and biotechnology industries.

Market Key Players:

Pentair plc

Porex Corporation

Berghof Membranes

Microdyn-Nadir GmbH

Dynatec Systems, Inc.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

0 notes

Text

Ceramic Membrane Market is valued at approximately USD 15,184.8 million and is projected to grow at a compound annual growth rate (CAGR) of 9.3% over the forecast period, reaching around USD 24,355.2 million by 2032. The ceramic membrane market has been experiencing steady growth in recent years, driven by increasing demand for efficient filtration and separation technologies across various industries. Ceramic membranes, known for their robustness, chemical resistance, and long operational life, are increasingly replacing traditional polymeric membranes in critical applications. This article delves into the market's current trends, driving factors, challenges, and future potential, offering a comprehensive overview of this dynamic industry.

Browse the full report https://www.credenceresearch.com/report/ceramic-membrane-market

Market Overview

Ceramic membranes are porous filtration systems made primarily from inorganic materials such as alumina, titania, and zirconia. They are widely used in industries such as water and wastewater treatment, food and beverage, pharmaceuticals, and chemical processing. The global ceramic membrane market was valued at approximately USD 5.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of around 9% from 2023 to 2030.

Key Drivers of Growth

Rising Demand for Water Treatment Solutions: Water scarcity and stringent environmental regulations are propelling the adoption of ceramic membranes in water and wastewater treatment. Their ability to withstand high temperatures, extreme pH levels, and abrasive particles makes them ideal for industrial and municipal water treatment facilities.

Advancements in Filtration Technologies: The development of advanced ceramic membrane technologies has enhanced filtration efficiency and reduced operational costs. Innovations in manufacturing processes have also made these membranes more accessible and affordable.

Increasing Adoption in the Food and Beverage Industry: Ceramic membranes are gaining traction in the food and beverage sector due to their ability to maintain product purity while offering high durability. Applications include milk and whey processing, beer clarification, and juice concentration.

Growth in Pharmaceutical and Biotechnology Sectors: The demand for high-purity filtration systems in pharmaceutical manufacturing is another significant driver. Ceramic membranes play a crucial role in processes such as protein separation and cell harvesting, ensuring consistent product quality.

Challenges Facing the Market

Despite its promising growth, the ceramic membrane market faces several challenges:

High Initial Costs: The manufacturing and installation of ceramic membranes require significant investment, which can deter small and medium-sized enterprises from adopting this technology.

Limited Awareness and Expertise: Many industries still rely on traditional filtration systems due to a lack of awareness about the benefits of ceramic membranes and the technical expertise required for their operation and maintenance.

Competition from Polymeric Membranes: Polymeric membranes remain dominant in several applications due to their lower upfront costs and widespread availability, posing stiff competition to ceramic alternatives.

Future Outlook

The future of the ceramic membrane market looks promising, driven by ongoing research and development efforts aimed at enhancing membrane performance and reducing costs. Emerging applications, such as gas separation and energy recovery, are expected to open new growth avenues. Additionally, the increasing emphasis on sustainability and circular economy principles will likely boost the adoption of ceramic membranes across various industries.

Key Players

GEA Group Aktiengesellschaft

Pall Corporation

Hyflux Ltd

Kovalus Separation Solutions

Nanostone

Veolia

TAMI Industries

METAWATER Co., Ltd.

ITN Nanovation AG

SIVA Unit

Segmentations:

Based on Product Type:

Microfiltration Membranes

Ultrafiltration Membranes

Nanofiltration Membranes

Reverse Osmosis Membranes

Based on Technology:

Traditional Sintering Methods

Sol-Gel Processes

3D Printing and Advanced Fabrication Techniques

Based on End-User:

Water Treatment

Food and Beverage

Pharmaceuticals

Chemicals

Others

Based on Region:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report https://www.credenceresearch.com/report/ceramic-membrane-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

0 notes

Text

0 notes

Text

The Top Innovations in Dewatering Equipment You Need to Know

Introduction

In today’s fast-paced industrial landscape, the need for efficient and sustainable dewatering solutions has never been more critical. Industries such as mining, wastewater treatment, and construction rely heavily on dewatering equipment to separate solids from liquids, ensuring smooth operations and adherence to environmental regulations. With rapid advancements in technology, the dewatering sector has seen groundbreaking innovations that are revolutionizing the way we manage sludge and wastewater. Here, we delve into the most significant innovations in dewatering equipment, shedding light on the technologies shaping the future of water and waste management.

Advanced Centrifuge Technology

Centrifuges have long been a staple in dewatering, renowned for their ability to separate solids from liquids at high speeds. Recent advancements in centrifuge design have focused on energy efficiency and improved separation performance. Modern centrifuges now come equipped with automated control systems that optimize operations based on real-time sludge characteristics.

High-performance decanter centrifuges, for instance, are designed to handle a broader range of sludge consistencies while maintaining low energy consumption. These innovations reduce operational costs while maximizing throughput, making them indispensable in industries that prioritize cost-effectiveness and sustainability. For more on how advanced centrifuge technology integrates into comprehensive sludge treatment systems, explore sludge treatment solutions.

Membrane Filtration Systems

Membrane filtration systems are redefining precision in dewatering processes. Utilizing advanced polymer or ceramic membranes, these systems achieve ultra-fine filtration, separating even the smallest particulates from water. Recent developments have introduced self-cleaning membranes, which significantly reduce downtime and maintenance efforts.

In wastewater treatment plants, membrane systems are often employed alongside other filtration technologies, such as bag filters, to enhance efficiency. Their ability to operate under extreme pressure and temperature conditions makes them a versatile choice across various industrial applications.

Geotextile Dewatering Bags

Geotextile dewatering bags represent a sustainable and cost-effective innovation in solid-liquid separation. These bags, made from high-strength permeable fabric, allow water to escape while trapping solid materials within. Ideal for sludge management in construction and environmental remediation projects, geotextile bags reduce the need for complex machinery.

Recent advancements in material engineering have enhanced the durability and filtration efficiency of these bags, enabling them to handle larger volumes of waste with ease. Their eco-friendly design aligns with global sustainability goals, offering industries a green alternative to traditional dewatering methods.

Screw Press Technology

The screw press, an innovation celebrated for its simplicity and effectiveness, has seen significant upgrades in recent years. This equipment operates by compressing sludge between rotating and stationary components, squeezing out water in a highly efficient manner.

Modern screw presses are now equipped with variable-speed drives and enhanced screw designs, ensuring optimal performance across diverse sludge types. These upgrades have expanded their applicability to industries like food processing and paper manufacturing, where managing organic waste is a priority.

Moreover, the reduced energy footprint of advanced screw presses makes them a sustainable option for businesses aiming to lower their environmental impact while maintaining productivity.

Smart Dewatering Equipment

The integration of IoT (Internet of Things) technology into dewatering equipment has been transformative. Smart dewatering systems leverage sensors and real-time data analytics to monitor performance and predict maintenance needs. These systems automatically adjust operating parameters to ensure optimal efficiency, reducing human intervention and minimizing errors.

For instance, automated loading systems, such as loading bellows, work seamlessly with smart dewatering equipment to streamline the handling and transfer of dewatered material. This synergy enhances operational efficiency, particularly in industries dealing with bulk solids and granular materials.

Belt Filter Press Innovations

Belt filter presses, a longstanding workhorse in the dewatering industry, have undergone significant improvements to enhance their efficiency and reliability. Modern designs incorporate advanced polymers for the belts, reducing wear and tear while improving water drainage.

Additionally, multi-stage belt filter presses now feature pre-thickening zones and optimized pressure application, ensuring higher dryness levels in the final output. These innovations make belt filter presses ideal for large-scale operations requiring consistent performance over extended periods.

Vacuum-Assisted Dewatering

Vacuum-assisted dewatering technology is gaining traction for its ability to achieve rapid and efficient water removal. This innovation combines vacuum systems with traditional filtration methods, enhancing the overall performance of dewatering units.

One standout development in this area is the rotary vacuum drum filter, which has been reengineered for higher throughput and lower maintenance. Such advancements are particularly beneficial in industries like mining, where managing high volumes of slurry is a constant challenge.

Hybrid Dewatering Systems

Hybrid systems that combine multiple dewatering technologies are becoming increasingly popular, offering unparalleled flexibility and efficiency. For instance, integrating screw press technology with centrifuges can achieve higher separation efficiency while reducing energy consumption.

These hybrid solutions are tailored to specific industrial needs, ensuring that businesses can address unique challenges without compromising on cost or performance.

Conclusion

The evolution of dewatering equipment underscores the industry’s commitment to innovation, efficiency, and sustainability. From advanced centrifuge designs to IoT-enabled systems, these technologies are setting new benchmarks in water and waste management.

By embracing these cutting-edge solutions, industries can enhance their operational efficiency while contributing to global sustainability goals. Whether you’re exploring options like geotextile bags, advanced filtration systems, or smart dewatering equipment, the future of water management is brighter and more promising than ever.

To delve deeper into innovative dewatering solutions, visit dewatering equipment and learn how these advancements can transform your operations. Explore related solutions like bag filters uk for enhanced filtration, and discover the latest in sludge treatment to optimize waste management. For seamless handling of dewatered materials, consider integrating loading bellows into your workflow. The journey toward efficient and sustainable water management begins with the right innovations — let these technologies pave the way.

0 notes

Link

0 notes

Text

The Benefits and Applications of Floor Strippers: Unlocking Efficiency with Tyrolit Australia

When it comes to removing tough floor coverings efficiently, the right equipment makes all the difference. Floor strippers play a critical role in the floor preparation process, helping contractors save valuable time and effort. Tyrolit Australia offers a robust line-up of floor strippers designed to tackle a range of applications, from small-scale renovations to larger commercial projects. Let’s dive into the benefits and applications of these high-performance machines.

Benefits of Floor Strippers

1. Powerful Performance for Heavy-Duty Tasks: Tyrolit’s floor strippers are designed for challenging jobs that involve removing stubborn materials like carpets, vinyl, rubber flooring, coatings, membranes, and more. Equipped with powerful motors, these machines make it possible to strip floors quickly and efficiently, saving contractors hours of manual labour.

2. Precision and Versatility: Tyrolit floor strippers come with adjustable settings, allowing operators to tailor the machine’s power to the material being removed. Whether you’re working with tough commercial carpeting or delicate hardwood, the adjustable settings provide the versatility needed for a range of flooring types, helping achieve clean removal without damaging underlying surfaces.

3. Ergonomic Design for Ease of Use: Floor stripping is often a physically demanding task. Tyrolit’s floor strippers, however, are built with operator comfort in mind. Featuring adjustable handlebars, vibration-dampening technology, and compact yet robust designs, these machines make long hours on the job far more manageable. Their user-friendly controls also simplify operation, meaning less training time for your crew and more focus on completing the task at hand.

4. Efficient Blade Pressure: The integration of adjustable and removable weights ensures maximum blade pressure during tough removals. By concentrating pressure exactly where it’s needed, Tyrolit’s floor strippers excel at breaking down thick layers of adhesive, tile, and other tough materials. This feature ensures a clean surface, ready for the next phase of floor preparation.

5. Transportability and Mobility: Tyrolit floor strippers are designed for ease of transport. Their compact size, foldable components, and removable weights make it simple to load them onto trailers or vans for jobs in different locations. Despite their smaller footprint, these machines don’t compromise on power or effectiveness, making them a favourite choice for professionals working on a variety of sites.

Applications of Floor Strippers

1. Removing Commercial Carpets and Tiles: For large commercial spaces that require removing wall-to-wall carpeting or hard tiles, Tyrolit floor strippers offer speed and reliability. The machines are powerful enough to lift glued-down carpeting, ceramic tiles, and vinyl sheets, helping contractors efficiently clear surfaces for refurbishment or new installations.

2. Floor Coatings and Membranes: When dealing with older floors that have heavy layers of protective coatings or membranes, such as epoxy or polyurethane, Tyrolit floor strippers are essential tools. These machines easily cut through thick layers of coatings, removing them entirely and allowing contractors to access the bare floor for further treatment or refinishing.

3. Gymnasium and Sport Surface Removal: Tyrolit’s range of floor strippers are highly effective for removing rubber flooring or sport surfaces in gyms, fitness centres, or recreational facilities. Their powerful motors and adjustable blade pressure are ideal for dealing with thicker, more resistant materials, ensuring an efficient stripping process that leaves the subfloor intact.

4. Removing Adhesives and Thinset Mortar: In renovation projects where old floor adhesives or thinset mortars need to be removed, Tyrolit floor strippers offer a quick and effective solution. Their adjustable blade settings allow the operator to apply just the right amount of pressure to break down these materials without damaging the underlying surface, which is especially important in preparation for new flooring installation.

5. Industrial and Warehouse Applications: For larger industrial projects such as warehouses, where time and efficiency are paramount, Tyrolit’s floor strippers provide an excellent solution. Whether you are dealing with large surfaces of tiles, vinyl, or linoleum, these strippers are engineered to handle high volumes, making them perfect for contractors working on industrial floors.

Conclusion: Choose Tyrolit for Your Floor Stripping Needs

Tyrolit Australia offers high-quality floor strippers that make challenging tasks simple and efficient. By providing advanced features like adjustable weight systems, ergonomic designs, and powerful motors, these machines are essential for contractors working on a range of projects. Whether you need to remove carpets, tiles, coatings, or adhesives, Tyrolit floor strippers deliver excellent performance, durability, and operator comfort. For more information on the floor strippers and other floor preparation equipment, visit Tyrolit Floor Strippers or contact our team for expert advice on contact us.

0 notes

Text

Transforming Water Purification: Trends and Innovations in the Membrane Filtration Market

Membrane filtration is a powerful separation technology used across various industries for processes that involve filtering particles, microorganisms, and molecules from liquids and gases. By applying a semi-permeable membrane, it allows selective passage based on size, shape, or chemical properties. The four primary types of membrane filtration include microfiltration, ultrafiltration, nanofiltration, and reverse osmosis, each suited to specific particle sizes and applications. For instance, microfiltration membranes typically filter particles larger than 0.1 microns, while reverse osmosis can remove ions as small as 0.0001 microns. Industries such as water and wastewater treatment, food and beverage processing, pharmaceuticals, and biotechnologies widely utilize membrane filtration systems to achieve high purity, maintain quality standards, and ensure compliance with safety regulations.

The Membrane Filtration Market Size was projected to reach 20.96 (USD Billion) in 2022 based on MRFR analysis. By 2032, the membrane filtration market is anticipated to have grown from 22.8 billion USD in 2023 to 48.5 billion USD. It is anticipated that the membrane filtration market would develop at a rate of about 8.75% between 2024 and 2032.

Membrane Filtration Size and Share

The membrane filtration market has witnessed considerable growth due to rising demands for clean water and safe food processing standards globally. Factors like population growth, industrialization, and stringent environmental regulations contribute to the expanding Membrane Filtration Share across different sectors. In recent years, the Asia-Pacific region has shown substantial market expansion, driven by growing industrial sectors and investments in water treatment projects. Europe and North America continue to maintain a significant Membrane Filtration Share due to their advanced infrastructure, research in filtration technologies, and stringent regulatory guidelines. Additionally, the size of the membrane filtration market is expected to grow steadily, with forecasts predicting robust demand in the pharmaceutical and biotechnology industries where membrane filtration is used for drug development, protein purification, and pathogen removal.

Membrane Filtration Analysis

Membrane Filtration Analysis involves assessing market trends, types of membranes, applications, and competitive landscape. The analysis often focuses on the materials used for membranes, such as polymers, ceramics, and metals, as these determine filtration efficiency, durability, and chemical compatibility. Companies in the market invest in R&D to innovate materials that enhance filtration performance and reduce operational costs. Membrane Filtration Analysis also examines the influence of environmental regulations on the market. As governments impose stricter laws to reduce pollutants, membrane filtration systems have become essential in water treatment, with manufacturers developing systems to comply with environmental and industry-specific standards.

Membrane Filtration Trends

Technological advancements are shaping the future of membrane filtration. One notable trend is the integration of smart technologies, allowing systems to optimize filtration processes through data analytics and real-time monitoring. Another trend is the development of sustainable membrane materials, including biodegradable or energy-efficient options, which cater to environmentally-conscious industries. Compact, modular filtration systems are also gaining popularity due to their flexibility and ease of use in space-limited applications. Lastly, there is an increased focus on reducing operational costs, driving demand for long-lasting, low-fouling membranes that require minimal maintenance. These Membrane Filtration Trends indicate a growing emphasis on efficiency, environmental sustainability, and adaptability to meet evolving industry needs.

Reasons to Buy the Reports

Comprehensive Market Insight: Gain an in-depth understanding of the membrane filtration industry, including key trends, market size, and future projections.

Competitive Analysis: Identify leading players in the market, their strategies, and innovative approaches to enhance product offerings and operational efficiency.

Technological Developments: Stay updated on the latest technological advancements in membrane materials and filtration processes.

Regulatory Impact: Understand how global regulations impact the membrane filtration market and influence product design and material choices.

Investment Opportunities: Identify growth areas and potential investment opportunities in emerging markets and applications.

Recent Developments

The membrane filtration market has seen several recent developments. Many companies are focusing on sustainability by developing recyclable or eco-friendly membranes. Additionally, advancements in nanotechnology have enabled the creation of membranes with higher precision in removing contaminants. Companies are also investing in artificial intelligence and IoT for membrane filtration systems, improving real-time monitoring and reducing the need for manual maintenance. In the pharmaceutical sector, innovations in membrane filtration are aiding in faster and more efficient vaccine production. Moreover, governments worldwide are encouraging adoption through favorable policies, further fueling the growth and development in the membrane filtration market.

Related reports :

pharma 4 0 market

rapid microbiology testing market

reporter gene assay market

health and wellness product market

0 notes

Text

The Best Reverse Osmosis Membranes for Specific Applications

Reverse Osmosis (RO) is a widely used technology for purifying water by removing dissolved solids, impurities, and contaminants. At the heart of the RO system lies the membrane, which plays a crucial role in determining the efficiency, performance, and longevity of the water purification process. The choice of membrane can significantly impact the quality of the purified water and the overall effectiveness of the system. Here’s an in-depth look at the best reverse osmosis membranes tailored for specific applications, along with factors to consider when selecting a membrane.

Understanding Reverse Osmosis Membranes

RO membranes are semi-permeable barriers that allow water molecules to pass through while rejecting larger molecules, ions, and contaminants. These membranes are typically made from polymer materials, with polyamide thin-film composites being the most common. Membranes are classified based on their properties, such as pore size, flux rate, and rejection capabilities.

Types of Reverse Osmosis Membranes

Polyamide Thin-Film Composite Membranes These are the most commonly used membranes in RO systems due to their excellent rejection rates and durability. They are effective in removing a wide range of contaminants, including salts, bacteria, and organic compounds. Their high permeability allows for a greater flow rate, making them suitable for both residential and commercial applications.

Cellulose Acetate Membranes Cellulose acetate membranes are often used in older RO systems. They are less expensive than polyamide membranes but have lower rejection rates and are more susceptible to chlorine damage. These membranes are suitable for applications where water quality requirements are not as stringent.

Ceramic Membranes Ceramic membranes offer high durability and chemical resistance, making them suitable for harsh environments and specific industrial applications. They can withstand higher temperatures and pH levels, allowing for effective filtration of abrasive or corrosive substances.

Nanofiltration Membranes Nanofiltration membranes have a larger pore size compared to RO membranes, allowing them to remove divalent and multivalent ions while allowing monovalent ions (like sodium) to pass through. These membranes are ideal for applications requiring partial desalination and removal of specific contaminants, such as hardness.

Best RO Membranes for Specific Applications

1. Residential Water Purification

For home use, polyamide thin-film composite membranes are generally the best choice. They provide high rejection rates for a wide range of contaminants, including chlorine, lead, fluoride, and bacteria. Membranes such as the Dow Filmtec BW60-1812 are popular for their 99% rejection rate and 60 gallons per day (GPD) flow rate, making them ideal for family households.

Key Features:

High flux and rejection rates

Cost-effective for residential use

Compatible with standard RO systems

2. Commercial and Industrial Applications

In commercial settings, such as restaurants and hotels, where water quality is paramount, membranes like the Toray TMG20-4040 are highly recommended. These membranes provide high permeability and low energy consumption, allowing for efficient water purification.

Key Features:

High salt rejection (up to 99.7%)

Enhanced durability for long-term use

Reduced fouling and scaling

For industrial applications, such as food processing or pharmaceuticals, ceramic membranes like those from the KMS series offer excellent chemical resistance and durability, making them ideal for treating aggressive fluids or high-temperature applications.

Key Features:

Resistance to extreme pH levels

Long operational lifespan

Effective in high fouling environments

3. Desalination Plants

In desalination, where seawater is treated to produce potable water, membranes such as the Hydranautics SWC-4 are specifically designed to withstand the high salinity and pressure conditions present in seawater applications.

Key Features:

Designed for seawater desalination

High flux rates and salt rejection

Enhanced fouling resistance

4. Wastewater Treatment

For wastewater treatment, particularly in municipal or industrial applications, RO membranes like the GE Water ZW1000 are effective in treating contaminated water by removing various pollutants, including heavy metals and organic compounds.

Key Features:

High rejection of organics and contaminants

Robust design for challenging environments

Cost-effective for large-scale treatment

5. Food and Beverage Industry

Membranes used in the food and beverage industry, such as the Desalination Technology DTRO, are designed to remove unwanted flavors, colors, and contaminants while retaining essential minerals. These membranes ensure the quality and safety of the final product.

Key Features:

Selective retention of essential nutrients

High performance in low-temperature applications

Suitable for diverse food processing needs

Factors to Consider When Choosing an RO Membrane

Contaminant Removal Efficiency Different applications require different levels of contaminant removal. It’s essential to choose a membrane that meets the specific water quality standards for your application.

Flow Rate The membrane’s flow rate, usually measured in gallons per day (GPD), should match the water demand of your application. High flow rates are critical in commercial and industrial settings.

Durability and Longevity Consider the membrane’s resistance to fouling, scaling, and chemical damage. A durable membrane can reduce maintenance costs and downtime.

Temperature and pH Compatibility Ensure that the membrane can withstand the temperature and pH levels typical of your application, especially in industrial and wastewater contexts.

Cost and Availability Evaluate the cost of the membrane relative to its performance. While more expensive membranes may offer better performance, it's essential to balance cost with your specific needs.

Conclusion

Selecting the right reverse osmosis membrane is crucial for achieving optimal water purification results tailored to specific applications. "Get Premium RO Membranes for Enhanced Water Filtration" By understanding the various types of membranes available and their suitability for different contexts—whether residential, commercial, industrial, or specialized industries—users can make informed decisions that enhance water quality, improve efficiency, and reduce operational costs. The right membrane not only extends the lifespan of the RO system but also ensures compliance with health and safety standards, making it an essential component in the quest for clean and safe water. "Buy High-Quality RO Membrane for Clean Water Purification"

0 notes

Text

0 notes

Text

Understanding Hydrogen Electrolysers: The Key to a Clean Energy Future

Hydrogen electrolysers are devices that use electricity to split water into hydrogen and oxygen, playing a pivotal role in producing green hydrogen, a key component in the transition to a sustainable energy future. Unlike traditional hydrogen production methods that rely on fossil fuels, electrolysers can generate hydrogen with zero emissions when powered by renewable energy. In this article, we will explore how hydrogen electrolysers work, their different types, and the role they play in a cleaner, decarbonized world.

How Do Hydrogen Electrolysers Work?

At the core of a hydrogen electrolyser is the process of electrolysis, which involves passing an electric current through water (H₂O) to separate it into its component gases: hydrogen (H₂) and oxygen (O₂). The overall chemical reaction can be represented as:

The hydrogen produced can be stored and later used as a clean fuel for a variety of applications, including transportation, power generation, and industrial processes. The oxygen is often released as a byproduct, though it can also be captured for use in other industries.

Types of Hydrogen Electrolysers

There are several different types of electrolysers, each with its own set of advantages, challenges, and applications. The three main types are:

Alkaline Electrolysers (AEL)

Proton Exchange Membrane (PEM) Electrolysers

Solid Oxide Electrolysers (SOE)

Let’s dive into each one in detail.

1. Alkaline Electrolysers (AEL)

Alkaline electrolysers are the most mature and widely used electrolysis technology. They use a liquid alkaline electrolyte, typically potassium hydroxide (KOH), to conduct the electric current between two electrodes.

Advantages: AELs are known for their reliability and long operational life. They are relatively low-cost compared to other types of electrolysers and can handle large-scale hydrogen production.

Challenges: Alkaline electrolysers operate at lower current densities, meaning they are less efficient than some newer technologies. Additionally, they are slower to respond to fluctuations in power supply, making them less compatible with intermittent renewable energy sources like wind and solar.

2. Proton Exchange Membrane (PEM) Electrolysers

PEM electrolysers use a solid polymer electrolyte to conduct protons from the anode to the cathode during the electrolysis process. This newer technology is quickly gaining traction due to its high efficiency and operational flexibility.

Advantages: PEM electrolysers are highly responsive to changes in electricity supply, making them ideal for pairing with renewable energy sources that produce variable power. They operate at higher current densities, allowing for more compact and efficient systems.

Challenges: The materials used in PEM electrolysers, such as platinum and iridium, are expensive, which raises the cost of these systems. However, ongoing research aims to reduce material costs while maintaining performance.

3. Solid Oxide Electrolysers (SOE)

Solid oxide electrolysers operate at high temperatures (usually between 700°C and 1,000°C) and use a ceramic electrolyte to conduct oxygen ions. This type of electrolyser is still in the research and development phase but holds significant promise for large-scale hydrogen production.

Advantages: SOEs have the potential to be the most efficient of all electrolyser types, as high operating temperatures reduce the amount of electricity needed to split water. They can also be integrated with industrial processes that already generate high-temperature heat, improving overall system efficiency.

Challenges: The main drawback of SOEs is their high operating temperature, which leads to complex material challenges and durability issues. Developing materials that can withstand such extreme conditions for long periods is a significant engineering challenge.

0 notes

Text

0 notes