#catalytic heaters

Explore tagged Tumblr posts

Text

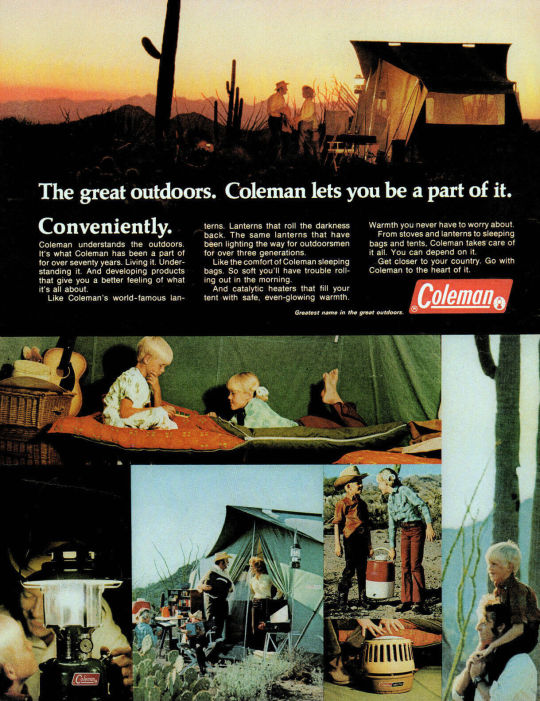

The Coleman Co, 1972

#camping supplies#1972#ad#tents#lanterns#sleeping bags#advertisement#1970s#desert#the outdoors#catalytic heaters#tent#lantern#stove#advertising#vintage#70s family

110 notes

·

View notes

Text

Why I like kerosene heaters

So, like, this sounds kinda stupid and bass-ackwards of me to say, when we live in The Year of Our Lord 2024 and have fancy-schmancy mini-split heat-pumps and 90+ percent efficient condensing furnaces and shit, but hear me out alright

Think back to your high school physics class, alright? There's three different kinds of heat: Conduction (not applicable to space heaters), Convection (how pretty much everything that doesn't visibly glow works) and Radiation (basically, anything you can feel without moving air)

If you get one of the radiant-style kerosene heaters, either a reflector-type (Sengoku or Kero-Sun), or one of those mop-wick stove/heater combos (Butterfly or Fire Wheel) you get the best of both worlds

Fuel burning is always gonna make quite a bit of convection to heat the air in the room BUT you also get a fuckton of radiant heat to warm YOU up immediately, along with all the surfaces in the room over time - walls, floor, ceiling, furniture, etc. all become thermal mass

AND, in addition, kerosene heaters aren't vented, so the burning fuel puts a bunch of water vapor and humidity out into the air as well, which is INVISIBLE thermal mass in addition to the aforementioned mass of surfaces in your house

So, you can run that heater for a few hours in the evening when you're at home and awake and turn it off before bed, and the house will still be a reasonably comfortable temperature when you wake up, even when you have whatever secondary heat (in my case, electric baseboards that are EXPENSIVE AS FUCK to run much cause the kWh cost on our light bill sucks) turned way down

Add to that the fact that the extra humidity keeps my nose from getting PAINFULLY FUCKING DRY EVERY MORNING and the fact that I, personally, enjoy the faint smell of kerosene a LOT more than the smell of the cat's litterbox and the sink full of un-washed dishes and the pile of dirty socks, and you got yourself a winning combo

Oh, and you know the best part about the catalytic radiant-style heaters over the orange-flame or blue-flame convection ones?

THEY RUN ON DIESEL JUST FINE! In the US, since we switched to Ultra Low Sulfur pump diesel back in 2008, the winter-blend stuff that's high in the lighter hydrocarbons and paraffins burns perfectly clean in a radiant kerosene heater. Works fine in the antique blue-flame heaters too, but the orange-flame ones you get at Tractor Supply these days tend to smoke like crazy still, no clue why.

But whatever, my broke ass will DEFINITELY take $3.35 a gallon at the corner store's diesel pump over having to actually fire up the car and DRIVE to fill up my jerry can with $5/gallon kero at the Thornton's out by the expressway.

#nerd shit#kerosene#heating#infodump#idk how the fuck to tag my ramblings on here#I'm used to being a microcelebrity on twitter but on here theres no algorithm

7 notes

·

View notes

Text

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Removes Up to 50 Tough Stains and Up to 48 hours Old Stains 360 Bloomwash Technology Catalytic Soak Power Dry Technology Hard Water Wash 8 Kg Capacity 5 Star Energy Rating In-Built Heater Removes Up to 50 Tough Stains and Up to 48 hours Old Stains 360 Bloomwash Technology Power Dry Technology Hard Water Wash 3 Years Product Warranty | 10 Years Warranty on Motor and Prime Mover [ad_2]

0 notes

Text

Detailed Report Ammonia Crackers Analysis | BIS Report

An ammonia cracker is a device used to break down ammonia (NH₃) into its constituent gasses, typically hydrogen (H₂) and nitrogen (N₂), through a process known as thermal cracking. This process involves heating ammonia to high temperatures (usually around 800–900°C) in the presence of a catalyst, often made of nickel.

The Ammonia Cracker market size is $196.07 million in 2022, and was expected to be $1574.44 million by 2023 growing at a CAGR of 25.7%

Ammonia Crackers Overview

Ammonia crackers are systems designed to break down ammonia (NH₃) into its constituent gasses, hydrogen (H₂) and nitrogen (N₂), through a catalytic process.

This process is known as "ammonia cracking" or "ammonia decomposition" and is typically carried out at high temperatures (between 800°C and 900°C) using a catalyst, often nickel-based.

Download our Report Page to know more !

Key Components

Ammonia Feedstock

Heater/ Furnace

Catalytic Reactor

Applications

Hydrogen Production

Energy Storage and Transport

Decarbonization

Advantages of Ammonia Crackers

Hydrogen Storage Solutions

High Energy Density

Hydrogen and hydrogen compounds such as ammonia play a key role in green transition, replace natural gas, and support a sustainable future. Moreover, hydrogen facilitates use as an economically viable energy vector in various applications, including transport and industrial applications, owing to its low volumetric density even when compressed to high pressures or liquefied.

Visit our Sample Page to know more !

Market Segmentation

1 Based on demography

Age

Gender

Income Status

Marital Status

2 Psychographic Segmentation

Lifestyle

Value

Attitude

3 End Users Segmentation

Patients

Healthcare Providers

Application for Ammonia Crackers Market

Infertility Treatment

Genetic Disorder Prevention

Single Parents and same sex couples

Advanced Maternal Age

Hormonal and Menstrual Disorders

Secondary Infertility

Key Market Players

Cooper Surgicals

Vitrolife AB

Cook Medical

Thermo Fisher Scientific

Merck KGaA

OvaScience, Inc.

And many others

Market Drivers

Increasing Infertility Rates

Technological Advancements

Increasing Awareness and Acceptance

Growth of Fertility Clinics

Support for Fertility Preservations

Visit our Advanced Materials Chemicals and Fuels vertical page for better understanding click here!

Recent Developments in Ammonia Crackers Market

• In April 2021, Uniper undertook the initiative "Green Wilhelmshaven" with the intention of creating a prominent hydrogen hub in Wilhelmshaven, Germany. To support this endeavor, the company is currently engaged in developing a feasibility study. As part of the plan, Uniper intends to construct an import terminal dedicated to green ammonia. The proposed terminal will feature an "ammonia cracker" designed for the production of green hydrogen. Additionally, the terminal will be seamlessly integrated into the envisaged hydrogen network.

• In June 2023, Proton Ventures undertook diverse studies related to ammonia cracking on behalf of clients and maintains engagement in multiple research consortia. Centralized ammonia cracker solutions, designed for pure hydrogen production, exhibit functional parallels with natural gas processing plants utilized for hydrogen production. Apart from this, efforts are underway to develop decentralized ammonia cracker solutions, which do not invariably necessitate complete conversion and purification of hydrogen. This approach enhances system energy efficiency and cost-effectiveness. The upcoming objective entails the construction of a commercial pilot for ammonia cracking. This represents a critical intermediate phase in the industry's progression toward establishing hydrogen production facilities on a global scale. Proton Ventures conducted a comprehensive front-end engineering and design (FEED) study for a renewable ammonia facility in a closely coordinated effort with Switzerland's Casale S.A.

Conclusion

In conclusion, ammonia crackers play a pivotal role in the emerging hydrogen economy by providing an efficient method to extract hydrogen from ammonia. This technology offers a promising solution for hydrogen storage and transportation, addressing some of the challenges associated with the use of pure hydrogen.

0 notes

Text

Understanding Water Softeners: A Comprehensive Guide

Have you ever noticed that your soap doesn’t lather well, or your skin feels dry and itchy after a shower? These could be signs that you have hard water in your home. Hard water is a common issue that many people face, but luckily, there’s a solution: a water softener. In this blog, we will explore what a water softener is, how it works, and the benefits it brings to your household.

What is a Water Softener?

A water softener is a system designed to eliminate minerals such as calcium and magnesium from your water source. These minerals cause water hardness, which can lead to various problems in your home. By installing a water softener, you can enjoy soft water, which is gentler on your skin, hair, and appliances.

How Does a Water Softener Work?

A water softener operates through a method known as ion exchange to eliminate minerals that cause hardness in your water. Here’s an easy-to-understand overview of the process:

Water Enters the Softener: Hard water from your main water supply flows into the water softener.

Ion Exchange Process: Inside the water softener, there is a tank filled with resin beads. These beads are covered with sodium ions. When hard water passes through the resin beads, the calcium and magnesium ions in the water are exchanged with sodium ions.

Soft Water Flows Out: After the ion exchange process, the water that comes out of the softener is now soft. This soft water then flows through your home’s plumbing system.

Benefits of Using a Water Softener

Adding a water softener to your home offers a range of valuable benefits. Here are some key advantages:

Better Skin and Hair: Soft water is much gentler on your skin and hair. You will notice that your skin feels softer and less dry, and your hair is smoother and more manageable.

Longer-Lasting Appliances: Hard water can cause a buildup of scale in your appliances, reducing their efficiency and lifespan. A water softener prevents this scale buildup, helping your appliances last longer.

Cleaner Dishes and Laundry: Soft water allows soap to lather better and rinse more completely, resulting in cleaner dishes and laundry. You’ll also use less detergent, saving you money.

Reduced Energy Bills: When your water heater is free of scale buildup, it operates more efficiently. This means you’ll spend less on energy to heat your water.

Less Cleaning: Scale buildup from hard water can leave spots and streaks on your sinks, faucets, and showers. With a water softener, you’ll spend less time cleaning these unsightly marks.

Types of Water Softeners

Various types of water softeners offer distinct benefits, each tailored to different needs. Here are the most common types:

Salt-Based Water Softeners: These are the most traditional and commonly used water softeners. They use sodium ions to replace calcium and magnesium ions in the water.

Salt-Free Water Softeners: These water softeners use a different method to reduce water hardness. They typically use a catalytic media that changes the structure of the hardness minerals, preventing them from forming scale.

Dual-Tank Water Softeners: These systems have two resin tanks, allowing for continuous soft water even during the regeneration process. They are perfect for sizable homes with substantial water consumption.

Magnetic Water Softeners: These devices use magnets to alter the structure of the hardness minerals. While they are easy to install and maintain, their effectiveness can vary.

Installing a Water Softener

Installing a water softener can be a straightforward process, but it’s often best to hire a professional to ensure it’s done correctly. Here are the basic steps involved in the installation:

Choose the Right Location: The water softener should be installed close to the main water supply line. It’s usually placed in a basement, garage, or utility room.

Turn Off the Water Supply: Before installation, the main water supply must be turned off to prevent any leaks or water damage.

Connect the Water Softener: The inlet and outlet pipes of the water softener are connected to the main water supply line. This usually involves some plumbing work, which is why a professional can be helpful.

Add the Resin Beads: The resin tank is filled with the appropriate amount of resin beads, which are essential for the ion exchange process.

Regenerate the System: Once installed, the water softener needs to go through a regeneration cycle to prepare the resin beads for use.

Maintaining Your Water Softener

To keep your water softener working efficiently, regular maintenance is important. Here are some essential tips for keeping your water softener in top shape:

Check Salt Levels: For salt-based water softeners, regularly check the salt levels in the brine tank and add more salt as needed.

Clean the Brine Tank: Over time, the brine tank can accumulate sludge. Clean it periodically to ensure the system operates smoothly.

Inspect the Resin Beads: Resin beads can wear out over time. Consistently monitor and update them as necessary.

Monitor Water Hardness: Occasionally test your water hardness to ensure your water softener is working effectively.

Conclusion

A water softener can significantly improve the quality of your water and bring numerous benefits to your household. From better skin and hair to longer-lasting appliances, the advantages of using a water softener are clear. By understanding how a water softener works and properly maintaining it, you can enjoy soft water and all the perks that come with it. If you’re experiencing issues with hard water, consider installing a water softener and experience the difference it can make in your home. Originally Published Here:- https://medium.com/@indiailios6/understanding-water-softeners-a-comprehensive-guide-adec7ef5ddea

0 notes

Text

CH 4250: Process Engineering Assignment 3 solved

Develop a flowsheet in Aspen Plus to simulate the following process for the production of cyclohexane via benzene hydrogenation. Calculate the size of all the equipment in the flowsheet. Fresh benzene and hydrogen feed streams are first fed through a heater to bring the streams up to the reactor feed temperature and pressure conditions. This feed is then sent to a fixed-bed catalytic reactor…

0 notes

Text

Choosing Tents with Heat: A Guide to Year-Round Comfort

As the weather turns colder, many people find themselves seeking ways to enjoy the outdoors without compromising on comfort. Tents with heat have emerged as a popular solution, offering a warm and cozy environment even in chilly conditions. In this blog post, we’ll explore the benefits of tents with heat, various heating options available, and key considerations to keep in mind when selecting the right tent for your needs.

Why Opt for Tents with Heat?

Tents with heat provide a practical solution for enjoying outdoor events or camping trips during the colder months. They come with several significant advantages:

Tents with heat ensure a comfortable and warm environment regardless of the external weather conditions. They are versatile enough for a range of events, including weddings, corporate gatherings, and camping trips. Additionally, these tents help protect against cold drafts and dampness, enhancing overall comfort.

Types of Heating for Tents with Heat

Selecting the appropriate heating system is crucial for the effectiveness and comfort of tents with heat. Here are the most common heating options:

Electric Heating

Electric heating is a popular choice for tents with heat. It uses electric heaters or panels to provide warmth, offering ease of use and control.

Electric heaters allow for precise temperature adjustments and do not require fuel. However, they necessitate access to an electrical power source and may result in higher operational costs.

Propane Heating

Propane heating involves using gas heaters to generate warmth inside the tent.

This option provides independence from electrical power and is effective for maintaining warmth on colder days. Nonetheless, it requires regular refills of propane bottles and proper ventilation to ensure safety.

Oil Heating

Oil heating systems are known for their efficiency in larger tents. They use oil to generate and distribute heat throughout the space.

Oil heaters are effective in larger areas and offer long-lasting warmth. However, they require large oil containers and may produce odors.

Catalytic Heating

Catalytic heaters employ a chemical reaction to produce heat, offering a safe and efficient heating method for tents with heat.

These heaters generate low emissions and do not have open flames. On the downside, they tend to be more expensive and require regular maintenance.

0 notes

Text

DEF Pump Replacement

Modern diesel engines rely on a diesel exhaust fluid (DEF) system for reduced fuel combustion and emissions. This system, which includes a DEF pump, a filter, and a heater plays a crucial role in maintaining vehicle performance. Unfortunately, there are critical issues that can affect the DEF pump, and it can be really frustrating because it will disrupt the overall efficiency of the vehicle. There are ways to identify and address problems associated with this component. In addition to a model new generation of catalytic converter, SCR Technology requires the usage of DEF. It allows automobiles to satisfy EU6 emissions legislation by lowering the levels of nitrogen oxide (NOx) emitted from the exhaust system by as much - Complete DPF Cleaning Service in Dallas.

A DEF system involves a simple principle of fuel delivery. It dispenses fluid from its tank through metal piping into an engine's Catalytic Reduction (SCR) system. This process converts toxic emissions into water and nitrogen compounds that are less harmful to the environment. It also supplies the engine with the amount of fuel it needs to run daily. You'll be surprised to hear that the DEF Pump consists of a filter for cleaning the DEF and a heater that prevents freezing of the DEF in colder conditions - Professional Truck Alignment Service in Dallas.

The fluid quality greatly influences the lifespan of your DEF fluid. For example, when poor quality or contaminated DEF is used, it can cause damage to the pump and its components. This, in turn, affects and damages the pump. It is wiser and safer to use high-quality pumps that last longer and require fewer repairs. Some brands are known for their durability, so it's better you go for those brands. The materials they used in manufacturing a DEF pump give it a longer life shelve.

The DEF pump is important for keeping the environment safe as well as the vehicle itself. We have provided you with all the information you need to know about the DEF pump, from the possible issues to its symptoms, solutions, and cost of replacement. However, you must understand that the cost of DEF pump replacement varies with vehicles. We have more satisfying and peaceful driving, less stress from constant repairs, and also an extra buck saved as you properly maintain your DEF pump. For more information, please visit our site http://dpffilter.com/

0 notes

Text

U.S. Refractories Market Set for Strong Growth Outlook

Market Research Forecast added research publication document on Worldwide U.S. Refractories Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide U.S. Refractories Market. The study provides valuable market size data for historical (Volume** & Value) from 2019 to 2023 which is estimated and forecasted till 2032*. Some are the key & emerging players that are part of coverage and have being profiled are HarbisonWalker International (U.S.),Alsey Refractories Co. (U.S.),Plibrico Company, LLC (U.S.),Seneca Ceramics (U.S.),Metsch Refractories Inc. (U.S.),Ultramet (U.S.),Saint-Gobain (France),Industrial Refractory Services (U.S.),Imerys (France),McNeil USA (U.S.),Morgan Advanced Materials (U.K.). Get free access to Sample Report in PDF Version along with Graphs and Figures @ https://marketresearchforecast.com/report/us-refractories-market-1348/sample-report

The U.S. Refractories Marketsize was valued at USD 3.02 USD Billion in 2023 and is projected to reach USD 3.64 USD Billion by 2032, exhibiting a CAGR of 2.7 % during the forecast period.Refractory is a material that is resistant to decomposition by heat or chemical attack that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compounds that may be porous or non-porous, and their crystallinity varies widely. Refractory materials must be chemically and physically stable at high temperatures. Refractories have other high temperature applications such as fired heaters, hydrogen reformers, ammonia primary and secondary reformers, cracking furnaces, utility boilers, catalytic cracking units, air heaters, and sulphur furnaces. They are used for surfacing flame deflectors in rocket launch structures. as having a very high melting point, refractory metals can conduct heat and electricity very well. This is because they are a heavy metal that can carry these currents in a way that very few materials can, making them an asset in products that deal with high amounts of heat and electricity. North America is poised for rapid growth in the refractories market due to a surge in industrial activities and a revival of construction projects. The region's robust manufacturing sector, particularly in steel, glass, and cement industries, is driving increased demand for refractory materials. Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Impact and Economic Slowdown globally. Maintain a competitive edge by sizing up with available business opportunity in U.S. Refractories Market various segments and emerging territory. Influencing Market Trend

Increasing demand for refractories in the iron and steel industry

Growing adoption of monolithic and unshaped refractories

Rising demand for high-performance and energy-efficient refractories

Stringent environmental regulations driving demand for low-emission refractories

Challenges:

Fluctuations in raw material prices

Intense competition from global players

Limited availability of skilled labor

Stringent environmental regulations

Have Any Questions Regarding Global U.S. Refractories Market Report, Ask Our Experts@ https://marketresearchforecast.com/report/us-refractories-market-1348/enquiry-before-buy Analysis by Form (Bricks & Shaped and Monolithic & Unshaped), by Product (Clay and Non-Clay), by Alkalinity (Acidic & Neutral and Basic), by End-Use Industry (Iron & Steel, Non-Ferrous Metals, Glass, Cement, and Others), by North America (U.S., Canada) Forecast 2024-2032

Competitive landscape highlighting important parameters that players are gaining along with the Market Development/evolution

• % Market Share, Segment Revenue, Swot Analysis for each profiled company [HarbisonWalker International (U.S.),Alsey Refractories Co. (U.S.),Plibrico Company, LLC (U.S.),Seneca Ceramics (U.S.),Metsch Refractories Inc. (U.S.),Ultramet (U.S.),Saint-Gobain (France),Industrial Refractory Services (U.S.),Imerys (France),McNeil USA (U.S.),Morgan Advanced Materials (U.K.)]

• Business overview and Product/Service classification

• Product/Service Matrix [Players by Product/Service comparative analysis]

• Recent Developments (Technology advancement, Product Launch or Expansion plan, Manufacturing and R&D etc)

• Consumption, Capacity & Production by Players The regional analysis of Global U.S. Refractories Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2023-2028. Table of Content Chapter One: Industry Overview Chapter Two: Major Segmentation (Classification, Application and etc.) Analysis Chapter Three: Production Market Analysis Chapter Four: Sales Market Analysis Chapter Five: Consumption Market Analysis Chapter Six: Production, Sales and Consumption Market Comparison Analysis Chapter Seven: Major Manufacturers Production and Sales Market Comparison Analysis Chapter Eight: Competition Analysis by Players Chapter Nine: Marketing Channel Analysis Chapter Ten: New Project Investment Feasibility Analysis Chapter Eleven: Manufacturing Cost Analysis Chapter Twelve: Industrial Chain, Sourcing Strategy and Downstream Buyers Read Executive Summary and Detailed Index of full Research Study @ https://marketresearchforecast.com/reports/us-refractories-market-1348 Highlights of the Report • The future prospects of the global U.S. Refractories Market during the forecast period 2023-2028 are given in the report. • The major developmental strategies integrated by the leading players to sustain a competitive market position in the market are included in the report. • The emerging technologies that are driving the growth of the market are highlighted in the report. • The market value of the segments that are leading the market and the sub-segments are mentioned in the report. • The report studies the leading manufacturers and other players entering the global U.S. Refractories Market. Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia. Contact US : Craig Francis (PR & Marketing Manager) Market Research Forecast Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 201 565 3262, +44 161 818 8166 [email protected]

#Global U.S. Refractories Market#U.S. Refractories Market Demand#U.S. Refractories Market Trends#U.S. Refractories Market Analysis#U.S. Refractories Market Growth#U.S. Refractories Market Share#U.S. Refractories Market Forecast#U.S. Refractories Market Challenges

0 notes

Text

Revive Your Ride: Top Auto Repair Services Unveiled

Introduction

Your vehicle is more than just a mode of transportation; it's an essential part of your daily life. Whether you rely on it for your daily commute, family trips, or weekend adventures, your vehicle plays a significant role in your life. However, like any other machine, cars require regular maintenance and, occasionally, auto repair services to keep them in top condition. In this article, we will unveil the top auto repair services that can help you revive your ride and ensure it continues to serve you well.

Routine Maintenance Routine maintenance is the foundation of a healthy vehicle. Services like oil changes, tire rotations, brake inspections, and fluid checks should be performed at regular intervals. These services prevent minor issues from turning into major problems and help maintain your car's overall performance and efficiency. Be sure to follow your vehicle's recommended maintenance schedule to keep it running smoothly.

Brake System Repairs Your brakes are a critical safety component of your vehicle. If you notice any signs of brake issues, such as squeaking or grinding noises, a spongy brake pedal, or reduced stopping power, it's essential to address them promptly. Brake system repairs may include brake pad replacement, rotor resurfacing or replacement, and brake fluid flushes. Keeping your brakes in top shape ensures your safety on the road.

Engine Diagnostic and Repair The engine is the heart of your vehicle, and any problems with it can lead to significant performance issues. If you experience symptoms like strange noises, reduced power, poor fuel efficiency, or warning lights on the dashboard, an engine diagnostic is crucial. Skilled technicians can identify and repair engine issues, whether they involve the ignition system, fuel delivery, or other components.

Transmission Services Your vehicle's transmission is responsible for shifting gears and transferring power from the engine to the wheels. Transmission issues can be costly if left unattended. Common problems include slipping gears, erratic shifting, and leaks. Regular transmission services, such as fluid changes and inspections, can prevent major transmission failures and keep your vehicle running smoothly.

Electrical System Repairs Today's vehicles are equipped with intricate electrical systems that control various functions, from the lights to the entertainment system. If you experience electrical problems, such as dead batteries, malfunctioning power windows, or faulty sensors, it's essential to seek professional help. Skilled technicians can diagnose and repair electrical issues, ensuring all systems function as intended.

Suspension and Steering Repairs A smooth and controlled ride is dependent on your suspension and steering system. Issues like a rough ride, vibrations, or difficulty steering can be indicative of problems with these components. Suspension and steering repairs may include realigning the wheels, replacing worn-out components, or addressing issues with the power steering system. Proper maintenance of your suspension and steering system improves your vehicle's handling and comfort.

Air Conditioning and Heating Services Maintaining a comfortable cabin temperature is essential for a pleasant driving experience. If your vehicle's air conditioning or heating system is malfunctioning, it can make your rides uncomfortable. Auto repair services for these systems include diagnosing and fixing issues like refrigerant leaks, compressor failures, or heater core problems, ensuring you stay comfortable in all weather conditions.

Exhaust System Repairs The exhaust system is responsible for expelling harmful gases from the engine and reducing noise. A damaged exhaust system can lead to increased emissions and noise pollution. Common issues include rust, holes, and damaged catalytic converters. Auto repair services for the exhaust system involve repairs or replacement of damaged components to ensure your vehicle operates within legal emissions limits and is quiet on the road.

Wheel Alignment and Tire Services Proper wheel alignment and tire maintenance are essential for your vehicle's safety and performance. Improper alignment can lead to uneven tire wear, reduced fuel efficiency, and compromised handling. Auto repair services in this category include wheel alignment, tire balancing, and tire replacement. Maintaining your tires and alignment ensures a smooth and safe ride.

Body and Paint Repairs In addition to mechanical repairs, the appearance of your vehicle matters. Body damage from accidents or wear and tear can be unsightly and even affect your vehicle's resale value. Auto body shops can perform a range of services, from dent removal and scratch repair to complete paint jobs. Restoring your vehicle's appearance not only enhances its aesthetics but also protects it from rust and corrosion.

Conclusion

Your vehicle is a significant investment, and proper maintenance and timely auto repair services are essential to keep it running smoothly and safely. Whether it's routine maintenance, critical repairs, or cosmetic improvements, there are various services available to help you revive your ride. Regularly scheduled maintenance and prompt attention to any issues can extend your vehicle's lifespan and ensure it continues to serve you well on the road. Don't wait until a minor issue turns into a major problem; take care of your vehicle, and it will take care of you.

1 note

·

View note

Text

The Road to Reliable Rides: A Comprehensive Guide to Car Repair and Maintenance

Cars are more than just machines; they're an integral part of our daily lives. They take us to work, help us run errands, and provide the freedom to explore the world. However, to ensure that they serve us well and last for years, proper car repair and maintenance are crucial. In this comprehensive guide, we will delve into the world of car repair and maintenance, discussing various types of repairs and the best practices to keep your vehicle running smoothly.

I. The Importance of Car Maintenance

Before we dive into the types of car repairs, let's first understand why car maintenance is essential:

Safety: Regular maintenance helps keep your car in optimal condition, reducing the risk of accidents caused by mechanical failures.

Reliability: A well-maintained car is less likely to break down, leaving you stranded on the side of the road.

Cost Savings: Preventive maintenance is usually cheaper than major repairs. Ignoring small issues can lead to expensive repairs down the road.

Fuel Efficiency: Properly maintained cars tend to be more fuel-efficient, saving you money on gas.

Resale Value: A well-maintained car commands a higher resale value when you decide to upgrade.

II. Types of Car Repair and Maintenance

Routine Maintenance:

Oil Changes: Regular oil changes are crucial to keep your engine running smoothly. It ensures that the engine components are well-lubricated and free from debris.

Filter Replacements: Air filters, cabin filters, and fuel filters need periodic replacements to maintain air quality, engine efficiency, and fuel cleanliness.

Tire Maintenance: Regularly check tire pressure, rotate tires, and inspect for signs of wear. Proper tire care ensures better handling and fuel efficiency.

Brake Inspections: Brake pads, rotors, and brake fluid should be checked periodically to ensure your car can stop safely.

Electrical System Repairs:

Battery Replacement: Car batteries have a limited lifespan and must be replaced when they weaken to prevent starting issues.

Alternator and Starter Repairs: These components are essential for the car's electrical system. If they fail, your car may not start.

Lighting System: Regularly inspect and replace bulbs, fuses, and wiring to ensure proper lighting for visibility and safety.

Engine and Transmission Maintenance:

Engine Tune-ups: Periodic tune-ups involve checking spark plugs, ignition timing, and other components to optimize engine performance.

Transmission Service: Regular transmission fluid changes and inspections help extend the life of this vital component.

Cooling System: Maintain the radiator, thermostat, and coolant levels to prevent overheating.

Suspension and Steering Repairs:

Alignment and Balancing: Proper alignment and tire balancing enhance handling, reduce tire wear, and improve fuel efficiency.

Shock and Strut Replacement: Worn-out shocks and struts can lead to poor handling and a bumpy ride.

Steering System: Regularly inspect and maintain the steering system for safe and responsive driving.

Exhaust System Repairs:

Muffler and Catalytic Converter: Replacing these components when necessary ensures proper emissions control and quiet operation.

Exhaust Leaks: Address exhaust leaks promptly to prevent harmful fumes from entering the cabin and to maintain fuel efficiency.

Air Conditioning and Heating:

AC Recharge: If your AC is blowing warm air, it may need a refrigerant recharge.

Heater Core Maintenance: Keep your heater core in good condition for comfort during winter months.

Body and Interior Repairs:

Dent and Scratch Removal: Repair cosmetic damage to maintain your car's appearance and resale value.

Upholstery and Interior Cleaning: Regular cleaning and maintenance keep the interior comfortable and appealing.

Fuel System Maintenance:

Fuel Injector Cleaning: Periodic cleaning prevents clogs and maintains fuel efficiency.

Fuel Pump Replacement: A failing fuel pump can lead to engine stalling and poor performance.

III. DIY vs. Professional Repairs

While routine maintenance tasks like oil changes, tire rotations, and filter replacements can often be performed by car owners with basic mechanical skills, complex repairs are best left to professionals. Attempting advanced repairs without the necessary expertise can lead to further damage and safety risks.

IV. Creating a Maintenance Schedule

To ensure your car remains reliable, create a maintenance schedule based on your car's make and model. Consult your owner's manual or a trusted mechanic for guidance. Adhering to a schedule will help you stay on top of routine maintenance and address issues before they become major problems.

Conclusion

Car repair and maintenance are essential aspects of car ownership. By staying proactive and addressing issues promptly, you can keep your vehicle safe, reliable, and efficient. Remember that safety should always be your top priority, and when in doubt, consult a professional mechanic to ensure your car is in the best possible condition. A well-maintained car not only saves you money in the long run but also provides peace of mind as you hit the open road.

0 notes

Text

Sunshine of Savings: Brian Plain and Catalytic Consulting Provide Reliable Cost Reduction Services for Businesse

Below are some possible solutions for businesses and organizational cost reduction that may be relevant to the MetroWest area:

1. Energy Efficiency: Conduct an energy audit to identify sources of energy waste, and invest in improvements such as LED lighting, programmable thermostats, and energy-efficient appliances.

1. Identify the sources of energy use: Make a list of all the equipment, appliances, and systems that use energy in your home or workplace. Include lighting, heating and cooling systems, water heaters, and other appliances.

2. Monitor energy use: Use an energy meter to measure energy use for each of the sources identified in step 1. Keep track of the energy use data over time to identify peak usage periods.

3. Identify energy waste: Look for areas where energy is being wasted. These may include areas where lights are left on unnecessarily, appliances are not switched off when not in use, or heating and cooling systems are not operating efficiently.

4. Invest in improvements: Once you have identified the sources of energy waste, invest in improvements to reduce energy use. Some examples of energy-efficient improvements include: A)- Replacing incandescent light bulbs with LED bulbs B)- Installing programmable thermostats to control heating and cooling systems more efficiently C)- Upgrading to energy-efficient appliance D)- Installing insulation to reduce heating and cooling losses E) - Sealing leaks in ductwork and around windows and doors

5. Re-assess energy use: After making improvements, monitor energy use again to see if it has been reduced. Compare data from before and after the improvements were made to identify any areas where further improvements could be made.

6. Maintain energy-efficient practices: Encourage energy-efficient behaviors in yourself and those around you. Make sure that appliances and equipment are properly maintained and used efficiently. This will help to ensure that the energy savings achieved through improvements are sustained over time.

2. Outsourcing: Evaluate which business activities can be outsourced, such as bookkeeping, IT support or administrative services, which can save on office space, equipment, salaries and benefits.

Outsourcing: Evaluate which business activities can be outsourced, such as bookkeeping, IT support or administrative services, which can save on office space, equipment, salaries and benefits.

3. Cloud Computing: Consider cloud-based solutions such as SaaS, IaaS and PaaS for storage, software, and infrastructure requirements, which can eliminate the need for physical servers or equipment.

Cloud computing is a technology that allows users to access information and software applications over the internet, without the need for physical servers or equipment. This technology is increasingly popular among businesses, as it offers numerous benefits such as cost savings, scalability, and flexibility.

Cloud-based solutions such as SaaS, IaaS, and PaaS are becoming more and more prevalent in enterprise storage, software, and infrastructure requirements. SaaS (Software as a Service) provides access to applications and software through the cloud, without the need for on-site software installations. IaaS (Infrastructure as a Service) offers cloud-based computing resources such as servers, storage, and networking, while PaaS (Platform as a Service) provides a platform for developers to build and deploy applications.

One of the main advantages of cloud computing is cost savings. With cloud-based solutions, companies no longer have to invest in expensive hardware and data centers. Instead, they pay only for what they use, based on a subscription model. This reduces capital expenditures and also helps in cash flow management.

Scalability is another key benefit of cloud computing for your business near Boston/Cambridge/Framingham/Marlborough/Hudson/Northborough/Sudbury/Southborough/Westborough MA.

With cloud-based solutions, businesses can easily accommodate their growth without worrying about hardware limitations or costly upgrades.

As the business scales up, the cloud infrastructure can easily expand to meet the growing requirements.

Another advantage of cloud computing is flexibility. Cloud-based solutions are accessible from anywhere with an internet connection.

This is particularly useful for companies with a dispersed workforce, remote workers, or businesses that need to collaborate with partners and vendors located in different geographical locations.

Cloud-based solutions also offer enhanced security and data protection. Cloud providers typically use advanced security protocols to safeguard data and applications hosted in the cloud.

Backup and disaster recovery solutions are built-in to the cloud infrastructure, which minimizes the risk of data loss.

In conclusion, cloud computing is a technology that offers numerous benefits to businesses, especially for storage, software, and infrastructure requirements.

The cloud-based solutions such as SaaS, IaaS, and PaaS have emerged as a popular alternative to traditional on-premises infrastructure.

With the cloud, businesses can save costs, scale up and down easily, and benefit from increased flexibility, security, and data protection.

4. Collaborative Workspaces: If a physical workspace is required, consider using shared or collaborative workspaces that can save on rent, utility costs, and equipment expenses.

Collaborative workspaces, also known as co-working spaces, are shared offices where professionals from various industries work in the same space.

They are typically run by a management team that provides facilities such as kitchens, meeting rooms, and communal areas.

Collaborative workspaces offer a range of benefits, including reduced rental and utility costs, flexibility, networking opportunities, and access to shared resources.

By sharing space with other businesses or freelancers, you can reduce your rental costs significantly.

You will also have access to amenities that you might not be able to afford on your own, such as high-speed internet, printers, and scanners.

Collaborative workspaces are often fully furnished, which reduces your equipment expenses.

Another advantage of collaborative workspaces is the flexibility they provide.

Many co-working spaces offer short-term leases, allowing you to adapt your workspace as your business grows or shrinks.

You can also rent a desk or office space on an as-needed basis, rather than being locked into a long-term lease.

Collaborative workspaces also offer a unique networking opportunity.

With so many like-minded professionals working in the same space, you can easily build relationships and make connections that can benefit your business.

You may even find new clients, partners, or employees in the co-working community.

In conclusion, collaborative workspaces provide a flexible and cost-effective alternative to traditional office spaces.

By sharing a workspace with others, you can reduce your overhead costs, access shared resources, and network with other professionals.

5. Flexible Work Arrangements: Consider offering flexible work arrangements such as telecommuting, compressed workweeks or job-sharing, which can reduce office space demands, commuting costs, and other related expenses.

It can also improve work-life balance for employees and increase job satisfaction, leading to higher productivity and retention rates.

With technology advancements, remote work is becoming increasingly popular and feasible, making it easier to implement flexible work arrangements.

However, it's important to set clear expectations, communication channels, and performance metrics to ensure the success of these arrangements.

-In Marlborough Massachusetts you can find flexible work spaces at a great price with "Venture X" and local area "businesses near Boston, Worcester, Springfield, Lowell, Cambridge, Framingham, and Westborough to Marlborough can lower costs and expenses with Brian Plain".

6. Employee Incentive Programs: Implement employee incentive programs such as wellness incentives, flexible benefit plans, and work from home bonuses, which can encourage employees to be more efficient and productive.

Furthermore, these incentive programs can improve employee morale and job satisfaction, resulting in reduced employee turnover and increased retention rates.

Wellness incentives can be in the form of gym membership discounts, healthy eating programs, or stress reduction programs.

Flexible benefit plans can allow employees to choose from various benefits such as health insurance, retirement plans, and vacation days.

Offering work from home bonuses can also increase productivity and reduce commuting time and expenses.

In addition to these benefits, companies can also implement recognition programs such as employee of the month awards, bonuses for meeting goals or milestones, or even paid time off.

These programs can encourage employees to work harder and achieve more, resulting in increased job satisfaction and employee loyalty.

Investing in employee incentive programs can lead to a positive impact on the overall productivity and success of a company.

By showing that the company values its employees and their well-being, employees are more likely to be dedicated and motivated to their work.

7. Process Streamlining: Analyze internal processes to identify inefficiencies, redundancies or unnecessary steps and streamline them to improve workflow and reduce costs.

Process streamlining is the act of analyzing organizational processes to identify inefficiencies, redundancies, and unnecessary steps.

The goal is to improve workflow and reduce costs, resulting in a more efficient and effective organization.

The process of streamlining involves a systematic review of each step in a process, looking for areas where improvements can be made.

The goal is to reduce the time, effort and resources required to complete a task while maintaining or improving quality.

The first step in the process is to map out the current process.

This involves creating a flowchart or diagram that outlines each step from start to finish.

Once the current process is mapped out, it's time to identify any inefficiencies, redundancies and unnecessary steps that can be eliminated.

To identify inefficiencies, it's important to question why each step is necessary and whether it adds value to the process.

For redundancies, it's important to identify steps that are repeated unnecessarily, such as requesting the same information multiple times.

Once the inefficiencies and redundancies have been identified, it's time to streamline the process.

This involves removing unnecessary steps, combining redundant steps and automating manual tasks with technology where possible.

By streamlining processes, organizations can reduce costs, improve productivity and increase customer satisfaction.

It's an ongoing process that requires commitment and dedication, but the benefits are well worth the effort.

8. Contract Negotiations: Evaluate vendor contracts regularly to see if renegotiation or replacement is feasible; lease agreements, maintenance contracts, and insurance policies can all be reviewed to identify potential cost savings.

information about the evaluation of vendor contracts to identify potential cost savings.

Regular evaluation of vendor contracts is important to ensure that the terms and conditions agreed upon still meet the needs of the organization. This evaluation process should include a thorough review of the contract terms, pricing, and services provided by the vendor. By doing so, organizations can identify areas where cost savings can be achieved.

Lease agreements should be reviewed to determine whether the current space being leased is still needed, or if it can be downsized or relocated to a more cost-effective location.

Additionally, organizations should evaluate the lease agreement to determine whether there are any areas where the lease terms can be renegotiated to reduce costs.

Maintenance contracts should also be reviewed to determine whether the vendor is providing the necessary level of service to meet the organization's needs.

If not, the contract should be renegotiated or replaced with a new vendor who can provide the necessary services at a more cost-effective price.

Insurance policies should be evaluated to ensure that the organization has the appropriate amount of coverage and that the premiums being paid are competitive.

If the premiums are too high, the organization should consider changing insurance providers or negotiating with the current provider to lower costs.

Overall, regular evaluation of vendor contracts is an important part of managing the costs of running an organization.

By identifying areas where cost savings can be achieved, organizations can ensure that they are getting the most value for their money from their vendors.

9. Prevention Strategies: Implement strategies to prevent losses and reduce claims such as risk management, safety protocols, and loss prevention programs.

Here are some general prevention strategies that can be applied:

1. Identify Risks: Conduct a risk assessment to identify potential risks and hazards in the workplace. This will help you to develop strategies that are tailored to the specific needs of your industry.

2. Create Working Protocols: Develop standard operating procedures (SOPs) for each task to ensure safe and efficient workplace practices that reduce the risk of accidents and injuries.

3. Provide Training: Provide comprehensive training programs to employees on how to use machinery, equipment, and materials safely.

4. Offer Personal Protective Equipment (PPE): Providing PPE such as hard hats, safety goggles, and gloves can mitigate potential risks, injuries, and losses.

5. Conduct Regular Inspections: Conduct regular inspections and maintenance of machinery, equipment and the overall workplace to identify and address risks and issues before they become more significant problems.

6. Implement Emergency Procedures: Develop and communicate emergency procedures to prevent losses in emergency situations such as fires, natural disasters, or accidents.

7. Engage Employees: Encourage and engage employees in maintaining a safe and conducive working environment, rewarding risk-free behaviors, and incentivizing personal responsibility.

Implementing these prevention strategies can help reduce losses and claims, creating a safer and more productive work environment.

10. Vendor Collaboration: Collaborate with suppliers and vendors to find ways to reduce costs through bulk purchases, shared marketing or promotional activities, or other mutually beneficial arrangements.

Vendor collaboration is a key component of business success, particularly when it comes to reducing costs and building stronger relationships with suppliers and vendors.

By working together to identify areas where both parties can benefit, businesses can find ways to streamline processes, reduce expenses, and improve productivity.

One of the most common forms of vendor collaboration is through bulk purchasing.

By pooling resources with other businesses that use the same vendors or suppliers, companies can often negotiate better prices on goods or services.

This can result in significant cost savings for everyone involved, while also ensuring a steady supply of high-quality products.

Another way to collaborate with vendors is through shared marketing or promotional activities. This can include joint advertising campaigns, cross-promotions, or co-branded products.

By working together to market their products or services, businesses can increase their exposure and reach a wider audience, ultimately driving sales and profits.

Finally, vendor collaboration can also involve exploring ways to optimize supply chain efficiency, reduce waste, or improve quality control.

By working closely with suppliers and vendors to identify areas for improvement, businesses can find ways to streamline processes and reduce costs, while also ensuring that they receive high-quality products and services.

Overall, vendor collaboration is a powerful tool for businesses looking to achieve long-term success.

By building stronger relationships with suppliers and vendors, companies can reduce costs, improve efficiency, and drive growth and profitability.

(THIS is the Business Card for Business Cost Reduction Plan Specialist & Agent for Insurance Business Card for cost Reduction Company Solutions with Brian Plain learn more about how to drive growth and profitability for businesses in Massachusetts online and Near Boston & Marlborough MA 01752)

Contact us today

This article is presented by Brian Plain, New Business Development Manager at Catalytic Consulting Inc.

"We specialize in drive growth and profitability for businesses in Massachusetts online and Near Boston & Marlborough MA" - Local MA Business Consultant Brian Plain

Call 📞 Brian today at 1-508-203-1776 or "visit us online at Catalytic Consulting"

#MA Cost Reduction Services for Businesses#Cost Reduction Services for Businesses MA#business#Cost Reduction Services for Businesses#boston#cambridge#marlborough#framingham#worcester#springfield#massachusetts#ma#brian plain#catalytic consulting inc#Cost Reduction Services for Business#IT support or administrative services#cost reduction firm#cloud-based solutions for businesses#cloud-based solutions for employers#cloud-based solutions SaaS#SaaS cost#cost SaaS#Lower SaaS cost#Cheaper SaaS#SaaS cost reduction services#cost reduction SaaS#Insurance policies#drive growth and profitability for businesses in Massachusetts online and Near Boston & Marlborough MA

0 notes

Text

Carbon Steel versus Stainless steel what is better?

Steel is the most requisite metal of modem world technology. Being versatility, it offers a broad range of applications. Due to varying alloys and compliant grades availability, first preference to decide what type of steel to use. Iron treated with chromium become stainless steel, and when treated with carbon as main alloy, it is called carbon steel. This is the primary difference between carbon & stainless steel. Carbon steel consisted of 95% iron and 2% of carbon. This ratio provides considerable strength to carbon steels than the stainless steel. On the contrary, stainless steel contains iron with at least 10.5% of chromium. This alloying composition prevent stainless steel against oxidation and makes highly resistant than carbon steels. The mechanical properties of both metals vary respective of many grades availability. Stainless steel is more ductile than carbon steel as it contains significant amount of nickel. The other judging parameters age price, appearance, and post maintenance process. The carbon steel is denoted by using a four-digit number whereas stainless steel can be forms in different grades of 300 and 400 series. Various applications of the two, creates best fit for future designing and manufacturing. To conclude, it is the nature of the project that imply, the best steel to use.

Application of Carbon Vs Stainless steel

As per their classification, carbon steel is divided in to 2 main categories – low carbon steel, medium carbon steel.

Below are the applications for all 3 carbon steels

Cold Headed Fasters are made from low carbon steel.

Low carbon steel is used to make Shafts, spindles, pins, rods, sprocket assemblies.

Low carbon steel used for simple structural applications such as cold formed fasteners.

Medium carbon steel is used to make crankshafts, couplings, and cold headed parts.

Medium carbon steel is used for hand tools such as screwdrivers, pliers, and similar items.

Application of Stainless steel

Austenitic Stainless Steel found use in different sectors depending upon the type of grade as follows:

· SS 304 / 304 L – Tanks, Storage vessels, Sinks, Cutlery, Architecture.

· SS 309/ 310- Furnace, Kiln, Catalytic convertors.

· SS 318, 316 L – Chemical Storage Tanks, Pressure Vessels and Piping.

· SS 321, 316 Ti – After burners, Super Heaters, Compensators, Expansion Bellows.

· SS 200 series – Dishwashers, Washing Machines, Cutlery, Cookware, Food beverage equipment.

Martensitic Stainless Steels are used in making surgical and dental instruments, wire, screws, razor strips, springs, blades, cutting tools, fasteners, gears, gauge blocks, moulds and dies, ball bearings and races & aerospace.

Ferritic Stainless Steels can also be used as an alternative to austenitic stainless steel in the manufacturing of thin film products like exhaust tubing and systems, washing machine drums, containers, buses, train compartments, LCD monitor displays, microwave and solar water heaters.

Duplex Stainless Steels are used in products which have high endurance in hot working conditions. Some of the applications are as follows :

· Pressure vessels, heat exchangers.

· Marine and high chloride conditions.

· Paper and pulp industry-digestors, bleaching equipment and stock handling systems.

· Food processing equipment.

· Biofuel plants.

Precipitate Hardened Stainless Steels are used specifically in aerospace applications, pump shafts, oil and gas industry and nuclear reactor components.

1 note

·

View note

Text

Has anyone noticed in watching SCOOB! where--

--Dick Dastardly’s ur-airship is spewing black, smoky exhaust from its thruster engines in the rear ... perhaps a sign of his fondness (as it were) for using Bunker oil as a likely fuel therefor?

And where would he be procuring the Bunker oil, pray?

(Until recent innovations in refining technology went “on stream,” to use refiners’ phraseology, Bunker oil was a thick, heavy waste oil which was rather difficult to “crack” through the catalytic crackers so its particles can break down easier for refining into distillates such as gasoline, diesel fuel, heating oil, kerosene and solvents. When the Union Pacific Railroad had their legendary turbine locomotives in the West through the 1950′s and 1960′s, Bunker oil was the fuel of choice for the turbine engines, kept fluid by electric heaters in the tender ... only to have refinements in diesel-electric road power cut into any continued viability for turbine power, such eventually being phased out through the late 1960′s.)

@warnerarchive @hanna-barbera-land @warnerbrosentertainment @hanna-barbera-blog @hanna-barberians

3 notes

·

View notes

Text

🚨MOBILE MECHANIC🚨

☎️ 859-797-2233 ☎️

🔵 OPEN 24/7 🔵

Servicing Kentucky Lexington,Frankfort,Georgetown, Louisville, Paris, Sadieville, Richmond, Cynthiana, Brea, Lawrenceburg, & more

Brakes, water pump, alternator, wheel bearings, semi truck and trailers, emergency roadside repair, diesel repair on site repair,

Servicing Kentucky Lexington,Frankfort,Georgetown, Louisville, Paris, Sadieville, Richmond, Cynthiana, Brea, Lawrenceburg, & more

Brakes, water pump, alternator, wheel bearings, semi truck and trailers, emergency roadside repair, diesel repair on site repair, heavy equipment, tune up, cars, trucks, suv, mechanic that comes to me, mobile mechanic.

#mobilemechanic #859-797-2233 #kentucky #wecometoyou #cometoyoumechaic #wecometoyouanddoitall #servicingkentucky #open24/7 #lexingtonky #diesel #autorepair #carrepair #HireRush

Mobile Mechanic

mobile mechanic

Mobile Mechanic Lexington Kentucky

Mobile Mechanic Louisville Kentucky

Brakes

Rotors

Calipers

Brake lines

Master cylinder

Tensioner pulley

Serpentine belt

Timing belt

Timing chains

Valve cover gasket

Spark plugs

O2 sensors

Motor mounts

Shocks

Struts

Hub bearings

Tie rods

Ball joints

Upper Lower control arms

Sway bar & linkage

Alternators

Starters

Electrical issues

Radiators

Radiator hoses

Water pumps

Fuel pumps

AC compressors

AC Condenser

Expansion valve

Mufflers

Oil/water leaks

upgrades and custom work

Even Engines and Transmissions swaps

24-7 Emergency Repairs

Roadside Assistances

Auto Repair

#Mobile Car Repair Service

#Mobile Auto Repair Service

#Mobile Car Repairs

#Mobile Auto Repairs

#Mobile Car Repair

#Mobile Auto Repair

#Mobile Auto Mechanic

#Mobile Car Mechanic

#Auto Mechanic That Comes to You

#Auto Repair Shop

#Brakes and Traction Control

#Parking Brake Cable Replacement

#Parking Brake Switch Replacement

#Brake Master Cylinder Replacement

#Brake Safety Inspection

#Check Brake Fluid Level

#Brake Caliper Replacement

#Bleed Brakes

#Brake Fluid Flush

#Brake Booster Unit Replacement

#Brake Pads Replacement

#Brake Drum Replacement

#Brake Shoes Replacement

#Brake Pedal Linkage Lubrication

#Brake Adjustment

#Brake Rotor Replacement

#Brake Line Replacement

#Diagnostic

#Check Engine Light

#Car Won't Start

#Car Running Rough

#Fluids Are Leaking

#Warning Light

#Diagnostic

#Used Car Inspection

#Engine, Cooling, Exhaust

#Front Pipe Replacement

#Fan Shroud Assembly Replacement

#Idle Control Valve Replacement

#Fan Shroud Replacement

#Distributor Replacement

#EGR Valve Replacement

#Ignition Wire Set Replacement

#Cooling System Drain and Fill

#Oil Pan Gasket Replacement

#Intake Manifold Gasket Replacement

#Intake Camshaft Position Sensor Replacement

#Freeze Plug Replacement

#Exhaust Manifold Gasket Replacement

#Exhaust Camshaft Position Sensor Replacement

#Tail Pipe Replacement

#Carburetor Replacement

#Exhaust System Replacement

#Manual Transmission Oil Level Check

#Check Engine Oil Level

#Engine Oil and Filter Change

#Engine Mount Replacement

#Engine Coolant Temperature Sensor Replacement

#Engine Oil Pressure Sensor Switch Replacement

#Expansion Tank Replacement

#Harmonic Balancer Replacement

#Serpentine Belt Replacement

#Drive Belt Replacement

#Drive Belt Tensioner Replacement

#Distributor Cap Replacement

#Cooling Fan Replacement

#Radiator Replacement

#Radiator Fan Motor Replacement

#Radiator Hose Replacement

#Thermostat Replacement

#Engine Tune-up

#Water Pump Replacement

#Valve Cover Gasket Replacement

#Timing Belt Replacement

#Emissions Failure Repair

#Crankshaft Position Sensor Replacement

#Coolant Drain and Fill

#Catalytic Converter Replacement

#Camshaft Position Sensor Replacement Intake and Exhaust

#External Vehicle Parts

#Antenna Mast Replacement

#Mirror Glass Replacement

#Door Lock Replacement

#Headlight Door Replacement

#Header Panel Replacement

#License Plate Bracket Replacement

#Emblem Replacement

#Metal License Plate Bracket Replacement

#Trunk Strut Replacement

#Grille Insert Replacement

#Engine Splash Shield Replacement

#Fuel Tank Cap Replacement

#Hood Strut Replacement

#Splash Guard Backing Plate Replacement

#Rear Lift Gate Locking Mechanism

#Rear Distance Sensor Replacement

#Door Weather Stripping Replacement

#Power Seat Switch Replacement

#Energy Absorber Replacement

#Heating and Air Conditioning

#Blower Motor Resistor Replacement

#Heater Core Replacement

#Cabin Air Filter Replacement

#Heater and A/C Blower Motor

#A/C Recharge

#A/C Compressor Replacement

#A/C Condenser Replacement

#Defroster Grid Repair

#A/C Line or Hose Replacement

#Heater Core Hoses Replacement

#HVAC Electronic Control Module Replacement

#HVAC Blower Motor Resistor Replacement

#HVAC Blower Motor Replacement

#HVAC Blend Door Actuator Replacement

#A/C Evacuate and Recharge

#Lighting and Horns

#Turn Signal Switch Replacement

#Turn Signal Bulb Replacement

#Brake Light Bulb Replacement

#Headlight Bulb Replacement

#Fog Light Assembly Replacement

#Corner Light Bulb Replacement

#Side Marker Light Assembly Replacement

#Turn Signal Light Assembly Replacement

#Headlight Assembly Replacement

#Park Light Assembly Replacement

#Headlight Cover

#Tail Light Bulb Replacement

#Tail Light Assembly Replacement

#Brake Light Switch Replacement

#Headlight Switch

#Maintenance

#Fuse Replacement

#Tire Rotation

#Scheduled Maintenance - 30K, 60K, 90K, etc.

#Powertrain

#Throttle Body Replacement

#Throttle Position Sensor Replacement

#Oxygen Sensor Replacement

#Fuel Injector Replacement

#Fuel Filter Replacement

#Air Filter Replacement

#Mass Airflow Sensor/Meter Replacement

#Fuel Pressure Regulator Replacement

#Ignition Coil Replacement

#Spark Plugs Replacement

#Starting and Charging

#Ignition Switch Replacement

#Battery Replacement

#Battery Cable Replacement

#Battery Cable Terminal End Service

#Alternator Belt Replacement

#Alternator Replacement

#Starter Replacement

#Steering and Suspension

#Power Steering Hose Replacement

#Power Steering Fluid Drain and Fill

#Outer Tie Rod End Replacement

#Power Steering Pump Replacement

#Wheel Hub Assembly Replacement

#suspension-control-arm-replacement

#Check Tire Pressure

#Check Power Steering Fluid

#Power Steering Fluid Replacement

#Wheel Bearing Replacement

#ABS Control Unit Replacement

#Wheel Cylinder Replacement

#Ball Joint Replacement

#Shock Absorber Replacement

#Strut Assembly Replacement

#Transmission and Drivetrain

#Axle Assembly Replacement

#CV Joint Boot Replacement

#CV Joint Replacement

#CV Axle Assembly Replacement

#Driveshaft Replacement

#Transfer Case Fluid Replacement

#Transmission Fluid Change

#Windows and Glass

#Window Regulator with Motor Replacement

#Window Belt Strip Replacement

#Power Window Switch Replacement

#Wiper and Washer System

#Windshield Wiper Motor Replacement

#Windshield Wiper Blades Replacement

#Washer Pump Replacement

1 note

·

View note