#cardanshafts

Explore tagged Tumblr posts

Text

Cardan Shaft Manufacturer and working principle

Cardan Shaft Manufacturer in India

There are several manufacturers of cardan shafts in India. Here are some of the prominent ones:

AARIV PRECISION - Aariv Precision Pvt ltd, is a leading heavy equipments manufacturers, suppliers, dealers in India. Our wide range of Cardan Shafts are manufactured by using the highest quality raw materials to ensure optimum performance. AARIV PRECISION is one of the best Cardan Shafts suppliers & manufacturers in Faridabad.

Gelenke India - Gelenke India is a leading manufacturer of cardan shafts, universal joint shafts, and drive shafts in India. They have a state-of-the-art manufacturing facility in Pune and offer a wide range of products for various industries.

Industrial Cardan Shafts - Industrial Cardan Shafts is another prominent manufacturer of cardan shafts in India. They have been in the business for over 25 years and offer high-quality products that are used in industries such as steel, cement, sugar, and mining.

AIC Drive Technologies - AIC Drive Technologies is a leading manufacturer of drive shafts, universal joint shafts, and cardan shafts in India. They have a manufacturing facility in Chennai and offer products that are used in various industries such as steel, power, and mining.

Hi-Tech Engineering Services - Hi-Tech Engineering Services is a well-known manufacturer of cardan shafts in India. They offer a wide range of products for various industries such as automotive, agriculture, and mining.

Inco Drives - Inco Drives is a manufacturer of cardan shafts, gear couplings, and other power transmission products in India. They have a manufacturing facility in Kolkata and offer high-quality products for various industries.

These are just a few of the many cardan shaft manufacturers in India. It is always advisable to do your own research and choose a manufacturer based on their reputation, quality of products, and customer reviews.

Cardan Shaft working principle

A Cardan shaft, also known as a universal joint shaft, is a mechanical component that is used to transmit torque and rotation between two shafts that are not in line with each other. The working principle of a Cardan shaft is based on the concept of a universal joint.

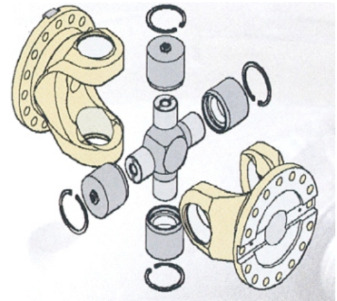

A universal joint is made up of two yokes or forks and a cross-shaped component known as a spider. The yokes are connected to the shafts that need to be joined, and the spider connects the two yokes. The spider has four arms that are perpendicular to each other and can move in any direction.

When one shaft rotates, it causes the spider to rotate, which in turn causes the other shaft to rotate in a different direction. The Cardan shaft is designed to compensate for the misalignment between the two shafts and transmit torque without causing any excessive vibration or stress.

The working principle of a Cardan shaft can be explained as follows:

When the first shaft rotates, it causes the spider to rotate along with it.

As the spider rotates, it causes the second yoke to move in a different direction from the first yoke.

The second yoke then transmits the rotation and torque to the second shaft.

The Cardan shaft is commonly used in automotive applications, industrial machinery, and marine equipment where there is a need to transmit power between two shafts that are not in line with each other. The Cardan shaft is an efficient and reliable method of transmitting torque and rotation, and it is widely used in various industries.

Referral link - https://www.linkedin.com/pulse/cardan-shaft-manufacturer-working-principle-aariv-precision/

0 notes

Link

We at Nuhydro manufacture best quality cardan shafts, universal joints and adapter hubs. We aim to provide best planning and design solution to our clients with the best quality control and assurance. We are the leading manufacturer and supplier company with operations in abroad also. We drive the growth of some of the most reputed names of this nation and are proud to be a part of the growth story of the nation. Nuhydro always aims to keep at par with recent technologies so as to keep the high standard of benchmarks for the industry and use the current technology to solve the problems quickly.

1 note

·

View note

Link

If you are looking to buy Cardan Shafts for industrial use, Visit Green Gear Trasmissioni Srl offer Cardan Shafts facilitate reliable torque transfer between spatially remote drive and output trains. We offer suitable mechanical drive solutions in nearly all industrial sectors due to their versatile design and their high efficiency. Our weight-optimised, energy-efficient, high-performance cardan shafts are developed by using advanced methods and FEM calculations to provide optimal tube wall strengths and diameters for high torsion and bending resistance. Our production technology develops customized solutions in order to provide to our end customer the best technical solution without impacting on actual budgets.

0 notes

Photo

Green Gear Transmissioni Srl Universal Shafts

0 notes

Photo

El 1 de noviembre se celebra en varias partes del mundo el Día de Todos los Santos, una fecha católica que busca rendir homenaje a todos los santos que han existido a lo largo de la historia e incluso aquellas almas que ya han pasado el purgatorio y se encuentran en el reino de los cielos. Estas almas ya se consideran santas porque están bajo la presencia de Dios. Un poco de historia sobre esta fecha solemne La iglesia primitiva solía celebrar el día de la muerte de un mártir que dio su vida por la obra de Dios. Era bastante común que estas muertes se produjeran en grupos, dado que los primeros cristianos se reunían para trasmitir las enseñanzas del evangelio de Cristo. En esas ocasiones se realizaba una única festividad común. Pero con el paso del tiempo y sobre todo después de la Persecución de Diocleciano, conocida también como la Gran Persecución, donde un inmenso número de cristianos murieron a manos del ejército romano, la Iglesia tuvo que agrupar a sus mártires en una sola festividad. Cómo se celebra el Día de Todos los Santos en el mundo A pesar de que el Día de Todos los Santos es una fecha solemne, la tradición se ha desvirtuado un poco con el paso de los siglos y cada país o región del mundo lo celebra de forma muy diferente. En Latinoamérica se acostumbra ir a visitar las tumbas de los antepasados y en países como México, no solo se visita, también se realiza un picnic alrededor de la tumba, se colocan máscaras, cintas de colores y hasta se cocinan platillos exclusivos para ese día. Qué hacer para celebrar el Día de Todos los Santos Ese día debes dedicárselo a la memoria de tus familiares difuntos, pero no con tristeza sino con alegría. Es una excelente fecha para trasmitir a las generaciones más pequeñas el legado familiar, hacerle saber de dónde provienen, qué cosas han hecho sus antepasados y cómo poder hónrales el simple hecho de estar vivos. Fuente: www.diainternacionalde.com #santos #todo #elcardan #cardanes #deprimera #diainternacional #día #escudodelecuador ecuador #cardanesloja #mundo #mundial #propellershaft #propshaft #cardanshaft #driveline #vireindustries #driveshaft #autocomponents #japan #autoparts #torque #lojacardanes #brasil (en El Cardan) https://www.instagram.com/p/CHDN1FKAbJN/?igshid=254rt4l3rtzx

#santos#todo#elcardan#cardanes#deprimera#diainternacional#día#escudodelecuador#cardanesloja#mundo#mundial#propellershaft#propshaft#cardanshaft#driveline#vireindustries#driveshaft#autocomponents#japan#autoparts#torque#lojacardanes#brasil

0 notes

Photo

#cardans #cardanshaft #kardan #driveshaft #europetrucks #Mercedes #Man #Volvo #scania #iveco #kamaz #Gaz #Lada https://www.instagram.com/p/CArQaInDqgs/?igshid=uwy6liousgej

0 notes

Link

0 notes

Photo

Welte cardanshaft in a skilift ⛷️🏂 #alsace #weyersheim #welteweyersheim #cardanservice #driveshaft #cardanshaft https://t.co/Xfwl2wADbE <3 http://twitter.com/welte_group/status/1369639645869408262

0 notes

Text

Rolling Mill Cardan Shaft Manufacturers

Rolling Mills Cardan Shafts Manufacturers

In choosing the right cardan shaft for rolling mills, there are several factors that need to be taken into consideration such as the size of the load, the transmission speed, the installation accuracy of the two connecting parts, the rotational stability and the price. The type of joint is chosen based on the other characteristics of the joints.

How to choose the right cardan shaft?

There are a few factors that need to be kept in mind when choosing the right cardan shaft for rolling mills. These are:

Due to several factors such as temperature change, load deformation, manufacturing and installation, it becomes very difficult to keep shafts in accurate alignment after installation. There will certainly be a shift. A sliding joint is selected in cases where the radial displacement is large. Universal shafts are used to connect two axes with large angular intersection or displacement. Flexible couplings are selected in cases where a large additional relative displacement is produced by the two shafts during the work process.

It is also necessary to take into account the centrifugal force caused by the working speed of the coupling. Couplings with high balancing accuracy should be chosen for high speed drive shafts. These include membrane joints and others. There are others such as eccentric slider joints which should be avoided in these cases.

The nature and extent of the torque to be transmitted and the additional requirements for the vibration damping function are also important factors. For example, if the process requires a heavy-duty transmission with high power, then gear couplings should be selected. Tire couplings should be chosen in cases where a severe shock load needs to be transmitted in order to eliminate torsional vibrations of the shaft system.

Basic steps when selecting Shafts

The cardan shafts of the rolling mills must be chosen according to the following steps:

The nature and size of the torque to be transmitted and the requirements for the damping and buffering function are also necessary to make the right choice. For example, gear couplings are chosen in cases where a transmission for heavy loads is required.

It is also necessary to take into account the direction and extent of the relative displacement between the two axes.

The working environment and the reliability of the cardan shaft of the rolling mills also play an important role. Usually, universal joints made of metal without lubrication are quite reliable. However, the performance of the coupling is affected by the perfection of the lubrication, thus polluting the environment. Joints that contain non-metallic elements such as rubber are highly sensitive to corrosive fluid, light and temperature.

For satisfactory performance, couplings with a convenient disassembly and installation process along with low cost and easy maintenance must be selected. For example rigid couplings are not only simple in structure but are also convenient in installation and disassembly.

Cardan shaft rolling mills are available in different types and varieties. Choose the right one from the cardan shaft manufacturers of the nearest rolling mills for trouble-free installation and operation of your machine.

Referral Link:

https://blogrankz.com/rolling-mills-cardan-shaft-manufacturers-in-india/

0 notes

Link

Industrial universal shaft.jpg

#universal shaft#universal joint shaft#pto shaft#pto drive shaft#cardan shaft#universal spindle#universal coupling#universal joint spindle#universal joint coupling

0 notes

Video

Universal Joint Manufacturer in India by neel nk Via Flickr: Cardanshaft Engineers India Commercials is the top Cardan shaft manufacturer. We are among the best Universal Joint Manufacturer in India and export company from India supplying to Indian native and even world auto industry

0 notes

Link

Green Gear Transmissioni Srl

0 notes

Photo

Bienvenido al terreno de #elcardan. Calidad sin disfraz.....🇪🇨 Por el día del escudo nacional del #Ecuador #naciones #onu #elcardan #cardanes #deprimera #diainternacional #día #halloween #escudodelecuador ecuador #cardanesloja #mundo #mundial #propellershaft #propshaft #cardanshaft #driveline #driveshaft #autocomponents #japan #autoparts #torque #lojacardanes #brasil #vireindustries #madeinec (en El Cardan) https://www.instagram.com/p/CHBlwLYAiwZ/?igshid=1bdsw0bxdwtae

#elcardan#ecuador#naciones#onu#cardanes#deprimera#diainternacional#día#halloween#escudodelecuador#cardanesloja#mundo#mundial#propellershaft#propshaft#cardanshaft#driveline#driveshaft#autocomponents#japan#autoparts#torque#lojacardanes#brasil#vireindustries#madeinec

0 notes

Photo

Kinds of replacement driveshaft and components be supplied Inquiry:[email protected] #driveshaft #drivelines #cardanshaft #1310 #1350 #cars #trucks #4wD #jeep #mercedes #cárdenas #propshaft #kardan https://www.instagram.com/p/B8VNTb9H8oA/?igshid=zwmdq9y9a1t6

#driveshaft#drivelines#cardanshaft#1310#1350#cars#trucks#4wd#jeep#mercedes#cárdenas#propshaft#kardan

0 notes

Link

Timothy Holding Co., Ltd.was founded in 1993. It has been specialized in producinguniversal joint shafts (also called cardan shaft or universal spindle) for more than twenty years. Our products are largely used in rolling mills,Pipe straighteners,Steel mill,tube mill,Continuous casting machinery,Paper machines ,Piercing mills,Bridge cranes,Steckel mill,Punchers,Roller conveyor, Rotating furnace,Mining machinery and other heavy duty machinery .

#cardan joint shaft#universal joint shaft#cardan joint#universal joint#cardan shaft#universal shaft#universal spindle#universal joint coupling#universal coupling

0 notes

Text

What are the Importance of Cardan Shaft for Rolling Mill

Cardan shafts are known to play an important role in the rolling process. Let's first try to understand what cardan shafts are and then we will discuss their importance.

What are cardan shafts?

Cardan shafts refer to the driveshaft between the rear axle and the gearbox. Acts as a power transmitter to the final drive at the front end of the rear and front frame. Also known as drive shafts, they were originally used in the automotive industry. It includes a telescopic sleeve, two cross joints and a shaft tube. The telescopic sleeve helps in the automatic adjustment of the change of distance between the drive axle and the transmission. In various high-load power transmission processes, certain types of cardan shafts are used for vibration damping, damping and performance improvement of the shaft system.

Importance of cardan shafts in rolling mills

Cardan shafts are used to transmit more torque and power even when the machine is running. However, many people are looking for a manufacturer of cardan shafts for rolling mills due to the importance of this component in its processes.

Function: Cardan shafts are used to connect different types of shafts, allowing them to rotate together and helping to achieve the purpose of the transfer torque. These shafts include the driven shaft bearing and the driveshaft bearing. There are some cardan shafts that also perform the damping and buffering function.

Materials: Cardan shafts are made from four main types of steel materials. These are: 45 # steel, 40 # chrome, 45 # forged steel and cast iron.

Structure Type: Various types of cardan shafts are available with the cardan shaft manufacturer for rolling mills. These include the cross type, spherical yoke type, ball cage type, ball pin type, piece type and many more. Of all these, the cross type is the most commonly used by industries.

Advantages: Using the cardan shaft for power transmission has a number of advantages that make them a popular choice. They have good transverse angle compensation capability. It has a compact structure with a high transmission capacity which makes it the preferred choice even for high capacity power transmissions.

Choice: To make the right choice when visiting the cardan shaft manufacturer for the rolling mill, it is necessary to understand and compare all the main factors that make it up. Some of the important factors that are taken into consideration are rotational speed, installation accuracy, load and rotational stability.

Replace the old cardan shaft or get a new one?

Cardan shafts must be chosen based on the required structure and model and the requirements of the drive system. While they don't require a lot of maintenance, the joint itself has a lifespan of about a year. During their use, these need to be refilled regularly and it is advisable to avoid any exceeding of the limit torque specified by the product. The prices of different cardan shafts at different cardan shaft manufacturers for the rolling mill are different. Replacing old cardan shafts is not a waste of money but an investment for the best functioning of the machinery.

Source Link:

https://www.linkedin.com/pulse/what-importance-cardan-shaft-rolling-mill-aariv-precision/

0 notes