#camshaft machining Center

Explore tagged Tumblr posts

Text

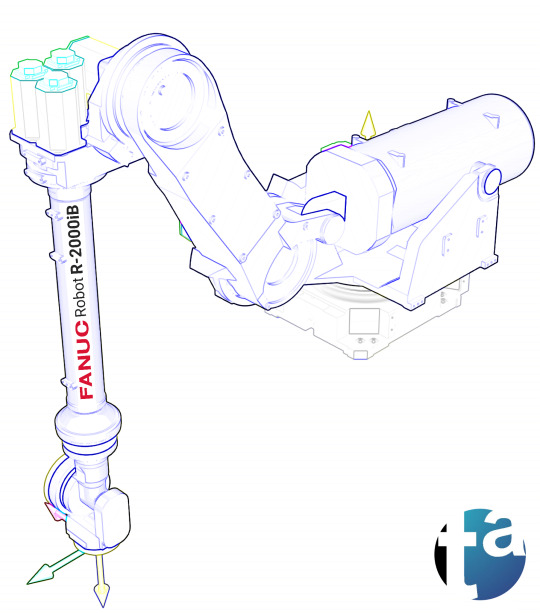

🦾 A010 - Robot FANUC R-2000iB Camshaft Machining Center automotive appl engineparts machining TranTek's Courtesy Robotics RTU Transfer Unit - linear motion track ▸ TAEVision Engineering on Pinterest

Data A010 - Jul 23, 2023

#automation#robot#robotics#FANUC#R-2000iB#FANUC R-2000iB#camshaft machining center#automotive applications#machining center#engineparts machining#TranTek courtesy#RTU#RTU Transfer Unit#transfer unit#TransferUnit#linear motion track#automation linear motion

4 notes

·

View notes

Text

Grinding Machines - Essential Tools for Precision and Efficiency

Grinding machines are pivotal in various industrial and manufacturing processes. These machines are designed to achieve high levels of precision by removing material from a workpiece, often for shaping, finishing, or improving surface quality. They play an indispensable role in producing parts with tight tolerances, a key factor for industries such as automotive, aerospace, and toolmaking. Their versatility and precision make them a cornerstone of modern manufacturing.

The Role of Grinding in Manufacturing

Grinding is a machining process that utilizes an abrasive wheel to remove material from a workpiece. Unlike cutting or milling, grinding employs friction to shave off material, making it ideal for achieving fine finishes or precise dimensional tolerances. The grinding process is usually used after other machining operations, such as turning or milling, to refine the surface and remove any imperfections that may have resulted. Whether the task involves sharpening tools, smoothing rough surfaces, or shaping complex geometries, grinding machines are equipped to meet the demands.

Types of Grinding Machines

Grinding machines come in various types, each suited to specific tasks. Surface grinders, one of the most common types, are designed to provide a flat finish on a workpiece. They feature a rotating wheel that moves across the surface of the material, removing thin layers to create a smooth, even surface. Cylindrical grinders are another key type, ideal for working on cylindrical parts. They allow the grinding of both the outer diameter and the inner diameter, which is critical in the production of parts such as shafts, bearings, and pistons.

Centerless grinders are used for high-precision grinding of parts without requiring the need for centers or fixtures. These machines work by holding the workpiece between two rotating wheels—one that drives the part and another that performs the grinding. This type of grinding is highly effective for producing parts in large quantities due to its efficient design. Internal grinding machines are specifically designed for grinding the inner surfaces of workpieces, such as holes, bores, or tubes.

Advancements in Grinding Technology

Over time, grinding technology has evolved to meet the increasing demands for precision, speed, and efficiency. Modern grinding machines incorporate advanced features such as computer numerical control (CNC), which allows for greater automation and precision. CNC grinding machines enable manufacturers to input complex geometries directly into the machine, reducing the likelihood of human error and enhancing repeatability. The use of digital controls also allows for faster setup times, shorter production cycles, and the ability to handle more complex tasks.

Additionally, the development of high-performance grinding wheels and abrasive materials has significantly improved the grinding process. Diamond and cubic boron nitride (CBN) wheels, for instance, offer longer tool life and greater cutting efficiency. These materials are especially effective in grinding harder materials like ceramics, hardened steels, and superalloys used in critical applications such as aerospace and automotive engines.

Applications of Grinding Machines

The applications of grinding machines span a wide range of industries. In the automotive sector, grinding is used for parts like camshafts, crankshafts, gears, and other components requiring tight tolerances. Aerospace companies rely heavily on grinding to produce precision components like turbine blades and engine parts, where surface integrity and dimensional accuracy are crucial for safety and performance.

Grinding machines are also essential in tool and die making. The ability to create intricate features and sharp cutting edges on tools, dies, and molds is made possible through grinding. Moreover, medical device manufacturers use grinding to create components such as orthopedic implants and surgical instruments, where precision and surface finish directly impact functionality and patient safety.

Challenges and Future Trends

Despite their advantages, grinding machines face certain challenges. The high heat generated during the grinding process can cause thermal damage to both the workpiece and the grinding wheel. To address this, modern machines are designed with advanced cooling and lubrication systems to manage heat and reduce wear. Additionally, the use of superabrasives, which are more efficient and durable than traditional abrasives, has helped overcome some of these challenges.

Looking ahead, there is a growing focus on increasing the automation and integration of grinding machines with other manufacturing processes. With the rise of Industry 4.0 and smart manufacturing, grinding machines are becoming more connected and capable of exchanging data in real-time. This allows for predictive maintenance, more efficient production scheduling, and improved process monitoring, ensuring that grinding remains a vital tool in precision manufacturing.

In conclusion, grinding machines are crucial to modern manufacturing due to their ability to achieve high levels of precision and quality. As technology continues to advance, these machines are evolving to meet the ever-growing demands of industries that require fine finishes, tight tolerances, and the ability to handle increasingly complex materials. Their continued development will undoubtedly contribute to the future of manufacturing, supporting innovation and efficiency across multiple sectors

0 notes

Text

Harley Sportster Nightster: A Modern Classic Reimagined

The Harley-Davidson Sportster Nightster has long been a symbol of raw power, rebellious spirit, and timeless design. As one of the most iconic models in the Harley-Davidson lineup, the Nightster combines the essence of old-school Americana with contemporary engineering to deliver a ride that resonates with both seasoned bikers and a new generation of motorcycle enthusiasts.

A Legacy of Performance

The Sportster line has been a cornerstone of Harley-Davidson’s offerings since its introduction in 1957. Originally designed as a lightweight, high-performance alternative to the heavier cruisers of the time, the Sportster quickly garnered a reputation for its agility and speed.

The Nightster, first introduced in 2007, took the Sportster's legacy and infused it with a dark, minimalist aesthetic that appealed to those looking for a motorcycle that was as much a statement of style as it was a machine built for the open road.

Design That Speaks Volumes

One of the defining features of the Harley Sportster Nightster is its stripped-down, blacked-out design. The Nightster embodies the “less is more” philosophy, with a minimalist approach that emphasizes the bike’s essential elements.

The low-slung profile, combined with the solo seat and chopped fenders, gives the Nightster an aggressive stance that is both intimidating and alluring.

The dark, matte finishes on the engine, exhaust, and other components create a cohesive look that exudes an understated confidence.

The Nightster’s design isn’t about flashy chrome or bright colors; it’s about a quiet power that draws attention without demanding it. For riders who prefer a stealthy, no-nonsense look, the Nightster is the perfect choice.

Power and Performance

Underneath its brooding exterior, the Sportster Nightster is powered by Harley-Davidson’s Revolution Max 975T engine, a liquid-cooled, 60-degree V-twin that delivers a punchy performance.

This engine is a departure from the traditional air-cooled engines that have been a hallmark of the Sportster line, offering smoother power delivery, increased reliability, and better heat management.

The Revolution Max 975T engine produces a healthy 90 horsepower and 70 lb-ft of torque, ensuring that the Nightster has the muscle to back up its tough looks. The engine’s dual overhead camshafts and variable valve timing contribute to a broad powerband, making the bike equally at home on city streets as it is on winding country roads.

Riding Experience

The Harley Sportster Nightster isn’t just about looking cool; it’s about delivering a riding experience that is both thrilling and comfortable.

The bike’s lightweight chassis and low center of gravity make it surprisingly nimble, while the mid-mount foot controls and low-rise handlebar offer a balanced riding position that suits a variety of riders.

Harley-Davidson has equipped the Nightster with modern technology that enhances the riding experience without detracting from the bike’s classic feel.

Features like selectable ride modes, traction control, and ABS provide added safety and versatility, while the LED lighting and digital instrumentation bring the Nightster firmly into the 21st century.

Customization Potential

One of the joys of owning a Harley-Davidson is the ability to make it your own. The Sportster Nightster is no exception, with a wide range of aftermarket parts and accessories available to customize the bike to suit individual tastes.

Whether you’re looking to add some chrome accents, upgrade the suspension, or install a louder exhaust, the Nightster serves as a blank canvas for personalization.

Conclusion

The Harley Sportster Nightster is a bike that perfectly blends the past and the present. It pays homage to the classic Sportster models that have come before it while embracing modern technology and design trends.

For riders who want a motorcycle that offers a unique combination of style, performance, and customization potential, the Nightster is a compelling choice.

0 notes

Text

Understanding Sprockets: The Unsung Heroes of Mechanical Systems

Understanding Sprockets: The Unsung Heroes of Mechanical Systems

Sprockets are fundamental components in many mechanical systems, serving as the pivotal link in chains and gears that drive everything from bicycles to industrial machinery. Despite their crucial role, sprockets often don't get the attention they deserve. This article explores what sprockets are, how they function, and their applications across various industries.

What Are Sprockets?

Sprockets are wheels with teeth that engage with a chain or a track. Unlike gears, which mesh directly with each other, sprockets work in conjunction with chains or belts to transmit rotational motion and torque between shafts. Their design can vary significantly based on their application, but the core principle remains the same: to convert rotational motion into linear movement or vice versa.

How Do Sprockets Work?

Sprockets function by gripping the links of a chain or belt and turning them. As the sprocket turns, it pulls the chain along, which in turn drives other components of the machine. The key to effective sprocket operation is the precise alignment of the sprocket teeth with the chain links, ensuring smooth and efficient power transmission.

There are a few essential factors to consider in sprocket design:

Number of Teeth: The number of teeth on a sprocket affects the gear ratio, which determines the speed and torque of the system. More teeth generally mean higher torque and lower speed, while fewer teeth result in higher speed and lower torque.

Pitch: This is the distance between the centers of two adjacent teeth. It must match the pitch of the chain or belt to ensure proper engagement and prevent slippage.

Material: Sprockets are made from various materials, including steel, aluminum, and plastic. The choice of material depends on factors such as load, speed, and environmental conditions.

Size and Design: The size and design of sprockets vary depending on their specific application. They can be simple single-tooth designs or complex multi-tooth configurations.

Applications of Sprockets

Sprockets are versatile and find applications in numerous fields:

Bicycles: In bicycles, sprockets (often referred to as cogs) are part of the drivetrain system. They work with the chain to transfer pedal power to the wheels. Different sizes of sprockets on the front and rear allow for gear changes that affect speed and climbing ability.

Industrial Machinery: In industrial settings, sprockets are used in conveyor systems, where they drive chains that move materials along a production line. Their robust design ensures reliable performance under heavy loads and harsh conditions.

Automotive Applications: Sprockets are integral to the timing mechanisms in internal combustion engines. They synchronize the camshaft and crankshaft to ensure that the engine’s valves open and close at the right times.

Agricultural Equipment: In agriculture, sprockets drive various machinery such as harvesters and tillers. Their durability and efficiency are crucial for the demanding conditions of farm work.

Entertainment and Leisure: Sprockets also appear in amusement park rides and other recreational equipment, where they contribute to the smooth operation of moving parts.

Maintenance and Troubleshooting

Proper maintenance of sprockets is essential for ensuring the longevity and efficiency of mechanical systems. Key maintenance tasks include:

Regular Inspection: Check for wear and tear, such as tooth degradation or chain slack.

Proper Lubrication: Lubricate the chain and sprocket to reduce friction and prevent rust.

Alignment Checks: Ensure that sprockets are correctly aligned to avoid uneven wear and potential damage.

Common issues with sprockets include chain slippage, excessive noise, and premature wear. Addressing these problems often involves adjusting the chain tension, replacing worn sprockets, or realigning the sprockets and chain.

Conclusion

Sprockets may not be the flashiest components in machinery, but their role in translating rotational motion into useful work cannot be overstated. Understanding their function, design, and maintenance is crucial for anyone involved in mechanical systems. From bicycles to industrial equipment, sprockets are the unsung heroes that keep our world moving smoothly.

Whether you're a hobbyist or a professional engineer, appreciating the intricacies of sprockets can lead to better maintenance practices, improved performance, and a deeper understanding of mechanical systems.

0 notes

Text

The Versatility of CNC Grinding Machines

In the fast-paced world of manufacturing, two crucial factors stand out as the keys to success: precision and efficiency. Enter CNC machines, the unsung heroes that have transformed the manufacturing landscape. Among them, CNC grinding machines take center stage, serving as indispensable tools that shape industries in remarkable ways. In this article, we'll delve into the versatile world of CNC grinding machines and their profound impact on various sectors.

Unveiling the Essence of CNC Grinding Machines

Before we embark on the journey to explore the multifaceted nature of CNC grinding machines, let's take a moment to grasp what they truly are. CNC grinding machine is not your average tools; they are automated marvels designed for the precise grinding and shaping of materials. Equipped with computer-controlled systems, they possess the remarkable capability to execute intricate grinding tasks with unparalleled accuracy.

Precision Redefined in Every Dimension

Picture this: CNC grinding machines, the masters of precision, redefine the very meaning of accuracy. Whether it's the grinding of metal components for aerospace applications or the creation of intricate parts for medical devices, these machines accomplish tolerances that were once deemed unattainable. The precision they offer is a guarantee that each part they produce meets the most stringent quality standards, ensuring excellence in every dimension.

Versatility Across Myriad Industries

Driving the Automotive Industry

In the realm of the automotive industry, precision takes the driver's seat. CNC grinding machine plays an irreplaceable role in crafting components like crankshafts, camshafts, and gears. Their unwavering precision ensures a perfect fit, ultimately leading to smoother engine performance and enhanced fuel efficiency.

Soaring Heights in the Aerospace Industry

The aerospace industry soars to new heights, demanding components characterized by unwavering precision and durability. CNC grinding machines like gundrilling machine enter the scene to craft critical elements such as turbine blades and landing gear parts. Their ability to grind complex shapes and materials makes them indispensable in the intricate world of aerospace manufacturing.

Lifesaving Precision in Medical Device Manufacturing

Medical devices demand nothing short of perfection, especially when it comes to their intricate components. CNC grinding machines step in as the heroes behind surgical instruments, orthopedic implants, and dental prosthetics. Their unmatched accuracy and repeatability contribute significantly to the overall quality and safety of medical devices.

Precision-Crafted Moulds and Dies in Tool and Die Making

In the tool and die making industry, the spotlight shines on CNC grinding machines as they create moulds and dies with unparalleled precision. These moulds and dies serve as the backbone for manufacturing a wide array of products, from plastic components to metal parts, ensuring flawless quality.

Cost-Effective Production - A Game Changer

CNC grinding machines not only excel in precision but also redefine the economics of production. By automating the grinding process, manufacturers experience a reduction in labor costs and minimal material wastage. The ability to consistently produce high-quality components leads to fewer defects and rework, ultimately resulting in substantial savings in production costs.

The Future of Manufacturing

In conclusion, the world of manufacturing owes much of its success to the remarkable versatility and significance of CNC grinding machines. Their unparalleled precision, coupled with cost-effective production, positions them as invaluable assets for manufacturers worldwide. Companies like WIDMA continue to be pioneers in this field, ensuring that CNC grinding machines and their companions like steering machines, such as the steering machine, remain at the forefront of modern manufacturing.

As industries evolve, demanding ever higher levels of precision, CNC grinding machines will undoubtedly continue to play a pivotal role in shaping the future of manufacturing. The next time you encounter a perfectly crafted automotive part or a precision-engineered medical device, take a moment to appreciate the silent but essential role played by CNC grinding machines in their creation.

0 notes

Text

My Review of the Caballero

I find this motorcycle truly exceptional, as it possesses some rare qualities and a set of flaws, fortunately all of which are easily rectifiable.

What I particularly appreciate:

Simplicity and Agility: It combines the lightness of a 125cc motorcycle with the power of a 500cc. There's hardly any electronics onboard, just fuel injection, mandatory ABS, and a starter. The absence of excessive power to manage is truly enjoyable, offering a straightforward and carefree riding experience with sufficient horsepower.

General Design: The overall aesthetics of the motorcycle are appealing, and some parts, such as the machined side plates, fork yokes, and hubs, are simply gorgeous.

Gromono Character: Unlike competitors like the KTM 390 or Suzuki 400DR-Z, which offer similar performance, the Caballero stands out due to its extra cubic centimeters and a "Big Single" engine personality that I appreciate (although not as powerful as a KTM 640). It's closer to a 500XT (with better brakes and more horsepower).

Engine Performance: It's excellent, and I have no frustrations for urban or suburban solo riding. This was a concern before purchase (without a test ride), but the torque and power curve are perfectly suited. The gearbox's ratios and shifting are also well-matched to my usage.

Original Exhaust Sound: It's lively and makes noise but not excessively so. With the expensive racing exhaust system, it becomes downright captivating. It's a true pleasure to ride a motorcycle that hasn't been overly muffled or made excessively loud.

What I don't appreciate as much:

Low-Speed Engine Behavior: When riding at 30/40 km/h with minimal throttle input, the engine exhibits a lot of jerks. It appears that combustion is suboptimal, possibly due to the cylinder head architecture with its camshaft and four valves actuated by pushrods, causing the spark plug to be in a corner of the cylinder and thus not centered. Fortunately, by slightly adjusting the mixture and adding a heavier flywheel from Fantic's catalog, the issue becomes quite manageable.

Left Handlebar Switchgear: It might seem minor, but it's really annoying, especially the turn signal switch that resembles a bedside lamp switch and the hard-to-reach horn button. I replaced it with a standard switchgear, which solved the problem.

Original Exhaust Manifold: It has an unattractive shape, likely to accommodate a pre-catalytic converter. Thankfully, there's a superb racing exhaust system available, albeit a bit expensive.

Ugly White Plastic Coolant Reservoir: It's highly visible at the front of the motorcycle. Fortunately, a coat of black paint makes it much less conspicuous.

Some Grey Plastics: They look fine from a distance but appear cheap up close. Fortunately, there are genuine carbon replacement parts available to address this.

0 notes

Text

JHY Company Introduction

Company Profile: Yuhuan Huayang Machinery Co., Ltd. was established in 2001, with headquarters in Yuhuan City, Zhejiang Province, two wholly owned subsidiaries in Baiyun District and Yuexiu District, Guangzhou, and a large number of shares in several factories in Hebei, Shandong & Fujian. The headquarter and Guangzhou subsidiary focus on R&D, production, manufacturing, sales and service of brake calipers and spark plugs, and the Guangzhou marketing center is also the sole agent of several joint-stock companies. The company starts from quality control, process and cost control, and strictly follows the IATF16949:2016 quality management system certification standard to serve our customers. Our products are cost-effective, reliable and safe, and exported to Europe, America, Asia, Middle East, Africa and other global regions, which are well received by customers.

In terms of brake calipers and spark plugs, the company now has a production base with a factory production workshop area of more than 20,000 square meters, high-precision machining centers and advanced production and testing equipment and a team of skilled technical workers and engineers, enabling us to provide OEM/ODM services according to customer needs, and the current international brands correspond to matching more than 10,000 part numbers. With nearly 200 employees under our direct supervision, we have customers in more than 30 countries around the world and serve more than 60 automotive brands. For other engine parts, such as pistons, piston rings, cylinder liners, overhaul kits, and main bearings, con-rod bearings, our joint stock factory also has strong production and supply capabilities, and the quality of products is reliable and safe. In addition, in Guangzhou, we also operate a professional repair and maintenance store for Porsche, Bentley and other luxury cars. The company adheres to the policy of "integrity first, customer first, advancing with the times, quality first", and is committed to continuously provide customers with first-class products and quality service!

1、Caliper 2、Brake pads and caliper repair kit 3、Spark plugs 4、Coil Pack 5、Piston and ring 6、Cylinder liner 7、Head gasket, overhaul kit, valves 8、Main and con-rod bearings, thrust washer 9、 crankshaft and connecting rod, camshaft 9、Water pump, oil pump and others 10、Steering gear and others

0 notes

Text

And yet the Merovingians abolished slavery in the Latin West (originally just enslavement of Christians, but of anybody by the early 1000s), and it didn’t come back till 1436. That’s 700 years—I’d be very surprised if our 19th century abolition lasts that long.

The question is never “why would people be assholes”. It’s “why won’t they”. In the case of the Merovingians, it was because several of their queens had been their husband’s household slaves—apparently when you took the maid to bed, the Franks really made you take responsibility. Those queens pushed for outlawing the slave trade and freeing existing slaves. It was also that lack of slavery that enabled the growth of technology, mostly centered on the camshaft and waterwheel, like mills, mechanical saws, and machines for processing paper and felt. You don’t want slaves to have leisure to plot rebellion, but workers who aren’t slaves want their jobs to be easier.

Or, medieval Europe gave women all the same property and political rights as men—owning property and holding titles in their own names, filing lawsuits and testifying in court, voting in any assembly where people of their rank voted. Why? Convents. Push your daughter too hard about an arranged marriage and she might suddenly discover a vocation, and dragging her out of a nunnery was picking a fight with the Church. So you needed her buy-in on that, and from there, women making their own decisions became normal.

Moral failure is not interesting, any more than you could make a movie about people not making discoveries. It’s why people don’t suck that’s interesting (“that’s mostly just the novelty” sure granted).

I think necromancy wouldn't be outlawed in your typical wizards-are-common fantasy world. Not for moral reasons, but for economic reasons. I think most lords would be unable to resist the allure of having their peasants continue to plow their fields after death or having guards that never fall asleep or need to step away from their station. Your local baron probably already has a court wizard. They would probably command their court wizard to at least learn the fundamentals of necromancy.

Also, considering how many real world nobles pursued immortality, at least some of your wealthier nobles should be liches or ghosts. What king would choose to die and bequeath their kingdom to their squabbling failsons when they can just become a death knight?

From a religious angle, if ghosts are a real and observable phenomenon, then surely any sensible church would tell people that their soul goes to heaven while their body stays on earth. What kind of virtuous person wouldn't want their corpse to help provide for their children? In fact, don't you kind of have a moral obligation to leave behind your physical attachments when you ascend to the afterlife?

Adventure hook: kill the lich lord of this land, but only so that their son can claim the throne and enact some moderate necromantic reforms. No more ghosts, but of course your corpse is still the property of your liege lord.

2K notes

·

View notes

Photo

Comprehensive restoration Green with Gold pinstriping Engine makes 13 HP at 3,800 RPM and weighs 130 kg

Exposed flywheel Dell'Orto carburetor Bosch ignition Lucas acetylene headlamp Frame no. 2793 Engine no. 2591 Sold on a Bill of Sale Purchases by a Nevada resident or Nevada dealer are on a Bill of Sale for display purposes only Not for highway or public road use

This 1927 Moto Guzzi Sport 13 is a fantastic, historic Italian sports machine. The Sport series was the only model Moto Guzzi produced between 1923 and ‘28, and it was well regarded for its good performance, beautiful lines and excellent build quality. The Sport 13 has a 500cc, 82x88mm motor that produces 13 HP at a leisurely 3,800 RPM. Everyone loves the external flywheel motor (the “bacon slicer”) of this horizontal IOE (F-head) single; the external flywheel meant a very narrow crankcase was possible, which made for an extremely robust crankshaft that was free of flex.

Moto Guzzi engines were always unit-construction, with the gearbox housed in the crankcases and a geared primary drive, which was very advanced for the day. The Sport 13 has a strong twin-tube frame, a very low center of gravity, and thus excellent handling and lively performance with a 286-pound weight and 60 MPH top speed. The Sport 13 follows the original 1921 Moto Guzzi design, although the prototype had an overhead camshaft. The F-head was much easier to produce, so from 1921-23, the Normale was the sole model of the range. The Sport 13 was painted a beautiful green with gold and black pinstriping until its final year, 1928, when it was painted red. The Sport 13 used a Dellorto carburetor and Bosch magneto ignition. This machine was originally ordered without electric lights, and as such, carries a Lucas acetylene headlamp. Total production of the Sport 13 was 4,107 machines.

This 1927 Moto Guzzi Sport 13 is a very rare, beautifully restored, early Italian machine. It was a harbinger of the future of the Italian motorcycle industry, which always combined elegant lines with advanced engineering and great performance on the road. This Guzzi is a real stunner.

16 notes

·

View notes

Text

MOPAR FLATHEADS

(taken from ‘49plymouth.com)

Valves

The valve train is lubricated entirely by the splash effect of the camshaft and valve train. The only pressure feed to the system is to the cam bearings. The oil that escapes the camshaft journals and any splash resulting inside the crankcase from the reciprocating crank mass are the sole source of lubrication for cam followers, springs and valve guides.

Common sensed says that exhaust valves and guides run at a higher temperature than intake valves and guides. Coupled with this temperature differential is the fact that intake guides are subjected to manifold vacuum, (meaning that they tend to suck oil into the guide), while exhaust guides work in the environment of exhaust pressure and heat. These two facts, temperature and pressure, mean that exhaust guides get virtually no lubrication. As a result of this fact, they are one of the more likely components in the valve train to wear out first.

Having said this, a quick look at these engines shows that they, like most automotive engines, sit high in the front. This means that in a splash lubricated valve train, the highest component is also the farthest from the source of splash lubrication – the cam bearings and followers.

Happenstance (and perhaps MoPar engineering) have dictated that the frontmost engine valve in MoPar flathead engines is an exhaust valve – the ones that wears first, anyhow. All this combines to mean that the front valve guide is the hottest, least lubricated and most prone to wear out. Disassembly and inspection of many of these engines have led this writer to believe the front valve guide nearly always exhibits the greatest amount of wear of all the engine guides. Second in likelihood of wear are the remaining exhaust guides, while intake guides rarely if ever show wear. If intake guides do leak, they tend to draw oil into the guide, which tends to aid lubrication. No valve seals are used on flathead engines

MoPar engines use hardened valves and seats as standard equipment. In this area, these engines are truly overbuilt. When valves show wear, they are invariably exhaust valves. Experience has proven that worn exhaust valves are nearly always caused by worn valve guides. Exceptions to this rule can be a piece of carbon or other debris causing a valve to hang open and burn.

Lubrication Systems

Mopar flathead engines were manufactured at a time when the technology of engine oil was still primitive, by today’s standards. Much of the wear restorers encounter upon disassembly is the result of the poor state of available lubricants. The oil we buy and use today is light years ahead of that available fifty years ago.

Bypass oil filtration systems were never very helpful, but happened to be the only thing available in the forties and early fifties for these engines. The nature of bypass filtration is that likely ten percent or less of the total oil circulated by the oil pump ever gets to pass through the filter. The line that feeds these filters is the smallest diameter steel line used in automotive manufacturing. Even this meager amount of volume allowed to pass through the filter system is shut off during periods of low oil pressure, and only opened for circulation when oil pressure rises above a given pressure point. These bypass filters were optional, for many engines were produced without them.

Full-flow oil filter systems, by comparison, filter ALL oil that is picked up by the pump and circulated inside the engine. Several restorers have performed work-around adaptations for these engines to adapt full-flow filtration to them. This improvement, in this writer’s estimation, goes a long way toward extending engine life. Full-flow oil filtration coupled with modern high detergent oil technology, will allow these already-well-built engines to last much longer between overhauls.

Engine Blocks

Do not be fooled by the small (218/230) cubic displacement of these engines. They are heavy block castings that warm up slowly due to their large mass. The water jacket inside the block is only present in the top several inches of the casting, where the heat of combustion is greatest. On the passengers’ side is the valve chamber, and there is no coolant flow below the level of the water distribution tube, well above the camshaft level. On the driver’s side, the water jacket extends down to the block core plugs and thingy, but the flow is mainly limited to the upper section. The area on the thingy side is typically where sediment and dirt settle inside the block. I have seen these blocks filled with sediment above the tops of the core plugs at the rear. This of course must all be cleaned out as part of any overhaul. Remove all block core plugs and use whatever method you have at hand to make sure everything is clean and free of sediment and dirt.

It is logical to believe that these fifty-plus year old engines may have several hundred thousands of miles on them, in spite of what you want to believe. Logic further dictates that cylinder heads have been removed several times for valve and piston work during the life of the engine. While the head is off, it is a good thing to check the deck with a straight edge, both for warppage and for distortion. It is not likely that an engine has been overheated sufficiently to warp the entire block casting, but close inspection usually shows some heaving or mushrooming of the deck surfaces around each head bolt hole. I have been successful in removing these distortions with a sharp flat file. Just start at one end and swipe crossways over the deck area. This will reveal high spots around each head bolt hole. These can be filed down to a true flat area with a little diligence. The result is a more precise deck surface against which the head gasket can seat. Most folks know that heads can be safely milled sixty or seventy thousandths to improve compression ratios. Even if this is not important to you, a resurfacing of the head is recommended, just to be sure of a flat surface for the gasket. If you can afford it and your block is at the machine shop for cleaning anyhow, have them resurface the deck a few thousandths to get a true surface. The same advice would not hurt a bit for the manifold gasket surface on the block.

Crankcase Ventilation

Another element of engine technology that has gained vastly from modern engineering understanding is crankcase ventilation. Originally designed only to ventilate the crankcase of fumes and condensation, this system is forced into double duty when an engine begins to wear excessively, for now it also has to handle blow-by products of combustion that have escaped past worn pistons and rings..

Positive crankcase ventilation (PCV) systems were originally mandated with a view toward limiting crankcase emissions. A secondary benefit of the PCV system is its ability to remove much more of the condensation and moisture from the crankcase than was originally possible with the primitive road draft tube that was always open to the atmosphere. Yet another advantage of the PCV system is its ability to disperse any blow-by from the crankcase by returning it in the engine.

It is easy to modify these flathead six engines from the original road draft system to the newer, superior PCV system. This is true mainly due to Chrysler’s involvement in military vehicle production during WWII. Many of these military vehicles were equipped from the factory with engines designed to ford streams and run in semi-submerged conditions for short periods of time. One part of these engine sealing systems was the PCV system designed to keep water OUT of the crankcase.

A direct result of this fact is that most military vehicle parts suppliers are equipped to offer the PCV adapter necessary for this conversion. This writer found one at Vintage Power Wagons. The adapter is a round, cast metal piece that bolts to the rear of the block in the same spot as the original road draft tube. From this adapter, 3/8-inch tubing is routed forward and up to the intake manifold. A pipe plug in the center of the intake on the outboard side can be removed and this line connected to it as a vacuum source. In series in this line must be a PCV valve, of the type typically used on any engine of equivalent cubic inch displacement. Because of the closeness of this vacuum line to the hot exhaust manifold, this writer chose to use an all-brass PCV valve, available from the same military source. A PCV system on these engines, coupled with modern oil and a by-pass filter, offer a recipe for extended engine life.

Thermostats

It is impossible to operate an internal combustion engine without generating condensation in the crankcase. It is just a fact of life. If the moisture is removed, it presents no problem. If it is not removed, the result is an eventual buildup of sludge.

The only way by which the moisture of condensation can be removed from a crankcase is evaporation. This evaporation can only take place in the presence of heat and air movement. If the crankcase and engine block heat is not high enough for evaporation to occur, the condensation moisture will remain inside the block. Since this is water, which is heavier than oil, it will go to the bottom of the crankcase or valve chamber. It is for this reason that these are the areas where sludge is typically found in greatest quantity on tear-down. This writer has disassembled many of these engines were more than one pint of sludge was present in the valve chambers alone.

The best remedy for condensation removal is a high temperature thermostat. Vehicles built in the forties and fifties (and before) were designed to use alcohol based antifreeze. This required the use of low temp thermostats. Today we use glycol based antifreezes with much higher boiling points. Actually, the use of a 50/50 mixture of permanent antifreeze and water RAISES the boiling point of the coolant. All this is in aid of explaining why higher, rather than lower temperature thermostats are beneficial to longer engine life. The use of a 160 or 170 degree thermostat today with permanent antifreeze is an invitation for sludge to form in the crankcase. You are doing your engine no favor at all by keeping it running cool, in spite of how it may seem to your own sensitivities.

Not only do higher temp stats cause higher engine operating temperatures which aid in condensation removal, but they also help to raise the temperature more quickly, resulting in less cold engine operating time. Once stat temperature is reached, normal cooling will take place, but at a little higher temperature. Yet another reason why these flatheads need more heat than some engines is that they are heavy castings. A flathead six cylinder 218 cid engine weighs several hundred pounds more than a small block Chevy 350. This casting mass takes TIME to heat up and get up to operating temperature.

Many owners believe that when their dash gauge shows normal temperature, the engine is truly warmed up. Nothing could be further from the truth. Remember this one idea: an engine may warm up and the thermostat open to full circulation long before the block casting around the valve chambers has come up to full operating temperatures. It is this writer’s estimate that it takes nearly thirty minutes of engine operation for a typical flathead block to reach normal operating temperature in cool weather.

Please remember, I’m not talking about the thermostat or the top radiator tank, but the block casting, itself. This is where the condensation occurs and must evaporate from. In order to keep these block casting spots free of sludge, they must get up to full operating temperature. Proof that many of these engines have spent much of their lives running too cold is the sludge found inside the blocks. Granted, engine oils and filtration were of poor quality by comparison to today’s technology, but those engines that are run warmer are always cleaner. An example of this is the fact that larger truck engines are usually found to have less sludge than small trucks and automobiles. Check it out.

Consider a newly restored vehicle with a completely new and clean engine assembly. To keep this engine clean, it should not be started and driven short distances, again because the block will not have an opportunity to achieve operating temperatures. When I use my old stuff, I start it, let it run at idle for a while, then drive it, hopefully at least thirty minutes. I will jack up a car and push it in or of a stall to avoid starting a cold engine for only a few minutes, for this very reason.

It goes without saying that all this talk about getting engines up to temperature is doubly true for the exhaust systems. Exhausts live linger in an atmosphere where they warm up completely each time they are used. Why do you think tail pipes rot off three or four times before head pipes and mufflers? They are always cooler and warm up slower, since they are farther from the source of heat.

Cooling Systems

Cooling systems seem to be one of the more misunderstood components of older engines. In order to understand them, it is necessary to understand the combustion process. A typical gasoline engine running at 2000 rpm under no load will generate a certain amount of heat, but this will soon be realized and stabilized.

Add to this engine now an increased load on the crankshaft, and many things happen at once. First, in order to maintain rpm, the throttle plates must be opened further. This is done automatically if the engine is governed, or manually in an automotive application. The amount of fuel entering the engine increases, the result of which is an immediate increase in combustion chamber pressures and temperatures. It is this sort of use that cooling systems must handle in order to protect an engine. Normal driving under light load barely works the cooling system at all. It is at higher engine loads that the cooling system must be able to function well.

From the engine’s perspective and from a combustion standpoint, the hotter an engine temperature, the better and more efficiently the engine will. Fuel atomizes more freely and the combustion process thrives in an atmosphere of heat. This is difficult for many older vehicle owners to comprehend, yet it is fundamentally true . . . . . . Up TO THE POINT where the engine will begin to suffer metallurgical from the heat. Therefore, the job of the cooling system is to allow the engine to run as hot as safely possible in order to aid the combustion process, yet keep it cool enough to protect it.

Engines are designed to withstand lots of heat safely. Unfortunately, the margin for safety between “hot enough to run well” and “too hot for engine safety” is not a very wide one. When metal parts are heated, they expand. When they cool again, they contract. This cycle can happen over and over with complete safety, as long as the extremes of the heat range are not reached. If metal parts are heated so much that they do not contract to their normal tolerance after cool-down, the metal is said to have warped. This action is most often noticed on cylinder heads and manifold castings that have been subjected to hundreds of heat/cool cycles.. Typically, the remedy for a warped casting is resurfacing.

An example of this action is the typical small block Chevy cylinder head, where the valve arrangement is such that two exhaust valves sit adjacently in the middle of the cylinder head. This is nearly always the point of failure with these castings, for this is the hottest spot on the component.

How does this all relate to MoPar flatheads? The design of these engines is such that a water distribution tube is used in the cooling system to aid in dispersing coolant to the bottom of the exhaust valve seat castings. In this sense, these engines are truly overbuilt, for this is a feature not used by very many other manufacturers of the time. An analogy to this feature would be oil nozzles directed to piston crowns in modern diesel engines – a feature that goes far to extend engine life. Flathead radiators are also overbuilt from a size standpoint, and are truly impressive in their ability to transfer heat from the engine and transfer it to the air. When these engines are warmed up to 180 – 200 degrees F, they run happily all day, run more efficiently and stay cleaner. They live linger, as well.

Having said all this, the water distribution tube is a critical link in the cooling system. Never pull a water pump without at least pulling and checking the distribution tube. It goes without saying that no engine overhaul should ever be contemplated without inspection of this part as well. The tubes are reproduced by several vendors and are available.

Bottom Line

If you truly want to do the best you can for your MoPar flathead, here’s my recipe:

• Modern high detergent motor oil in a clean engine

• Full-flow oil filtration system in place of the part time bypass system

• PCV system instead of the primitive road draft tube

• High temperature (180 or higher) thermostat

• Good quality paper air filter instead of an oil bath system

Rear Main Bearing Seals

Engines built before 1951 used a rear main seal that incorporated a flat metal flange with three screw holes in it. These seals required removal of the flywheel to allow replacement of the top half. Later flathead engines used a different neoprene seal design that could be rolled into place in the top half by loosening the crankshaft, much as you would in replacing a top rear main bearing. The two types of seal are not compatible reciprocally, due to block casting differences.

Timing Chain/Gear Lubrication

Engines built before 1951 use a pressurized oil nozzle of about 1/16-inch diameter to lubricate the timing chain and components. This tube protrudes from the block above the center of the crankshaft gear and points downward, and has a small bracket attached by one screw to the front of the block. The oil is sourced from the front oil passage leading from the main galley on the left side of the block to the front camshaft bearing.

This system provides positive lubrication to timing components and is very nice . . . . . . as long as it stays clean and free from sludge. It was abandoned in later production in favor of an oil slinger disc placed behind the crankshaft timing gear that supposedly slung oil up and onto the chain. Since the slinger lives above the normal oil level in the oil pan, it can operate only when the engine is running. In this writer’s humble opinion, the earlier pressurized system was far superior, and was discontinued only because of the poor quality oil available at the time and the difficulty in getting the block hot enough for this oil component to get warm enough to keep sludge from forming. It would be interesting to compare timing chain wear between two otherwise identical engines, to observe which of the two systems really provides best lubrication and least wear.

Connecting Rods/Caps

Somewhere around 1951 again, a change was made in connecting rod and cap design on the 218/230 engines. Earlier engine design used a special very thin-wall lock washer that sat in a relief on the cap to retain the rod nut. Later engines dispensed with this relief area and used a flat boss on the cap and instead of the thin lock washer used a split lock nut with several small perforations in the top half. What is interesting is that both rod types carry the identical casting number.

The two rod cap types each require use of the correct fastener, and cannot be mixed or matched. If you have the earlier type rods, you must use the lock washers and nuts. This writer has been unsuccessful in finding a vendor source for these washers. They are quite easy to loose on disassembly, especially if you don’t know they are even there. When installed, they are not visible due to the recess in which they sit. And they are hard to find when they are dropped. Ask me how I know. It goes without saying that rod caps can never be interchanged on connecting rods.

Oil Pans – Oil Leaks

The front of the oil pan area on these engines presents a small challenge for first time restorers. There are several places from which oil can leak, all of which will show up at the front pan area. In order to understand the nature of the situation, it is necessary for the reader to have seen the individual parts.

The front of the oil pan has a wide cork gasket which rides against an aluminum saddle, designed just for this purpose. The aluminum saddle is held in place by two machine screws, and must be removed before access can be had to the front main bearing bolts, for they are partially covered by the saddle.

The engine timing cover gasket must seal the cover itself, the front of the block and this aluminum saddle on which rides the oil pan gasket. It is at the juncture of these three pieces of metal – block, timing cover and aluminum saddle, that oil leaks can easily arise if proper assembly is not observed. This might be a good place to mention that the timing cover has one bolt on the passenger’s side that enters the cover from the rear of the block flange, in direct opposition to all the other cover bolts.

In addition to this area of potential leakage is the front main oil seal that sits in the timing cover and rides on the crankshaft pulley. Always check the seal area on these pulleys for wear. It is not unusual to find a definite groove worn into the pulley seal area from seal lip and dirt wear at this point. A worn pulley will cause a new seal to leak. Speedy sleeves are available, as are “trick” seals that ride on a new and different spot on the pulley to avoid the worn groove spot.

This writer also likes to incorporate a good sized magnet inside the oil pan on reassembly for attracting any wear metal pieces that may get into the crankcase. Old flat speaker magnets are perfect for this purpose. Never throw one away. An ounce of prevention . . . . . .

Miscellany

Engine assembly involves using many bolts that thread into water jacket passages. This is true for head bolts, manifold bolts and a few of the upper timing cover bolts as well as the three water pump bolts. It is important that these bolt threads have some form of waterproof sealer used on them. Clean, tight threads can still leak fluid past them if not sealed. There are no shortcuts to cleanliness that work here. Never use or hang a dirty part on a rebuilt engine.

Engine reassembly is fairly critical work. It cannot he done in a less than clean environment. With all the engines I have ever overhauled, I spent about two hours of parts cleaning time for every half hour of assembly. Fasteners and related block thread holes must be completely clean. The only way this writer has been successful at this task is to use thread taps and dies on each individual part. I have cleaned head bolts on a wire wheel grinder to the point that they shined, yet when the threads were chased with a die, a pile of dirt and carbon showed up on the vise. Do not worry about removing metal with a tap or die. If you are using the correct size, the threads will not be damaged.

MoPar flathead engines were manufactured with very low compression ratios, even for their day. This engineering was based much on the octane levels of fuel available to the public. Flatheads respond very nicely to an increase in compression ratio. This can be accomplished quickly and cheaply by milling material from the bottom of the cylinder head. Doing this will also assure that the head surface is true and free from warpage, as well as offering an opportunity to increase compression and engine performance.

Unleaded fuel offers no problems to these engines, in this writer’s opinion. They certainly do NOT need high octane fuel. Using it in flathead engines will not be beneficial in any way, contrary to the opinions of many. Valves and seats are already of superior quality from the original manufacturer. Just make sure when you set initial engine timing that the engine does not ping or preignite under load.

On the subject of engine timing, here is one often ignored area of performance – the distributor. Distributors have two timing advance mechanisms incorporated in their design – vacuum and centrifugal. The vacuum advance is visible on the outside of the distributor and can easily be tested by mouth or vacuum pump. If it doesn’t leak it will be okay, as long as the distributor breaker plate moves freely inside the cap.

Centrifugal advance units are harder to see, for they are underneath the breaker plate that holds the contact points and condenser. These mechanisms are usually trouble free, but may wear over time. Short of removing the distributor and having it tested on a stand, the only way to test a centrifugal advance unit is with an advance-type timing light and a knowledgeable mechanic. Specs for both vacuum and centrifugal advance units are available with other tune-up data, and of course are a requirement before checking either advance unit. Suffice to say that lots of flatheads are weak in these areas. When one performs well, it is usually a sign that both systems are functioning correctly.

This still leaves the issue of initial timing, which refers to the relationship of the engine to the distributor, and is adjusted by turning the distributor in the block while the engine is running, with the use of a timing light. Power timing, advocated by a few, aids little with these engines, unless you are a performance buff. If such is the case, have at it . . . .

__________________

5 notes

·

View notes

Text

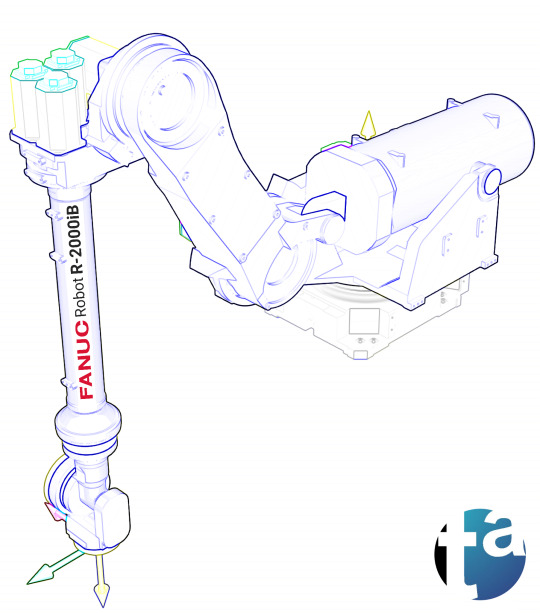

🦾 A010 - Robot FANUC R-2000iB Camshaft Machining Center automotive appl engineparts machining TranTek's Courtesy Robotics RTU Transfer Unit - linear motion track ▸ TAEVision Engineering on Pinterest

Data A010 - Jun 29, 2023

#automation#robot#robotics#camshaft machining Center#automotive applications#FANUC#R-2000iB#FANUC R-2000iB#engineparts machining#Trantek's courtesy#linear motion track#RTU#RTU Transfer Unit#TransferUnit#transfer unit

2 notes

·

View notes

Text

The Highly Qualified Research-Based Machines Through Innovation

AVTEC is a universally recognized manufacturing industry specializing in Automobile parts and Defence engineering parts. The facilities of the company are IATF 16949 and ISO 14001 certified. The state of the infrastructure makes anything possible under the roof of high-precision components.

AVTEC is famous for:

Globally acclaimed for supporting the automotive industry, off-highway, and Defence units. AVTEC has its own products and also manufactures products under different brands for their internal and integral usage, especially in the Powershift transmission areas. They are specialized in manufacturing products like transmissions and high-precision components like

· Cylinder heads

· Cylinder blocks

· Crank Shafts

· Camshafts

· Cam rods

Highly Skilled Efforts:

The experienced professional at AVTEC offers its clients the précised parts required. The Powershift transmissions and gears are the best in the industry and stand on par with international guidelines.

The company has massive records. Holding 3 manufacturing units across India has 1500+ highly skilled employees working. Utilizing these experienced employees, AVTEC has the manufacturing capacity of making 60000 engines per year and more than 1 lakh Powershift transmissions.

The absolute strength lies in technology integration. The prototype building sets the tone for the client to see the precision. The exact replica of the model is done through the expertise of the employees.

Top Notch Technology supporting Highly precise machines

Product and Design analysis in application engineering is an impeccable journey. Optimizing the design as per the cost makes it customized. The licensed employees shall also suggest the maximum performance design that can be offered for a customized option.

The highly improved systems are manufactured through highly flexible machinery. The testing team and their validation is the key to their success. Step-by-step testing of every part is carried out by specific machines and it is completely automated.

This helps them procure the certification for every machine part with ease. The R&D center in India facilitates this work in a wonderful way. The special strength of AVTEC is a technology development and application engineering.

https://www.avtec.in/avtec-automotive-engines-and-transmissions.php

#Precision auto component#Automatic Transmissions#Powershift Transmissions#Off-Highway Transmissions#Powertrain Gears and Shafts#Transmission for commercial vehicles#Auto components manufacturers in India#Transmission components

0 notes

Photo

@zrodz.customs 1970 Dodge Charger Facts ⬇️⬇️⬇️⬇️⬇️⬇️⬇️ Engine: Indy Cylinder Head’s 572 Super Street Hemi, built with an Eagle forged stroker crankshaft and connecting rods, custom 10.7:1 compression Diamond pistons, Comp Cams hydraulic-roller camshaft, and a FAST dual-throttle-body system atop an Indy Mod Man intake, tti headers and Spintech oval mufflers in a custom exhaust system by Competition Fabrications. it makes 811 rear wheel horsepower. Transmission: Tremec TKO five-speed from American Powertrain, who also supplied the installation kit with a Pistol Grip shifter. Rear: A custom-fabbed housing, with a Strange third member, 4.11 gears, and S/T 35-spline axle shafts. Suspension: Competition Fabrications set up the Magnumforce tubular upper/lower front A-arms, front sway bar and Prolink rear suspension, and added QA1 adjustable coilovers. Brakes: Big Wilwood discs with six-piston (front) and four-piston (rear) calipers. Wheels/Tires: Billet Specialties’ Velocity wheels (18×10 inches front, 20×12 inches rear) wear custom center caps machined by Odom Tool, along with a set of Michelin Pilot Sport tires (245/45ZR18 front, 335/35ZR20 rear) Paint/Body: steel Shaker hood, scalloped front fenders, ’69 Charger-style outer sculpting on the doors, flush-mount door handles, functional rear-quarter scoops, cut and raised rocker panels, and a custom tail panel. They also tailored the bumpers to fit. Paint is a special-mix two-stage PPG Orange, mixed and sprayed on by Z-Rodz & Customs. Interior: Track-ready full custom with a six-point cage by Competition Fabrication, Corbeau “Legacy” bucket seats, Billet Specialties pedals and steering wheel, ididit tilt column, AutoMeter carbon-fiber gauges, Vintage Air’s Gen IV HVAC, Electric Life power windows, and custom-built gauge cluster and console. 🚀🍊🚀🍊🚀🍊🚀🍊🚀🍊🚀 #mopar #dodge #charger #challenger #plymouth #cuda #roadrunner #musclecar #v8 #hotrod #ford #chevy #classic #hemi #car #shaker

#musclecar#classic#car#ford#hemi#hotrod#shaker#plymouth#v8#chevy#charger#dodge#challenger#mopar#roadrunner#cuda

182 notes

·

View notes

Text

Volvo VN,VHD V2 and VT Trucks 2007 Sensor Instruction

This document instruct sensors on Volvo VN,VHD version2 and VT trucks 2007.

Related Contents:

2022 Volvo PTT Premium Tech Tool PTT 2.8.120 & 2.7.116 Free Download

Volvo Impact 2021 2019 EPC Parts Catalogue Free Download

Sensors on Volvo VN,VHD V2 and VT Trucks 2007: Ambient Air Temperature Sensor The Ambient Air Temperature Sensor is used to detect the outside air temperature. The sensor modifies a voltage signal from the ECM. The modified signal returns to the ECM as the ambient air temperature. The sensor uses a thermistor that is sensitive to the change in temperature.

The electrical resistance of the thermistor decreases as temperature increases. The Ambient Air Temperature Sensor is located in the front of the vehicle.

Ambient (Atmospheric) Pressure Sensor The Ambient (Atmospheric) Pressure Sensor contains a pressure sensitive diaphragm and an electrical amplifier.Mechanical pressure applied to the diaphragm causes the diaphragm to deflect and the amplifier to produce an electrical signal proportional to the deflection. The Ambient (Atmospheric) Pressure Sensor is built into the Engine Management System (EMS) Module.2021 Volvo Impact 9116 EPC+Service Manual Download

Camshaft Position Sensor The Camshaft Position (Engine Position) Sensor is located in the rear face of the timing gear cover at the rear of the engine, near the bottom of the valve cover. It uses magnetic induction to generate a pulsed electrical signal. It senses the passage of seven (7) timing bumps on the edge of the camshaft dampener. Six of the holes correspond to the phasing of the electronic unit injectors, while the seventh hole indicates the top dead center position.

Cooling Fan Speed (CFS) Sensor On engines with an electronically controlled viscous fan drive, the electronic fan drive contains a Hall effect speed sensor. When the engine is running, a series of vanes in the fan drive housing rotates past a magnet in the fan drive solenoid generating a pulsed voltage signal. The Engine Management System (EMS) Module monitors the status if the air conditioning system and signals from the Engine Coolant Temperature (ECT) Sensor, the Engine Oil Temperature (EOT) Sensor, and the Engine Speed/Timing (RPM/TDC) Sensor and calculates the optimal cooling fan speed. The Cooling Fan Speed Sensor is located in the fan drive on the front of the engine. Crankshaft Position (Engine Speed) Sensor The Crankshaft Position (Engine Speed) Sensor uses magnetic induction to generate a pulsed electrical signal. Notches are machined into the edge of the flywheel. When one of the notches passes close to the sensor, D Design and Function electric pulses result. The Crankshaft Position (Engine Speed) Sensor also indicates when the crankshaft is at the top dead center position.

2022 Volvo TechTool 2.8 Diagnostic Software Download

Differential Pressure DP Sensor The differential pressure sensor is used for flow measurement of the Diesel Particulate Filter (DPF). This sensor has two pressure ports and senses the difference in pressure between the two ports. Measurement of the pressure before and after the DPF is used to calculate diesel filter regeneration. The Differential Pressure DPF Sensor is located on the side of the Diesel Particulate Filter (DPF).

EGR Differential Pressure Sensor The EGR differential pressure sensor is used for flow measurement of the Exhaust Gas Recirculation (EGR) valve. This sensor has two pressure ports and senses the difference in pressure between the two ports. Measurement of the pressure before and after the EGR valve is used to calculate EGR flow. The EGR Differential Pressure Sensor is located on the left or right side of the engine.

EGR Temperature Sensor The EGR temperature sensor detects exhaust gas temperature for EGR system. The sensor modifies a voltage signal from the control unit. The modified signal returns to the control unit as the exhaust temperature of the EGR system to confirm EGR operation. The sensor uses a thermistor that is sensitive to the change in temperature. The EGR Temperature Sensor is located near the EGR valve.

Engine Coolant Level (ECL) Sensor The Engine Coolant Level (ECL) Sensor is a switch. If engine coolant level falls below a calibrated point the contacts open and the driver will be notified of the low coolant level. The Engine Coolant Level (ECL) Sensor is located in the cooling system reservoir tank. Engine Coolant Temperature (ECT) Sensor The Engine Coolant Temperature Sensor is located at the front of the engine. The sensor will indicate a high coolant temperature caused by problems like radiator blockage, thermostat failure, heavy load, or high ambientD Design and Function temperatures. This sensor is also used for cold start enhancement and for fan clutch engagement.

Engine Oil Pressure (EOP) Sensor The Engine Oil Pressure Sensor contains a pressure sensitive diaphragm and a electrical amplifier. Mechanical pressure applied to the diaphragm causes the diaphragm to deflect and the amplifier to produce an electrical signal proportional to the deflection. The Engine Oil Pressure Sensor is located on the oil filter assembly. The sensor monitors engine oil pressure to warn of lubrication system failure.

Engine Oil Level (EOL) Sensor The Engine Oil Level Sensor is located in the oil pan.

Engine Oil Temperature (EOT) Sensor The Engine Oil Temperature Sensor is a thermistor whose resistance varies inversely to temperature. The sensor has a negative temperature coefficient, which means the sensor resistance will decrease as the engine oil temperature increases. The Engine Oil Temperature Sensor is located in the oil pan. Exhaust Temperature Sensor (DPF Sensors) The exhaust gas temperature sensor detects exhaust gas temperature for DPF protection as well as DPF regeneration control. The sensor modifies a voltage signal from the control unit. The modified signal returns to the control unit as the exhaust temperature at that specific location of the exhaust. The sensor uses a thermistor that is sensitive to the change in temperature. The Exhaust Temperature Sensors are located in the DPF assembly.

Fuel Pressure Sensor The fuel pressure sensor contains a diaphragm that senses fuel pressure. A pressure change causes the diaphragm to flex, inducing a stress or strain in the diaphragm. The resistor values in the sensor change in proportion to the stress applied to the diaphragm and produces an electrical output. The Fuel Pressure Sensor is located on top of the fuel filter housing. Intake Air Temperature and Humidity (IATH) Sensor

The Intake Air Temperature and Humidity (IATH) Sensor contains a thermistor and a capacitive sensor. D Design and Function The resistance of the thermistor varies inversely to temperature. The output of the capacitive sensor increases as the humidity of the surrounding air increases. By monitoring the signals from both portions of the sensor, the Engine Management System (EMS) Module calculates the temperature and humidity of the air passing through the air filter housing. The Intake Air Temperature and Humidity (IATH) Sensor is located in the air intake tube just downstream from the air filter canister.

Intake Manifold (Boost) Temperature Sensor The Intake Manifold (Boost) Temperature Sensor is a thermistor whose resistance varies inversely to temperature. The sensor has a negative temperature coefficient, which means the sensor resistance will decrease as the inlet air temperature increases. The Intake Manifold (Boost) Temperature Sensor is located in the intake manifold.

Intake Manifold Pressure Sensor The Intake Manifold Pressure Sensor contains a pressure sensitive diaphragm and an electrical amplifier. Mechanical pressure applied to the diaphragm causes the diaphragm to deflect and the amplifier to produce an electrical signal proportional to the deflection. The Intake Manifold Pressure Sensor is located on the air inlet pipe before the intake manifold.

Throttle Position (TP) Sensor The Throttle Position Sensor is a potentiometer that is mechanically linked to the accelerator pedal. A potentiometer is a variable resistor whose resistance will change as the pedal is pressed. As the resistance changes, the signal voltage of the sensor changes indicating the accelerator pedal position. The Throttle Position Sensor is located above the accelerator pedal. The sensor is designed to improve the driver’s control by reducing sensitivity to chassis motion. This sensor provides the driver’s fuel request input to the VECU.

Turbo Speed Sensor The Turbo Speed Sensor informs the EMS of the turbo shaft speed. The sensor does not read from the vanes,but reads from the shaft. The Engine Management System (EMS) Module uses this signal in conjunction with the VGT position sensor signal to control the speed of the turbocharger and therefore optimize the intake manifold pressure.

The Turbo Speed Sensor is mounted in the center of the turbocharger.

Source:https://volvotruckrepair.blogspot.com/2022/04/volvo-vnvhd-v2-and-vt-trucks-2007.html

0 notes

Text

BMW introduced the all-new 7th generation 2019 BMW 3 Series at the Paris Auto Show. The design is very complimentary to the previous generation. They announced we will see an M version in the Spring of 2019. Another big announcement was that there will be a plug-in electric version of the 3 Series available in summer 2019. Everything you ever wanted to know about the new 3 series is below.

3 Preview videos below Highlights images.

Full photo gallery below the videos

Full press release from BMW below the photo gallery

Scroll to the bottom to view the full specs for both the 330i and 330xi.

BMW released a few videos to showcase the all-new 2019 3 Series.

Video: 2019 BMW 3 Series 330i Introduction by BMW

youtube

Video: 2019 BMW 3 Series Driving, Interior and Personal Assistant

youtube

Video: BMW 3 Series Being Built at the Factory in Munich

youtube

2019 BMW 3 Series 330i and 330xi Photo Gallery

The seventh generation of BMW’s iconic sports sedan.

New generation of design, suspensions, engines and technology.

330i and 330i xDrive on sale March 2019.

Pricing starts at $40,250 + $995 Destination for the 330i.

M340i and M340i xDrive Sedans to arrive in Spring 2019.

330e model planned for 2020.

Woodcliff Lake, NJ – Oct. 2, 2018. Today, BMW proudly introduces the seventh generation of the iconic sports sedan, the BMW 3 Series. Over the past 40 years, no single model has embodied the concept of the Ultimate Driving Machine better than the BMW 3 Series Sedan. Modern design, agile handling, exceptional efficiency and innovative equipment features, all signature characteristics of a BMW, have been raised to a higher level through tireless engineering and testing. The new 2019 BMW 3 Series sedan represents not only the core of the BMW 3 Series range (of which over 15 million units have been sold worldwide) but also the heart and passion of the BMW brand.

When the first BMW 3 Series arrived on U.S. shores in 1976 as a successor to the iconic BMW 2002, it built upon the sport sedan foundation pioneered by that model and launched a new name: the BMW 3 Series that would become BMW’s most successful model – a status it retains to this day. Over the course of six model generations, the BMW 3 Series has ranked as the world’s biggest-selling premium car, led the way for high-performance powertrain and chassis technology and earned a reputation as a pioneer of technological innovations in its segment. The latest edition of the car sees BMW building on the sporting tradition of the 3 Series, whose exploits in race competition have earned it many accolades. The seventh generation of the sports sedan moves the game on once again in terms of driving dynamics, not to mention premium quality and innovation, in its segment.

BMW 330i: more power and torque Boasting numerous detail upgrades, the new 2.0-liter, inline 4-cylinder powering the new 2019 BMW 330i unit delivers 255 hp between 5,000 and 6,500 rpm and a peak torque of 295 lb-ft from 1,550 to 4,400 rpm. The 7 hp increase in output and the extra 37 lb-ft of torque compared with the predecessor engine are the result of the focused optimization of the BMW TwinPower Turbo system – which is made up a twin-scroll turbocharger, High Precision Injection direct petrol injection, VALVETRONIC fully variable valve timing and Double-VANOS variable camshaft timing. The High Precision Injection system ensures precise fuel metering and particularly clean combustion, its new fuel pump generating maximum pressure of 350 bar compared with the 200 bar of the previous version. The improved direct injection system enables optimal fuel flow through the combustion chambers with atomized fuel delivered by multi-hole injectors. Other characteristics of this engine include a lighter crankshaft, reduced internal friction, optimized heat management and a new digital engine management system. An impressive 0 to 60 mph time of 5.6 seconds belies the enhanced efficiency of the new BMW 330i Sedan.

The 2019 BMW 330i arrives in March 2019 with a starting price of $40,250 plus $995 destination. The 330i xDrive sedan will start at $42,250 plus $995 destination.

In addition to the 4 cylinder 330i, the line-up will expand further to include a BMW M Performance version with extremely sporting characteristics and a BMW iPerformance model with the latest plug-in hybrid drive technology.

BMW M340i and M340i xDrive M Performance Spring of 2019 will see the arrival of the BMW M340i and M340i xDrive Sedans. The new BMW M Performance model will showcase the full dynamic potential of the new BMW 3 Series Sedan. An updated six-cylinder in-line gasoline engine, M Performance chassis tuning, optional xDrive intelligent all-wheel drive and the standard M Sport rear differential will deliver performance attributes that will impress any driver.

The new version of the straight-six engine developed for the BMW M340i xDrive Sedan will produce 382 hp and peak torque of 369 lb-ft. A 0–60 mph time of 4.2 seconds (provisional figure) takes the BMW M Performance model into performance territory inhabited by high-caliber sports cars.

8-speed Sport Steptronic transmission: improvement and greater integration The new 2019 BMW 330i and 330i xDrive Sedans are equipped with the 8-speed Sport Steptronic transmission as standard. The latest upgrade of this sport automatic transmission sees a wider gear spread (from 7.8 to 8.2 and also increases internal efficiency and improves vibration suppression. There is a new control unit and further enhanced gearshift dynamics. In addition to the optimized hydraulic control system, the shorter gearing for the lower ratios boosts the acceleration capability of the new BMW 3 Series Sedan. The 8HP 8-speed Sport Steptronic transmission delivers even shorter shift times and a Launch Control function for highly dynamic, traction optimized acceleration off the line than previous versions. Shift paddles on the steering wheel allow manual gear selection.

Intelligent connectivity enables the sport automatic transmission to adapt its shift strategy according to the route and driving situation. With the optional Navigation system, the 8-speed Sport Steptronic transmission uses data from this system and from the Active Cruise Control system’s radar sensor. This makes it possible for the transmission to avoid unnecessary gear changes when negotiating a series of fast corners and, when approaching a vehicle ahead, for example, to shift down early in order to use the engine braking to scrub off speed.

The Auto Start Stop function and the coasting function available in conjunction with the 8-speed Steptronic transmission in the new BMW 3 Series Sedan also use data supplied by the optional navigation system with data from the standard Active Guard driving assistance systems’ front camera. In this way, inefficient engine shutdown – for example when stopping briefly at junctions or roundabouts – can be prevented. Movement of vehicles ahead is registered in order to determine the ideal moment for the Auto Start Stop function to stop and start the engine. The coasting function is now available when either ECO Pro or COMFORT mode is selected using the Driving Experience Control switch between 9 and 99 mph. The efficiency-enhancing decoupling of the powertrain only takes place in driving situations where performance and comfort are not compromised. If the driver suddenly lifts off the accelerator, the powertrain stays connected so that engine braking can be used to support deceleration. For the same reason, powertrain disconnection is also prevented when approaching a junction or a vehicle ahead.

BMW xDrive: fully variable and more efficient. The latest version of the intelligent all-wheel-drive system splits drive torque between the front and rear wheels more efficiently than in the previous 3 Series model. The fully variable power transfer ensures maximum traction and directional stability in all road and weather conditions while also promoting sportier handling. This functionality comes courtesy of the electronically controlled multi-plate clutch in the transfer case which links up with the Dynamic Stability Control (DSC) system and constantly adjusts power transmission – precisely and in a fraction of a second – in response to the driving situation. In this way, any tendency of the vehicle to oversteer or understeer greatly reduced.