#brass nozzles

Explore tagged Tumblr posts

Text

Minneapolis Natural Stone Pavers Front Yard

Summertime image of a sizable, full-sun, stone water fountain in a front yard in the Mediterranean.

0 notes

Text

Minneapolis Natural Stone Pavers Front Yard

Summertime image of a sizable, full-sun, stone water fountain in a front yard in the Mediterranean.

0 notes

Text

Minneapolis Natural Stone Pavers Front Yard

Summertime image of a sizable, full-sun, stone water fountain in a front yard in the Mediterranean.

0 notes

Text

Minneapolis Natural Stone Pavers Front Yard

Summertime image of a sizable, full-sun, stone water fountain in a front yard in the Mediterranean.

0 notes

Photo

Minneapolis Natural Stone Pavers Front Yard Summertime image of a sizable, full-sun, stone water fountain in a front yard in the Mediterranean.

0 notes

Photo

Traditional Landscape - Driveway An example of a huge traditional full sun front yard stone landscaping in spring.

0 notes

Text

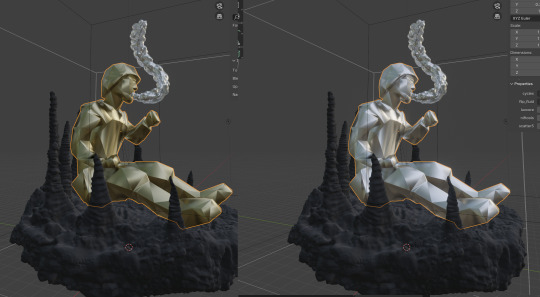

To no one's surprise the LED lamp project I've been tag rambling about is yet another goddamn benrey but hrrrng colour choice? Gold matches my decor but silver might look better with LEDs. Maybe even white. Thoughts? Base will be matte black or gunmetal spray.

#hlvrai#printing starts tomorrow im too sleepy#ouuuuuhhhh i cant wait to install the lights wled is so fun#the led strip is a delicate 2.7 mm wide nightmare though#i was gonna loosely fold it to be double sided cus wled lets you split the LEDs into sections and mirror the patterns#but i think im gonna have to split it into two separate strips which means tiny scary resoldering#also tried out the clear glow filament in a brass nozzle which no one recommends#it was fine but i'll get a new nozzle anyway

33 notes

·

View notes

Text

T&S Brass B-0133-ADF12 Wall Mount Pre-Rinse Assembly With 8" Centers PartsFe CA

The T&S Brass B-0133-ADF12 Wall Mount Pre-Rinse Assembly With 8" Centers, crucial for efficient dishwashing in commercial kitchens. Designed with 8" centers for secure wall installation, it offers a reliable solution for high-volume cleaning. This assembly features a powerful spray valve, simplifying the removal of food debris before dishwashing. Its durable brass construction ensures longevity, while the flexible hose provides extended reach and maneuverability.

To keep your restaurant running smoothly, it's crucial to invest in T&S Brass Wall mount pre-rinse assembly with 8" centers that ensure long-lasting performance.

#B-0133-ADF12#T&S Brass#Nozzle Valve#Foodserviceparts#Restaurantequipmentparts#Kitchenequipmentparts

0 notes

Text

Upgrade Your Bathroom with a Trendy Bib Cock in india | Frikly

Elevate Your Bathroom with Premium Bib Cock from Leading Manufacturers at Frikly. Discover a wide selection of branded Bib Cock online, offering unparalleled quality and style. Whether you seek a sleek and modern design or a bold and unique statement piece, our collection has it all. Transform your bathroom into a stunning sanctuary with our lowest-cost options, without compromising on quality. Shop now and buy the perfect Bib Cock for your space, exclusively at Frikly!

#Bib cock price#2 way bib cock#Brass bib cock#Two way bib cock#Long body bib cock#2 in 1 bib cock#Bib cock tap#2 way bib tap#Nozzle bib cock#Long nose bib cock

1 note

·

View note

Text

Precision Turned Brass Components Manufacturer

We Are Manufacturer, Supplier Exporters for Precision Turned Brass Components – CNC Machined Parts, Electrical Brass Components Offered By Ok Engineers in Jamnagar India. In addition to their dedication to quality, OK Engineers is equipped with cutting-edge machinery and processes, such as CNC machining, that enable them to create brass turned components with the highest level of precision and consistency.

#brass electrical components in Jamnagar#brass inserts and Brass Moulding Inserts#Brass nozzles in Jamnagar

1 note

·

View note

Text

"It was a pleasure to burn. It was a special pleasure to see things eaten, to see things blackened and changed. With the brass nozzle in his fists, with this great python spitting its venomous kerosene upon the world, the blood pounded in his head, and his hands were the hands of some amazing conductor playing all the symphonies of blazing and burning to bring down the tatters and charcoal ruins of history."

-- Fahrenheit 451 by Ray Bradbury

#palestine news#genocide in palestine#us news#global news#united nations#un#blinken#usa news#palestine#book quotations#book quote#fahrenheit 451#books#united states

46 notes

·

View notes

Text

FDM printed and hand painted Stolas. Never have I ever did painting of figurines, but it sure was fun - and I will definitely redo it. I (and probably much more people) miss his royal onsie and the hat so here you have it all of it's glory.

Sadly few pieces snapped during processing and it's visible.

Next up on the list is Blitz figurine so Stolas isn't alone (but don't expect much updates because I will loose access to 3D printer for quite some time)

author of the 3D model: printedobsession and link to his model Used setup: Crality Ender 3 with glass bed and 0.4mm brass nozzle, Rosa 3D quick print PLA, Prusa Slicer Printed with 0.08 mm layer height and organic supports *this model should be printed on resin printer for more fidelity and detail, but I don't own one, so I had to deal with the stuff that I own

7 notes

·

View notes

Text

How do you get so empty? he wondered. Who takes it out of you?

It was a pleasure to burn.

It was a special pleasure to see things eaten, to see things blackened and changed. With the brass nozzle in his fists, with this great python spitting its venomous kerosene upon the world, the blood pounded in his head, and his hands were the hands of some amazing conductor playing all the symphonies of blazing and burning to bring down the tatters and charcoal ruins of history.

Books were only one type of receptacle where we stored a lot of things we were afraid we might forget. There is nothing magical in them, at all. The magic is only in what books say, how they stitched the patches of the universe together into one garment for us.

#reading#books read in 2024#bookblr#books#book photography#book blog#bibliophile#books reading#books and reading#fahrenheit 451#451#dystopian#dystopia#ray bradbury#bradbury#1984#dystopian society#burning books#this should be required#cant believe i never read this in school#short read#explosive#thought provoking#thinking#feeling#fast society#review#five stars#will definitely reread in the future#july reads

19 notes

·

View notes

Text

Fanfic: The Cuppatronic 3000 (Wallace and Gromit)

READ NOW ON AO3!

The chimes of the old mahogany grandfather clock in the sitting room broke through the gentle clattering of my knitting needles. One bong, two bong, three bong sounded before the clock resumed its normal ticking, its brass pendulum swinging to and fro without a care. The Pavlovian response to that particular sequence of bells moistened my chops for a particular set of biscuits we bought yesterday at the shops. I set my latest project (Scarf? Jumper? Too soon to tell) down on the arm of my chair and slid all four paws upon the floor. My master was in the basement tinkering away and therefore was too far or too engrossed in his project to hear the clock chiming for the grandest of all simple British pleasures. Thus it was I who made tracks to the door in the hall with soft pawsteps upon the rug to alert him.

Once in position, I relaxed onto my haunches and threw the door open. There down the stairway was my companion, Wallace, leaning against a cylindrical device as tall as him, splicing wires together behind a rivet-bordered control panel.

I knocked on the door just as Wallace jumped backwards with a yelp. Poor boy must’ve caught a stray spark. It was par for the course with his inventing. You never knew who would hurt who first.

He met my gaze above him and I waved. “Oh, Gromit!” he greeted. “Is it tea time already?” I nodded and gestured my head toward the kitchen. Just as I was about to pad away to begin preparation, he stopped me with a whistle. “No, no, you needn’t bother this time. I shall take it upon myself to prepare tea today.” He straightened his tie and brushed down his green knitwear vest with confidence.

I cocked my head and gave him a skeptical raise of the brow, to which he responded with a nod.

“Now, I realize I’m not as adept a cook as you are.” That was an understatement. “And I know that in most matters culinary, you are the foremost expert.” It felt nice to be acknowledged. “However, I have a machine that will allow even me to brew the perfect cup of tea every time, and if that’s the case, just think of the time it will save you!”

I was even more suspicious now. But it was a deep-seated curiosity that drove my paws down those cold stone steps so I could behold with my own eyes the machine my master had spent the day creating.

Wallace shut the control panel and screwed it into place as I sat once more at the foot of it. The creation would likely fit into where our refrigerator currently occupied, though I’d have to stop Wallace from replacing it with this machine if he began to get ahead of himself. It was fully cylindrical apart from a dome top making it look like the pillarbox down the street. A riveted sign under the top edge of the machine read, “Wallace’s Cuppatronic 3000.” The control panel had dials labeled “Temperature,” “Milk,” “Time,” and “Sugar.” An indentation below the control panel was just big enough for a teacup to slot into, and a nozzle pointed down upon its topside, likely to dispense something or other into the vessel of choice placed inside. I walked around to see three separate clear reservoirs in a row labeled “Water,” “Milk,” and “Sugar” along with a slot labeled “Teabag.” The process and purpose of this machine was becoming clear to me.

“Shall I tell you how it works?” Wallace asked. I would indulge him. Explaining his inventions to others was his favorite part of inventing, after all. Wallace flipped a switch and the aforementioned signs lit up clear as the familiar sound of water boiling tickled my ears. “All you need to do is top up your ingredients as I’ve done, dial in your recipe, and the machine dispenses the perfect cup.” A green light came on to indicate the water was now ready to go. “Now I don’t have a recipe, nor do I know which one you use for our tea, but I’m sure a few simple samples will get us there. Care to be my assistant, lad?” Usually, I was hesitant to play test subject, but unlike the other times, this invention seemed unlikely to kidnap, brainwash, or otherwise inconvenience, so I nodded in agreement. “Righto, let’s begin. I suppose the best way to start is with all dials bang in the middle.”

Wallace turned the dials accordingly and pressed the button labeled “Start.” An unseen voice began to speak suddenly and my ears stuck straight up in surprise. “Two lumps, three tablespoons milk, two minutes.”

“I may have forgotten to mention the Cuppatronic speaks,” said Wallace. “I obtained the necessary voice synthesis chip on our outing yesterday.” So that’s where he disappeared to while I was left with the shopping. The machine whirred to life and I braced myself for a leaky hose or an unshielded wire to throw a spanner in the works as was often to happen. But as those two minutes wore on and Wallace walked over to a nearby workbench to retrieve a teacup, I wondered if for once, I was fretting over nothing. The Cuppatronic hissed as the water inside boiled and converted the loose tea inside into my favorite afternoon beverage. Wallace placed the teacup under the nozzle just as a tan liquid began to stream into it, filling the white ceramic vessel until the stream slowed to drips and a bell dinged.

“Enjoy your tea,” said the machine in its metallic approximation of an English voice. I had half a mind to say thank you for the simple fact that it had worked perfectly. It was fantastic.

“Ha-ha!” Wallace cheered. “All according to plan!” He gingerly removed the cup from its perch and held it up to his nose. The steaming mug wrapped him and me in the familiar aroma of darjeeling comfort and he took a sip. Almost immediately, the giddy smile left him to be replaced by disappointment. He took another sip and smacked his lips together. “I say,” he declared, “I think this recipe needs adjusting.” He set the teacup down on the workbench and I took it for myself to try the concoction. The heavy amount of milk and sugar blanketed my tongue and I couldn’t hide my own displeasure. It was certainly tea, and it was good for someone, but not for us.

Wallace rubbed his chin then retrieved a clipboard and pencil. “I’ve crossed that combination off the list. That leaves 11 more combinations to test.”

My ears straightened and my eyes widened. 11?? This was to be a long afternoon.

+++

Just as I predicted, it did take a rather long time to test the flavor of every single dial combination on the Cuppatronic. Mathematically, Wallace was being kind with his estimation of 11, for as each new combination was tried, he came up with a new combination not previously accounted for. By the time we had gotten to this point in time, we each had a pile of cups and saucers next to us on the floor, some empty and stained in brown, most half-full after we both realized we couldn’t sustain finishing a cup for each test. At this point, we had refilled the sugar, and milk tanks once over and the teabags thrice over, and there was only one more adjustment to test, the last hurdle on this extremely long race.

As the machine settled to stillness, it said once more, “Enjoy your tea.” I rolled my eyes and drew my fill from the cup before handing the rest to Wallace. “Buck up, lad,” he encouraged, “we’ll have scaled the mountain after this.” Indeed, the mountain of tea would be scaled, and I would switch to coffee permanently. I took a sip of fizzy water and swished it around in my mouth before swallowing it down. I needed the clearest palate to pick up on every nuance if we were ever to put this to bed. I raised the cup to my face and looked down at the tea, the same shade of tan as all the others. As I tipped the cup and the liquid hit my tongue, all the pieces slid into place. At last, it was what I was used to. Not too milky, just sweet enough to pique the palate, but with a strong foundation of darjeeling. It was just like I was used to, just like I made it for us every day.

And yet, as I looked back up to see my master’s reaction, apparently it wasn’t quite enough.

Wallace tapped a finger repeatedly on the cup, staring into it as if an answer were floating atop that was waiting to be deciphered. I set my cup down and walked over to look inside as well. Seeing nothing but a beige abyss, I turned to Wallace, placing my hands on my hips. I wanted him to tell me what he really sought to accomplish with this machine.

“I don’t know, lad,” he said, rubbing the bridge of his nose with his fingertips. “I’ve about worn out my mouth for this. The recipe is perfect. It just doesn’t taste the same. …Maybe the tea should brew at 98 degrees rather than 99.”

That was it. We would be here all night if I were to enable this a moment longer. I shook my head and took the cup from his hands. He stuttered, caught between words, clearly at his wit’s end. As if I couldn’t tell. “What do you suppose is missing, then?” Wallace griped.

It was time for me to show him what I knew all along. I took his hand and led him back upstairs and to the kitchen. I sat him down at the breakfast nook and held up one finger, instructing him to wait right there. The kettle was standing vigil upon the stove and once I made my way to it, I lifted it and sloshed the water around. There was enough for my purposes, so I set it back on a burner and turned it on to high. Next, I opened a drawer to the right of the stove and pulled out a little black book, my treasured recipes. The pages flew by in a flurry as I turned to the recipe I wanted and held it out to Wallace.

“What’s this, Gromit?” he inquired, delicately taking the book from me. I tapped the recipe, and gave him a wink. I led the horse to the water and now he had to drink, so I returned to the stove and began doing another breed’s job, retrieving teabags and sugar from the cabinet, and milk from the fridge. This supply thankfully was kept out of the basement during our previous exploits. As I methodically performed the same actions I had done for many a teatime before, a Formula 1 pit crew for hot beverages, Wallace read the recipe to himself, as if I were cueing his actions with mine.

“Brew for two minutes and 24 seconds at 98 degrees.” The kettle began to whistle, and I lifted it off the burner before dousing the heat with the turn of a knob.

“Fill three quarters of the mug and brew for three minutes and 24 seconds.” I deposited the teabag in the cup and filled it, guided by my muscle memory.

“Once brewed, add two and a half teaspoons milk, one sugar lump. Serve immediately with biscuits and cheese.” Wallace looked up. I leaned against the counter and crossed my arms. “Gromit, what are you playing at? This is the same recipe as we just tried, to the letter! What makes this different?” I tapped the top of the page then the bottom of the page, telling him he hadn’t yet seen what I wanted him to. Rolling his eyes, he returned to reading while I turned back to finish the cup, never breaking the count of time in my mind.

“The Perfect Tea,” he mumbled, “Revision number…23?” The number sputtered from his throat like a car kicking over on a cold day. Ah, now he was starting to see. With each day and each mug, I’d notice Wallace’s reactions, such as how when he didn’t like it that day, he’d stare at the mug as if it yelled at him, and if it was especially good, his ears would perk up. And each time, I’d make a change, aiming to perfect the cup for next time. It had been years since I’d made the last change.

As I lifted the teabag out with a spoon and delicately added the milk and sugar, I knew the kicker was coming.

“Always remember, the loving touch is important. No matter how hard of a day you’ve had, whether an invention has blown a hole in the roof again, whether a killer robot or penguin or former Bake-O-Lite girl is after you, when all is quiet and normal, you are sharing tea with the most important person in your life whom you couldn’t imagine being without. So put that love and gratitude into each cup and enjoy every moment with Wallace, your master.”

I gave the cup a final stir, and took it into my hand. Wallace put the book upon the table, mouth agape. I held the cup out to him and he swallowed before taking it from me. He looked down upon it, then to me. I nodded. He lifted it to his mouth and drew a small sip. The way his eyes lit up with sparks confirmed my theory. What a machine could never ever provide, the care, attention, and devotion of a living being, had made all the difference. He wanted to save me time with the Cuppatronic but this was always time well spent.

Wallace stood up and approached me slowly. I held my hand out to ask how it tasted, though I already knew the answer. He just needed to tell me. Wallace grabbed the hand and pulled me into a hug. As we stood embraced in the kitchen, he said, “Well done, lad. It’s perfect.” That was all I needed to hear.

Though we could not communicate through the same avenues, the message always found its way to its destination. Quirky though he may be and even misguided at times, there was no other master I would rather have, and a dog’s word is worth its weight in gold.

“Thank you, Gromit,” said Wallace.

You’re welcome, old boy.

BOOM!

We tensed in each other’s arms at the sudden explosion, and resulting echoing crunch of wood and brick collapsing onto the floor. We looked at each other, thoroughly broken out of our moment of sentimentality, then I let all fours carry me toward the basement like a rocket. I flew down the stairs and skidded to a halt upon landing at the bottom. I stood up at my full height and just stared.

The understated chrome dome was gone from the machine, while a frayed hose spraying steaming water from the opening onto the floor, and sparking wires dotted the gaping cavity that remained.

While we were in the kitchen and I was enlightening Wallace, the Cuppatronic had, for lack of a better phrase, blown its top, obsoleting itself as if it knew what was happening upstairs.

Wallace’s footsteps approached behind me and I turned to see him at the top of the stairs, eyes wide and hand over his mouth. After a moment, he removed it slowly and exclaimed, “Oh, crackers!” He swallowed, no doubt searching for something to say to the debacle in front of him. Finally, he snapped his fingers. “I knew I should have used a band clamp for the hot water line instead of a spring clamp.”

Before my paw could meet my forehead, the doorbell rang. Upon opening it, a short and squat older lady in a bonnet and apron was at our doorstep, looking slightly cross. A wagon containing the top in question was in her tow.

“Oh, hello, Mrs. Mulch,” Wallace greeted with a grimacing yet polite smile.

Mrs. Mulch huffed. “I have something what landed in my garden that I believe belongs to you.” She then pulled the wagon with great effort until the plastic wheels clattered against our stoop and the dent the top had taken, no doubt from its impact upon the dirt, became evident.

All we could do was show the poor madam our teeth, graciously take what was ours off her hands and apologize profusely. Such was life with my dear master, and every moment was, like our daily teatime, time well spent.

6 notes

·

View notes

Text

The Hearth and the Salamander

It was a pleasure to burn. It was a special pleasure to see things eaten, to see things blackened and changed. With the brass nozzle in his fists, with this great python spitting its venomous kerosene upon the world, the blood pounded in his head, and his hands were the hands of some amazing conductor playing all the symphonies of blazing and burning to bring down the tatters and charcoal ruins of history. With his symbolic helmet numbered 451 on his stolid head, and his eyes all orange flame with the thought of what came next, he flicked the igniter and the house jumped up in a gorging fire that burned the evening sky red and yellow and black. He strode in a swarm of fireflies. He wanted above all, like the old joke, to shove a marshmallow on a stick in the furnace, while the flapping pigeon-winged books died on the porch and lawn of the house. While the books went up in sparkling whirls and blew away on a wind turned dark with burning.

I really like this book, so I thought I’d share it. It just came back to me and now I want to reread it!

Here’s the link to a pdf if anyone wants to read it with me.

#farenheit 451#firemen#reverse firemen#my favourite#booklr#book recommendations#burning#burning books is bad#Montag#guy montag

8 notes

·

View notes

Text

Character Creation Challenge 2025, Day 3: A Song of Ice and Fire Role-Playing Game

In the Low Tower at Skystone, there is a fire ever-burning. The fumes climb up from the slit windows and paint the sky silvery-grey. A light flickers in the evening sky to mirror the hills' scattered smelters and oil-houses. Next year, some new refinement to claw back a portion of the day into the waiting hands of the workmen.

Along the Wind Road run couriers in the shadow of the mountain. They are given a strip of black braided leather to wear at their throat, to warn off the more reasonable raider clans; false packages to appease the others. No women; the raiders will rob a man but take a woman, and it is critical the packages reach their destination. Good pay in the employ of the Opal Lord's unmarried daughter. Safer than most courier work in the Mountains of the Moon.

Some jostle on the gravel of the Wind Road, or bring the wrong horses and stumble on changing terrain. Some burn in an unquenchable fire sprang from a secret satchel, diamond-bright heat sticking to the skin and consuming even the sand under the body. No scavengers will touch the things after; the brass of their buttons and buckles melts into the stone. She comes out for these, accompanied by a few seasoned killers of the Black Band. Prods the char with arcane instruments, makes notes in her little book. Heaps the gravel over the mess and is gone. Takes nothing.

They see her at holidays, at tourneys, at wargames. The family Syelle, they go grey early: pale blue eyes and hair painted streaks of red and ash-white. Precise hands, surgeon's hands, with pits and gouges in the nail beds. She eats, she says pleasant things; she stays removed. She plays what games are put before her.

Point Pride is a wealthy mountain and Skystone a wealthy estate; this is a known thing, and it brings the usual grifters and mummers, the fortune-tellers and wizards from far-distant lands. The Opal Lord's unmarried daughter gives these creatures more of an ear than would be decorous. Some are sent away with nothing, some with little less than they asked for. Some speckle those cold blue eyes with fascination and are invited inside for tea and conversation.

Sometimes they are even seen to leave.

In the Low Tower at Skystone, there is a fire ever-burning. The gas that lights the lanterns is odorless and is piped to their nozzles in delicate tubes strung in curlicues along the walls. New advancements in the mines spur pistons into new seams with thunderclap force. The smallfolk in their pits and taverns have learned to speak of the Opal Lord's unmarried daughter with kindness, should they speak of her at all.

Enough gravel and char for everyone in the shadow of the mountain.

*****

Lady Erin Syelle Adult Expert The barren first daughter of Lord Bale Syelle dedicated herself from a young age to her education, learning engineering and alchemy to make best possible use of her family's fortifications and natural resources. Destiny Points: 3 Benefits: Lucky Drawbacks: Fear (Confinement) Awareness 3 (+1B Notice), Cunning 3 (+1B Decipher, Logic), Education 5 (+1B Research), Healing 3, Language 2 (Valyrian), Marksmanship 3, Persuasion 3, Status 4, Warfare 3 (+1B Tactics), Will 3 (+1B Coordinate, Dedication), All Others 2 Background Events: Held hostage by another house as a ward or prisoner (bad betrothal - promised to House Royce upon her moonblood, which never arrived); Achieved a significant deed (alchemical, if not petrochemical in nature - can make fire wax and refined rock oil, keeps the secret real close); Traveled across the narrow sea (Educational trade - her ciphered secret for deeper mysteries unknown in the West). Possessions: 10 gold (Stiletto, mace, light crossbow, hard leather armor, travel kit (tent included), maester's kit, myrish lens and far-eyes, traveling clothes, noble's clothes, rounsey (Clever), sweetsleep (3 pinches), salt and spices for barter)

Intrigue Defense: 10 Composure: 9 Combat Defense: 7 Health: 6 Armor Rating: 3 Damage: Stiletto 2, Mace 2, Light Crossbow 3

Goal: Knowledge - Erin has had more contact with true and magical power than most, and craves it. Motivation: Fear - Her position is precarious, and knowledge has ever been her shield. Virtue: Humble - Her station matters only in the doors it opens; knowledge is in all places, great and small. Vice: Cruel - Capable of deploying the most heinously inventive revenges.

*****

House Syelle Realm: The Mountains of the Moon Motto: "Quality Endures" Coat of Arms: Sable and argent, embattled per fess, charge of a winged eye displayed. Defense: 41 (Excellent defenses, man-made but utilizing the mountain's natural features.) Influence: 43 (A powerful minor house with a colorful history; Maximum Lord's Status 5.) Lands: 31 (A large-ish area of land, holding multiple terrains.) Law: 26 (Typical level of law, crime common but under control.) Population: 21 (Typical population, with steppe farms and nomadic homesteads, larger communities near the fortress.) Power: 29 (A modest force of soldiers, including some trained career troops.) Wealth: 51 (Rich, wanting for nothing.) Holdings: Castle (Skystone Castle, defending the mines); Three heirs (Erin, first-born daughter; Vincen, second-born son, with wife Hanna of Red Lake; Carina, third-born daughter); Mountain (with hamlet), Hills (with road); Elite Guerrillas (The Black Lord's Band, elite mountain troops derived from the clans), Trained Infantry, Trained Archers x2, Trained Support (combat engineers!), Trained Peasant Levies (miner brigade!); Mine, Maester, Artisan (all weapons forged in-house are castle-forged), Sept.

First Founding: Established, founded during Aegon's conquest. Declared around Point Pride, one of the largest mountains in the Vale, as a Valyrian-led watch-house for the Vale's child lord - and, later, to exploit the gemstone mines found in its belly. Produces opal, chalcedony, onyx, quarried stone, lead, tin, and staggering amounts of rock oil; agricultural resources tomatoes, potatoes, tea, wool, cheese, clear spirits, but mineral resources far outstrip these in export value. Historical events:

11, Infrastructure. The house was established during a period of expansion and prosperity.

15, Villain. The rightful lord utilized his newly-established power to rule over the local bandits and wild men from the shadows, rather than crush them as was his mandate. Decades of tacitly permitted banditry resulted.

13, Favor. Motivated by the headsman's axe, the lord turned his bandit army over to the direct control of the king, both winning favor and fulfilling his familial oath in one go.

8, Scandal. A string of assassinations rocked the house's leadership, ending with a feeble lord on the throne, though the true power - and, many say, the orchestrator of the murders - was his lowborn lady.

6, Madness. Later in life, the rumored-murderous lady perished after a short illness, leaving the now extremely elderly and thoroughly insane lord to rule the mountain in truth for a distressingly long span.

12, Ascent. Through strong trade ties with the Maesters of Oldtown, a later lord and his elder bastard brother were given a startlingly comprehensive education, leading to a strong trend of capable administration and scientific advancement in the house.

*****

I really, really enjoyed this one.

I bought SIFRP, like most of my role-playing books, secondhand. I bought it not long before the show puked on itself and fell over. I had just enough time to flip through the book and wonder at the fascinating house creation rules, all the little bits and pieces built in to add flavor and a place in the world, right before no one wanted to play it with me anymore.

Everything I've built for this challenge, prior to this one, felt like an exercise - something I had to do more than something I wanted to do. Something I was going through as a process of discovery. This was something I wanted to play with for a long while and had never gotten the chance. The house creation rules looked bitey and detailed - I love whenever an RPG gives players a shared resource, something like a ship or a big manor, that they have to build themselves, invest themselves into. In a setting like A Song of Ice and Fire, I knew this had to be the big selling point, bigger than the individual characters, and from what little I'd engaged with the book before the show stopped being culturally relevant, the whole endeavor in the RPG looked just as comprehensive as I hoped it'd be.

It was fascinating going into this after ruefully building a character in Burning Wheel. The amount of bookkeeping inherent in building a house and a character in SIFRPG was a little bit greater than in Burning Wheel, but I found myself going back to the numbers well by choice, over and over, to add more details and discover the next stage of my weird little mountain billionaires' story. That's actually a good word for it, discovery - fortunes shifted about as much, if not more, in SIFRPG's house/character creation as it did in Burning Wheel, but in all aspects I felt like I was uncovering something about the character, rather than trying to wrestle it into place.

And, really, the house and the character feed into one another. The sense of place given by the shared history and location absolutely informs what pops out at the end, and the order in which the book guides you to take it, with that shared house and history first, is absolutely the right way to go. The end result is a tangible sense of place and persona, a character who both knits into and has the potential to meaningfully change their environment - something that feels capable of standing in the world it came from, with all its established characters and history, which is also markedly unusual when creating a character in a world with such an impactful IP.

Next up: Capitalism, by way of industrial metal.

#character creation challenge#new year new character#sifrpg#a song of ice and fire#asoiaf#no really this is the first one i've made for this challenge that i'm pissed i don't get to immediately play#oh hey what would make this world worse ONE-WOMAN OIL INDUSTRY WOOO#and this character has all of the hallmarks of any one of my early self-insert RPG characters except#y'now#being in ASOIAF apparently just makes you... like that

3 notes

·

View notes