#bipolar stepper

Explore tagged Tumblr posts

Text

H bridge motor driver, Analog motor drivers, Bipolar stepper, Dc motor driver

L6208 Series 52 V 5.6 A 0.3 Ohm DMOS Driver For Bipolar Stepper Motor-POWERSO-36

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--analog--drivers--motor-drivers/l298n-stmicroelectronics-5532882

Brushless DC motor driver, Dc motor driver, what is a motor driver

L298 Series 46 V 2 A Dual Full Bridge Driver Vertical - Multiwatt-15

#Drivers Motor Drivers#L298N#STMicroelectronics#Brushless DC motor driver#Dc motor driver#what is a motor driver#bipolar stepper#Stepper motor drivers#Bipolar stepper#Motor driver circuit#programmable motor driver#chip#H bridge

1 note

·

View note

Text

https://www.futureelectronics.com/p/semiconductors--analog--drivers--motor-drivers/l298n-stmicroelectronics-5319967

STMicroelectronics, L298N, Drivers Motor Drivers

L298 Series 46 V 2 A Dual Full Bridge Driver Vertical - Multiwatt-15

#STMicroelectronics#L298N#Drivers Motor Drivers#DC motor driver control#circuit#h bridge#4 Phase Bridge Driver#multi MOSFET driver#Bipolar stepper#motor driver chip#Programmable motor driver#brushless motor driver

1 note

·

View note

Text

How to Vary the Speed of a Bipolar Stepper Motor

Stepper motors are versatile electromechanical devices used in a wide range of applications that require precise motion control. Bipolar stepper motors, in particular, are widely favored due to their torque efficiency and simpler winding structure compared to unipolar stepper motors. One of the most important parameters when working with a stepper motor is speed control. Varying the speed of a bipolar stepper motor can be essential for applications like 3D printing, CNC machines, robotics, and automation systems.

This article explores how to vary the speed of a bipolar stepper motor effectively, providing a thorough understanding of the principles involved, techniques for controlling speed, and important considerations. It also integrates key terms related to the topic for a comprehensive guide to optimizing bipolar stepper motor speed.

Table of Contents

What is a Bipolar Stepper Motor?

Basic Working Principles of a Bipolar Stepper Motor

Why Speed Control is Important

Factors Affecting the Speed of a Bipolar Stepper Motor

Techniques to Vary Speed

a) Microstepping

b) Pulse Width Modulation (PWM)

c) Voltage Control

d) Current Limiting

Using a Microcontroller for Speed Control

Considerations When Varying Speed

Common Applications

Conclusion

#100 days of productivity#academia#bujo spread#classroom#college#college life#duolingo#education#educhums#etymology

3 notes

·

View notes

Text

Performance characteristics and applications of bipolar stepper motors

1.Basic structure of bipolar stepper motors The basic structure of bipolar stepper motors includes three parts: stator, rotor and winding. The stator is the stationary part of the motor, usually composed of multiple stator teeth, each of which is wound with two-phase bipolar windings, namely A-phase winding and B-phase winding. The A-phase winding is wound from stator tooth 1 and then wound on stator teeth 3, 5, and 7 in sequence, where stator teeth 1 and 5 have the same winding direction, and stator teeth 3 and 7 have the same winding direction. The B-phase winding is also wound on the same principle, where stator teeth 4 and 8 are a group, and stator teeth 2 and 6 are a group.

2.Working principle of bipolar stepper motors The working principle of bipolar stepper motors is based on the interaction between electromagnetic fields and permanent magnets. When current passes through the electromagnet on the stator, a magnetic field is generated, which attracts the poles on the rotor and causes it to rotate. As the direction of the current changes, the rotor will continue to rotate until it encounters external resistance. Specifically, each winding of a bipolar stepper motor can be energized in two directions, so one end of each winding can be either N-pole or S-pole. This design makes the bipolar stepper motor more flexible in control mode, and can achieve more precise position control and higher dynamic performance.

3.Performance characteristics of bipolar stepper motors 1.High-precision positioning: Bipolar stepper motors use stepping technology, and each step position is very accurate, which can accurately locate the required position. This high-precision positioning feature gives bipolar stepper motors obvious advantages in situations where precise position control is required. 2.Strong reversibility: Bipolar stepper motors have two independent coils, and the direction of the current in the coils can be changed to achieve forward and reverse rotation of the motor. This strong reversibility makes bipolar stepper motors very adaptable in situations where the direction of the motor needs to be changed frequently. 3.Large static torque: Bipolar stepper motors can also provide high torque output in a stationary state, which allows them to withstand various loads and provide good starting power when they start to rotate. This characteristic of large static torque makes bipolar stepper motors have good application prospects in occasions where they need to bear large loads. 4.Sensitive dynamic response: Bipolar stepper motors have a fast dynamic response speed and can quickly adjust the control amount to cope with system changes. This makes bipolar stepper motors have good application effects in occasions that require fast response. 5.High control accuracy: The speed and angle of bipolar stepper motors can be accurately adjusted according to the size and frequency of the control signal. This high control accuracy makes bipolar stepper motors have good application effects in occasions that require high-precision control. 6.Simple design: Compared with other types of motors, bipolar stepper motors are also very easy to design and manufacture due to the simplicity of their working principles and easy control.

4.Application of bipolar stepper motors 1.Medical equipment: Bipolar stepper motors have important applications in medical equipment. Due to their miniaturization and high precision, they can be precisely controlled in the body and support high-level operations in medicine and surgery. 2.Chemical Industry: In the field of chemical industry, bipolar stepper motors are used for the control of powders and liquids. Their precise control and high efficiency make their application in the subtle field more prominent. 3.Instrumentation: In the field of instrumentation, bipolar stepper motors are mainly used for flow control in pipelines and the regulation of moving powders in the production process to ensure precise measurement and control. 4.Industrial Automation: Bipolar stepper motors are widely used in industrial automation equipment, robots, CNC machine tools, textile machinery and other fields. It can provide precise position control and reliable operating performance, and is suitable for occasions requiring high precision and fast response. 5.Computer Peripherals: In computer peripherals such as printers and scanners, bipolar stepper motors are used for precise position control and fast response speed. 6.Photography and Filmmaking: Bipolar stepper motors are also used in photography and filmmaking, where precise control is required.

Similar articles:https://plaza.rakuten.co.jp/yixing/

0 notes

Text

Bipolar stepper motor-power, H bridge motor driver, Current Limit Switch

L6208 Series 52 V 5.6 A 0.3 Ohm DMOS Driver For Bipolar Stepper Motor-POWERSO-36

0 notes

Text

How to Set Up and Configure the A4988 Stepper Motor Driver

The A4988 Stepper Motor Driver Carrier Black is a versatile and widely-used driver for controlling bipolar stepper motors. Setting up and configuring the A4988 correctly is crucial to ensure optimal performance and prevent damage to your motor and driver. This article provides a comprehensive guide on how to set up and configure the A4988 Stepper Motor Driver.

1. Unboxing and Initial Inspection

Before you begin, ensure that you have all the necessary components:

A4988 Stepper Motor Driver Carrier Black

Stepper motor

Power supply (typically 8V to 35V)

Microcontroller (e.g., Arduino)

Breadboard and connecting wires

Inspect all components for any visible damage.

2. Wiring the A4988 Stepper Motor Driver

Proper wiring is crucial for the safe operation of the A4988. Follow these steps:

Connect the Motor:

Connect the stepper motor coils to the A4988’s output pins (2A, 2B, 1A, 1B). Ensure the connections are correct to avoid damaging the motor driver.

Connect Power Supply:

Connect the motor power supply (8V to 35V) to the VDD and GND pins of the A4988. Ensure the power supply can deliver sufficient current for your motor.

Connect Microcontroller:

Connect the step, direction, enable, and ground pins of the A4988 to the corresponding pins on your microcontroller. Typically, these connections are:

STEP pin to a digital output pin on the microcontroller

DIR pin to another digital output pin

ENABLE pin to ground (or a digital output pin if you want to control it)

Optional Connections:

You may also connect the MS1, MS2, and MS3 pins to configure microstepping settings. These can be connected to logic high (5V) or low (GND) according to your desired microstepping mode.

3. Configuring Current Limit

Setting the correct current limit is vital to prevent overheating and ensure smooth motor operation. Follow these steps to configure the current limit:

Adjust the Potentiometer:

Locate the small potentiometer on the A4988 board. This potentiometer adjusts the current limit.

Use a small screwdriver to turn the potentiometer. Turning it clockwise increases the current limit, while turning it counterclockwise decreases it.

Measure VREF:

To set the current limit accurately, measure the VREF voltage with a multimeter. Place the positive probe on the potentiometer’s test point and the negative probe on a ground pin.

Calculate Current Limit:

The formula for setting the current limit is: Current Limit = VREF / (8 * R_SENSE), where R_SENSE is the current sense resistor value (typically 0.05 ohms).

Adjust the potentiometer until the desired VREF voltage is reached.

4. Setting Microstepping Mode

The A4988 supports various microstepping modes, which can be set by configuring the MS1, MS2, and MS3 pins:

Microstepping Table:

Full step: MS1 = 0, MS2 = 0, MS3 = 0

Half step: MS1 = 1, MS2 = 0, MS3 = 0

Quarter step: MS1 = 0, MS2 = 1, MS3 = 0

Eighth step: MS1 = 1, MS2 = 1, MS3 = 0

Sixteenth step: MS1 = 1, MS2 = 1, MS3 = 1

Connecting MS Pins:

Connect the MS1, MS2, and MS3 pins to logic high (5V) or logic low (GND) according to the desired microstepping mode.

5. Programming the Microcontroller

To control the A4988, you’ll need to write a program for your microcontroller. Upload the code to your Arduino. Adjust the delay Microseconds value to control the speed of the stepper motor.

6. Testing and Fine-Tuning

Once everything is connected and configured, it’s time to test your setup:

Power On:

Turn on your power supply and microcontroller.

Initial Test:

Run the microcontroller program to ensure the motor steps as expected.

Adjustments:

Fine-tune the current limit and microstepping settings if necessary.

Monitoring:

Monitor the motor and driver for any signs of overheating or unexpected behavior.

Conclusion

Setting up and configuring the A4988 Stepper Motor Driver Carrier Black requires careful attention to wiring, current limiting, and microstepping settings. By following this guide, you can ensure your stepper motor operates efficiently and reliably, making the most of the A4988’s capabilities. Happy tinkering!

0 notes

Text

Servo motor driver, Programmable motor driver, dc motor speed control

L6208 Series 52 V 5.6 A 0.3 Ohm DMOS Driver For Bipolar Stepper Motor-POWERSO-36

0 notes

Text

H bridge motor driver, Analog driver, what is motor driver, Stepper motor driver

L6208 Series 52 V 5.6 A 0.3 Ohm DMOS Driver For Bipolar Stepper Motor-POWERSO-36

0 notes

Link

A full selection of bipolar transistors from many transistor manufacturers including bipolar junction transistor (bjt) switch, insulated gate, NPN or high voltage transistor for your circuits. Also explains what is a bipolar transistor.

1 note

·

View note

Photo

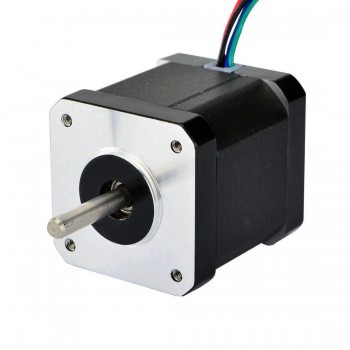

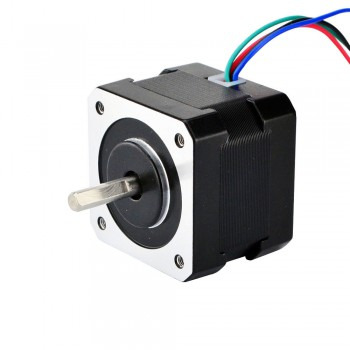

Mectex DC Stepper Motor

We have various types of stepper motors like Unipolar stepper motor, bipolar stepper motor, micro stepper motor and stepper driver that use in Applications like welding, textile machines and printing presses.

Visit us at https://www.mechtex.com

1 note

·

View note