#best epoxy pigment

Explore tagged Tumblr posts

Text

Buy Top Grade Epoxy Pigment for Durable Coatings.

#epoxy pigment#best epoxy pigment#epoxy resin color#resin manufacturers#epoxy resin manufacutures#resin manufacturer in india#epoxy resin manufacturer in india#epoxy resin manufacturers in india

0 notes

Text

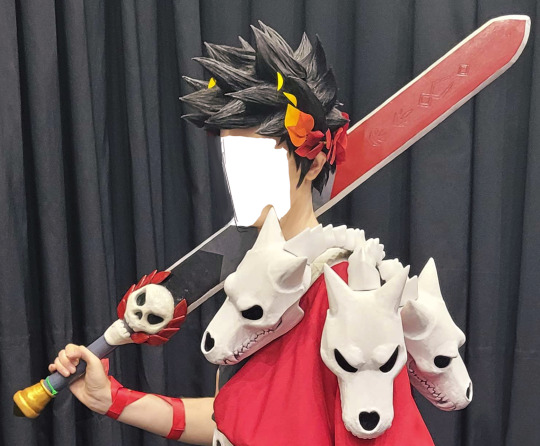

EPOXYSHİNE - DRAGON+ (3)

Epoxy floor coating is not just a practical choice for enhancing the durability of your flooring; it's also a stylish solution that can transform any space. Whether you're a homeowner looking to revamp your garage or a business owner seeking reliable commercial flooring solutions, understanding the benefits of epoxy will help you make informed decisions. As you search for "floor polishing near me," consider how an expertly applied epoxy coating can elevate your interiors while providing a long-lasting finish.

Epoxy Floor Coating

Epoxy floor coating is a highly durable and resilient flooring solution that has gained popularity in both residential and commercial spaces. This type of coating is made from a combination of resin and hardener, creating a strong bond when applied to existing concrete surfaces. The result is a seamless surface that can withstand heavy foot traffic, chemicals, and abrasions.

One of the major benefits of epoxy floor coating is its versatility. It can be customized in various colors and finishes, including high-gloss and matte textures. This means that property owners can choose a look that complements their interior design while still providing the durability they require. Additionally, the smooth finish of epoxy makes it easy to clean and maintain, which is particularly advantageous in commercial settings.

Furthermore, the installation process for epoxy floor coating is relatively quick, often completed within a few days. However, it’s essential to hire professionals who have the expertise and equipment to ensure a flawless application. The right team will properly prepare the surface, allowing for optimal adhesion and longevity of the coating.

Floor Polishing Near Me

When searching for floor polishing near me, it's essential to find a service that not only meets your expectations but also understands the unique needs of your flooring. Professional floor polishing can revitalize old surfaces, restoring their shine and luster while protecting them from future wear and tear.

Many local companies offer specialized services in floor polishing that cater to various materials, including hardwood, tile, and concrete. A quick search in your area will yield numerous options, allowing you to compare prices, services, and customer reviews to find the best fit for your needs.

Additionally, hiring professionals for floor polishing ensures that the job is done correctly and efficiently. They use advanced equipment and high-quality products that not only enhance the appearance of your floors but also extend their lifespan. So, don't hesitate to reac

Commercial Flooring Solutions

Commercial flooring solutions are essential for businesses seeking to enhance their aesthetic appeal while also ensuring durability and functionality. The choice of flooring can greatly influence the overall atmosphere of a commercial space, leading to improved employee morale and customer satisfaction.

Among the various options available, epoxy floor coatings stand out due to their seamless finish and resistance to heavy foot traffic. These coatings not only provide a sleek look but also protect the underlying surface from wear and tear, making them ideal for warehouses, retail spaces, and industrial environments.

Moreover, businesses often explore additional options such as vinyl flooring, carpet tiles, and laminate surfaces to meet specific needs. Each of these materials offers unique advantages, allowing business owners to choose the most suitable flooring solution that aligns with their operational demands and aesthetic preferences.

Metallic Epoxy Floor

A metallic epoxy floor offers a stunning visual appeal that enhances the aesthetic of any space. The reflective properties of the metallic pigments create a unique look, resulting in a three-dimensional effect that can mimic a variety of surfaces, such as water, marble, or even molten metal. This type of flooring is especially popular in modern homes, showrooms, and commercial spaces, providing an eye-catching yet durable surface.

One of the significant advantages of a metallic epoxy floor is its durability. This flooring solution is resistant to stains, chemicals, and impacts, making it ideal for high-traffic areas. Additionally, it is easy to clean and maintain, which means that business owners and homeowners can save time and resources. The seamless nature of epoxy flooring also contributes to a hygienic environment, especially in spaces like hospitals or laboratories.

Installing a metallic epoxy floor can be a customized process, allowing property owners to choose their preferred colors and patterns. Whether you’re looking for a sleek, industrial look or a vibrant, artistic finish, this flooring solution can be tailored to meet your unique vision. By consulting with professionals, you can ensure that your metallic epoxy floor is installed correctly and maximizes its longevity and beauty.

598 notes

·

View notes

Text

"...Stygius, the Blade of the Underworld, must have been amongst the finest weapons ever wielded..." - Stygian Blade entry, Codex of the Underworld.

Unfortunately this one isn't so fine and needs a remake, but here's how it was made while I work on Stygius 2

(Full process under the cut)

[Skull pauldron] [Belt] [Greaves] [Toga + sash] [Wig + Laurels] [Armbands] [Flaming feet] [Satyr Sack] [Stygius v1] [Stygius v2] [Nectar]

Unfortunately Stygius was the victim of con time crunch, and I wasn't even sure I'd be able to make the rest of my outfit in time for the con so Stygius, as a prop, had the lowest priority. But hey for a sword done from scratch in a week, not too bad.

I guessed all the measurements (which ended up making Styg 1 a hand and a half sword instead of the one handed sword it should be) and made a pattern. From there I was able to cut out a base, attach a handle, and then cover it in EVA foam. I then proceeded to so a VERY wonky job on the blade bevels, and even took a few chunks out, which meant I had to use foam clay on some parts of the edges which ended up leaving an inconsistent finish once it was painted.

For the skull I used spare EVA foam for the base, built up the bulk with aluminum foil and hot glue, then used more foam clay to sculpt the features and create depth (and ideally for that thickness it should have had several more days to set). The leaves were just some cut and dremelled EVA foam, and the pommel base was, you guessed it, more EVA foam and foam clay.

The gem was made from epoxy resin, and poured into a mould I made out of cardboard, sticky tape and some plastic lining, and coloured with some watercolour pigment. Somehow that actually worked.

I primed the whole thing with plastidip, and next was Spray Paint Hell. I had to do it all in one day, and the masking tape I was using to protect the parts I'd already done started pulling off the actual paint and sometimes the plastidip when I tried to remove it. I don't have a lot of experience with spray paints so my coats also weren't to the standard I wanted, and there was overspray despite my best efforts.

The spray paints I used were cheap and it showed. So I decided that they would be a base coat, and that the whole thing should be hand painted over most of the sections in order to achieve the correct colours, and in the case of the skull, match the other bone accessories. My sister helped do a lot of the base coats while I was at work so I could focus on detail work when I got home, and even there I was still painting the night before.

To tie everything together I did a few coats of gloss spray the morning of the con. Unfortunately, it didn't quite dry so it stuck to the surface it was resting on when I did the other side, which caused most of the paint defects. However, it was finished in time for the con and luckily the worst of the marks were on the back.

The main issue to address with Stygius 2, besides not doing an absolute catastrophe of a paint job last minute, is to fix up the hilt. It's too long and thick, the pommel is too chunky and badly shaped, and the gem is the wrong colour. The skull could also use more sculpted depth and a bit more shading to make it really stand out.

#my cosplay#cosplay process#hades game#zagreus cosplay#cosplay prop#stygius#first time making a sword not too shabby but I am unfortunately a perfectionist#shout out to my sister for helping with both the painting of stygius and the wax seals on the bottles of nectar#also to my dad for the base of styg and allowing me to steal a bunch of his tools and miscellaneous shed stuff for my EVA foam accessories

18 notes

·

View notes

Text

A Guide To Choose The Right Concrete Sealers For Home

Maintaining the efficiency of the commercial property is extremely important especially the concrete that makes the floor pitch perfect. In fact, not just maintaining but preventing the damage to concrete is equally essential. Concrete is one of the crucial construction elements owing to its strength and longevity. However, because concrete is porous, it can absorb soluble salts and water, which can be harmful. Furthermore, the absorption of salts by the concrete, especially chlorides, can eventually lead to corrosion problems when steel reinforcement is inserted in the concrete to strengthen it.

As a result, opting for the right type of concrete sealers is of utmost necessity. It ensures protection by shielding surfaces from a wide range of water-related issues caused by the cycles of thawing and freezing, stains from dirt, oil, and other impurities. In addition, it also prevents an individual from investing unnecessarily.

Understanding The Role Of Concrete Sealers

The sealers for concrete are intended to provide protection for the concrete's surface against degradation, rust, and discolouration over time. Most concrete surface degradation is usually caused by surface moisture penetration. It's essential to safeguard and preserve the concrete surfaces while doing regular maintenance to increase their lifespan. Concrete sealers function by covering your concrete's surface or by penetrating into its pores and attaching to its inherent attributes. There are several types of sealers and choosing the right one can be the game changer.

How To Choose The Right Concrete Sealers?

In order to choose the right kind of sealers for a concrete surface, one must be aware of the different types of concrete sealers in the market and their benefits.

Waterproof Concrete Sealers

A sealer should be a product that has the ability to penetrate deep into the surface as well as the substrate in order to seal and act as a protective covering. A waterproof sealer protects the concrete surface from penetrating water deep into the seal on which it turns into a solid form enclosing all alkali and lime in its impenetrable layer.

As a result, the concrete surface coated with waterproof sealers becomes water resistant along with other dirt, grease and acid which extends the overall life of the surface.

Epoxy Concrete Sealers

Epoxy concrete sealers are a great option for heavily utilized interior floors. This specific sealer not only offers a durable finish but also deters excessive abrasion. The most popular applications for epoxy coatings are concrete flooring and countertops. As a matter of fact, this type of sealer offers a glossy finish with a thick composition.

Depending on the requirement of an individual, pigments can be added to the sealers for better colours and one can choose either some mid-level sheen or highly glossy one.

Acrylic Concrete Sealers

If an individual is looking for a cost-effective option, acrylic sealers are the best. Not only is it easy to apply but is also best suited for the interiors and exteriors for sealing the concrete. In addition, this type of sealer is well resistant to UV and therefore doesn’t fade away with time.

If one is looking for sealers for the garage or wants to seal the pool decks and walkways, individuals can opt for acrylic sealers as they offer protection against chlorine water. The paint dries really fast and enhances colours while protecting against damage.

Final Thoughts

Choosing the right concrete sealers perth and applying them correctly is extremely crucial. To find the ideal balance of protection, durability, and affordability, consider the specific needs, surface, and location.

Spraypave Pro is a concrete sealer expert in Perth and can help with the process of concrete sealing.

2 notes

·

View notes

Text

Epoxy Resin Table Top, Handmade Furniture Epoxy Resin Table Top Live Edge Wooden Table Patio Decor

Thecrafthoucreations one of a kind painstaking work sells the Best class, Imaginative, and Genuine craftsman Indian Handiworks and Homestyle items like Dining Epoxy Dining Tables Top, Footstool Tops, Side Table, Edge tables, Corner Tables, Special Gifts for Friends and family, and Numerous Different Items In Marble Trim Craftsmanship This is an Epoxy Feasting Table Top or Exchanging Work area made with Pecan which is decorated with shaded color. The tar waterway table is fresh out of plastic new and the contemporary plan would be a remarkable expansion to your home.

This is an Epoxy Dining Tables Top or Trading Desk made with Walnut which is beautified with colored pigment Each one is created with high-quality resin and individually handcrafted. Resin is a highly reflective medium that will catch anyone’s eye walking into the room. All tables are finished to the highest standard. The epoxy resin is very strong & durable with specialized UV resistance. The tables are delivered flat-packed. Simply bolt the legs.

3 notes

·

View notes

Text

Top 5 Creative New Year Gift Ideas Using Epoxy Resin

The New Year is a time for fresh beginnings, and what better way to celebrate than with heartfelt gifts? Handmade presents always stand out, and epoxy resin is an amazing medium to create unique, personalized treasures. Whether you’re a seasoned crafter or a beginner, these five ideas are sure to inspire and delight your loved ones this holiday season.

1. Personalized Coasters

Coasters are both practical and decorative, making them a thoughtful gift for anyone. Use epoxy resin products to create stunning designs by embedding dried flowers, colorful stones, or even photos. Customize them to match the recipient’s personality or home decor, and they’ll have a piece of art to use and admire daily.

2. Elegant Jewelry

Epoxy resin is perfect for making gorgeous accessories. You can craft earrings, necklaces, or bracelets by pouring the resin into molds and adding glitter, charms, or pigments. Jewelry made with epoxy resin feels special and unique, making it a cherished gift for friends or family.

3. Decorative Photo Frames

Preserving memories in style is easy with a handmade photo frame. Start with a plain frame and enhance it with layers of clear resin. Add embellishments like metallic flakes or tiny ornaments to make it extra festive. When you buy epoxy resin online, you’ll find endless options to customize your design.

4. Resin Trinket Trays

A resin trinket tray is both functional and artistic. It’s perfect for holding jewelry, keys, or small items and can be customized with swirls of vibrant colors or embedded items like shells or beads. With quality supplies from epoxy resin suppliers, you can create a practical yet beautiful gift.

5. Fun Keychains

If you’re looking for a quick but meaningful gift, keychains are a fantastic choice. Mold epoxy resin into fun shapes and personalize them with initials, glitter, or tiny decorations. They’re an easy way to create something that’s both stylish and useful.

Getting Started on Your Crafting Journey

To bring these creative ideas to life, it’s important to use the best materials. You can find top-quality epoxy resin products from trusted sellers. Start by sourcing your supplies, and let your imagination take over! Handmade gifts not only stand out but also carry a personal touch that store-bought items simply can’t replicate.

Craft the Perfect Gift This New Year

The New Year is the perfect opportunity to show your loved ones how much you care. By using epoxy resin, you can create personalized gifts that are as beautiful as they are meaningful. Take your time, enjoy the process, and make something unforgettable.

When you're ready to start crafting, trust MB Epoxy for high-quality products to make your New Year gifts truly special. Let your creativity shine and leave a lasting impression with every handmade creation!

0 notes

Text

Transform Your Space with the Best Metallic Epoxy, Polyaspartic Garage Flake Flooring, and Decorative Concrete Coatings

When it comes to enhancing your floors with durability and aesthetic appeal, choosing the right flooring solutions is essential. Whether you're renovating your garage, upgrading commercial spaces, or adding a decorative touch to your property, the options of metallic epoxy, polyaspartic garage flake flooring, and decorative concrete coatings stand out as industry leaders. These advanced flooring solutions provide not only a durable and low-maintenance finish but also an opportunity to customize the look and feel of your space.

1. Metallic Epoxy Flooring: Luxury Meets Functionality

Metallic epoxy flooring is a premium choice for those who want to combine functionality with an exquisite appearance. This type of flooring is created by adding metallic pigments to an epoxy base, resulting in a high-gloss, three-dimensional effect that resembles marble or flowing lava.

Benefits of Metallic Epoxy Flooring:

Durability: Resistant to stains, cracks, and abrasions, making it perfect for high-traffic areas.

Unique Aesthetics: Customizable designs to match your style, with endless color and pattern options.

Low Maintenance: Easy to clean and maintain, making it ideal for both residential and commercial spaces.

Metallic epoxy flooring is popular in showrooms, luxury garages, and retail spaces where visual appeal and toughness are equally important.

2. Polyaspartic Garage Flake Flooring: A Versatile and Reliable Option

For garages and industrial spaces, polyaspartic garage flake flooring is a go-to choice. This flooring solution involves a base coat of polyaspartic material with decorative flakes embedded for added texture and visual appeal.

Advantages of Polyaspartic Garage Flake Flooring:

Quick Installation: Cures faster than traditional epoxy, minimizing downtime.

Extreme Durability: Withstands heavy loads, chemical spills, and wear, making it perfect for garages and workshops.

Slip Resistance: The flake system provides extra grip, ensuring safety in wet or oily conditions.

Customizable Flake Patterns: Choose from a range of colors and flake sizes to create a unique look.

3. Decorative Concrete Coatings for Commercial and Residential Spaces

Decorative concrete coatings are an affordable and versatile solution for enhancing floors in residential, commercial, and industrial environments. From stamped overlays to polished finishes, these coatings can mimic the appearance of natural stone, tile, or even wood.

Features of Decorative Concrete Coatings:

Eco-Friendly: Made with sustainable materials, reducing environmental impact.

Cost-Effective: Achieve premium aesthetics without the high cost of natural materials.

Custom Design Options: Add textures, patterns, or colors to fit your design preferences.

High Durability: Resistant to fading, cracking, and wear.

Commercial spaces, like restaurants and retail stores, often use decorative concrete coatings to create an inviting and professional look that stands the test of time.

Why Choose a Professional Contractor?

Hiring a professional flooring contractor ensures flawless results and long-term satisfaction. Expert contractors offer tailored solutions that match your specific needs, whether it’s installing metallic epoxy in a showroom, polyaspartic flooring in a garage, or decorative concrete coatings in a restaurant.

Conclusion When selecting a flooring solution, it’s essential to consider the unique benefits of metallic epoxy, polyaspartic garage flake flooring, and decorative concrete coatings. These options not only enhance the functionality and safety of your space but also add a personalized aesthetic touch that stands out. Partnering with a professional contractor guarantees quality and expertise, ensuring your floors look stunning and perform exceptionally for years to come.

#Metallic Epoxy Flooring#Polyaspartic Garage Flake Flooring#Decorative Concrete Coatings#Commercial Floor Solutions#Durable Flooring Contractors

0 notes

Text

Enhancing Idols and Sculptures with Premium Pigments by SP Colour & Chemicals

SP Colour & Chemicals Mica powders and pigments covered with metallic oxides, such as titanium dioxide, metal flakes are used to create pearl pigments, which are fine powders. These pigments produce stunning pearlescent, metallic, or iridescent effects by reflecting light. Pearl pigments do not produce solid hues like regular pigments do. Rather, they give every surface they adorn a dazzling shine that delicately changes depending on the angle of the light, giving it refinement and fascination.

Why Choose Pearl Pigments by SP Colour & Chemicals for Sculptures and Idols?

There are numerous benefits of using our pearl pigments:

Aesthetic Appeal: Pearl pigments give sculptures and idols an opulent sheen that enhances their visual appeal and makes them appropriate for both classic and contemporary designs.

Versatility: Our Pearlescent pigments perform well with a wide range of materials, including metal, wood, clay, plaster, and resin.

Durability: The sculptures will continue to shine over time because of SP Colour & Chemicals’ pigments’ lightfastness, resistance to weather, and non-toxicity.

Cultural Significance: Pearl pigments by SP Colour & Chemicals can replicate the appearance of valuable metals and stones in religious and cultural idols, giving them a regal or hallowed atmosphere.

How to Apply SP Colour & Chemicals’ Pearl Pigments on Sculptures and Idols?

Step 1: Preparing the Surface of your products

Make sure your idols and sculptures surface is clean, smooth, and primed if needed before adding pearl pigments. A primer improves the colors’ adhesion and brightness on materials like clay or plaster.

Step 2: Applications used on your products

Dry Brushing: This technique is ideal for emphasizing fine details since it uses a gentle, dry brush to apply pigments to the surface.

Mixing with Mediums: For painting or pouring applications, mix pigments with transparent binders such as varnish, resin, or acrylic medium.

Layering: To achieve a rich, multi-tonal appearance, apply several layers of color.

Step 3: Finish Sealing

Apply a clear coating, like epoxy resin or spray varnish, to the pigments to seal them. This stage guarantees longevity and improves the pigments’ sheen in addition to protecting them.

How to Use Pearl Pigments in Candle Making?

Pearl pigments are simple to use, but meticulous attention to detail is necessary to achieve professional effects. Here are some pointers:

Preparation: Melt the wax to the temperature specified for the type you have selected (paraffin, soy, etc.). For best results, measure out the appropriate amount of AMP Pigments, usually 1% to 2% of the wax weight.

Mixing: To guarantee even distribution of coloring effect, gently add the premium pigment to the heated wax while mixing constantly.

Pouring: Before pouring, divide the pigmented wax into pieces and work as required to create layered or marbled effects. To avoid the wax cooling too soon, work swiftly.

Final Details: After the candle has set, you can use a soft brush to add more pigment to the surface for more glitter effect.

Creative Applications for Pearl Pigments

Combination of Colors: To create distinctive hues with delicate sheen, mix SP Colour & Chemicals pearl pigments with any color pigments.

Glow-in-the-Dark Effects: To create idols that glow in low light and have a mysterious appearance, combine pearl paints with phosphorescent powders.

Antique Finishes: Ideal for classic idols with a historic appearance, metallic pearl colors can be used to simulate aged gold or bronze.

Why Choose SP Colour & Chemicals’ Pearl Pigments?

We at SP Colour take great satisfaction in manufacturing high-quality varieties of pearl pigments that are specific to the requirements of both manufacturers and artists. The pigments we use are:

High Quality: Constructed from premium materials for exceptional durability and brilliance.

Broad Variety: Every artistic vision can be satisfied with our selection of metallic golds and color-shifting iridescents.

Sustainable and Safe: They are perfect for use in religious and decorative objects because they are non-toxic and environmentally friendly.

The pearl pigments from SP Colour offer the ideal finish to make your creations come to life, whether you are making a massive sculpture for public display or a tiny handcrafted idol.

To know more: Visit us : www.spcolour.in | www.amppigments.com OR Contact us: +91 9990286664

0 notes

Text

Best Epoxy Pigmented Manufacturer in Ahmedabad, Gujarat

Angel Coating Pvt. Ltd. is offering high quality & affordable “Epoxy Pigmented” in Ahmedabad, Gujarat, India.

Discover The Value Of Epoxy Pigmented Coatings By Angel Coating. Explore Their Importance Across Industries. Epoxy Pigmented ManufactureriIn Ahmedabad, Gujarat

For Further Details 👇

📱 Call Now: +91 94290 02704

💬 WhatsApp: https://wa.me/919429002704

0 notes

Text

Buy Industrial-Grade Epoxy Pigment for Durable Coatings

When it comes to industrial coatings, durability is key. Buy industrial-grade epoxy pigment for durable coatings that stand up to the toughest environments. Our high-quality epoxy pigments are specially formulated to provide superior color retention, chemical resistance, and long-lasting performance. Whether you're working on flooring, machinery, or other industrial applications, our epoxy pigment ensures a strong, vibrant finish that won’t fade or crack under pressure.

Designed for professionals, this pigment blends seamlessly with epoxy resins to create coatings that not only look great but also protect against wear and tear. Don't settle for less when it comes to your industrial projects. Trust MB Enterprises for the best in epoxy pigment solutions.

#Epoxy Pigment#Best Epoxy Pigment#resin manufacturers#epoxy resin manufacturers#epoxy resin manufacturers in india#epoxy resin#best epoxy pigments

0 notes

Text

Epoxy Flooring Solutions: Durable, Stylish, and Perfect for Any Space

Epoxy flooring has gained popularity for its durability, aesthetic versatility, and ease of maintenance, making it a preferred choice for residential and commercial spaces. Unlike traditional concrete floors, epoxy flooring provides a glossy, seamless surface that is visually appealing and resistant to wear, chemicals, and heavy traffic. Whether you want to upgrade your garage floor, warehouse, or retail space, epoxy flooring offers a long-lasting daily-use solution.

This guide will explore everything you need about epoxy flooring, from its benefits and application process to why Armor Coatings Inc. is the go-to expert in concrete contractor services, including stained concrete floors and other specialized finishes.

What is Epoxy Flooring?

Epoxy flooring is a surface solution made by combining resin and hardeners to create a durable, high-gloss finish that bonds to the concrete surface. Once applied, the epoxy coating cures to form a robust and seamless layer that can withstand various conditions, from heavy foot traffic to spills and abrasions. Here are some common types of epoxy flooring:

Solid Color Epoxy: Offers a clean, simple look ideal for garages, basements, and commercial spaces.

Metallic Epoxy: This creates a unique, reflective finish with metallic pigments, giving the floor a one-of-a-kind appearance.

Quartz-Filled Epoxy: This contains quartz grains for added durability and slip resistance, making it ideal for high-traffic areas.

Epoxy Flake Flooring: Features decorative flakes that add color and texture to the surface, often used in residential garages and commercial spaces.

Each type offers different aesthetic and functional benefits, so you can select the one that best suits your style and usage needs.

Benefits of Epoxy Flooring

Epoxy flooring offers numerous advantages over traditional options, making it an excellent investment for any space. Here are some key benefits:

Extreme Durability: Epoxy is known for resisting wear, stains, and damage. This makes it a top choice for areas exposed to heavy traffic or machinery.

Chemical Resistance: Epoxy flooring is highly resistant to chemicals, which is why it’s popular in industrial and commercial settings. It can withstand spills from substances like oil, bleach, and gasoline without losing its integrity.

Aesthetic Appeal: The glossy finish and customizable options (like concrete staining and concrete coloring) make epoxy floors a visually striking choice.

Low Maintenance: Epoxy’s smooth, non-porous surface is easy to clean and requires minimal upkeep, saving you time and effort in the long run.

Slip Resistance: Many epoxy floors can be treated with slip-resistant additives, making them safer for high-traffic or wet areas.

Cost-Effective: With its long lifespan and low maintenance, epoxy flooring offers a cost-effective solution that requires fewer repairs and replacements over time.

Epoxy flooring provides the perfect combination of style and strength for upgrading a garage, warehouse, or office space.

Epoxy Flooring Process

Achieving a flawless epoxy finish requires precise application techniques and attention to detail. Here’s a breakdown of the typical process followed by Armor Coatings Inc. for installing epoxy flooring:

Surface Preparation: The concrete surface must be thoroughly cleaned and prepped to ensure proper adhesion. This may involve grinding, sanding, or acid washing to remove dirt, oil, or old coatings.

Repairing Imperfections: Cracks and holes are filled and leveled to create a smooth base. Any surface defects can affect the finish, so proper repair is essential.

Priming the Concrete: A primer coat enhances adhesion between the concrete and epoxy layers. This step also helps to seal the concrete and prevent air bubbles in the final coating.

Applying the Epoxy Coating: The epoxy mixture is poured and spread evenly across the surface, often in multiple layers, to achieve the desired thickness and durability.

Adding Finishes (Optional): Depending on the style chosen, decorative elements like flakes or metallic pigments may be added for a customized look.

Curing Time: After application, the epoxy must cure for at least 24-48 hours. The surface should be kept free from traffic and moisture during this time to ensure a solid, long-lasting bond.

This meticulous process results in a smooth, resilient, attractive floor that enhances the space.

Popular Epoxy Floor Designs and Styles

Epoxy flooring offers a variety of design possibilities, from solid colors to intricate patterns. Here are some popular options available with Armor Coatings Inc.:

Stained Concrete Floors: Add color and depth with stained epoxy finishes that mimic natural stone or polished concrete. This style is ideal for homes, offices, and retail spaces.

Metallic Epoxy Finishes: Create a high-end, luxurious look with reflective metallic pigments that produce a marble-like effect on the floor.

Flake Epoxy Flooring: Incorporates decorative flakes for added color and texture, commonly used in garages, showrooms, and commercial spaces.

Concrete Coloring: Choose from various colors to match your decor and branding, giving your floor a unique, custom look.

With the help of Armor Coatings Inc., you can select an epoxy style that reflects your personality or brand while meeting practical needs.

Why Choose Armor Coatings Inc. for Epoxy Flooring

Armor Coatings Inc. is a leading concrete contractor in San Jose with nearly 40 years of experience in epoxy flooring and concrete restoration. Here’s why clients trust us for their epoxy projects:

Professional Expertise: Our skilled technicians have extensive knowledge of epoxy flooring products and application methods. We use only the best materials and ensure precision at every step.

Quality Assurance: Our commitment to high standards means we never cut corners. We meticulously prepare each surface and apply multiple coats for durability and longevity.

Customized Solutions: Whether you want a glossy stained concrete floor or a unique metallic epoxy finish, we work with you to create a floor that matches your vision.

Customer Satisfaction: With an A+ BBB rating and a solid reputation for quality, Armor Coatings Inc. prioritizes customer satisfaction. We guide you through the process, offering color, texture, and design advice.

Comprehensive Services: Besides epoxy flooring, we offer a range of concrete services, including concrete waterproofing, driveway resurfacing, and basement sealing.

With Armor Coatings Inc., you’ll have a partner dedicated to making your project a success from start to finish.

Conclusion

Epoxy flooring is a durable, stylish, and low-maintenance solution that can elevate any space. From homes to commercial buildings, this versatile flooring option provides a seamless finish that withstands heavy use while enhancing aesthetics. With various styles, colors, and finishes, epoxy flooring offers endless design possibilities.

Armor Coatings Inc. has the expertise, experience, and commitment to excellence needed to create the perfect epoxy floor for your property. Whether you’re interested in a simple solid color, a decorative flake finish, or a custom metallic look, our team is here to help. Contact Armor Coatings Inc. today to learn more about our epoxy flooring solutions and schedule a consultation for your next project.

1 note

·

View note

Text

Enhance Your Tile Surfaces with Epoxy Solutions from Durofill

With its cutting-edge epoxy materials, Durofill raises the standard for tile joint solutions. Durofill offers the ideal option whether you want to guarantee longevity and ease of maintenance or improve the visual attractiveness of your flooring. Let's examine Durofill epoxy's product line and how it might improve your tile work.

Durofill Glass Epoxy: An Innovative Approach Glass Epoxy: What is it? Glass epoxy is a resin-based substance that produces a smooth, glossy surface. With a transparent or tinted joint that blends in perfectly with the tiles, it offers a strong and water-resistant adhesive while improving the tile's beauty. This solution is regarded for being aesthetically pleasing, long-lasting, and low maintenance, which makes it appropriate for both residential and busy commercial spaces. Glass Epoxy's advantages Radiant Glossiness for Effortless Elegance: The high-gloss finish produces a vivid and sophisticated appearance by elegantly reflecting light. Stain-Free, brilliant Brilliance: Preserves a stain-free, brilliant finish that is as good as new for many years. Durable Sturdiness for Effortless Style: Offers durable stability, guaranteeing that your tile joints stay lovely and intact even in high-traffic areas. Dust-Defying Cleanliness: Your tiles will remain cleaner for longer because of the smooth, non-porous surface's ability to repel dust and grime. Easy-to-use Implementation in Just Twelve Hours: The application process is simple and fast, enabling you to get expert results in as little as 12 hours.

GL-250 Durofill Epoxy: A Combination of Durability and Shine Designed as an epoxy tile joint filler, Durofill Epoxy GL-250 offers a gorgeous high-gloss surface along with remarkable durability. Anyone may easily apply this product, which is ideal for creating floors that are glossy and long-lasting. Durofill Epoxy Gel: Unmatched Durability and Shine Presenting Durofill Epoxy Gel, the ideal way to give your tile walls and floors a glossy, glass-like appearance. Your place will be transformed into a faultless and sophisticated environment with this product's unmatched brilliance and durability.

How to Apply Durofill Epoxy Gel

Preparation: Gather all necessary materials, including the Durofill Epoxy Gel resin kit, which contains essential components such as resin, hardener, scraper blades, cutting blades, measuring spoons, gloves, stirring stick, and a wide range of pigments for customization.

Color Selection: Explore the variety of metallic and plain color pigments to find the perfect hue for your space.

Mix Resin and Hardener: Follow the recommended mixing ratio of 2:1 for resin and hardener. Combine two measuring spoons of resin with one measuring spoon of hardener and blend thoroughly.

Add Pigments: Add four to five drops of your chosen color pigment and mix vigorously for 2 to 3 minutes to ensure even distribution.

Application: Use a scraper blade to apply the Durofill Epoxy Gel onto the tile joints. Allow the gel to rest for 20 minutes, then wipe the joints using a stirring stick to prevent sagging and remove excess epoxy.

Drying Period: Allow the applied gel to dry for a minimum of 24 hours to cure and harden.

Final Touches: Use a cutting blade to carefully peel off any excess epoxy gel, revealing the gleaming, glass-like finish beneath. In conclusion A variety of advantages provided by Durofill epoxy solutions, such as Durofill Glass Epoxy, Durofill Epoxy GL-250, and Durofill Epoxy Gel, raise the level of sophistication and elegance of your tile surfaces. These products are essential for every tiling project because of their brilliant glossiness, stain-resistant brilliance, durability, dust-resistant cleanliness, and ease of application. With Durofill Epoxy Gel and Durofill Glass Bond Epoxy, you can transform your tile walls and floors and take advantage of its long-lasting beauty and low care requirements. To discover the revolutionary potential of Durofill, stop by the closest retail tile store in Kerala.

#epoxy tile joint filler#glass bond epoxy#glass epoxy#benefits of glass epoxy#epoxy for floor tiles#glass epoxy for tiles#what is glass epoxy

0 notes

Text

1 note

·

View note

Text

The Benefits of Metallic Epoxy Brisbane

Interior design in Brisbane has turned on its head with metallic epoxy flooring, which can be widely found in residential spaces as well as commercial and industrial spaces. These floors speak for themselves in their visual appeal and durability-none other than the best. Not only is it an ornamental delight to the senses, but it also serves as a practical solution to meet diverse needs.

Stylish Brilliance

Metallic epoxy flooring boasts some incredible visual effects, like imitating natural elements of marble, liquid water, or even liquid metal. This unique appearance is made possible by adding metallic pigments to the epoxy mixture, providing a three-dimensional look with depth and movement. For Metallic Epoxy Brisbane property owners who value design and style, this flooring option offers luxurious finishing touches to any space. Be it a sleek and glossy appearance or a subtle and matte finish, the design possibilities are truly endless.

Exceptional Hardiness

Metallic epoxy flooring is known for its durability. It is because its resin-based composition creates a tough protective layer on concrete, keeping it nearly resistant to cracks, abrasions, and impacts. In high-traffic locations, such as the busy commercial spaces of Brisbane or the extensive garages in residential areas, metallic epoxy is resistant to the daily beating it receives. It also has chemical spill-and-stain resistance, making it excellent for industrial facilities and locations where heavy machinery and vehicles are frequently used. This makes your flooring investment last for many years without frequent repairs and replacements.

Low Maintenance

Metallic epoxy flooring is incredibly easy to maintain, which is a major advantage for both homeowners and business owners in Brisbane. Its seamless and non-porous surface prevents dirt, dust, and spills from penetrating, allowing for effortless cleaning. A simple mop and occasional sweep are usually all that’s needed to keep metallic epoxy floors looking pristine. This no-maintenance feature is particularly useful in commercial and industrial applications, where more hours dedicated to cleaning would translate directly to productive hours lost.

Moisture and Stain Resistance

Brisbane has a subtropical climate, and at times even flooding can occur. Metallic epoxy flooring does not allow for moisture penetration, which will not harm or damage it, unlike other flooring options that are vulnerable to warping and cracking due to damp conditions. Also, it is resistant to stains. This is particularly convenient in kitchens, workshops, and garages. Metallic epoxy flooring will stand oil spills and wine stains without permanent damage.

Lighting Enhancement

Since it has good reflective qualities, metallic epoxy flooring is ideal for lighting enhancement in areas that require bright conditions to enhance visibility. Its high gloss finish can brighten up any room by reflecting both natural and artificial light that creates a more inviting ambiance. Such commercial applications as showrooms, retail stores, or offices improve ambiance and make the space attractive to customers. For residential in Brisbane, this feature adds class and elegance while maximizing light efficiency.

Slip-Resistant Options for Safety

Safety is the most significant consideration for any property owner, and metallic epoxy flooring meets this need with slip-resistant coatings. Added grip is generally given to the floors, making them safer to be walked on when wet or in highly trafficked regions. For homes in Brisbane, this is especially valuable in kitchens, bathrooms, and outdoor patios. For commercial and industrial spaces, it ensures a safer environment for employees and customers alike as risks of accidents are minimized.

Eco-Friendly Flooring Solution

Most people in society seek sustainable solutions when renovating their homes or businesses. Metallic epoxy flooring is an environment-friendly solution since it can extend the lifespan of concrete floors for a longer time without the need for replacement. It also results in many advanced epoxy products having low VOC levels, which ensures better indoor air quality. Therefore, for Brisbane property owners seeking to make more environmentally conscious decisions, metallic epoxy may be the answer.

Cost-Effective Investment

Metallic epoxy flooring has a one-time installation cost that may seem a little higher than the traditional options. However, it proves to be a prudent investment if evaluated over a long term due to its cost-effectiveness. The durability associated with this product means less repair, replacement, and cleaning expenses will have to be borne by the businesses within Brisbane, thus meaning less downtime for repairs, which results in losses. Homeowners will receive value-added aesthetic appeal and durability that requires minimal upkeep.

Fast and Efficient Installation

Professional installation of metallic epoxy flooring is fast and efficient, minimizing disturbance to your daily schedule. In Brisbane, property owners always juggle busy schedules. So, with this fast turnover, a lot of invaluable advantages are guaranteed with its fast turnaround. The floor is instantly ready for use after installation to bring residential and commercial facilities back into full functionality without delay.

Conclusion

Metallic epoxy flooring quickly became a favorite among Brisbane property owners because of its beauty, durability, and practicality. Whether it's for a luxury living room, modern office space, or a heavy industrial facility, metallic epoxy flooring delivers high-performance value with style. This flooring option meets the demands of any space through resistance to Brisbane's climate challenges and low-maintenance features with customized design possibilities. Invest in metallic epoxy flooring to transform your property with long-lasting, visually stunning floors that stand the test of time.

0 notes

Text

Epoxy Flooring in Dallas: A Durable and Stylish Solution

Epoxy flooring has become a popular choice for homeowners and businesses in Dallas due to its durability, versatility, and aesthetic appeal. Whether you're renovating your home, office, or industrial space, epoxy floors offer a solution that combines practicality with visual impact. This article explores the key features, benefits, and local trends of epoxy flooring in Dallas.

What is Epoxy Flooring?

Epoxy flooring is created by applying a mixture of resin and hardener onto a concrete surface. Once cured, this mixture forms a hard, durable coating that bonds with the substrate. The result is a seamless, glossy finish that is both functional and decorative.

Epoxy flooring systems can be customized in various ways, including the addition of color pigments, metallic flakes, and even textured finishes for slip resistance. This versatility makes it an excellent choice for a range of applications—from residential garages to commercial showrooms and industrial warehouses.

Why Epoxy Flooring is Ideal for Dallas

In Dallas, the climate and lifestyle demand flooring that can withstand high traffic, temperature changes, and occasional moisture, while still looking great. Here are some reasons why epoxy floors are perfect for this region:

Durability and Longevity

Dallas experiences a variety of weather conditions, from hot summers to occasional heavy rains. Epoxy flooring provides a tough surface that resists wear and tear from foot traffic, vehicles, and even spills. In homes with busy families or garages with heavy machinery, epoxy floors can last for years without cracking or staining.

Low Maintenance

Epoxy floors are incredibly easy to maintain. With a seamless, non-porous surface, they resist dirt, oil, and other contaminants, making cleaning a breeze. Regular sweeping and occasional mopping are usually all that’s needed to keep them looking new. In the fast-paced Dallas lifestyle, low-maintenance flooring is a major benefit.

Customizable Design

The design possibilities with epoxy floors are endless, making them a perfect fit for the stylish homes and businesses in Dallas. Whether you prefer a sleek, minimalist look or a bold, decorative finish, epoxy floors can be tailored to your specific taste. Popular designs in Dallas include metallic epoxy finishes, 3D effects, and custom colors to match branding or interior design themes.

Heat and Chemical Resistance

With Dallas being known for its hot summers, homeowners and business owners need flooring that can handle extreme temperatures. Epoxy floors are resistant to heat, and they can also withstand exposure to chemicals, making them ideal for both residential and industrial applications.

Cost-Effective

Epoxy flooring is an affordable solution compared to other flooring options like marble or hardwood, while still offering a premium look. For businesses in Dallas looking to renovate or expand, epoxy floors provide a durable, cost-effective option that doesn’t sacrifice style or quality.

Popular Applications in Dallas

Residential Garages

One of the most common uses for epoxy flooring in Dallas is in residential garages. The durable, non-slip surface makes it ideal for protecting the garage floor from oil stains, tire marks, and daily wear and tear.

Commercial Spaces

Retail shops, restaurants, and offices in Dallas have embraced epoxy flooring for its aesthetic appeal and practical benefits. It’s easy to clean, looks professional, and can handle high foot traffic without showing signs of wear.

Industrial and Warehouse Settings

Epoxy flooring is frequently used in industrial spaces like warehouses, manufacturing plants, and automotive shops. It can endure heavy machinery and equipment, while its smooth surface ensures safety and ease of movement for workers.

Finding the Right Epoxy Flooring Contractor in Dallas

Choosing a reliable contractor is key to getting the best epoxy flooring results. Look for professionals with extensive experience in both residential and commercial installations, as well as positive customer reviews. Local contractors often understand the unique needs of Dallas properties, including how to best prepare and treat concrete surfaces for the local climate.

Epoxy flooring is an excellent option for both residential and commercial properties in Dallas. With its combination of durability, low maintenance, and customization options, it meets the needs of a wide variety of spaces, from sleek downtown offices to functional home garages. If you’re considering upgrading your floors, epoxy offers a stylish, cost-effective solution that will stand the test of time in Dallas’s dynamic environment.

For more info:-

commercial epoxy flooring houston

epoxy flooring dallas

0 notes

Text

Epoxy Flooring in Dallas: A Durable and Stylish Solution

Epoxy flooring has become a popular choice for homeowners and businesses in Dallas due to its durability, versatility, and aesthetic appeal. Whether you're renovating your home, office, or industrial space, epoxy floors offer a solution that combines practicality with visual impact. This article explores the key features, benefits, and local trends of epoxy flooring in Dallas.

What is Epoxy Flooring?

Epoxy flooring is created by applying a mixture of resin and hardener onto a concrete surface. Once cured, this mixture forms a hard, durable coating that bonds with the substrate. The result is a seamless, glossy finish that is both functional and decorative.

Epoxy flooring systems can be customized in various ways, including the addition of color pigments, metallic flakes, and even textured finishes for slip resistance. This versatility makes it an excellent choice for a range of applications—from residential garages to commercial showrooms and industrial warehouses.

Why Epoxy Flooring is Ideal for Dallas

In Dallas, the climate and lifestyle demand flooring that can withstand high traffic, temperature changes, and occasional moisture, while still looking great. Here are some reasons why epoxy floors are perfect for this region:

Durability and Longevity

Dallas experiences a variety of weather conditions, from hot summers to occasional heavy rains. Epoxy flooring provides a tough surface that resists wear and tear from foot traffic, vehicles, and even spills. In homes with busy families or garages with heavy machinery, epoxy floors can last for years without cracking or staining.

Low Maintenance

Epoxy floors are incredibly easy to maintain. With a seamless, non-porous surface, they resist dirt, oil, and other contaminants, making cleaning a breeze. Regular sweeping and occasional mopping are usually all that’s needed to keep them looking new. In the fast-paced Dallas lifestyle, low-maintenance flooring is a major benefit.

Customizable Design

The design possibilities with epoxy floors are endless, making them a perfect fit for the stylish homes and businesses in Dallas. Whether you prefer a sleek, minimalist look or a bold, decorative finish, epoxy floors can be tailored to your specific taste. Popular designs in Dallas include metallic epoxy finishes, 3D effects, and custom colors to match branding or interior design themes.

Heat and Chemical Resistance

With Dallas being known for its hot summers, homeowners and business owners need flooring that can handle extreme temperatures. Epoxy floors are resistant to heat, and they can also withstand exposure to chemicals, making them ideal for both residential and industrial applications.

Cost-Effective

Epoxy flooring is an affordable solution compared to other flooring options like marble or hardwood, while still offering a premium look. For businesses in Dallas looking to renovate or expand, epoxy floors provide a durable, cost-effective option that doesn’t sacrifice style or quality.

Popular Applications in Dallas

Residential Garages

One of the most common uses for epoxy flooring in Dallas is in residential garages. The durable, non-slip surface makes it ideal for protecting the garage floor from oil stains, tire marks, and daily wear and tear.

Commercial Spaces

Retail shops, restaurants, and offices in Dallas have embraced epoxy flooring for its aesthetic appeal and practical benefits. It’s easy to clean, looks professional, and can handle high foot traffic without showing signs of wear.

Industrial and Warehouse Settings

Epoxy flooring is frequently used in industrial spaces like warehouses, manufacturing plants, and automotive shops. It can endure heavy machinery and equipment, while its smooth surface ensures safety and ease of movement for workers.

Finding the Right Epoxy Flooring Contractor in Dallas

Choosing a reliable contractor is key to getting the best epoxy flooring results. Look for professionals with extensive experience in both residential and commercial installations, as well as positive customer reviews. Local contractors often understand the unique needs of Dallas properties, including how to best prepare and treat concrete surfaces for the local climate.

Epoxy flooring is an excellent option for both residential and commercial properties in Dallas. With its combination of durability, low maintenance, and customization options, it meets the needs of a wide variety of spaces, from sleek downtown offices to functional home garages. If you’re considering upgrading your floors, epoxy offers a stylish, cost-effective solution that will stand the test of time in Dallas’s dynamic environment

For more info:-

epoxy floors dallas

concrete polishing dallas

0 notes