#bar bending machine supplier India

Explore tagged Tumblr posts

Text

Hydraulic Bar Bending Machine India | KGRK Enterprises

Efficiency Redefined with Hydraulic Bar Bending Machines in India - KGRK Enterprises. Discover our cutting-edge bar bending solutions at the provided link. Our hydraulic machines offer precision, speed, and reliability, ensuring seamless reinforcement bar bending for construction projects of all scales.

#bar bending machine supplier India#bar bending machine manufacturer in india#automatic bar bending machine India#hydraulic bar bending machine India#bar bending machine supplier in Haryana

0 notes

Text

A Trusted Construction Equipment Manufacturer and Supplier in India : IRI EQUIPMENT INDIA PVT. LTD.

IRI Equipment India Pvt. Ltd. stands as a reputable construction equipment manufacturer and supplier in India, carving a niche in the industry with a commitment to quality and innovation. Specializing in a range of construction solutions, IRI Equipment has become a trusted name for builders and contractors alike.

At Iri Equipment, we specialize in creating high-grade equipment like Suspended Rope Platforms, TMT Bar Bending Machines, TMT Bar Cutting Machines, and Mini Cranes. Our focus is on providing innovative and reliable solutions that cater to our customers’ evolving requirements.

Our commitment revolves around ensuring each piece of equipment meets stringent quality standards, promising reliability and satisfaction. From small-scale projects to large construction endeavors, Iri Equipment stands as your trusted partner, providing the tools essential for success.

Our Product

Suspended rope platform Bar bending machine TMT bar cutting machine Mini Crane Machine

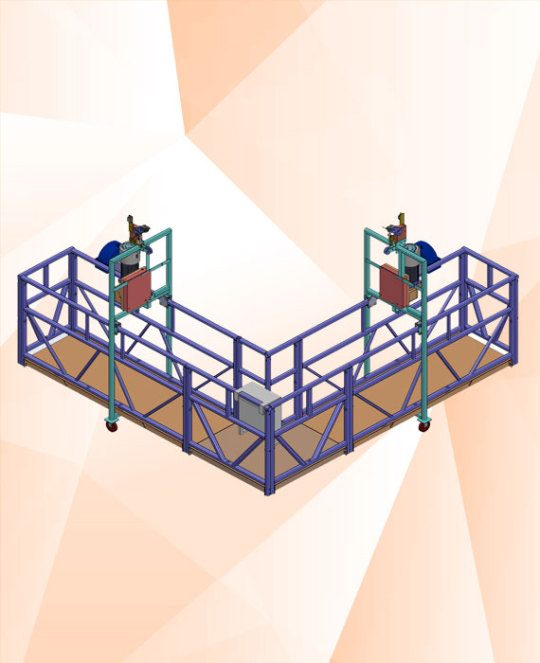

Suspended Rope Platform

For vertical construction challenges, IRI Equipment provides the secure Suspended Rope Platform, a reliable solution for accessing elevated areas during construction and maintenance tasks. This platform ensures the safety and convenience of workers while facilitating work at height.

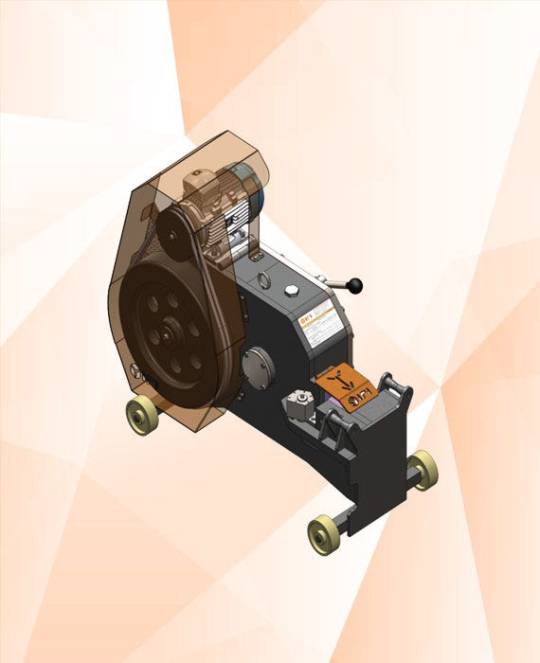

Bar Bending Machine

At the forefront of their product lineup is the high quality Bar Bending Machine, a precision tool designed to efficiently bend reinforcing bars with accuracy and speed. This crucial equipment ensures the seamless shaping of bars, contributing to the structural integrity of buildings and infrastructure projects.

Bar Cutting Machine

Our high power Bar Cutting Machine, another cornerstone in IRI Equipment’s portfolio. Engineered for precision cutting, this machine provide the accurate sizing of reinforcing bars, ensuring they meet the exact specifications required for diverse construction applications.

Mini Crane Machine

In addition , IRI Equipment India Pvt. Ltd. extends its expertise to the Mini Crane Machine, a versatile lifting solution designed to navigate confined spaces and handle varying loads efficiently. The Mini Crane machine enhances on-site logistics, contributing to a smoother construction process.

Driven by a commitment to excellence, IRI Equipment India Pvt. Ltd. consistently delivers high-quality products that meet the stringent demands of the construction industry. Their focus on technological advancement and customer satisfaction solidifies their position as a leading player in the realm of construction equipment manufacturing and supply.

#construction equipment#suspended rope platform for plastering#buy suspended rope platform#bar bending machine#suspended rope platform#machinery#IRI EQUIPMENT INDIA PVT. LTD.#reputable construction equipment manufacturer and supplier

1 note

·

View note

Text

Supplier of Stainless Steel Flats in West Bengal

Keshar Bhawani Metal & Tubes Pvt. Ltd. is a leading Manufacturer and Supplier of Stainless Steel Flats in West Bengal, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. Stainless Steel Flats are flat, rectangular bars made from stainless steel, characterized by their uniform thickness and smooth surface. These versatile materials are available in various widths, lengths, and grades, offering resistance to corrosion, high strength, and aesthetic appeal. Features: Structural Support: Provide essential reinforcement for various applications, ensuring stability and strength. Load Bearing Capacity: Engineered to support heavy loads without bending, crucial for construction and manufacturing. Rigidity and Stability: Offer exceptional rigidity, preventing flexing and maintaining structural integrity. Easy Installation: Lightweight and uniform dimensions facilitate quick and efficient installation. Corrosion Resistance: The chromium content protects against rust, making them suitable for various environments. Cost-effectiveness: Durable and low-maintenance, leading to long-term savings despite higher initial costs. Applications: Structural Framing Building Construction Industrial Machinery Agricultural Equipment Automotive Industry Architectural Design What are the common grades of stainless steel used for flats? The most common grades are 304, which offers good corrosion resistance, and 316, which is more resistant to chloride environments. Manufacturers use Grade 410 for applications that require high strength and moderate corrosion resistance. Are stainless steel flats weldable? Yes, most grades of stainless steel flats are weldable. You should choose proper welding techniques and filler materials based on the specific grade and application. How are stainless steel flats manufactured? Manufacturers can produce stainless steel flats through various processes, including hot rolling, cold rolling, and machining, based on the required specifications and finish. Keshar Bhawani Metal & Tubes Pvt. Ltd is Supplier of Stainless Steel Flats in West Bengal, India including locations Kolkata, Asansol, Siliguri, Durgapur, Bardhaman, Malda, Baharampur, Habra, Kharagpur, Shantipur, Dankuni, Dhulian, Ranaghat, Haldia, Raiganj, Krishnanagar, Nabadwip, Medinipur, Jalpaiguri, Balurghat, Basirhat, Bankura, Chakdaha, Darjeeling, Alipurduar, Purulia, Jangipur, Bolpur, Bangaon, Cooch Behar. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Supplier of Stainless Steel Wire Rod in Jharkhand

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Wire Rod in Jharkhand. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel. Stainless Steel Wire rod is a semi-finished product made from stainless steel. Our wire rods are produced in various diameters and grades to meet the specific needs of different industries. Key Properties: Corrosion Resistance: Resists oxidation and corrosion, making it suitable for various environments. Strength: Offers excellent mechanical strength and durability. Aesthetic Appeal: Maintains a polished and attractive appearance. Specification: Stainless steel Wire Rod Grades: ASTM: 201, 202, 204Cu, 301, 302, 303, 304, 304Cu, 304HC, 304L, 304H, 310, 310S, 312, 314, 316, d16L, 316LN, 316TI, 316LCu, 321, 410, 420, 430, 430L, 904L DIN/EN: 1.4301, 1.4306, 1.4307, 1.4310, 1.4401, 1.4404, 1.4567, 1.4841, 1.4842, 1.4541, 1.4845, 1.4570, 1.4571, 1.4578, 1.4597, 1.4362, 1.4370 and 1.4016 Size: 0.03mm to 16mm Heat Treatment: Solution Annealing for Austenitic Grades Normal Annealing for Martensitic Grades Finish: Black, Bright, Matte Finish, Soap Coated, Electro Polish Quality Other Special Grade: Electrode Grades: ER304, ER304L, ER307, ER307SI, ER308, ER308L, ER308LSI, ER310, ER316, ER316L, ER316LSI, ER347, ER347SI, ER309L, ER430 And ER420 Condition: Soft, 1/4 Hard, 1/2 Hard, Full Hard, HRP & Solution Annealed Packing: Simple 4-steel Strip Packing for Coil Poly Packing with Plastic Strip for HRP and HRAP Wrapping with Plastic Strip As Per Customer Requirements Testing: Computerized Tensile Testing Machine Bend Testing Wrap Testing Torsion Testing Machine Hardness Testing Machine IGC Testing Facilities Cold Upset Test Facility PMI Tester Chemical Composition Analyses Radioactive Contamination Testing Application: Construction and Architecture Automotive Industry Oil and Gas Industry Power Generation Arisa Impex is a Supplier of Stainless Steel Wire Rod in Jharkhand including locations like Ranchi, Bokaro, Jamshedpur, Dhanbad, Giridih, Hazaribagh, Ramgarh, Hazaribagh, Chirkunda, Mango, Chaibasa, Koderma, Sahibganj, Jhumri Telaiya, Jamtara, Dumka, Gumia, Madhupur, Phusro, Chakradharpur. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

0 notes

Text

The Role of Straightening Machines in Manufacturing Industry

Straightening machines are used to straighten metal bars, tubes, and shafts by applying controlled bending and stretching forces. They are essential in the production of straight and defect-free metal components for various industries including construction and manufacturing. For more details visit our website.

0 notes

Text

Flanges Stockist in Oman

A350 LF2 flanges are designed for low-temperature applications. These flanges are made from carbon steel or low alloy steels. There are A350 LF2 Class 1 and Class 2 flange types. Both types require a notch toughness test to ensure they meet the necessary quality standards. The ASTM A350 LF2 flanges come in various shapes, sizes, dimensions, and grades. We are a manufacturer and supplier of all these different types. Our company has been in operation for many years, producing various types of flanges in different material grades.

The ASTM A350 LF2 manufactured flanges are stronger because they are made from a single piece of metal, making them suitable for applications requiring high strength. Purchase directly from ASTM A350 LF2 Class 1 flange manufacturers in Dubai. These flanges can also be easily welded with piping systems. For applications requiring durability and hardenability, the ASME A350 LF2 flanges are suitable. In certain conditions, killed carbon products are preferred. For such applications, we supply A350 LF2 killed carbon steel flanges to meet the requirements. Different dimensions and scales are also available. Please feel free to contact us to learn more or to inquire about our products. All forgings provided by the SA 350 Gr LF2 Cl1 flange manufacturer are typically ultrasonically tested.

Specification Chart of ASTM A350 LF2 Flanges

Size Chart:

1/2″ to 48″ (15 NB to 1200 NB)

Pressure Rating Chart:

ANSI: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

DIN Pressure Calculation: PN6, PN10, PN16, PN25, PN40, PN64 (6 Bar, 10 Bar, 16 Bar, 25 Bar, 40 Bar, 64 Bar)

JIS: 5 K, 10 K, 16 K, 20 K, 30 K, 40 K, 63 K

Manufacturer Standards:

UNI, BS, AS2129, ANSI, DIN, GOST, JIS, SABS, NFE, AWWA, EN, etc.

Testing Methods:

X-ray detector

Ultrasonic flaw detector

Direct-reading spectrograph

Magnetic particle detector

Hydrostatic testing machine

Coating Options:

Zinc plated

Yellow transparent

Cold and hot dip galvanized

Anti-rust paint

Oil black paint

Common Types:

Threaded / Screwed

Forged

Plate

Equipment Used:

Press machine

Bending machine

Sand-blasting machine

Pushing machine

Electric bevelling machine, etc.

UNI / EN Pressure Ratings:

6 Bar, 10 Bar, 16 Bar, 25 Bar, 40 Bar

Connection / Flange Face Types:

RF (Raised Face)

Small Tongue

RTJ (Ring Type Joint)

FF (Flat Face)

LJF (Lap Joint Flange)

Large Tongue & Groove

Origin:

West Europe, Japan, India, USA, Korea

Standards:

API7S-43, API605, ISO70051, JISB2220, API7S-15, ANSI/ASME B16.5, BS4504, BS 10, EN-1092, DIN, B16.47 Series A & B, MSS S44, BS1560-3.1, B16.48, EN1092

#ASTM A350 LF2 Flanges Manufacturers in UAE#ASTM A350 LF2 Flanges Suppliers in UAE#ASTM A350 LF2 Flanges Stcokists in UAE#ASTM A350 LF2 Flanges Exporters in UAE#CS Flanges in UAE

0 notes

Text

Are you looking for M2 High Speed Steel for your automotive, and precision engineering work?

DIN 3343 / M2 is a standard high-speed steel grade. Having balanced alloy composition forms the basis of its high toughness and good cutting edge retention, rendering it suitable for a large variety of applications.

Equivalent Grades: M2 / DIN 3343 / AISI M2 / X100CRMOV5

Let’s explore the significant features of DIN 3343 (also known as M2 Steel), which plays a crucial role in the world of tool steels:

Exceptional Hardness and Wear Resistance: M2 Steel stands as a pinnacle in the realm of high-speed tool steels. Its unmatched hardness and wear resistance make it ideal for cutting, machining, and forming applications. When precision and longevity matter, M2 Steel delivers.

Heat Resistance: In demanding environments where tools are exposed to high temperatures during cutting and shaping processes, M2 Steel maintains its mechanical properties. It can withstand the heat generated during operations, ensuring consistent performance.

Toughness and Thermo-Plasticity: The combination of toughness and thermo-plasticity sets M2 Steel apart. Its bending strength and toughness are 50% greater than that of T1 steel, making it a preferred choice in various applications.

Versatility: Whether it’s cold work punches, dies, or high-speed, light-cutting tools, M2 High-Speed Steel shines. Its adaptability across industries—such as aerospace, automotive, and precision engineering—makes it indispensable.

Remember, proper heat treatment and maintenance are essential to maximize the benefits of M2 Steel. If you’re looking for a reliable supplier, consider exploring Virat Special Steels’ offerings Now.

We supply steel bars to forging companies across #Ludhiana, #Faridabad, #Bhiwadi, #Sonipat, #Rohtak, #Haryana, #Punjab, #Jamshedpur, #Trichy, #Aurangabad, #Pune, #Gurgaon, #Noida, #Ghaziabad, #Indore, and all locations in India.

Virat Special Steels being a trusted supplier in India, it’s worth exploring their offerings for both DIN 3343 and M2 Steel.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📬[email protected] ☎+91 098140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#high speed steel#Din3343#m2steels#t1steels#Faridabad#Bhiwadi#Sonipat#Rohtak#Jamshedpur#Ghaziabad#Noida

1 note

·

View note

Text

🛠️ Mastering Roll Forming: Ensuring Quality Products with Proper Machine Care 🏭

Introduction: Roll forming is like metal sculpting magic ✨, shaping coils into precise products for various industries. In Navi Mumbai, India, Allied Ispat India Pvt. Ltd. shines as a leading "Rolling Shutter Parts Manufacturer & Supplier." Today, let's explore the fascinating world of roll forming machines and how taking care of them ensures top-notch product quality.

Understanding Roll Forming : Roll forming is a continuous bending operation where a long strip of metal, typically steel coils, is gradually shaped through a series of rollers to achieve the desired cross-section profile. This process involves several key steps, including uncoiling the metal strip from large coils, feeding it through rollers, gradually forming the metal, cutting it to the desired length, and collecting the finished product.

How Roll Forming Machines Work :

🌀 Uncoiling: Metal coils are unwound to provide a steady supply of material.

🚚 Feeding: The flat strip is fed into the machine, grabbed by the first set of rollers.

🔄 Roll Forming: Each set of rollers bends the metal slightly more than the previous set, gradually forming the desired shape.

✂️ Cutting: Once the desired profile is achieved, the strip is cut to the required length.

📦 Output: The finished product is collected and prepared for further processing or packaging.

Ensuring Consistent Quality : Consistency is paramount in roll forming, and achieving it requires a combination of factors:

📏 Material Consistency: Ensuring the metal strip's uniform quality and thickness.

🔍 Regular Inspection: Periodically checking machine alignment and functionality.

🛠️ Calibration: Regularly calibrating the machine to maintain precision.

⛽ Lubrication: Keeping moving parts well-lubricated to minimize wear and tear.

🔧 Tooling Inspection: Inspecting and replacing worn-out tooling to ensure clean cuts and efficient operation.

Maintenance Tips for Longevity : Proper maintenance is crucial for ensuring the longevity and efficiency of roll forming machines. Here are some essential tips:

📖 Know Your Equipment: Read the manual and provide proper training to operators.

🛠️ Routine Checks: Conduct regular visual inspections and functional tests.

🧼 Cleanliness Matters: Keep machines clean and dry to prevent damage.

⚙️ Regular Lubrication: Use the right lubricants to keep moving parts operating smoothly.

🛠️ Replace Worn-out Parts: Don't wait for breakdowns; replace worn-out components promptly.

🛡️ Protect from External Factors: Shield machines from extreme temperatures and physical damage.

Allied Ispat India Pvt. Ltd.: Leading by Example : Allied Ispat India Pvt. Ltd. exemplifies the importance of proper machine care in achieving consistent product quality. As a leading manufacturer and supplier of rolling shutter parts, they prioritize maintenance and quality control to deliver superior products to their customers.

Conclusion : Mastering the art of roll forming requires not only skillful operation but also diligent maintenance practices. By understanding how roll forming machines work and following proper maintenance procedures, companies can ensure consistent product quality, prolong machine lifespan, and uphold industry standards. With industry leaders like Allied Ispat India Pvt. Ltd. setting the bar high, the future of roll forming looks promising.

0 notes

Text

Explanation of TMT Bars and Their Production Process

TMT bars, short for Thermo-Mechanically Treated bars, have revolutionized the construction industry with their superior strength, durability, and flexibility. These bars are a critical component in reinforced concrete structures, providing the necessary strength to withstand various loads and stresses. Shree Ji Steel Private Limited (formerly known as Shree Ji Steel Corporation) is a leading supplier and wholesaler of TMT bars, committed to providing high-quality products for construction projects across India.

Production Process of TMT Bars:

Raw Materials:

The production of TMT bars begins with the selection of high-quality raw materials. Iron ore, coal, and limestone are the primary ingredients used in the production of steel. These materials are carefully selected to ensure the desired chemical composition and metallurgical properties.

Steel Making:

The raw materials are melted in a furnace to produce liquid steel. This process, known as steelmaking, involves the use of various techniques such as the basic oxygen furnace (BOF) or the electric arc furnace (EAF). During steelmaking, impurities are removed, and alloying elements are added to achieve the desired steel grade.

Continuous Casting:

Once the liquid steel is produced, it is poured into a continuous casting machine. This machine solidifies the steel into billets, which are long, rectangular-shaped pieces of steel. The size of the billets can vary depending on the final product specifications.

Hot Rolling:

The billets are then reheated and passed through a series of rolling mills to reduce their cross-sectional area and shape them into the desired final product. During this process, the steel undergoes significant deformation, which aligns the grain structure and improves its mechanical properties.

Thermo-Mechanical Treatment:

After hot rolling, the bars are subjected to a thermo-mechanical treatment process. This process involves rapid cooling of the bars using high-pressure water jets, followed by controlled cooling in atmospheric conditions. This treatment imparts unique properties to the bars, such as high strength, ductility, and weldability.

Quenching and Tempering:

The final step in the production of TMT bars is quenching and tempering. In this process, the bars are heated to a high temperature and then rapidly cooled by quenching in water. This rapid cooling causes the surface of the bars to harden, while the core remains ductile. The bars are then tempered at a lower temperature to achieve the desired balance of strength and ductility.

Advantages of TMT Bars:

High Strength: TMT bars have superior strength compared to traditional mild steel bars, making them ideal for use in high-rise buildings and infrastructure projects.

Improved Ductility: The thermo-mechanical treatment process imparts excellent ductility to TMT bars, allowing them to withstand bending and twisting without breaking.

Corrosion Resistance: TMT bars are more resistant to corrosion compared to traditional bars, thanks to their surface hardening during the quenching process.

Cost-Effectiveness: While initially more expensive than traditional bars, TMT bars offer long-term cost savings due to their durability and low maintenance requirements.

Ease of Use: TMT bars can be easily bent and shaped on-site, reducing the need for complex and expensive fabrication processes.

In conclusion, TMT bars have become the preferred choice for construction projects due to their superior strength, durability, and cost-effectiveness. Shree Ji Steel Private Limited (formerly known as Shree Ji Steel Corporation) is committed to providing high-quality TMT bars that meet the stringent requirements of the construction industry, ensuring the safety and longevity of structures across India.

0 notes

Text

Vibratory Roller Compactor Supplier in India | KGRK Enterprises

KGRK Enterprises is a leading supplier of high-quality vibratory roller compactors in India. Our equipment is designed to efficiently compact various types of soil and asphalt surfaces, making it an essential choice for construction and roadwork projects.

0 notes

Text

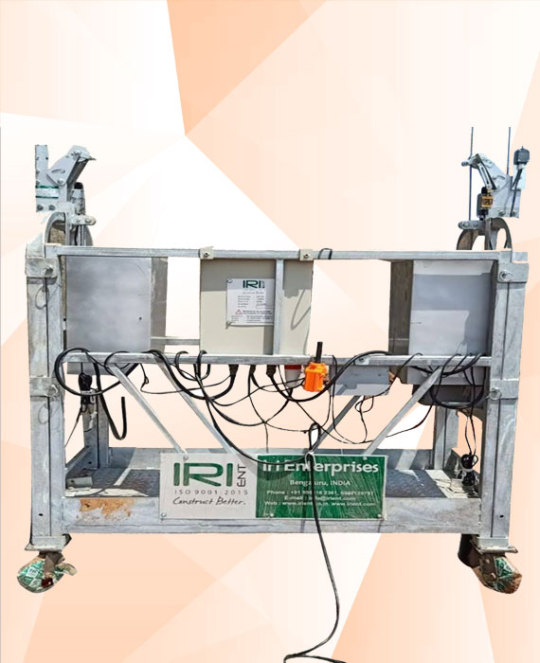

Suspended Rope Platform: How to Use It Safely

Suspended rope platforms, also known as gondolas, play a pivotal role in construction, facilitating work at considerable heights while ensuring safety and efficiency. These platforms are essential equipment used for transporting workers and engineers during installations and maintenance work in various construction projects.

Understanding the Significance

Suspended rope platforms are advanced overhead operating equipment that serves as a viable alternative to traditional scaffolding systems. There are primarily two types available in the market: manual and electric. Their usage spans across high-rise building construction, curtain wall installations, and exterior wall maintenance and cleaning.

Advantages of Using Suspended Rope Platforms

The shift from conventional bamboo and metal scaffolding to suspended rope platforms is underpinned by multiple advantages:

Enhanced Safety Features: These platforms incorporate crucial safety elements like Digital Load Cells, Anti-Tilting mechanisms, and Anti-Sway Restriction Devices, ensuring a safer work environment.

Ease of Assembly and Transport: They are simple to assemble, disassemble, shift, and store, requiring minimal manpower. Installation typically takes only 1-2 days, contributing to operational efficiency.

Longevity and Maintenance: These platforms boast a long lifespan, are easy to maintain and repair, and retain a high resale or reuse value, making them a cost-effective investment.

Versatile Design: The flexibility and ample size of these platforms offer enhanced comfort to workers, promoting productivity and safety.

Safety Gadgets Integrated into Suspended Rope Platforms

Ensuring the safety of workers is a top priority in the design and implementation of suspended rope platforms. Some crucial safety devices incorporated into these platforms include:

· Centrifugal Speed Limiter

· Electromagnetic Brake with Manual Release

· Over Hoist/Top Limit Switch

· Anti-Tilting Cut-off Mechanism

· Anti-Sway Restriction Features

· Locking Arrangement for Upper Counterweights

· Hammer Weight for Wire Rope Locking

· Panelboard Lock & Key Mechanism

Ensuring Safe Usage

As esteemed suppliers of suspended rope platforms in Gujarat, ensuring the safe usage of gondolas is a primary responsibility. Accidents involving these platforms often stem from inadequate knowledge of their operation. Thus, it's imperative to highlight the necessary precautions for their safe utilization.

Implementing a Safe Work System

Every operation involving a suspended working platform must adhere to a comprehensive safe work system. Project engineers, safety professionals, Jobsite staff, and building management should collaboratively establish and endorse safety protocols. A competent individual should oversee and supervise the implementation of this system, ensuring the safety of all personnel associated with the platform.

What is suspended rope platform?

A suspended rope platform, also known as a gondola, is a crucial construction tool for working at heights. It's an overhead operating equipment used to transport workers during installations and maintenance. With safety features like Anti-Tilting and Anti-Sway devices, it ensures safe, efficient work at elevated levels in construction projects.

Rope Suspended Platform manufacturers in India

In India, several manufacturers specialize in rope suspended platforms. Irri Equipment one of them offering high-quality equipment for construction needs They manufacturers prioritize safety features and efficient design, catering to the diverse demands of the construction industry. They provide reliable solutions for working at heights with precision and safe.

Safety Protocols and Best Practices

To guarantee the safe operation of suspended rope platforms, adherence to strict safety protocols is crucial:

· Thorough Operational Planning: This involves selecting the appropriate platform for the job and evaluating the working environment.

· Secure Installation Methods: Employ tried-and-tested installation techniques to ensure stability.

· Regular Maintenance: Implement both on-site and periodic maintenance routines to keep the platform in optimal condition.

· Documentation and Certification: Maintain detailed operation and maintenance records, repair logs, and certificates of examination.

· Competent Personnel: Only qualified individuals should handle the installation, movement, and dismantling of these platforms.

· Avoiding Hazardous Conditions: Use of the platform should be prohibited in hazardous conditions to prevent potential risks.

· Continuous Supervision: Regular monitoring and supervision of safety measures should be in place to ensure ongoing compliance.

Prioritizing safety protocols and measures is pivotal for the seamless and secure operation of suspended rope platforms. At our company, we emphasize these precautions to safeguard the well-being of our customers and all involved in construction projects. Should you require further guidance or assistance in utilizing these platforms safely, our team of suspended rope platform suppliers is always available to offer support and expertise.

Source - https://iriequipment.com/

#Buy Suspended Rope Platform#Suspended Rope Platform#Rope Suspended Platform#Suspended rope platform for plastering#Bar bending machine#Construction Equipment Manufacturer and Supplier in India#Construction Equipment

1 note

·

View note

Text

Supplier of Industrial Fittings in Maharashtra

Meghmani Metal Industries is one of the leading Manufacturer and Supplier of Industrial Fittings in Maharashtra, India.

Meghmani Metal Industries was established in 2011, We are committed to delivering top-notch products to the metal industry, prioritizing customer satisfaction, and environmental stewardship.

We offer a wide range of stainless steel products including plates, coils, bars, wires, pipes, tubes, industrial flanges, valves, fittings, fasteners, SS channels, and flats.

Industrial Fittings are devices connecting parts of machinery, designed to endure harsh conditions. They're vital in manufacturing, construction, and utilities for tasks like piping and plumbing.

Our testing and inspection services for industrial fittings include mechanical testing, chemical analysis, corrosion testing, microstructure examination, hydro testing, surface finish analysis, and non-destructive testing using various techniques and equipment.

Technical Specifications:

Size: 1/8” NB TO 48” NB (Seamless & 100% X-Ray Welded, Fabricated).

Thickness: SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS, Custom Thickness.

Dimension: B16.5, BS 4504, EN-1092.

Specialization: Long Bend with Radius – R = 1D, 1.5D, 2D, 3D, 5D, 6D, 8D, 10D or custom Pigabble Bend & As per your drawing.

Value Added Services: Polish (Electro & Commercial), Heat Treatment Annealed & Pickled, Sand Blasting, Machining, etc.

Applications :

Waste treatment facilities

Chemical processing

Breweries

Petrochemical facilities

Cryogenic plants

Nuclear power plants

Meghmani Metal Industries is one of the leading Manufacturer and Supplier of Industrial Fittings in Maharashtra and places like Ahmednagar, Akola, Amravati, Aurangabad, Bhandara, Jalgaon, Kalyan, Karli, Kolhapur, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane.

If you have any queries or would like more information, please get in touch with us.

0 notes

Text

Unicorn Equipment (A brand of Global Link’s) are the leading manufacturer of a wide range of Concrete Cutter Machine, Tamping Rammer, Bending Machines, Roller Machine, etc. All offered ranges are made in conformity with the universally accepted standards of quality. Owing to their durability, sturdy design, and resistance to crack, these are appreciated among our patrons. Apart from this, we are offering these products at very reasonable rates in the market.

Visit us at https://barbendingmachines.com/

1 note

·

View note

Text

Stainless Steel T Patti

INTRODUCTION:-

The above Decorative SS “T” Profile Sections are made by CNC Bending. Before Bending, these Sheets are cut to their required sizes by Laser Cutting Machines. Our SS T-Profiles Grooving is done on Metal Sheets before bending them. By following this Process, we can achieve 90 right angle on the bend area.

Our Profile Sections are also available in various colours as per your Requirement. Decorative SS “T” Profile Section are used in many Applications such as exterior cladding, interior decoration, Skirting, Wall Edge Protection, Floor Partitions, Wall Partitions and Many More.

BENEFITS:-

Durability: Stainless steel T Pattis are highly durable and resistant to corrosion, making them suitable for both indoor and outdoor use, even in harsh environments.

Strength: T Pattis made of stainless steel exhibit high strength-to-weight ratio, providing structural stability and support in various applications.

Aesthetic Appeal: Stainless steel T Pattis have a sleek and modern appearance, adding an aesthetic appeal to architectural designs and interior spaces.

Low Maintenance: These T Pattis require minimal maintenance, as they are easy to clean and do not require painting or coating to maintain their appearance.

Environmentally Friendly: Stainless steel is a recyclable material, making T Pattis an eco-friendly choice for sustainable construction projects.

PRODUCT OVERVIEW:-

Stainless steel T Patti, supplied by various suppliers in India, is a versatile construction material used in various architectural and structural applications. These suppliers offer a wide range of T Pattis in different sizes, grades, and finishes to meet the diverse needs of their customers. Stainless steel T Pattis are commonly used in construction, interior design, fabrication, and industrial settings.

ABOUT US:-

Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2015. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications.

MORE DETAILS:- CONTACT US: +91 22-6651 8642 EMAIL ID: [email protected] WEBSITE: https://www.decorativecoatedprofiles.com/stainless-steel-t-patti-profile.html

#Stainless Steel T Patti in Mumbai#Stainless Steel T Patti Suppliers in Mumbai#Stainless Steel T Patti Stockists in Mumbai.

0 notes

Text

Bar Bending Machine Manufacture in Hyderabad

In the realm of construction, efficiency and precision are paramount. Whether it's erecting skyscrapers or laying down bridges, every component must be meticulously crafted to ensure structural integrity and safety. bar bending machine supplies in hyderabad Bar bending machines play a crucial role in this process, offering a streamlined solution for shaping reinforcement bars with accuracy and speed. In Hyderabad, steel bar bending machine suppliers in hyderabad a burgeoning hub for industrial innovation, the manufacture of these essential machines has reached new heights, driving advancements in the construction industry. Hyderabad: A Hub of Industrial Excellence Nestled in the heart of India, Hyderabad has emerged as a thriving center for manufacturing and technological innovation. bar bending machine for sale in hyderabad bar bending machine manufacturers in hyderabad With a robust infrastructure and a skilled workforce, the city has attracted investments from across the globe, establishing itself as a premier destination for various industries, including construction equipment manufacturing. The Significance of Bar Bending Machines Bar bending machines are indispensable tools in the construction sector, used to bend reinforcement bars to precise angles and shapes as per project specifications. These machines streamline the bending process, significantly reducing manual labor and bar bending machine manufacturing company in hyderabad minimizing errors, thus enhancing overall productivity and quality in construction projects. From residential buildings to infrastructure ventures, bar bending machines are ubiquitous in the construction landscape. Innovations in Bar Bending Machine Manufacturing The manufacture of bar bending machines in Hyderabad epitomizes the city's commitment to innovation and excellence. Leading manufacturers leverage cutting-edge technology and engineering expertise to develop machines that meet the diverse needs of the construction industry. best industrial bar bending machine suppliers in hyderabad Advanced features such as digital controls, automatic bending mechanisms, and ergonomic designs characterize these state-of-the-art machines, empowering construction companies to optimize their operations and achieve superior outcomes. Quality Assurance and Compliance Ensuring the reliability and durability of bar bending machines is paramount to their success in the construction sector. steel bar bending machine equipment suppliers in hyderabad Manufacturers in Hyderabad adhere to stringent quality control measures and regulatory standards to deliver products of the highest caliber. Rigorous testing procedures and meticulous attention to detail are integral parts of the manufacturing process, guaranteeing that each machine meets or exceeds industry benchmarks for performance and safety. Meeting Diverse Requirements undertaking, manufacturers collaborate closely with clients to understand their needs and deliver tailored solutions that optimize efficiency and cost-effectiveness. Driving Sustainable Development manufacturing processes to the use of eco-friendly materials, sustainability is ingrained in every aspect of production. bar bending machine machinery supply in hyderabad By minimizing environmental impact and promoting responsible resource management, these manufacturers contribute to the advancement of sustainable development goals in the construction industry. Looking Ahead In conclusion, the manufacture of bar bending machines in Hyderabad represents a convergence of technological innovation, quality craftsmanship, and a commitment to sustainable development. bar bending machine exporters in hyderabad As these machines continue to play a pivotal role in enhancing efficiency and precision in the construction sector, Hyderabad's manufacturers stand at the forefront, driving progress and shaping the future of the industry.

0 notes

Text

Motorized Notch Machine

Motorized Notch Machine is a selfcontained floor-mounted unit, specially designed for cutting ‘V’ and ‘U’ notches in standard 10mm square, sub-size and 0.45″ diameter specimens. Our V/U Notch Broaching Machines are suitable for ferrous & non-ferrous material for sample preparation of ‘V’ or ‘U’ notches for Impact Testing Machines. Motorized notch machine is a specialized tool or equipment used in metalworking and other industries to create notches or grooves in various materials, such as metal plates, tubes, and bars. Notches are commonly used to facilitate bending, joining, or assembly of materials.

Key Features Motorized Operation: The machine is powered by an electric motor, which drives the cutting tool to create notches automatically. Cutting Mechanism: The machine usually employs a rotating cutting tool, such as a saw blade or a milling cutter, to remove material and create the notches. Adjustable Parameters: The machine may have adjustable settings for controlling the depth, width, and angle of the notches, allowing for customization based on the specific requirements of the project. Safety Features: To ensure operator safety, a motorized notch machine might include safety guards, emergency stop buttons, and other safety mechanisms. Workholding Devices: The machine may feature clamps or fixtures to hold the workpiece securely in place during the notching process. Versatility: Motorized notch machines can be designed for various industries, such as metal fabrication, woodworking, construction, and engineering. Applications of a motorized notch machine include: Metal Fabrication: Creating notches in metal sheets or bars for welding and joining purposes, as well as for making structural components. Woodworking: Cutting notches in wooden beams, boards, or panels for joinery, allowing for stronger connections in furniture, cabinetry, or construction. Plastic Processing: Forming notches in plastic components for assembly or fitting purposes. Electronics: Making notches in PCBs (Printed Circuit Boards) for component insertion or PCB assembly.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#cutting machine#notch machine#notch cutting machine#motorized notch machine#motorized notch cutting machine#uv notch machine#uv notch broaching machine#uv notch cutting machine#motorized notch broaching machine#best price motorized notch machine#motorized notch machine in best price#motorized notch machine supplier#motorized notch machine manufacturer#motorized notch machine dealer#motorized notch machine exporter

1 note

·

View note