#backhoe loader tooth

Explore tagged Tumblr posts

Video

youtube

Art and milktart: A Creative Odyssey with a sweet tooth.

Embark on a sensory journey like no other in this captivating YouTube video, where art, nature, and culinary delights unite in a symphony of creativity and craftsmanship. " Art and milktart: A Creative Odyssey" invites you to immerse yourself in a mesmerizing time-lapse experience. The video unfolds as we take you on an artistic odyssey, beginning with the creation of a heavily textured acrylic painting. Watch as vibrant colors come to life and textures take form in this visual masterpiece. But the journey doesn't end there. We offer a glimpse of the transformative power of a TLB (Tractor-Loader-Backhoe) as it shatters colossal boulders with a thunderous hammer. Witness the relentless energy of progress in motion. And what's a journey without indulging your taste buds? The video also features Annalie expertly baking a South African favorite – milktart, a delectable treat that warms the heart. This video is not just a feast for the senses; it's an invitation to join our creative community. Subscribe to our YouTube channel to stay connected with our adventures, creations, and the boundless wonders of the world around us.

0 notes

Text

Backhoe Heavy Construction Equipment – Its Uses

What are the used of backhoe heavy construction equipment? The backhoe, often known as the swiss army knife of heavy equipment, is ideal for all types of excavation and digging jobs, with one end used to dig up soil and the other used to carry it around. It’s the machine that can handle any task. It’s a common piece of machinery on construction sites.

The Backhoe’s Different Attachments

Hydraulic power attachments can be added to the backhoe. This enables the machine to perform duties other than lifting and excavating.

Breakers and hammers are the most typical backhoe attachments used by contractors. They give the operator the ability to break up rocky soils, asphalt, and concrete with ease. The tiger tooth attachment is useful for breaking through frost or harder soil, making the backhoe a useful tool, especially in colder climates.

Attachments in High Demand

Thumbs-up buckets

Hammers

Couplers

Compactors

Rippers

Street sweepers and brooms

Snowplows and snow shovels are two types of snow removal equipment.

Augers

Backhoe manufacturers are people who make backhoes.

Backhoe loader manufacturers can be found in both the United States and Europe. Backhoe loader manufacturers and models are discussed in the following section.

Caterpillar

C. L. Best Tractor Company and Holt Manufacturing Company merged to form Caterpillar (CAT) in 1925. Caterpillar is named after Benjamin Holt, who invented the continuous-tracked system. He dubbed the track system a “caterpillar” since it allowed the machine to creep around the ground. The name Caterpillar accompanied Holt when he joined the C.L. Best Tractor Co.

Backhoes and specialized attachments are manufactured by Caterpillar to replace both the hoe and the loader. The backhoe can be equipped with soil excavation buckets, coral buckets, ditch cleaning buckets, and rock buckets. In addition to backhoe loaders, CAT manufactures rakes, snowplows, angle blades, asphalt cutters, and material handlers.

The CAT 450 is equipped with a 131 horsepower engine, an innovative hydraulic system, and a CAT C4.4 ACERT engine. The CAT 415F2 and 415F2 IL are on the other extreme of the range. The engine in these two variants produces 68 horsepower. The 415F2 IL has a lower maximum operating weight than the previous model, but they are nearly identical in almost every other manner.

John Deere

In 1837, John Deere founded the John Deere Company, which began with the invention of the steel plow. Since then, John Deere has become one of the most well-known machinery brands.

Backhoes are currently available from John Deere in seven different models. The 710L is their largest backhoe, with a 148 horsepower engine turning at 2,240 rpm and a maximum operational weight of 11,607 kg (25,588 lbs). The 310L EP backhoe is John Deere’s smallest backhoe. This equipment has a peak operational weight of 6,270 kg (13,822 lbs), powershift gearbox, and a dipper stick dig depth of 4.3 m with 69 horsepower at 2,010 rpm (14 ft 1 in).

JCB

JCB was the first company to build a backhoe, having been founded in 1945 by Joseph Cyril Bamford. JCB has developed to become the world’s largest backhoe maker and producer, with 22 plants spread across four continents. Their products are sold in over 150 countries. Every year, JCB sells more backhoes worldwide than all other manufacturers combined.

The 3CX 15 Super Backhoe, with a 109 hp engine and a bucket breakout force of 12,603 lb / ft, is JCB’s most popular loader. The 3CX Compact Backhoe Loader, 3CX Backhoe Loader, and 4CX-15 Super Backhoe Loader are some of their other models.

Operation of a Backhoe Can Be Dangerous

Operating a backhoe, like any other piece of heavy equipment, can provide a number of risks and perils. Always operate the equipment only after having sufficient training, and never use a backhoe – or any other type of equipment – unless it is safe to do so.

Working too close to a cliff or on steep or uneven ground are the two most common causes of backhoe and backhoe operator accidents. Take the planning step seriously, and always study site plans, do hazard surveys, and circle check equipment before starting to work.

Other dangers include…

Raising the bucket to an excessively high level. This is especially dangerous if the equipment is on shaky ground since it may lead it to tumble over.

Working on a steep incline When working on a steep slope, be cautious because they can overturn or tumble over.

Not fastening your seatbelt. Falling out of the cab can endanger the machine, the operator, and people in the vicinity. Always fasten your seatbelt.

The act of striking an object. Be careful of people, buildings, trees, and other things that may be near the equipment, especially when operating on difficult terrain.

A burden that is descending. Be aware of those around the bucket when lifting or shifting goods. A worker can be injured by falling dirt, debris, or material.

By prioritizing safety and taking the time to follow procedures, all workers will be able to return home safely at the end of the day.

Practices for Using Backhoes in a Safe and Effective Manner

Here are a few easy methods to keep safe:

Always fasten your seatbelt.

Never use the equipment without first lowering the stabilizers.

Never exceed the machine’s maximum operational weight.

When transporting loads, keep them low and near to the ground.

When transferring loads or materials, keep visibility in mind.

Before moving, always check for blind spots.

Never lift or transport anyone with a bucket.

On-site driving speeds should not exceed 5 mph (approximately 8 kph)

The Backhoe’s Evolution

The utilization of mini-excavators and skid steers has reduced the demand for backhoe loaders nowadays. Contractors all over the world still appreciate them for their versatility and ability to execute a variety of chores well.

The first backhoe was introduced when the hydraulic system was established, and Vaino J Holopainen and Roy E Handy, Jr. invented the first backhoe swing frame in July 1947. One year later, it was copyrighted, and the two men joined forces to become Wain-Roy. The swing frame was a game-changer because it allowed the hydraulic guiding arm to swing to the bucket’s side.

Wain-Roy Company sold the first hydraulic backhoe in 1948. Between 1948 and 1954, Wain-Roy sold around 7,000 backhoes, mostly through Ford dealers.

In the midst of all of this, JCB introduced the first European hydraulic loader in 1948. With the invention of two-wheeled trailers, Joseph Syril Bamford founded JBC in England. With the installation of a hydraulic power system, this evolved into a four-wheel tipping trailer, which eventually led to the development of the loader. In Ireland and the United Kingdom, the backhoe is known as the “JCB.”

In 1953, JCB combined their hydraulic loader with the hydraulic arm on the other side of a tractor to create the versatile backhoe loader. Although JCB did not introduce their loaders to the United States until the 1960s, the machines were already on the market.

The first factory-integrated backhoe loader was introduced in 1957 by CASE Corporation, an American business. Before JCB came on American soil, American contractors and farmers had already recognized the backhoe’s power and versatility due to increased equipment manufacture. The extensible backhoe didn’t come out for another 14 years.

The Backhoe: Frequently Asked Questions

Is it possible to swap buckets on a backhoe?

Backhoes can be equipped with a variety of attachments and buckets to expand their capabilities. Some attachments may be limited by the machine piece’s size and weight capacity. Before adding a piece of equipment, always check the owner’s manual to make sure the machine is capable of handling it.

Is it possible for backhoes to dig in frozen ground?

A backhoe can dig in frozen ground with the help of suitable attachments. A frost bucket, hydraulic hammer, rotary cutter, or static ripper are all attachments that can assist a backhoe in digging in frozen ground.

What does a backhoe and an excavator have in common?

An excavator is a shoveling machine with a revolving cab that rotates 360 degrees. It is generally used for excavation work and has an arm with a bucket attachment – or any other type of excavator attachment. While excavators are often tracked machines, they can also be wheeled.

A backhoe is a tractor cab equipped with a loader on the front and an arm on the back. Other attachments can be used in place of the arm and bucket. These devices, which are mainly wheeled, are used for minor digging operations, transferring loads and goods, and a variety of other tasks.

Backhoes are more more adaptable than excavators, and can be employed in virtually any industry.

What does a backhoe and a loader have in common?

A backhoe has an arm and bucket on the rear, with the loader attachment on the front, whereas a loader simply has the loader bucket.

0 notes

Text

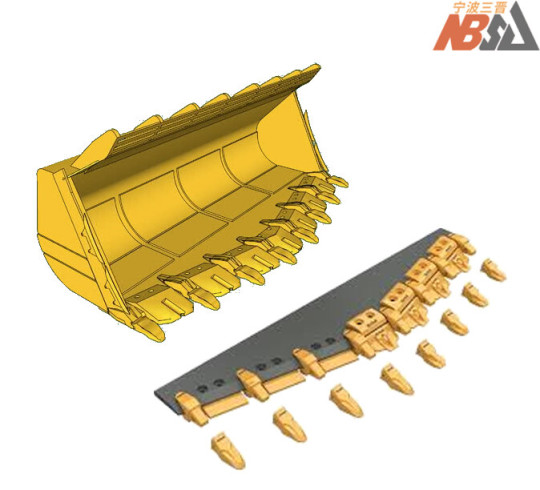

Caterpillar Loaders Tooth Family

Caterpillar Loaders Tooth Family

Caterpillar Loaders Tooth Family For Caterpillar Loaders,normally they divided into wheel loaders and crawler loaders.Below is what we think most-used loader machinery mode,normally they use Caterpillar J series tooth family. Hereby we sort out some Caterpillar J series tooth family which matches Cat Loader Machinery model. Some Loaders’ bucket have two options,one is for general purpose,the…

View On WordPress

#Backhoe Loader Bucket Adapters#Cat Loader Machinery#Caterpillar#Caterpillar bucket teeth#Caterpillar J Series#Caterpillar tooth system#crawler loaders#G.E.T Parts#ground engaging tools#J series tooth family#Loader Bucket Teeth#Loader Tooth#loaders#wheel loaders

1 note

·

View note

Photo

2008 KUBOTA M59

https://2008kubotam593rdvalve.weebly.com/

4x4, 3rd Valve, Kubota TL1350 SSL Quick Attach Loader with 84" GP Bucket, Kubota BT1200 Backhoe with 18" Tooth Bucket, 59 HP Diesel Engine, Hydrostatic Transmission, 8400 LB Operating Weight, 3 Point Capability without Arms, 540 PTO, 17.5 - 24 Rear Tires ...

... more »

1 note

·

View note

Text

What are the pointers for picking the ideal kind of excavator bucket?

You will need to consider numerous vital points prior to you get the excavator bucket for your machine. If you own an ideal excavating device, the productivity in the routine construction jobs will be a lot better. There are several systems using skid guide tooth bucket offer for sale, however it is not required that every one of them will supply extremely sturdy as well as flawlessly made buckets.

Tips for Selecting the Right Kind of Excavator Buckets

Although many excavator operators depend on the same standard digger bucket teeth for ending up all kinds of earth relocating and also excavating tasks, this strategy can influence the excavator machine's performance and your performance in a very adverse method. You need to think about the following variables before you select brand-new buckets for your excavator machine. First, take into consideration the dirt problem and afterwards pick the bucket type: As you know, there are various sorts of earth moving heavy equipment. Construction firms heavily rely on excavators, bobcat, skid-steer loaders, excavators, backhoe, as well as various other such devices. If skid steer tooth bucket is the best suited for bobcat, the excavator machine will certainly call for a different layout's bucket. Most notably, you must constantly recognize the dirt problem in the job area to pick the right bucket for the excavation task. You can locate severe-duty as well as durable buckets in the marketplace. Durable buckets are created to function flawlessly in all kinds of dirt conditions. These are abrasion-resistant buckets, however severe-duty buckets are made for both excavating and truck loading applications. You ought to select severe-duty buckets if you are going to continuously deal with highly unpleasant products in serious excavating. Know the right bucket style for your task: You can locate buckets created for digging, dumping, and angle tilt buckets for earthmoving tasks. Trenching or digging buckets can conveniently dig deep as well as slim trenches by using phenomenal outbreak pressure. Trenching buckets are prepared from abrasion-resistant material to create enormous stamina and minimize the weight. Dropping buckets also have the same profile as normal trenching buckets, however these buckets include a deeper and wider layout for smooth excavating in sand and clay. Finally, Angle tilt buckets are extensively chosen for completing, land cleaning, and also grading applications. As a driver, you can turn this bucket 45 ° in both directions to finish the work faster. The maintenance price: When operating an excavator machine or other planet relocating hefty equipment, you would not like to spend a whole lot of loan on purchasing new buckets and loader bucket tooth bar.Here is my webpage: casoki.com You should make sure you purchase a bucket developed with extremely wear-resistant product to sustain a long-term smooth service. You should thoroughly evaluate the bucket teeth and how much time these teeth can give smooth excavating and also loading service. Make certain you get buckets from an extremely trustworthy manufacturer, that is prominent for providing top quality devices for bobcat, excavator, and various other ground relocating devices. If you examine online, acquiring excavator as well as bobcat devices would certainly be simpler. There are on-line retailers supplying bobcat bucket teeth for sale in addition to various other accessories at really affordable cost. Think about the discussed elements and then get high-quality buckets for excavating, loading, as well as clearing up work.

1 note

·

View note

Text

Indications That Indicate It is the Right Time to Change the Loader Bucket Teeth

If you are operating the planet moving company, you are going to function on numerous building tasks. Individuals will hire your support time after time if you are outfitted with very sophisticated equipment such as bobcat, excavator, loader, backhoe, excavator, and so on. The productivity in this company mainly depends on how successfully you maintain your machines before the work starts as well as throughout the job. In addition to other elements of the machine, you will need to continuously change excavator tooth of the machine to make sure maximum performance. You have to take note of some simple indications that show you have to replace tiny bucket loader teeth.

How to recognize the Right Time to Replace the Loader Bucket Teeth

Fractures in the bucket: Excavator devices are developed to dig with all type of premises. This machine includes a standard set of teeth that get worn really quickly. Expect you continue to dig through broken teeth, these teeth will certainly break very promptly and after that it will certainly place extra stress and anxiety over the bucket. As a result, you might see some splits in the loader bucket, backhoe bucket, and excavator bucket. You should recognize that it is the ideal time to change bucket teeth if you check the excavator bucket and also locate splits in it.

Teeth are broken: Excavator makers frequently take part in ground permeating as well as building material tons works. These work require continuous involvement with hard materials like solid rocks, dirt, sand, bricks, etc. Excavator bucket teeth are developed to be durable however that constant engagement can cause excessive wear. Eventually, your bucket's teeth will certainly not continue to be sharp adequate to dig completely. If it is utilized for excavation or loading, currently you must understand that it is the time to replace bucket teeth. If you will not change quickly, you will certainly need to buy a whole brand-new collection of rock teeth for the excavator. Teeth are deformed: Lots of excavator machine operators utilize their pails to dig with the surface area which is as well difficult for the bucket geared up in the machine. As soon as the tensile stress and anxiety limitation is exceeded, Bucket teeth obtain deformed. It eventually warps the natural shape of the teeth. An excavator bucket with warped teeth can never ever carry out to its maximum efficiency. That's why you should examine all the teeth of your bucket remain in excellent shape or not. If some teeth are warped, you must change them before these teeth cause added tension over the bucket. Ask a specialist to check the whole equipment to ensure every little thing is great: It will be a pretty discouraging situation if the construction project gets on and excavator teeth were damaged.My webpage: CASOKI Instead of taking such dangers and also waiting a whole lot throughout the progress of the task, you ought to call a specialist and allow him check the whole machine together with its bucket and also teeth. It will certainly guarantee you will continue working without spending a great deal of cash on way too much upkeep. It is better to prepare yourself for the maintenance demands of the bucket and the excavator machine rather than awaiting some damages to occur. So, check all the indicators thoroughly and also keep your machine in the best possible means.

1 note

·

View note

Photo

#indiasbestdealers #bestoffersindia #Qualityproducts #trustedseller #bestoffersindia #ontimeservice #RoadSafetyFirst#specialoffers #savewater #planttreessavelife #DrugFreeIndia#earthmovingmachineryEarth moving or earthworks is a major application of heavy equipment. Earth moving involves digging, grading, and moving earth. Excavating, landscaping, moving large amounts of earth, and laying of the foundation are examples of earth moving tasks.Typical earthworks include road construction, railway beds, causeways, dams, levees, canals, and berms.What material is excavator pin?Excavator pins are usually made of a AISI 4130 or 4140 steel. The AISI 4000 series of steels are chromium molybdenum steels. Chromium improves corrosion resistance and its ability to be hardened while molybdenum increases strength and hardenability, tooThe pins and bushings are made from 4140 material and heat treated to a 65 Rockwell hardness for extended wear life.It consists of a tractor, a loader, and a backhoe. Their mobility makes them suitable for earth-moving activities in urban areas. They are used for excavation works, digging trenches, placing pipes, filling trenches, lifting materials, etc. Backhoe loaders are one of the most popular earthmovingSteel. The most common material used in fasteners, this material is predominantly iron mixed with carbon. It offers the highest strength compared to other metals and elements, but is the least corrosion resistant. Also known as Carbon Steel.They are manufactured using high-quality alloy steel and can be manufactured up to any dimensional standard that you require. They come with a hardness of 60-64 HRC as per DIN 2269Wire composed of carbon steel or stainless steel is run through a punch and die to create steel pins. These simple metal pieces can be made using the cold heading (or cold forming) technique, which does not require heat to change a metal's shape.

0 notes

Text

Indicators That Indicate It is the Right Time to Replace the Loader Bucket Teeth

You are mosting likely to work with various construction tasks if you are running the earth relocating organisation. Individuals will hire your assistance time and again if you are equipped with very innovative equipment such as bobcat, excavator, loader, backhoe, bulldozer, etc. The performance in this company primarily depends upon exactly how properly you preserve your machines before the job begins and during the project. Together with other components of the machine, you will have to regularly replace excavator bucket tooth of the machine to ensure optimum efficiency. You must focus on some basic indicators that suggest you must replace small bucket loader teeth.

Take notice of the indication of changing the Correct time to Loader Bucket Teeth

Cracks in the bucket: Excavator machines are created to dig with all kinds of premises. This machine includes a common set of teeth that obtain broken extremely rapidly. Intend you continue to dig through worn teeth, these teeth will certainly break really promptly and afterwards it will place additional anxiety over the bucket. Subsequently, you may see some fractures in the loader bucket, backhoe bucket, and also excavator bucket. If you inspect the excavator bucket as well as locate splits in it, you need to know that it is the right time to replace bucket teeth. Teeth are worn out: Excavator machines constantly take part in ground passing through and also building and construction material tons works. These jobs call for consistent engagement with hard materials like strong rocks, soil, sand, bricks, etc. Excavator bucket teeth are made to be durable but that consistent engagement can create excessive wear. At some point, your bucket's teeth will not continue to be sharp adequate to dig completely. If it is made use of for excavation or loading, now you must recognize that it is the time to replace bucket teeth. You will have to buy an entire new set of rock teeth for the excavator if you will certainly not change quickly. Teeth are deformed: Several excavator machine drivers use their containers to dig via the surface which is as well tough for the bucket equipped in the machine. Bucket teeth get warped when the tensile tension limit is surpassed. It at some point warps the natural shape of the teeth. Here is my page: https://www.casoki.com An excavator bucket with deformed teeth can never carry out to its maximum effectiveness. That's why you ought to inspect all the teeth of your bucket remain in perfect shape or not. If some teeth are warped, you must replace them prior to these teeth create added tension over the bucket. Ask a professional to examine the entire equipment to ensure every little thing is great: It will be a pretty irritating circumstance if the building and construction project is on and also excavator teeth were damaged. Instead of taking such threats and also waiting a lot during the development of the job, you need to call a specialist as well as allow him check the whole machine along with its bucket and also teeth. It will guarantee you will certainly continue working without spending a lot of loan on excessive maintenance. It is far better to prepare for the maintenance requirements of the excavator and also the bucket machine as opposed to waiting on some damages to occur. So, check all the signs carefully and also preserve your machine in the best feasible way.

1 note

·

View note

Text

Screening Bucket Its Types And Working Circumstances – Learn More

A Screening Bucket is a piece of equipment that separates materials by utilizing an impeller that rotates at a high speed inside the screen.

The material that consists of bigger particles is expelled via its side neck, while the material that is composed of finer particles utilizes intense jet action at high speeds to move up into the following size in line.

For the purpose of separating materials into particles of varying sizes, screening buckets are utilized. It is common to find one attached to a wheel loader or an excavator, and it is also common for smaller backhoes to have one attached in order to remove stuff from traps. They come equipped with high-pressure jets that power the machine through smaller screens, and the bigger chunks of rock are expelled out of a side neck aperture at extremely high speeds (upwards of sixty feet per second).

This makes it simple to swiftly clear away rocks before transporting them to another location, where they will either be put onto dump trucks, crushed further down the line, or stored for future production if their size does not allow transportation by any other method.

The following are the features of the Screening Bucket’s

The screening bucket may be used for sorting natural materials before and after age. Moreover, the screening bucket cuts crushing time by sixty percent, making it suited for the management of recyclable materials appropriate for the required processing type.

It is appropriate for use in fretting hydraulic systems, even wet materials can be screened, and output has increased by thirty percent compared to the previous year.

Perfect for cleaning sand and gravel from beaches and screening gravel in streams. It is an effective aid in the process of sifting fine sand and other tiny trash.

In addition to this, it has a low weight and a compact construction, which perfectly represent the beauty of the machinery.

Types of Screening Bucket:

Star Screening Bucket

Rotary Screening Bucket

Star Screening Bucket:

Star Screening Bucket: Out of all the many kinds of screens, the most common one is the star screening bucket. They have a variety of applications, including excavation, usage in quarries and landfills, and other similar uses. Typically, the following dimensions are offered for purchase: The bucket has a cylindrical shape, and its potential applications are rather diverse. The inside of the cylinder features toothed ridges that are designed to separate larger rocks from more finely divided materials such as sand, gravel, or other aggregates. They are also capable of managing exceptionally heavy loads, although they perform their best when coupled with rotary screeners, which may enhance their productivity by as much as fifty percent.

Rotary Screening Bucket:

A rotary screening bucket is a piece of equipment that has changed how digging and mining are done. Most of the time, they are used with loaders, but they can also be adapted to work with bulldozers or front-end loaders.

Rotary screen buckets are more efficient than traditional screens and can increase productivity by up to 50% while lowering operating costs.

Material is pushed against the side of the machine by the spinning motion, where it falls through a grate into a collection hopper and is then taken away from the mine or trenching site.

Working Mechanism Consists of:

The Rotating Screening Bucket causes the centre separating drum of the equipment to revolve in a reasonable manner using a gear box-type deceleration mechanism. The centre separation drum is a screen made up of several circular flat steel rings.

The placement of the centre separation drum is slanted relative to the plane of the ground. The material enters the drum net from the top end of the separating drum during operation.

During the rotation of the separation drum, the fine material is separated from top to bottom through the screening interval comprised of round flat steel, and the coarse material is released from the lower end of the separation drum into crushing. In the apparatus is a device for the automated cleaning of nets using plates.

During the separating process, by the relative movement of the sieve cleaning mechanism and the sieve body, the sieve body is continuously "combed" by the sieve body cleaning mechanism, ensuring that the sieve body stays intact throughout the working process. Clean and will not compromise the screening performance owing to clogging of the screen holes.

Working Circumstances:

The working circumstances include screening wet materials, demolition, excavation and filling, rock surface regeneration, pebble screening, beach cleaning, and other instances when thin materials need to be handled.

An extremely high level of screening efficiency

It does not matter how sticky, wet, or dirty the material that is entering the separation screen because the equipment is equipped with a plate-type screen cleaning mechanism. This ensures that during the screening process, the relative movement between the screen cleaner and the screen body will not block the screen. screen, which resulted in an improvement to the gadget. screen processing effectiveness.

0 notes

Text

When Should You Replace Backhoe Bucket Teeth?

When to replace crucial part of your hefty equipment when you are in planet moving company, it is really essential to recognize. It is pretty important to maintain your heavy planet relocating makers in terrific condition to end up all the given tasks successfully as well as promptly. You need to constantly examine the condition of backhoe teeth in order to ensure your device can penetrating difficult ground quickly. It will at some point damage the bucket and also enhance the operating cost of your equipments if bucket teeth got used you do not replace them quickly. For that reason, you must understand when to replace backhoe bucket teeth to run this equipment smoothly. Why should you change backhoe bucket teeth? A backhoe operator loader counts on all of its three major parts when operating this equipment on a building and construction site. These 3 important parts are the tractor, backhoe connected at the back, and also a loader attached to the front side of the tractor. Because it is used for penetrating difficult ground and also small product, the backhoe plays the most crucial role among all three. It is likewise used for raising heavy tons. Although you can make use of backhoe for digging all type of holes, it primarily developed to dig ditches. When passing through tough ground and also digging ditches, skid steer bucket teeth provide an edge. Despite the fact that your bucket is outfitted with highly durable teeth, you will need to prepare yourself for backhoe bucket teeth replacement. These teeth will certainly get put on after frequently excavating tough soil, sandy ground, and also rocks. So, in order to ensure your machine will run to its optimum capability, you will have to change those worn teeth of the bucket. Locating premium bucket teeth for replacement: Whether it is backhoe bucket tooth or caterpillar bucket teeth, these digging devices go through high deterioration as a result of the hefty tasks they do. The planet moving devices as well as equipment manufacturers know it as well as therefore they create these devices in a way that you can conveniently as well as cost effectively change bucket teeth. Intend there is a tooth bar attached to the bucket as opposed to separate teeth, you will certainly need to change the entire tooth bar. You should recognize what type of teeth is affixed to your backhoe or excavator device's bucket so that you can place an order for the best sort of teeth. Where to get bucket teeth for substitute? It may be a little bit confusing to recognize where to get the substitute teeth for the backhoe bucket. Instead of seeing the excavator display room and also various other such stores, you ought to go on the internet and look for these tools. It will certainly be a lot easier way of buying bucket teeth rather than looking this device in a typical means. Always remember that bobcat, backhoe, as well as excavator suppliers usually gear up containers with more affordable quality teeth. Also visit my weblog: casoki.com You ought to look for independent makers who produce extremely long lasting bucket teeth. It will be much easier to acquire the bucket teeth online due to the fact that you can think about all the features, top quality, building quality, and others features and afterwards place the order for the best top quality teeth. That's exactly how you can purchase premium backhoe bucket teeth.

1 note

·

View note

Text

When Should You Change Backhoe Bucket Teeth?

When to replace crucial part of your heavy devices when you are in earth moving organisation, it is very important to recognize. It is pretty important to keep your hefty planet moving devices in excellent problem to complete all the offered work successfully as well as on schedule. You ought to constantly check the problem of backhoe teeth in order to guarantee your equipment can penetrating difficult ground conveniently. It will eventually harm the bucket and raise the operating expense of your makers if bucket teeth obtained worn you do not replace them quickly. As a result, you need to recognize when to replace backhoe bucket teeth to run this equipment efficiently. Why should you change backhoe bucket teeth? When operating this equipment on a building and construction site, a backhoe driver loader counts on all of its 3 primary components. These 3 essential components are the tractor, backhoe attached at the back, and a loader attached to the front side of the tractor. The backhoe plays one of the most vital duty amongst all 3 because it is utilized for permeating difficult ground and compact product. It is likewise utilized for raising hefty lots. Although you can use backhoe for excavating all kinds of holes, it mostly created to dig ditches. When passing through tough ground and digging ditches, excavator teeth provide an edge. Despite the fact that your bucket is equipped with highly durable teeth, you will have to prepare for backhoe bucket teeth replacement. These teeth will certainly obtain worn after constantly digging tough soil, sandy ground, and also rocks. So, in order to guarantee your device will certainly operate to its optimum capability, you will need to replace those worn out teeth of the bucket. Locating premium bucket teeth for replacement: Whether it is backhoe bucket tooth or caterpillar bucket teeth, these digging devices go through high damage as a result of the hefty tasks they do. The earth moving tools and maker suppliers know it and consequently they create these equipments in a way that you can easily as well as economically change bucket teeth. Intend there is a tooth bar affixed to the bucket as opposed to separate teeth, you will have to change the whole tooth bar. You need to understand what kind of teeth is connected to your backhoe or excavator device's bucket to make sure that you can put an order for the ideal sort of teeth. Where to buy bucket teeth for substitute? It could be a little bit confusing to recognize where to acquire the substitute teeth for the backhoe bucket. Rather than visiting the excavator showroom and also various other such shops, you need to browse the web as well as search for these devices. Feel free to surf to my web: https://www.casoki.com It will be a lot easier way of getting bucket teeth rather than searching this tool in a typical way. Constantly keep in mind that backhoe, bobcat, as well as excavator makers typically outfit containers with more affordable top quality teeth. You should search for independent makers that generate very resilient bucket teeth. It will be a lot easier to get the bucket teeth on the internet due to the fact that you can take into consideration all the attributes, top quality, building and construction quality, and others attributes and then position the order for the very best top quality teeth. That's how you can acquire premium backhoe bucket teeth.

1 note

·

View note

Text

Esco Style Mini Backhoe Skid Steer Tooth Point V17VY V17T

Esco Style Mini Backhoe Skid Steer Tooth Point V17VY V17T

Esco Style Mini Backhoe Skid Steer Tooth Point V17VY V17T, ESCO SUPER V Pick Non-centerline Tooth V17VY, DIENTE Pick Tooth for Backhoe-Loader or Mini Skid Steer Bucket, Single Tiger Tooth, Esco Style Tiger Chisel Tooth for Mining Excavators, Tooth Point, Wheel Loader Bucket Attachments ESCO tooth system, DRP Esco bucket teeth and adapters, Replacement Digging Tip Point, GET Spare Parts China…

View On WordPress

0 notes

Text

John Deere Parts ADVISOR AG + CF + CCE + HITACHI for John Deere Service Advisor EDL V3 or V2 Free Download

What is John Deere Parts Advisor? John Deere Parts ADVISOR makes doing that as comfortable and productive as possible. However, its flexibility enables you to quickly find the parts you need in a way that matches your preferred workflow.

John Deere Parts Advisor Functions: 1.Maintenance 2.Spare Parts 3.Technical specifications 4.Tables 5.Diagrams and many other data

John Deere Parts Advisor Free Download: John Deere Parts Advisor 2020 https://mega.nz/file/DkgniSwL#rJVAqWODRnxQp8m_KJtTQ4vTAYFCUp7mmY0CPazK3oc

John Deere Parts ADVISOR v1.7.1 [06.2017] AG + CF + CCE + HITACHI https://mega.nz/file/KW5l1SJR#7YFZMu3z6509CgrV9sNOLCKaF1a5USPluXzo0CcsMR4

John Deere Service Advisor EDL (Electronic Data Link) heavy duty diagnostic adapter for construction equipment, agriculture, engines John Deere.

John Deere Diagnostic kit includes software John Deere Service Advisor Agriculture or Construction and Forestry version.

John Deere Service Advisor Agriculture workshop service manual, repair manual, electrical wiring diagram, hydraulic diagram, diagnostic, assembly and disassembly engine, transmission.

John Deere AG Management Solutions, Attachments, Backhoes, Combines and Headers, Cotton Harvestings, Excavators, ForkLifts, Hay and Forages, MAte Hand Cut and Shredderses, Plantings and Seedings, Skid Steers, Sprayers, Sugar Cane Harvesters, Tillages, Tractors, Worksite Pro Attachments.

John Deere Service Advisor CF (Construction and Forestry), workshop service manual, repair manual, diagnostic, electrical wiring diagram, hydraulic diagram John Deere.

John Deere Service Advisor CCE (Commercial and Consumer Equipment)dealer technical assistance, diagnostics, connection readings, calibrations, interactive tests, specification, tools, assemble and disassemble presented all models John Deere Construction Equipment and some models Hitachi, Euclid, Bell and Timberjack.

John Deere Parts Advisor Support Models: AGRICULTURE * 2-Way Integral Disk Plows * Aerator * Air Conditioning System * AMS * AMT * Applicator * Attachment, 60-in Mower Deck (2520 Tractor And X495, X595 X-Series Lawn Tractors) * Attachment, Combine * Attachment, Mid-Mount Rotary Mower, Mower Decks, And 3-Bag MCS (2210 And 4×10 Series Cuts) * Attachment, Mower Deck (4000 Series Cuts) * Attachments * Axle * Backhoe * Backhoe, Loader * Bagger * Bale Accumulator * Bale Conveyor * Bale Ejector * Bale Processor * Bale Unroller * Baler * Baler Engines * Baler, Hand-Tie * Baler, Large Square * Baler, Round * Bar, Tool * Bedder * Bicycle * Binder, Corn * Binder, Grain * Blade * Blower, Ensilage And Forage * Blower, Power * Boom * Bottom * Box Blade * Broom, Rotary * Bucket * Bulldozer * Cab * Carrier, Implement * Carrier, Killefer * Carrier, Rear * Carrier, Tool * Carrier, Tool, Drawn * Carrier, Tool, Integral * Carrier, Toolbar * Cart, Commodity * Cart, Coulter * Cart, Dump * Cart, Grain * Cart, Seed * Charger, Battery * Chassis, Vehicle * Chipper, Shredder * Chopper * Chopper, Hay * Chopper, Rotary * Clod-Buster * Combine * Combine, Attachment * Combine, Belt Pickups & Pickup Platforms * Combine, Cab, Operator * Combine, Corn Head * Combine, Engine (Power Unit) * Combine, Platform (Cutting) * Combine, Platform (Flex Cutterbar/Rigid) * Combine, PTO * Combine, Row-Crop Head * Combine, Sprayer * Combine, Transport Frame (For Combine Header) * Combine, Windrow Spreader * Compactor * Component, Remanufactured * Compressor, Air * Conditioner, Field * Conditioner, Hay * Corn Head * Corrugator * Cotton Plow * Crane * Cuber, Hay * Cuber, Stationary * Culta-Carrier * Cultivator * Cultivator, Beet-Bean-Vegetable * Cultivator, Field * Cultivator, Listed Corn * Cultivator, Listed Crop * Cultivator, Planting Attachment * Cultivator, Row-Crop * Cummins Engine * Cutter, Corn * Cutter, Rotary * Cutter, Stalk * Cutting Platform * Deck * Defoliator, Beet * Digger, Posthole * Digger, Potato * Disc Mower * Disk * Disk Plow, Border * Ditcher * Drawbar, Cart * Drawbar, Harrow * Drill * Drill, Air * Drill, Grain * Drill, Grain (Attachment) * Drill, Grass Seed * Drill, Grassland * Drill, Rangeland * Drill, Soybean And Grain * Drill, Tru-Vee * Driver, Post * Driver, Crop * Driver, Grain * Duster * Ejector * Elevator * Engine * Engine, Combine * Engine, Cummins * Engine, Marine (Series 300 Diesel) * Engine, Marine (Series 400 Diesel) * Engine, Miscellaneous * Engine, Natural Gas * Engine, OEM (Series 200 Diesel) * Engine, OEM (Series 300 Diesel) * Engine, OEM (Series 400 Diesel) * Engine, OEM (Series 500 Diesel) * Engine, OEM (Series 700 Diesel) * Engine, OEM For Irrigation * Engine, OEM For Multi-Purpose And Stationary * Engine, Powertech * Engine, Powertech Plus * Excavator * Feeder, Bunk * Fertilizer Attachmnet * Fertilizer, Distributor * Finisher, Mulch * Finisher, Seedbed * Flail Shredder * Fluffer, Swath * Food Plot Seeder * Forklift * Front Loader * Frontier * Gang Bolt Dimensions * Generator * Genset * Grapple * Green System * Greenstar * Grill, Barbecue * Grill, Gas * Grinder, Knife * Grinder, Mixer * Grooming Mower * Grub Breaker * Hagie * Harrow, Disk * Harrow, Disk (Bush And Bog) * Harrow, Finishing * Harrow, Offset (Plowing) * Harrow, Roller * Harrow, Spike Tooth * Harrow, Spring Tooth (Drawn) * Harvester * Harvester Head * Harvester, Bean * Harvester, Beet * Harvester, Beet (Attachment) * Harvester, Cotton * Harvester, Ensilage And Forage * Harvester, Ensilage And Forage (Attachment) * Harvester, Ensilage And Forage (Engines) * Harvester, Ensilage And Forage (Pull-Type) * Harvester, Ensilage And Forage (Self-Propelled) * Harvester, Forage * Harvester, Potato * Hay Merger * Header Transport * Hi-Crop Implements * Hi-Cycle * Hitch * Hitch, 3-Point * Hitch, Grain Drill * Hitch, Minimum Tillage * Hitch, Multiple Planter * Hitch, Tandem (For Mowers And Hay Conditioners) * Hitch, Tandem (Moldboard Plow, Disk Tillers) * Hoe, Bed * Hoe, Power * Hoe, Rotary * Hoist, Bolster * Husker, Corn * Hydraulic Marker * Implement, Tillage * Incorporator, Herbicide * Integral Disk Harrow * Ivs * Jack, Lift * Kernel Processor * Land Leveler * Land Plane * Landshaper * Lifter, Beet * Lifter-Loader, Beet * Lister, Drawn * Lister, Integral * Lister, Middlebreaker (Integral) * Lister, Planting Attachment * Loader * Loader, Bale * Loader, Farm * Loader, Four-Wheel Drive * Loader, Skid-Steer * Loader, Skid-Steer, Attachment * Loader, Tractor-Mounted * Loader, Two-Wheel Drive * Material Collection System * Mill, Double-Geared * Mill, Hammer * Mill, Roller * Miscellaneous Products * Mixer, Feed * Monitor, Seed * Motor, Cam-Lobe * Mover, Stack * Mower * Mower Bar, Forage Harvester * Mower, Attachment * Mower, Conditioner * Mower, Dain * Mower, Flail * Mower, High Lift * Mower, Hydraulic Gang * Mower, Power * Mower, Reel-Mounted * Mower, Rotary * Mower, Sickle * Mower, Tractor-Mounted * Mulch Finisher * Mulch Master * Overseeder * Packer, Crowfoot * Packer, Rooller * Picker, Corn * Picker, Cotton * Pickup, Forage Harvester * Planter * Planter, Attachment * Planter, Cotton And Corn * Planter, Lister * Planter, Narrow * Planter, Potato * Planter, Unit * Platform * Platform (Cutting) * Plow * Plow, Cable * Plow, Chisel * Plow, Disk * Plow, Disk (Drawn) * Plow, Disk (Integral) * Plow, Disk (Semi-Integral) * Plow, Moldboard * Plow, Moldboard (Drawn) * Plow, Moldboard (In Furrow) * Plow, Moldboard (In-Furrow) * Plow, Moldboard (Integral) * Plow, Moldboard (On-Land) * Plow, Moldboard (Semi-Integral) * Plow, Moldboard (Two-Way Drawn) * Plow, Moldboard (Two-Way Integral) * Plow, Reversible Moldboard * Plow, Snow * Plows * Power Unit * Powr-Till * Product Identification Number Guide * Progrator * PTO * Pulverizer * Pump * Pump Drive * Pump, Chemical Transfer * Pump, Portable Centrifugal * Pump, Radial Piston * Pump, Tire * Rake * Rake, Bean * Rake, Hay * Rake, Sweep * Rate Drive * Reed Cart * Reed Loader * Ripper * Ripper, Disk * Ripper, Mulch * Ripper, Row Crop * Ripper, Toolbar * Rotary Tiller * Row Crop Cultivator * Row-Crop, Forage Harvester * Saw, Chain * Scarifier * Scoop * Scraper * Scraper, Farm * Scraper, Utility Box * Seeder, Air * Seeder, Central Metering * Seeder, Combine * Seeder, Endgate * Seeder, Landscape * Seeder, Air System * Shaver, Corn * Sheller, Corn * Sheller, Cylinder * Sheller, Hand * Sheller, Power (Spring) * Shredder, Feeder * Shredder, Flail * Sickle Bar * Silage Defacer * Single Unit Planter * Snapper, Corn * Snow Blower * Snow Blower (Tractor-Mounted) * Special Tools * Sprayer * Sprayer, 3-Point Hitch * Sprayer, Attachment * Sprayer, Highway * Sprayer, Hooded * Sprayer, Integral * Sprayer, Orchard And Grove * Sprayer, Paint * Sprayer, Pull-Type * Sprayer, Self-Propelled * Sprayer, Skid-Mounted * Spreader * Spreader, Fertilizer * Spreader, Fertilizer And Grain * Spreader, Fertilizer And Seed * Spreader, Manure * Spreader, Spin * Stacker * Stacker, Hay * Stripper, Bascket Attachment * Stripper, Cotton * Stripper, Trailer Air Attachments * Subsoiler * Support Wheel * Sweeper, Lawn * Tedder * Telescopic Handler * Thinner, Synchronous * Threshing Cylinder * Tiller, Disk * Tiller, Disk (Attachment) * Tiller, Mulch * Tiller, PTO * Tiller, Seeding * Tiller, Tractor-Mounted * Tool Bar * Tool, Cabinet * Tool, Seeding * Topper, Beet * Topsaver, Beet * Track * Tractor * Tractor Attachments * Tractor, Compact Utility * Tractor, Compact Utility, Attachment * Trailer * Trailer Cart * Transmission * Transporter, All Material (AMT) * Treader, Mulch * Unloader, Silo * Utility Trailer * Utility Vehicle * Utility Vehicle, Attachment * V-Ripper * V-Ripper (Integral) * Vacuum, Blower * Variable Speed * Wagon * Wagon, Auger * Wagon, Boxes * Wagon, Chuck * Wagon, Ensilage And Grain * Wagon, Forage * Wagon, Hi-Dump * Wagon, Stack * Washer, High-Pressure * Weather Enclosure And Sunshade * Weeder, Rod * Welder * Wheel, Lift Assist * Wheel, Reel Lift Assist (Toolbar) * Windrower * Windrower, Cab Operator * Windrower, Engine * Windrower, Platform * Wood Chipper (PTO) TURF AND UTILITY * 2-Cycle * 32cm * 36cm * 4 Cycle * 4-Cycle * 40cm * 43cm * 47cm * 52 * 52cm * 54cm * Aerator * Air Conditioning System * Alternator * AMT * Applicator * Attachment, 2-Bag Bagger, Tiller, Snow Thrower, Blade, Power Flow (Scotts Lawn Tractors) * Attachment, 2-Bag Bagger, Tiller, Snow Thrower, Blade, Power Flow, Cart, (Sabre Lawn Tractors) * Attachment, 2-Stage Snowblower, Front Blade, And Rotary Broom (1400 And 1500 Front Mowers) * Attachment, 36-In Lawn Roller * Attachment, 40-In Aerator Spreader, 40-In Plug Aerator, 40-In Thatcherator, 48-In Plug Aerator) * Attachment, 60-In Mower Deck (2520 Tractor And X495, X595, X-Series Lawn Tractors) * Attachment, Mid-Mount Rotary Mower, Mower Decks, And 3-Bag MCS (2210 And 4×10 Series Cuts) * Attachment, Mower Deck (120, 140, 300, 312, 314, 316, 317, 318, 322, 330, 332, 425, 445, 455 Lawn Tractors) * Attachment, Mower Deck (1400 And 1500 Series Front Mowers) * Attachment, Mower Deck (4000 Series Cuts) * Attachment, Mower Deck And Power Flow Blower Assembly (325, 335, 345, 355D Lawn Tractors) * Attachment, Mower Decks (F620, F680, F687 ZTrak Front Mowers) * Attachment, Mower Decks And 2 & 3 Bag PowerFlow Material Collection System Power Flow Blower Assembly (LX And GT Series Lawn Tractors) * Attachment, Mower Decks, Front Blade, Power Flow Blower Assembly (GX255) * Attachment, Mower Decks, Front Blade, Power Flow Blower Assembly (LX280) * Attachment, Mower Decks, Front Blade, Power Flow Blower Assembly (LX289) * Attachment, Power Flow Blower Assembly (LT, LX, STX, GT, And 400 Series Lawn Tractors) * Attachment, Snow Blower, Snow Thrower, Snow Blade, MCS (Scotts Lawn Tractors) * Attachment, Snowblower, Snow Blade, And MCS (Sabre Lawn Tractors) * Attachment, Tractor Trunk * Attachment, V-Flex 7-Iron Mower Deck (1400 And 1500 Series Front Mowers) * Attachments * Backhoe * Backhoe, Loader * Bagger * Bale Unroller * Baler * Battery * Bicycle * Blade * Blade, Snow * Blower, Golf Turf * Blower, Power * Bottom * Box Blade * Broom, Rotary * Brushcutter * Bucket * Bulldozer * Bunker * Cab * Cart, Dump * Cart, Utility * Charger, Battery * Chipper, Shredder * Chopper, Rotary * Clipper * Compactor * Component, Remanufactured * Compressor, Air * Consumer Product Accessories * Cotton Plow * Cultivator, Field * Cutter, Rotary * Deck * Digger, Posthole * Disc Mower * Disk * Ditcher * Drill, Grain * Driver, Post * Edger * Engine * Engine, OEM (Series 200 Diesel) * Engine, Powertech * Engine, Repower * Europro * Excavator * Eztrak * Fertilizer, Distributor * Field Vehicle * Finisher, Mulch * Food Plot Seeder * Forklift * Front Attachments * Front Loader * Frontier * Generator * Generator, Portable * Genset * Grapple * Green System * Grrensmower * Grill, Barbecue * Grill, Gas * Grooming Mower * Harrow, Disk * Harvester * Hay Merger * Header Transport * Heater, Space * Hitch, 3-Point * Implement, Tillage * Injection System * Land Leveler * Land Plane * Lawn Tractors * Loader * Loader Attachment * Loader, Bale * Loader, Farm * Loader, Four-Wheel drive * Loader, Skid-Steer * Loader, Skid-Steer, Attachment * Loader, Tractor-Mounted * Log Splitter * Material Collection System * Miscellaneous Products * Mower * Mower Deck * Mower, Attachment * Mower, Boom * Mower, Electric * Mower, Fairway * Mower, Flail * Mower, Front * Mower, Gang * Mower, Green * Mower, Hydraulic Gang * Mower, Professional Turf * Mower, Reel-Mounted * Mower, Riding * Mower, Rotary * Mower, Sickle * Mower, Tractor-Mounted * Mower, Turf System * Mower, Walk-Behind * Mower, Walk-Behind (Commercial) * Mower, Wide Area * Mulch Finisher * Mulcing * Overseeder * Packer, Roller * Planter * Planter, Unit * Plow * Plow, Disk * Plow, Moldboard (Integral) * Power Unit * Product Identification Number Guide * Profi * Progator * Pulverizer * Pump * Pump, Portable Centifugal * Quik-Trak * Rake * Rake, Bunker And Field * Rake, Hay * Riding Mowers * Rotary Tiller * Sabo * Sabre * Saw, Chain * Saw, Multi-Purpose * Scarifier * Scotts * Scraper * Scraper, Utility Box * Seeder, Landscape * Shredder * Shredder, Leaf * Sickle Bar * Silage Defacer * Snow Blower * Snow Blower (Tractor-Mounted) * Snow Blower (Walk-Behind) * Snow Thrower * Snowmobile * Spin Steer * Sprayer * Sprayer, Paint * Spreader * Spreader, Fertilizer * Spreader, Manure * Sweeper, Lawn * Tedder * Telescopic Handler * Thatcher * Tiller, Disk (Attachment) * Tiller, PTO * Tiller, Tractor-Mounted * Tiller, Walk-Behind * Tool Bar * Tool, Cabinet * Tractor * Tractor Attachments * Tractor, Compact Utility * Tractor, Compact Utility, Attachment * Tractor, Lawn * Tractor, Lawn And Garden * Trailer * Trailer Cart * Trailer, Snowmobile * Trailer, Utility * Transporter, All Material (AMT) * Trimmer * Trimmer, Cutter * Trimmer, Edger * Trimmer, Edger (Electric) * Trimmer, Edger (Gas) * Trimmer, Edger (Hedge) * Trimmer, Cutter * Utility Triler * Utility Vehicle * Utility Vehicle, Attachment * Vacuum, Blower * Wagon * Walk-Behind Mower * Washer, High-Pressure * Weather Enclosure And Sunshade * Welder * Wood Chipper (PTO) * Ztrak CONSTRUCTION AND FORESTRY * AMT * Arches, Log * Attachments * Axle * Backhoe * Backhoe, Loader * Bar, Tool * Bicycle * Blade * Blower, Power * Boom * Box Blade * Broom, Rotary * Brushcutter * Bucket * Bulldozer * Bundler * Cab * Charger, Battery * Compactor * Component, Remanufactures * Components * Compressor, Air * Crane * Crawler * Crawler Loader * Deeretrax * Delimber * Dozer, Crawler * Engine * Engine, Marine (Series 300 Diesel) * Engine, Marine (Series 400 Diesel) * Engine, Natural Gas * Engine, OEM (Series 200 Diesel) * Engine, OEM (Series 300 Diesel) * Engine, OEM (Series 400 Diesel) * Engine, OEM (Series 500 Diesel) * Engine, OEM (Series 700 Diesel) * Engine, OEM For Multi-Purpose And Stationary * Engine, Powertech * Engine, Powertech Plus * Excavator * Excavator – EX-5 * Excavator Logger * Feller Buncher * Feller Buncher, Track * Felling Head * Forestry Swing Machine * Forklift * Forwarder * Frontier * Genset * Grader, Motor * Grapple * Grill, Barbecue * Grill, Gas * Harvester * Harvester Head * Heater, Space * Land Leveler * Land Plane * Loader * Loader, Crawler * Loader, Four-Wheel Drive * Loader, Front * Loader, Knuckleboom * Loader, Log * Loader, Rear * Loader, Skid-Steer * Loader, Skid-Steer, Attachment * Loader, Two-Wheel Drive * Logger * Logger Components * Master Trax * Miscellaneous Products * Mower * Packer, Roller * Plow, Cable * Plow, Moldboard (Integral) * Power Unit * Product Identification Number Guide * Progrator * Pump Drive * Pump, Portable Centrifugal * Rake * Rake, Brush (Integral) * Rake, Landscape * Ripper * Ripper, Hydraulic * Saw, Chian * Scarifier * Scarifier, Scraper * Scraper * Scraper, Elevating * Scraper, Utility Box * Seeder, Landscape * Shear Head * Sideboom * Skidder, Log * Slash Bundler * Slasher * Tractor * Tractor, Compact Utility, Attachment * Trailer * Transmission * Transporter, All Material (AMT) * Tree Harvester * Truck, Articulated Dump * Undercarriage * Utility Vehicle * Utility Vehicle, Attachment * Vacuum, Blower * Variable Speed * Weather Enclosure And Sunshade * Welder * Winch POWER SYSTEMS * Axle * Engine * Engine, Marine (Series 300 Diesel) * Engine, Marine (Series 400 Diesel) * Engine, Natural Gas * Engine, OEM (Series 200 Diesel) * Engine, OEM (Series 300 Diesel) * Engine, OEM (Series 400 Diesel) * Engine, OEM (Series 500 Diesel) * Engine, OEM (Series 700 Diesel) * Engine, Powertech * Engine, Powertech Plus * Genset * Power Unit * Pump Drive * Transmission HITACHI * Excavator – EX * Excavator – EX-7 * Excavator – EX-7B * Excavator – EX-2 * Excavator – EX-3 * Excavator – EX-5 * Excavator – EX-6 * Excavator – UH * Excavator – Zaxis * Forester – EX-5 * Forester – Zaxis * Truck

#John Deere Service Advisor EDL#John Deere Service Advisor#John Deere Diagnostic Kit#John Deere Diagnostics Kit

0 notes

Photo

Earth moving or earthworks is a major application of heavy equipment. Earth moving involves digging, grading, and moving earth. Excavating, landscaping, moving large amounts of earth, and laying of the foundation are examples of earth moving tasks.Typical earthworks include road construction, railway beds, causeways, dams, levees, canals, and berms.What material is excavator pin?Excavator pins are usually made of a AISI 4130 or 4140 steel. The AISI 4000 series of steels are chromium molybdenum steels. Chromium improves corrosion resistance and its ability to be hardened while molybdenum increases strength and hardenability, tooThe pins and bushings are made from 4140 material and heat treated to a 65 Rockwell hardness for extended wear life.It consists of a tractor, a loader, and a backhoe. Their mobility makes them suitable for earth-moving activities in urban areas. They are used for excavation works, digging trenches, placing pipes, filling trenches, lifting materials, etc. Backhoe loaders are one of the most popular earthmovingSteel. The most common material used in fasteners, this material is predominantly iron mixed with carbon. It offers the highest strength compared to other metals and elements, but is the least corrosion resistant. Also known as Carbon Steel.They are manufactured using high-quality alloy steel and can be manufactured up to any dimensional standard that you require. They come with a hardness of 60-64 HRC as per DIN 2269Wire composed of carbon steel or stainless steel is run through a punch and die to create steel pins. These simple metal pieces can be made using the cold heading (or cold forming) technique, which does not require heat to change a metal's shape.

0 notes

Text

Basic building construction equipment and its uses

Basic building construction equipment and its uses

Construction requires several tools and equipment to achieve the desired result. For building construction to be achievable, the engineers need to buy building construction equipment required for the building project.

Every construction tool and equipment is necessary to achieve good results in the whole project. Engineers rely on survey equipment, earth-moving equipment, heavy machinery, and other tools to make their jobs more comfortable and efficient.

Survey Equipment

Surveying equipment is usually used for measuring the earth's surface to determine the property boundaries in the preparation of a construction site. They serve as proper assistants in the delivery of proper construction work. Surveying equipment are namely: chains and tapes, compass, Transistors, poles, tripods and mounts, safety gears, magnetic locators and, prisms reflectors.

Earth-moving Equipment

These are equipment responsible for construction operations that involve earth-work such as Digging (Foundation), Land scraping, etc. Earth-moving equipment can also be referred to as heavy trucks, heavy vehicles and, heavy machines.

Below is the list of Equipment that facilitates construction progress.

· Excavator

· Drag line Excavator

· Backhoe

· Bulldozer

· Grader

· Wheel Tractor Scraper

· Trencher

· Loader

Excavator

The excavator is responsible for all excavation process on a site, although it can also be used for lifting heavy and hard properties on the site. Demolition, river dredging and, cutting down of trees are done by the excavator. Excavators are identified by their long arm, with a digging bucket attached to the end.

Drag-line Excavator

The drag-line excavators are generally used for larger depth excavations such as underwater excavations, sediment removal in water bodies and, construction ports. A drag line excavator is identified by its long length boom and digging bucket that is suspended from the top of the boom using a cable.

Backhoe

The backhoe is digging equipment. The digging arrangement is done on the backside of the equipment, with the loading bucket at the front. They can also be used for small demolition, breaking up concrete or asphalt, dig trenches and, both loading and unloading of materials.

Bulldozer

The bulldozer is one of the commonly used equipment in construction. It is used for rough grading on a construction site. The bulldozer is recognized through its sharp tooth (blade), ripper (located at the back of the equipment) and, plate.

Grader

The Grader is majorly used for road construction, it helps in leveling the soil surface. It has a horizontal blade between the rear and front wheels.

Wheel Tractor Scraper

The wheel tractor is the equipment needed to flatten the surface of the soil by scraping.

Trencher

The Trencher is needed to evacuate trenches in the soil. The trenches are needed to lay the pipeline, cable, or for drainage purposes.

Trenching machines are available in chain trenchers and wheeled trenchers.

They all contain a fixed long arm with a digging chain.

Chain trenchers are used when the ground is too hard for an excavator to cut through it. With the adjustable boom, chain trenchers are used for cutting wider trenches.

Wheeled trenchers have a metal wheel that has a digging tooth around it.

Wheeled trenchers are more suitable to excavate hard soil layers. Because of its wheel, this equipment can dig trenches at variable depths.

Loader

A loader is equipment used to remove material from the construction site into dump boxes or trucks.

Building construction tools for construction works such as concrete, brick masonry, leveling, woodwork, floor works, slab works, bricklaying, plastering, etc. are provided on site by the civil engineer.

1 note

·

View note

Text

What Types Of Equipment Are Used In Civil Construction?

what Types of equipment are used in civil construction?

The job of a civil engineer is to build different structures like bridges, highways, and waterways.

To do this, they use specialized construction equipment, tools, and instruments to guide them.

Civil engineering relies on survey equipment, earth moving equipment, heavy machinery, and other tools to make their jobs more comfortable and efficient.

Without the heavy equipment they use, the structures they build and design wouldn’t be safe.

Civil engineers also use geographic information systems and various drafting tools to map out and plot specific locations.

Civil construction also uses software to help them design the structures that need to be built at that location.

This is in addition to the different types of survey equipment civil engineers use to measure land and water areas, which may include a sophisticated GPS system designed for these types of applications.

In the article below, we will take a closer look at the heavy machinery used in civil construction projects.

Table of Contents

Excavator

Dragline Excavator

Backhoe

Bulldozer

Grader

Wheel Tractor Scraper

Trencher

Loader

Tower Crane

Paver

Stevens

Excavator

Excavators are essential construction equipment widely used in the civil construction industry.

Their general purpose is excavation, but other than that, they are also used for many purposes like heavy lifting, demolition, river dredging, cutting of trees, etc.

Excavators contain a long arm, with a digging bucket attached at the end.

The operator maneuvers the heavy equipment, from the cab of the excavator, throughout the construction site

The cabin arrangement can be rotated up to 360 degrees, giving the operator the ability to work multiple areas from one location.

Excavators are available in both wheeled and tracked forms of vehicles.

-back to top

Dragline Excavator

A dragline excavator is another piece of heavy equipment integral to the construction industry.

It is generally used for larger depth excavations.

A dragline excavator consists of a long length boom and a digging bucket that is suspended from the top of the boom using a cable.

Dragline excavators can be used for the construction of ports, for excavations underwater, or sediment removal in water bodies.

-back to top

Backhoe

A backhoe is another widely used piece of earth-moving equipment used in construction that can fulfill multiple purposes.

The name itself implies that the digging arrangement is on the backside of the equipment, while the loading bucket is on the front.

Backhoe loaders are one of the most versatile pieces of construction equipment. They have a wide variety of uses across the construction industry. They can be used as:

earth moving equipment

small demolitions at the construction site

digging holes

excavation

landscaping

breaking up of concrete, or asphalt.

dig trenches

loading and unloading materials

The bucket can be also replaced with other pieces of equipment like an auger, grappler, or hammer.

The backhoe is a useful piece of heavy equipment in the construction industry. With its many uses it's an integral piece of equipment to use on construction projects.

-back to top

Bulldozer

Bulldozers are a commonly used piece of equipment used in construction.

Thanks to their wide tracks the bulldozer are able to maneuver through difficult terrain no matter the construction site, and despite it being heavy equipment, this track helps to disperse the bulldozer's weight across a wide footprint, allowing it to work on different types of sites that may be muddy or sandy.

The bulldozer is primarily used as earth moving equipment. The blade on the front of the bulldozer is used to push or remove the soil, sand, and debris on construction sites.

This plate is lowered and raised using hydraulic pistons.

Bulldozers can also be equipped with an attachment called a ripper. A ripper is located on the back of the bulldozer and is used to break up surface rock, pavement, asphalt, or concrete.

-back to top

Grader

Graders, or motor graders, are a type of heavy equipment used for the construction of roads.

They are mainly used to level the soil surface.

Graders contain a horizontal blade between the front and rear wheels, and this blade is lowered into the ground while working.

The operating cabin is on the top of the rear axle arrangement.

Motor Graders are earth-moving equipment and can also be used to remove snow or dirt from the roads, flatten the surface of the soil before laying asphalt, or to remove the unnecessary soil layer from the ground.

While a bulldozer is used for rough grading on construction projects, the grader is primarily used to finish grade. Thanks to the adjustable blade on the grader, it can be adjusted to achieve a high level of precision.

-back to top

Wheel Tractor Scraper

A wheel tractor scrapers is a piece of earth-moving equipment needed to flatten the surface of the soil through scraping.

The front part contains a wheeled tractor vehicle, and the rear section includes a scraping arrangement including a horizontal front blade, conveyor belt, and a soil collecting hopper.

When the front blade is lowered onto the ground, and the vehicle is moved, the blade starts digging the soil above the blade level.

The soil excavated is collected in hopper through a conveyor belt.

When the hopper is full, the rear part is raised from the ground, and the hopper is unloaded at a soil dump yard.

The wheel tractor scraper is very efficient earth moving equipment when the cut and dump areas are close to each other.

-back to top

Trencher

The heavy equipment trencher is used in construction to excavate trenches in the soil.

The trenches are needed to lay pipeline, cable, or for drainage purposes.

Trenching machines are available in chain trenchers and wheeled trenchers.

They all contain a fixed long arm with a digging chain.

Chain trenchers are used when the ground is too hard for an excavator to cut through it. With the adjustable boom, chain trenchers are used for cutting wider trenches.

Wheeled trenchers have a metal wheel that has a digging tooth around it.

Wheeled trenchers are more suitable to excavate hard soil layers. Because of its wheel, this equipment is able to dig trenches at variable depths.

Either type of trencher is available in tracked as well as wheeled vehicle forms.

-back to top

Loader

Loaders are a piece of equipment used on the construction site to load the material onto dump boxes, dump trucks, etc.

Loaders are used in the construction industry to help remove materials from the construction site. Some of the materials that a loader moves may be excavated soil, demolition waste, raw materials, etc.

A loader contains a large-sized bucket at its front with a short moving arm.

The loader may be either tracked or wheeled.

Wheeled loaders are seen in construction sites, while tracked or crawled loaders are needed in places where wheeled vehicles cannot reach.

-back to top

Tower Crane

Tower cranes are fixed cranes needed for hoisting purposes in the construction of tall structures.

Heavy materials like concrete blocks, steel trusses, and frames can be easily lifted to the required height.

They consist of a mast, which is the vertical supporting tower, a jib that is the operating arm of the crane, a counter jib that is the other arm that carries a counterweight on the rear side of the crane, and an operator cabin where the crane can be operated.

-back to top

Paver

A paver or asphalt paver is a pavement laying equipment that is needed in road construction.

A paver contains a feeding bucket where the asphalt is continuously loaded by the dump truck.

The paver distributes the asphalt evenly on the road surface with slight compaction.

A roller is required after laying the asphalt layer for perfect compaction.

-back to top

STEVENS

These are just a few of the pieces of equipment utilized by civil engineers in the construction industry.

As your Single Source Solution, STEVENS has the engineers and the tools needed to handle your Civil Construction Projects.

They also have a team to build and complete your project on schedule, on budget, and up to the specific local codes.

To see how STEVENS can help with your Construction Project, click on the link below.

Check Out Our Most Recent Articles:

New Trends In The Construction Industry

How Technology Is Increasing Productivity In The Construction Industry

What Is Civil Construction?

0 notes