#automatic carton case erector

Explore tagged Tumblr posts

Link

Nichrome’s case erectors are reliable and designed to specifically address the usual problems in automatic erection of cases owing to the quality of the corrugated board and the imperfections in its forming process.

0 notes

Text

How Nichrome’s End of Line Machines benefits businesses with efficiency

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

Importance of Case Erectors in Modern Packaging Operations

In today's fast-paced industrial world, efficient packaging processes are key to ensuring the timely delivery of goods and maintaining competitive production costs. One critical piece of equipment that has revolutionized packaging lines is case erector. By automating the assembly of cardboard boxes, case erectors streamline operations, increase productivity, and reduce labor costs. But what exactly are case erectors, and why are they essential for businesses that deal with high-volume packaging?

What is a Case Erector?

A case erector is a machine that automates the process of forming, folding, and sealing corrugated boxes or cartons, turning flat, pre-cut cardboard into rigid, ready-to-fill cases. The machine grabs a flat box from a stack, shapes it into a 3D form, and then seals the bottom flaps using adhesive tape or glue. After this, the newly formed boxes are transferred down the packaging line, ready to be filled with products.

Case erectors come in different sizes and configurations, depending on the production speed and the size of the boxes. They can be semi-automatic, where some manual intervention is required, or fully automatic, capable of continuous high-speed operation with minimal human input.

Key Benefits of Using Case Erectors

Increased Efficiency: Automating the box-forming process allows packaging lines to operate faster and more smoothly. Case erectors can handle hundreds of boxes per hour, significantly improving throughput and ensuring that products are packed and shipped without delay.

Reduced Labor Costs: Manually assembling boxes is a time-consuming task, especially in industries that require large volumes. By implementing a case erector, companies can reduce the need for manual labor, freeing workers to focus on more value-added tasks. This reduction in labor can lead to substantial cost savings in the long run.

Consistency and Precision: One of the main advantages of case erectors is their ability to create perfectly formed boxes every time. Human error can lead to poorly folded or sealed boxes, which can compromise product safety during shipping. Case erectors ensure consistent and precise folding, improving the quality and durability of the packaging.

Versatility: Modern case erectors are highly customizable and can be adjusted to form different box sizes and styles. This versatility is particularly beneficial for businesses that package various products with diverse packaging requirements.

Improved Safety: Case erectors reduce the need for repetitive manual tasks that can lead to strain or injury over time. Automation reduces the physical demands on workers, creating a safer workplace environment.

Applications of Case Erectors

Case erectors are widely used across industries, including:

Food and Beverage: Companies in this sector need to package products quickly and securely to ensure freshness and prevent contamination. palletizer machine help meet these high standards while keeping up with the demands of large-scale production.

Consumer Goods: From electronics to personal care items, case erectors enable the rapid packaging of a wide variety of products for retail distribution.

Pharmaceuticals: In this industry, precise packaging is critical for product integrity. Case erectors ensure that boxes are assembled and sealed to exact specifications, minimizing the risk of damage or tampering.

E-commerce: With the growing volume of online orders, e-commerce businesses rely on case erectors to handle high-demand packaging efficiently, ensuring that orders are fulfilled on time.

Factors to Consider When Choosing a Case Erector

When selecting a case erector for your business, several factors should be taken into account:

Production Speed: Evaluate the machine’s speed to ensure it aligns with your production line’s capacity.

Box Size Range: Ensure the erector can handle the box sizes required for your products.

Footprint: Depending on your workspace, the size of the machine may be a deciding factor.

Maintenance: Look for a machine that is easy to maintain and has a track record of reliability.

Integration: Consider how easily the case erector can be integrated into your existing packaging line.

Conclusion

Case erectors are invaluable in today's automated packaging environments, providing speed, accuracy, and cost savings. As businesses continue to seek ways to optimize their operations, investing in a reliable case erector can offer a significant return on investment by enhancing the efficiency and consistency of packaging processes. Whether you’re in food production, consumer goods, pharmaceuticals, or e-commerce, a case erector can be a vital tool in improving your packaging line's performance.

0 notes

Text

How can a case erector benefit you?

There are different types of case and carton erectors available on the market. We separate them into two categories:

Semi-automatic case erectors: They require some manual intervention, typically in loading flat boxes into the system. Once loaded, the case erector automates the process of erecting and sealing the boxes.

Often, semi-automatic carton erectors can be a good first step for box automation. They can sometimes be used as a stand-alone machine, to help with easy packing, or paired with a case sealer.

Automatic case erectors: Fully automated, this type of carton erector performs the entire box assembly process without the need for manual input. Automated carton erectors often offer case sealers that can use glue or tape. They are highly efficient, reducing labor requirements and increasing overall productivity. This type of erector is good for higher-demand environments.

Speed and Efficiency: Automatic carton erectors drastically reduce the time and effort required for box assembly. Some models offer a 233% productivity increase compared to manual processes. Case erecting machines erect and seal boxes at a much faster rate than manual methods. This significantly boosts overall productivity.

Precision and Consistency: Manual processes come with the risk of human error. Case erectors ensure precise and consistent results when assembling cardboard boxes. This leads to improved product protection during transit and enhances the overall quality of your packaging. Plus, if you are palletizing your product, case erectors can provide square cases every time, which means they are easier to stack as well.

Environmental Impact: The precision and consistency associated with a case erector can also reduce your environmental impact. Erectors eliminate waste that human error can produce, resulting in less waste to recycle or dispose of.

Enhanced Workplace Safety: Many manual processes, such as box assembly, packing and sealing, can lead to repetitive strain injuries and staff fatigue. By automating the box erecting process, case erectors contribute to a safer working environment by minimizing physical strain on your team.

Improved Brand Image: Consistently well-packaged products contribute to a positive brand image. Using a case erector ensures that your boxes are neatly and professionally assembled – reflecting your brand image. This can be particularly important in the online retail sector, where packaging is often the first physical touchpoint with a business!

Cost Savings: When you think about investing in a case erector (or any packaging machinery) cost savings might not be the first thing that comes to mind! However, while the initial investment in a case erector may seem substantial, the long-term cost savings are significant.

Introducing a case erector into your packaging line is an intelligent move that can pay dividends. Opting for automation will help you move towards efficiency, cost savings, and improved packing quality.

#stretch film pricing#resin pricing#quick pak inc#stretch film#quickpakinc#free pallet wrapper#coreless film#carton erector#eastey case erector#pricing news#free machine

0 notes

Text

An Automatic Case Erector Machine PR-30T is used to erect carton which have been shaped automatically and use tape as sealing materials to seal the bottom cover of carton.

A stack of corrugated blanks are knocked down and placed into the machine. The blanks are pulled out of the machine one-by-one and formed into cases, the newly formed cases are sealed at the bottom with tape or glue.

#case erector#case former machine#box packaging#packaging solutions#packaging machine#industrial packaging

0 notes

Video

youtube

Automatic high speed box erector carton erector case erector machine Cas...

0 notes

Text

Streamlining Your Business with Packaging Machines Suppliers in the UAE

In today's fast-paced business world, efficiency and productivity are key to staying ahead of the competition. One area where many businesses can streamline their operations is in their packaging process. From food and beverage companies to pharmaceutical manufacturers, investing in advanced packaging machinery can revolutionize the way products are packaged and shipped. That's where Ideas Machinery, a leading packaging machines supplier in the UAE, comes in. With a wide range of state-of-the-art packaging solutions, Ideas Machinery is dedicated to helping businesses optimize their packaging operations, reduce waste, and increase output. In this blog post, we will explore the benefits of partnering with Ideas Machinery and how their innovative machines can transform your business's packaging process, saving you time, money, and resources.

Ideas Machinery, one of the leading packaging machines suppliers in the UAE, offers a wide range of innovative solutions to streamline your business operations. With their cutting-edge technology and top-notch quality, they provide businesses with reliable and efficient packaging machines to enhance productivity and reduce costs. Their extensive product portfolio includes flow wrappers, case erectors, carton sealers, and labeling machines, among others. By investing in these state-of-the-art machines, businesses can optimize their packaging processes and ensure consistent product quality. Moreover, Ideas Machinery also offers comprehensive after-sales support and maintenance services to cater to the specific needs of their clients. With their expertise and commitment to customer satisfaction, they are dedicated to helping businesses achieve operational excellence in the competitive market. So, whether you are a small-scale business or a large manufacturing plant, Ideas Machinery provides tailored solutions that meet your unique requirements and deliver tangible results. Take advantage of their expertise and technological advancements and streamline your business with Ideas Machinery's packaging machines for a competitive edge in the market.

Ideas Machinery, one of the leading packaging machines suppliers in the UAE, offers a comprehensive range of innovative solutions designed to streamline your business operations. With an emphasis on efficiency and quality, Ideas Machinery aims to revolutionize the way you package your products. By utilizing cutting-edge technology and adopting intelligent automation systems, we enable businesses to optimize their production processes while minimizing costs. Our state-of-the-art packaging machines are designed to handle a wide variety of materials, ensuring that your products are packaged securely and professionally. Whether you're in the food and beverage industry, pharmaceuticals, or any other sector requiring efficient packaging solutions, Ideas Machinery has got you covered. We understand that every business has unique requirements, which is why our experienced team works closely with you to tailor a solution that best fits your needs. So, streamline your business with Ideas Machinery and experience the difference in efficiency and productivity.

In conclusion, Ideas Machinery offers state-of-the-art packaging machines that are versatile and reliable, ensuring your products are securely packaged to meet professional standards. Whether you operate in the food and beverage industry, pharmaceuticals, or any other sector in need of efficient packaging solutions, our team is committed to providing you with tailored solutions that cater to your unique business requirements. With Ideas Machinery, you can streamline your operations and experience increased efficiency and productivity. Contact us today to discover how our innovative machinery can revolutionize your packaging process.

For more information about Semi Automatic Capping Machine visit Ideas Machinery.

0 notes

Text

Revolutionizing Packaging and Logistics: The Power of Industrial Automation Equipment

In today's fast-paced world of packaging and logistics, meeting customer demands while maintaining a competitive edge is paramount. Fortunately, industrial automation equipment has emerged as a transformative force, introducing advanced technologies that streamline processes, boost productivity, and ensure precise handling of goods. In this comprehensive blog, we will delve into the profound impact of industrial automation equipment in packaging and logistics. Our focus will be on key equipment solutions that drive efficiency, optimize operations, and pave the way for future growth and success.

Section 1: Automated Packaging Equipment

1.1 Robotic Packaging Systems:

Robotic pick-and-place systems have revolutionized the packaging industry by offering unparalleled speed, precision, and flexibility. These robots can quickly and accurately pick products from a conveyor and place them into packaging containers.

Collaborative robots, or cobots, work alongside human operators, enhancing safety and enabling collaborative packaging tasks. They are designed to handle delicate or irregularly shaped items with care.

Automated case erectors and carton sealers streamline the packaging process by efficiently erecting and sealing boxes, eliminating the need for manual labor and reducing the risk of errors.

Robotic palletizing and depalletizing systems automate the loading and unloading of products onto pallets, optimizing efficiency and reducing physical strain on workers.

1.2 Automated Filling and Labeling Machines:

Automatic filling machines are employed in a wide range of industries, including food and beverages, pharmaceuticals, and personal care. These machines accurately fill containers with liquids, powders, and granules, ensuring consistent product quality and reducing waste.

High-speed labeling systems are capable of applying labels to products at remarkable speeds, enhancing efficiency and accuracy. These systems often integrate vision systems for label verification and quality control, ensuring labels are placed correctly and legibly.

Automatic capping and sealing machines ensure secure and uniform closure of containers, preventing leakage or contamination. These machines guarantee consistent and tamper-proof packaging, promoting product integrity.

1.3 Conveyor Systems and Sortation Equipment:

Conveyor systems play a vital role in packaging and logistics, facilitating the smooth flow of goods throughout the process. Belt conveyors, roller conveyors, and modular conveyor systems are widely used to transport products between various stages, reducing manual handling and minimizing bottlenecks.

Automated sorting and diverting systems utilize advanced sensors and algorithms to sort and redirect packages based on predefined criteria such as destination, weight, or size. These systems optimize the packaging and distribution process, ensuring accurate and timely delivery.

Conveyor belt scales accurately weigh and measure products during the packaging process, enabling precise inventory control and ensuring compliance with regulatory requirements.

The integration of barcode scanning and Radio Frequency Identification (RFID) technologies with conveyor systems enhances tracking and traceability, improving inventory management and supply chain visibility.

Section 2: Automated Warehouse and Distribution Solutions

2.1 Automated Storage and Retrieval Systems (AS/RS):

High-density AS/RS solutions maximize space utilization by vertically storing and retrieving products using automated cranes or robotic systems. These systems optimize storage capacity, reduce manual labor, and facilitate efficient inventory management.

Automated crane systems perform vertical and horizontal movements within warehouses, efficiently retrieving and placing items. These systems increase operational speed, accuracy, and overall productivity.

AS/RS with integrated inventory management and order picking systems provide seamless control over inventory levels, order fulfillment, and stock rotation. The integration of automation equipment streamlines processes, minimizes errors, and enhances overall efficiency.

In the context of cold chain logistics, AS/RS solutions offer temperature-controlled storage, ensuring the integrity and safety of perishable goods.

2.2 Autonomous Mobile Robots (AMRs):

AMRs have emerged as a game-changer in warehouse and distribution operations. These intelligent robots navigate autonomously within the facility, performing various tasks such as goods transportation, order picking, and inventory replenishment.

Collaborative AMRs work hand in hand with human operators, creating a harmonious work environment that leverages the strengths of both humans and robots. They assist in order picking, minimizing physical strain and improving overall productivity.

The integration of AMRs with warehouse management systems (WMS) enables real-time communication and coordination, ensuring optimized task allocation and resource utilization.

AMR fleet management and coordination systems enhance operational efficiency by intelligently managing and coordinating the movement of multiple robots, minimizing congestion and optimizing workflow.

2.3 Automated Guided Vehicles (AGVs):

AGVs have become indispensable in automating material transport within warehouses and distribution centers. These vehicles are equipped with advanced navigation systems, such as laser guidance, magnetic guidance, or vision-based systems, enabling them to navigate and transport goods autonomously.

AGVs seamlessly integrate with conveyor systems and picking stations, facilitating the efficient movement of products throughout the facility.

AGVs are also utilized for loading and unloading goods from trucks or containers, reducing manual labor and enhancing operational efficiency.

Section 3: Data Integration and Optimization

3.1 Warehouse Management Systems (WMS):

WMS software plays a critical role in managing warehouse operations, including inventory control, order management, and resource allocation. WMS provides real-time visibility into inventory levels, locations, and movements, facilitating effective decision-making and efficient resource utilization.

The integration of WMS with automation equipment enables seamless operations and real-time synchronization of inventory data. This integration optimizes order fulfillment, minimizes errors, and enhances customer satisfaction.

Advanced analytics and reporting capabilities offered by WMS provide valuable insights into warehouse performance, enabling data-driven decision-making and continuous process improvement.

3.2 Enterprise Resource Planning (ERP) Integration:

Integrating automation equipment data with ERP systems streamlines end-to-end processes, from order processing to invoicing and financial management. The synchronization of data ensures accurate and timely information exchange, reducing manual errors and enhancing operational efficiency.

Inventory synchronization between automation equipment and ERP systems enables real-time visibility into stock levels, ensuring effective demand planning and preventing stockouts or excess inventory.

The integration of automation equipment data with ERP systems enhances supply chain visibility, enabling stakeholders to track and manage inventory, monitor production, and make informed decisions based on real-time data.

3.3 Predictive Analytics and Machine Learning:

Predictive maintenance techniques leverage data from automation equipment to identify potential equipment failures before they occur. By analyzing sensor data and performance metrics, predictive analytics algorithms can anticipate maintenance requirements, allowing for proactive interventions that minimize downtime and maximize operational efficiency.

Machine learning algorithms are employed to analyze historical data and identify patterns, enabling accurate demand forecasting and optimization. By understanding demand trends, businesses can optimize inventory levels, production schedules, and distribution strategies, ultimately reducing costs and improving customer satisfaction.

Real-time analytics capabilities enable route optimization and delivery time estimation, empowering logistics operations to respond dynamically to changing conditions, minimize transit times, and enhance customer experience.

Continuous process improvement, driven by data-driven insights obtained from automation equipment, fosters innovation and operational excellence. By analyzing operational data, identifying bottlenecks, and implementing targeted improvements, businesses can optimize processes, reduce waste, and achieve higher levels of efficiency. The advent of industrial automation equipment has revolutionized packaging and logistics operations, bringing unprecedented levels of efficiency, accuracy, and customer satisfaction. From robotic packaging systems to automated warehouse solutions, the integration of advanced technologies has redefined industry standards and opened up new avenues for growth. By embracing industrial automation equipment and harnessing its capabilities, businesses can streamline packaging processes, optimize warehouse operations, and ensure timely and accurate delivery of goods. In an increasingly competitive market, leveraging the power of industrial automation equipment is essential for staying ahead of the curve and meeting the evolving demands of customers and the industry at large.

#industrial automation#marine spare parts#industrial equipment#marine automation#industrial spare parts#industrialpower supply#industrial automation equipment#industrial and marine automation equipment#auto2mation

0 notes

Text

Machines that pack bottles and cases quickly and automatically

Bundling is a fundamental part of any assembling cycle, and it assumes a basic part in the show and security of items. One of the most difficult parts of bundling is the last stage, which includes pressing and fixing the items in the holder. This is where container case packer machines come in, giving a mechanized and effective method for pressing items into cases or containers for delivery or capacity.

At AFASystemsinc.com, we offer an extensive variety of container case packer machines intended to meet the different requirements of our clients. Our machines are intended to deal with different sorts of containers, including glass, plastic, and metal jugs of various sizes and shapes. Our machines are additionally equipped for pressing numerous items without a moment's delay, fundamentally further developing your bundling interaction's proficiency and result.

Advantages of Our Container Case Packer Machines

Expanded Proficiency: With our jug case packer machines, you can smooth out your bundling cycle, diminishing difficult work, and further developing efficiency. Our machines are intended to work at high velocities, empowering you to pack more items in a more limited time span.

Adaptability: Our machines can deal with different sorts of containers and items, making them ideal for use in various businesses. We can modify our machines to meet your particular necessities, guaranteeing that they can deal with your items with accuracy and care.

Consistency: Our machines give steady outcomes, guaranteeing that your items are pressed and fixed accurately without fail. This assists with limiting blunders and diminishes the gamble of harm during travel.

Further developed Security: Our machines are intended to satisfy well-being guidelines, giving a protected workplace to your representatives. They likewise highlight security interlocks, which keep the machine from working when entryways or gatekeepers are open, lessening the gamble of mishaps.

Sorts of Jug Case Packer Machines

Mechanical Case Packers: These machines utilize automated arms to pick and place bottles into cases or containers, further developing exactness and speed.

Drop Case Packers: These machines use gravity to drop Bottle Case Packing, causing them ideal for delicate items that require delicate taking care of.

Pick and Spot Case Packers: These machines use vacuum or mechanical grippers to pick and place bottles into cases or containers, giving exact control and adaptability.

At AFASystemsinc.com, we offer a multitude of sorts of jug case packer machines, and we can modify them to meet your particular necessities.

End

Bottle case packer machines are fundamental in the bundling business, assisting with smoothing out the bundling system and further developing productivity. At AFASystemsinc.com, we offer an extensive variety of jug case packer machines, intended to meet the different requirements of our clients. Our machines are flexible, effective, and safe, giving predictable outcomes and further developing your bundling cycle's general presentation. Reach us today to become familiar with our machines and how they can help your business.

Source of url :-

For more info :-

Carton Formers

carton forming equipment

case erector bottom sealer

horizontal cartoner

packaging automation systems

0 notes

Text

Streamline Your Business with Qualis Engineers- Top-Quality Packaging Solutions provider in Pune

When it comes to business operations, packaging plays a crucial role in ensuring that products are delivered to customers in a timely and efficient manner. However, finding the right packaging solutions can be a challenge, especially if you’re looking for top-quality packaging systems in Pune. That’s where Qualis Engineer comes in! We offer a wide range of packaging systems, including protective packaging, pallet wrapping machines, pneumatic strapping tools, and more.

In this guide, we will explore our range of packaging systems and explain how they can help you streamline your business operations. Table of Content: ⦁ Packaging Solutions ⦁ Protective Packaging Solutions. ⦁ Corrugated Sheet Shredding Machine ⦁ Strapping tools and Pneumatic Strapping Tools ⦁ Pallet Wrapping Machines ⦁ End of Line Packaging ⦁ Packaging Automation ⦁ FAQs About Packaging Systems

Packaging Solutions for automobile and manufacturing sector in Pune

At our packaging solutions provider company at Pune, we offer a range of packaging solutions to meet your business needs. Here are some of the most popular packaging solutions we offer:

Protective Packaging Solutions Protective packaging is essential for businesses that deal with fragile or delicate products. We at a packaging company in Pune, we offer a range of protective packaging solutions, including:

⦁ Cardboard shredding ⦁ Foam packaging ⦁ Air pillows ⦁ Void fillers

Corrugated Sheet Shredding Machine in Pune

Corrugated sheet shredding machines are ideal for businesses that need to dispose of large quantities of cardboard waste. At our packaging company in Pune, we offer a range of corrugated sheet shredding machines, including:

⦁ Single-shaft shredders-for low volume ⦁ Double shaft shredders- Heavy duty for large volume of shredding

Strapping Tools ,Pneumatic Strapping Tools in Pune

Strapping Tools, Pneumatic strapping tools are ideal for businesses that need to secure packages quickly and efficiently. At our packaging company in Pune, we offer a range of manual operation and battery-operated strapping tool, and pneumatic strapping tools, including

⦁ Battery-powered strapping tools ⦁ Manual strapping tools ⦁ Combination strapping tools

The below Chart gives you guidelines about how to select the right-hand strapping tool for your application.

Pallet Wrapping Machines in Pune

Pallet-wrapping machines are ideal for wrap large quantities of products and boxes quickly and efficiently. At our packaging company in Pune, we manufacture and offer a range of pallet wrapping machines, including:

⦁ Semi-automatic pallet wrappers ⦁ Fully automatic pallet wrappers ⦁ Ring wrapping machines ⦁ Orbital stretch wrapping machines ⦁ Small box stretch wrap machines

End-of-Line Packaging

End-of-line packaging refers to the final stage of the packaging process, where products are prepared for shipment. At our packaging company in Pune, we offer a range of end-of-line packaging solutions, including:

⦁ Carton erectors ⦁ Case sealers ⦁ Online strapping machines ⦁ Online pallet wrapping machines ⦁ Pick and place ⦁ Palletizers

Packaging Automation machines in Pune

Packaging automation can help businesses streamline their packaging processes, reduce labor costs, and improve efficiency. At our packaging company in Pune, we offer a range of packaging automation solutions, including:

⦁ Automated case sealers ⦁ Robotic palletizers ⦁ Conveyor systems ⦁ Pick and place machines ⦁ Vacuum lifters

FAQs About Packaging Systems in Pune

Here are some frequently asked questions about packaging systems in Pune: Q: How do I choose the right packaging system for my business? A: To choose the right packaging system for your business, you need to consider several factors such as your product size & weight ,Box size and weight ,packaging volume, product dimensions, packaging materials, and production requirements. It’s important to assess your business needs and goals to determine which packaging system will work best for your business.

Q: What are the benefits of packaging automation in Pune? A: The benefits of packaging automation in Pune include increased productivity, reduced labor costs, improved efficiency, and reduced risk of product damage or loss. Packaging automation can also help businesses meet production deadlines and ensure consistency in product quality.

Q: What kind of packaging solutions does your packaging company in Pune offer? A: We work to reduce pain points of packaging people in the ecosystem like-pain points of the packaging managers,supervisors and packaging operators. Our packaging company in Pune offers a wide range of packaging solutions, including customized packaging solutions including protective packaging, pallet wrapping machines, pneumatic strapping tools, corrugated sheet shredding machines, end-of-line packaging solutions, export packaging machines, and packaging automation solutions.

Q: What is protective packaging, and why is it important for businesses? A: Protective packaging refers to materials used to protect products during shipping and handling. It’s important for businesses that deal with fragile or delicate products to use protective packaging to prevent product damage or loss during transit. Nowadays plastic use becomes less and about to replace by paper packaging options. In protective packaging we recommence craft paper packaging solutions.

Q: What is a pallet wrapping machine, and how can it benefit my business? A: A pallet wrapping machine is a machine used to wrap products on a pallet quickly and efficiently. It can benefit your business by reducing labor costs, increasing productivity, and ensuring consistent wrapping quality. Advantages of the pallet wrap machine over manual wrapping is high stretchability of the film ,less consumption of the consumables and high quality of the holding of the box over pallet .This will ensure the safe movement of the box or pallet till reaching the destination .

Q: What are pneumatic strapping tools, and when should I use them? A: Pneumatic strapping tools are used to secure packages with strapping quickly and efficiently. They are ideal for businesses that need to secure packages for shipping or handling. Pneumatic strapping tools are especially useful for businesses that require high-volume strapping applications.

Q: What is a corrugated sheet shredding machine, and how can it benefit my business? A: A corrugated sheet shredding machine is used to dispose of large quantities of cardboard waste. Every company received the cardboard boxes from their sub venders and companies .Companies make it scrap after removing the raw material in it. With the shredding machine you can shred the waste cardboard into the soft cushioning material and use again to fill the gaps between the product and boxes and cushioning and filler material. By using this option you will reduce your protective material cost to zero and use the recycle material which is environment friendly, It can benefit your business by reducing waste disposal costs and providing a more sustainable solution for disposing of cardboard waste.

Q: What is end-of-line packaging, and why is it important for businesses? A: End-of-line packaging refers to the final stage of the packaging process, where products are prepared for shipment. It’s important for businesses to have efficient end-of-line packaging solutions to ensure that products are prepared for shipment quickly and accurately. This system covers input of the product from the quality test and ends up in the final dispatch/ stacking pallet into rack.

We hope these FAQs have answered any questions you may have had about our packaging systems in Pune. If you have any additional questions or need further information, please don’t hesitate to contact us.

1 note

·

View note

Link

Nichrome’s case erectors are reliable and designed to specifically address the usual problems in automatic erection of cases owing to the quality of the corrugated board and the imperfections in its forming process.

0 notes

Text

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

Benefits of a Case Erector

Speed and Efficiency: Automatic carton erectors drastically reduce the time and effort required for box assembly. Some models offer a 233% productivity increase compared to manual processes. Case erecting machines erect and seal boxes at a much faster rate than manual methods. This significantly boosts overall productivity.

Precision and Consistency: Manual processes come with the risk of human error. Case erectors ensure precise and consistent results when assembling cardboard boxes. This leads to improved product protection during transit and enhances the overall quality of your packaging. Plus, if you are palletizing your product, case erectors can provide square cases every time, which means they are easier to stack as well.

Environmental Impact: The precision and consistency associated with a case erector can also reduce your environmental impact. Erectors eliminate waste that human error can produce, resulting in less waste to recycle or dispose of.

In addition, square cases every time can help manage your package cubage minimizing CO2 emissions during transport. Another eco-friendly benefit is reducing damage in transit. This is because it cuts out the potential emissions (and cost) associated with reverse logistics.

Enhanced Workplace Safety: Many manual processes, such as box assembly, packing and sealing, can lead to repetitive strain injuries and staff fatigue. By automating the box erecting process, case erectors contribute to a safer working environment by minimizing physical strain on your team.

Improved Brand Image: Consistently well-packaged products contribute to a positive brand image. Using a case erector ensures that your boxes are neatly and professionally assembled – reflecting your brand image. This can be particularly important in the online retail sector, where packaging is often the first physical touchpoint with a business!

Cost Savings: When you think about investing in a case erector (or any packaging machinery) cost savings might not be the first thing that comes to mind! However, while the initial investment in a case erector may seem substantial, the long-term cost savings are significant.

Due to the efficiencies offered by a case erector, you can reduce labor costs, including the need for temporary labor during peak times. Plus, you can often reduce the amount of packing material you are using, which results in further savings.

So, if you need help with a case erector (or any packaging machinery), please speak with one of our experts today at 813 242 6995 or sales@@quickpakinc.com.

#pricing news#stretch film pricing#quickpakinc#resin pricing#stretch film#coreless film#quick pak inc#free pallet wrapper#youtube#free machine#case sealing#eastey case erector. eastey tapers

0 notes

Text

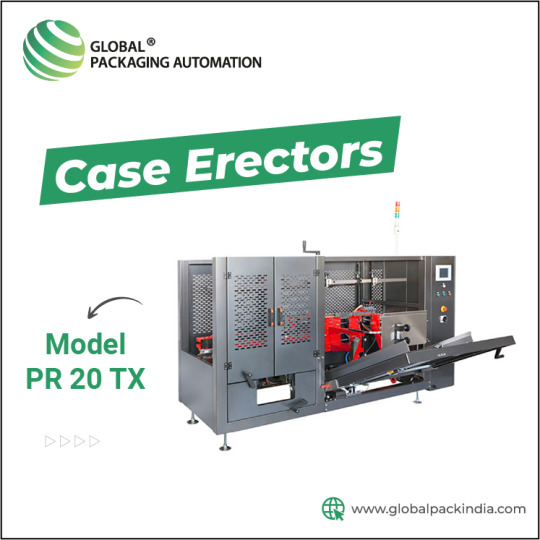

The PR 20TX is an automatic case erector machine. The machine is used for forming boxes from their collapsed corrugated form.

This machine is built for heavy usage and can achieve speeds of up to 12 boxes/min. The machine can also be customized as per your requirements of carton dimensions or tape size.

0 notes

Photo

Infinity Automated Solutions Pvt. Ltd. Is a leading manufacturer of End of line solutions, secondary packaging machines & Systems, automatic weighing machine, cartoning machines, check weigher machine, Case erectors and all kind of conveying systems. We serve with world class solutions for Food, Pharma, spices, tea, dairy industries for all kind of process, packaging and conveying challenges. We have state of art manufacturing facility at Pune. We have a Team of 80 highly talented and skilled people to serve our customers with there heart and souls

1 note

·

View note

Link

Automatic horizontal carton erecting forming machine horizontal type case box carton erector machine

Model: GR-H20

Maximum working speed:20-30ctn/min

Carton Length:200-510mm

Carton Width:240-400mm

Carton Height:120-400mm

Output height:750mm

Motor Drive:1.2KW

Put Tape:Manual

Tape specification:48/60/75mm(alternative)

frame Color:White Color

Tape cutter:High speed steel

Pneumatic:5kg/cm3

Storage quantity:100 carton

Control Type:PLC

Lack carton Alarm system:Have

Operation panel:Touch screen

Machine Weight:800KG

Machine Size:L2375×W1526×H1740mm

Language:According to custom

#Automatic box erecting machine#automatic carton erecting forming machine#box carton erector machine#automatic carton forming machine#box erecting forming machine

0 notes