#automatic Fly ash brick making machine

Text

Top Brick and Paver Machine Manufacturers in Morbi: Revolutionizing Construction with Advanced Technology

In the bustling hub of Morbi, Gujarat, a revolution in construction technology is taking place. Companies like Lomango Machinery are at the forefront, providing state-of-the-art machines that are transforming the way we build. From brick machines to paver block machines, Lomango Machinery stands out as a leading manufacturer, offering a range of products that cater to various construction needs. In this blog, we'll delve into the details of their offerings, highlighting the key features and benefits of each.

Bricks Machine Manufacturer in Morbi

Lomango Machinery is a prominent bricks machine manufacturer in Morbi. Their machines are designed to produce high-quality bricks that meet industry standards. The advanced technology used in these machines ensures efficient production processes, reducing manual labor and increasing output.

Key Features:

High Efficiency: The machines are designed for high output, ensuring a steady supply of bricks for large construction projects.

Durability: Made from robust materials, these machines are built to last, providing long-term value for money.

User-Friendly: The intuitive design makes them easy to operate, even for those with minimal technical expertise.

Brick Machine Manufacturer in Gujarat

As a brick machine manufacturer in Gujarat, Lomango Machinery caters to a wide market, supplying machines to various regions across the state. Their reputation for quality and reliability has made them a preferred choice among builders and contractors.

Advantages:

Local Support: Being based in Gujarat, they offer excellent customer support and after-sales service to their clients.

Cost-Effective: Their machines are competitively priced, offering excellent value for money.

Fly Ash Brick Making Machine Manufacturer

The fly ash brick making machines from Lomango Machinery are a game-changer in the industry. These machines utilize fly ash, a by-product of coal combustion, making them an eco-friendly option for brick production.

Key Benefits:

Environmental Impact: Using fly ash reduces the need for clay, preserving natural resources and reducing environmental degradation.

Strength and Durability: Fly ash bricks are known for their superior strength and durability compared to traditional clay bricks.

Automatic Fly Ash Brick Making Machine

For those seeking to automate their brick production, Lomango Machinery offers automatic fly ash brick making machines. These machines streamline the production process, reducing the need for manual intervention and increasing efficiency.

Features:

Automation: Fully automated systems ensure consistent quality and high production rates.

Precision: Advanced technology ensures precise brick dimensions and uniformity.

Fly Ash Brick Making Machine Fully Automatic

The fully automatic fly ash brick making machines from Lomango Machinery represent the pinnacle of modern brick manufacturing technology. These machines are designed for large-scale production, making them ideal for big construction projects.

Advantages:

Labor Savings: Automation reduces the need for manual labor, cutting down on labor costs.

Consistency: Ensures consistent quality and uniformity in every batch of bricks produced.

Fly Ash Brick Making Machine Supplier

As a trusted fly ash brick making machine supplier, Lomango Machinery ensures that their clients receive top-quality machines that meet their specific needs. Their commitment to customer satisfaction sets them apart in the industry.

Services:

Customization: They offer customized solutions to meet the unique requirements of their clients.

After-Sales Support: Comprehensive after-sales support ensures that any issues are promptly addressed.

Paver Block Machine Manufacturer in Morbi

In addition to brick machines, Lomango Machinery is also a leading paver block machine manufacturer in Morbi. Their machines are designed to produce high-quality paver blocks that are widely used in landscaping and paving projects.

Features:

Versatility: Capable of producing various shapes and sizes of paver blocks.

Durability: Built to withstand the rigors of continuous use, ensuring long-term reliability.

Paver Making Machine for Sale

Lomango Machinery offers a range of paver making machines for sale, catering to different budgetary and production requirements. Their machines are known for their efficiency and reliability.

Benefits:

Cost-Effective: Competitive pricing makes their machines accessible to a wide range of customers.

High Output: Designed for high production rates, ensuring timely completion of projects.

Paver Block Making Machine Manufacturers

As leading paver block making machine manufacturers, Lomango Machinery's products are trusted by contractors and builders across the region. Their machines are designed to deliver high performance and reliability.

Advantages:

Innovative Technology: Incorporating the latest technology to ensure superior performance.

Customer Satisfaction: A strong focus on customer satisfaction ensures long-term relationships with their clients.

Automatic Paver Block Making Machine

For those looking to streamline their paver block production, Lomango Machinery offers automatic paver block making machines. These machines automate the production process, reducing manual labor and increasing efficiency.

Features:

Automation: Fully automated systems ensure high efficiency and consistent quality.

Ease of Use: Designed for easy operation and maintenance.

In conclusion, Lomango Machinery stands out as a leader in the construction machinery industry. Their range of brick and paver block machines is designed to meet the diverse needs of their clients, offering advanced technology, reliability, and excellent value for money. Whether you're looking for a bricks machine manufacturer in Morbi or a paver block machine manufacturer, Lomango Machinery has you covered. Visit their website at Lomango Machinery to learn more about their products and services.

#Bricks Machine Manufacturer Morbi#brick machine manufacturer in gujarat#fly ash brick making machine manufacturer#automatic fly ash brick making machine#fly ash brick making machine fully automatic#fly ash brick making machine supplier#paver block machine manufacturer morbi#paver making machine for sale#paver block making machine manufacturers#automatic paver block making machine

0 notes

Video

youtube

Automatic Fly Ash Brick Making Machine in Gujarat – Brick Machinery

Automatic Fly Ash Brick & Paver & Concrete Block Making Machine. Our expertise in hydraulics and manufacturing systems and automated machines enables us to innovate and develop world-class products.

#automatic Fly ash brick making machine#Concrete block making machine#Paver Block Machine#Hydraulic Brick Making Machine Exporters#Fly Ash Brick Machine in India

0 notes

Text

The Ultimate Startup Guide for Fly Ash Brick Manufacturing

🔥 Wanna be your own boss? Start by mastering the art of Fly Ash Brick Manufacturing! 🧱💼 Let's unlock your entrepreneurial potential! 💥 #SmallBusinessTips #flyashbrickmachine #manufacturingbusiness #flyashbricksmakingmachine

With India’s construction industry adopting sustainable practices, the popularity of eco-friendly fly ash bricks is rising. Previously, clay bricks dominated the market; however, cement bricks have gradually become favoured, and now fly ash bricks are gaining traction. Fly ash is a coal combustion byproduct, and India has it in abundance, making it ideal for brick production. Launching a fly ash…

View On WordPress

#automatic fly ash bricks machine#best business ideas#business ideas#fly ash brick machine#fly ash brick making#fly ash bricks#fly ash bricks business#fly ash bricks business plan#fly ash bricks machine#fly ash bricks making business#fly ash bricks making machine#fly ash bricks manufacturing process#how to start a fly ash brick manufacturing business#how to start fly ash brick business#manufacturing business ideas 2024#manufacturing business ideas in india#mini manufacturing business ideas#new business ideas#new business ideas 2024#small business ideas

0 notes

Text

Brick vs Block: Which Construction Material Is Right for You?

Introduction

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

Best Quality Automatic Batching System Manufacturers Rexnear

Rexnear stands out as a prominent Automatic Batching System Manufacturers with state-of-the-art, specially designed for brick manufacturing plants. These cutting-edge systems are designed to streamline the batching process with advanced automation, optimizing production efficiency. Rexnear's automatic batching systems are equipped with the latest technology, ensuring precise and consistent measurement of materials, resulting in reduced waste and increased productivity.

Call Us: +91-8750287752,9990342299

Email id: [email protected]

Address: Plot No. 358 B, Udyog Kendra – 1, Ecotech – 3, Greater Noida - Uttar Pradesh (India.) - 201306

URL: https://www.flyashbrickmakingmachines.in/automatic-batching-system.html

#Fly Ash Brick Making Machine Manufacturers#Hydraulic Brick Machine Manufacturers#Tile Press Paver Block Machine Manufacturers#Automatic Batching System Manufacturers

0 notes

Text

Check Valve Manufacturer in Gujarat

We have established ourselves as a renowned manufacturer and supplier of Hydraulic Power Pack. Power Pack Hydraulic Cylinder Manufacturer in Ahmedabad, Gujarat. Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

SnPC Machines BMM410 with a production more than 25K bricks in just 01 hour.

Brick making machine: BMM410

instagram

BMM410 is a fully automatic red clay brick making machine by Snpc companies which has greatly revolutionize brick production due to its high speed and less raw material requirement. It can produce 24000 brick/hr with a reduction of 45%cost and natural resources like water, it requires only one-third of water for brick making as required during manual production. This machines requires a fuel consumption of 16-18 liters/hour for its working. Raw material needed for its working can be mud, clay or mixture of clay and fly ash. This machine is widely used by itta Bhatta, brick making factories or brick kiln and clay brick manufacturers around the globe. Different types of brick produced by this machines are clay brick, fly ash brick etc. Different types of brick this machine can produce are red bricks, clay bricks, fly ash brick. This machine give kiln owner to produce brick independently anywhere anytime. This machine consumer 16-18 liters of fuel for its working. Other mobile brick making machines are BMM-160, BMM-310, SBM-180 with different production capacities. Consumers can order from any state, Country or can visit us for their own satisfaction. Thankyou for visiting us.

8826423668

#Brick making machine#clay bricks#fast brick production#Team SnpC#SnPC Machines#top quality bricks#BMM410#BMM310#SBM180#construction machinery#building material suppliers#Instagram

7 notes

·

View notes

Text

Efficient Fly Ash Brick Making Machines for Sustainable Construction

In today's rapidly evolving construction industry, sustainability has become more than just a buzzword – it's a necessity. As we strive to build a greener future, innovative technologies are paving the way for eco-friendly construction practices. At the forefront of this revolution are fly ash brick making machines, offering a sustainable alternative to traditional clay bricks.

BTM Product is proud to be a leading provider of cutting-edge fly ash brick making machine empowering builders and manufacturers to create high-quality, environmentally friendly construction materials. Our state-of-the-art equipment combines efficiency, durability, and sustainability to meet the growing demands of the modern construction sector.

The Rise of Fly Ash Bricks in Sustainable Construction

Fly ash, a byproduct of coal combustion in thermal power plants, has emerged as a valuable resource in the production of eco-friendly building materials. By utilizing this industrial waste, we can significantly reduce the environmental impact of brick production while creating strong, durable bricks suitable for various construction applications.

Fly ash bricks offer numerous advantages over traditional clay bricks:

1. Reduced carbon footprint: The production process requires less energy and emits fewer greenhouse gases.

2. Conservation of natural resources: Fly ash bricks minimize the need for clay excavation, preserving valuable topsoil.

3. Improved strength and durability: These bricks often surpass the compressive strength of clay bricks.

4. Enhanced thermal insulation: Fly ash bricks provide better insulation, leading to energy savings in buildings.

5. Water resistance: They absorb less water, making them ideal for areas prone to moisture-related issues.

As the demand for sustainable construction materials continues to grow, fly ash brick making machines have become indispensable tools for forward-thinking manufacturers and construction companies.

Pioneering Fly Ash Brick Making Technology

At BTM Product, we understand the unique challenges and opportunities presented by fly ash brick production. Our team of experienced engineers and technicians has developed a range of fly ash brick making machines that combine innovation, efficiency, and reliability to meet the diverse needs of our clients.

Our fly ash brick making machine lineup includes:

1. Fully Automatic Systems: These high-capacity machines are designed for large-scale production, capable of producing thousands of bricks per day with minimal human intervention.

2. Semi-Automatic Units: Ideal for medium-scale operations, these machines offer a balance between automation and manual control, allowing for flexibility in production.

3. Mobile Brick Making Plants: Perfect for on-site brick production, these portable units reduce transportation costs and carbon emissions associated with brick delivery.

Each fly ash brick making machine in our portfolio is built to exacting standards, ensuring consistent quality, optimal performance, and long-term reliability.

The BTM Product Advantage

When you choose a fly ash brick making machine from BTM Product, you're investing in more than just equipment – you're partnering with a company committed to your success and environmental stewardship. Here's what sets us apart:

1. Cutting-edge Technology: Our machines incorporate the latest advancements in brick making technology, ensuring maximum efficiency and product quality.

2. Customization Options: We understand that every operation is unique. That's why we offer customizable solutions tailored to your specific production requirements.

3. Comprehensive Support: From installation and training to ongoing maintenance and troubleshooting, our expert team is always ready to assist you.

4. Energy Efficiency: Our fly ash brick making machines are designed to minimize energy consumption, reducing both operational costs and environmental impact.

5. Quality Assurance: Rigorous quality control measures ensure that every brick produced meets or exceeds industry standards.

6. Scalability: As your business grows, our machines can be easily upgraded or integrated into larger production lines.

Our Other Machines

interlocking tiles making machine

paver block making machine

Revolutionizing Brick Production: The BTM Product Process

Our fly ash brick making machines employ a sophisticated process to transform raw materials into high-quality, sustainable bricks:

1. Material Preparation: Fly ash, sand, lime, and other additives are precisely measured and mixed to create the optimal brick composition.

2. Moisture Control: Advanced sensors ensure the perfect moisture content for consistent brick quality.

3. Molding and Pressing: The mixture is fed into molds and compressed under high pressure to form dense, uniform bricks.

4. Curing: Freshly molded bricks are transferred to curing areas where they develop their strength and durability.

5. Quality Inspection: Each batch undergoes rigorous testing to ensure compliance with industry standards and client specifications.

This streamlined process results in fly ash bricks that are not only environmentally friendly but also superior in quality and performance.

Empowering Sustainable Construction Worldwide

BTM Product's fly ash brick making machines are making a significant impact on sustainable construction practices around the globe. From bustling urban centers to remote rural areas, our equipment is enabling builders to create stronger, greener structures while reducing their environmental footprint.

Case studies from our clients demonstrate the transformative power of our technology:

- A housing development in India reduced its carbon emissions by 40% by switching to fly ash bricks produced on-site using our mobile brick making plant.

- A commercial builder in Australia achieved LEED certification for a major project, thanks in part to the use of fly ash bricks made with our fully automatic system.

- A small-scale manufacturer in Africa expanded its production capacity by 300% after investing in our semi-automatic fly ash brick making machine.

These success stories underscore the versatility and effectiveness of our equipment in diverse settings and applications.

The Future of Sustainable Construction

As we look to the future, the role of fly ash brick making machines in sustainable construction is set to grow even further. Ongoing research and development efforts are focused on:

1. Enhancing brick strength and durability through advanced material formulations.

2. Improving energy efficiency in the production process.

3. Incorporating recycled materials beyond fly ash to further reduce environmental impact.

4. Developing smart manufacturing systems for optimized production and quality control.

BTM Product remains at the forefront of these innovations, continuously refining our fly ash brick making machines to meet the evolving needs of the construction industry and our planet.

Investing in a Greener Tomorrow

Choosing a fly ash brick making machine from BTM Product is more than a business decision – it's an investment in a sustainable future. By embracing this technology, you're not only positioning your company for success in an increasingly eco-conscious market but also contributing to global efforts to reduce carbon emissions and conserve natural resources.

Our commitment to sustainability extends beyond our products. BTM Product adheres to strict environmental standards in our manufacturing processes and actively supports research into new, even more sustainable construction materials and methods.

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

Conclusion

The construction industry stands at a crossroads, with the choices we make today shaping the world we'll inhabit tomorrow. Fly ash brick making machines represent a significant step towards a more sustainable, resilient built environment.

BTM Product is proud to be a leader in this green revolution, providing innovative, efficient, and reliable fly ash brick making machines that empower businesses to thrive while minimizing their environmental impact. By choosing our technology, you're not just acquiring equipment – you're joining a movement dedicated to transforming the construction industry for the better.

As we continue to push the boundaries of sustainable construction, we invite you to partner with us in building a greener, stronger future. Contact BTM Product today to learn more about our fly ash brick making machines and how they can benefit your business and our planet.

Together, we can lay the foundation for a more sustainable world, one eco-friendly brick at a time.

0 notes

Text

Automatic Brick Making Machine in Tamil Nadu

Company Overview:

Robexo Industries is a Manufacturer, and Supplier of Automatic Brick Making Machine in Tamil Nadu, India.

Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India.

An automatic brick making machine produces bricks of various shapes and sizes with minimal human intervention.Using hydraulic pressure or vibration, these machines compress raw materials such as clay, fly ash, sand, and cement into high-quality bricks, ensuring consistent quality and strength.

Process:

Mixing: We mix raw materials in a specific proportion.

Tempering: We temper the mixture to achieve the right consistency.

Molding: We press the mixture into molds to form bricks.

Pressing: The bricks are pressed to remove excess water and air.

Curing: The bricks are cured in a controlled environment to achieve strength.

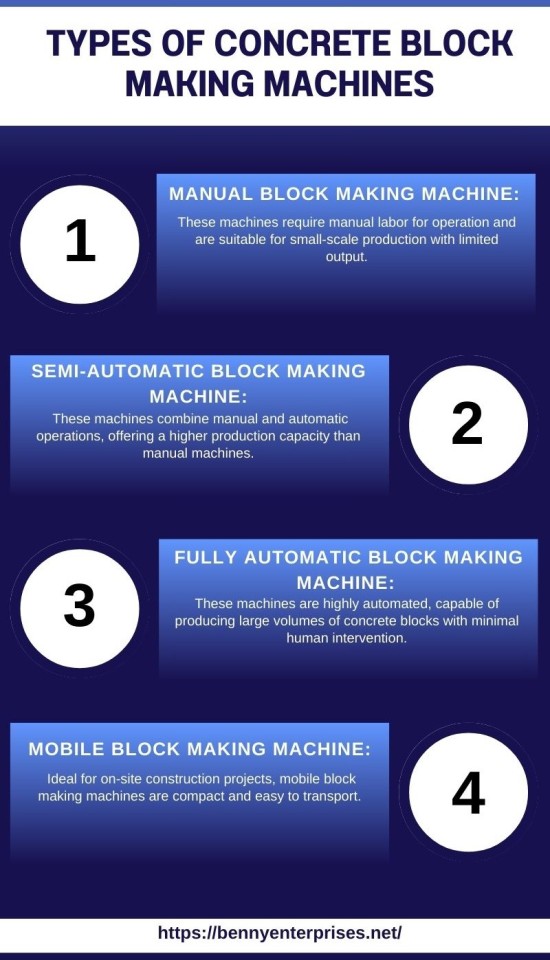

Types of Automatic Brick Making Machines:

Fully Automatic Brick Making Machine: Operates with minimal human control, performing all processes automatically, from mixing materials to shaping and curing the bricks.

Hydraulic Brick Making Machine: Uses hydraulic pressure to mold bricks, offering greater strength and durability.

Vibration Brick Making Machine: Utilizes vibration technology to compact the raw material into bricks, ensuring uniform density and shape.

Robexo Industries is a Manufacturer, and Supplier of Automatic Brick Making Machine in Tamil Nadu,

India Including Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore,

Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai,

Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam,

Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli,

Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar,

Salem, Udhagamandalam.

For more information and inquiries, feel free to contact us.

Read the full article

#Ahmedabad#AutomaticBrickMakingMachine#AutomaticBrickMakingMachineinIndia#AutomaticBrickMakingMachineinTamilNadu#Exporter#ExporterofAutomaticBrickMakingMachine#India#Manufacturer#ManufacturerofAutomaticBrickMakingMachine#ManufacturerofAutomaticBrickMakingMachineinAhmedabad#SupplierofAutomaticBrickMakingMachine#SupplierofAutomaticBrickMakingMachineinTamilNadu#TamilNadu

0 notes

Text

Automatic Block Making Machine: A Comprehensive Guide

Introduction

The construction industry is continuously evolving, with innovations designed to enhance productivity, efficiency, and sustainability. Among these innovations, automatic block making machines have gained significant attention for their ability to produce a variety of building materials, including hollow and solid blocks, pavers, kerbstones, and fly ash bricks. These machines offer ideal and economical solutions for initial start-ups, enabling entrepreneurs to enter the construction materials market with a relatively low investment while ensuring high-quality output. This article delves into the workings, benefits, and types of automatic block making machines, with a focus on paver block machine, cement bricks machines, and cement bricks making machines.

Understanding Automatic Block Making Machines

Automatic block making machines are advanced machinery designed to automate the process of producing construction blocks. Block machines use a combination of raw materials such as cement, sand, gravel, fly ash, and other aggregates to create blocks of various shapes and sizes. The automation aspect significantly reduces the need for manual labor, thereby increasing production efficiency and consistency in the quality of blocks produced.

Key Components and Functionality

An automatic block making machine typically comprises the following key components:

Batching System: This system accurately measures and mixes the raw materials according to specified proportions.

Conveyor Belt: Transports the mixed materials to the block forming machine.

Block Forming Unit: Uses molds to shape the blocks. The unit applies high pressure and vibration to ensure the blocks are compact and durable.

Control System: A computerized system that controls the entire operation, from batching to the final block formation, ensuring precision and consistency.

Curing System: Ensures that the blocks are cured properly to attain the desired strength and durability.

Advantages of Automatic Block Making Machines

High Efficiency and Productivity: Automation reduces manual labor, allowing for higher production rates.

Consistency and Quality: Automated processes ensure uniformity in the size and strength of blocks, meeting stringent quality standards.

Cost-Effective: Reduces labor costs and minimizes material wastage.

Versatility: Capable of producing various types of blocks, including hollow and solid blocks, pavers, kerbstones, and fly ash bricks.

Eco-Friendly: Many machines can utilize waste materials such as fly ash, contributing to environmental sustainability.

Paver Block Machines

Paver block machines are a specific type of automatic block making machine designed to produce high-quality pavers used in driveways, walkways, and patios. Paver block making machines are equipped with specialized molds to create pavers in different shapes, sizes, and patterns.

Features of Paver Block Machines

Precision Molding: Ensures accurate dimensions and smooth finishes.

High Pressure and Vibration: Compacts the materials to produce durable and strong pavers.

Customization: Offers a variety of mold options to create different designs and textures.

Efficient Curing: Advanced curing systems ensure the pavers attain the required strength.

Applications

Paver blocks produced by these machines are widely used in:

Residential driveways and walkways

Commercial and public sidewalks

Landscaping projects

Industrial flooring

Cement Bricks Machines

Cement bricks machines are designed to produce cement bricks, which are commonly used in building construction. These machines automate the mixing, molding, and curing processes to produce high-quality concrete bricks machine efficiently.

Features of Cement Bricks Machines

Automatic Mixing: Ensures the raw materials are mixed in the right proportions.

High-Pressure Molding: Produces bricks with uniform density and strength.

Versatile Molds: Capable of producing different sizes and types of bricks.

Efficient Production: High output rates suitable for large-scale production.

Benefits

Durability: Cement bricks are known for their strength and long-lasting properties.

Thermal Insulation: Provides better thermal insulation compared to traditional clay bricks.

Eco-Friendly: Utilizes industrial waste products such as fly ash, reducing environmental impact.

Applications

Cement bricks are extensively used in:

Residential building construction

Commercial building projects

Industrial constructions

Paving and flooring

Types of Cement Brick Machines

Manual Cement Brick Machines: Suitable for small-scale operations, these machines require manual intervention for mixing and molding.

Semi-Automatic Cement Brick Machines: Partially automate the process, offering a balance between manual and automated operations.

Fully Automatic Cement Brick Machines: Completely automate the production process, ensuring high efficiency and output.

Conclusion

Automatic block making machines represent a significant advancement in the construction industry, offering efficient and cost-effective solutions for producing a variety of building materials. Whether for producing pavers, cement bricks, or other types of blocks, concrete block making machine provide the necessary automation to ensure high-quality and consistent output. For initial start-ups, investing in such machinery can be a strategic move, offering a competitive edge in the construction materials market. As technology continues to evolve, block machine manufacturers will likely become even more efficient and versatile, further revolutionizing the way we produce and utilize building materials.

youtube

0 notes

Text

Automatic Hydraulic Brick Press Machine

Automatic hydraulic brick press machine is a kind of equipment specialized in producing bricks, which is controlled by hydraulic system and can realize fully automatic operation. Full-automatic and semi automatic hydraulic brick press machine usually consists of feeding system, pressure mold system, hydraulic system, control system and other parts.

The working principle of the automatic hydraulic brick press machine is to feed the mixed raw materials of bricks into the press mold system through the feeding system, and then use the hydraulic system to pressurize the raw materials and press them into the shape of bricks. The control system can set the pressing pressure, time and other parameters to ensure that the quality and specifications of the bricks meet the requirements. With automatic control system, the hydraulic press brick making machine is superior to manual brick making machine.

The advantages of fully automatic hydraulic brick press machine include high production efficiency, good quality of bricks, simple operation and high degree of automation. Due to the hydraulic system control, high pressure pressing of bricks can be realized to improve the denseness and strength of bricks. In addition, the fully automated operation can reduce manual labor, improve production efficiency and reduce production costs.

Fully automatic hydraulic brick press is suitable for producing bricks of various specifications, including solid bricks, hollow bricks, interlocking bricks, fly ash bricks, porous bricks and so on. It is widely used in construction projects, road projects, landscaping and other fields, providing a reliable supply of bricks for various projects.

In a word, the automatic hydraulic brick press machine is an efficient, energy-saving and environmentally friendly brick production equipment with wide application prospects and market demand.

This resource is from http://www.haomeibatchplant.com/news/automatic-hydraulic-brick-press-machine.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

#Bricks Machine Manufacturer Morbi#brick machine manufacturer in gujarat#bricks machine manufacturer rajkot#fly ash brick making machine manufacturer#automatic fly ash brick making machine#fly ash brick making machine fully automatic#fly ash brick making machine supplier#paver block machine manufacturer morbi#paver making machine for sale#paver block making machine manufacturers#automatic paver block making machine

1 note

·

View note

Text

Top Model in automatic fly ash brick making machine in India

In this growing field and profession, the use of technology has become crucial. Specifically, the Automatic Fly Ash Brick Making Machine in India has proved to be an innovative solution to the brick making industry by revolutionizing the whole process of making bricks. These machines provide not only capacity and product quality but are vital tools for any contemporary manufacturer of bricks.

Automated manufacturing of bricks is important to increase productivity and improve the quality of bricks being produced. An automatic fly ash brick making machine in India can increase the production rate many folds in comparison to the manual production line while also decreasing the overall cost of labor. These machines work without much variation, meaning that human factors like tiredness do not affect the quality of the bricks produced.

Key Features to Look

The productivity of a fly ash brick making machine defines the number of bricks that it is capable of churning within a given period of time. This is important in regard to large orders, as the ability to produce a large quantity of products in a short amount of time is quite valuable. Look for the machines which can produce large numbers of bricks within a short time to enable you meet the market demand.

One of the most important factors that may determine the level of efficiency of a brick making machine and the ease of its operation is the degree of its automation. It requires little human interjection while providing quality control for the bricks as well as cutting cost on labor. Choose machines that incorporate the key aspects of automation such as the feeding, mixing, molding, and ejection systems.

Energy efficiency is the key to minimizing cost and ensuring that the best practices are followed at all times. An automatic fly ash brick making machine with low energy intake supports high production without wasting much energy. Look for machines made with efficiency features to reduce the cost of your electricity bill and the effects on the environment.

It is of great importance for a user to be able to operate, control or even maintain the fly ash brick making machine easily. Choose machines with clear physical controls, documented procedures, and easily accessible service parts. Maintenance is important in order to avoid failures and to work in the best conditions, so, select a model that will guarantee easy maintenance processes.

Brick machinery is the top name in brick making machine industry. Brick machinery offers various types of Automatic fly ash brick making machine in India with advanced technology. Brick machinery has range of product with advanced automation features that gives you satisfied output and high production. Here we are presenting you some of our best machines.

Top Models of Automatic Fly Ash Brick Making Machine in India

FAM-1440 Automatic Fly Ash Brick Making Machine

The FAM-1440 Automatic Fly Ash Brick Making Machine is one of the most efficient models which is quite popular among users due to its high performance and maximum longevity. This machine is technically designed to lower operational complexities and require very little maintenance. That makes it perfect for medium to large manufacturing operations; the FAM-1440 is capable of producing up to 1920 bricks per hour. According to users, the FAM-1440 is easy to use and dependable.

FAM-1080 Automatic Fly Ash Brick Making Machine

The FAM-1080 is another top model from Brick Machinery that is specifically designed to be versatile and highly efficient in its operations. It involves high levels of automation and control in an effort to produce high standard dimensioned bricks with minimal deviations. The FAM-1080 can produce up to 1440 bricks per hour, making it best choice to use in small to medium industries. The FAM-1080 has been positively received by customers who have complimented it as being well built and reliable.

FAM-2520 Automatic Fly Ash Brick Making Machine

FAM-2520 is the model with the highest technical level and automation rate among all of them and is considered to be the most successful and perspective one. This machine is intended for high-production mode and is amazing in its functionality and quality of the produced bricks. The FAM-2520 has a production capacity of up to 3360 bricks per hour and is suitable for large scale operations. The FAM-2520 has been praised highly in terms of its high production output and performance.

Each of the machines has special features aimed at improving your production of bricks making them worthy of consideration.We would like to invite you to also check out some of the most popular models and determine whether they will fit your need. For further details, please visit or get in touch with us at Brick Machinery to know how we may meet your needs.

#fly ash brick making machine#brick making machine#brickmakingmachine#automatic fly ash brick making machine in India#fly ash brick plant manufacturers#fly ash brick making machine in gujarat#fly ash brick plant#block making machine#brick making machine in india#brick making machine manufacturer#brickmachine

0 notes

Text

Selecting the right concrete block making machine for your construction business is a significant decision that can impact your productivity, profitability, and overall success. Benny Enterprises is the best choice for all your needs, we are the finest Concrete Brick Making Machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

Best Fly Ash Brick Making Machine in India | Indian Trade Bird

Indian Trade Bird is a leading manufacturer of Fly Ash Brick Making Machine. We are the supplier and exporter of Fly Ash Brick Making Machine like Automatic Fly Ash Brick Making Machine, Semi-Automatic Fly Ash Brick Making Machine, Manual Fly Ash Brick Making Machine. Fly ash is a readily available and inexpensive material, making fly ash bricks more cost-effective than clay bricks. Fly ash bricks are known for their high compressive strength and durability, making them suitable for various construction applications. Fly ash is the fine powder formed from the mineral matter in coal, consisting of the noncombustible matter in coal and a small amount of carbon that remains from incomplete combustion. Fly ash is a fine powder generated by burning pulverised coal in electric power plants. These machines are highly beneficial as it provides complete automation, excellent performance, high production rates, and the best quality production.

For more details clicks here - https://www.indiantradebird.com/product/fly-ash-brick-making-machine

0 notes

Text

Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes