#aql inspection

Explore tagged Tumblr posts

Text

Amazon is believed to be one of the best places for online sales. In case you have a product, you wish to sell, it has numerous categories that can help you find the right place for it. One of the keys to successful Amazon sales is good reviews. But how to get them? Recently, the company tightened its rules for reviewing. Now vendors are not allowed to contact their buyers directly and ask them to leave a good rating.

0 notes

Text

Our mission at GQC is to make all process of manufacturing more transparent. Our main goal is not just quality control, but to establish trust and better communication between both side of the business partnership.

Contact us for more information on our website :- https://www.gqc.io

0 notes

Text

What is AQL?

Details

Acceptable Quality Limit (AQL) is a standard used by professional inspectors when conducting sampling inspections, following the ISO 2859 standard and the tables it provides. This document is published by ISO and is equivalent to all national regulations (ANSI/ASQC Z1.4, NF06-022, BS 6001,) and is an international standard.

Necessity of random sampling:

Whether it is a brand, online store or quality control professional, it is necessary to evaluate the quality of the product before shipment. If your goods are high-priced, high-risk, or your order quantity is small, you may need a fully inspection service.

Benefits of AQL and random sampling:

1.Save time 2.Save cost 3.Set clear criteria 4.Give the flexibility 5.Ease the communication of quality expectations

0 notes

Text

The Importance of Sampling in Quality Control: How AQL Inspection Levels Can Help

As manufacturers strive to maintain high-quality products, statistical sampling techniques have become an essential tool in quality control. Understanding the relationship between Acceptable Quality Level (AQL) inspection levels and sampling size can be a complex task. However, with the help of AQL sampling calculations, manufacturers can simplify the process by inputting specific parameters to obtain the corresponding sample size and acceptance and rejection numbers.

Understanding AQL Inspection Levels and Sampling Size

AQL inspection levels provide a framework for manufacturers to determine the sample size required for quality control. By using AQL sampling calculations, manufacturers can establish reliable and statistically sound sampling plans that align with their quality objectives.

What is AQL?

AQL is a critical factor in quality control, representing the minimum quality standard that a product must meet to be accepted by customers. It is used to determine the number of defective items in a batch of products that are acceptable.

The Importance of Sampling in Quality Control

Sampling is a critical component of quality control, as it allows manufacturers to verify the quality of their products without inspecting every single item. By using statistical sampling techniques, manufacturers can identify defects or irregularities in their products and take corrective action to prevent future occurrences.

How AQL Inspection Levels Can Help

AQL inspection levels provide a framework for manufacturers to determine the sample size required for quality control. By using AQL sampling calculations, manufacturers can:

Determine the sample size required for a specific product or batch

Establish acceptance and rejection numbers for quality control

Develop reliable and statistically sound sampling plans

Conclusion

In conclusion, understanding the relationship between AQL inspection levels and sampling size is crucial for manufacturers to maintain high-quality products. By using AQL sampling calculations, manufacturers can establish reliable and statistically sound sampling plans that align with their quality objectives, ultimately upholding their quality standards.

0 notes

Text

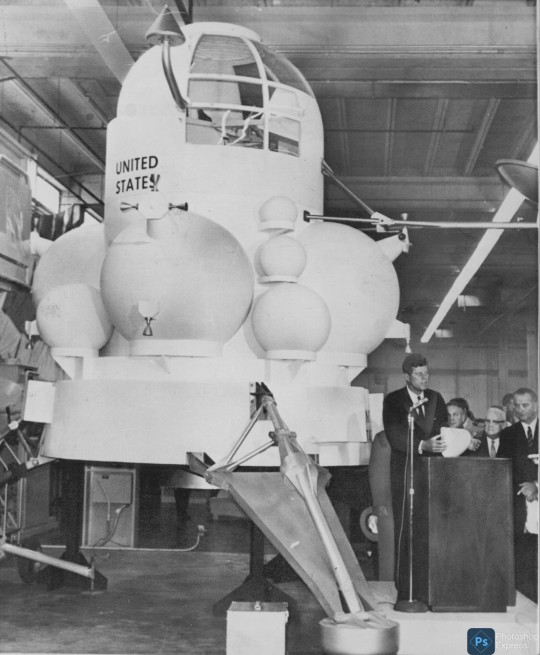

President John F. Kennedy speaks next to a prototype model of the Lunar Excursion Module, to be built by Grumman Aircraft Corporation of Long Island.

"PRESIDENT SEES 'THE BUG'

President John F. Kennedy stands before a model of the craft, known as 'The Bug' which the U.S. hores to make a lunar landing. Vice President Johnsen is at extreme right. Kennedy saw the model during his visit NASA installation in Houston today."

"President John F. Kennedy (at lectern) delivers remarks, following a tour of spacecraft displays inside a hangar at the Rich Building of the Manned Spacecraft Center, Houston, Texas. President Kennedy holds a scale model of the Apollo command module, presented to him by Director of the Manned Spacecraft Center, Dr. Robert Gilruth; a mock-up of the lunar lander (also known as 'the Bug') sits in background. Standing in back (L-R): Administrator of the National Aeronautics and Space Administration (NASA), Dr. James E. Webb; Governor of Texas, Price Daniel; Associate Administrator of NASA, Dr. Robert C. Seamans, Jr.; Director of Operations for Project Mercury, Dr. Walter C. Williams; Senator Alexander Wiley (Wisconsin); Vice President Lyndon B. Johnson; Dr. Gilruth. The President visited the Center as part of a two-day inspection tour of NASA field installations."

Other views of the Mockup.

Date: September 12, 1962

Long Island Daily Press Identifier: aql:33184 ldp-003526 ldp-003526

FK lib assession no. ST-387-20-62

NM Museum of Space History: link, link

#Lunar Module#NASA#Apollo Program#Mock-Up#Mock Up#Mockup#Grumman Aerospace Corporation#Grumman#Lyndon B. Johnson Space Center#Johnson Space Center#Manned Spacecraft Center#Houston#Texas#President#September#1962#my post

30 notes

·

View notes

Link

Are you in search of high-quality sterile surgical gloves? Look no further than Guilin HBM Health Protections, Inc. As the top surgical gloves factory in China, we are dedicated to providing our customers with the best products possible. Each of our gloves goes through a rigorous inspection process, ensuring that they are 100% air inflated and inspected seven times before delivery. We take pride in delivering high-quality and safety medical gloves to our customers. Our annual production capacity is 800,000,000 pairs, making us the leading surgical gloves factory in China. We specialize in producing 100% blow-checked surgical gloves with a high AQL of 0.65. Our gloves are sterilized in-house using E-Beam sterilization, ensuring the highest level of safety and quality. We are proud to have received several certifications, including CE, EN455, ISO13485, FDA 510K, SATRA, PPE, and CCPIT certifications. Our clients include well-known organizations such as Medline, UNICEF, UN Migration, and UNOPS. At Guilin HBM Health Protections, Inc., our team is composed of over 2,000 dedicated professionals who are committed to providing our clients with the best service possible. We take pride in our work and are dedicated to making sure our customers receive the best products and services. So why wait? Visit our website at surgicalgloves.com to learn more about our products and services. And if you have any questions or would like to place an order, our team is here to help. #SterileSurgicalGloves#SurgicalGlovesFactory#MedicalGloves#EBeamSterilization, #QualityControl

2 notes

·

View notes

Text

Product Inspection service in China

Product Quality Control and Quality Assurance Inspection: Enduring your Quaity Sourcing in China

Product quality control inspection is a process of ensuring that products or services meet specified requirements and standards before they are delivered to customers or released into the market.

Quality Inspection involves evaluating, verifying and testing items for defects, deviations, or non-conformities that may affect their performance, safety, reliability, and usability. They help to ensure quality control in the manufacturing process, and can protect against product recalls, customer complaints, and reputational damage.

GIS quality control inspections verify product quality and quantity to meet customer requirement and comply with regulations and standards.

3 Types of GIS Product Quality Inspection Services

GIS quality inspection services cover comprehensive inspections throughout the entire manufacturing process from Pre-production inspection, during production inspection, and pre-shipment inspection.

1. Pre-Production Inspection

Pre-production inspection can highlight quality risks before that of manufacturing mass production.

LEARN MORE

2. During Production Inspection

During-production inspection helps correct quality issues and avoid affecting the shipping schedule.

LEARN MORE

3. Pre-Shipment Inspection

Pre-shipment inspection ensures that products meet requirements and quality standards before shipped.

LEARN MORE

How GIS Conduct a Product Inspection?

GIS quality inspectors usually check products at certain production stages against a comprehensive checklist which is based on the specifications of the product and the requirements of the client. They inspect the products to check whether they are fit for production or semi-finished goods, as well as finished goods ready for shipment to customers.

For each inspection, the checklist is tailored according to the product regulation and standards and the requirements of the client. However, checks typically assess the following:

Specifications

Function

Appearance

Performance

Workmanship

Packaging

Quantity

Checklists can also be made according to the type of the inspection. For example, pre-production inspection checklists will include checks of raw materials and components.

In most cases, it is not feasible to inspect every single unit of a product or evaluate every aspect of a service. Instead, a representative sample is selected for inspection. In performing products sampling inspection, GIS exclusively apply the ISO 2859 sampling standard which specifies a sampling scheme: Acceptable Quality Level (AQL), to find whether the lot order has met the client’s specifications.

The results of the inspection are then compiled into an inspection report. Once the pre-shipment inspection is completed, a report is compiled with a conformed/not conformed result, an overview of key findings, and a detailed account of the inspection results.

All the original photos, videos, original testing data are contained, so you can see exactly what was discovered. A full and detailed inspection report, together with a photographic record within 24 hours of the inspection allows you to see the work undertaken.

Check a Sample Report

Why you need Product Inspection Services?

An effective quality control inspection is essential for any company that manufactures products or provides services. Here’s why you need them:

Product Quality and Consistency Ensuring

The primary objective of Quality Control Inspection is to ensure product quality and consistency. In today’s market, even minor deviations in quality can result in customer dissatisfaction and damage to brand reputation. GIS Inspection services ensure that each product aligns with the specifications and expectations set forth at the onset.

Regulatory and Standards Compliance

Various industries are governed by specific standards and legal requirements, often designed to ensure safety, reliability, and efficiency. GIS ensures that products adhere to industry regulations and safety standards, reducing the risk of legal issues and penalties.

Risk Mitigation

GIS inspection services identify potential defects early in the production process to prevent costly recalls, returns, and damage to brand reputation. Also save money by detecting problems before products are shipped, thus minimizing expenses related to rework and returns.

Process Improvement

By consistently monitoring and evaluating products and processes, quality inspections provides valuable insights into areas that require refinement.

Supplier Quality Management

In the globalized supply chain, the quality of raw materials and components significantly impacts the final product’s quality. Through rigorous inspection processes, businesses can ensure that their suppliers adhere to the same high standards of quality, creating a unified front in the pursuit of excellence.

The GIS Benefits

Quality inspection in manufacturing is crucial for ensuring that products meet required standards and specifications before they reach the consumer. This process helps identify defects and non-conformities early, preventing costly recalls and enhancing customer satisfaction.

GIS is an international third-party quality control inspection company in China. GIS provides comprehensive quality control designed to protect you supply chain safety. We have set up an inspection network covering China, Vietnam, India and Malaysia.

GIS only employs full-time inspectors. Our highly trained and experienced inspectors are product experts who receive regular training in their field of specialization.

Our inspections can be carried out on all types of consumer products including apparel, textile, footwear, fabric, suitcase, toys, tools, kitchenware, electronics, furniture, home appliances, lighting, and mechanical products.

GIS product inspection services ensure that your products match your desired specifications. Contact us to know more about how GIS can help guarantee your suppliers produce high-quality products.

CONTACT US

0 notes

Text

Why Pre-Shipment Inspections Are Critical for Quality Control

Pre-shipment inspections (PSI) serve as your last line of defense before products leave the manufacturer's facility. These vital quality control checks help ensure that your goods meet specifications and standards before shipping, potentially saving thousands in returns and reputation damage.

During a PSI, qualified inspectors thoroughly examine product quality, quantity, packaging, and labeling. They verify critical elements like:

Product specifications and measurements

Functionality and performance testing

Packaging integrity and durability

Accurate labeling and markings

Proper documentation

Many importers conduct PSIs when the production is 80-100% complete and packed. This timing allows for corrections if issues are discovered while minimizing shipping delays.

Beyond quality assurance, PSIs offer several key benefits:

Reduced risk of receiving defective products

Prevention of costly shipping returns

Protection of brand reputation

Compliance with regulatory requirements

Documentation for insurance claims

To maximize PSI effectiveness, provide detailed inspection criteria and quality standards to your inspection team. Focus on critical checkpoints based on your product type and previous quality issues. Consider random sampling using AQL (Acceptable Quality Limits) standards to ensure statistical reliability.

Remember that while PSIs add upfront costs, they typically prove far less expensive than dealing with quality issues after shipment. Making PSIs a standard part of your quality control process helps maintain consistent product quality and customer satisfaction.

#china product inspection services#service supply chain management#supplier quality audit#consumer product testing company#quality inspection service in china#china inspection company#third party inspection company#inspection services in china#quality control china

0 notes

Text

AIM Control I AIM Group is third party inspection company and 3rd marine surveying in providing the services of aql quality inspection of goods product and garment

See more:

https://aimcontrolgroup.com/en/aql-quality-inspection-of-goods-product-and-garment.html

Best Regards

Dr Capt. Nguyen Te Nhan / G.D

Agriculture Industry Marine Control Inspection Group of Companies® E-mail: [email protected]

MSN : [email protected]

#Tally #Survey #Inspection #Certification #Investigation #Expertise #Witness

#Diving #Underwater #Warranty #Approval #Asia #American #Africa #EU #Middleeast #Global .

#Surveyors #Inspectors #Consultant #Tallymen #Divers #Experts #investigator #controller #auditor #testing #laboratory #certificate #certification

#aimcontrol #aimgroup #thirdpartyinspection #marinesurvey #cargoinspection #qualitycontrol

1 note

·

View note

Text

Surgical gloves powder free

Armour Powder free Latex Surgical gloves made from natural rubber Latex offer high dexterity, comfort and protection. The low modulas gloves are polyurahtene coated with derma shield which makes it powder free (polymer coated gloves). The chlorination (chlorinated gloves) done on the gloves reduces the protein level significantly low. The gloves are made in different colours for double donning in OR. The gloves are 100% inspected to meet high quality standards.

Features

The powder free gloves are manufactured to different thickness and formulations for different procedures.

No chemical residues on gloves which terminate type IV allergies.

The protein content of the powder free gloves is < 50µg/dm2 which reduces the risk to have type-1 Latex protein allergy.

The powder content of powdered gloves < 2 mg/dm2.

The shelf life of our formulated powder free gloves is 4 years.

Manufactured in clean environment to achieve low bio-burden level and the gloves have low pyrogen level and are non-cytotoxic.

The product is manufactured in a clean environment and packed in clean room.

The sterilization is done on a validated chamber. Ethylene Oxide (ETO) / Gamma sterilization available as per customer requirements.

Freedom from holes is 0.65 AQL.

0 notes

Text

Custom Design Umbrellas Manufacturer

Founded in 2001, Septrainbow Industry & Trade Co Ltd is an innovative manufacturer, factory, exporter and wholesaler, which has more than 24 years manufacturing and design experience in all kinds of custom design umbrellas, includes folding umbrellas, inverted umbrellas, golf umbrellas, promotional umbrellas, custom umbrellas, windproof umbrellas, luxury umbrellas, kids umbrellas, RPET umbrella, clear umbrellas, custom made umbrellas, and so on. Our umbrellas are environmentally friendly and low lead, and can pass REACH, CALIFORNIA 65 and other tests. With many years' development, now, our umbrella manufacturing workshop covers 2,000㎡ with more than eighty employees, most of the workers have more than 10 years manufacturing experience in umbrellas.

Our outdoor products factory is located in Tong'an Industrial Zone, Xiamen, and the manufacturing workshop covers 10,000㎡ with more than 500 workers; It specializes in the R&D and production of outdoor products such as custom tents, custom sunshade canopy, and custom beach umbrellas. The factory is also a supplier of emergency disaster relief materials to the Ministry of Civil Affairs and the National Grain and Material Reserve Administration of China.

We are proud to offer our most professional OEM/ODM production services, product design & development, and supply chain solutions to our global clients. In past 23 years, we designed and manufactured high quality umbrellas and outdoor products for many industry-leading customers around the world, the products are well appreciated by our clients. We have the complete raw materials supply chain, strict inspection standards and complete supporting services, from design and development of products, screening of raw materials, production and assembly processes, finished products, printing and dyeing, packing, testing, quality control and related logistics service, etc. AQL 2.5 is our regular inspection standard. On-time delivery is our basic production principle.

Today, With more flexible production methods and wider range of customizable products, we have won favors from more partners, including retailers, wholesalers, importers, distributors, promotional and gift agents, S2B intelligent supply chain service platform, e-commerce sellers, etc.

Septrainbow supply the best manufacturing service solutions all over the globe to a wide range of companies, ranging from large multinational organizations to small individual companies, Welcome to visit our factories!

In order to adapt to the customers' growing demand for small quantity customization, we launched the latest Custom Printed Products series in 2022 and set up 9 dedicated custom printing production lines; Our customizable printing products cover nearly 200 products in 9 categories, includes Custom Umbrellas, Custom Car Sunshades, Custom Bags, Custom Caps, Custom Home Supplies, Custom Clothing, Custom Festival Supplies and Custom Fashion Accessories; The main clients are Small retail sellers, E-commerce sellers and Small batch gifts & promotional items buyer, etc. Any designs of the client can be custom printed on the product as requested, and no minimum order quantity requirements. Our Purpose: Flexible Customization, Fast Production, Fast Delivery!

Tell us your needs and ideas to get our professional advice and best offer!

https://www.septrainbow.com

1 note

·

View note

Text

Manufacturing supervisors are responsible for the control of the various elements critical to producing and delivering your product, such as production staff, equipment, and processes.

0 notes

Text

AQL - Acceptable Quality Level - Definition, Defining The Key Terms : Defects, Lot Size, Sampling Plan, AQL Inspection Process, Sample Size Calculation, Acceptance and Rejection Criteria, Types of Sampling Plans; Plan à Échantillonnage Unique, Plan à Double Échantillonnage, Plan à Triple Échantillonnage, Plan à Échantillonnage Séquentiel, Plan à Échantillonnage Multiple

Qu'est-ce que l'AQL et Pourquoi est-ce important ?Acceptable Quality Level (AQL) fait référence à une mesure statistique largement utilisée dans le contrôle de la qualité qui aide à déterminer le nombre maximal acceptable de défauts ou de non-conformités dans une taille d'échantillon à partir d'un l [...] https://academypedia.info/fr/index-du-glossaire/aql-acceptable-quality-level-definition-defining-the-key-terms-defects-lot-size-sampling-plan-aql-inspection-process-sample-size-calculation-acceptance-and-rejection-criteria-types-of-sam/

#business #communication #data #education #ict #information #intelligence #technology - Created by David Donisa from Academypedia.info

0 notes

Text

AQL - Acceptable Quality Level - Definition, Defining The Key Terms : Defects, Lot Size, Sampling Plan, AQL Inspection Process, Sample Size Calculation, Acceptance and Rejection Criteria, Types of Sampling Plans; Single-Sampling Plan, Double-Sampling Plan, Triple-Sampling Plan, Sequential-Sampling Plan, Multiple-Sampling Plan

What is AQL and Why is it Important ?Acceptable Quality Level (AQL) refers to a widely used statistical measure in quality control that helps determine the maximum acceptable number of defects or nonconformities in a sample size from a production batch . It is used by manufacturers, importers and [...] https://academypedia.info/glossary-index/aql-acceptable-quality-level-definition-defining-the-key-terms-defects-lot-size-sampling-plan-aql-inspection-process-sample-size-calculation-acceptance-and-rejection-criteria-types-of-sam/

#business #communication #data #education #ict #information #intelligence #technology - Created by David Donisa from Academypedia.info

0 notes

Text

Pre-Shipment Inspection

Looking for the most effective way to ensure the quality of your shipment? Wonder no more! Introducing Pre-Shipment Inspections - the ultimate solution for confirming your shipment's quality level. With 100% production completion and 80% of goods packed into cartons, we've got you covered. Our randomly selected samples, following AQL standards, undergo thorough inspections based on style, function, specifications, and crucial details. Don't compromise on quality – choose our tailored inspections today! Visit now: https://www.vicc.com/inspection/psi-pre-shipment-inspection/

0 notes

Text

AQL Calculator | AQL Sampling Table | AQL Chart | AQL Level | GIM

GIM AQL Calculator is an effective way to perform quality inspection on a sample size. It allows you to input specific information in order to determine an AQL level.

0 notes