#animal feed mixer machine

Explore tagged Tumblr posts

Text

SLHS Shaft Paddle Mixer

SLHS Shaft Paddle Mixer Introduction Herm Machinery’s latest dedicated double-shaft paddle mixer has many advantages. These feed mixers are very gentle on the product, have low energy consumption, high capacity, low space requirements, and flexible filling. It can be equipped with multiple atomizing nozzles for liquid addition, which is convenient for maintenance. Herm Machinery’s newest…

View On WordPress

0 notes

Text

Efficient Livestock Management with Tractors

Managing livestock efficiently is crucial for any farm’s success, and modern tractors play a pivotal role in this process. Tractors, with their versatility and power, have revolutionized livestock management, making it easier and less labor-intensive. Here’s how tractors can significantly enhance livestock management:

Transporting Livestock

One of the primary uses of tractors in livestock management is transporting animals. By attaching a trailer to a tractor, farmers can move livestock from one location to another with ease. This is particularly useful during seasonal changes when animals need to be relocated to different pastures or shelters. The ability to transport livestock quickly and safely reduces stress on the animals and minimizes the risk of injury. Additionally, using tractors for transportation ensures that the process is more efficient, allowing farmers to manage larger herds without the need for extensive manual labor.

Feeding Livestock

Tractors are also invaluable for feeding livestock. They can be used to transport large quantities of feed from storage areas to feeding sites. This not only saves time but also ensures that each animal receives the correct amount of feed. By using a tractor with a feed mixer attachment.

Shelter Management

In cases of harsh weather, tractors can be used to move livestock to shelters quickly. This is essential for protecting animals from extreme conditions such as heavy rain, snow, or heatwaves.

Tractor-trailers can transport animals to safe locations, ensuring their well-being and reducing the risk of weather-related health issues. The ability to swiftly relocate livestock during adverse weather conditions can prevent significant losses and ensure the safety of the animals.

Furthermore, tractors can be used to maintain and repair shelters, ensuring that they are always in good condition and ready to provide protection when needed.

Manure Management

Another critical aspect of livestock management is manure handling. Tractors equipped with manure spreaders can efficiently collect and distribute manure across fields. This not only helps in maintaining cleanliness in livestock areas but also enriches the soil, promoting better crop yields. Proper manure management is essential for maintaining a healthy environment for the livestock and preventing the spread of diseases. By using tractors for this task, farmers can ensure that manure is handled in an efficient and hygienic manner, contributing to the overall health and productivity of the farm.

General Farm Maintenance

Tractors are versatile machines that can be used for various other farm maintenance tasks. From plowing fields to transporting equipment, tractors help in maintaining the overall infrastructure of the farm. This versatility makes them indispensable for modern livestock management.

Tractors can be equipped with various attachments and implements, allowing them to perform a wide range of tasks. This adaptability ensures that farmers can use their tractors for multiple purposes, maximizing their investment and improving the efficiency of their operations.

Conclusion

In conclusion, tractors have become an essential tool in livestock management. Their ability to transport livestock, feed animals, manage shelters, handle manure, and perform general farm maintenance tasks makes them invaluable for farmers. By reducing the need for manual labor

and increasing efficiency, tractors help farmers manage their livestock more effectively, ensuring the health and productivity of their animals. The use of tractors in livestock management not only improves the overall efficiency of farm operations but also enhances the well-being of the animals. By leveraging the power and versatility of tractors, farmers can achieve more efficient and sustainable livestock management practices, ultimately leading to a more productive and profitable farming operation.

Tractor Seva’s comprehensive maintenance and repair services are crucial for efficient livestock management. By ensuring tractors are always in optimal condition, they help farmers transport livestock safely, feed animals efficiently, manage shelters effectively, handle manure properly, and perform general farm maintenance tasks. This reliability and efficiency lead to better health and productivity of the livestock, ultimately contributing to a more successful and sustainable farming operation. Partnering with Tractor Seva provides farmers with peace of mind, knowing their equipment is well-maintained and reliable, allowing them to focus on managing their livestock and farm operations more effectively.

For farmers seeking to optimize their livestock management practices, reliable tractor maintenance is a key factor, and Tractor Seva is here to provide the necessary support. With innovative solutions and a farmer-first approach, Tractor Seva is empowering farmers across India to maximize their productivity and ensure a prosperous future for the livestock sector.

#tractor#high maintenance#farmers market#mahindra#john deere#Swaraj#eichertractors#massey ferguson#new holland

0 notes

Text

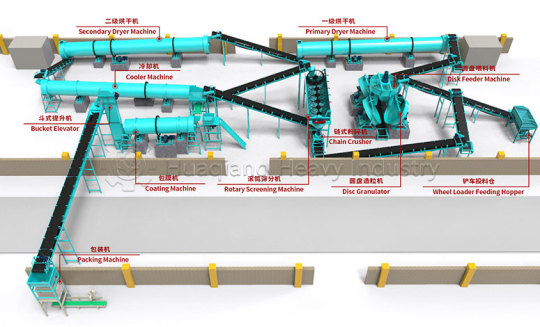

In the vast pastures of Australia, a new trend is emerging, that is, the use of environmentally friendly fertilizer granulators to improve the quality and yield of forage. The application of this technology not only helps to protect the environment, but also promotes the sustainable development of animal husbandry.

The Organic Fertilizer Production Line has played an important role in this process. Through this production line, organic waste in the pasture, such as animal waste and crop residues, can be converted into high-quality organic fertilizer. These fertilizers are rich in key nutrients such as nitrogen, phosphorus and potassium, which are essential for grass growth.

The Fertilizer Granules Compaction Machine in the fertilizer granulator series is the key equipment to achieve this transformation. It extrudes organic fertilizers into pellets by physical methods, which is not only easy to store and transport, but also improves the application efficiency and uniformity of fertilizers.

The Horizontal Ribbon Mixer also plays a crucial role in the production of organic fertilizers. It ensures a uniform mix of various raw materials, resulting in the production of organic fertilizers of consistent quality. The design of this mixer helps to evenly mix the raw materials, avoiding the problem of local too wet or too dry, thus ensuring the stability and consistency of the organic fertilizer.

The Rotary Screening Machine is responsible for grading the resulting fertilizer particles to ensure that the fertilizer particles are uniform in size and suitable for grass absorption. The use of screening machine improves the application quality of fertilizer and avoids the problem that the fertilizer effect is affected by too large or too small particles.

Finally, Uniform Feeder as the front end of the production line, can evenly feed raw materials into the pelletizer, to ensure the continuity and uniformity of the production process. This not only improves production efficiency, but also helps maintain the quality of the final product.

Through the application of these advanced organic fertilizer granulation technologies and equipment, Australian pastures can promote pasture growth in a more environmentally friendly and efficient way. This will not only help to improve the economic efficiency of livestock farming, but also reduce the impact on the environment and achieve a true green revolution.

#Organic Fertilizer Production Line#Fertilizer Granules Compaction Machine#Horizontal Ribbon Mixer#Rotary Screening Machine#Uniform Feeder

0 notes

Text

In India, the cultivation of spice crops has a long history, and its increase has been an important goal of local agricultural development. With the progress of science and technology, the application of organic fertilizer granulator technology has opened up a new way for the increase of spice crops in India.

Organic Fertilizer Production Line Organic fertilizer production line converts organic matter such as agricultural waste and animal waste into high-value organic fertilizers. This production line not only improves the recycling rate of resources, but also provides rich nutrition for spice crops, enhances the water retention and air permeability of the soil, and thus promotes the growth and increase of crops.

Fertilizer Granules Compaction Machine In spice growing in India, the application of Fertilizer Granules Compaction Machine has effectively improved the utilization of fertilizer. This granulator squeezes fertilizer raw materials into pellets through physical action, making fertilizer particles more uniform, stable, and easy to apply and store. The application of granular fertilizer helps to improve the speed and efficiency of nutrient release in the fertilizer, thereby increasing the yield of spice crops.

Horizontal Ribbon Mixer An even mixture of fertilizers is essential to ensure a nutritionally balanced soil for spice crops. Horizontal Ribbon Mixer, with its unique mixing method, ensures the full mixing of various fertilizer ingredients. The application of this mixer makes the products on the fertilizer production line more uniform, improves the effect of fertilizer use, and ensures the healthy growth of spice crops.

Uniform Feeder In the Organic Fertilizer Production Line, the role of a Uniform Feeder is to ensure that the raw material enters the granulator at a constant speed and consistent granularity. This uniform feeding method helps to improve the working efficiency and granulation quality of the pelletizer, thus ensuring the stability and yield increase effect of the organic fertilizer.

Through the application of these advanced organic fertilizer granulators and production lines, the agricultural production of spice crops in India has not only improved efficiency, but also achieved environmental protection and sustainable use of resources. The application of these technologies provides valuable experience for the sustainable development of global agriculture.

#Organic Fertilizer Production Line#Fertilizer Granules Compaction Machine#Horizontal Ribbon Mixer#Uniform Feeder

0 notes

Text

In the Australian livestock industry, the use of fertilizer granulators is of great importance for optimizing cattle and sheep feed. By converting organic and inorganic substances into high-quality granular fertilizers, these machines not only improve the nutrient value of fertilizers, but also increase their suitability in feed.

NPK Fertilizer Production Line

Australia’s fertilizer production line combines key elements such as nitrogen, phosphorus and potassium with precise ratios to produce composite fertilizers that meet the growth needs of cattle and sheep. The efficiency of this production line lies in its ability to adjust the nutrient ratio in the fertilizer according to the different nutrient requirements of the cattle and sheep at different growth stages, thus optimizing the feed formula.

Organic Fertilizer Production Line

Organic fertilizer production line is produced by processing agricultural waste and animal waste. These organic fertilizers can not only provide nutrients, but also improve the soil structure and improve the growth quality of feed crops. In Australia, the proliferation of such production lines is helping to drive sustainability in the livestock sector.

Fertilizer Granules Compaction Machine

Fertilizer Granules, such as Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine, can make particles from mixed fertilizer raw materials. This granular fertilizer is easy to store and transport, and is more evenly distributed in the feed, helping cattle and sheep to better absorb nutrients.

Horizontal Ribbon Mixer

The Horizontal Ribbon Mixer plays an important role in fertilizer production. It is able to ensure that various raw materials are fully mixed during the production process, thus producing a uniform quality fertilizer. This is essential to ensure nutritional consistency from batch to batch.

Through these advanced fertilizer lines and granulation technologies, Australia’s livestock industry is able to produce better feed to meet the growing needs of cattle and sheep while reducing their environmental impact. The application of these technologies not only improves the production efficiency of animal husbandry, but also provides valuable experience for the sustainable development of global animal husbandry.

#NPK Fertilizer Production Line#Organic Fertilizer Production Line#Fertilizer Granules Compaction Machine#Horizontal Ribbon Mixer

0 notes

Text

Cost of Cattle Feed Plant

Establishing a cattle feed plant is a profitable business venture, especially in countries like India, where agriculture and animal husbandry form a large part of the economy. With the growing demand for milk and meat, the need for high-quality cattle feed is on the rise. However, understanding the financial aspects, especially the cost of setting up a cattle feed plant, is crucial for anyone looking to venture into this business.

In this blog, we will discuss the factors that influence the cost of a cattle feed plant, the role of why choosing the right cattle feed machine manufacturer in India is critical for success.

1. Key Factors Influencing the Cost of a Cattle Feed Plant

The overall cost of setting up a cattle feed plant can vary significantly depending on several factors, including:

a. Plant Size and Capacity

One of the primary factors influencing the cattle feed plant cost in India is the size and production capacity of the plant. A smaller plant with a production capacity of 1 to 2 tons per hour will cost significantly less than a large-scale plant that can produce 10 tons or more per hour.

b. Location and Infrastructure

The geographical location of the plant also plays a critical role in determining its cost. Urban locations tend to have higher land and labor costs compared to rural areas. Infrastructure, including access to water, electricity, and transportation, also adds to the cost.

c. Machinery and Equipment

The type and quality of machinery used in the cattle feed plant significantly influence the cost. A reliable cattle feed plant manufacturing company can offer various machinery types, including mixers, grinders, pellet machines, and more, each with varying price points. Opting for automated machinery can reduce labor costs but will require a higher initial investment.

d. Raw Materials

The availability and cost of raw materials such as maize, barley, wheat bran, and soybean meal can also affect the overall expenditure. In India, raw material prices may fluctuate depending on seasonality, transportation costs, and regional availability, directly impacting the cost of production.

e. Labor Costs

Labor costs vary widely based on the location of the cattle feed plant. Urban areas generally have higher labor rates compared to rural areas. Additionally, the complexity of the machinery used in the plant may require skilled labor, further increasing costs.

2. The Role of a Cattle Feed Plant Manufacturing Company

Choosing a reliable cattle feed plant manufacturing company is one of the most critical decisions you’ll make when setting up your cattle feed business. The right manufacturer will provide durable, high-quality machinery that ensures efficient production and minimizes downtime.

A trusted cattle feed plant manufacturing company typically offers comprehensive services, including:

Customized plant designs based on specific production needs.

Installation and maintenance of machinery.

Providing operator training to ensure smooth operations.

Offering warranty and after-sales services.

Investing in a reputable cattle feed machine manufacturer in India can ultimately save you money in the long run by reducing equipment failure rates and ensuring maximum productivity.

3. Cattle Feed Plant Cost in India: A General Overview

The cattle feed plant cost in India can vary depending on several factors mentioned earlier. However, to give you a general idea, the cost of setting up a small to medium-sized plant (with a capacity of 1 to 5 tons per hour) ranges between ₹20 lakhs to ₹1 crore. For larger plants with higher production capacities, the cost can go up to ₹2 crores or more.

Here’s a rough breakdown of the major cost components:

Land and Infrastructure: Depending on the location, this can range from ₹5 lakhs to ₹50 lakhs.

Machinery and Equipment: A complete set of machinery, including mixers, grinders, and pellet machines, typically costs between ₹10 lakhs to ₹70 lakhs, depending on the capacity and automation level.

Installation and Commissioning: Setting up the machinery and getting it operational can cost an additional ₹3 lakhs to ₹15 lakhs.

Labor and Operational Costs: These can vary but are an ongoing expense you should account for when planning your budget.

It's essential to work closely with a reliable cattle feed machine manufacturer in India to get an accurate estimate based on your plant size, production capacity, and specific needs.

4. Finding the Right Cattle Feed Machine Manufacturer in India

India is home to several cattle feed machine manufacturers, but selecting the right one requires careful research. Consider the following factors:

Reputation: Check reviews, ask for references, and do thorough research to ensure the manufacturer is reputable and experienced in producing high-quality machinery.

Customization: The manufacturer should be willing to customize the machinery according to your specific needs and production capacity.

After-Sales Service: After-sales service is critical, as it ensures your machinery continues to function optimally. Ensure the manufacturer offers prompt support and warranty services.

Cost and Quality: Strike a balance between cost and quality. Don’t opt for the cheapest machinery available, as it might not be durable or efficient in the long run.

Conclusion

Setting up a cattle feed plant is a significant investment, and understanding the cost dynamics is crucial for success. The cattle feed plant cost in India depends on various factors like plant size, machinery, location, and labor. Partnering with a reliable cattle feed plant manufacturing company can make a considerable difference in the overall profitability of your venture. By carefully planning and making informed decisions, you can establish a successful cattle feed plant that meets the growing demand for high-quality feed in the livestock industry.

0 notes

Text

Car and Equipment Finance For Businesses

Whether it's a car, truck or machinery, business vehicle and equipment finance provides flexible loan repayment terms to help you buy the assets your business needs. It can also be structured with an end balloon or residual payment to lower the regular payments if you need to manage cash flow.

Commercial Vehicles

Whether you need a new fleet of commercial vehicles or specialised equipment for your business, our team can help. We work with a wide range of lenders that offer car and equipment finance Sydney products that can be tailored to your needs.

Generally, all businesses from large companies to sole traders can get business car loans, provided you have an ABN, use the vehicle for business purposes, and can meet the lender’s criteria. Business loans can also include additional features like tax deductions and flexible repayment options like weekly, fortnightly or monthly.

ANZ offers various options to finance your business assets, including chattel mortgage, hire purchase and lease purchase. We can assist you, in conjunction with your accountant or tax advisor, in determining which financing type will be most beneficial to your business operations and cash flow. The best option is based on several factors including:

Construction Equipment

Whether you need a dental chair for your practice or a dump truck for your construction company, equipment and vehicle finance allows businesses to acquire the tools they need without exhausting their existing lines of credit. This loan type usually involves financing 80% to 100% of the equipment cost with monthly repayments (including interest) over a set term.

Lenders typically ask for an active ABN or ACN, federal tax file number and financial records to assess a business’s health and cash flow. This compilation streamlines the application process and instils confidence in lenders that a business is ready to access equipment.

Providing security for an equipment loan helps to minimise risk and lower interest rates. This could be the equipment itself, a deposit or other forms of security such as a personal guarantee. Generally, businesses that offer equipment finance are required to hold an Australian credit licence unless they are exempt. However, this isn’t always necessary.

Machinery

Equipment finance (also known as commercial loans or business leases) can be used to finance any tangible assets you need for your operations. This includes vehicles, machinery, technology and tools.

Depending on the size of your business, you might need specialised equipment to meet your needs. These can range from earthmoving machines to medical and dental equipment. These costs can add up quickly and put a dent in your cash reserves.

Business equipment finance is designed to allow you to update your fleet and increase your productivity without a large upfront cost. Our team will assist you as you explore your options.

We can help you choose the best option for your business, including chattel mortgages and hire purchase. These options let you keep your other assets and cash flow debt-free, and also enable you to claim GST back in the BAS cycle of each purchase.

Agricultural Equipment

Agricultural equipment is any type of machinery used in agriculture to perform tasks like cultivating, harvesting, planting, and even transporting. Some examples include tractors, harvesters, animal feed mixers, field-wide weed removers and more. These machines help farmers grow more food in less time, which is essential for feeding a growing world population.

Purchasing equipment can be expensive and often requires substantial cash reserves. To reduce the impact on your business and cash flow, equipment finance offers a flexible repayment structure. Repayments can be matched to periods of higher business activity and you only own the equipment once it’s paid off.

From vehicles to coffee machines and everything in between, ANZ has a range of equipment financing options for businesses of all shapes and sizes. To find out more, talk to one of our local business bankers today.

0 notes

Text

Corrosion-Resistant Steel Silos for Grain / Dry Bulk Storage with AWWA D103 Standard

As a leading grain storage tanks manufacturer, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in the production of corrosion-resistant steel silos for grain and dry bulk storage. Our innovative bolted steel tanks are designed to meet the stringent requirements of the AWWA D103 Standard, ensuring long-term durability, reliability, and protection for valuable stored materials. These steel silos offer a robust solution for the agricultural, industrial, and commercial sectors, making them the ideal choice for grain storage, dry bulk materials, and other sensitive products.

Why Choose Bolted Steel Silos for Grain and Dry Bulk Storage?

Grain and dry bulk materials, such as feed, corn, and fertilizers, are highly susceptible to environmental factors like humidity, temperature changes, and contamination. Ensuring the quality and safety of stored materials is crucial for businesses that rely on them. This is where Center Enamel’s bolted steel silos come into play, providing excellent protection and maintaining the integrity of stored products.

As a leading storage tank manufacturer in China. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Features of Our Corrosion-Resistant Steel Silos:

AWWA D103 Standard Compliance: Our steel silos are designed and manufactured to meet the AWWA D103 Standard, guaranteeing high structural strength and quality control. This ensures that our silos are capable of handling large volumes of grain or dry bulk materials, making them ideal for industrial and agricultural use.

Corrosion Resistance: The Glass-Fused-to-Steel (GFS) coating technology provides superior protection against corrosion, even in harsh environmental conditions. This feature extends the service life of the silo, ensuring optimal performance over time.

Durable and Versatile Design: Our bolted steel tanks are modular in design, which allows for quick and easy installation on-site. The versatility of these tanks makes them suitable for a wide range of storage applications, from grains and animal feed to industrial raw materials and dry bulk goods.

Ease of Installation and Maintenance: The modular, bolted structure of our steel silos enables faster construction and installation, reducing downtime and labor costs. Additionally, the GFS coating minimizes maintenance needs, lowering overall operational costs for businesses.

Customizable Solutions: At Center Enamel, we understand that every storage project is unique. We offer customizable silos in terms of size, capacity, and design to meet the specific requirements of our clients, ensuring that the storage system fits seamlessly into their operations.

Applications of Corrosion-Resistant Steel Silos

Grain Storage: Our grain storage tanks provide secure and efficient storage solutions for a variety of grains, including wheat, corn, barley, and rice. The corrosion-resistant properties of our silos ensure that the grain is kept safe from moisture and pests, preserving its quality during long-term storage.

Dry Bulk Storage: Whether it’s raw materials for industrial processes or agricultural feed, our steel silos are perfect for storing dry bulk materials. Their robust design and weather-resistant properties make them ideal for outdoor installations in challenging environments.

Agricultural and Commercial Use: From large-scale farming operations to commercial grain storage facilities, our bolted steel tanks are trusted by clients around the world to provide reliable storage solutions for their products.

The Benefits of Bolted Steel Tanks for Grain Storage

Enhanced Protection: The GFS coating ensures that our steel silos can withstand corrosion, protecting stored materials from contaminants and environmental degradation.

Long-Term Durability: Our steel tanks are designed for longevity, capable of maintaining their structural integrity and protective properties over decades of use.

Cost-Effective: The reduced maintenance needs and long service life of our silos make them a cost-effective solution for grain and dry bulk storage.

Quick Installation: The modular, bolted design of our tanks allows for rapid assembly, minimizing the time required for construction and enabling quicker integration into existing facilities.

Why Center Enamel?

As a trusted steel silos and grain storage tanks manufacturer, Center Enamel brings decades of expertise in the design, manufacturing, and installation of bolted steel tanks. With over 30 years of experience, we are at the forefront of storage solutions for agriculture, industry, and municipal projects. Our commitment to quality, innovation, and customer satisfaction sets us apart as a global leader in the industry.

We have completed projects in more than 100 countries, delivering custom storage solutions that meet the specific needs of each client. Our ability to comply with international standards, such as AWWA D103, underscores our commitment to providing high-quality storage systems that adhere to the highest safety and performance standards.

Center Enamel’s corrosion-resistant steel silos are the perfect solution for the secure and efficient storage of grain and dry bulk materials. With the ability to meet AWWA D103 standards, our bolted steel tanks provide long-term durability, superior protection, and customizable designs for various storage needs. Whether you’re in the agricultural, industrial, or commercial sector, our tanks offer unmatched performance and reliability.

Contact us today to discuss your grain storage needs and discover how our corrosion-resistant steel silos can benefit your operations.

0 notes

Text

Ribbon Mixer/Ribbon Blender Machine

Pioneers in the machinery industry based in Kolkata, West Bengal, India, Maabharti Industries Private Limited provides Ribbon Mixer Machines to clients. Ribbon Blender Machine is a kind of mixing equipment that can be used to blend and mix various materials including powders, granules, and liquids.

Applications:

1. Food processing (e.g., mixing spices, cereals, and snack foods) 2. Pharmaceutical industry (e.g., blending powders and granules) 3. Chemical processing (e.g., mixing fertilizers and pesticides) 4. Cosmetic industry (e.g., blending powders and liquids) 5. Agricultural industry (e.g., mixing animal feed and fertilizers)

Whoever wants to buy a Ribbon Mixer Machine nearby at an affordable prices, Contact us at, +91 7595938888 or Email us now, [email protected]

#ribbonmixermachine#ribbonblendermachinemanufacturers#ribbonmixermachinenearme#ribbonblendermachinesuppliers#ribbonblendermachine#ribbonblendermachineforsale#aribbon#canmixer#heavymachinery#production#machineribbon#ribbonblendermixer#ribbonmixingmachine#ribbontypemixer#machine#manufacturing#technology#machinery#industrial#mechanical#industry#machineshop#usedmachines#manufacturer#exporter#machineforsale#kolkata#westbengal#odisha#jharkhand

0 notes

Text

Heavy Duty Animal Feed Mixer Machine by Finix Agro Tech

The Heavy Duty Animal Feed Mixer Machine by Finix Agro Tech is a robust and reliable solution for efficiently mixing animal feed. Designed to handle large volumes with ease, this machine ensures a homogeneous blend of ingredients, enhancing the nutritional value of the feed.

The Heavy Duty Animal Feed Mixer Machine is crafted with durability at its core. Finix Agro Tech has utilized premium materials and state-of-the-art technology to create a mixer that can handle the toughest tasks, ensuring that it remains a valuable asset for years to come.

Click here to know more about Heavy Duty Animal Feed Mixer Machine.

Finix agro Tech

Contact; 93613 66651

Website: https://finixagrotech.com/

1 note

·

View note

Text

Are you in the market for reliable used farm machinery and agricultural equipment? Lockwood AG offers a wide range of products including animal feeders, grain mixer machines, vertical feed mixers, feed wagon mixers, mixer wagons for sale, and sports rollers. Whether you're looking to upgrade your farm equipment or expand your operations, Lockwood AG provides robust solutions designed to meet your agricultural needs efficiently.

0 notes

Text

The Self Loading Feed Mixer Market is anticipated to grow from USD 719.4 million in 2024 to USD 996.73 million by 2032, achieving a compound annual growth rate (CAGR) of 4.16%.The agricultural industry is witnessing a revolution, driven by advancements in technology and machinery. One of the pivotal innovations reshaping this landscape is the self-loading feed mixer. These sophisticated machines are designed to streamline the process of mixing and distributing feed, offering substantial efficiency gains for farmers. The global self-loading feed mixer market is experiencing significant growth, propelled by the increasing demand for automated farming solutions, the need for enhanced feed quality, and the overall push towards sustainable agricultural practices.

Browse the full report at https://www.credenceresearch.com/report/self-loading-feed-mixer-market

Market Overview

Self-loading feed mixers are multifunctional machines that combine the capabilities of loading, mixing, and discharging feed. They are engineered to handle various types of feed, including silage, hay, and grains, ensuring a homogeneous mixture that meets the nutritional needs of livestock. The market for these machines is expanding rapidly, with significant demand from both small-scale and large-scale farming operations.

Key Drivers of Market Growth

1. Technological Advancements: Continuous innovation in agricultural machinery has led to the development of more efficient and user-friendly self-loading feed mixers. Advanced models come equipped with features such as programmable controls, precise weighing systems, and real-time monitoring capabilities, which enhance operational efficiency and feed quality.

2. Labor Shortages: The agricultural sector is grappling with a shortage of skilled labor, prompting farmers to adopt automated solutions. Self-loading feed mixers reduce dependency on manual labor, allowing for more consistent and timely feeding schedules.

3. Rising Livestock Production: With the global demand for meat and dairy products on the rise, livestock producers are under pressure to improve productivity. Self-loading feed mixers play a crucial role in optimizing feed management, contributing to better animal health and higher yields.

4. Sustainability Concerns: Environmental sustainability is becoming a priority in agriculture. Self-loading feed mixers can minimize feed wastage and reduce the environmental footprint of farming operations by ensuring precise feed distribution.

Market Segmentation

The self-loading feed mixer market can be segmented based on several factors:

1. Type: - Vertical Mixers - Horizontal Mixers

2. Capacity: - Small (up to 10 cubic meters) - Medium (10-20 cubic meters) - Large (above 20 cubic meters)

3. Application: - Dairy Farms - Poultry Farms - Swine Farms - Others

4. Region: - North America - Europe - Asia-Pacific - Latin America - Middle East & Africa

Regional Insights

North America and Europe dominate the self-loading feed mixer market, driven by advanced farming practices and significant investments in agricultural technology. In these regions, the adoption of automated feeding solutions is particularly high, supported by government initiatives and subsidies aimed at modernizing the agricultural sector.

The Asia-Pacific region is emerging as a lucrative market, with countries like China and India experiencing rapid growth in livestock production. The rising population and increasing demand for animal protein are key factors propelling market expansion in this region. Furthermore, improving economic conditions and growing awareness about the benefits of automated feed mixers are encouraging farmers to invest in these machines.

Competitive Landscape

The self-loading feed mixer market is highly competitive, with several key players vying for market share. Prominent companies include Kuhn Group, Trioliet, Faresin Industries, and Storti SpA. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position.

For instance, Kuhn Group has introduced a range of self-loading feed mixers equipped with advanced features such as the IntelliMix control system, which enhances mixing efficiency and reduces fuel consumption. Similarly, Trioliet’s Solomix series is renowned for its robust design and versatility, catering to the needs of different farming operations.

Future Prospects

The future of the self-loading feed mixer market looks promising, with several trends expected to shape its trajectory. The integration of smart technologies, such as IoT and AI, is anticipated to revolutionize feed management, offering farmers real-time insights and predictive analytics. Moreover, the shift towards sustainable farming practices will continue to drive demand for efficient and eco-friendly feed mixers.

Key Player Analysis

Supreme International

Trioliet

KUHN

RMH Lachish Industries

Jaylor

Casale

Segments:

Based on Capacity:

5 to 12m³

12 to 20m³

20 to 28m³

28 to 36m³

Others (more than 36m³)

Based on Application:

Farms:

Small Farms

Medium Farms

Large Farms

Feed Factories:

Small Feed Factories

Medium Feed Factories

Large Feed Factories

Based on the Geography:

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

The Dairy Expo at the India Expo Center & Mart in Greater Noida

Advance Hydrau Tech is excited to announce our participation in The Dairy Expo at the India Expo Center & Mart in Greater Noida from August 9-11, 2024. We warmly invite all dairy owners, farmers, and traders to visit us at Stall No. A1 for business discussions. Don't miss the opportunity to see our innovative animal feed block making machines, including our fodder block and TMR mixer, in action

0 notes

Text

Animal Feed Making Machine

We have the best deals for Animal Feed Making Machine at Indian Trade Bird. We are the leading manufacturer, supplier and exporter of Animal Feed Making Machine like Biomass Machine, Pelleting Machine 20HP, Bar Feeder Machine, Cattle Feed Plant, Poultry Feed Plant, Cattle Feed Mixer Machine, Hammer Mill Feed Grinder, Feed Mixer Machine and many more are available. A animal feed making machine is also called a animal feed maker, where they can be used to make animal feed from other animals. The feed machines are animal feed machines and animal feeders in large-scale, small-scale, and home animal feed making machines. Our Animal Feed Making Machine are highly demanded in the market due to their optimum efficiency, utility, and durability. The machines manufactured is assembled from the top quality component and advanced technology. These machines are highly beneficial as it provides complete automation, excellent performance, high production rates, and the best quality production.

0 notes

Text

Plastic Granules Mixer Machine in Chennai

Plastic Granules Mixer Machine in Chennai: Company Overview: Invoit Plast Machinery Pvt. Ltd. is located in Ahmedabad, Gujarat, India. Invoit Plast Machinery Pvt. Ltd., is manufacturer, supplier and exporter of plastic processing machineries. We are Specializes in Manufacturer and Supplier of Plastic Granules Mixer Machine. Offers Plastic Granules Mixer Machine as well as plastic raw material mixer machines. Emphasizes stringent quality criteria to ensure high-quality products for customers. Advantages: Overcomes traditional deficiencies and ensures even and adequate blending. Ideal for plastic extrusion, animal feed mixing, and building materials blending. Offers numerous benefits in various industrial applications. Features: Precisely engineered for fast and homogeneous mixing. Easy to operate with control panel featuring overload motor relay protection. Three-side material discharge options (Left, Right, Back). Equipped with inspection and cleaning windows for convenience and safety. Applications: Essential for achieving the perfect recipe of raw materials in plastic component production. Used in various industries including injection molding, blow molding, blown film production, etc. Facilitates homogeneous mixing of masterbatch, virgin granules, and regrind materials. Invoit Plast Machinery Pvt. Ltd. Provide Plastic Granules Mixer Machine in Chennai, Tamil Nadu Including Poonamallee to Sriperumbudur across Irrungattukottai, Mannur, Sengadu, Mappedu & Pillaipakkam, Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam. For further details and inquiries, interested parties are encouraged to contact the company. Read the full article

#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Easytooperate#Erode#Exporter#Irrungattukottai#Kallakurichi#kanchipuram#Kanniyakumari#Karur#Krishnagiri#Madurai#Mannur#Manufacturer#Mappedu&Pillaipakkam#Mayiladuthurai#Nagapattinam#Namakkal#Nilgiris#Perambalur#PlasticGranulesMixerMachine#PlasticGranulesMixerMachineinChennai#PlasticGranulesMixerMachineinIndia

0 notes