#and then one of the purchases was on 'awaiting delivery to warehouse'

Explore tagged Tumblr posts

Text

The purchase of the new CyberHelix cards got cancelled, which is Frustrating because that's why I bought any cards today, but I did use the refund to go buy two new auctions. Still getting the basic versions of the two Riku cards, but the one with the shiny signature is a no-go 😩

#thistale rambles#but upside#i ordered things at a Reasonable Time for once#and so the payments processed with the merchant quickly#like - i hit pay#and then one of the purchases was on 'awaiting delivery to warehouse'#by the time i clicked back to my orders

5 notes

·

View notes

Text

The usefulness of managing inventories

Interlinked and overlapping functions exist in all businesses. The backbone of any business delivery function is logistics, supply chain management, and inventory management. That makes these functions as important to marketing managers as they are to financial controllers. Managing the inventory is a very vital task that gives you a complete picture of the supply chain. It is also reflected in the financial health as seen on the balance sheet. All organizations strive to keep an optimum inventory. That enables it to meet all its requirements. Over or under-inventory is avoided. It directly impacts the financial figures. Inventory is always on the move. Meticulous control through planning and review, and constant and careful watch on internal and external factors are essential requirements for managing the inventory. Most organizations have professionally qualified inventory planners. They constantly monitor, control, and review the inventory. They also interface and liaise with production, procurement, and finance departments. What actually is inventory Inventory is an idle stock of physical goods. These goods have a certain economic value. Organizations hold on to them in assorted forms. They are held because they await packaging, processing, alteration, use, or sale at some point in time in the future. The organizations that are involved in manufacturing, trading, selling, and servicing a certain product, hold stock of assorted physical resources. These resources are kept for future consumption and sale. Keeping inventory is a mandatory compulsion of businesses. Different businesses keep inventories for different reasons. The reasons could be speculative, functional, or even physical needs. Keeping in mind the points above, we reach the following verdicts with reference to inventory: - Production, manufacturing, and selling organizations have to hold an inventory in one form or another. - Inventory can be in a completely finished state or even in an incomplete or partially complete state. - Inventory is managed for future consumption, future sales, and future processing/value addition. - All resources held in the inventory have an economic value. They even count as assets of the business. The various kinds of inventory Materials inventory is a necessity at all stages and departments of an organization. A business concerned with manufacturing should hold an inventory comprising raw materials and consumables that are essential for production. Partially finished goods are also kept in the inventory. The finished goods are held in an inventory located at the plant, stores, and distribution hubs. Raw materials and finished goods that are in transit at different stages are also kept in the inventory. Goods that are finished are held by organizations at their stocking junctions or even with the dealers and warehouses, till the time they reach the market and then the end users. Other than raw materials and finished goods, organizations keep spare parts for servicing products in the inventory too. There is a designated place in the inventory warehouse for defective products, scrap, and defective parts provided these have an economic value and are part of the inventory records of the company. Kinds of inventory with respect to functions INPUT PROCESS OUTPUT Raw materials Work in process Finished goods Consumables required for processing. E.g.: fuel, stationary, bolts & nuts, etc. Required in manufacturing Partially completed production, in various stages, stored with various departments like production, WIP stores, QC, final assembly, paint shop, packing, outbound store, etc. Finished goods at distribution centers throughout the supply chain Maintenance items/consumables Production waste and scrap Finished goods in transit Packing materials Rejections and defectives Finished goods with stockiest and dealers Locally purchased items required for production Spare parts stocks & bought out items Defectives rejects and sales returns Repaired stock and parts Sales promotion & sample stocks Read the full article

0 notes

Text

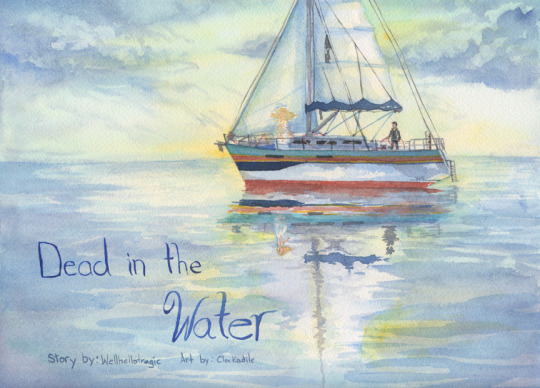

Dead in the Water (1/2)

You guys!!! It’s here! It’s our @csrolereversal drop date and I’m so excited for you all to see the amazing art @clockadile created for this event. Everyone, please go to her page, check out this amazeball painting, and send her all of the love that she deserves because this fic would never have existed without her! She is just such a wonderful person and I feel so honored that I got to make words in an effort to bring her art to life in a different way. I hope that I’ve done it, and her, justice and that you guys enjoy this. Shout out to @darkcolinodonorgasm for pulling this event together and to everyone in the rolereversal discord chat. It truly has been such a wonderful event and everyone has been so amazingly supportive of one another, so thank you all for being so awesome! Also tagging @cshalloweek even though my theme doesn’t completely match the day.

Summary:

Killian Jones may have just had the worst year of his life. The loss of his hand, of his career, and of his pride were almost more than he could take. In a bid to reclaim his life, Killian decided it was time to face his fears, and get back on the metaphorical horse, or in his case, back on the water. Only, the purchase of a haunted second-hand boat may just come at the cost of his sanity.

“The sea is like a cruel mistress. You can love her, you can hate her, but you can never trust her.” - author unknown

Rating: M (foul language sprinkled in and some adult themes)

Also on AO3

“Mayday! Mayday!”

Nothing.

“Please, is anyone out there?” The faint words were met with radio silence. The only noise a high pitched whining from what was likely a busted eardrum. Weak and dizzy, blood continued to drip into the water filling the cabin. The once brown floor now covered in pink.

Searing pain, a sinking boat, and all hope lost. There was little to do but wait. Wait for the inevitable. There was nowhere to go, no reason to have hope. Climbing to higher ground had been a struggle, and pointless as the vessel continued to dip lower and lower into the icy water.

That night, prayers went unanswered. The heavens laughed as they flashed their pearly white teeth and the crackle of a thousand laughs filled the air. The rain continued to fall all around.

There was nothing to do but wait until the water finally claimed her prize. Until the sea took it’s claim. Until the world went black.

***

It was unseasonably hot in Boston. Granted, summertime was hardly a perfect oasis in the northeast on a usual year, but that July had seen it’s hottest temperatures in over sixty years, and the city had been a sweltering mess. The usually pristine buildings along Freedom Trail were littered with blinding metal as each window had suddenly become occupied with ac units overnight. There had even been rolling blackouts as the power company struggled to keep up with the city’s demands.

Why Ariel’s Antiquities had insisted on holding their event outdoors was a mystery to Killian. Women and men dressed in their best, hoping that fancy clothes would somehow insinuate that they had money and could easily out bid their competitors. Unfortunately for them, their power suits became far less intimidating by the minute as sweat lines began to appear sometime just before ten. As the hours drifted on, people became puddles, their shoes sticking to the sidewalks.

Killian found himself near constantly tugging on the collar of his shirt, peeling it away from his sticky skin. Unlike him, his brother had refused to undo the top two buttons on his shirt and seemed even more miserable, if that were somehow possible.

The two men had been sniping at each other for the better part of the morning, and now with the sun at full intensity above them, they’d resorted to silence as they milled their way through lot after lot. The auction advertisement Killian had seen online seemed to have mostly a mishmash of memorabilia and collectables, with a few actual antiquities mixed in.

But unlike the other bidders, the two men weren’t there for random knick knacks. There was one specific item that had caught his eye on the online inventory. A tiny thumbnail the only indication of its existence and he could only hope that it hadn’t been from a previous auction.

For over an hour, Killian traipsed through the old fair grounds, Liam in tow behind him, searching with no luck.

“Killian, I hate to be the one to say this, but it’s not here. We’ve been to every lot and it’s just garbage.” He turned to see his brother giving him a look of pity, infuriating his very being. “Perhaps this is a sign.”

“A sign of what? False advertising?”

“That’s not what I meant and you know it. I just-” Liam took a deep breath, pushing the air out on an audible huff. “I just worry about you.”

With that, all of the anger and frustration from the day left Killian’s body. He couldn’t be mad at Liam any more, not when he knew it was true. When he still had memories of waking in the hospital, of seeing Liam’s eyes red and puffy from tears. It was the first time he’d seen his brother cry since their mother had passed years before.

“Liam, this is something I need to do. I need to prove to myself that I can get back out there. I can’t let this cripple me for the rest of my life.”

His choice of words hadn’t meant to convey the irony, but as his brother glanced down at the metal and leather covering his wrist, Killian couldn’t help but notice the cruelty of the universe. That even the most benign of words could cause such pain, even a year later. How even thinking about that day caused his missing hand to throb in pain.

“Killian, you are one of the strongest people I know. You don’t have anything to prove. Not to me or anyone else.”

Gone were the days where Liam teased him and called him little brother. Now, he was lucky if Liam said anything cheeky around him at all. And while he didn’t have anything to prove to anyone else, the truth was that he needed to show his brother that he wasn’t broken. Not anymore. That he didn’t need to be coddled like a wounded duck.

Before he could respond though, a glimmer caught his eye from a passing bidder’s reflective earrings, causing him to whip his head to the left. And there, tucked behind an old telephone booth, 2 huge entertainment centers, and a large canopy bed, there it was. There she was.

He didn’t wait for his brother, his jogging nearly breaking into a full stride. She was hard to see, tucked away behind items too heavy to move, but even in his limited view he could see that she was battered and bruised. Still, Killian knew that with a little sweat equity, she could be a marvel. He let his hand run down the fiberglass, feeling the strength of the hull, despite the hole in her port side. A gaping wound about the size of a bowling ball.

She was damaged, just as he was, but together they’d mend each other. He was sure of it.

“That’s it? That’s the boat you brought us all the way out here for?” Killian could only smile to himself. “Brother, she’s a mess. Where’s the mainmast? And did you see that hole? There’s no telling what kind of dry rot is on the inside.”

“Yes. I know she’s not much to look at right now, but-”

“No. You can’t be serious. She’s better off torn apart for scraps.”

Killian couldn’t explain to his brother the draw that he felt. He’d been searching auction houses for months. All of the boats he’d seen were either grossly overpriced, or faced the Goldilocks conundrum. Too small. Too big. But this one, it was just right. From the instant he’d seen that tiny thumbnail picture on his laptop screen, he’d felt it deep within his gut. He was meant for that boat, just as she was meant for him.

“And what kind of name is Jewel of the Real?”

“Realm.”

“Excuse me?”

“It’s Jewel of the Realm.”

Killian’s hand brushed over the faded wood, tracing the faintest outline of where an ‘M’ used to reside.

The rest of their time there was a bit of a blur for Killian. Liam trying his best to talk him out of buying The Jewel as people threw their paddles up in the air, capturing the trinkets on the stage. Killian fighting with a man two rows ahead of him for the winning bid, going over the maximum price he’d set in his head. Giving the auction house the delivery address, ignoring the way his brother huffed as Killian wrote them a check.

But none of that mattered, because in the end, she was his. The auction house delivered her a few days after his check cleared. The address he’d given them was for a warehouse another expat had told him about. Cheap monthly rates and all of that. What Will Scarlet had neglected to mention was that the warehouse was actually an abandoned building in a rather questionable part of town. Killian never should have trusted the man with a deposit sight unseen. The building lacked windows or doors, and Killian immediately knew he’d been had by the huxter.

He’d scrambled to find another place to fix up the Jewel. The drydocks at the marina were expensive and lacked space for him to spread out with tools, not to mention the absence of privacy while he worked. It was bad enough that people stared at his hook while he was picking up food from the local pub or out with Liam and his wife. He’d be damned if he was going to have people watch him work on a boat one handed. He even considered trying to work out of his friend, Robin’s, garage but the thirty two foot boat simply wouldn’t fit. No matter how imaginative he got with his sketches.

In the end, it was the most unlikely of allies that came to his rescue. The last man he ever expected to aid him with the Jewel. Liam owned a shipping company, specializing in European imports, with English ales and German lagers making up the bulk of his business. The main office was based in downtown Boston, but there was also a small warehouse down by the port where items were stored as they awaited inspection. His brother, still not happy with his decision made him an offer anyway. Come to work at Jones Shipping Monday through Friday, and he’d have the warehouse all to himself in the evenings and on weekends to work on the “abomination.”

Killian accepted begrudgingly. He wasn’t necessarily in need of a salary. He had the monthly stipends from the Navy to live on, the only benefit of losing his left hand, and the idea of becoming a corporate stooge maddened him to no end. He’d already sold his soul once, and they spit him back out once they deemed him of no further use. He wasn’t quite ready to lose the rest of himself to a full time day job pushing paperwork, schmoozing potential clients, and taking orders from Liam. But the perk of Liam’s harbor warehouse was too great to pass up.

So he took the job. He started on a Monday and the boat was delivered on the following Tuesday. Liam had neglected to mention his need for a key, so after driving across town, Killian ended up having to turn around without seeing her. The next day he’d nearly ripped into Liam when he saw him, but seeing three other men in suits sitting in front of Liam’s desk made him rethink his anger. Or at least rethink giving his brother a piece of his mind at work in front of people he’d only ever met at staff parties. He’d already had to deal with stares and questions from a rather bold intern. The stress from his own self-consciousness only amplified his frustration with Liam.

He finally got the key from Liam later that afternoon, along with another gift that he wasn’t particularly fond off. One that actually left him offended. One that he threw back in his brother’s face as he stormed out of his office, not caring one bit what anyone thought of him. Not when his brother obviously thought so little.

He was too upset to even go check on The Jewel at that point, choosing to head to a pub near the harbor instead. The Rusty Anchor was a fan favorite for expats. It’s where he’d met Scarlet, which unfortunately didn’t actually say much about the place. He’d met a few good blokes there as well though, like the bartender Robin. They’d become friends in a grief counseling group. It was mandated for Killian, but optional for the other man who was grieving his wife. Listening to Robin talk at their monthly meetings had helped put Killian’s loss into perspective. Suddenly his missing hand didn’t seem so catastrophic.

Robin had invited him to the pub knowing Killian was new in town with few friends, and the two men had formed a bond in the months since. In a way, he felt closer to the man than he did to Liam. Like he could tell him anything without the brotherly judgment that always radiated from the elder Jones.

After a few pints and a good talk with Robin, Killian had calmed. Liam was still a moron, but that wasn’t on him. And as Robin said, he just had to continue to remind himself that the only reason he was even working for his brother was so that he could fix up the Jewel. As soon as she was sea worthy, he could leave his job without breaking his word to Liam.

In a slightly better mood, he headed a few streets over to the warehouse, ready to take a full inventory of all of the repairs she’d need. The hole in the hull was obvious, as well as new paint all over, and she needed a new mast and sails, but there was always the concern of dry rot. That was the biggest worry. Having to replace every plank of wood and all of the fiberglass on the boat would defeat the entire purpose of restoring her.

Not to mention the difficulties he’d face using his hook. He was more than proficient with it for everyday use after eight months of practice, but some things still tested his limits. As he walked up to the warehouse, thinking about how he’d hoist the sails on without tearing them, he was completely lost in thought, oblivious to the man standing next to his boat. He was more than a little embarrassed by the shriek that escaped from his lips, but upon realizing that it was Liam there waiting for him, his distress turned to anger again. Especially when he saw the box from earlier on a nearby table.

“Killian, before you say anything, it’s not what you think. I never meant to imply-”

“What? That I’m a freak. That I’ll scare away all of the clients?”

“Actually, it was quite the opposite. I got it for you.” Killian looked down, unable to meet his brother’s gaze. “What? You don’t think I see you? The way you shrink in on yourself when you’re out with Elsa and me?”

Liam had him there.

“Look, Killian. I just thought that maybe it would help you to feel more comfortable. I never meant to insinuate anything by it.”

Perhaps he had overreacted. In his mind’s eye, it was just the cherry on top of a horrible year. The whole world judged him. Wasn’t it only a matter of time before his brother saw him as a disfigured beast as well? Except, that wasn’t what happened. He’d made a snap judgement, and thought the worst of Liam in the process.

“You’re right. I... it’s harder than I expected it to be sometimes. I thought,” he had to fight to keep his emotions in check as he remembered those first few weeks in the hospital. How he’d lost more than just his hand. “I thought it would be easier than this.”

“And I’m sorry that I didn’t handle it in a more sensitive way. I think I was just so excited to show it to you that I assumed you’d be just as enthusiastic. Obviously, it’s not all that functional, but it’s remarkably realistic and Elsa and I just thought it would make you more comfortable dealing with clients.”

Killian laughed to himself. A sad little thing. It was very realistic in a way that nauseated him when he first opened the box. Even now, as he walked over to it and lifted the top, he couldn’t help the catch in his throat. The prosthetic hand looked incredibly realistic, right down to the synthetic hair on the back of the silicone. There was a metal clip that popped into place in his arm sleeve and a metal wire that hooked into his shoulder strap, just like with his hook that allowed some slight mobility in the hand. It opened and closed, allowing him to grab objects if he needed to, but it wasn’t nearly as advanced as the mechanical hands he’d seen in the clinic. Although this one probably didn’t cost the same as Liam’s house either like the mechanical ones, which was a plus.

He lifted it from the box, testing the weight of it. It was slightly heavier than his hook, something that would take some getting used to. It was also probably going to end up being longer when all was said and done. Wearing suits might be a problem. He’d have to wait until he got home to check.

Liam, for his part, didn’t seem to want to make it any bigger of a deal than he already had. Instead, he changed the subject back towards The Jewel.

“Do you want the good news or the bad first?”

He’d already had a hard enough day. He didn’t need the bad news at all, much less first.

“The good.”

“Well, she’s not a total loss. I’ve been checking her over, and the bulk of the damage seems to be located here, in the hull where this hole is. The fiberglass is badly splintered around it. I’ve been trying to work out what exactly could have caused it, but aside from an act of Poseidon himself, it makes no sense. Whatever made the hole, it came from the inside of the boat. The furniture inside the cabin is also ruined. Smashed to pieces or rotted away. But the rudder and keel are still in perfect shape.”

Killian leaned in closer, allowing his hand to move along the edges of the hole. Liam was right. The edges was splintered towards the outside of the boat, and the fiberglass around it was all badly cracked. The auction house had sent him home with documents explaining that the ship had been docked at the marina and it had been hit by some object during a storm. They’d clearly been mistaken.

“And the rest of her? What shape does she seem to be in?”

“Well, the wood planks on the deck could use a good sanding, but if you’re just talking about integrity, I think she’ll hold up just fine.” Killian and Liam both climbed the ladder Liam had set up, allowing him his first good look at her. “You know about the mast and roping already. A full redo on both of those. But come look at this!”

Killian followed, letting his hand glide upon the metal railing. For the first time, it felt real. Look at this! It’s the original certificate showing the builder. You realize what this means don’t you?”

“That you’re excited she’s older than you are?”

“No! She’s vintage Killian! Once we fix her up, you can sell her for twice what you paid for her! Well done little brother.”

Killian took a deep breath, already out of patience with his brother for the day.

“Liam, I see three things wrong with what you’ve just said. First, it’s younger brother. Second, when exactly did this become a joint endeavor? Just a week ago you thought the very idea of my purchasing her was the single greatest mistake of my life. Thirdly, and listen closely Liam because I’m not going to say this again, I am not selling this boat.”

“Well you are my little brother. And I’m just trying to protect you. Why do you think I worry and watch after you so much?”

“You don’t need to worry about me!”

“Well apparently I do!” There was something about the way Liam’s voice, the way it broke as he screamed the words that tugged at Killian’s heart. “You almost died! I waited and waited while they searched for your body, sure that there was no way you’d survived that storm. And then I waited and waited again at your bedside in the hospital, praying to God that he didn’t take you away from me like he had mother. So don’t you dare tell me that I can’t or shouldn’t worry about you!”

Killian had to will back the tears threatening to fall from his eyes. He knew that Liam had been at his bedside in the hospital, but he had never thought of what it must have been like for him getting the call that his brother was lost at sea in a storm. He spent a great deal of time clinging to some wreckage, just trying to stay afloat as the waves crashed over his head, and his body plummeted over and over for what felt like years. Once the storm had passed, he found a piece of the destroyed ship large enough for him to crawl on top of and he let the exhaustion take over. When he woke again it was to intense agony in the hospital ICU.

“Liam, I’m not out there anymore. I’m not adrift at sea anymore. I’m here, and I’m fine.”

“But you aren’t. You aren’t here. You say you are, but I think a part of you died out there that day, and I-” Liam gave up all pretense of hiding, letting the tears flow free, “I think part of you wants to get lost again. Why else are you so intent of fixing up this boat?”

“That’s what you think? That I want to put in all of this work just to go out and vanish into the ocean? Liam, I’m doing this to prove to myself that I can. Because the idea of going back out there sends a bolt of terror through my spine right to my very core. I need to show myself that it was just a freak accident. To get back up on that proverbial horse.”

Liam said nothing, just walked back down to the stern of the boat and down the ladder, walking straight out of the warehouse, leaving Killian alone with the guilt of everything he’d put his brother through. Even as children he was always managing to get into trouble, and poor Liam had always been the one to pick up after him. As he heard Liam’s car start up from the open warehouse door, he couldn’t help but wonder how much more Liam had left in him.

If it weren’t for the fact that he had work at eight in the morning, he very likely would have found himself back at Robin’s, downing a full bottle of rum all on his own. As it stood, he had a debt to Liam, far more than for the agreement he’d made for the warehouse space. He owed his brother everything, and though he couldn’t give Liam the one thing he wanted most, he could give him everything else. He could be the prodigal son in a way. Arrive to work everyday in nice clothes, rubbing elbows with Boston’s elite.

So instead of heading back to Robin’s he went down into the ship’s cabin. The space was small, not that he expected much. The boat was only thirty two feet long, and not that tall. There was enough space for a small kitchenette with a tiny sink and grill top. Across from that stood what should have been a small dinette area. Where a table and bench seat should have been was nothing but wood scraps and moldy torn fabric.

He nearly gagged when he opened the door to the tiny lavatory. The toilet was covered in black mold, or what he hoped was mold as nothing else seemed like an attractive option. And then he went to the bedroom area up at the front of the boat. He wasn’t quite sure what to expect, knowing that the hole was in that area. What he found was nothing though. The bed and mattress had been removed, as well as the padding in the seat next to it. The wood forming the cabinets and closet had been torn out as well, leaving behind only the impressions of where they once fit in.

It was evident that the Jewel needed work when he bought her. And he knew that had he known at the time just how much work she needed at the auction house, he likely still would have bought her. But as he stood there, in the torn apart interior, he couldn’t help but feel scammed by Ariel’s Antiquities. They’d purposefully positioned her in a way that no one could see just what shape she was truly in.

Repairing her would take longer than anticipated, which only meant more time working for Liam. Exhausted, Killia headed back to his one bedroom apartment, crashing nearly the moment his head hit the pillow. The next morning, he rose well before the sun, even without the use of an alarm. Apparently you could take the man out of the navy, but not the navy out of the man.

After a nice run, Killian readied himself for the day by showering. Once dry, Killian placed his sleeve over his stump, followed by the hook he’d become so used to. He then picked out one of his better suits, not that he had all that many to choose from, dressed, combed his hair, and stepped back to take stock of himself in the mirror. It wasn’t a look he was used to. In fact, the last time he’d been dressed in such a way had been his mother’s funeral. He was still a teenager, Liam barely an adult himself, wearing suits they hadn’t yet grown in to.

Not wishing to dwell on that thought any longer, he headed for the door, grabbing his keys from the bowl on the side table.

And that’s when he saw it. The gift that Liam had given him the day before. His brother had left it in the warehouse in his haste to escape, and Killian had grabbed it on his way out, still not sure how he felt about it. He’d never really intended to wear it, not for everyday office use at least, but as he stood there in his suit, feeling completely uncomfortable and out of place, he decided to, just for once, do something for Liam.

It took him a few minutes to undress, removing his suit jacket and dress shirt so that he could disconnect his hook from the shoulder strap. The hand felt clunky on his arm, and it was difficult to get it through his sleeves, but in time he managed.

The drive to Liam’s, and now his office, wasn’t a long one, but at seven in the morning, it may as well have been a full county away. The traffic was horrible, not something he’d become accustomed to driving in. He’d always avoided rush hour like the plague, and now it would be a part of his daily routine. He also found that the hand was difficult to use. Because of his sitting position, it wouldn’t quite clamp shut around the steering wheel the way his hook would have.

By the time he arrived, he was over ten minutes late, and the morning staff meeting had already started. He did his best to sneak in, sitting at the back of the room, hoping to go unnoticed by Liam, but because the world was already against him that day, he failed.

Liam called him up to the front of the room, officially introducing him to everyone as the new head of client relations. Killian gave an awkward wave and that was it. He’d been inducted into the company, and day after day, week after week, he sat at a desk, working up contracts, researching possible leads. His nights were often spent at dinners, flirting with wives and schmoozing husbands into signing with Liam’s company. He hated it, and more still, he hated how little time he had for repairs on the Jewel.

Repairing the hull had been easy. He sent off for a patch kit, a misleading name considering the size of the hole to be touched up. After carefully cutting away the excess damaged fiberglass and setting the patch in place, he waited for the epoxy to harden, sanding down the excess so it was smooth. Aside from the lack of paint, she looked good as new. The hardest part had been placing everything where it needed to go with just one hand.

He soon realized just how difficult repairing the rest of the boat would be. The entryway to the Jewel was narrow, hardly wide enough for one person to enter at a time. He’d never be able to get fully assembled furniture and cabinets in. So slowly, he brought in all of the material, piece by piece. It took time, considering he’d had to carry all of the materials from the parking lot down the dock, and onto the ship. It was exhausting work, and there was still the matter of assembly. It took him weeks to get everything cut just to size, and assembly space had become a real issue after the new bench and table had been installed. Finding a place to store the cabinetry wood had almost broken him. The boat had almost broken him.

But he persevered. Slowly the cabinets came together. The bedroom in the bow of the boat found itself with a bed and a small closet, and the bathroom got a shiny new toilet. After two months, he’d finally finished the interior of the boat. All that stood in his way from land and sea was a new mast, the part Killian had been dreading most.

It was the very first thing Killian had ordered after he’d purchased The Jewel, but as with any special order, it had taken over a month to arrive, and then when it did, it wasn’t even the right size. He and Robin had spent the better part of a day trying to make it work, to somehow force the new mast into place, huffing and puffing at the weight. Hours later, Killian finally admitted defeat, and with shaky arms sent the company a firmly worded email chastising them for their incompetence.

Two full months and one paint job later, a new one arrived. Robin was unable to help him again though. Setting his pride aside, Killian was forced to ask for help. He and his brother’s relationship had soured. It wasn’t that there was ill will between the brothers, but there was a small bit of resentment on Killian’s part. Sometimes it seemed as if Liam was giving him extra work and setting extra meetings for the sole purpose of stalling his repairs. Some of the clients that Liam set him up with were too small to even have shipping needs.

We just want to make sure that they keep us in mind incase the expand Killian. You have to always be selling Killian. It’s called networking Killian.

He’d had enough. Eventually he’d declined enough of Liam’s offers to spend time together on the weekends that Liam had stopped inviting him over. The brothers discussed business needs, but outside of the office, they may aswell have not even have been related. Killian did feel bad. His brother was the only family he had left after all, but there was just the matter of his pride. He’d had so many arguments with Liam in his mind that he couldn’t remember which conversations were real, and which were made up. He just knew that he was right in all of them.

Which is why it was so hard for him to turn to Liam for his help. Unfortunately, the mast weighed a few hundred pounds and while the dock, where the boat finally resided, had a crane to help them move it in place, someone still needed to help him slide it into place and hold it steady as he secured it to the boat. The dock had a firm policy on not helping with certain repairs. They didn’t want to be held liable for any damages or injuries that occurred as a result of human error.

Asking Liam for help had been hard. It took him full two days of building up the courage. He’d nearly walked into Liam’s office three times before turning around at the last minute. Finally, he just had to man up. To his surprise, Liam agreed without much opinion on the matter, and that weekend the two brothers finally made up as they struggled together to install the mast. They tried seating it in place, but despite their best efforts, it was slightly off, leaning just a degree or two. While most people might have shrugged it off, both of the Jones boys were determined to get it in straight.

To the chagrin of the crane worker, they demanded he raise it back up so they could check to make sure the surface was level. Nothing seemed off to the naked eye, but again, the mast wouldn’t sit straight. After one final raising, Killian stuck his hand in the seat, trying to feel if there was bubbling or warping in the wood, and to his surprise, he felt something cold and smoothe, not at all like the wood plank he’d expected. After some fiddling, he was able to loosen the object enough to pull it from its hiding place. It was small, so small he wasn’t surprised that anyone at the auction house had missed it.

Liam, for his part hadn’t said much, but Killian could tell by the way Liam was breathing that his brother was annoyed, not with him but with the delay, and ready to finish working. Killian threw the gold piece in his pocket and together, he and Liam finished installing the mast and all of the rigging lines. Afterwards they went for drinks at Robin’s bar, a place Liam had never been before. They shared a few beers, caught up on all of the things they’d missed in the past few months, and each departed like it was no big deal, both ready for a good night’s sleep.

Killian had hoped to crawl into bed and fall straight asleep, but for some reason, as he laid there, his brain seemed to kick into overdrive. It started with thoughts of how he’d have to map out the currents and winds in the boston area before he could ship out. Before long though, all he could think about was work. He’d planned on leaving Liam’s company as soon as he was done, and while he hated some aspects of the job, he did like the structure it provided him with. It forced him to get back into the world again, something he hadn’t realized that he needed to do until Liam tricked him into it.

Unable to sleep, Killian got up to clean, something that usually relaxed him. He started with the dishes, washing and drying them all by hand before moving on to tend to his laundry. Most of his suit items were dry clean only, but his weekend clothes were soaked with sweat and best washed sooner rather than later. Checking all of the pockets and making sure everything was right-side out, he threw items in the washer one by one until he got to the jeans he’d been wearing that day. He’d managed to completely forget about the trinket he’d found on the boat, until just then.

He finished sorting his clothes and started the machine up before heading back into his bedroom, turning on the nightstand table lamp as he crawled back under the sheets. He let the metal turn in his fingers, inspecting the perfectly polished gold. It was a small locket with a bird etched onto one side. There wasn’t an engraving to go with it and told him nothing about the person who’d lost it. The chain that it was attached to was short and the links where tiny, meaning it likely belonged to a woman, but that was all he was able to gather. He continued to turn the locket, just feeling the weight of it in his hand, the surprising warmth of it, when his finger caught on a hidden clasp and the locket snapped open.

It wasn’t what he’d expected. Most women’s lockets contained tiny photographs, but the inside of this one held a small compass. The opposite side featured an engraving, but it didn’t have any names. It simple read: So you always find your way.

He should have wanted to search for the owner, to return what was probably a meaningful gift. There were plenty of news stories all the time about people helping to reunite lost items and owners. The soldier who had his purple heart stolen. The bride that lost her wedding ring on a beach vacation. They were always happy endings, and he knew that the locket didn’t belong to him, but for some reason, he just felt a call to it. Like he also needed it to help him find his way. So he kept it, slipping it on over his own head, having to pull it past his ears. He fell fast asleep soon after.

The next week at work had been grueling. Liam had lined up three dinners for him, one of them with a very sexually aggressive woman that ran a dog breeding company. Apparently there was a high demand for designer dogs and people were willing to pay high prices to have them shipped over the water during the summer and winter seasons when airlines restricted their pet travel policies. He’d had to pry her off of him at the end of the evening, promising he’d call her soon. A complete lie.

The whole encounter had left him feeling dirty. He hadn’t even so much as looked at a woman since his accident, not really, and he just wasn’t ready to move forward in a romantic capacity, even just a physical one. Not after having his heart shattered before. The woman in question wasn’t even interested in him. Not as anything more than a gigalo.

The weekend couldn’t have arrived fast enough. He just needed to get out of town. To get away from everyone, from his responsibilities. He was ready to hit the water and shed the ghosts he carried around with him. He’d planned meticulously. There were charts filling half of his closet and he’d popped by the Tuesday before to fill the kitchenette with snacks for his inaugural trip. He didn’t have a refrigerator yet so he’d done his best to stick with ready to assemble meals. Nothing big, just some bread and jams. A few tea bags and bottled water in case it got cold out on the water.

The plan had been to set sail just as the sun was rising that Saturday. To greet the new day on the water, but for some reason his alarm hadn’t sounded that morning, and for the first time since he’d joined the navy, he overslept. By the time he made it down to the docks it was just after ten, and the area was filled with people. Families going out on day trips. Tour groups trying to enjoy the last few weeks before the winter season. Before everyone would have to winterize their boats and leave them stored away until spring.

He was lost in his thoughts as he walked along the wood planks at the docks, past other ships, nearly tripping on a rope that someone has carelessly left out. Cursing under his breath, collecting himself from the slight embarrassment of it all, he glanced back at The Jewel. It was hard to see with the sun reflecting back on the water, but for just a few seconds, he could have sworn that he saw a shadow moving along her port side. There was a person on his boat.

It wasn’t unheard of, finding a vagrant living on an unused boat, or some random person lost and on the wrong ship. The Jewel had a very specific and unique paint job though. Mistaking her for any other vessel on the harbor would have been impossible. And he’d been there only a few nights before. He would have seen signs of a stowaway using her for shelter.

That could only mean that whoever was aboard his boat was looking for trouble, and after the morning he’d had, he was more than willing to give it to them. Swearing to himself, he picked up his pace, ready to give the trespasser a piece of his mind, but when he finally made it to The Jewel, she was empty. Thinking perhaps they’d gone below deck, he crept down the narrow stairs, doing his best to avoid making noise. There was no one though. She was empty. Just a trick of the mind.

Feeling foolish, Killian reemerged, on the deck, ready to give all of the lines one final check before setting sail when he heard a noise, a creaky wooden plank from down below. This time he ran, not giving a damn if the person knew he was coming or not. He was ready to find whoever was hiding.

Once again though, he came up empty. Even after searching in all of the cupboards and storage spaces under the kitchen bench and his bed. He checked all of the closets, but there was no one. He was all alone.

It was just in his head. Not surprising considering what a huge step he was about to take. The idea of going back on the water leaving him with an uneasy queasy feeling in his gut. Which was also the exact reason that he needed to do it. Why he’d tried to stress to Liam the importance of buying The Jewel.

He needed to conquer his fear. Even if his brain tried to scare him out of it. Because that’s all it was. A shadow from a person on a boat near his. An old creaky boat groaning from the change in humidity. It was all in his head, and it needed to stay there.

More determined than ever, Killian went back upstairs, ready to set sail, distraction free, but when he emerged from the cabin, he was met once again with an odd sensation. A feeling of being watched.

“Permission to come aboard?”

“Bloody hell, Liam? How long have you been here?”

“Not long.”

And there it was. His older brother, his protector, playing games with his head to place doubt. Liam had done more than his fair share of things to delay the boat becoming ready, but to actually try to scare him away was just too much.

“What the hell’s wrong with you?”

“Come again now?”

“I’m talking about you playing games with my head, trying to frighten me away from taking my boat out. You’ve made it very clear that this wasn’t something you wanted me to do, but this is a new form of low, Laim.”

He was furious.

“Killian, I assure you, I have no idea what you’re talking about. I’ve only just arrived.”

He watched the elder Jones, the way his brow furrowed. Liam may have been a great many things to Killian, but he’d never known his brother as a liar.

“Then what are you doing here?”

“I’ve actually come bearing a gift.”

It was only then that Killian noticed the neatly wrapped bundle in Liam’s left hand. Liam didn’t ask permission again, choosing to come aboard The Jewel to hand the gift to Killian. He felt more than a little guilty for accepting it, especially after having just yelled at his brother, but Liam was insistent.

Carefully he peeled back the wrapping paper, careful not to tear it, lest he find paper scraps for weeks to come blown into every nook and cranky. Inside, he found a book, an old one by the look of it.

“It’s a first edition. Took some time to track down or I would have had it to you sooner.”

The significance of Liam’s thoughtfulness was evident. It was a first edition of Peter Pan. The book their mother used to read to them nightly. Each time she finished, Killian would beg her to start again from the beginning. It was the thing that first ignited his love for the sea.

“Thank you, Liam. This means more than you know.”

Liam just gave him a nod, understanding the emotional weight they both held in that moment.

“I, uh, guess you haven’t checked the stern of the boat just yet?”

It was on his list. First the ropes, then a walk around above deck to ensure everything was properly secured, before walking around the dock to check that everything was good on the exterior.

Intrigued, Killian climbed down from the boat and walked around to the back side of The Jewel. But what he found was that she’d been renamed.

“The Jolly Roger?”

“I very specifically remember you telling mum and me that when you grew up, you were going to own a huge ship, and you were going to name her The Jolly Roger-”

“Just like Captain Hook.”

He’d completely forgotten. As a small eight year old, he was determined that one day he’d own a pirate ship. That he’d sail the seven seas taking whatever he wanted from whoever he wanted. Probably in part because he was sick of getting Liam’s hand me downs.

“I hope you don’t mind. I know she’s not exactly what child Killian had in mind, but you’ve done exactly what you said you were going to do. And I know I’ve been a prick about this entire thing, so I wanted to do something to make up for it. To show you that I really am in your corner.”

Killian was touched. It was possibly the first time his brother had apologized to him since before their mother died. Even then, it was probably the first time he’d ever done it without being scolded into it.

“Thank you, brother.”

There’s one final thing. Last night, Robin and I came out here and installed a motor on the back.” Killian was about to say something, but Liam barreled on. “I know. But I just want to keep you safe. If you should find yourself without wind, you’ll still have a way to get back to shore.”

“Marvelous.” His annoyance only slightly tempered by Liam’s attempt at a kind gesture.

From his inside coat pocket, Liam produced a manual for the motor. ‘A guide to your new Stern Mounted Electronic Engine.’ He had to give it to Liam. He’d thought of everything. Even a Mr. SMEE.

Together, he and Liam set about getting The Jolly ready. After checking everything over twice, they finally set out, both men trying not to hold their breath as the docks become smaller and smaller. After about thirty minutes, they were able to relax, realizing that the ship hadn’t yet sunk, and likely wouldn’t anytime soon.

The trip was relaxing for the most part. The brothers argued still, as Killian realized that Liam had completely rearranged all of the food in the kitchenette. It wasn’t surprising and he’d seen Liam do it at his house, whenever Elsa would just quickly throw things back in the pantry. But what did shock him was how Liam adamantly denied it, even though Killian knew he’d left the tea bags in the cupboard above the tiny stove top, not under the sink. And the chips had been moved as well as other items. Still though, Liam swore he hadn’t touched them.

Killian eventually let it go, finding it not worth bickering over anymore than they already had. The real fist-to-cuffs came at the end of the day, as the two men had already redocked and were setting the boat back to rights. Liam had grabbed the trash and told Killian that he was going to take it all to the dumpster in the parking lot while Killian secured all of the sails.

Liam couldn’t have been gone for more than a minute when Killian stood to turn and move on to the other sail when he slipped and fell flat on his back. It hurt more than he wanted to admit, and in his haste to stop himself from falling, he’d somehow managed to catch his hook in the jib sail, tearing it as he fell.

Killian took a moment to compose himself, waiting for the sting of hitting his back on the rail to subside. He must have taken longer than he realized, because by the time he sat back up he heard Liam call his name and scramble across the boat to check on him.

Killian assured him that he was fine, or that he would be as Liam helped him back up. Careful of his steps, he turned to see just what exactly he’d slipped on when he caught sight of small water puddles in the shape of shoe prints. Absolutely sure that Liam had made them somehow, the two brothers had it out, causing Liam to storm away in a huff once more.

Killian stayed long enough to dry all of the water and to watch the sunset over the horizon before heading back to his place to grab a much needed ice pack. His back was still sore two hours later, so he opted for a shower instead hoping that the warm water might help soothe the muscles.

Slowly he undressed, trying not to twist or bend too much. Catching just a glimpse of himself in the mirror are he removed the small gold locket he’d found, he caught sight of his red cheeks, realising that even in October, he’d still managed to get a bit too much sun.

Getting to sleep had been tough. It was only after a glass or two, or three of rum that he was able to find a comfortable position. He drifted off, dreaming of being a child again. Of Neverland and Captain Hook.

The next morning he was still quite sore, so he’d opted not to take a second trip out on the water. Instead, he’d spend the day shopping for groceries and flicking through television programs until he settled on Wicked Tuna. Before he knew it, it was time to ready himself for bed and another dreaded week at work.

It ended up not being as bad of a week as he expected it to be. Liam hadn’t scheduled any meetings for him outside of normal office hours, and the clients that came into the office to settle contracts all seemed relatively normal for once. The brothers had quazied made up, but both felt it was best if Liam didn’t go out with Killian again for a while.

By the time the next weekend came, Killian was eager to set sail again, alone. No distractions. No mind games. Just him and The Jolly. Unable to hide the gold chain under his work shirt, Killian had chosen to leave the compass at home all week, but slid it back over his head before getting in his car to drive down to the water.

For a few moments he worried that his plans would be dashed as his car had refused to turn on. The starter trying to turn over and failing. Finally though, he got her started and headed straight for the docks.

He went through his usual routine, checking everything over, checking the weather once more. It was a little windier than he would have preferred, but the local station said that the wind would die down a bit by mid day. With everything ready, he set out, heading up the coast line just a bit.

The wind stayed stead for nearly four hours, despite the weather stations promise, and at one point, his life preserver ring had managed to come loose and blow straight off the ship. Not wanting to waste sixty dollars on a new one, he turned into the wind, stalling the boat, and dove dove in after it. A foolish endeavour on his part, considering he was alone if anything had gone wrong, but he figured if he could just get to the ring, he’d be fine.

The water was colder than he’d expected. In the navy he’d done cold water drills, letting his body adapt to it. But it had been a year, and his body simply wasn’t used to it yet. The moment he hit the water, his leg cramped up, and for just a second, he sunk under the surface of the water as he grabbed at his leg. When he resurfaced, it was with a mouth full of salt water. His nose burned and his eyes stung.

Once he managed to make it to the preserver, he tried wiping his eyes, but it only made things worse. Looking around to see just how far he was from The Jolly, his eyes had difficulty focusing. Everything became blurry as it felt like he’d had sandpaper rubbed against his cornea. At one point, it looked as if there was a figure standing at the bow of the boat. An impossibility given how far out he was and the lack of other boats.

He closed his eyes, giving them a few minutes to calm down, and when he reopened them, the figure was gone, and The Jolly was more in focus. Killian managed to swim back to the boat, a freezing mess in his wet clothes. He hadn’t actually thought about bringing a change of clothes with him for such a short journey. He stood there on the deck a shivering mess, ready to give up on the day.

As he tried to turn the wheel he began to feel slightly warmer. The wind had finally died down just as local weather woman Alfina Merryweather had promised, except that Merriweather had neglected to mention that her version of a slight breeze was actually a dead stop.

There was nothing, not even the slightest hint of movement. He waited and waited, at one point removing his clothes and doing his best to squeeze as much water out as he could. He thought of Liam, of how his brother would probably be worried if he didn’t hear from him soon. Thoughts that eventually reminded him of the motor his brother had installed for just such an occasion. The motor that Killian never wanted, and certainly wasn’t going to admit to using.

It took him forty two minutes to read the manuel enough to understand what he was doing, the whole thing one long novel of gibberish. Unfortunately, no matter how hard he tried, and how many times he went through the manuel again, twenty minutes later he was just as stuck as before.

After another thirty minutes of attempting to start it and pretending that hyperthermia wasn’t a real threat, he finally caved, ready to call for help over the radio to a towing company. But the radio was just as dead as SMEE, and all of his calls for help were met with static. He began to worry, checking his phone to see the time only to realize that his phone was dead as well. He continued to plea for assistance, the static only becoming louder, eventually there was a spark as he felt a strange nasty shock from the microphone

He jumped back, yelling every curse word he could think of until he was nearly hoarse. Just as he’d quieted, shaking out his hand, he’d heard it. A creaky noise coming from above deck, The same sound he’d heard on his first day out. The sound of boards buckling under the weight of a person. He was sure of it this time, unless the jolt had managed to shock his brain too.

Slowly he crept back up the stairs, feeling every hair raise along his arm as he went. Something felt off. Something just felt very very wrong. But he persisted still, opening the door as quietly as possible. He crept along the deck, treading lightly as not to make any noise. As he moved high enough to see the front of the boat, he noticed a figure. An eerie ethereal blur of a woman.

But before he could say anything she turned and looked right at him. He watched her for a moment, as she seemed to float above the bow of the boat, somehow both there and not quite real. And then her mouth opened, and with the anguished scream of a hundred voices at once, she yelled at him to get out.

He nearly fell as he scrambled backwards, feeling his heart in his throat, trying to leap clear from his body. And just as quickly as she appeared, she was gone. He was paralyzed in fear, completely unable to move when he heard the boat’s engine spring to life, snapping him out of his trance.

92 notes

·

View notes

Text

Importance Of Data Architecture In The Age of Digital Transformation

Understanding and swiftly adjusting to the shifting behaviors and expectations of digital users are prerequisites for a successful digital engagement. They need data, analytics, and applications to adapt to real-time digital processing for their digital experiences, which calls for a next-generation enterprise digital data architecture.

The gap between businesses that successfully use data and those that don't, according to our experience and deliverables in digital transformation services in Singapore, corresponds to a 1% margin boost for leaders.

A business need is the capacity to quickly use cutting-edge technology to supply goods and services in previously impossible ways. On the other hand, any company that does not leverage integrated digital transformation solutions and new technology runs the danger of being irrelevant to modern consumers.

Some of the most rapidly expanding global businesses are ‘born digital’, which implies that the power of digital is ingrained into the very fabric of their business strategies. Consumer expectations have been molded in several different ways by these and other cutting-edge businesses.

It seems that customers have come to assume that by just clicking a few buttons, a cab will be at their location in a matter of minutes. Or that the entertainment service they select would suggest programs that they are most likely to appreciate. Or that the movie or other stuff they're seeking will be delivered instantaneously through social media networks.

What technological elements support digital transformation, and what should you think about if you want to advance your company? The trendy, cutting-edge ones attract the greatest interest, and although you should invest in those that will offer you an advantage, it's equally critical to think about the data architecture required to support them. The crucial but sometimes disregarded component of digital transformation solutions is what can be referred to as data architecture.

Data: Core of the Digital Transformation

Let's take a look at how modern digital consumers purchase to better grasp the requirement for data sharing and analytics at high speed and scale.

Imagine Sarah, an individual using a search engine or social media platform. She comes across an advertisement for something that’s on her mind. The advertisement directs her to an e-commerce website, where she may view the item that drew her attention while the site suggests further items that she might enjoy. She may verify the date of delivery to her address once she has chosen her selections and made her purchase.

The website is completing her purchase by optimizing delivery routes and warehouses while she awaits her package. Her order is fulfilled, and the e-commerce website reviews her preferences to offer her more products, services, or discounts in the future.

This type of purchase is made possible by the data that is practically examined in real-time.

The data and search are optimized by many top digital transformation companies like TransformHub. Data architecture includes this as a key component.

Real-time analytics and predictive modeling are used to provide suggestions. They retrieve information from several systems, including the user profile, purchase history, and the search terms being used in the current session.

Customer’s delivery address and the locations of the warehouses are analyzed to determine the optimum delivery route and schedule, which optimizes order fulfillment.

Digital transformation solutions have been realized by retailers that effectively meet consumer expectations and innovate consistently in marketing, design, distribution, support, and other areas.

This transformation is based on scalable, linked, and smart models. Some established companies have effectively adapted by implementing an omnichannel strategy and combining physical and digital procedures.

This physical and digital integration now encompasses marketing and supply chain management procedures in addition to sales channels. A smart strategy used by many companies offering digital transformation services in Singapore.

Digital Architecture Framework & Its Significance

There are two key elements that digital architecture must consider. 1. Digital engagement

The first is that platforms are used in digital interaction. For iOS and Android, mobile apps are created. Alexa, Cortana, Google Assistant, and Siri are used in the development of digital assistants. Standards, SDKs, and development guidelines specific to these platforms must be followed.

To improve the client experience, they also provide tools that may be used, such as maps, auto-dialing phone numbers, language vocabularies, and others. To keep digital engagement apps up to date, these platforms also have continual requirements and adjustments. 2. Users

The second is that consumers and other digitally active users expect all channels, regardless of the channel they use, to have the same knowledge about them and to work consistently. This affects a data architecture in the following ways:

To ensure that information about a consumer is accessible to all the digital platforms, the data must be separated from each one of them.

To have a comprehensive history of a customer's interactions available whenever required, data will need to be collected from a digital platform.

Real-time interactions will be driven by digital events started by customers.

Instead of the transaction or report data requirements of an application or data mart, interactions are little, bite-sized chunks of data.

New digital interactions will be formed as platforms develop; therefore, a digital data architecture must be flexible and quick to adapt as well.

Guidelines For Implementing Digital Data Architecture

An event-responsive, digital data architecture grows through a continuous series of initiatives, unlike a data warehouse or data mart. For a few reasons, this may be done without requiring a data architecture to begin work.

The accepted practice for digital and cloud-based computing has developed as containers and APIs utilizing Docker and Kubernetes.

The consumer of event-responsive data is liberated from exploring data structures, thanks to APIs for data interactions, which decouple data structures from data consumption.

For event-responsive data, using data objects rather than data tables offers flexibility, meaning that adding new data items and data pieces does not affect previously developed API services.

The instructions for putting into practice a digital architecture and event-responsive data, project by project, are as follows: 1. Ensure that jobs are finished swiftly:

Digital platforms and consumers' preferences and habits change often, making digital interaction unstable. In response, projects adopt new digital interactions and must be finished rapidly. 2. Create an efficient user interface:

To engage people, digital platforms must have a well-designed user experience. The data that each event requires is also identified by the user experience. 3. Define the APIs and their data content:

When an event interacts with the event-responsive data repository via an API, it produces or consumes data. Designing data objects and their data content is based on this. 4. Control the APIs' data content:

Data objects, connections between them, and data pieces that are new to the event-responsive data repository can go through governance before they are physically in place or utilized since the APIs are a result of the user experience design. 5. Fill up the data repository for events:

Only add data objects and data components to the event-responsive data repository that support defined APIs and have been completely approved by this before-the-fact governance procedure, such as customer data for a new digital engagement platform. 6. Deliver data components to processing systems:

Existing processing systems must be informed when new data objects or modified data are added by digital events to the event-responsive data repository:

Both batch processing systems and near real-time systems may be supported by providing these as a data stream utilizing the pub-sub pattern.

To ensure a consistent view of corporate data from origination to delivery, the new or modified data objects should comprise the stream's content.

Repeat this procedure for each project that follows. Because the only requirements are the ability to build APIs, regulate data content, and fill the event-responsive data repository with whatever data is necessary for a project to operate, projects may also be run concurrently.

Creating The Right Data Architecture

Organizations may innovate with business models and shorten time-to-market because of the power, speed, and flexibility that a cloud environment offers. Without cloud technology, digital transformation is almost unimaginable. It is no longer just up to the IT department to decide how to implement these; CXOs are now debating this as a strategic business mandate.

High-speed data analytics and the capacity to handle bigger amounts of data are made possible by cloud engineering services and data analytics consulting services that provides computing power in the cloud. Utilizing cloud services helps you save costs and increase company agility by enabling you to scale up or down your infrastructure and processing capacity as needed. M

Minimizing capital cost, application deployment, processing power, and storage capacity become on-demand and essentially pay-as-you-use resources. The ability to deploy system resources as needed and distribute data among many processes is made possible by the cloud environment.

Some of your databases and apps may already be in the cloud, while others may need to be transferred as part of your digital transformation plan. Data synchronization must be planned and maintained if you're employing both on-premises and cloud infrastructure.

Your data architecture could be built on a public, private, or hybrid cloud. Private clouds are more affordable for larger firms, whereas public clouds often perform better for smaller companies.

Nowadays, many businesses use a hybrid cloud strategy that combines their private cloud with many public cloud service providers. AWS, Google, Azure, and other service providers might be utilized for particular services.

Let’s Connect

You can confidently embrace the best digital transformation solutions and continually develop your business models with the correct data architecture in place.

To create a tailored digital transformation roadmap and data architecture based on your current assets and future ambitions, get in touch with the experts at TransformHub.

0 notes

Text

New Cold Storage Tips In Washington

As COLD STORAGE SEATTLE for perishable products grows worldwide, environment friendly and efficient cold chain administration requires robust partnerships and quick reactions. Lineage Logistics stated it has acquired Seattle Chilly Storage and its amenities at Algona, Wash., and the Port of Tacoma, Wash. Phrases weren't disclosed. I felt welcome on the NewCold workplace right from the start. It was the primary time that I have been in a position to gain expertise inside such a big organization, and that has given a whole lot of perception. I always came to my internship with pleasure. All this together has given me the motivation to proceed studying. Cold Storage Lofts is as handy as it's up to date. Our pet-pleasant community is beautifully located to offer incredible views of downtown Kansas City proper out of your house window. Located simply off of Grand Boulevard on 3rd Avenue, in the heart of the vibrant River Market district, all the sights and sights of town are at your front door. We are found near all kinds of high-quality eating, entertainment, and procuring options, as well as the famous City Market, Central Library, and Power & Mild District - all simply steps away! With glorious entry to major highways, including I-35, I-70, Highway seventy one, and I-29, your morning commute might be quick and easy. A handy MAX Orange Line Bus Stop can also be situated close to our property, allowing you to be wherever within the KC Metro space inside minutes. Our chilly storage facility in Tacoma, WA is now operational. On Might 24, 2018 we celebrated the festive opening of the site. The group is in full swing to fill the excessive bay and to serve our anchor customer Trident Seafoods. The cold storage facility might be utilized by Fieldbrook Foods of Dunkirk to store completed product while it awaits delivery to its many customers throughout the United States. Fieldbrook Foods is a producer of ice cream and different frozen desserts together with many personal-label brands. The Talbot household's maritime roots date again to 1941, when Archibald Talbot purchased and began working the Bellingham Shipyards, which constructed minesweepers and barges for the U.S. Navy throughout World Battle II and the Korean Battle. Talbot established the cold storage business in 1946 next to the shipyard as a way to diversify after WWII ended. It provided local fishermen and farmers entry to refrigerated warehousing and shipping. Unicold offers Container Services, Warehousing, and Distribution - together with Oahu and the neighbor islands. With the most important refrigerated food warehouse on the islands, we have now the facilities, manpower and expertise to assure your refrigerated shipments are properly cared-for. I improved upon many skills by interning at NewCold, including enterprise communication, Excel, planning & organizing, and of course business development.

1 note

·

View note

Text

Light in the box reviews - Is Lightinthebox Safe to Purchase from?

Light in the box is a worldwide shop that are experts in some primary categories: fashion, small home appliances, home decor, and different electronics. Inspecting Light in the box reviews on the internet, you'll find out that it is best famous for its customizable wedding party apparel and evening apparel.

This online shop lures potential customers who think that they'll find the wedding event garments of their desires at a small percentage of the cost of traditional sellers. In addition to this, the customizable features of the online store mean that they won’t need to pay money for personalized tailoring.

However, for every delighted bride-to-be who gets her beautiful white bridal gown, there is another opinion that describes a completely different history.

On not too expensive products, for example clothing, it's not really a problem.

Nonetheless, for those who are thinking about utilizing the Lightinthebox.com site for larger purchases, for example home appliances or gadgets, the Lightinthebox reviews (called a “Lightinthebox.com scam” or a “Light in the box rip off”) on online forums would advise you must consider one more time.

On the net they are popular review net sites that contain many client comments about Lightinthebox.com. Below are the internet sites with the comments which we discovered:

Trustpilot.com

Out of 14400 opinions on Trustpilot.com, Lightinthebox.com has an overall result of 4 out of 5 stars.

Approx 62 percent of those who posted assessments gave the internet retailer a total 5 stars, and almost 16 percentage evaluated their purchasing experience with 1 star.

In general, it's a general favourable outcome, especially when considering evaluations on Trustpilot.com about comparable websites, such as AliExpress or Tomtop.

Light in the box review on ConsumerAffairs.com

On Consumer Affairs, Light in the box has the different result when compared with other review portals, because there're 640 ratings and a general result is one star.

Most of the comments concerning Light in the box showed irritation with prolonged delivery time and as well as miscommunication on sizes, most of them came from shoppers who had purchased footwear.

The SiteJabber website

SiteJabber’s gave Lightinthebox ratings almost like those found on Trustpilot.

Based on 3842 feedback gathered, Lightinthebox wound up with a rate of four stars, with approx 60 % of the comments being graded at five stars.

Whilst you might find a large amount of discontented clients if you search any online site presenting Lightinthebox review, you’ll also find many domestics who were fully happy with their purchases and the customer service.

Generally, a lot of the clients who were pleased with their orders appeared to be ordering smaller wares: different outfits, wigs, add-ons or small electronic products.

We've detected that the more expensive things have much more unfavorable opinions, a fact that online shoppers should take note of.

Light in the box hoax reviews are attainable on forums and message boards where buyers write that they've never gotten their wares. Sometimes, those Lightinthebox reviews are posted too fastly.

When we responded to the question, “What's Light in the box?” we debated that this shop is headquartered in Beijing.

That's why the majority of its items ship from another country, and as a consequence shipment times aren’t exactly the swiftest. And also the processing time might be very long.

How Exactly Does Delivery Work? Light in the box reviews concerning shipment service

Some goods process within only one day, but the rest may span from 3 days to a whopping 15 days before they depart the stockroom.

A primary gripe is the length of the shipment times, outlined below:

Mail Service-Tracking

Goods delivered by this option can make it to the United States Of America in 10-20 days from the time it leaves the warehouse. In the time of high season, this delivery time is prolonged to 15-30 business days.

Check a calendar, this means that it can be about 6 weeks (counting weekends) before your wares come.

Our own Lightinthebox Review About Postal Fast

Selecting this option will surely accelerate the shipping process, lowering your wait time down to 5-8 days. It provides it to approximately an 1 week wait, even during peak season time. This is faster.

Express Fast Shipping

For people who expect their goods as quickly as possible, it can be the ideal shipment solution to take into consideration. With Quick Delivery, worldwide shipment is reduced to 3-5 working days.

We cannot find any information concerning specified rates for each shipment option, however the company does state that shipment will depend both on the size of the item and on the shipping time period as Lightinthebox reviews shows.

When it comes to the universal Mail Tracking Service shipment method, the longest time wait is lower than nine weeks for goods to come after ordering.

It is a long period of time to await and think if you’ve become a victim of the Lightinthebox hoax, or whether it is a standard shipping time for a package coming from overseas.

It is a sufficient quantity of time to ask the difficult question, “Is Light in the box trustworthy?” after awaiting too long for a probably expensive packet and publishing unfavorable Lightinthebox review.

Earlier than believing you have get swindled by a Lightinthebox.com hoax, make certain that you have waited all the 45 days that your item may take to come to your home.

After that get in touch with customer support to ascertain if they are able to deliver any sort of additional tracking data or details affirming the dispatch of your product that shows it is arriving to you.

Summary: Is Lightinthebox reliable? Why some Lightinthebox reviews are weak?

When we have extensively answered to the query, “What exactly is Lightinthebox.com?” it is time to ask the real question: Is Light in the box reliable to buy from for my daily shopping wants?

Despite the fact that evaluations appear to be favourable generally speaking, we're on this blog to response whether there may be a Lightinthebox.com scam.

Shopping on Light in the box is a superb way to get discounted rates on a tailor made wedding gown or to order a few products that you need in large amounts.

General, is Lightinthebox.com trustworthy? It has many risk-free payment possible choices that suggest that it isn’t a rip-off online site.

The actual Light in the box reviews indicate that you need to try two or three cheaper goods first to verify if you are pleased with the customer service and shipping times earlier than you're begining to purchase more costly things.

3 notes

·

View notes

Text

Here Are 5 Tips For Shopping Online

The past was when Christmas shoppers had to dress up and shower, as well as endure frigid temperatures to shop for presents. In the past, avid bargain seekers eagerly awaited store openings on Black Friday (the day after Thanksgiving) like engines that sat idle waiting for ignition. Doe-eyed automatons, kids flipped through catalogs of toy stores in hopes that it will take them to the mall. It was a traumatic, brutal time. Uncertainty was the rule.

It was quite shocking to realize that Christmas shopping was never the identical. We no longer needed to go to the store for a long time! Online shops were opened by companies instead. Online shopping was possible for shoppers at any time during the day, regardless of whether they were dressed in sexy clothing or completely naked.

Be Secure