#and power transmission industries

Explore tagged Tumblr posts

Text

Medium Din Rail Patch Panel/LIU

UNISOL Medium Din Rail Patch Panel offers up to 24 ports for connection and is designed to be compact in order to save cabinet space. These DIN rail LIUs can be installed in substation automation networks to give as many fiber connections as possible in the smallest amount of space. The maximum number of cable entries that the fiber enclosure can support is four. They are used in the oil and gas, cctv surveillance, rail signalling and control, process automation and control systems, renewable energy, and power transmission industries, where they can be mounted on the backplane or side panel of a compact cabinet. Various adapters, including ST, SC, FC, and LC, can be added to this fiber patch panel.

#UNISOL Medium Din Rail Patch Panel offers up to 24 ports for connection and is designed to be compact in order to save cabinet space. These#cctv surveillance#rail signalling and control#process automation and control systems#renewable energy#and power transmission industries#where they can be mounted on the backplane or side panel of a compact cabinet. Various adapters#including ST#SC#FC#and LC#can be added to this fiber patch panel.

0 notes

Text

their bodies in the dark ♡

#mine#industrial#power lines#powerline valley#electricity pylon#pylon#night photography#fog#transmission tower

696 notes

·

View notes

Text

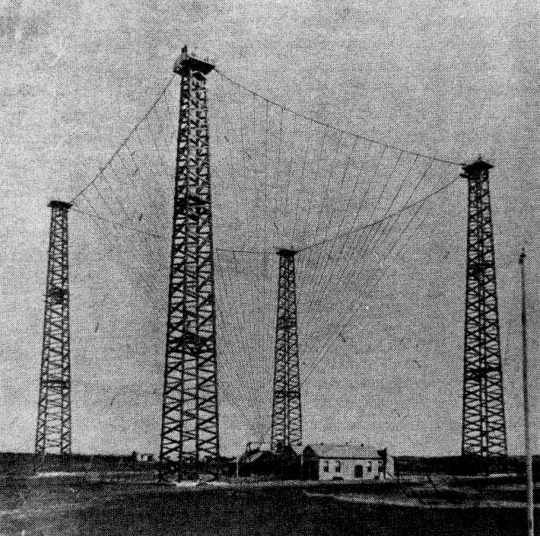

Macaroni Station at Poldhu, Cornwall, England, around 1905.

328 notes

·

View notes

Text

High voltage power lines ⚡ in Baltic states (Lithuania, Latvia, Estonia)

#aesthetic#cyberpunk#tech#tech aesthetic#electricity#engineering#technology#industrial#electrical engineering#high voltage#elektrostantsiyapost#lithuania#latvia#estonia#techwave#electrical engineer#pylons#power lines#wires#power substation#switchyard#insulators#engineers#engineer#engblr#power transmission#baltic states#pylon#steel#electrical

46 notes

·

View notes

Text

2 notes

·

View notes

Audio

✰Bourgeoiz Music Discovery✰

#music discovery#music#spotify link#spotify#genres#avant-garde metal#death industrial#electra#mandible#new isolationism#noise#power electronics#music genres#music artists#pharmakon#song#transmission#Bourgeoiz Music Discovery#MORE MUSIC ON MY BLOG

9 notes

·

View notes

Text

The global Gas Insulated Switchgear Market Share is expected to grow from estimated USD 24.93 billion in 2024 to USD 33.53 billion by 2029, at a CAGR of 6.1% during the forecast period. This is attributed to the increase in strength across the power distribution infrastructure to meet the high demand for electricity, in addition to increasing investments into renewables and industrial production. In addition, the rapid growth in the deployment of high-voltage direct current (HVDC) systems will further boost market expansion during this period.

#gas insulated switchgear#gas insulated switchgear industry#gas insulated switchgear market#energy#energia#power generation#utilities#power#utility#renewable power#renewableenergy#electricity#renewable resources#switchgear industry#switchgears#switchgear#electrical equipment#power transmission#power distribution#transmission and distribution#power grid

0 notes

Text

United States lubricants market size reached USD 32.6 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 41.9 Million by 2033, exhibiting a growth rate (CAGR) of 2.9% during 2025-2033. The escalating advances in lubricant technology, including the development of high-performance synthetic lubricants, which contribute to increased efficiency and extended equipment life, are driving the market.

#United States Lubricants Market Report by Product Type (Engine Oil#Transmission/Hydraulic Fluid#Metalworking Fluid#General Industrial Oil#Gear Oil#Grease#Process Oil#and Others)#Base Oil (Mineral Oil#Synthetic Oil#Bio-Based Oil)#End Use Industry (Power Generation#Automotive and Other Transportation#Heavy Equipment#Food and Beverage#Metallurgy and Metalworking#and Region 2025-2033

0 notes

Text

Aluminium and Cast Iron Worm Gearboxes: Differences and Applications

When choosing a worm gearbox for industrial use, the material plays a critical role in its performance, durability, and suitability for specific applications. Aluminium and cast iron worm gearboxes are two common options, each offering distinct advantages and limitations. This article will explore the key differences between aluminium and cast iron worm gearboxes, discuss their applications, and provide insights on choosing the right gearbox for your needs.

Aluminium Worm Gearboxes

Characteristics and Features

Aluminium worm gearboxes are known for their lightweight construction, making them ideal for applications that prioritize portability and ease of handling. Typically, these gearboxes are designed for low to medium-duty applications where the focus is on efficient performance with reduced weight. Aluminium gearboxes also have excellent resistance to corrosion, making them suitable for environments where exposure to moisture or chemicals is common.

Advantages of Aluminium Worm Gearboxes

Lightweight: One of the standout features of aluminium gearboxes is their low weight, making them easier to install and handle.

Corrosion Resistance: Aluminium provides natural resistance to corrosion, which reduces the need for maintenance in damp or chemically exposed environments.

Heat Dissipation: Aluminium has superior thermal conductivity, allowing it to dissipate heat faster, which helps to maintain optimal performance during extended operation.

Energy Efficiency: These gearboxes typically operate with less friction, translating to improved energy efficiency.

Limitations of Aluminium Gearboxes

Lower Strength: While aluminium offers several benefits, it lacks the strength and durability required for heavy-duty applications.

Limited Load Capacity: Aluminium worm gearboxes are not well-suited for high-load environments, as they may wear down more quickly under intense pressure.

Cast Iron Worm Gearboxes

Characteristics and Features

Cast iron worm gearboxes are designed for robustness and durability. These gearboxes can withstand higher loads and harsher conditions than their aluminium counterparts. They are commonly used in heavy-duty applications where the machinery operates under high pressure and demands greater strength. Cast iron gearboxes are known for their rigidity and ability to absorb vibrations, making them reliable under tough operating conditions.

Advantages of Cast Iron Worm Gearboxes

High Durability: Cast iron gearboxes are incredibly strong and durable, built to last even under high-pressure conditions.

Better Vibration Damping: The dense structure of cast iron absorbs vibrations effectively, ensuring smooth operation even in heavy-duty industrial settings.

Heat Resistance: Cast iron can endure higher operating temperatures without losing strength, making it suitable for more demanding applications.

Long Lifespan: These gearboxes generally have a longer lifespan due to their toughness and resistance to wear.

Limitations of Cast Iron Gearboxes

Heavier Weight: Cast iron gearboxes are significantly heavier, which can make installation and handling more challenging.

Prone to Rust: Unlike aluminium, cast iron is more vulnerable to corrosion, especially in humid or chemically aggressive environments. Regular maintenance and protective coatings are required.

Lower Energy Efficiency: Due to higher friction levels in cast iron, these gearboxes may be less energy-efficient than aluminium versions.

Applications of Aluminium Worm Gearboxes

Industries and Uses

Aluminium worm gearboxes are commonly used in industries where lightweight machinery and corrosion resistance are essential. Some of the typical applications include:

Food and beverage processing

Pharmaceutical manufacturing

Packaging machinery

Light conveyor systems

HVAC systems

Why Aluminium Gearboxes are Chosen in These Applications

The lightweight and corrosion-resistant properties of aluminium make these gearboxes ideal for industries where hygiene is critical, and exposure to moisture or chemicals is frequent. Their ability to dissipate heat quickly ensures continuous performance without overheating, especially in fast-paced production environments.

Applications of Cast Iron Worm Gearboxes

Industries and Uses

Cast iron worm gearboxes are primarily found in industries requiring heavy-duty machinery. Common applications include:

Mining and quarrying equipment

Steel production

Heavy-duty conveyors

Agricultural machinery

Construction equipment

Why Cast Iron Gearboxes are Preferred for Heavy-Duty Applications

Cast iron gearboxes are chosen for their strength, vibration damping, and ability to handle high loads. In demanding industries like mining and construction, where machines operate in challenging conditions, the durability and resilience of cast iron make it the preferred choice. They also excel in environments where temperature extremes are common.

Key Differences Between Aluminium and Cast Iron Worm Gearboxes

Material Strength: Cast iron is significantly stronger and more durable, suitable for heavy-duty tasks, while aluminium is more suited for light to medium-duty applications.

Weight: Aluminium gearboxes are lightweight and easier to handle, while cast iron gearboxes are heavier and more robust.

Corrosion Resistance: Aluminium offers better corrosion resistance, reducing maintenance in moist environments, whereas cast iron requires more upkeep to prevent rust.

Heat Dissipation: Aluminium dissipates heat more efficiently, making it suitable for applications requiring continuous operation.

Vibration Absorption: Cast iron absorbs vibrations better, ensuring smoother operation in heavy-duty environments.

Factors to Consider When Choosing Between Aluminium and Cast Iron Worm Gearboxes

Application Requirements: Consider the load capacity, operating conditions, and environmental exposure when selecting a gearbox material. For high-load applications, cast iron is ideal, while aluminium is suitable for lighter tasks.

Maintenance Needs: Aluminium gearboxes require less maintenance in corrosive environments, while cast iron gearboxes need protective coatings or regular upkeep.

Installation: If ease of handling and installation is a priority, aluminium gearboxes are a better option due to their lightweight nature.

Cost: Cast iron gearboxes are generally more expensive, but their durability offers long-term cost savings in heavy-duty operations.

Get Expert Advice on Choosing the Right Worm Gearbox for Your Industry

Choosing between aluminium and cast iron worm gearboxes depends on various factors, including application, environment, and performance needs. If you are unsure which material is best for your operation, consult with experts who can guide you in making the right choice for your industry.

For more information, Visit Aluminium and Cast Iron Worm Gearboxes: Differences and Applications

0 notes

Text

Industrial Lubricants

When it comes to optimizing industrial performance, choosing the right lubricants can make all the difference. Shield Oils’ Industrial Lubricants are meticulously engineered to provide superior protection, reduce downtime, and enhance the efficiency of your machinery and equipment. Contact us now to learn more or place your order!

#industrial lubricants#lubricants#automatic transmission fluid#turbine oil#power steering fluid leak#lubricant manufactures#lubricating oil uses#lubricant company

0 notes

Text

Black and white picture of Chilean flag waving between power cables. Shot taken in the Elqui Valley in the north of Chile.

#flag#electricity#power#sky#cable#pole#electric#wire#line#energy#electrical#voltage#lines#industry#high#transmission#pylon#tower#wires#post#technology#communication#power line#chile#black and white#b&w

0 notes

Text

Powering the Country: Exposing India's Transmission and Distribution System

India's extensive network makes sure that power is available everywhere. This investigation explores the fields of power distribution, which is the last step in supplying electricity to homes and businesses, and power transmission, which is the unseen force that carries electricity over long distances.

0 notes

Text

pylon 007

#mine#industrial#power lines#pylon#night photography#black and white#powerline valley#bwphotography#electricity pylon#transmission tower

550 notes

·

View notes

Text

The Importance of Quality Control in Electrical Component Manufacturing

As an electrical components manufacturing company, ensuring the quality of our products is of paramount importance. At Popular Engineering, we understand that the reliability and performance of our electrical components have a direct impact on the overall functionality of the devices and systems they are used in. In this blog, we will discuss the importance of quality control in electrical component manufacturing and how it affects the entire supply chain.

Why Quality Control is Crucial

Electrical components are used in a wide range of applications, from consumer electronics to industrial machinery, medical devices, and even aerospace systems. The failure of a single component can have catastrophic consequences, resulting in equipment downtime, financial losses, and even risk to human life. Therefore, it is essential to ensure that electrical components meet the required standards of quality, reliability, and performance.

Quality control is a critical aspect of electrical component manufacturing, as it helps to identify and eliminate defects, ensuring that only high-quality products are delivered to customers. A robust quality control process involves testing and inspecting components at various stages of production, from raw material sourcing to final product assembly.

The Consequences of Poor Quality Control

The consequences of poor quality control in electrical component manufacturing can be severe. Some of the potential risks include:

Component Failure: A faulty electrical component can fail prematurely, leading to equipment downtime, repair costs, and even safety risks.

System Failure: The failure of a single component can cause an entire system to malfunction, resulting in significant financial losses and reputational damage.

Recalls and Litigation: If a faulty component is discovered after it has been shipped to customers, the manufacturer may be forced to issue a recall, which can be costly and damaging to the brand.

Loss of Customer Trust: Repeated instances of poor quality can erode customer trust and loyalty, leading to a loss of business and revenue.

The Benefits of Quality Control

On the other hand, a robust quality control process can bring numerous benefits to an electrical components manufacturing company like Popular Engineering. Some of the advantages of quality control include:

Improved Product Reliability: By identifying and eliminating defects, quality control ensures that products are reliable and perform as expected.

Reduced Warranty Claims: Fewer defects mean fewer warranty claims, resulting in cost savings and reduced administrative burdens.

Increased Customer Satisfaction: High-quality products lead to increased customer satisfaction, loyalty, and repeat business.

Enhanced Reputation: A reputation for quality and reliability can help to attract new customers and partners, driving business growth and success.

Quality Control Measures in Electrical Component Manufacturing

At Popular Engineering, we take quality control very seriously. Our quality control measures include:

Raw Material Inspection: We inspect all raw materials to ensure they meet our quality standards.

In-Process Inspection: We conduct regular inspections during production to identify and correct any defects.

Final Product Testing: We test all finished products to ensure they meet our quality and performance standards.

Certification and Compliance: We ensure that all our products comply with relevant industry standards and regulations.

The Role of Electronic Components Dealers and Distributors

Electronic components dealers and distributors, such as Popular Engineering, play a critical role in ensuring the quality of electrical components. We work closely with our suppliers to ensure that all components meet our quality standards, and we conduct regular audits to verify compliance.

As a responsible electrical components manufacturing company, we also provide our customers with detailed documentation, including certifications, test reports, and material declarations, to ensure transparency and trust.

Conclusion

In conclusion, quality control is a critical aspect of electrical component manufacturing. At Popular Engineering, we understand the importance of delivering high-quality products that meet our customers’ expectations. By implementing robust quality control measures, we can ensure the reliability and performance of our electrical components, reduce the risk of defects and failures, and build trust with our customers.

As an electronic components dealer and distributor, we are committed to providing our customers with the highest quality products and services. By working together, we can ensure the quality and reliability of electrical components, driving innovation and success in the industry.

About Popular Engineering

Popular Engineering is a leading electrical components manufacturing, providing high-quality products and services to customers around the world. With a strong focus on quality control, we ensure that our products meet the highest standards of reliability and performance. As an electronic components dealer and distributor, we work closely with our customers to understand their needs and provide tailored solutions that meet their requirements. Contact us today to learn more about our products and services.

electrical components manufacturing company| electronic components dealer| electrical component distributors| oem original equipment manufacturer| oem equipment manufacturer| industrial electrical product| power transmission equipment| siemens electric motor distributor| siemens motor dealer in mumbai| siemens motor distributor in india| siemens gear motor distributor| Siemens motors in Mumbai| hindustan motors products supplier in india| hindustan motors products supplier| hindustan electric motors dealers| hindustan electric motors dealers in India| siemens gear motor distributors| siemens gearbox manual| siemens gearbox supplier in india| best Industrial Motor Providers in India| Electric Motors| Best Motor Dealer in Mumbai| Motor Dealer in Mumbai|Motor Gearbox Dealers in Mumbai| Top Gearbox Dealers in Mumbai| Gear Boxes Manufacturers| Gear Boxes Supplier in India| industrial gearbox manufacturers| gearbox manufacturers in india| industrial gearbox manufacturers in india| helical gearbox manufacturers| Siemens Electric Motors| siemens electric motors dealers in mumbai| siemens dealer in mumbai| elecon gearbox dealer| bharat bijlee motor dealers| kirloskar pump dealer in mumbai| siemens motor dealer in mumbai| pbl gearbox| siemens motor dealer

#Electric Motors#electrical components manufacturing company#electronic components dealer#electrical component distributors#oem original equipment manufacturer#oem equipment manufacturer#industrial electrical product#power transmission equipment#siemens motors#siemens electric motors

1 note

·

View note

Text

Industrial Pulley Manufacturer - Muratech Eng

Keeping the World Moving: The Importance of Industrial Pulleys

Muratech Engineering Company, located in Ahmedabad, Gujarat, India, is a prominent manufacturer of industrial pulleys and other mechanical power transmission equipment. But what are industrial pulleys, and why are they so important in today's world?

Why are industrial pulleys essential in today's world?

Imagine a world without pulleys. Simple tasks like lifting heavy objects, running machinery, and even operating everyday appliances would become incredibly difficult. Industrial pulleys are the hidden heroes that transmit power and motion smoothly and efficiently. They're the workhorses behind a vast array of machines, from massive factory equipment to the belts driving the fans in your home.

What is the use of an industrial pulley?

Think of a pulley as a grooved wheel that works in conjunction with belts or ropes. The grooves help the belt grip the pulley, allowing it to transmit power between a driving force (like a motor) and a driven load (like a machine). By changing the size of the pulleys, we can alter the speed and direction of the rotating motion.

The different types of Industrial Pulley

Muratech Engineering offers a wide range of industrial pulleys to cater to diverse needs. Here are some common types:

V-belt pulleys: These have V-shaped grooves that mesh with V-belt pulleys, which are renowned for their strength and durability. Ideal for applications that require high-power gearbox.

Timing pulleys: These have precisely spaced teeth that interlock with toothed belts, ensuring exact synchronization and speed control. Essential in machinery like printers and conveyor belts.

How do pulleys make it simpler to lift?

Pulleys can significantly reduce the amount of force required to lift heavy objects. Imagine pulling a rope directly upwards to lift a weight. Now, imagine using a pulley system with a rope looped around it. By pulling the rope downwards at an angle, you can lift the same weight with less effort. Pulleys act as mechanical advantage tools, making seemingly impossible tasks manageable.

Which company is best for buying Industrial Pulleys in India?

Muratech Engineering, with its commitment to quality and expertise in pulley manufacturing, stands out as a reliable choice. They offer a vast selection of industrial pulleys for sale, catering to various applications and requirements.

Why Choose Muratech Engineering Company?

Muratech Engineering uses only the best materials to ensure their pulleys are strong, durable, and resistant to wear and tear. They offer a wide variety of pulleys to meet the specific needs of your project. With years of experience in the industry, Muratech Engineering has the knowledge to help you choose the right pulley for the job.

Contact Muratech Engineering Today

Whether you need industrial pulley for your factory or timing pulleys for a precise machine, Muratech Engineering has the industrial pulley solution for you. Visit our website at https://www.timingpulley.biz/or contact at +919586823032 to discuss your requirements and find the perfect pulley to keep your world moving.

#Timing Pulley#Industrial Pulley#Industrial Pulleys For Sale#Power Transmission Pulley#Timing Pulley Manufacturer#Industrial Pulley Manufacturer#Industrial Pulley In India#Timing Pulley In India

0 notes

Text

1 note

·

View note