#Wires Manufacturers

Explore tagged Tumblr posts

Text

Welding Cables

At RR Kabel, we offer premium quality welding cables designed for durability, flexibility, and superior electrical performance. Our welding cables are engineered to withstand the toughest industrial environments, ensuring a reliable connection between your welding equipment and power source. Made with high-grade copper conductors and robust insulation, these cables provide excellent conductivity and heat resistance, essential for smooth and efficient welding operations. Whether you’re working on heavy-duty industrial projects or need dependable cables for smaller-scale applications, RR Kabel’s welding cables are built to deliver consistent performance and safety. Trust RR Kabel for your welding needs and experience the difference in quality and reliability.

0 notes

Note

speaking of yarn ive been meaning to ask since ive heard of it elsewhere, is the general quality of yarn you can get going down? ive been looking into fibercraft but ive been told its getting harder and harder to find actual good thread without some sort of plastic in it, especially for a good price. so ive been wondering is this true or was it made out to be a much larger problem than it really is (in your experience)?

i've only been into crochet for a couple of years, so i'm not a Fiber Arts Veteran who can tell you the difference between shopping for supplies now vs 30 years ago! i don't really have anything to compare Current Yarns to. in my experience, the only thing i can speak on is cost, and it seems like the cost for yarn has probably been going up. animal fibers are certainly more expensive, acrylic yarns are budget-friendly but are synthetic, if that's something you're worried abt.

so i don't think that stuff is Untrue, but i also don't think it's any reason at all to avoid getting into fiber arts, and you can absolutely find yarns made from cotton / wool / bamboo fiber and stuff like that for good prices! it would probably be harder in-person, like in the aisles of a hobby lobby. but i think lion brand and lovecrafts are good sites to browse for yarn/supplies. it's really not a small-scale problem, someone like moi who's recently gotten into crochet and does it for funsies based on my whims/needs isn't going to really notice, i don't think. as an aside, if we're talking about crochet specifically, you can really crochet with anything at all- i've been making a tote bag out of plastic grocery bags, lmao. reduce reuse recycle or whatever. people will also use strips of fabric instead of yarn, and that's good for stuff like rugs / bags / baskets, chunkier projects. (though ig you could probably make some clothing if you cut the strips of fabric thin enough.) so as far as accessibility to the craft, there is that!

#or also what the fuck else. paper... wire. ribbon. rope. string. twine.#anyway!! it's really less of a fiber arts conversation and more of a capitalism conversation#which. obv. does not extend Only to fiber arts#just think it has to do with Product Manufacturing as a whole being done cheaper and cheaper#and the state we're in rn where everything gets more expensive every year. but again that's not specific to yarn#sergle answers#crochetposting#edit: i put a link for lovecrafts in there bc lol teehee. and so on and so forth

60 notes

·

View notes

Text

chinese wire manufacturing

99 notes

·

View notes

Text

omg I am truly PLAGUED by people not using their headphones in public spaces lately

#please invent cheap wired headphones again#I know some of this is on the phone manufacturers#I am BEGGING you

4 notes

·

View notes

Text

Touch the sky with Glory! On Indian Air Force Day, we salute the fearless warriors of the sky. Thank you for your unwavering commitment to protecting our nation. Happy Indian Air Force Day! ✈️🇮🇳

For enquiry via WhatsApp click: https://wa.link/0hzdl7

Contact us: 0172-4625538, 8926415415, 7986924115

Website: https://www.vishalindustrieschd.com/

Address: Plot no. 415, Industrial Area Phase 2 Chandigarh, 160002, India Follow us: Instagram, Facebook, LinkedIn, YouTube, Twitter, Pinterest

#vishalindustries#mswires#MS#MSwire#MSWire#HHBwire#HBwire#hbwires#hhbwires#mswireprice#msprice#vsp#esl#jswsteel#jspl#wire#wirerod#bestquality#bindingwire#manufacturer#wiremanufacturer#annealing#nutbolt#screw#rivets#mildsteel#GIwire#wiredrawing#fasteners

2 notes

·

View notes

Text

The Ultimate Choice for PTFE Wires

What are PTFE Wires?

PTFE wires, also known as Polytetrafluoroethylene wires, are a type of electrical wire that uses a unique material called PTFE as its insulation. PTFE is a synthetic fluoropolymer that is known for its exceptional non-stick properties, high temperature resistance, and excellent dielectric strength.

Properties of PTFE Wires

PTFE wires have several properties that make them ideal for use in a wide range of applications. Some of the key benefits of PTFE wires include:

High Temperature Resistance: PTFE wires can withstand extremely high temperatures, making them suitable for use in applications where other wires would melt or degrade.

Chemical Resistance: PTFE wires are resistant to corrosion and damage from chemicals, making them ideal for use in harsh environments.

Low Friction: The non-stick properties of PTFE make it easy to strip and terminate the wires, reducing the risk of damage during installation.

High Dielectric Strength: PTFE wires have a high dielectric strength, which means they can withstand high voltages without breaking down.

Polytetrafluoroethylene wires

Applications of PTFE Wires

PTFE wires are used in a variety of applications, including:

Aerospace: PTFE wires are used in aircraft and spacecraft due to their high temperature resistance and ability to withstand extreme conditions.

Automotive: PTFE wires are used in high-performance vehicles due to their ability to withstand high temperatures and harsh environments.

Medical Devices: PTFE wires are used in medical devices such as catheters and guidewires due to their biocompatibility and resistance to corrosion.

Industrial Applications: PTFE wires are used in industrial applications such as chemical plants and oil refineries due to their ability to withstand harsh environments.

Conclusion

In conclusion, PTFE wires are a unique type of electrical wire that offers a range of benefits and advantages over traditional wires. Their high temperature resistance, chemical resistance, low friction, and high dielectric strength make them ideal for use in a wide range of applications. Whether you're working in aerospace, automotive, medical devices, or industrial applications, PTFE wires are an excellent choice for any project that requires high-performance and reliability.

visit- https://www.insulatedwires.com/ptfe-wires Address- Factory 46-Vedvyaspuri industrial Area,Sector-8 Meerut Pin-250103, INDIA

2 notes

·

View notes

Text

Occasionally we debate on illustrating random bits from our Discord PMs that we find really funny but then we remember that we're, like, the physical embodiment of the "ace that makes sex jokes" stereotype and phrases like "iterator dick discourse" would both be remarkably difficult to illustrate and probably require us drawing something at least somewhat NSFW (we do not particularly care to learn how to draw this)

#we speak#realistically it would just require more specific tinkering w what we choose to include but we still think the dickscourse is funny#it's the image of a bunch of ancient monks gathering around to very seriously debate decisions with the upcoming iterator project#and then the whiteboard is just like. “ITERATORS: dick or no?”#(vital context: we got hung up on the semantics of people giving their iterators actual genitals in smut)#(as the existence of that on the puppet implies that someone had to design and manufacture and ship that shit for the finished iterator)#(and the general aura of the ancients instantly catapults this to fucking hilarious because it implies job titles like “dick director”)#(and work emails about iterator pipe written in the exact same cadence as all of the ancient correspondence we see in-game)#we dont think a lot of people designing iterators really Get the sheer amount of semantics and construction and effort and PEOPLE#that go into a project of the iterator's scale#especially when hundreds of them have been constructed! theres gonna be a whole ass trail of design changes and iterations!#youre gonna have hundreds of years of iterators being designed and technology coming into fashion and out of fashion#and things being integrated and things becoming obsolete and things being more or less practical as time goes on!#you cant really say that All Iterators have a trait because the sheer scale and timeframe theyre built on means thats near impossible#our windows 95 writing computer has different construction and deeply different design to a laptop from 2023#despite them technically being the same type of technology#you expect tech developed hundreds of years apart to be The Same? absolutely not. theres gonna be eight trillion weird design quirks#accumulated both in the construction process and in the continued design refinement and improvement stage#...which is to say that you can and should write what u want but if youre gonna include pleasure inducing wires then we want like#a 40k word essay on how this got into the design how it wound up in future designs what function the wires perform that makes them Like Tha#and so on and so forth#we admire the confidence and ingenuity of the people who want to fuck the robots but we cannot get into their fantasies with good conscienc#we live in the same house as an engineer who manages largescale construction and we also know too much about designing technology#...we should segment these tags into a separate post or something. we've gone WAY off-topic.

8 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

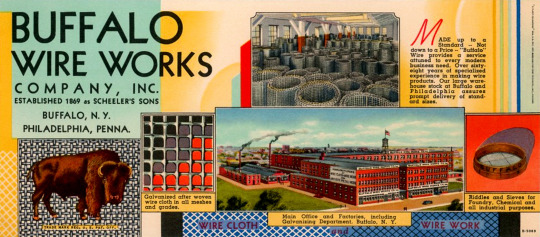

The Buffalo Wire Works Company.

4 notes

·

View notes

Text

AN UNFORTUNATE FACT: Kitty is the Vees biggest simp / cheerleader / hypeman. She would take a bullet for them [ quite literally; she is programmed to never bring them physical harm as she is literally incapable of doing so & to prevent physical harm, should someone ever perform an attempt assassination on one of them ] just as she was programmed to & to always return to them, no matter how much they hurt her,

... but there is a question as to where her true loyalties lie; Mammon or The Vees? Or hell, even Asmodeus? Who has actual authority over her? Still figuring that out,

#⠀﹙ ➛ 𝐊𝟕𝐓𝐓𝐈.𝐄𝐗𝐄 ﹚⠀:⠀ㅤmoderator 🎀 me tome un selfie,#⠀﹙ ➛ 𝐊𝟕𝐓𝐓𝐈.𝐄𝐗𝐄 ﹚⠀:⠀ㅤheadcanons 🎀 chuck a cupcake,#ㅤ she is a PAID COLLABORATION between Mammon's brand & VoxTek#ㅤ no question she is of Mammon's brand; it gets tricky however because aside from being a personalized commission she's more than just a-#ㅤ -personalized unit; see she HAS VoxTek tech IN HER & not just simple modifications either. full blown motherboard & such ( probably )-#ㅤ -internal fans & wiring & the programming as well; she's just as much VoxTek branded as she is Mammon's. AND THEN THERE'S the extra layer#ㅤ -of her physical manufacturing; meaning the individual materials and default programming; i would assume those are Oz's?? idek anymore#ㅤ NOT ONLY THAT BUT the way I write is that Vox 'legally' owns her; he's the one that commissioned her; all paperwork is under his name#ㅤ & honestly? I'M HERE FOR IT; GIVE THE KITTY BOT AN EXISTENTIAL CRISIS#ㅤ ( cue Oz & Mammon & Vox each calling for Kitty like a puppy-dog to see who she'll go to adsfkjhh )

5 notes

·

View notes

Text

Duplex Steel S32205 Wire Exporters in India

Duplex Steel S31803/S32205 Wire, which is alloyed with tungsten correspondingly as copper. Duplex S31803 Wire takes its name from its two-make microstructure out of ferrite and austenite in approx. looking at degrees. Duplex S31803 Circle Wire contains more than 20 % chromium and around 5 % nickel, and it is a spot of the party of set up gets ready.

In Duplex S31803 Wound Wire, the base chromium, molybdenum, and nitrogen substances have been extended to move out of other materials. Duplex S31803 Wire safeguards their ideal properties with a reasonable ferrite-austenite part of around 50/50. Move out of the austenitic set plans, Duplex S31803 Wire contains less nickel (approx. 4 % to 8 %), which brings about an ordinarily stunning lift for cash.

Duplex S32205 Wire might be utilized in the temperature relax between - 40 Degree C and 280 Degree C. The standard piece of Duplex S32205 Wire is depicted with 25 % chromium, 7 % nickel, 4 % molybdenum and 0.25 % nitrogen. Duplex S32205 Wire is similarly saw by its broad security from setting, opening and stress use part, and an extra advancement in its mechanical quality credits.

Duplex S32205 Wire is now the widest social affairs and is seen by magnificent application properties and by high responsiveness in all the fitting thing plots.

DUPLEX STEEL S31803/S32205 WIRE SPECIFICATIONS

Specifications: ASTM A276 ASME SA276

Dimensions: ASTM, ASME

Thickness: 10mm to 100mm

Diameter: 100 mm To 6000 mm

Specialize: Wire, Filler Wire, Coil Wire

For More Information :

Visit Our Website: https://sankalpalloys.com

Contact No: 91-8828369483

E-Mail ID: [email protected]

7 notes

·

View notes

Text

https://berlin-machineries.com/

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

Top Steel Wire Manufacturers and Suppliers in India - Dp Wires

Dp Wires proudly stands as one of the top Steel Wire Manufacturers and suppliers in India, renowned for setting industry standards for reliability and quality. We not only lead the industry in the production of steel wires, but we also excel at providing a large selection of single-strand stainless steel wires.

Our products, which are carefully packaged in bundles or drums weighing 20 to 250 kg, are used in a wide range of industries, including the chemical, oil and gas, textile, machinery and pumping industries. Dp Wires guarantees excellent quality with finishes ranging from dull to bright drawn and shiny, making us the go-to option among those looking for dependable steel wire solutions in India.

For more information, Visit our site - Https://www.dpwires.co.in

#Steel Wire Manufacturers#Steel Wire Industry in India#Lrpc Strands#Geomembrane Sheet#Spring Steel Wire

2 notes

·

View notes

Text

A Single Source To Your Filtration Needs – Wire EDM Filter Supplier

With more than a decade’s experience as wire EDM filter supplier, Ankok specialises in the sale of filters for wire electrical discharge machines (WEDM).

Wire EDM filters specialising in wire cut EDM processing mainly consists of filter paper and metal mesh. The quality of filter paper determines the filtration accuracy and service life.

Do you know that EDM filters keep your technology clean and in good working order, even after long periods? By lubricating the system and removing waste and harmful residues, filters save energy, cut costs, and increase productivity and efficiency.

However, it is important to regularly change your wire EDM machine filters because they are continuously put through their paces and, over time, the waste and dirt that build up can compromise their effectiveness.

Ankok brand wire EDM filters adopts great quality filter paper with fibre for different processing condition and cutting materials.

In the EDM world, the variety of materials machined has increased. Three micron, five micron, and ten micron filtration requirements have emerged. We have developed most type of OEM filter media to answer to the challenges of EDM process on specific materials with new styles of Sodick EDM Filters, Mitsubishi EDM filters, Fanuc EDM filters, and Charmilles EDM filters.

Looking for EDM advice and sales you can count on? Ankok Wire EDM filter supplier is a trusted source for all things EDM. Our superior service and customer care is what truly sets us apart. Our mission is to always provide unparalleled customer care and service in a one-stop-shop for EDM filter supplies and accessories.

The EDM consumables market is larger than just filters of course. But Ankok has stay focused on the filtration requirements of wire EDMs. We continue to design, manufacture and supply lower cost EDM filters that provide exceptional deionized water cleanliness and service life equivalent to the best original equipment filters.

We supply a large variety of EDM wear parts and consumables for most EDM machines including the following brands:

HITACHI, JAPAX, MITSUBISHI, AGIE CHARMILLES, ONA, SEIBU, FANUC, MAKINO, CHMER, BROTHER, SODICK, OKI, MANN HUMMEL.

Contact us for a quote and include the product code of the filter you are interested in for more information. We are here to answer any questions or meet any special requests you may have.

#EDM Filter Suppliers#EDM Filter Manufacturers#Wire EDM Filter Suppliers#Wire EDM Filter Manufacturers#EDM Machine Parts Suppliers#Charmilles Edm Filters#Sodick Edm Filters#Sodick Wire Edm Filters#Mitsubishi Wire Edm Filters#Mitsubishi Edm Filters

2 notes

·

View notes

Text

Exploring the World of Leading Wire Harness Innovators

Wire harness manufacturers play a crucial role in various industries, providing essential components that ensure seamless connectivity and electrical integration in a wide array of applications. These manufacturers design and produce intricate wire harness systems tailored to specific requirements, adhering to strict quality standards and industry regulations.

For More Information Please visit, top wire harness manufacturers

key aspects of wire harness manufacturing

Industry Overview : Wire harness manufacturers operate in a highly competitive and evolving industry. They serve sectors such as automotive, aerospace, electronics, telecommunications, and healthcare, among others. The demand for custom wire harness solutions continues to grow as industries advance technologically.

Customization and Design : One of the significant aspects of wire harness manufacturing is customization. Manufacturers work closely with their clients to understand their unique needs. This involves designing wire harnesses that meet specific requirements, including size, shape, number of wires, insulation materials, and connector types.

Quality Assurance: Quality is paramount in wire harness manufacturing. Manufacturers invest in state-of-the-art testing equipment and employ skilled technicians to ensure that each harness meets the required standards. Rigorous testing procedures are in place to check for electrical continuity, insulation resistance, and overall durability.

Materials and Components: Wire harnesses consist of various materials and components, including wires, connectors, terminals, tubing, and insulation materials. Manufacturers carefully select these components based on the application's requirements, taking into account factors such as temperature, voltage, and environmental conditions.

Compliance and Certification: Wire harness manufacturers adhere to industry standards and regulations to guarantee the safety and performance of their products. Compliance with standards such as IPC/WHMA-A-620 ensures that the manufactured harnesses meet the necessary criteria for reliability and functionality.

Advanced Manufacturing Techniques : Modern wire harness manufacturing involves advanced techniques such as automated assembly, which enhances efficiency and precision. Computer Numerical Control (CNC) machines are employed for accurate cutting, stripping, and crimping of wires and connectors.

Supply Chain Management : Efficient supply chain management is crucial for timely production and delivery of wire harnesses. Manufacturers work closely with suppliers to source high-quality materials and components, ensuring a seamless flow of production.

Research and Development : Continuous research and development efforts drive innovation in the wire harness industry. Manufacturers invest in developing new materials, manufacturing processes, and technologies to improve the performance and longevity of wire harnesses.

Environmental Sustainability : Many wire harness manufacturers focus on sustainable practices, including the use of eco-friendly materials and recycling initiatives. Sustainability efforts contribute to reducing the environmental impact of manufacturing processes.

Conclusion

Wire harness manufacturers operate at the intersection of technology and precision engineering. Their commitment to quality, innovation, and customer satisfaction drives the industry forward, enabling seamless integration of electrical systems in various applications across the globe.

2 notes

·

View notes

Text

"Unbreakable Quality, Unbeatable Prices" At Vishal Industries, we believe that quality shouldn't come at a cost. That's why we proudly offer MS Wires that are as tough as your toughest projects. Book Today!

For enquiry via WhatsApp click: https://wa.link/0hzdl7

Contact us: 0172-4625538, 8926415415, 7986924115

Website: https://www.vishalindustrieschd.com/

Address: Plot no. 415, Industrial Area Phase 2 Chandigarh, 160002, India

Follow us: Instagram, Facebook, LinkedIn, YouTube, Twitter, Pinterest

#vishalindustries#mswires#MS#MSwire#MSWire#HHBwire#HBwire#hbwires#hhbwires#mswireprice#msprice#vsp#esl#jswsteel#jspl#wire#wirerod#bestquality#bindingwire#manufacturer#wiremanufacturer#annealing#nutbolt#screw#rivets#mildsteel#GIwire#wiredrawing#fasteners

2 notes

·

View notes