#What is a Power thyristors

Explore tagged Tumblr posts

Text

High- Power Thyristor Technology, Triac Power Thyristor, TSPD, TRIAC switches

T435 Series 700 V 35 mA Ihold 4 A SMT Snubberless Triac AC Switch - TO-252

#STMicroelectronics#T435-700B-TR#Thyristor Surge Protection Devices (TSPD)#What is a Power thyristors#High- Power Thyristor Technology#Triac Power Thyristor#TSPD#TRIAC switches#Light-Triggered Thyristors#Phase Control Thyristors

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--circuit-protection--protection-thyristors/mac4dhmt4g-littelfuse-7876436

Thyristor surge suppressors, Thyristor high current, types of thyristors

600 V 4 A Surface Mount Sensitive Gate Logic TRIAC -TO-252, (D-Pak)

#Littelfuse#MAC4DHMT4G#Circuit Protection Devices#Protection Thyristors#surge suppressors#Thyristor high current#Power Thyristors#what is thyristor#power electronics#Phase Control Thyristors#gate turn-off#Fast Switching#Voltage Thyristors#phase control

2 notes

·

View notes

Text

Triac thyristor circuits, what is a power thyristor, Types of Power Thyristors

Snubberless Triac AC Switch Surface Mount - TO-252

#STMicroelectronics#T435-600B-TR#Circuit Protection#Protection Thyristors#triac thyristor#Power thyristors#What is a power thyristor#Types of Power Thyristors#Alternating current#Silicon controlled rectifier#Triac thyristor circuit

1 note

·

View note

Text

Digital or analog?

First off, Welcome to Hi-Phi.

In this inaugural post, I will highlight the main difference between a fully digitalized amplifier, which is the most common today, to a completely (or almost completely) analog amplifier, plus a little extra, just for you <3. Please enjoy.

PS:please bear in mind this blog is for everyone and I will be explaining as much as possible to the best of my ability. Do not expect an extremely detailed run down!

Analog:

(taken from hi-fi news, Vacuum-packed: the "Airtight" amplifier)

Analog or valved amps were the first amplifiers to be created and are the living embodiment of: Grandpa is old, but he's no slouch! These bad boys can deliver amazing sound at great volume with a lower wattage than the new kids on the block. These things are also very customizable since all the sound depends on the type of vacuum tubes you put in. You want more bass? Change the tubes for a different family. You like the tubes already in the amp, but want more power? Stay in the same family, but switch to the next step-up!

These are the sort of shenanigans that would be harder to do on a digital amp, as you can't just unplug a transistor or a thyristor without having some technical know-how. Speaking of which, one of the glaring (yet stunning) problems with valved amps is in its namesake. The tubes (or valves) are very pretty to stare at, but, they require special treatment. The tubes are made from quartz. Quartz is known for not enjoying oils being rubbed on it, and the skin on our fingies have oils on them. YOU MUST NEVER TOUCH A VACUUM TUBE WITHOUT WEARING GLOVES. If you do, you must shower the tube in surgical spirit and wait for the spirit to evaporate, if you don't, I can almost guarantee that the tube will crack within one heat cycle. Keep a set of cotton gloves with the amp, just in case. Speaking of heat, tubes get hot, and quick, which is either a downside or an upside depending on the person!

Now, let us get technical. As I mentioned above, these amps can still deliver amazing sound with lower wattage, but what does any of that mean?.

To put it simply, Wattage means Power (literally) and the more power the more volume (usually), valved amps can still get loud with low wattage, yet, they shine with lower volumes as they keep their clarity without needing volume. They also usually have a great top end (treble), usually sounding clearer and more sparkly*, while still holding good sub-bass* and bass, of course this depends on the types of tubes you use. However, there is some objectivity to this, as with a valved amp you aren't distorting the sound as much as a digital amp would. Valved amps have the ability to produce smoother peaks* due to there being less digitalization of the music, this depends on how you are playing your music however, as if you are playing off a digital source than the type of file you are using still very much matters as well as the digital to analog converter* (DAC for short) and I've also heard that Upsampling* plays a major part in it, if your DAC is equipped with it.

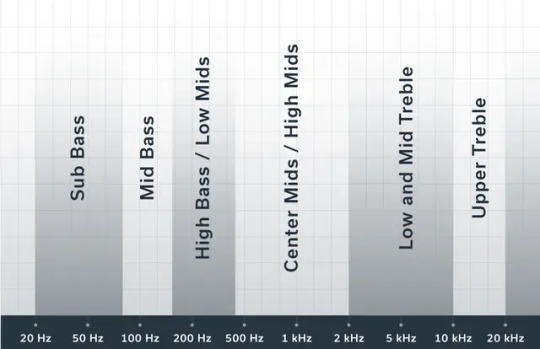

(*Sparkly, in the audiophile world means a great and clear and defined treble, treble is where the high notes of music live, like Cymbals, flutes, and trumpets. Please refer to fig 1, this image also explains helps to explain sub-bass.)

(*Sub-bass, is the part of the music below the bass, this is where the very low notes in music live, like kick drums, cellos and low notes in bass guitars, please refer to fig.1 to help explain.)

(*Peaks referring to the Peaks of a wave, all sound is a form of a wave, and digitalization usually leaves small distortions or also known as artefacts in the peaks of music, please refer to fig.2)

(*Digital to analog converters, simply turn the 1s and 0s into a wave, which means sound. *Upsampling, uses complicated math that I am deffo not qualified to explain to fill in the gaps of 1s and 0s meaning a larger file size, this isn't detailed as this is a blog about amps not dacs. I If you are still interested, headphonesty this website has a great about dacs)

(fig.1) (taken from: https://www.status.co/blogs/the-journal/explaining-the-audio-frequency-spectrum-bass-mids-and-treble)

(fig.2) (taken from: https://opened.cuny.edu/courseware/lesson/33/student/?section=2)

Digital/Solid state:

(taken from MV audio lab)

Digital amps are a little harder to talk about, as they are not only the most common but also harder to visualize with all their semiconductors and such. I shall still try my best to simplify and remove as much of the subjectivity as possible. Digital amps generally have a lot more “comforts” than valved amps, usually that’s because digital amps are a lot more beginner-friendly thanks to them ridding themselves from expensive tubes and bespoke design. Chances are, if you buy a basic amplifier, you are getting a black (or silver if you are feeling luxurious), if you spring the money or get a real good deal, you will get a cute little screen.

On the other hand, this design isn’t a bad thing, you can virtually fit digital amps everywhere, and you can even really compact models that the tubes simply don’t allow. The lack of tubes also means that your amplifier won’t double as a space heater, no cotton gloves for delicate quartz, and an overall more predictable sound, did I mention Bluetooth?

Bluetooth or Wi-Fi connectivity is extremely comfortable and helps to rid pesky phone Amps and dongles that will affect sound, no wires mean less clutter in a small space. However, even if you have an older digital amp or analog there are DACs that have such features and at a decent price.

Digital Amps offer more power for cheaper, these things and easily push out 80 watts or more from something that can fit in a bag and sometimes a pocket! This power, comes at the cost of the sweet sounds of the tube, and often times, if you only focus on power you loose in the treble clarity and sometimes clarity in general.

Again, always note that with Digital amps, you will get some form of distortion due to said digitalization, meaning that the peaks will be stepped rather than smooth. However, amps nowadays deal quite well with that. You will lose the customizability of the tubes, but in return, usually you will get 2 small knobs for controlling the treble and the bass.

Again, what you lose in smoothness, you will get back in power however, if valved amps are wine, then solid state is whiskey, both can suck or as smooth as hell to the taste. But like I said, it all depends on the taste, and some people will naturally prefer whiskey than wine.

Now I won't go into the different classes of amps and such, but It's important to note that digital amps do have different classes and make-ups. There are some amps to avoid, (or so I've read), mainly the "New class A" technics amps, but the "Class AB" amps should be fine, (again so I have read, I haven't heard any of these Amps.)

Now if you are a beginner, and you probably are if you are reading this, you are probably going to get a digital amp, and I will not blame you. They are everywhere and sound great, even the older Pro stuff sounds damn good today (proud owner of a Kenwood KA-6100). However, let's say you are a person that wants the treble of the analog stuff, but you're a beginner or don't want to spend too much on an amp, you are in luck, Mr. President, there has been a third option.

THE CHEATER OPTION: Hybrid amplifier

(taken from the Mcintosh website, McIntosh MA252)

There is a reason why I called this the "Cheating Option", because like the examples I mentioned above, you will simply get the downsides of both styles of amps. You will need to spend the money to get a good hybrid amp. There are some decent picks and for good money, but I recommend not picking one up for your first proper amp. However, they are a great bridge between the 2 styles of amps, IF you can find a good one for decent money.

I will not talk about them here because I find them so fascinating that I want to talk about them alone in detail another time! However, there is this great blog I found on the matter that sums up the reason on why I wrote about them like I did: https://www.tubecad.com/april_may2001/

The end note:

Thank you so much for reading this decently sized blog, as you will notice I spent a lot of time talking about analog amps, that's because they are rarer and so there isn't an excellent starting point for people who know nothing about Hi-fi (I'm coping here). After all, i never even mentioned squeeze and push-pull set-ups (not to mention, I want to talk about in detail the make-ups of digital amps soon). Again, thank you so much, and I will see all of you wonderful tumblr people soon ;3 love you all, keep on rockin! <3

5 notes

·

View notes

Text

What Type Of Inverter Is Most Efficient?

As the name implies, what type of inverter is the most efficient? We usually associate this question with our high-frequency inverters, in reality this is true. In the industry, if we define efficiency, we most often talk about low frequency inverters and high frequency inverters.

The IFB inverter is designed based on the traditional analog circuit principle and consists of thyristor (SCR) rectifier, IGBT inverter, bypass and IFB step-up isolation transformer. Because the working frequency of both rectifier and transformer is 50 Hz, it is called IFB inverter as the name suggests.

High frequency inverters usually consist of IGBT high frequency rectifiers, battery converters, inverters and bypasses. IGBTs can be turned on and off by controlling the drive added to the gate, and the switching frequency of IGBT rectifiers is usually in the range of several KHZ to tens of KHZ, or even up to hundreds of KHZ, which is much higher than that of low frequency inverters, hence the name high frequency inverter.

Comparing the two inverters, it can be seen that the same power inverter, low frequency inverter is much heavier than the high frequency inverter. The high frequency inverter adopts the high frequency core material which is small in size and light in weight, thus greatly improving the power density of the circuit, making the no-load loss of the inverter very small and the inverter efficiency has been improved. Usually the peak conversion efficiency of high-frequency inverter reaches more than 90%, but it also has significant disadvantages, high-frequency inverter can not be connected to a full load of inductive load, and the overload capacity is poor.

HP PLUS and HP PRO series high frequency inverters manufactured by Xindun Power Technology Co., Ltd. have super high conversion efficiency and stable output capability. The products are cost-effective and have been well received by customers in many sales. If you are interested in our high frequency inverters or other products, you are more than welcome to contact us.

0 notes

Text

Thyristor Manufacturers in India: Powering Efficient Solutions

Thyristors, also known as Silicon-Controlled Rectifiers (SCRs), are integral components in modern electronic and electrical systems. These semiconductor devices are widely used for controlling power flow and ensuring efficiency in various industrial applications. India has emerged as a hub for thyristor manufacturing, thanks to its skilled workforce, advanced manufacturing facilities, and growing demand in sectors like power electronics, industrial automation, and renewable energy.

What Are Thyristors?

Thyristors are semiconductor devices that act as switches, allowing electrical current to flow in one direction when triggered. Their unique capability to handle high voltage and current makes them indispensable in applications such as:

Power conversion and rectification

Voltage regulation in power systems

Motor control in industrial machinery

Light dimming and heating controls

Their robustness and efficiency make them crucial in both consumer electronics and heavy industrial equipment.

India's Thyristor Manufacturing Landscape

India has become a prominent destination for thyristor manufacturing due to its strong engineering expertise, cost-effective production capabilities, and supportive government policies. Thyristor manufacturers in India cater to both domestic and international markets, offering high-quality products that meet global standards.

Key factors driving the growth of thyristor manufacturing in India include:

Industrial Growth: The rapid expansion of sectors such as power generation, electric vehicles, and renewable energy has increased the demand for thyristors.

Technological Advancements: Indian manufacturers are investing in cutting-edge technologies to produce thyristors with higher efficiency and reliability.

Export Opportunities: Indian thyristor manufacturers are gaining recognition globally, exporting their products to Europe, the Middle East, and Asia.

Applications of Thyristors

The versatility of thyristors makes them suitable for diverse applications. Here are some key areas where thyristors are indispensable:

Power Electronics: Thyristors are widely used in AC/DC conversion, voltage control, and power distribution systems.

Renewable Energy: In solar and wind energy systems, thyristors play a critical role in regulating power flow and integrating energy into grids.

Industrial Automation: Thyristors enable precise control of motors and machinery, ensuring efficient and reliable operations.

Transportation: They are used in electric trains and vehicles for power regulation and motor control.

Consumer Electronics: Thyristors are used in devices like air conditioners, refrigerators, and washing machines for efficient energy management.

Leading Thyristor Manufacturers in India

Several companies in India specialize in the design and production of thyristors, offering products tailored to various industrial needs. These manufacturers focus on quality, innovation, and customer satisfaction. Some prominent players include:

Bharat Heavy Electricals Limited (BHEL): Known for producing high-capacity thyristors for industrial applications.

Littelfuse India: Offers a wide range of thyristors for automotive and industrial sectors.

Powersem Semiconductors: Specializes in high-power thyristors for renewable energy systems.

Semikron India: Focuses on power modules and thyristors for industrial and transportation applications.

The Future of Thyristor Manufacturing in India

With the global shift toward renewable energy and energy-efficient technologies, the demand for thyristors is expected to grow significantly. Indian manufacturers are well-positioned to capitalize on this trend by:

Expanding Production Capacities: Increasing manufacturing output to meet rising domestic and international demand.

Investing in R&D: Developing advanced thyristors with improved performance and reliability.

Collaborating with Global Partners: Strengthening partnerships to enhance technological expertise and market reach.

Conclusion

Thyristors are vital components driving efficiency and reliability in modern electrical and electronic systems. The growing demand for these devices across various industries underscores their significance. Thyristor manufacturers in India are at the forefront of this transformation, offering world-class products that cater to diverse applications.

As India continues to evolve as a global manufacturing hub, the thyristor industry is poised for sustained growth, contributing to the nation’s industrial progress and global competitiveness. Whether for powering renewable energy systems or optimizing industrial machinery, Indian thyristor manufacturers are empowering solutions for a sustainable future.

0 notes

Text

Industrial Float Cum Boost Battery Charger (FCBC): Reliable Power Management for Industrial Applications

Industrial Float Cum Boost Battery Charger (FCBC): In this paper, the authors present the backbone of reliable power management.

When it comes to industries, which cannot afford power cuts, then Float Cum Boost Battery Charger (FCBC) is used. This sophisticated system means that batteries are always fully charged as required under normal circumstances and quickly recharged during an emergency. The Industrial FCBC from EnerTech is designed to provide specifically advanced technology that is suitable to respond to the various needs of contemporary industries.

Types of FCBC

Single-Phase FCBC:

These are preferably suited to small scale application.

Compact and cost-effective.

For systems with lower power consuming capacity these PSs are very efficient.

Three-Phase FCBC:

Built for utilization in big manufacturing industries.

Performs well to handle high power loads.

Guarantees the highest effectiveness and reliability of the system.

Thyristor-Based FCBC:

Is charged with thyristor-controlled rectifiers in addition to possessing accurate charging.

Enables the best charging and discharging processes to be established.

Certified for applications when voltage stability is critical.

Switch Mode FCBC:

Uses trans-inductor (SMPS) technology to offer compact size and high power conversion efficiency.

Light weight and have low energy usages.

Most adaptive in the new and compact built structures.

Advantages of Industrial Float Cum Boost Battery Charger

Dual Functionality:

Runs on float to keep a constant charge during normal operation and service.

Switches into the boost mode where the charging happens at the highest possible speed for a few minutes in a disaster.

High Reliability:

It guarantees the un-intermittent power supply for any crucial equipment in the organizations that undertake the project.

Prevents the buildup of excessive charge or discharge current on batteries.

Energy Efficiency:

Another characteristic is its capability of reducing energy losses during the operation.

Saves cost and ensures environmentally friendly business is conducted.

Durability:

Design with strong material used on areas that may come into contact with industrial conditions or pollution.

It provides adequate durability and almost negligible maintenance.

Customizability:

Adapted to match certain needs of one industry over the other.

It has outputs voltage options, current rating choices, as well as additional features one can select from.

What Makes EnerTech’s FCBC Unique?

EnerTech’s Industrial Float Cum Boost Battery Charger is designed with advanced technology and customer-centric features that set it apart:

Precision Charging: Smart charging algorithms for maximum battery and superior performance of the battery.

Built-In Protections: Equipped with over voltage and current protection, reverse polarity connection and a thermal overload protection for optimum safe use.

Scalability: It is relatively easier to update a modular designed device and incorporate it into other systems.

Advanced Monitoring: Combined with an efficient interface, comprising of touch screen features and remote control and monitor the gadget’s operations.

Eco-Friendly Design: Outlines energy efficiency and low carbon impact compatible with sustainable practice.

FCBC Solutions with EnerTech: Why Choose EnerTech?

Among all companies, EnerTech UPS is exceptional thanks to its sheer focus on the ideas behind the UPS systems, high-quality services, and focused response to customers’ needs. Having been in business for more than two decades, the company specializes in delivering products that meet specific performance thresholds that accompany various industries. Industrial Float Cum Boost Battery Charger is one of the samples of how EnerTech`s company cares about its client’s needs by offering reliable and efficient power products for industries around the world. Upgrade your power management systems with EnerTech’s Industrial FCBC.

#IndustrialFCBC#BatteryCharger#FloatCumBoostCharger#EnerTechUPS#PowerManagement#EnergySolutions#EfficientCharging#IndustrialEquipment#FCBC

1 note

·

View note

Text

Thyristor Rectifiers: An In-Depth Overview

Thyristor rectifiers are pivotal in the realm of power electronics, providing crucial capabilities for converting alternating current (AC) to direct current (DC). These devices, integral to many industrial and commercial applications, harness the unique properties of thyristors to deliver efficient and controlled power conversion. This article explores the core concepts, advantages, and applications of thyristor rectifiers, offering a comprehensive understanding of their role in modern power systems.

What is a Thyristor Rectifier?

A thyristor rectifier is a type of rectifier circuit that utilizes thyristors—semiconductor devices known for their ability to handle high voltages and currents. Unlike traditional diodes, thyristors can be controlled and turned on or off by applying a gate signal, which allows for precise regulation of power.

How Thyristor Rectifiers Work

AC Input: The thyristor rectifier receives an alternating current input, which alternates between positive and negative phases.

Thyristor Operation: A thyristor is a four-layer, three-junction device with four terminals: anode, cathode, gate, and a small gate terminal for triggering. During the positive half-cycle of the AC input, the thyristor can be triggered into conduction by a gate pulse. Once triggered, it remains in the conducting state until the AC input goes through a zero-crossing point.

Rectification: As the AC input varies, the thyristors alternate between conducting and blocking states, effectively converting the AC into a pulsating DC output. The output DC voltage is controlled by adjusting the firing angle of the thyristors, which determines when during each cycle the thyristor will conduct.

Controlled Firing: The timing of the gate pulses—referred to as the firing angle—is crucial. By varying this angle, the average DC output voltage can be controlled, allowing for dynamic power regulation.

Benefits of Thyristor Rectifiers

Thyristor rectifiers offer several significant advantages:

High Power Handling: Thyristors are designed to handle high voltages and currents, making them suitable for demanding applications.

Precise Control: The ability to control the firing angle allows for precise adjustment of the DC output voltage, which is essential for applications requiring variable power.

Efficiency: Thyristor rectifiers provide efficient power conversion with minimal energy losses, improving overall system performance.

Durability: Thyristors are robust and reliable, capable of withstanding harsh operational environments and high power levels.

Applications of Thyristor Rectifiers

Thyristor rectifiers find applications across various sectors:

Industrial Motor Drives: Thyristor rectifiers are used to control the speed and torque of electric motors in industrial settings, enabling precise motor control.

HVDC Transmission Systems: In high-voltage direct current (HVDC) systems, thyristor rectifiers convert AC power into DC for long-distance transmission, reducing losses and improving efficiency.

Power Supplies: Thyristor rectifiers are employed in power supply units to convert AC from the grid into stable DC for electronic devices and systems.

Battery Charging: They are used in battery chargers to regulate the charging current, ensuring efficient and safe charging of batteries.

Welding Equipment: Thyristor rectifiers provide the controlled DC necessary for electric arc welding, ensuring consistent welding quality and performance.

Challenges and Considerations

Despite their advantages, thyristor rectifiers present certain challenges:

Complex Control Systems: The precise control of firing angles and synchronization with the AC supply can be complex and requires sophisticated control circuitry.

Thermal Management: High-power applications can generate significant heat, necessitating effective cooling and thermal management to maintain reliable operation.

Harmonic Distortion: Thyristor rectifiers can introduce harmonic distortions into the power system, which may require additional filtering to mitigate.

Conclusion

Thyristor rectifiers are crucial components in modern power systems, offering efficient and controlled conversion of AC to DC. Their ability to handle high power levels, coupled with precise control capabilities, makes them invaluable in industrial motor drives, HVDC systems, power supplies, and more. As technology advances, ongoing improvements in thyristor rectifiers are likely to enhance their efficiency and applicability, solidifying their role in the future of power electronics.

0 notes

Text

Solid State Relay: The Silent Power of Modern Switching Technology

In modern electrical and electronic systems, the need for reliable, fast, and efficient switching mechanisms is essential for controlling power flow. While traditional electromechanical relays have been used for decades, the advent of Solid State Relays (SSR) has revolutionized switching technologies by offering silent operation, longer lifespan, and improved performance. This article explores the workings, types, applications, and advantages of solid state relays, highlighting their critical role in contemporary industrial, commercial, and residential electrical systems.

What is a Solid State Relay?

A Solid State Relay (SSR) is an electrical switching device that uses semiconductor components—such as transistors, thyristors, or triacs—to switch electrical loads without the mechanical contacts that characterize traditional relays. Unlike electromechanical relays, which rely on physical contacts that open and close to control the flow of electricity, SSRs switch the load on or off by changing the state of the internal semiconductor material.

Solid state relay are widely favored for their silent operation, long operational life, and high-speed switching capabilities. These attributes make them particularly suitable for applications that require frequent switching, minimal maintenance, and reliable performance under various environmental conditions.

Key Components of a Solid State Relay

Solid state relays are built using several essential components that work together to achieve their efficient switching capabilities:

Input Circuit: The input circuit, often referred to as the control side, accepts the triggering signal (typically a low-voltage control signal from a microcontroller or other control devices) to activate the relay. The input is optically isolated from the output to protect sensitive control circuitry from high voltage fluctuations.

Optocoupler: The optocoupler is the key isolation component in SSRs, ensuring electrical separation between the control and output sides. It converts the input signal into light, which is then detected by a photodetector on the output side to trigger the switching process.

Output Circuit: The output circuit, consisting of solid-state components such as thyristors, triacs, or MOSFETs, performs the actual switching of the electrical load. These components provide the necessary switching functionality by allowing or blocking the flow of electrical current.

Heat Sink: Since SSRs can generate heat during operation (especially in high-power applications), they are often equipped with heat sinks to dissipate thermal energy and prevent overheating.

How Does a Solid State Relay Work?

The operation of a solid state relay can be summarized in the following steps:

Input Signal: A low-voltage control signal is applied to the input terminals of the SSR, typically ranging from 3V to 32V, depending on the relay's design.

Optical Coupling: The input signal activates the internal optocoupler, causing an LED within the optocoupler to emit light. This light is detected by a photosensitive semiconductor device on the output side, ensuring electrical isolation between the control and load circuits.

Switching Process: Once the light is detected, the output circuit is triggered, causing the semiconductor components (triacs, thyristors, or MOSFETs) to switch on or off, allowing or blocking the flow of current through the load.

Silent Operation: Unlike traditional relays, which make a clicking noise due to the mechanical contacts moving, solid state relays operate silently because there are no moving parts involved.

Types of Solid State Relays

Solid state relays come in various types, designed for specific applications and load conditions. The primary types of SSRs include:

AC Solid State Relays: These relays are used to switch alternating current (AC) loads. They typically use thyristors or triacs for switching and are commonly found in applications such as heating controls, lighting systems, and industrial motors.

DC Solid State Relays: DC SSRs are used to switch direct current (DC) loads. They rely on MOSFETs or IGBTs for switching and are often employed in applications such as automotive systems, solar energy inverters, and battery management systems.

Zero-Crossing SSRs: These relays are designed to switch the load precisely at the zero-crossing point of the AC waveform, minimizing electrical noise and reducing stress on the connected load. They are ideal for applications where reduced electromagnetic interference (EMI) is critical.

Random Turn-On SSRs: Unlike zero-crossing SSRs, random turn-on relays can switch the load at any point in the AC waveform. This allows for faster switching, which is useful in applications requiring rapid response, such as motor control and phase angle control.

Applications of Solid State Relays

Solid state relays are used in a wide range of applications across multiple industries due to their versatility, reliability, and superior performance. Some of the common applications include:

Industrial Automation: SSRs are widely used in industrial automation systems to control heating elements, motors, pumps, and solenoids. Their fast switching and long lifespan make them ideal for high-cycle operations.

Temperature Control: In temperature-sensitive environments such as ovens, furnaces, and HVAC systems, SSRs ensure precise temperature regulation by switching heating and cooling elements with minimal wear and tear.

Lighting Systems: SSRs are often used in commercial and residential lighting control systems, especially in situations where silent operation and smooth dimming are desired.

Home Appliances: SSRs are found in modern household appliances such as washing machines, dishwashers, and microwave ovens, where they control motors and heating elements with high reliability.

Renewable Energy Systems: In solar power and wind energy systems, SSRs are employed to manage inverters and battery charging systems, ensuring efficient energy conversion and distribution.

Advantages of Solid State Relays

Solid state relays offer numerous advantages over traditional electromechanical relays, making them a popular choice for many applications:

Silent Operation: Since SSRs have no moving parts, they operate completely silently, making them ideal for noise-sensitive environments such as medical equipment or residential applications.

Longer Lifespan: With no mechanical contacts to wear out, solid state relays have a significantly longer operational life compared to electromechanical relays, especially in high-frequency switching applications.

High-Speed Switching: SSRs can switch loads much faster than mechanical relays, making them suitable for applications requiring rapid on/off cycles.

Reduced Maintenance: The absence of moving parts reduces the need for maintenance and periodic replacements, resulting in lower operational costs over time.

No Electrical Arcing: SSRs do not produce electrical arcing, a phenomenon that can degrade the performance and safety of traditional relays. This makes SSRs more reliable and safer for switching high-power loads.

Improved Durability in Harsh Environments: SSRs are more resistant to shock, vibration, and environmental factors such as dust and moisture, making them suitable for industrial and outdoor applications.

Conclusion

Solid state relay represent a significant advancement in switching technology, offering numerous benefits over traditional electromechanical relays. Their silent operation, fast switching capabilities, longer lifespan, and resistance to environmental factors make them an essential component in modern electrical and electronic systems. From industrial automation to home appliances, SSRs are proving to be the preferred choice for reliable and efficient switching in a variety of applications. As technology continues to evolve, the role of solid state relays is likely to expand, offering even greater levels of performance and versatility in the future.

0 notes

Text

Industrial Rectifiers Market Trends and Industry Research, Regional by 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Industrial Rectifiers Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Industrial Rectifiers Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Industrial Rectifiers Market?

The global industrial rectifiers market size reached US$ 694.5 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,105.5 million in 2032, exhibiting a growth rate (CAGR) of 5.3% during 2024-2032.

What are Industrial Rectifiers?

Industrial rectifiers are devices that convert alternating current (AC) into direct current (DC) for a range of industrial uses. They are vital for processes that require a stable and controlled DC power supply, such as in electroplating, battery charging, and driving DC motors. Featuring components like diodes or thyristors, these rectifiers efficiently handle the conversion, ensuring dependable performance with minimal energy loss. By providing a consistent DC output, industrial rectifiers enable accurate control and operation of equipment and processes in various industrial and manufacturing settings.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1921

What are the growth prospects and trends in the Industrial Rectifiers industry?

The industrial rectifiers market growth is driven by various factors and trends. The industrial rectifiers market is growing steadily, driven by the increasing need for reliable and efficient power conversion across various industrial sectors. Industries such as manufacturing, automotive, and energy require stable direct current (DC) power for processes like electroplating, battery charging, and operating DC motors, fueling demand for high-performance rectifiers. Market growth is supported by advancements in rectifier technology, a focus on energy efficiency, and expanding industrial activities globally. Hence, all these factors contribute to industrial rectifiers market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Silicon Rectifiers

Selenium Rectifiers

Schottky Rectifiers

Fast Recovery Rectifiers

Ultrafast Rectifiers

Other Rectifiers

By Application:

Power Supplies

Motor Drives

Welding Equipment

Battery Charging Units

Electrochemical Processes

Others

By End-Use Industry:

Automotive

Manufacturing

Energy & Power

Telecommunications

Aerospace & Defense

Consumer Electronics

Others

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

ABB Ltd.

General Electric Company

Siemens AG

Schneider Electric SE

Mitsubishi Electric Corporation

Eaton Corporation PLC

Rockwell Automation, Inc.

Delta Electronics, Inc.

Infineon Technologies AG

Fuji Electric Co., Ltd.

Toshiba Corporation

Emerson Electric Co.

View Full Report: https://www.reportsandinsights.com/report/Industrial Rectifiers-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Industrial Rectifiers Market share#Industrial Rectifiers Market size#Industrial Rectifiers Market trends

0 notes

Text

Low Harmonic Drives: Driving Towards a Greener Future How Clean Power is Empowering the Automotive Industry

Over the past few decades, variable frequency drives (VFDs) have become widespread in industrial and commercial applications for their ability to control motor speed and torque. Traditionally, VFDs utilize pulse width modulation (PWM) techniques to vary motor voltage and frequency. However, PWM generates high harmonic currents that can damage motors, heat up transformers and power cables, and potentially cause voltage distortions on the utility grid. To address these challenges, a new generation of low harmonic drives has emerged based on advanced switching algorithms. What are Harmonics? In electrical systems, harmonics refer to sinusoidal voltages or currents having frequencies that are integer multiples of the fundamental power supply frequency, usually 50 or 60 Hz. Harmonics are produced by non-linear loads like adjustable speed drives that draw non-sinusoidal currents from the power source. The extra frequencies generated interact with the system impedance and generate losses, heating, vibrations, torque pulsations and can even cause misoperation of protective devices if sufficiently high in magnitude. Harmonics cause additional power losses in distribution transformers and overvoltages that reduce insulation lifetime. They can also interfere with communication lines. Traditional PWM Drives and their Harmonic Impact Traditional PWM VFDs employ insulated-gate bipolar transistors (IGBTs) or thyristors to rapidly switch the motor voltages on and off, generating quasi-square wave voltages to control motor speed. However, when these non-sinusoidal voltages are applied to the motor windings, they produce harmonic currents in the supply lines that are integer multiples of the fundamental supply frequency. Specifically, PWM drive techniques generate dominant 5th and 7th order harmonics that can propagate back into the utility system if not properly filtered. The harmonic currents not only stress motor windings but also increase I2R losses in the supply feeders and distribution transformers. Low Harmonic Drives can cause overheating in older transformers not designed for harmonics. Harmonic distortions also increase circulating currents within delta-wye grounded transformers. To mitigate these issues, dedicated harmonic filters need to be installed, increasing overall system costs. Excessive harmonics if left unchecked can even cause protective relays to malfunction. Advancements in Low Harmonic Drive Technology To address harmonic pollution from VFDs, innovative drive manufacturers have developed new low harmonic drive technologies based on advanced switching algorithms that naturally minimize the generation of lower order harmonics. Pulse-Density Modulation

One such technique is pulse density modulation (PDM) where the IGBTs are switched at high frequencies using narrower pulses compared to traditional square waves. By spacing the pulses closer together over time, PDM produces quasi-sinusoidal drive output voltages that inherently contain lower harmonics. PDM drives generate less than 5% total harmonic distortion (THD) without additional filters. Active Front End Drives

Another option is active front end (AFE) drives with a front-end rectifier consisting of IGBTs or MOSFETs instead of diode bridges. The AFE rectifier actively shapes the supply current waveform to follow the voltage waveform and provide near unity power factor without harmonics. AFE drives come with integrated DC chokes to absorb any remaining higher order harmonics internally, keeping them well below 5% THD.

Get more insights on Low Harmonic Drives

Also read related article on Ransomware Protection Market

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Low Harmonic Drives#Harmonic Mitigation#Low Harmonic VFD#Variable Frequency Drives#Harmonic Distortion Reduction#Energy-Efficient Drives#Harmonic Filters

0 notes

Text

How Soft Starters Improve Motor Performance and Longevity

Electric motors are crucial components in various industrial, commercial, and residential applications. Their performance and longevity significantly impact the efficiency and reliability of the systems they power. One effective way to enhance motor performance and extend their lifespan is by using soft starters.

Soft starters play a pivotal role in controlling the inrush current and reducing mechanical stress on motors during startup. This not only improves motor performance but also prolongs the lifespan of the motor components. In this article, we will delve into how soft starters improve motor performance and longevity, their benefits, applications, and much more.

Key Takeaways

Soft starters are essential for reducing mechanical stress on motors during startup.

They enhance operational efficiency and extend motor lifespan.

Soft starters are suitable for various applications, including industrial, commercial, and residential.

Understanding the differences between soft starters and other motor control devices is crucial for making the right choice.

Understanding Soft Starters

What is a Soft Starter?

A soft starter is an electrical device used to control the acceleration of electric motors. It gradually increases the voltage supplied to the motor, allowing it to start smoothly and avoiding the high inrush current typically associated with motor startups.

How Do Soft Starters Work?

Soft starters work by controlling the voltage applied to the motor during startup. They use a series of thyristors to regulate the voltage, gradually increasing it until the motor reaches its full operating speed. This smooth transition reduces mechanical stress on the motor and connected equipment.

Benefits of Using Soft Starters

Improved Motor Performance

Smooth Start-Up and Reduced Mechanical Stress

One of the primary benefits of using soft starters is the smooth start-up they provide. By gradually increasing the voltage, soft starters reduce the mechanical stress on the motor's components. This minimizes the risk of damage and wear during the start-up phase.

Enhanced Operational Efficiency

Soft starters improve the operational efficiency of motors by reducing the amount of electrical and mechanical stress. This leads to a more stable and efficient motor operation, reducing energy consumption and maintenance costs.

Increased Motor Longevity

Decreased Wear and Tear on Motor Components

The gradual voltage increase provided by soft starters helps to decrease wear and tear on motor components. This results in less frequent maintenance and a lower likelihood of unexpected breakdowns.

Prolonged Motor Lifespan

By reducing mechanical and electrical stress, soft starters help to extend the overall lifespan of motors. This means longer periods of reliable operation and fewer replacements, saving time and money in the long run.

Applications of Soft Starters

Industrial Applications

In industrial settings, soft starters are used in a variety of applications, including conveyor belts, pumps, and fans. They help to ensure smooth operation and protect the motors from damage due to sudden starts and stops.

Commercial and Residential Uses

Soft starters are also beneficial in commercial and residential applications. They can be used in HVAC systems, elevators, and other motor-driven equipment to enhance performance and extend the lifespan of these systems.

Comparing Soft Starters with Other Motor Control Devices

Soft Starters vs. Variable Frequency Drives (VFDs)

While both soft starters and VFDs control motor speed, they do so in different ways. Soft starters are primarily used for reducing inrush current during startup, whereas VFDs provide continuous speed control. VFDs are more complex and expensive but offer more precise control over motor speed.

Soft Starters vs. Direct On-Line (DOL) Starters

Direct On-Line (DOL) starters provide full voltage to the motor at startup, resulting in high inrush current and mechanical stress. Soft starters, on the other hand, gradually increase the voltage, reducing stress and wear on the motor. This makes soft starters a better choice for applications where motor longevity and performance are critical.

Choosing the Right Soft Starter for Your Motor

Factors to Consider

When selecting a soft starter, consider factors such as motor size, load type, and the specific application. It's also important to choose a soft starter that is compatible with your motor's voltage and current requirements.

Popular Brands and Models

Several reputable brands offer high-quality soft starters, including Schneider Electric. Their range of soft starters is designed to meet various application needs and provide reliable performance.

Installation and Maintenance Tips

Step-by-Step Guide to Installing a Soft Starter

Read the Manufacturer's Instructions: Before installation, thoroughly read the manufacturer's instructions to ensure proper setup.

Prepare the Motor and Starter: Ensure that the motor and soft starter are compatible and in good working condition.

Connect the Soft Starter: Follow the wiring diagram provided by the manufacturer to connect the soft starter to the motor and power supply.

Test the Setup: After installation, test the setup to ensure the soft starter is functioning correctly.

Common Installation Mistakes to Avoid

Incorrect Wiring: Always follow the wiring diagram to avoid incorrect connections.

Ignoring Compatibility: Ensure the soft starter is compatible with the motor's voltage and current requirements.

Maintenance

Routine Checks and Servicing

Regularly check and service the soft starter to ensure it is functioning correctly. This includes inspecting the connections, cleaning the components, and testing the voltage control.

Troubleshooting Common Issues

Common issues with soft starters include improper voltage control and overheating. Refer to the manufacturer's troubleshooting guide to address these issues promptly.

Conclusion

Soft starters play a crucial role in improving motor performance and extending their lifespan. By providing smooth start-ups and reducing mechanical stress, they enhance operational efficiency and reduce wear and tear on motor components.

Investing in a soft starter is a smart choice for anyone looking to enhance motor performance and longevity. Consider the specific needs of your application and choose a reliable brand to ensure the best results.

FAQs

What is the primary function of a soft starter? The primary function of a soft starter is to control the inrush current and reduce mechanical stress on motors during startup by gradually increasing the voltage.

How does a soft starter differ from a VFD? A soft starter controls the voltage during motor startup, while a VFD provides continuous speed control throughout the motor's operation.

Can soft starters be used with all types of motors? Soft starters are suitable for most types of motors, but it's important to ensure compatibility with the motor's voltage and current requirements.

What are the signs that my motor needs a soft starter? Signs include frequent mechanical stress, high inrush current during startup, and excessive wear and tear on motor components.

How often should a soft starter be maintained? Regular maintenance checks should be performed according to the manufacturer's recommendations, typically every few months to ensure optimal performance.

0 notes

Text

What are the top companies leading in HVDC transmission technology?

The HVDC transmission market is estimated to be worth USD 11.4 billion in 2023 and is projected to reach USD 14.9 billion by 2028, at a CAGR of 5.4% during the forecast period. Shift towards renewable energy, increasing demand for VSC-based HVDC transmission projects, and supportive government policies and initiatives are the major factors driving the market growth.

HVDC Transmission companies include:

Hitachi (Japan),

Siemens Energy (Germany),

Mitsubishi Electric Corporation (Japan),

General Electric (US), and

Prysmian Group (Italy).

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1225

These players have adopted various inorganic growth strategies such as partnerships, agreements, collaborations, acquisitions, and joint ventures to strengthen their position in the HVDC transmission market.

Hitachi is a leading provider of HVDC transmission solutions. The company's comprehensive product portfolio of HVDC solutions includes switchgear, DC filters, thyristors, and more. Hitachi leverages its extensive experience and expertise in various sectors, such as power systems, information technology, and social infrastructure. The company extensively focuses on inorganic growth strategies such as agreements and partnerships to strengthen its position in the market.

Siemens Energy boasts a comprehensive product portfolio of HVDC transmission components that include switchgear, circuit breakers, and transformers, among others. Along with a comprehensive portfolio of products, Siemens Energy also boasts a strong geographic footprint with operations and sales in Germany, the Americas, Asia Pacific, the Middle East, and Africa. The company focuses on investing extensively in research and development activities to develop advanced products. For instance, Siemens Energy invested 3.6%, 4.7%, and 3.7% of its revenue in 2020, 2021, and 2022 respectively, for research and development activities.

Furthermore, the company extensively focuses on collaborations to strengthen its position in the market.

Mitsubishi Electric Corporation is one of the leading players in the designing and manufacturing of HVDC transmission components. Mitsubishi Electric Corporation's strengths include a strong presence in the Asian market, presence in various industries and markets, and substantial investments in research and development (R&D) to deliver high-quality customized products and services. The company mainly focuses on inorganic growth strategies such as acquisitions and collaborations to capture a significant market share of the HVDC transmission market.

General Electric (GE) offers a wide range of HVDC Transmission components that include converters. General Electric has strengthened its position through the acquisition of Alstom's power and grid businesses, diversifying revenue streams and reducing risk. The company excels in research and development with a highly capable workforce. GE's global presence and extensive project experience enable it to deliver reliable and efficient HVDC solutions to a wide range of clients and applications globally.

Prysmian Group is a leading player in the cable and energy solutions industry. The company specializes in the design, manufacturing, and installation of a wide range of cables and systems used in various sectors, including energy and telecommunications. The company boasts a strong product portfolio of HVDC transmission cables and a strong geographic presence in Europe and North American markets. The company focuses on strategies such as acquisitions to capture a significant market share and strengthen its geographic presence.

0 notes

Text

Heatcon Sensors: Leading Thyristor Manufacturers in India

Heatcon Sensors, a prominent name in the industrial sector, has established itself as a leading manufacturer of thyristors in India. Through unwavering dedication to quality, innovation, and customer satisfaction, the company has established a distinct presence in the competitive electronic components market.This article delves into the journey, products, and contributions of Heatcon Sensors in the realm of thyristor manufacturing.

The Journey of Heatcon Sensors

Founded with a vision to provide reliable and efficient electronic components, Heatcon Sensors has grown steadily over the years. The company's journey is marked by continuous improvement, technological advancements, and a customer-centric approach. From humble beginnings, Heatcon Sensors has expanded its operations, becoming a trusted supplier to various industries, including automotive, aerospace, power generation, and industrial automation.

What are Thyristors?

Thyristors are semiconductor devices that act as switches, controlling the flow of electrical power in a circuit. They are widely used in applications requiring high power and voltage control, such as motor speed controls, light dimmers, pressure control systems, and inverters. The reliability and efficiency of thyristors make them indispensable in modern electronic circuits.

Heatcon Sensors' Thyristor Products

Heatcon Sensors offers a comprehensive range of thyristors, designed to meet the diverse needs of its clientele. The company's product portfolio includes:

Standard Thyristors: These are used in general-purpose applications, providing efficient switching capabilities and robust performance.

Phase-Control Thyristors: Ideal for controlling power in AC circuits, these thyristors are used in motor control, light dimming, and heating applications.

Fast-Switching Thyristors: Designed for high-frequency applications, these thyristors offer rapid switching speeds and are used in inverters and frequency converters.

Bi-Directional Thyristors (Triacs): These devices are capable of conducting current in both directions, making them ideal for alternating current (AC) applications such as power control in household appliances.

Quality and Innovation

At Heatcon Sensors, quality is paramount. The company adheres to stringent quality control measures to ensure that every thyristor meets international standards. Advanced manufacturing techniques and rigorous testing procedures are employed to guarantee the reliability and durability of their products.

Innovation is another cornerstone of Heatcon Sensors' success. The company makes substantial investments in research and development to stay at the forefront of technological advancements.By embracing the latest technologies and continuously improving their products, Heatcon Sensors ensures that they meet the evolving needs of the market.

Customer-Centric Approach

Heatcon Sensors places great emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and provide tailored solutions. This customer-centric approach has earned Heatcon Sensors a loyal customer base and a reputation for excellence in the industry.

Contribution to the Industry

Heatcon Sensors' contributions extend beyond manufacturing thyristors. The company is instrumental in advancing the electronics industry in India. By providing high-quality components, Heatcon Sensors supports the growth of various sectors, including renewable energy, automotive, and industrial automation. The company's commitment to sustainability and energy efficiency also aligns with global efforts to reduce carbon footprints and promote green technologies.

Future Prospects

Looking ahead, Heatcon Sensors is poised for further growth and expansion. The company strives to expand into new markets and broaden its range of product offerings. With a focus on continuous improvement and innovation, Heatcon Sensors is well-positioned to meet the challenges of the future and maintain its leadership in the thyristor manufacturing sector.

Conclusion

Heatcon Sensors' journey from a small enterprise to a leading thyristor manufacturer in India is a testament to its commitment to quality, innovation, and customer satisfaction. By providing reliable and efficient electronic components, the company has significantly contributed to the growth of the electronics industry. As Heatcon Sensors continues to evolve and expand, it remains dedicated to delivering excellence and staying at the forefront of technological advancements.

0 notes

Text

Understanding the 3-Phase AC to DC Rectifier: A Comprehensive Guide

In modern electrical engineering, converting alternating current (AC) to direct current (DC) is essential for many applications, from industrial machinery to household electronics. A 3-phase AC to DC rectifier is a crucial device in this process, providing efficient and stable conversion. Here's a detailed look at what a 3-phase rectifier is, how it works, and its benefits.

What is a 3-Phase AC to DC Rectifier?

A 3-phase AC to DC rectifier converts three-phase alternating current into direct current. Three-phase power, which consists of three AC waveforms, is commonly used in industrial and high-power applications due to its efficiency in transmitting power over long distances and delivering steady voltage.

How Does It Work?

1. Input Stage

The process begins with the 3-phase AC input, which is typically supplied from the power grid or a generator. The AC power is characterized by three waveforms, each 120 degrees out of phase with the others.

2. Rectification Process

In the rectification process, the 3-phase AC voltage is converted to DC voltage using diodes or thyristors. A common configuration is the six-pulse rectifier, which employs six diodes arranged in a bridge configuration. Each diode conducts during one-sixth of the AC cycle, ensuring that the output is a pulsating DC voltage.

3. Filtering

To smooth out the pulsating DC voltage, capacitors and inductors are used. This stage reduces the ripple, resulting in a more stable DC output. The degree of filtering depends on the specific requirements of the application.

Benefits of 3-Phase Rectifiers

1. Efficiency

3-phase rectifiers are more efficient than single-phase rectifiers. They can handle higher power levels with less electrical stress on the components, reducing energy losses.

2. Smooth Output

The output of a 3-phase rectifier is inherently smoother compared to single-phase rectifiers. This is due to the overlapping nature of the three-phase input, which reduces the amplitude of voltage ripples.

3. Compact Design

For the same power output, a 3-phase rectifier can be more compact than its single-phase counterpart. This makes it ideal for applications where space is a premium.

4. Reliability

With balanced load distribution across three phases, 3-phase rectifiers offer improved reliability and longevity. They are less prone to voltage sags and other power quality issues.

Applications

3-phase AC to DC rectifiers are used in various applications, including industrial motor drives, battery charging systems, and power supplies for telecommunications and data centers. Their ability to efficiently convert power makes them indispensable in scenarios requiring stable and high-power DC output.

Conclusion

Understanding the operation and benefits of 3-phase AC to DC rectifiers is crucial for leveraging their advantages in appropriate applications. With their efficiency, smooth output, and compact design, these rectifiers play a vital role in modern electrical systems, ensuring reliable and stable DC power for various industrial and commercial uses.

More Info Contact us

Website https://fastron.com.au/

Ph: 397635155

Mail Id: [email protected]

Working Time : Monday to Friday 8.00am - 6.00 pm.

0 notes

Text

What is a FRAM

My study is to know more about Diodes Incorporated, B290-13-F, Diodes, Schottky Rectifiers, Power thyristor and What is a FRAM

0 notes