#Water-borne Epoxy Resins

Explore tagged Tumblr posts

Text

Floor Adhesives Market Challenges and Strategic Opportunities for Growth

Floor Adhesives Market Growth Strategic Market Overview and Growth Projections

The global floor adhesives market size was valued at USD 1.84 billion in 2022. It is estimated to reach 2.74 billion by 2031, growing at a CAGR of 4.56% during the forecast period (2023–2031)

The latest Global Floor Adhesives Market by straits research provides an in-depth analysis of the Floor Adhesives Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Floor Adhesives Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Floor Adhesives Market are

Sika AG

MAPEI S.p.A

Jowat SE

Arkema Group (Bostik SA)

HB Fuller Company

Ashland

Forbo Holding AG

Pidilite Industries Ltd.

LATICRETE International Inc.

Tesa SE

3M

Dow

Get Free Request Sample Report @ https://straitsresearch.com/report/floor-adhesives-market/request-sample

The Floor Adhesives Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Floor Adhesives Market: Segmentation

The Floor Adhesives Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Resin Type

Epoxy

Polyurethane

Acrylic

Vinyl

Other Resin Types

By Technology

Water-borne

Solvent-borne

Other Technologies

By Applications

Tile and Stone

Carpet

Wood

Laminate

Resilient Flooring

Other Applications

By End-User Industry

Residential

Commercial

Industrial

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/floor-adhesives-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Floor Adhesives Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Floor Adhesives Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Floor Adhesives Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Floor Adhesives Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

0 notes

Text

0 notes

Text

Epoxy Flooring: Everything You Need to Know

Have you ever entered a showroom, a manufacturing or healthcare facility or a pharmaceutical unit and admired their shiny and super-hard floors? Chances are that it may be epoxy flooring which has enthralled you. This innovative material is highly favoured because it can turn any concrete surface into a durable work of art which is easy to maintain.

But with all the options available, you might be wondering: what exactly is epoxy flooring, and is it right for your office or business? This guide will answer all your questions and make you an epoxy flooring expert in no time!

Understanding Epoxy Flooring

Epoxy floorings are versatile resinous systems that protect and enhance several substrates, especially concrete floors. It refers to resins with epoxide groups which forms an adhesive layer when mixed with an amine curing agent. This type of flooring is used widely in industrial, commercial and residential applications due to its durability as well as chemical resistant properties and range of finishes available for customization.

Different Types of Epoxy Floorings

There are different types of epoxy floorings available today each designed for specific applications:

Water-based Epoxies – These are environmentally friendly coatings which are easy to apply indoors.

Solvent-Based Epoxies- These types have excellent chemical resistance properties hence their common use in industrial setups where durability matters most.

100% Solid Epoxy Systems – These offer the highest durability and are ideal for high-traffic areas and heavy-duty applications.

How Epoxy Floorings Are Used

Some common uses include:

Garage/Showroom Floors: Epoxy-coated floors offer seamless finish that lasts long through strength against stains, chemicals as well as abrasion.

Commercial Spaces: Many businesses using epoxy floorings aim at getting attractive floors without compromising their need for durability and simplicity in cleaning routines.

Industrial Facilities: In factories, there must be an epoxy flooring that can resist noxious substances along with heavy device movement plus people’s mobility around it throughout the day while still serving its purpose as a wear-resistant protective layer.

Residential Areas: Epoxy floorings are getting popular in homes, especially for places like basements, kitchens and bathrooms where they are known to last long while being easy to clean.

Epoxy Flooring Cost Considerations

The cost of the epoxy flooring depends on several factors, including the type of epoxy used, the size of the area to be coated, surface preparation requirements, and additional customization like decorative flakes or patterns. On an average, epoxy flooring costs range from Rs 80 to Rs 250 per square foot, making it a cost-effective option considering its longevity and benefits.

A practical use case

Imagine a standard concrete manufacturing facility floor that always gets stained, cracked or damaged. This floor can be transformed by applying solvent-borne or solvent-free epoxy flooring. Not only does the glossy finish give the facility an appealing look but it also protects against oil spills, tyre marks and chemicals. Cleaning becomes easier while keeping the floor intact for many years ahead.

Conclusion

If you want to improve the durability of your industrial, commercial or residential floors and make them more beautiful then go for epoxy floorings. Its suitability in different types of flooring makes it versatile besides having numerous advantages. Whether designing floors in manufacturing industry or simply looking for better aesthetics in cmmercial spaces, epoxy flooring is worth considering seriously.

For more information on this subject and to explore suitable options for your flooring requirements please visit Dr Cipy. We offer various kinds of epoxy floorings depending on what one wants from them.

0 notes

Text

Exploring Market Trends and Opportunities in the Global Epoxy Resins Paints Industry: A Comprehensive Market Research Study

Epoxy Resins Paints Market poised to grow at highest pace owing to rapid industrialization Epoxy resins paints are durable, water and chemical resistant coatings finding wide application across industries like construction, automotive and manufacturing due to their advantages. These paints provide excellent adhesion to non-porous substrates and resistance to humidity, moisture, chemicals and corrosion. They form a protective barrier and are increasingly used for automotive OEM coatings, floor coatings, concrete primers and protective coatings. The global epoxy resins paints market is estimated to be valued at US$ 13.62 Bn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2024 to 2031 owing to rapid industrialization. The Global epoxy resins paints Market is estimated to be valued at US$ 13.62 Bn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2024 to 2031. Key players operating in the epoxy resins paints are Momentive Performance Materials, Kukdo Chemical, Huntsman Corporation, The Dow Chemical Company, Atul Ltd, Sika AG, Cytec Industries Incorporation, DuPont, 3M, BASF SE, Aditya Birla Chemicals Ltd, NAMA Chemicals, LEUNA-Harze GmbH, and Spolchemie A.S. Key Takeaways Key players operating in the epoxy resins paints are Momentive Performance Materials, Kukdo Chemical, Huntsman Corporation, The Dow Chemical Company, Atul Ltd, Sika AG, Cytec Industries Incorporation, DuPont, 3M, BASF SE, Aditya Birla Chemicals Ltd, NAMA Chemicals, LEUNA-Harze GmbH, and Spolchemie A.S. The rapidly growing construction industry coupled increasing automobile production is fueling the demand for epoxy resins paints. Technological advancements are focused on developing low volatile organic compound and bio-based epoxy resins paints. The construction industry has been growing at a strong pace backed by rapid urbanization and industrialization in emerging economies of Asia Pacific and Middle East countries. Epoxy resins paints find extensive application in flooring, primers, protective and marine coatings in construction sector. The rapidly growing automobile production driven by rising vehicle ownership particularly in developing countries has increased the uptake of these paints in automotive OEM coatings and auto-refinish paints. Recent technological developments are focused on developing advanced epoxy resins paints with properties like low volatile organic compound (VOC) content, bio-based formulations and UV resistant coatings to suit varied end-use applications. These innovations are aimed at meeting stringent environmental norms along with improving product performance. Market Trends Some of the key trends in the global epoxy resins paints market include shift towards bio-based formulations driven by sustainability concerns and growing demand for low VOC content paints to meet environmental regulations. Another trend gaining momentum is development of UV resistant and high performance protective coatings for infrastructure and industrial applications like pipe coatings, machinery coatings etc. Rapid adoption of powder coatings for industrial use due to their advantages over liquid coatings is another major trend. Market Opportunities Rising investments in infrastructure development across developing nations provide significant growth opportunities. The Indian government's investments of USD 1.4 trillion in infrastructure till 2024 will boost adhesive demand. Another major opportunity lies in developing water-based and environment-friendly epoxy resins paints that can replace solvent-borne varieties to comply with stringent norms.

0 notes

Text

Art Studio 1 Research: Biology of Slime (IDEA 2) PART 2

Artist Archive (both ideas): Markos Kay's aBioGenesis (2022)

aBioGenesis (2022, CGI-animated short film (57 secs))

vimeo

Markos Kay's works exist in between art and biology, in this case creating a visual 'reimagining' of the theory that early cellular life originated from 'primordial lipids'.

Organic forms (droplets, bubbles, vesicles/vacuoles, veins, flowers, cells, etc.) could perhaps influence how my 'slime-inspired work' may look (abstract?).

Abstract/biomorphic animation is definitely something I may use for my own work.

Artist Archive (both ideas, but primarily idea 2a): Aron Sanchez-Baranda

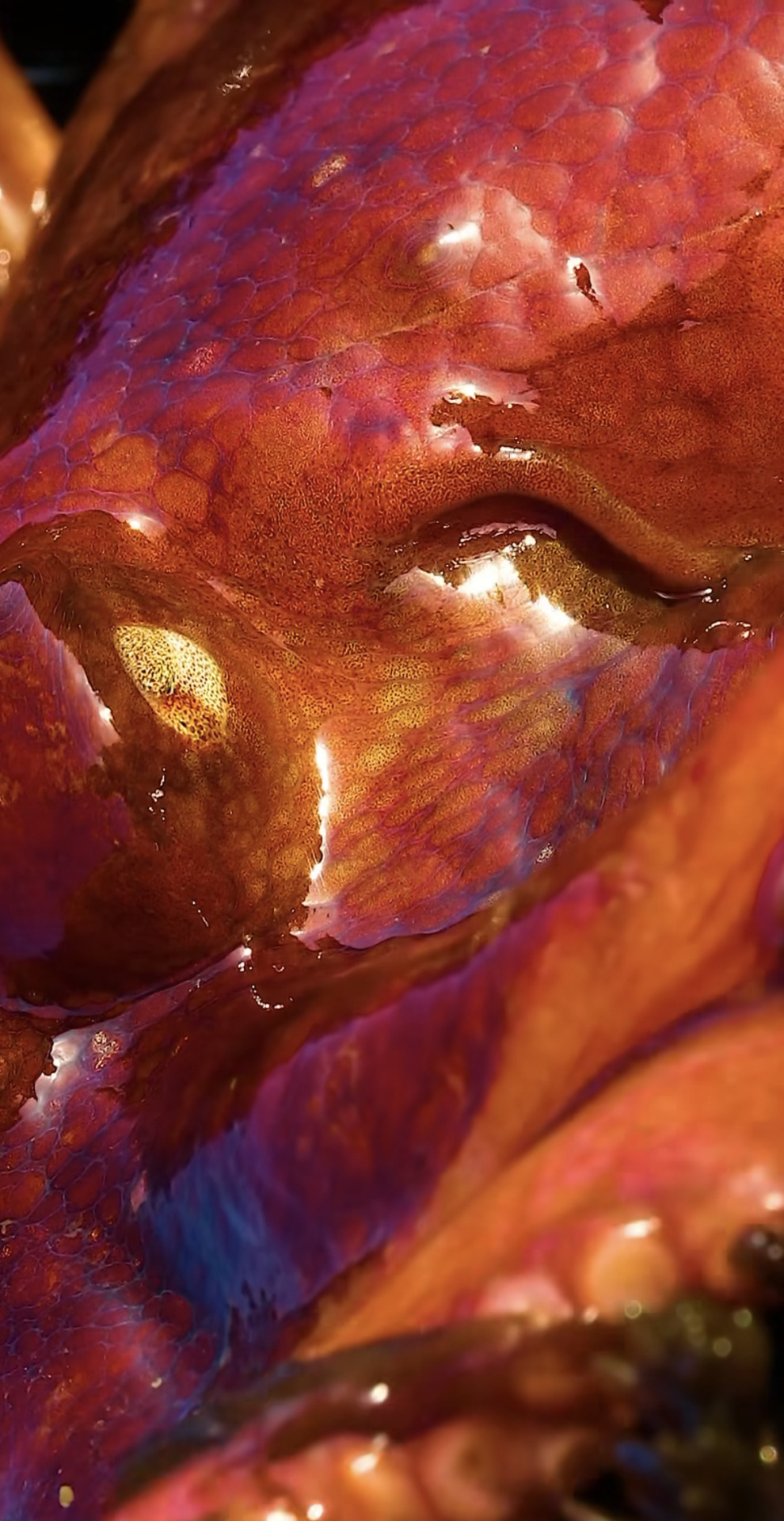

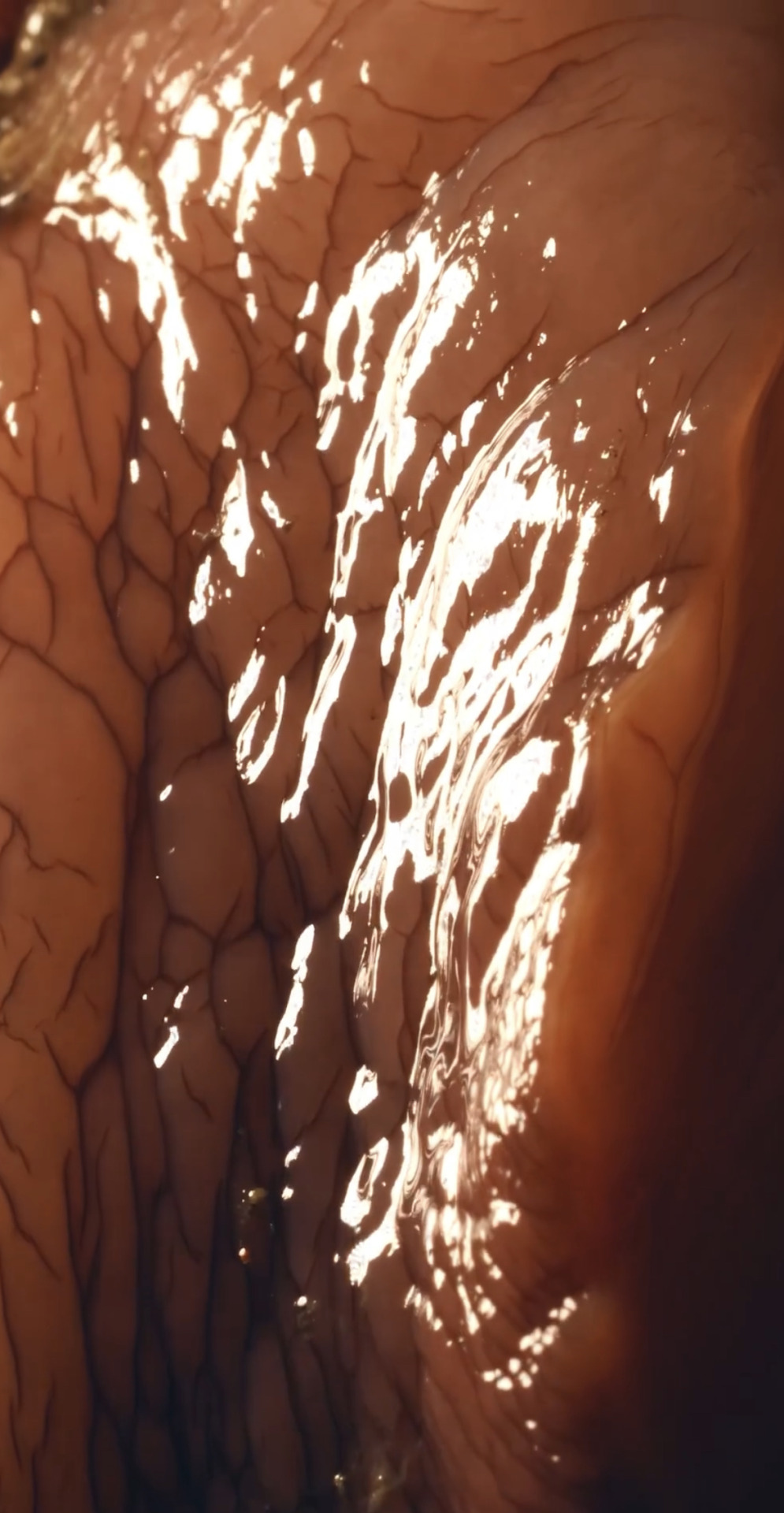

1st Row (left to right) - photographic prints: Fundament, Pisaster ochraceus/Anthopleura xanthogrammica (2021), Hair, Gum and Blood, Stemonitis sp. (2019), Febrile, Urticina eques (2021)

2nd Row (left to right) - short film screencaps: Take me to your heart, Phoca vitulina birth remnants (2017), Higher class tissue, Octopus rubescens (2021), Proportion dependent, Anthopluera sola (2023)

3rd Row (left to right) - short film screencaps: Cell wall, Aplysia californica (2023), World entire, Anthopluera sola (2023), Transactive memory, Anthopluera sola under UV light (2022)

4th Row (left to right) - short film screencaps: Lap, Neverita lewisii (2021), Cooperation offer, Ophiodromus pugettenis lives within patiria miniata (2022), Sparkling reflective stacks of purine crystals, Flabellinopsis iodinea (2023)

Aron Sanchez-Baranda's photographs and films exist as both documentation and art.

His close-ups of fungi and marine wildlife abstract the natural forms of the subject, focusing on the colours, the patterns, the shapes and textures interacting with each other, and the glistening water, mucus, etc. of their surfaces.

This may perhaps play into the natural vs. unnatural, familiar/comfortable vs. repulsive?

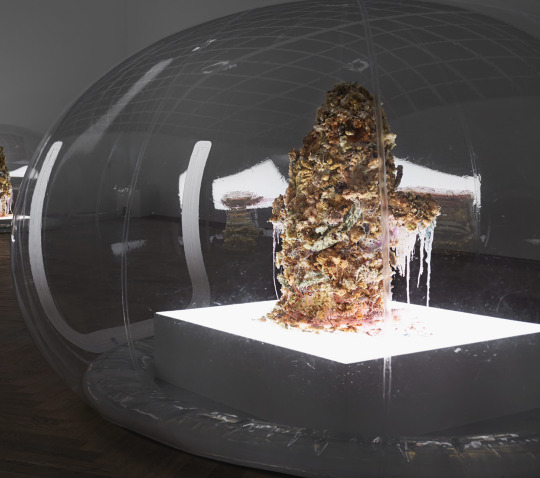

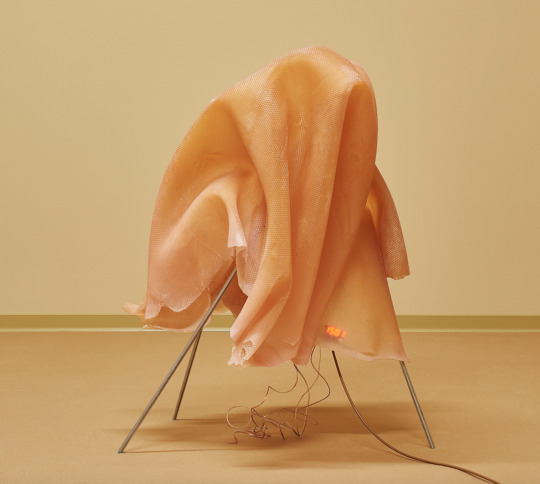

Artist Archive (both ideas, but primarily idea 2b): Anicka Yi's tempura-fried flower sculptures and artificial honeycomb lamps

1st Row (left to right): Maybe She's Born With It (2015), ALZ/AZN (2015), Lapidary Tea Slave (2015)

2st Row - tempura-fried flower sculptures: Installation shot of all three sculptures listed about

1st Row (left to right) - artificial honeycomb (epoxy resin) lamps: Escape From The Shade 1 (2016), Escape From The Shade 7 (2016), God Make It This Time Or Never At All (2017)

2nd Row (left to right) - artificial honeycomb (epoxy resin) lamps: Mausoleum Of Easy Going (2017), Slippage Between Law and Art (2022), One Bright Pearl (2022)

Anicka Yi is another artist who explores biology and art, but more within the context of sensory immersion and how it may trigger emotional responses.

In the case of her tempura-fried flower sculptures, the strong smell of oil, tempura batter and decaying plants exudes from a hybrid between crystallised and molten/dripping forms (interesting to play with both shape/texture and smell).

As for her artificial honeycomb lamps, she transforms the 'honeycomb' into a 'draping cloth' while maintaining its texture and translucency - with colours ranging from softer and more natural to more vibrant and emotive (perhaps textured sculptures and light/colour for a tangible, interactive form?).

0 notes

Text

Why Waterborne Coatings Are Becoming The Trend?

Traditionally, solvent-borne coatings are considered to have superior beauty features than waterborne coatings. With technological development, consumer concept change and government promotion of environmental awareness, waterborne coating solutions are superior, and eventually become the major trend of construction coatings.

Understanding Waterborne Coatings

Waterborne coatings are regarded as eco-friendly coatings because they use water as solvent or no solvent. Waterborne coatings are coatings in which water is used as a solvent or dispersing medium, and their makeup includes waterborne resins, pigment, additives, and water. Compared with solvent-based paints, waterborne coatings have low VOC content, and no odor. Based on the different film-forming materials, it can be categorized into waterborne acrylic coatings, waterborne epoxy resin coatings, waterborne polyurethane coatings, waterborne alkyd resin coatings, etc. Waterborne acrylic resin is the most important film-forming material, which is mainly used in the field of construction coatings, with good weather resistance, alkali resistance and adhesion, etc.

Coating Industry Market Demand Trends

Coating industry market demand changes are mainly affected by the level of economic development, consumer concepts, policies, etc. Coating industry market demand changes to the quality type, the performance, quality, function and other demands on the coating will be higher. The market demand of the coating industry is personalized and varied, and the demands for color, health and other demands for coatings will be more varied. With the change in consumer concepts, the demand for service and innovation of coatings will be higher. From the point of environmental protection policy, with countries paying attention to energy saving and emission reduction, the market demand of the coating industry will change to green type. Therefore, there is no doubt that waterborne coatings will eventually become the major trend of construction coatings.

China’s Waterborne Coatings Follow The Trend

China has become the world’s largest manufacturer and consumer of coatings in 2023. In 2021, global coatings volume increased by 4.8% to 453 million tons. By 2025, China’s eco-friendly coatings varieties will account for 70% of total coatings production, aiming for early achievement of the carbon peak and carbon neutral targets for the coatings industry. The government strongly supports waterborne coatings. Infinechem also recognizes the performance of waterborne coatings.

Discover Your Trusty Choice

We promote waterborne coating emulsions in various fields. Based on the function and application of the emulsions, waterborne coating emulsions are categorized into these categories: Construction, Waterproofing & Mortar, Industrial Anti-corrosion, Textile, Printing & Packaging, and Adhesive. MIT-IVY INDUSTRY CO.,LTD will strive to get consumers and builders to trust the comfort features of waterborne coatings and recognize waterborne coating solutions. Contact us for more information. Learn More: MIT-IVY INDUSTRY co., Ltd. | http://www.mit-ivy.com Tel /whatsapp/telegram: 008613805212761 [email protected] Read the full article

0 notes

Text

Chemical Resistant Coatings Market to Witness Excellent Revenue Growth Owing to Rapid Increase in Demand

Latest released the research study on Global Chemical Resistant Coatings Market, offers a detailed overview of the factors influencing the global business scope. Chemical Resistant Coatings Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Chemical Resistant Coatings The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are BASF SE (Germany), Metal Coatings Corp (United States), ITW Polymers Sealants (United States), The Jotun Group (Norway), PPG Industries Inc. (United States), Sika AG (Switzerland), The Sherwin-Williams Company (United States), VersaFlex Incorporated (United States), Wacker Chemie AG (Germany), The Protech Group (Australia)

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/88333-global-chemical-resistant-coatings-market

Chemical Resistant Coatings Market Definition:

Chemical resistant coatings are employed in different industries like construction, waste product treatment, organic compound, etc. There are other forms of chemical resistant coatings resins that are employed in the coating to avoid the corrosion of the structures and metals. chemical resistant coating and paint extremely corrosive chemical environments and industries to shield metal, wood, etc. For some purpose, the majority of coatings can get disclosed to chemicals and acids, whether clean-up product, spills, or fumes. This coating plays a considerable role in protection against harmful acids, oils, solvents, and even clean-up solutions which may simply result in erosion on floors.

Market Trend:

Product Development with Additional Benefits like Heat Resistance and Water Resistance

Market Drivers:

Rising Applications in Construction and Infrastructure for Layering, Varnishing, or Flooring Applications

Market Opportunities:

Increasing Applications of Chemical Resistant Coating in Automobile Sector

Rising Demand for the Chemical Resistant Coating in Wastewater Treatment Plants and Sewer for Better Efficiency

The Global Chemical Resistant Coatings Market segments and Market Data Break Down are illuminated below:

by Type (Solvent-borne, Water-borne, Others), Form (Liquid, Granules, Powder), Industry Verticals (Chemical, Oil and Gas, Marine, Construction and Infrastructural), Product (Epoxy, Polyester, Fluoropolymers, Polyurethane, Other Resins)

Region Included are: North America, Europe, Asia Pacific, Oceania, South America, Middle East & Africa

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

Enquire for customization in Report @: https://www.advancemarketanalytics.com/enquiry-before-buy/88333-global-chemical-resistant-coatings-market

Strategic Points Covered in Table of Content of Global Chemical Resistant Coatings Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Chemical Resistant Coatings market

Chapter 2: Exclusive Summary – the basic information of the Chemical Resistant Coatings Market.

Chapter 3: Displayingthe Market Dynamics- Drivers, Trends and Challenges of the Chemical Resistant Coatings

Chapter 4: Presenting the Chemical Resistant Coatings Market Factor Analysis Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying market size by Type, End User and Region 2015-2020

Chapter 6: Evaluating the leading manufacturers of the Chemical Resistant Coatings market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by manufacturers with revenue share and sales by key countries (2021-2026).

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, Chemical Resistant Coatings Market is a valuable source of guidance for individuals and companies in decision framework.

Data Sources & Methodology The primary sources involves the industry experts from the Global Chemical Resistant Coatings Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects.

In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age.

For Early Buyers | Get Up to 20% Discount on This Premium Report: https://www.advancemarketanalytics.com/request-discount/88333-global-chemical-resistant-coatings-market

What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837

0 notes

Text

The report covers Global Industrial Coatings Market Manufacturers and is segmented by Resin (Epoxy, Polyurethane, Acrylic, Polyester, and Other Resins), Technology (Water-borne Coatings, Solvent-borne Coatings, and Other Technologies), End-user Industry (General Industrial, Protective Coatings), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East & Africa).

Download Free Sample Report - Industrial Coatings Market

0 notes

Text

Industrial Floor Coating Market 2022 | Growth Strategies, Opportunity, Challenges, Rising Trends and Revenue Analysis 2030

The latest market report published by Credence Research, Inc. “Global Industrial Floor Coating Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The industrial floor coating market has been expanding steadily over the past several years, and between 2023 and 2030, it is anticipated to rise at a CAGR of 4.90%. In 2022, the market was estimated to be worth USD 5.9 billion, and by 2030, it is anticipated to be worth USD 8.24 billion.

The global industrial floor coating market is categorized by type, flooring material, coating component, technology, end use, and region. Epoxy industrial floor coatings are the most popular type, widely used in various industries. Concrete is the primary flooring material segment, known for its durability and versatility. One-component coatings dominate the market, and solvent-borne technology is the preferred choice. The manufacturing sector is the largest end-use segment, driving the demand for industrial floor coatings. Asia Pacific leads the market growth.

The demand for industrial floor coatings is anticipated to rise due to the increasing industrialization in developing countries and the growing demand from manufacturing facilities worldwide. Strict safety standards and the need for effective industrial processes further fuel the demand for high-quality industrial floor coatings. However, challenges such as high raw material costs and strict regulatory rules in the food sector hinder the growth of the global industrial floor coating market.

Despite these challenges, the global industrial floor coating market offers significant growth opportunities. Increased funding for green construction projects in the United States and the expansion of businesses, academic institutions, and infrastructure in the Asia Pacific region present growth prospects for the market.

Industrial Floor Coating Market Top Trends provide a comprehensive insight into the ever-evolving world of industrial floor coatings. With advancements in technology and increasing demand for durable and aesthetically appealing flooring solutions, this segment has witnessed significant growth over the years. One of the top trends in the Industrial Floor Coating Market is the shift towards environmentally friendly coatings, driven by growing awareness about sustainability and green building practices. Manufacturers are now focusing on developing water-based or low VOC (Volatile Organic Compounds) formulations that not only offer excellent protection but also minimize harm to both human health and the environment. Another prominent trend is the rising popularity of epoxy resin coatings due to their exceptional durability, chemical resistance, and high gloss finish.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Industrial Floor Coating Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Industrial Floor Coating Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/industrial-floor-coating-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/molecular-glues-market

Related Report: https://www.credenceresearch.com/report/nickel-coated-fiber-market

Browse Our Blog: https://www.linkedin.com/pulse/germany-industrial-floor-coating-market-global-industry-singh

0 notes

Text

Aerosol Paints Market - Forecast (2023 - 2028)

Aerosol Paints market size is forecast to reach US$302.6 million by 2026, after growing at a CAGR of 5.8% during 2021-2026. This growth can be attributed mainly due to the extensive utilization of aerosol paints in the construction industry. Aerosol paint or spray paint is paint that comes in a sealed, pressurized container and is released in as an aerosol spray. The paint is dispersed by depressing a nozzle on the top of the can, connected to a valve inside the can. Aerosol paint leaves a smooth, evenly coated surface, unlike standard, rolled or brushed paint finishes. It is applied on surfaces for both, aesthetics and protection. The most important resins used in aerosol paints are acrylic polymers, epoxy polymers and alkyd polymers. Spray painting is one of the most preferred ways of applying paint. As compared to conventional paints, aerosol paints have unique atomization, storage and application methods. Aerosol paints are designed to be used on a wide range of surfaces like metals, plastic, wood, glass, and masonry. Primarily due to their high quality, quick-drying, and easy applicability, aerosol paints can be used on both new and existing structures, such as monuments, private offices, factories, residential spaces, and public buildings, which is increasing their demand. Aerosol paints are also widely utilized in DIY projects which is the latest trend, led by the pandemic. For automotive DIY, acrylic enamel spray paints are used because they last a lot longer, as they form a hard shell when dry. The increasing DIY applications also fuel the growth of the aerosol paint market.

COVID-19 Impact

The pandemic has impacted every industry across the globe in one way or another. One key issue that has arisen is the availability of raw materials has dramatically reduced. This has severely impacted the overall paints market in general. The core industries, construction industry and automobile industries have been impacted owing to shortages of labour, rising safety concerns and government-imposed lockdowns which have led to closing down of manufacturing plants. This has result in lower demand and consumption of commercial purpose aerosol paints in 2020. However, during the lockdown consumers have taken up DIY projects utilizing aerosol paints. According to a DIY survey in the US, 60% of respondents said they started a new home DIY project in April 2020 and home improvement purchases grew from 55% in March 2020 to over 80% by April. The top product being searched for home improvement online is paint, up 700% from March to April. Hence the DIY sector helped boost the aerosol paint market.

Report Coverage

The report: “Aerosol Paints Market – Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Aerosol Paints Market.

By Resin: Acrylic, Alkyd, Epoxy, Polyurethane, Silicone, and Others.

By Technology: Solvent borne and Water borne.

By End-Use Industry: Building & Construction (Residential- Private Dwellings, Row Houses, Apartments, Commercial- Educational Institutes, Hotels, Restaurants, And Cafes, Sports Stadiums, Airports, Office Buildings, Shopping Malls & Supermarkets, Hospitals, Clinics and Healthcare Institutes and Others), Transportation (Automotive- Passenger Vehicles (PV), Light Commercial Vehicles, Heavy Commercial Vehicles; Aerospace- Commercial, Military and Others; Locomotive; Marine- Passenger, Cargo and Others), Furniture (Cabinets, Plywood and Others), Oil and Gas (Pipelines, Tanks and Others), Water and Wastewater (Water Tanks, Water Pipes, Wastewater Pipes), Electrical & Electronics, General Industry (Storage Tanks, Railing, Pipes, Fences) and Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Key Takeaways

Asia-Pacific dominates the aerosol paints market, owing to the increasing construction and automotive industries in the region.

The advent of electric cars is making waves in the automotive world. Also, auto refinish manufacturers are seeing a strong move into cosmetic repair where aerosol paints are extensively used.

The development of bio-based products and increasing government support due to Volatile Organic Compounds (VOC) emissions is likely to act as a driver for a growth of water borne aerosol paints market. In the automotive industry, water-based acrylic enamel is currently the most widely used paint for reducing the environmental impact.

The major opportunity for this market is to completely transition towards eco friendly products in a move to support sustainable development.

#Aerosol Paints Market#Aerosol Paints Market Size#Aerosol Paints Market Share#Aerosol Paints Market Analysis#Aerosol Paints Market Revenue#Aerosol Paints Market Trends#Aerosol Paints Market Growth#Aerosol Paints Market Research#Aerosol Paints Market Outlook#Aerosol Paints Market Forecast

0 notes

Text

Middle East Paints and Coating Market Trends | Segmentation, Outlook, Industry Report to 2032

The market has been significantly influenced by certain macro-economic and industrial factors including chemical industries development, growing construction sector, economic development, manufacturing sector, architectural sector development, and others.

According to research conducted by Future Market Insights on the middle east paints and coatings market, demand for paints and coatings to reach a valuation of US$ 7,447.9 Mn by the end of the forecast period. In the oil & Gas industry paints and coatings industry helps in the protection of offshore and onshore rigs, in the onshore plant coating is used to protect Pipework, Jacket, Flare bloom, Living quarter, and Riser.

The large Industrial & protective coatings market being created by the Middle Eastern oil and gas industry is particularly attractive to European, as well as North American and Japanese, coatings manufacturers because it requires global technical standards. In fact, its needs are even tougher because of the region’s climate which necessitates resistance against hot temperatures, UV rays, and potential abrasion from sand and dust.

Marine paints and coatings are utilized on a wide range of vessels, including freight and business ships. Marine polyurethane paints and coatings are utilized in business and recreation creates as well as on seaward designs, for example, big hauler stages, pipelines, oil apparatuses, and storage spaces. The growing marine industry is expected to boost the market for paints and coating in the middle east.

Get a Sample Copy of the Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-15681

Paints and Coating Market Segmentation

By Resin Type:

Acrylic

Alkyd

Polyurethane

Epoxy

Polyester

Others

Pure Acrylic

Styrene

Vinyl

By Technology:

Water-borne

Solvent-borne

Powder Coatings

By End-Use:

Architecture

Automotive & Transportation

Protective Coating

Wood

Refinish

Coil Coating

Packaging

Marine

General Industrial

Interior

Exterior

Competitive Landscape

The market of paints and coatings in the middle east is estimated to be a consolidated market, where key players are expected to account for a key share of the market. Some of the top manufacturers include Jotun Paint, Sigma Paint, Al Jazeera Paint, SAK Coat., The PPG Group, Sherwin-Williams, Nippon Paint ME FZE, Asian Paints, Akzo Nobel, Middle East Paints Company, Global Paints FZC, Kansai Paints, Henkel Jebel Ali FZCO, BASF SE, Arkema Group, DuPont de Nemours, Inc.: Cabot Corporation, Fosroc are some of the manufacturers of Paints and Coatings profiled in the full version of the report.

Key players are focusing on increasing their production capacity to enhance their market footprint all over the globe and to gain traction in the market. Further certain key players are focusing on investing in the latest Paints and Coatings products production owing to a significant increase in the demand from the architectural industry..

Browse latest Market Reports@ https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

Automotive Coating Resin Market Favourable Trends in Demand Which are anticipated To Experience Massive Growth during 2023-2028|

Automotive coating resin is a type of material used to protect and enhance the appearance of automobiles. These resins are typically applied in multiple layers and can be made from a variety of materials, such as acrylic, polyurethane, and epoxy. The primary function of automotive coating resin is to provide a durable and long-lasting finish that can withstand exposure to weather, UV radiation, and other environmental factors. Additionally, these resins can enhance the color and shine of the vehicle, creating a more visually appealing appearance.

The automotive industry has seen a significant shift towards environmentally friendly products, and coating resins are no exception. Many modern automotive coating resins are water-based and low in volatile organic compounds (VOCs), making them more environmentally friendly and safer to use. These resins also provide excellent performance characteristics, including resistance to abrasion, impact, and chemicals.

The Automotive Coating Resin Market is divided into three segments: resin type, technology, and application. Acrylic, polyurethane, epoxy, and other resin types are included in this segment. The polyurethane category is likely to dominate the market due to its better qualities such as durability and chemical and weather resistance. Solvent-borne, water-borne, and powder technologies are all part of the technological sector. The water-borne category is predicted to rise significantly in the future years, owing to an increased focus on environmental rules and a growing tendency towards the use of eco-friendly coatings. OEM and refinish are two application segments. Because of rising demand for new automobiles, the OEM segment is likely to dominate the market.

Read more@ https://techinforite.blogspot.com/2023/02/automotive-coating-resin-market-size.html

#Automotive Coating Resin Trend#Automotive Coating Resin size#Automotive Coating Resin growth#Automotive Coating Resin#Automotive Coating Resin Industry#Automotive Coating Resin Price#Automotive Coating Resin Size#Automotive Coating Resin Share#Automotive Coating Resin Analysis#Automotive Coating Resin Forecast#Automotive Coating Resin Consumption#Automotive Coating Resin Sales#Automotive Coating Resin Segmentation#Automotive Coating Resin Manufacturers#Automotive Coating Resin Prospectus#Automotive Coating Resin Industry Trends#Automotive Coating Resin Growth#Automotive Coating Resin Trends#Global Automotive Coating Resin Industry#Global Automotive Coating Resin Trends#Global Automotive Coating Resin Share#Global Automotive Coating Resin Size

0 notes

Text

White Spirits Market: Booming Paints & Coatings Industry facilitates Growth

White spirit is a colorless, clear, and flammable liquid. It is a mixture of chemicals known as petroleum hydrocarbons. These include aromatic hydrocarbons, cycloparaffins, and paraffin. As per Inkwood Research, the global white spirits market is expected to record a CAGR of 5.75% during the forecast period, 2023-2032.

White spirits are primarily used as a solvent in the paint industry. A solvent is used to dissolve or disperse various components used in the formulation of paints & coatings.

This blog primarily focuses on the role of solvents in paints & coatings.

Role of Solvents in Paints & Coatings

Conventionally, a solvent should have the following properties:

Volatility

Neutral Reaction

Slight/Pleasant Smell

Long-term Resistance to Chemicals

Clear & Colorless

Consistent Physical Properties as per Specifications

Cost-Effective

Biologically Degradable

Low Toxicity

Adjusting the viscosity and curing properties of the paint are a solvent’s central function. It is volatile and does not integrate with the paint film. Also, it regulates application and flow properties and influences the stability of the pain while in the liquid state. In addition, it primarily functions as a carrier for non-volatile components. This is because thinner oil is needed to spread heavier oils. For instance, an oil-based interior house paint.

Further, solvent-borne paints, also termed oil-based paints, entail different combinations of solvents as diluents. A diluent is an agent that dilutes a substance to obtain a less concentrated solution. These solvents include white spirits, ketones, alcohols, aromatics, and aliphatics.

In addition, solvent-borne paints include organic solvents such as glycol ethers, esters, and petroleum distillate. Also, at times, low-molecular and volatile synthetic resins serve as diluents. Resins are synthetic or organic compounds that comprise viscous or non-crystalline liquid substances. Such solvents are used when grease resistance or water resistance is needed.

Using additives reduces the surface tension of paints, further improving the appearance of the coating film. They also help avoid defects on the surface.

Additionally, the surface tension of the solvent blends in paints influences the following properties:

Sprayability

Wetting of the undercoating or substrate

Wetting of pigments and their dispersion quality

Low surface tension solvents can enhance such properties and improve the dispersibility of components or additivities difficult to disperse or dissolve, such as epoxies. For instance, solvents like aliphatic hydrocarbons, glycol ethers, and alcohols migrate to a coating’s surface. Thus, it lowers the surface tension and makes the surface more homogeneous. In addition, this improves leveling and minimizes the tendency to form surface defects like craters. Though this phenomenon occurs in waterborne coatings, it can also occur in solvent-borne coatings.

Moreover, the paint’s viscosity depends on the viscosity or dispersion of the resin-solvent solution and the interaction between the solvent, resin, and other components. Besides, the solvent electrical resistance is an important factor when spraying paints electrostatically. If the paint has too low a resistance, the spray equipment may short out due to overcharging. Overcharging can induce ‘wrap back’ in paints to the gun and the person spraying. Whereas if the paint has too high a resistance, the transfer efficiency will be low or even lower than traditional air sprays. (Source: American Coatings Association)

Our analysis of the global white spirits market product type includes type 0 (distillation fraction with no further treatment), type 1 (hydrodesulfurization), type 2 (solvent extraction), and type 3 (hydrogenation).

Different Solvent Types used in Paints & Coatings

Solvents are one of the three components in paints. They are petroleum-based chemicals that dissolve the binding agent and pigment for application. These include oxygenated solvents, aromatic hydrocarbon solvents, and aliphatic hydrocarbon solvents.

Oxygenated Solvents

Oxygenated solvents are majorly used as active solvents for synthetic resins and have oxygen functionality. They reduce the viscosity of lacquers, varnishes, and paints and dissolve films and resins. The four common oxygenated solvents are alcohols, glycol ethers, esters, and ketones.

Aromatic Hydrocarbon Solvents

Aromatic hydrocarbon solvents have a benzene ring structure and high solvency rates than aliphatic hydrocarbon solvents. They emit strong odors and are produced in the petroleum refining industry through the distillation of petroleum stock and other chemical conversion processes like alkylation and catalytic hydrogenation. Common aromatic hydrocarbon solvents used in paints & coatings are high-flash aromatic naphthas, mixed xylene (BTEX), ethylbenzene, toluene, and benzene.

Aliphatic Hydrocarbon Solvents

Aliphatic hydrocarbon solvents are produced through crude oil distillation and then treated to enhance the odor and color. They do not have the benzene ring and are used in paints and thinners. Kerosene and gasoline are examples of aliphatic hydrocarbon solvents. Common aliphatic hydrocarbon solvents used in paints & coatings are heptanes, hexanes, and white spirits.

Our assessment of the global white spirits market by grade includes low flash point, regular flash point, and high flash point.

White Spirits Market: Booming Paints & Coatings Industry facilitates Growth

According to our evaluation, the global paints & coatings market is predicted to garner a revenue of $207.72 billion by 2028, projecting a CAGR of 6.22% for the forecast period, 2021-2028. This is primarily attributed to the thriving infrastructure and construction industries and the increasing demand from automotive OEMs.

In essence, paints & coatings, in addition to offering an aesthetic appeal, facilitate a protective barrier to expand the functional use of the substrates and surfaces to which they are applied. For instance, coatings offer essential characteristics to the finished product and protect against degradation and destructive conditions. These include abrasion, corrosion, chemicals & ultraviolet rays, high or low temperatures, microbes, moisture, etc.

Moreover, the paints & coatings industry is a dynamic part of a nation’s economy. It undertakes a central role in manufacturing products that protect everything – from everyday objects to vital infrastructure. As a result, the booming paints & coatings industry is conducive to the global white spirits market growth.

FAQs:

Which are the key players in the global white spirits market?

A: Cepsa, ExxonMobil Corporation, HCS Group, DHC Solvent Chemie GmbH, etc., are among the key players in the global white spirits market.

What are ketones?

A: Ketones are a class of highly efficient solvents used for product formulation for inks, adhesives, and coatings. Isophorone, mesityl oxide (MO), methyl isobutyl ketone (MIBK), and methyl ethyl ketone (MEK) are examples of ketones.

0 notes

Text

Water-borne Epoxy Resins Market Size, Industry Manufacturers, Region and Forecasts 2023

Water-borne Epoxy Resins Market research report: information by type (high molecular weight, low molecular weight), by application (coatings, adhesives, composites) by end-use (construction, textiles, automotive) – Forecast till 2023

The extensive use of water-based coatings in end-use industries is projected to drive the market growth during the forecast period, 2018-2023

Market Defination:

Water-borne epoxy resins are used in a wide variety of applications, due to their capability of offering superior performance, enhanced efficiency, and reliable nature to the product. Thus, they are used in various applications such as construction, textiles, automotive, and others.

Water-Borne Epoxy Resins Market is spanned across five regions of the world namely Asia Pacific, Europe, North America, Latin America, and the Middle East & Africa. Among these, Asia Pacific holds a major share of the global market and is projected to continue leading, owing to the increasing consumption of the product in construction, textiles, packaging, and others.

It is estimated that the construction segment is set to observe the highest CAGR in the market due to growing and increasing constructional activities in the region. Moreover, increasing demand for ecofriendly coatings in automotive, polymers, and others is likely to witness a rapid growth during the forecast period. These factors have led China, India, and Japan to be the major players of this region

Key Players:

Hexion (U.S.), Allnex GmbH (Germany), Huntsman Corporation (U.S.), Nan Ya Plastics Corporation (Taiwan), KUKDO CHEMICAL CO, LTD (South Korea), ADEKA CORPORATION (Japan), Evonik Industries AG (Germany), Aditya Birla Chemicals (Thailand), Ltd.(Thailand), Olin Corporation (Germany), and Reichhold LLC (U.S), among others.

Regional Analysis:

The water-borne epoxy resins market is segmented across five regions: Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa. Among these, Asia Pacific holds a major share of the market due to the growing demand for water-borne epoxy resins in coatings, adhesives, composites, and others.

The coatings segment holds a major portion and is anticipated to continue its dominance in the market due to increasing consumption of products and this has led to a surge in demand for water-based coatings in end-use industries. Therefore, countries such as China, Japan, South Korea, and India are the major players in this market.

The North American region is growing significantly due to the growing demand for epoxy coatings in paints & coatings, automotive, construction, and other industries. It is predicted that growing investments in the end-use industries is likely to drive the market during the forecast period.

The growing consumption of epoxy resins in end-use applications has propelled the growth in countries such as the U.S, Canada, and Mexico to achieve a stunning growth in the market because they provide unique separation, recycling ability, and high standard performance to the product.

The European market has observed a steady growth in the last couple of years. It is projected that due to stringent rules and regulations implemented by the regional governments to follow water-based products in end-use industries, the market is set to grow at a higher rate during the forecast period.

It is driven by the application of this rule in polymer, chemical, oil & gas industries, and others. Moreover, it is estimated that the growing innovation and technological advancement of product, and other products is predicted to propel the growth in the countries such as the U.K, Italy, Germany, and France during the forecast period.

Segmentation:

The global water-borne epoxy resins market is segmented into the type, application, and end-use. On the basis of type, the market is sub-divided into high molecular weight, and low molecular weight segments. On the basis of application, the market is sub-divided into coatings, adhesives, and composites segments. On the basis of the application, the market is further segregated into construction, textiles, automotive, furniture, packaging, and others.

The Middle East & Africa region is estimated to witness a significant growth in the market due to the growing adoption of product in construction, paints & coatings, and others. Moreover, Latin America is anticipated to witness a higher growth in the market due to increasing demand for eco-friendly products in the end-use industries.

Geographical Analysis:

The report covers brief analysis of the major geographic regions namely Asia Pacific, Europe, North America, Latin America, and the Middle East & Africa.

Intended Audience:

Water-borne epoxy resins market manufacturers

Traders and Distributors of Water-borne epoxy resins market

Production Process Industries

Potential Investors

Raw Material Suppliers

#Water-borne Epoxy Resins Market#Water-borne Epoxy Resins Market Size#Water-borne Epoxy Resins Market Share#Water-borne Epoxy Resins Market Growth#Water-borne Epoxy Resins Market Key Players#Water-borne Epoxy Resins Industry#Water-borne Epoxy Resins

0 notes

Link

“Water-Borne Epoxy Resins” Detailed Study By Applications, Products, End Users, Regions, Major Deals, Trends, Key Players Analysis, Recent Developments

0 notes

Link

The “Water-borne Epoxy Resins market ” report provides a detailed analysis of global market size, regional and country-level market size, segmentation, market growth, market share, and competitive Landscape.

0 notes