#Water Supply Pipeline Accessories

Explore tagged Tumblr posts

Text

MS Dismantling Joints, Mild Steel Dismantling Joints, Manufacturer

Manufacturer, Supplier, Exporter of MS Dismantling Joints, Mild Steel Dismantling Joints, Mechanical Joints, Expansion Joints from Ahmednagar Maharashtra India.

#Dismantling Joints#MS Dismantling Joints#Mild Steel Dismantling Joints#MS Mild Steel Mechanical Joints#MS Mild Steel Slip Type Expansion Joints#Water Supply Pipeline Accessories#Manufacturer Supplier Exporter#Ahmednagar Maharashtra India.

0 notes

Text

Fire Protection Company in Qatar | GRP Lining Contractors

When it comes to safety and infrastructure resilience, Qatar is setting global benchmarks. One of the pivotal elements of this progress is ensuring fire protection and advanced GRP lining solutions. At RNS Qatar, we specialize in delivering top-tier fire protection systems and GRP lining services tailored to meet the stringent requirements of modern infrastructure.

Why Fire Protection is Essential in Qatar

Qatar’s rapidly growing urban and industrial sectors require robust fire safety measures to safeguard lives and assets. With high temperatures, sprawling skyscrapers, and extensive industrial zones, the risk of fire hazards is significant.

Investing in advanced fire protection systems is not just about compliance with safety regulations but also about ensuring business continuity, reducing property damage, and protecting the environment. Fire Protection Company in Qatar stands as a trusted partner in providing cutting-edge fire protection solutions to tackle these challenges.

Our Expertise in Fire Protection Systems

At RNS Qatar, we offer comprehensive fire safety services, including:

Fire Detection and Alarm Systems

Advanced smoke and heat detection systems.

Integrated alarm mechanisms for immediate response.

Fire Suppression Systems

CO2 and clean agent fire suppression solutions.

Foam-based systems for industrial and high-risk environments.

Sprinkler Systems

Customized designs for commercial and residential spaces.

Regular maintenance and testing services.

Fire Extinguishers and Accessories

Supply of portable and fixed fire extinguishers.

Training sessions for effective usage.

Maintenance and Inspections

Routine checks to ensure systems are in optimal working condition.

Compliance with international fire safety standards.

GRP Lining Contractors: Enhancing Durability and Safety

Glass Reinforced Plastic (GRP) lining has revolutionized infrastructure durability and safety. GRP is known for its strength, corrosion resistance, and cost-effectiveness, making it an ideal solution for:

Water Tanks and Pipelines

Preventing leakage and ensuring water quality.

Chemical Storage Tanks

Protection against chemical corrosion and wear.

Sewage Systems

Enhancing the lifespan of sewer lines and tanks.

Industrial Applications

Safeguarding against wear and tear in harsh environments.

At RNS Qatar, our GRP lining services are tailored to meet the specific requirements of each project, ensuring long-lasting protection and compliance with global standards.

Why Choose RNS Qatar?

Experience and Expertise: With years of experience, we have a proven track record in delivering fire protection and GRP lining services across diverse sectors.

Customized Solutions: We understand that each project is unique. Our team works closely with clients to design and implement solutions that align with their specific needs.

Compliance and Quality: Adhering to international safety and quality standards is at the core of our services.

24/7 Support: Our dedicated team is always ready to provide prompt assistance.

0 notes

Text

2BHK Flat for Sale at Newtown AA-2 |2mi from Biswa Bangla Sarani | Ready to Move | starting price Rs-52 Lakh

✦ CALL for more info - 9875369644 (Call Or WhatsApp)

★ PRICING FEATURES ★

___________________________________________

(F) -840 sqft - 2BHK - Rs- 51.68 Lakh

---------------------------------------------

(G) -970 sqft - 2BHK - Rs- 58.44 Lakh

___________________________________________

★ LOCATION - Newtown Action Area-2,Just Nearest Eco park gate-1 Metro. Newtown Metro - 3min, Eco Park - 2Min.Biswa Bangla Sarani 2 min.

★ PROJECT DETAILS ★

➤ G+4 Storied Building.

➤ Project Size :2 Buildings - 28 units.

➤ Basement Car Parking.

➤ Ground Floor Commercial Space.

➤ 2BHK - 840sqft & 970sqft.

➤ Available floor: 840sqft 2nd & 4th Floor,

970sqft 1st & 2nd Floor.

➤ All Leading Bank Loan Available Like SBI, BOB, LIC ETC.

➤ Possession - Ready to Move.

★★ Project Specifications ★★

★ Building Level ★

➤ Lobbies on all floors and staircase of the said Building.

➤ Lift machine room and lift well of the Said Building.

➤ Water reservoirs/tanks of the said Building.

➤ Water supply, pipeline in the Said Building (save those inside any Unit).

➤ Drainage and sewage pipeline in the Said Building (save those inside any Unit).

➤ Wiring, fittings and accessories for lighting of lobbies, staircase and other common portions of the Said Building.

➤ Space for Electricity meters.

➤ Lift and allied machinery in the building.

➤ Ultimate roof of the building will be treated as common space.

★ Complex Level ★

➤ Water Treatment Plant & 24 hour water supply arrangement.

➤ Water pump/s and motor/s.

➤ Central drainage and sewage pipeline and connection with Panchayet Authority.

➤ Wiring, fittings and accessories for lighting of common portions.

➤ Installations for receiving and distributing electricity from supply agency.

➤ Boundary walls and main gates.

➤ C.C.T.V., Water Treatment Plant & Generator Facility.

➤ Fire extinguisher & 24x7 Security Guards.

➤ Other such common areas, fittings and installations as may be specified by the developer to be common areas fittings and installations/equipments.

✔ STRUCTURE

Building designed with R.C.C. Frame structure which rest on individual column, design approved by the competent authority.

✔ EXTERNAL WALL

10" thick ash brick wall and plastered with cement mortar.

✔ INTERNAL WALL

3" thick brick wall and plastered with cement mortar.

✔ FLOORING

Flooring is of flat will be of Tiles. Flooring of car parking will be cement.

✔ BATH ROOM

Bath room fitted upto 5'-6" height with glazed tiles of standard brand.

✔ KITCHEN

Cooking platform and sink will be of Steel Sink with 2'-6" height standard tiles above the platform to protect the oil spot.

✔ TOILET

European type commode with standard P.V.C. ISI Cistem. All fittings are in standard type. One wash hand basin is in dining space.

• Common Toilet One two pin mixture bibcock.

One shower, one Tap.

• Attached Toilet One shower and two CP Bibcock.

✔ DOORS

Sal Wood Frame. All doors including Main Door & Other door palla of the flat of flash door.

✔ WINDOWS UPVC

Sliding. WATER SUPPLY Water supply around the clock is assured for which necessary 4" CRI Submartible pump/deep tube well will be installed.

✔ PLUMBING

Toilet concealed wiring with PVC Pipe (Supreme) all fittings are standard quality (Jaquar/Essco/Johnson/Cera).

✔ BALCONY

Upto 3'-0" height grill will be provided in the balcony.

✔ LIFT

Four persons capacity lift will be provided in each block of the building complex.

★ PRICING FEATURES ★

✦ PRICE - 5,200/- Per Sq. Ft. Rate.

✦ Car Parking - 5 Lakh.

✦ Amenities Cost 3 Lakh.

✦ Box Price - For 2BHK 840sqft Rs-51,68,000/- (all included),

and 2BHK 970sqft Rs-58,44,000/-(all included).

We are happy to help you find your DREAM HOME 🏡

✦ CALL for more info - 9875369644 (Call Or WhatsApp)

Thank you,

One Acre

#2bhk #2bhkflatsforsale #2BHKSALE #FlatInNewtown

0 notes

Text

Essential Bath Fittings For Stylish And Functional Bathroom

You want to live in a home, that looks aesthetic, stylish, and functional. It is essential for every family that their private moment space also gives the same vibe as home. You can make them even better by integrating a few essential Bath Fittings. Having new, modern, stylish, and functional bathroom-fitting accessories elevates the space environment. You can relax and have your time, The bath fittings will take care of your, water conservation and hygiene. Transforming your bathroom into a stylish and functional space is required to make daily life easy and accessible. Let us understand the Bath Fittings Accessories and their benefits in your daily usage.

Bath Fittings And Their Daily Usage Benefits

Health Faucets

There are a variety of faucets available in the market. But choosing the right one for your purpose is necessary. It is a source of keeping yourself clean and fresh. There is also a health faucet, which is specifically integrated into the bathroom to keep things hygienic.

Benefits Of These Bath Fitting Accessories

1. It is installed for water conservation.

2. To keep the germs away, so your family stays healthy.

3. They are durable and used for a long time.

Showers Bath Fittings & Accessories

5 types of shower accessories used in your Bath Fittings

1. Ceiling Shower

It is mounted on the ceiling. It gives a continuous flow of water and covers the maximum area of your body while bathing. It offers an aesthetic and elegant look to your bathroom.

2. Overhead Shower

This type of shower looks visually appealing. It is a rain shower, that is connected to a wall or rarely to the ceiling. The overhead shower is used to spread water in the larger bathroom area. So, the person batting beside it feels like showering in the rain.

3. Shower Arms

These Bath Fittings Accessories connect the water supply pipeline and shower head. It has a unique design. You can choose the shower arms according to your bathroom requirements and appearance.

4. Shower Rails

It can be one of the unique integrations of your Bathroom Fittings Accessories. These shower rails are used for safety and comfort purposes. If you have an elder member in your family with less mobility and strength, they can grab the rails while bathing. And, if your kids want to adjust the shower according to their height, they can easily do it.

5. Telephonic Shower

These are the handheld showers, which are attached to wall-mounted faucets. You can shower with it while carrying it in your hand. It is quite famous in India and you can wash every body part preciously.

Sanitary Ware

Sanity wares are made of ceramic mainly used for washbasins and toilets.

1. Washbasin Sink

The Wall-hung washbasin sink is the best integration of your bathroom space for aesthetic appeal and functionality. These are made of ceramic material and look shiny and elegant. It takes little space to keep yourself hygienic and wash your face instantly. Water gets drained smoothly simultaneously while you are using it. It saves you lots of time. You can create a storage space under the sink to keep your essential bathroom accessories. You can easily clean it as it is low maintenance.

2. EWC (European Water Closet)

EWC with a seat cover is the best choice for your bathroom, to freshen up in the morning or the evening after work. The Structure is made of ceramic structure, which is there to provide you with comfort and relaxation. People with knee issues can use it without any difficulty.

Sink Mixers

Sink Mixers have become an essential part of Bathroom Fittings Accessories. It comes with a faucet that is combined with hot and cold water. A person who likes hot water in the morning can use a hot tap. People who like cold water can use cold water taps. And, if someone who likes to have mild hot water can use both taps simultaneously. It is the best integration in any bathroom and provides so much functionality and comfort.

Get The Best Bath Fittings & Accessories For Your Bathroom

The best way to get the required Bath Fittings is to check the online brands. It will give you an idea of what is trending in the market or coming up with new functionality to change the course of the market. Have an elegant and comfortable bathroom in your home.

Source Link

0 notes

Text

Top 5 Industries That Benefit from Recycled Plastic Waste Products Suppliers

In the contemporary world, sustainability is turning into a need rather than a choice. Growing environmental concerns and a push towards eco-friendly solutions have led to an increasing number of sectors utilizing recycled materials. Waste plastic has become a crucial resource for various businesses. Polymer in Stock, one of the top plastic waste products suppliers in UAE, is crucial to the industry's supply of recycled plastic materials. Let's look at the top 5 industries that recycled plastic waste product suppliers are helping.

The Industry of Packaging

More than any other business, the packaging industry uses plastic. Plastic is widely used in everything from food packaging to shipping goods due to its strength and low weight. Conversely, traditional plastic manufacturing has a significant negative impact on the environment.

The packaging sector can reduce its reliance on virgin plastic by partnering with producers of plastic waste products. Recycled plastic is used to create eco-friendly packaging solutions such bags, containers, and protective packaging. This not only helps reduce the amount of plastic waste produced, but it also enhances the brand's environmentally friendly reputation and attracts environmentally conscious consumers.

The Building Industry

The construction industry has also recognized the need of using recycled plastic. These days, discarded plastic is recycled into durable materials that are utilized in construction for a range of purposes, including as pipelines, insulation, and outdoor furniture.

Composite lumber, for example, is created from recycled plastic and is used for decking, fences, and other exterior buildings. This material is resistant to weather and insects in addition to being sturdy. Building more cost-effective and environmentally friendly projects with materials obtained from plastic waste product suppliers is one way that construction companies can reduce the carbon footprint of their sector.

The Auto Industry

The automotive industry is another important area that benefits from recovered plastic. Automobiles use a lot of plastic, from dashboards to bumpers. Rather than relying exclusively on virgin plastic, a number of automakers are now looking to manufacturers of recycled plastic waste products to meet their production needs.

Many recycled plastic automobile parts contribute to overall vehicle weight reduction, improved fuel efficiency, and lower production costs. By using plastic recycling, the automotive industry is showcasing its dedication to environmentally friendly production methods while maintaining the highest standards of quality.

The Textile and Fashion Industry

Sustainability is rapidly rising to prominence in the fashion industry. The textile sector, which was formerly recognized for its harmful effects on the environment, is gradually shifting toward more environmentally friendly products. Polyester is a synthetic textile made mostly of recycled plastic that is widely used in clothing, accessories, and footwear.

By working with plastic waste product suppliers, fashion brands may produce sustainable, stylish, and eco-friendly collections. In addition to reducing waste, recycled plastic fibers also reduce the requirement for electricity and water—two natural resources typically utilized in the textile sector.

The Furniture Industry

The furniture business is using recycled plastic more and more to create both outdoor and indoor furniture. Recycled plastic is widely valued as a material for outdoor furniture, such as tables, chairs, and benches, because it is durable, weather-resistant, and low maintenance.

Furniture manufacturers can work with recycled plastic waste products suppliers to create eco-friendly furniture that appeals to consumers looking for green home solutions. These products also have the added benefits of being recyclable and long-lasting, but they are usually designed to look like metal or wood.

In summary

As one of the biggest plastic waste products suppliers in UAE, Polymer in Stock is committed to assisting companies in meeting their sustainability targets by providing high-quality recycled plastic materials. Whatever your industry—packaging, construction, or fashion—purchasing items from a reliable source is critical to supporting both company success and environmental responsibility.

The growing need for recycled plastic across many industries highlights the importance of producers of plastic waste products in the current market. A growing number of industries, including furniture, construction, automotive, textile, and packaging, are realizing the benefits of using recycled plastic into their production processes. This lowers the effect on the environment while also providing durable and reasonably priced solutions.

#Plastic Recycling#Plastic Waste#Plastic Waste products#Plastic Waste Products supplier#recycled plastic#Recycled Plastic Waste Products

0 notes

Text

Industrial Boilers and Parts Manufacturer & Supplier in Pune, India

Industrial Boilers and Parts Manufacturer & Supplier in Pune, India.

Sterling Engineers and Boilers Pvt. Ltd.

Top Industrial Boiler Pressure Parts Manufacturers in Pune

Founded in the year 2012, Sterling Engineers & Boilers Private Limited has admirable position in manufacturing and service providing of Industrial MFG, Pressure Vessel Tank, Industrial Tanks, Industrial BoilersCharcoal Filter, Regeneration Oxidation Plant, Industrial Piping Service Ducting Service. These products are extremely admired owing to their top nominal costs. Our products are developed employing the industry permitted and advanced technique. We Are Manufacturer Industrial MS Chimney Manufacturers in Pune | Boiler Pressure Parts In Pune | Industrial Pressure Vessel In Pune | Industrial Storage Tank In Pune | Industrial Bending Service In Pune | Industrial Fire Fighting System In Pune | Hot and cold insulation industrial piping service In Pune | Structural Fabrication Services In Pune | Industrial MS Chimney Suppliers in Pune.

Quality Assurance

Client Satisfaction

Mass Man Power

+91-968-901-1211 CALL US

Popular Products

Our company is committed to design, manufacture, supply, erect and commission Boiler Pressure Parts and its equipments in scheduled time as per the quality norms to the utmost satisfaction of our clients.

Pressure Vessel Tank:Fabricated chimneys manufactured with /without flanges or readymade pipes with all accessories used to discharge gases.

Industrial Chimney:Capacity from 1 KL to 10000000 Kl for Steam,water,molasses, Liquids, Petrol, Diesel, Chemical and all forms of semi liquids, liquids with or without lining

Industrial Tanks:While engrossing on varied demands of many industries, we have been offering SS Pressure Vessel Tank that is used for specific purposes.

OUR PRODUCTS

Industrial Chimney:

India’s Best manufacture company of Industrial MS Chimney In Pune

One of India’s premier manufacturers of Industrial MS Chimneys in Pune is renowned for its excellence in designing and fabricating high-quality chimney solutions for industrial applications. With a rich history of delivering reliable and efficient chimneys, this company combines cutting-edge technology with skilled craftsmanship. Their chimneys are built to withstand harsh industrial environments, ensuring durability and safety. They offer custom design and engineering services to meet specific client requirements, adhering to stringent quality standards and regulatory compliance. With a commitment to innovation and customer satisfaction, this company is a trusted partner for industrial chimney solutions in Pune and beyond.(https://www.sterlingengineers.in/industrial-ms-chimney-pune

2. Piping Services:

Supply, Fabrication, Welding, Laying & Testing of Pipelines (AG & UG) along with supply of pipe, pipe fittings, valves etc. We have capable supplier chain with us for supply of required pipe material along with fittings as per client spec. We execute pipe fabrication & laying projects for water reagent steam process in chemical plants, pharma plants, refineries, fertilizer plants, dairy plants, food processing units, sugar plants etc.Pune hosts India’s foremost manufacturer of diverse industrial piping solutions. Renowned for their expertise, they provide a wide range of high-quality piping products tailored to meet the rigorous demands of industrial applications. Trusted for their precision engineering and reliability, they are the industry leader in Pune.(https://www.sterlingengineers.in/industrial-piping-service-pune)

3. Boiler Pressure Parts:

Best manufacturers company of 80 TPH High pressure boiler in Pune

In Pune, one of the standout manufacturers for 80 TPH high-pressure boilers is renowned for its exceptional expertise and quality offerings. With a rich history of engineering excellence, this company specializes in crafting cutting-edge, high-capacity boilers capable of withstanding extreme pressures. These 80 TPH boilers are designed for industries that demand substantial steam generation, like power plants and large manufacturing units. The company’s commitment to innovation, precision engineering, and adherence to stringent quality standards make it a trusted provider in Pune. They ensure reliable and energy-efficient solutions, reflecting their dedication to meeting the demanding requirements of high-pressure industrial applications.(https://www.sterlingengineers.in/80-tph-high-pressure-boiler-pune)

4. Pressure Vessel:Best manufacturers company of industrial pressure vessels in Pune

Spherical or cylindrical subjected to internal pressure of steam or liquids. In Pune, a leading manufacturer stands out as the go-to provider for industrial pressure vessels. Renowned for their exceptional craftsmanship and precision engineering, this company specializes in designing and fabricating top-quality pressure vessels for a wide range of industrial applications. Their vessels are built to meet stringent safety and performance standards, catering to the unique needs of various industries such as petrochemical, pharmaceutical, and manufacturing. With a strong commitment to innovation and quality, they offer customized solutions, ensuring reliability and durability in the most demanding environments. Trusted for their expertise and reliability, they are the preferred choice for industrial pressure vessels in Pune.(https://www.sterlingengineers.in/industrial-pressure-vessel-pune)

GET QUOTE

5. Storage Tank:Stainless Steel Storage Tanks Manufacturers in Pune

Pune boasts reputable manufacturers specializing in Stainless Steel Storage Tanks. These companies are known for their expertise in crafting high-quality, corrosion-resistant storage solutions. Utilizing premium stainless steel materials and advanced fabrication techniques, they create tanks that excel in durability and hygiene. These tanks find applications across various industries such as food and beverage, pharmaceuticals, and chemical processing, ensuring the safe and efficient storage of liquids and materials. With a commitment to precision engineering, regulatory compliance, and customization options, these manufacturers are trusted partners in Pune’s industrial landscape, delivering reliable stainless steel storage solutions that meet the stringent demands of diverse industries.(https://www.sterlingengineers.in/ss-storage-tank-pune)

6. Fire Fighting System:

Industrial Fire Protection Systems and Service in Pune

Following safety norms and industry standards, we offer highly proficient Fire Fighting Services. Fire Fighting Services are important for providing utmost protection to people in a building in case of a fire hazard. Our highly skilled and experienced professionals are equipped with the latest tools required during such scenario. They execute the service as per industrial norms, and regarded for their flexibility, effectiveness and timely implementation in any environment. Customers from across the country can avail our Fire Fighting Services at nominal rates.(https://www.sterlingengineers.in/industrial-fire-fighting-service-system-pune

7. Insulation:India’s leading manufacturer company for hot & cold insulation in Pune

All insulations (cold and hot) as required at projects along with acoustic insulation. Pune is home to India’s leading manufacturer company specializing in hot and cold insulation solutions. With a stellar reputation for excellence, this company offers top-tier insulation materials and services for a wide range of industries. Their insulation solutions are designed to enhance energy efficiency, reduce heat transfer, and maintain temperature control in industrial processes. Using cutting-edge technology and adhering to rigorous quality standards, they provide custom-tailored insulation solutions that meet the specific needs of clients across Pune and beyond. Trusted for their expertise, commitment to sustainability, and impeccable service, they are the preferred choice for hot and cold insulation solutions in India’s industrial landscape.(https://www.sterlingengineers.in/hot-cold-insulation-service-pune)

Useful Links

Projects

Our People

Resources

Our Clients

Gallery

Contact Us

Sitemap

Contact Us

+91-968-901-1211

T-71/1-A/7, General Block

MIDC, Bhosari, Pune - 411026

#Industrial MS Chimney#Boiler Pressure Parts#Industrial Pressure Vessel#Industrial Storage Tank#Industrial Bending Service#Industrial Fire Fighting System#Hot and cold insulation industrial piping service#Various Structural Fabrication Services In Pune#Maharashtra.

0 notes

Text

Navigating Precision: The Role of Metering Pumps Suppliers in Dubai for Industrial Fluid Control

Introduction:

In the intricate world of industrial fluid control, Metering Pumps play a crucial role in ensuring precision, accuracy, and reliability. For businesses in Dubai seeking to optimize their fluid transfer processes, choosing reputable Metering Pumps suppliers in Dubai is essential. This article explores the significance of metering pumps, their diverse applications, and the pivotal role played by reliable suppliers in enhancing industrial fluid control systems.

Understanding Metering Pumps:

Metering Pumps are specialized devices designed to precisely control the flow rate of fluids in various industrial applications. Unlike traditional pumps, metering pumps suppliers in Dubai are characterized by their ability to deliver consistent and accurate dosages of liquids, making them indispensable in sectors where precision is paramount. These pumps find application in industries such as water treatment, chemical processing, pharmaceuticals, and more.

Applications of Metering Pumps:

Water Treatment:

Metering pumps are extensively used in water treatment processes, where precise chemical dosing is essential for maintaining water quality. They contribute to the efficient disinfection and treatment of water in municipal and industrial wastewater facilities.

Chemical Processing:

In the chemical industry, where accurate dosage of chemicals is critical for manufacturing processes, metering pumps suppliers in Dubai play a vital role. They ensure the precise injection of additives, catalysts, and other chemicals, contributing to the quality and consistency of the end product.

Oil and Gas:

Metering pumps are employed in the oil and gas sector for injecting chemicals into wells, pipelines, and processing facilities. This aids in tasks such as corrosion inhibition, scale prevention, and other chemical treatments essential for optimal production.

Pharmaceuticals:

The pharmaceutical industry relies on metering pumps suppliers in Dubai for the precise dosing of ingredients during drug manufacturing. This ensures the accuracy of formulations, contributing to the safety and efficacy of pharmaceutical products.

Food and Beverage:

Metering pumps are used in the food and beverage industry for dosing ingredients such as flavorings, colors, and preservatives. This precise control enhances the consistency and quality of food and beverage products.

The Role of Reliable Metering Pumps Suppliers in Dubai:

Product Variety:

Reputable Metering Pumps suppliers in Dubai offer a diverse range of pumps to cater to different industries and applications. This variety allows businesses to choose pumps that align with their specific fluid control needs.

Technical Expertise:

Established suppliers possess technical expertise and in-depth knowledge of metering pumps. This expertise is invaluable for businesses seeking guidance in selecting the right pump for their unique requirements, ensuring optimal performance.

Quality Assurance:

Choosing reliable suppliers ensures that businesses receive metering pumps suppliers in Dubai of the highest quality. Reputable suppliers source pumps from trusted manufacturers, adhering to international standards and regulations.

Custom Solutions:

Reliable suppliers understand that each industrial application may have unique requirements. They offer custom solutions, including pump configurations and accessories, to meet the specific needs of their clients.

After-Sales Support:

Robust after-sales support is a hallmark of trustworthy suppliers. This includes maintenance services, spare parts availability, and technical assistance, ensuring that businesses can maximize the lifespan and efficiency of their metering pumps suppliers in Dubai.

Timely Delivery:

Efficient supply chain management is crucial in industrial settings. Reliable suppliers prioritize timely delivery, minimizing downtime for businesses and allowing them to maintain smooth and continuous operations.

The Impact on Industrial Fluid Control Systems:

The choice of Metering Pumps suppliers in Dubai has a direct impact on the performance and efficiency of industrial fluid control systems. Businesses that partner with reputable suppliers benefit from enhanced precision, reduced maintenance costs, and improved overall reliability in their fluid transfer processes.

Conclusion:

Metering pumps are indispensable tools for industries that demand precision and accuracy in fluid control. The role of Metering Pumps suppliers in Dubai is pivotal in ensuring businesses have access to high-quality pumps that meet their specific needs. By choosing reputable suppliers, businesses can enhance their fluid transfer processes, achieve greater accuracy in dosing applications, and ultimately contribute to the overall efficiency and success of their operations. The strategic alliance between businesses and reliable suppliers sets the stage for optimal fluid control in the competitive industrial landscape of Dubai.

Metering Pumps suppliers in Dubai

0 notes

Text

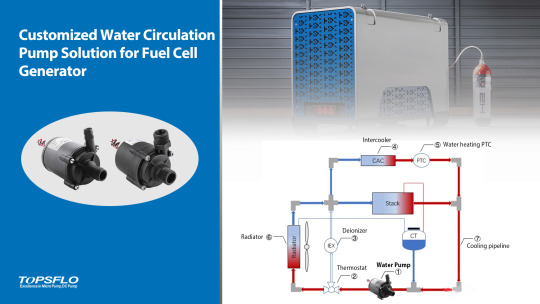

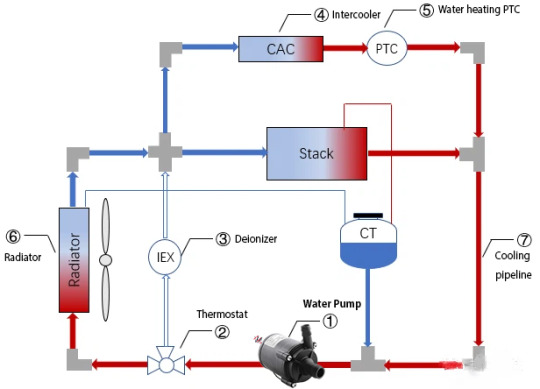

TOPSFLO Fuel Cell Generator Coolant Circulation Pump Solution

Market Overview

As power generation equipment and backup power supply, fuel cells can be widely used in transportation and industrial fields, greatly alleviating the energy pressure caused by the depletion of fossil fuels. Its zero-emission and renewable advantages make it one of the most potential energy supply solutions. The preferential policies currently implemented by various countries have promoted the rapid development of the global fuel cell market.

The system can be simply classified according to the internal electrolyte of the fuel cell: Alkaline Fuel Cell (AFC), Phosphoric Acid Fuel Cell (PAFC), Molten Carbonate Fuel Cell (MCFC), Solid Oxide Fuel Cell (SOFC), Proton Exchange Membrane Fuel Cell (PEMFC). Currently SOFC and PEMFC are the most popular research directions.

Market pain point

Research and improvement of fuel cells have always focused on improving efficiency and system operating stability, as follows:

Stable high-temperature operation: The precious metal catalyst of the fuel cell must be at an appropriate temperature to show good activity and stability. In order to ensure the most efficient electrochemical reaction, it usually needs to be stable between 80 and 95°C. If the temperature is too high or too low, the power generation efficiency will be reduced.

Precise control of water volume: In the actual operation of proton exchange membrane fuel cells (PEMFC), the dynamic water volume in the system is difficult to control. If excess water is not discharged in time, the membrane electrolyte will be flooded. If too little water is not replenished in time, it will reduce the overall performance of the battery and even have a negative impact on the life of the membrane.

Long-term stable operation: Fuel cell systems are usually designed for long-term operation. The core components of the system, such as the proton exchange membrane, need to have continuous operation performanceand a lifespan of several years to decades.All other accessories need to match its performance.

Leakage and cleanup: Core components are expensive, and system use requires regular maintenance and cleaning, and a special monitoring system. Once the pipeline liquid leaks, the electrochemical reaction will be interfered with, and even the key components of the battery stack will be corroded and damaged, polluting the environment, causing maintenance and economic losses.

TOPSFLO Fuel Cell Water Pump Solution

Circulation water pumps play an important role in fuel cell systems, and TOPSFLO brushless centrifugal water pumps perfectly solve the needs of multiple uses:

TOPSFLO brushless dc water pump has been measured to operate continuously for 3,000 hours at a high liquid temperature of 95 degrees, and can easily cope with the high-temperature liquid circulation requirements of the battery system. TOPSFLO TL-C01 micro brushless dc water pump circuit board fully considers the temperature rise margin in the design and material selection, and has divided the strong and weak currents. It is matched with internationally renowned brand electronic components to help the system continue to maintain a stable working state.

In response to the different water management requirements of the fuel cell system under different loads and working conditions, TOPSFLO fuel cell generator cooling pump with PWM speed regulation function can be customized. That is, the battery system sensor dynamically controls the water supply of the pump based on the monitored battery load and environmental conditions such as flow, pressure, temperature, and liquid level to ensure efficient operation of the system.

The laboratory testing service life exceeds 20,000 hours, directly matching the long life requirements of the core components of the fuel cell. The moving components adopt wear-resistant design to greatly reduce operating wear. For example, without carbon brushes, self-produced ECM brushless motor, imported graphite bearings and ceramic shafts with good self-lubricating properties. Extends the life of cooling components and significantly reduces the risk of equipment repairs and downtime.

In order to ensure no leakage, TOPSFLO fuel cell generator coolant circulation pump are 100% air tight tested before leaving the factory, and the ultimate pressure can reach more than 18 Bar. As a rare moving part in the fuel cell system, high-quality water pumps can reduce the risk of pipeline leakage in the fuel cell system, ensure that core components work in a safe environment, and reduce system failure maintenance costs.

Wanna to get pump expert recommendation or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Offcial Web: http://www.topsflo.com/

youtube

#fuel cell generator#fuelcellpump#fuel cell water pump#fuel cell pump#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#topsflopump#12vwaterpump#dc water pump#24vdcwaterpump#bldcpump#Youtube

0 notes

Text

Electric Actuated Valve Manufacturer in USA

SVR Global is the top Electric actuated valve manufacturer in USA supplying best quality valves to oil and gas industries, waster and wastewater industries and chemical industries in Seattle, Charlotte and Chicago. An electric actuated valve is a type of valve that is controlled by an electric motor or actuator, rather than by manual operation. It is typically mounted on top of the valve and is used to open or close the valve remotely using electrical power.

These valves are commonly used in industrial and commercial applications where automation and remote control are required. The electric actuator can be programmed to open or close the valve at specific times or under specific conditions, and can be controlled by a remote switch or a computerized control system.

SVR Global is the Electric actuated valve manufacturer in USA and it manufacture valves that are widely used for waste water, fire protection and in other industrial applications as well

Parts of Electric actuated valves

1.Valve body

2.Ball or disc

3.Stem

4.Seals

5.Actuator

6.Electrical control system

7.Accessories

Types of Electric actuated valve:

Electric actuated Ball valves: These valves have a spherical ball with a hole in the middle that allows or blocks flow when rotated. Electric actuated ball valves are commonly used in applications that require quick, quarter-turn on/off operation.

Electric actuated Butterfly valve: These valves have a disc or plate that rotates in the middle to regulate flow. Electric actuated butterfly valves are commonly used in applications where low profile and quick operation is required.

Electric actuated Globe valves: These valves have a plug that moves up and down to control flow.

Electric actuated Gate valves: These valves have a gate that moves up and down to allow or block flow.

Industries that use Electric Actuated Valves:

Electric actuated valves find applications in mining operations for automated control of fluid flow, slurry control, and process optimization in various mineral processing and handling operations.

Mining

Chemical

Textile

Power Industries

Boiler industries

Pulp and paper plants

Oil and gas

Applications:

In water and wastewater treatment plants, they regulate the flow of water, chemicals, and other fluids at different stages of the treatment process.

In industrial processes, they are used to manage fluid flow within pipelines, tanks, and vessels as part of process control measures.

Chemical and petrochemical plants: Electric actuated valves are used in chemical and petrochemical plants to control the flow of corrosive and hazardous fluids.

Building automation: Electric actuated valves are used in building automation systems to regulate the flow of water and other fluids in various building systems such as plumbing, heating, and cooling.

Advantages :

Tight shutoff: Electric actuated plug valves provide tight shutoff, which means that they can effectively stop the flow of fluids through the valve.

High flow capacity: Electric actuated plug valves have a high flow capacity, which means that they can handle large volumes of fluid. This makes them suitable for use in applications that require high flow rates.

Simple design: Electric actuated plug valves have a relatively simple design, which means that they are easy to install and maintain.

Provides tight seal service being an electric operated valve

Low failure Rate

Increased efficiency

Precise control

Consistent contol

Materials: CF8M, CF8, SS316, CF3M, WCB, and Stainless steel(SS304,SS316,CF8M, SS316L, SS904L).

Class: 150 to 2500

Size: ½’’ to 80’’

Pressure : PN6- PN450

End Connections: Butt weld, Threaded, Wafer, Lug, Flanged, Socket weld

Operation: Electric Actuator.

Electric actuator details-

Torque – 3 – 9 nm

Operating pressure- 8 Bar

Port Connection-NPT1.4”

Mounting Base-ISO5211

Temperature--20°C - +80°C For more details, visit our website- https://svrglobal.net/products/electric-actuated-valve/

0 notes

Text

MS Dismantling Joints, Mild Steel Dismantling Joints, Manufacturer

Manufacturer, Supplier, Exporter of MS Dismantling Joints, Mild Steel Dismantling Joints, Mechanical Joints, Expansion Joints from Ahmednagar Maharashtra India.

Dismantling Joints, MS Dismantling Joints, Mild Steel Dismantling Joints, MS Mild Steel Mechanical Joints, MS Mild Steel Slip Type Expansion Joints, Water Supply Pipeline Accessories, Manufacturer Supplier Exporter, Ahmednagar Maharashtra India.

0 notes

Text

A Comprehensive Guide to Irrigation Pump Station Maintenance

Irrigation pump stations play a crucial role in delivering water to agricultural fields, gardens, and landscapes efficiently. Just like any system application, proper maintenance of these pump stations is essential.

We at Dutco Tennant LLC specialise in distributing high-quality products for irrigation pump stations. From an extensive valve range to different pipeline accessories, you are sure to find the solution to fit in your project needs.

However, choosing the right products is not enough when it comes to the efficiency and longevity of an irrigation pump station. Appropriate maintenance work needs to be performed.

In this comprehensive guide, we will explore the key components of an irrigation pump station and enumerate the best practices for maintenance.

Essential Components in an Irrigation Pump Station

An irrigation pump station consists of several key components that work together to pump water from a water source to the irrigation system. These components ensure the smooth and efficient delivery of water to the fields, gardens and diverse landscapes.

Pump

This one is pretty obvious. What’s an irrigation pump station without a pump? The pump is the central component of the irrigation pump station.

Pumps for irrigation pumping station are responsible for drawing water from the water source and pressurising it to flow through the irrigation system. Various types of pumps are used in irrigation systems, including centrifugal pumps and submersible pumps.

Motor

The motor is connected to the pump and provides the mechanical power to drive the pump's impeller or other mechanisms. It can be an electric motor or a diesel engine, depending on the power source available and the size of the irrigation system.

Intake Structure

The intake structure is designed to control the flow of water into the pump station from the water source. It typically includes an intake screen or grate to prevent large debris from entering the pump, reducing the risk of clogs and damage.

Pipes and Fittings

A network of pipes and fittings transports water from the pump to the irrigation system. These pipes and fittings are carefully selected and installed so as to handle the flow rate and pressure required for efficient water distribution.

Control Panel

The control panel houses electrical components, including starters, relays, and switches, to control the pump's operation. It allows the user to start, stop, and control the speed of the pump, as well as monitor various parameters like pressure and flow rate.

Valves

Various types of valves are used in the pump station to regulate water flow and pressure. Irrigation gate valves, check valves, and pressure relief valves are common in irrigation pump stations.

Pressure Tank (Optional)

Some irrigation pump stations may include a pressure tank to store water under pressure. The pressure tank helps maintain a consistent pressure in the irrigation system and reduces the pump's cycling frequency.

Filters and Strainers

Filters and strainers are essential components to ensure water quality. They remove debris, sediment, and other contaminants from the water before it reaches the pump and the irrigation system. With their use, the equipment is protected from damage and maintains optimal water quality. We at Dutco Tennant LLC supply self cleaning filters for irrigation pumping station resulting in hassle-free operations.

Electrical Power Source

The irrigation pump station requires a reliable electrical power source to operate. For remote locations, where grid power is unavailable, alternative power sources such as solar panels or generators may be used.

Key Steps to Adopt for Appropriate Maintenance Work

1. Regular Inspection

Regular inspection forms the foundation of effective maintenance. Create a maintenance schedule to inspect your irrigation pump station at least once a month or as per manufacturer’s recommendation. During these inspections, pay close attention to the following components:

a. Pump and Motor: Check for any signs of leaks, strange noises, or excessive vibration. Ensure that the motor is running smoothly and the pump is adequately primed.

b. Electrical Systems: Inspect electrical connections, wires, and control panels. Look for any signs of wear and tear, overheating, or corrosion. Tighten loose connections and address any electrical issues promptly.

c. Flow and Pressure: Monitor water flow rates and system pressure regularly. Drastic changes in these parameters may indicate potential problems.

2. Lubrication

Proper lubrication is vital for the smooth functioning of moving parts in the pump station. Refer to the manufacturer's guidelines to determine the correct lubricant and lubrication schedule for your pump and motor bearings. Over-lubrication can be as detrimental as under-lubrication, so follow the recommended quantities carefully.

3. Check for Clogs and Debris

Regularly inspect and clean the pump station's intake screen and filters. Clogs and debris can reduce the flow of water, strain the pump, and lead to mechanical failures. Clear any blockages and ensure that the intake area is free from vegetation, rocks, or other obstructions.

4. Monitor Pump Efficiency

Efficiency is critical for an irrigation pump station. Regularly calculate the pump's efficiency by comparing the water output with the energy input. Minimised efficiency may indicate issues with the pump, motor, or other components, requiring further investigation and maintenance.

5. Test Safety Features

Various safety features or devices are installed in pumping stations. For example, pressure relief valves, air release valves for irrigation pumping station are commonly used. Test these safety mechanisms regularly to ensure they are working correctly. Faulty safety features can lead to accidents or severe damage to the pump and surrounding infrastructure.

6. Winterization

In regions with freezing temperatures, winterization is crucial to prevent damage to the pump and related components. Before the onset of winter, drain the system and protect it from freezing by adding antifreeze or using heat tapes.

7. Professional Maintenance

While some maintenance tasks can be performed by the system owner, it's essential to have a professional inspection and maintenance at least once a year. Trained technicians can identify potential issues that may go unnoticed during routine checks and ensure that the pump station operates optimally.

8. Keep Records

Maintain a detailed maintenance log that includes inspection dates, performed tasks, and any issues identified and resolved. These records will help in tracking the pump station's performance over time, aiding in timely maintenance and troubleshooting.

Conclusion

Irrigation pump station maintenance is a critical aspect of ensuring a reliable and efficient water supply for agricultural and landscaping needs. Regular inspections, lubrication, debris removal, and monitoring pump efficiency are fundamental practices.

Alongside proactive maintenance, engage professionals for annual inspections and keep accurate records to stay on top of the system's performance. With a well-maintained pump station, you can maximise water utilisation, minimise downtime, and extend the lifespan of your irrigation system.

Therefore, ultimately leading to higher yields and a healthier landscape. If you are looking to establish a stellar irrigation pump station then check out our DT website as we have extensive products to meet the project demand.

0 notes

Text

Wafer butterfly valve supplier in Dubai

Middleeast valve is a topmost Wafer butterfly valve supplier in Dubai. We supply to cities like Ajman, Hatta, and Kho Fakkan.

What is wafer butterfly valve?

A wafer butterfly valve is a type of industrial valve used for regulating and controlling the flow of fluids in a pipeline. It consists of a flat, disc-shaped closure element (resembling a butterfly) that rotates on a spindle to control the flow of fluid.

Wafer butterfly valve installation:

Verify the valve size: Ensure that the valve size matches the pipe size where it will be installed.

Check the valve for any damage: Inspect the valve body, disc, stem, and seals for any signs of damage or defects. If any defects are found, the valve should be repaired or replaced before installation.

Prepare the pipe: Clean the flange faces on both sides of the pipe and remove any debris or foreign materials. Ensure that the flange faces are smooth and free of burrs or scratches.

Position the valve: Place the valve between the two pipe flanges, making sure that the valve's arrow is pointing in the direction of flow.

Align the valve: Align the bolt holes on the valve flanges with the corresponding holes on the pipe flanges. Use alignment pins to hold the valve in place.

Install the bolts: Insert the bolts into the bolt holes and hand-tighten them in a crisscross pattern. Do not fully tighten the bolts yet.

Tighten the bolts: Using a torque wrench, tighten the bolts in a crisscross pattern according to the manufacturer's specifications. Do not overtighten the bolts, as this can damage the valve or the flanges.

Check for leaks: Test the valve for leaks by filling the pipe with water or another suitable fluid and pressurizing it to the maximum operating pressure. Check for any leaks around the valve body or seals.

Finalize the installation: Once the valve has been successfully tested, finalize the installation by removing the alignment pins and installing any necessary accessories, such as handles or actuators.

Middleeast valve is a topmost Wafer butterfly valve supplier in Dubai and are known for their compact design, ease of installation, and cost-effective operation. However, they are typically used for applications with moderate temperature and pressure conditions and may not be suitable for high-temperature or high-pressure applications without proper design considerations.

Advantages of wafer butterfly valve:

Compact size

Low cost

Ease of installation

Simple design

Quick opening and closing

Good flow control

Low pressure drop

Resistance to corrosion

Industries of wafer butterfly valve:

Water treatment

Chemical

Oil and gas

Petrochemical

Power generation

Plumbing

Description:

Body materials: Cast iron, Carbon steel, Ductile iron, SS304, SS316

Class: 150 to 300, PN6 to PN40.

Size: 2’’-72’’.

End: wafer.

Operation: lever operated, Gear Operated, electric actuated, pneumatic actuated.

Disc: Carbon steel, Cast iron, Ductile iron, SS304, SS316

Visit us: https://www.middleeastvalve.com/product-category/wafer-butterfly-valve/

0 notes

Text

Main design disadvantages of dual phase steel flange

The main design disadvantage of dual phase steel flange is no leakage. This is a deficiency in that design. The connection is dynamic, stainless steel flange, and periodic loads such as thermal expansion fluctuation will cause the movement between flange faces, affect the function of flange, damage the integrity of flange and lead to leakage. Then, let’s learn about the main design shortcomings of dual phase steel flange!

Due to these advantages of dual phase steel flange, sewage treatment pipeline, deep-sea operation, seawater desalination, various acid-base environment and good wear and corrosion performance, it can be used for 4 ~ 5 years more than ordinary stainless steel. For example, the service life of dual phase steel flange for pipeline in seawater will be shortened, and the labor cost is relatively high.

1 . The yield strength is more than one time higher than that of ordinary austenitic stainless steel, and has sufficient plastic toughness required for forming.

2 . It has excellent stress corrosion cracking ability, especially in chloride ion environment.

3 . Dual phase steel is highly corrosive. It can replace high alloy austenitic stainless steel or even etch alloy in some media such as acetic acid and formic acid.

4 . It has good local corrosion properties. Compared with austenitic stainless steel with the same alloy content, the wear corrosion and fatigue corrosion properties are better than austenitic stainless steel

The larger bolts of dual phase steel flange must be consistent with the larger nuts. Dual phase steel flange special steel flange means that larger diameter bolts need to create conditions for fastening nuts. Unexpectedly, the larger the diameter of the bolt, the more curved the flange applied. The method is to increase the wall thickness of the flange part. The whole device of American standard flange needs very large size and weight, which becomes a special problem in offshore environment. Because in this case, weight is always the main issue that must be paid attention to.

Dual phase steel flange is a movable flange, which is generally installed on water supply and drainage accessories. Expansion joints are common. When the manufacturer leaves the factory, there is a flange at both ends of the expansion joint, which is directly connected with the pipeline and equipment under construction through bolts.

Stainless steel and oxidant have passivation effect, forming a tough and dense chromium rich oxide protective film Cr2O3 on the surface, which can effectively prevent the further occurrence of oxidation reaction. Other metal pipe materials, such as galvanized pipe and Japanese standard flange copper pipe, have low passivation ability. This is an important reason why the corrosion resistance of galvanized pipe and copper pipe is far inferior to that of stainless steel pipe.

The two sealing surfaces of the flange bolt squeeze the flange gasket to form a seal, but this will also lead to the destruction of the seal. In order to maintain the seal, the neck flange must maintain a large bolt force. To do this, the bolts must be further enlarged.

0 notes

Text

Basic Plumbing Tools

If you face a pipeline issue in your home, the first and foremost solution that comes into your mind is calling a plumber. With the advent of new technologies, many advanced plumbing tools have emerged to the convenience of plumbers. With these accessories, you can get rid of pipeline problems within a short period. The most commonly used plumbing tools come in the form of basin wrenches, adjustable wrenches, pipe wrenches, tongue-and-groove pliers, hacksaws, metal files, thread seal tape, hand augers, Water Jetter machines, toilet plungers, etc. Firms that manufacture Water Jetter machines in Sydney implement cutting-edge technologies in their operations.

Commonly Used Plumbing Accessories

The Most Commonly Used Plumbing Accessories Are Listed As Follows:

Basin Wrench

It is undoubtedly one of the most common plumbing accessories. It is a staple accessory for any plumber’s toolbox. Plumbers use a basin wrench to tighten and loosen nuts on sink faucets. The presence of a long shaft and a swivel make it increasingly possible. This plumbing equipment has a clamp-like apparatus at the end. This makes it possible to penetrate deep, narrow spaces behind sinks and thereby, reaching the faucet bolts.

Adjustable Wrench

It is appropriate plumbing equipment for compression fittings and supply lines. An adjustable wrench has a firm jaw setting. As a result, an adjustable wrench doesn’t slip from the hands of plumbers. When it comes to size, six-inch and 10-inch adjustable wrenches are the most popular.

Pipe Wrench

This is another common plumbing accessory. Hardware stores that sell plumbing tools in Sydney offer a wide variety of choices to individuals. A pipe wrench is larger than an adjustable wrench. For this reason, plumbers use this equipment to tighten and loosen fittings and nuts.

Tongue-And-Groove Pliers

When there is a need for grabbing, twisting or pulling, plumbers use this equipment. It is versatile in every aspect. The presence of serrated jaws gives it a curved appearance.

Water Jetter Machines

This machine is used to remove clogs from blocked drain pipes. With the help of Water Jetter machines, plumbers pass high-pressure water through the pipelines. This eventually breaks the clog while making the pipe free from blockages. The Water Jetter machines in Sydney can remove high-volume clogs effectively.

Hacksaw

Plumbers use hacksaws to cut through metal and plastic pipes, screws, nuts and bolts, and other hardware. However, plumbers should keep extra blades in their toolbox if in case the blade of hacksaw turns dull or breaks. Hacksaws come in handy to plumbers in times of dealing with tough nuts.

Metal File

Metal files come in different sizes. This is a great advantage for both plumbers and homeowners. Plumbers use this equipment to cut metal pipes. Metal files are of two types, namely, a half-round file and a rat-tail file.

The above-mentioned plumbing accessories come in useful to individuals and plumbers under different circumstances. Companies that manufacture plumbing tools in Sydney conform to product quality standards in every aspect. Choose plumbing equipment that fits your needs.

0 notes

Text

Summer is a period of high incidence of sleep apnea syndrome. So it is better not to stop wearing a CPAP because of the recent high temperature, sweating and wearing silicone masks.

Due that higher temperatures and humidity, the machine is easy to breed mold, it is noted that more attention should be paid to CPAP cleaning maintenance, for masks, pipes and other accessories are recommended to clean every day.

In addition, after washing your face, you can smear talcum powder appropriately to reduce sweating and ease the discomfort of wearing a mask in summer.

When you clean the micro CPAP machine, you need to know below points.

Unplug the power supply before cleaning the Transcend minicpap.

Do not immerse the Transcend minicpap or power adapter in liquid.

Do not use rough or abrasive detergents to clean equipment or its components.

Do not put cleaning materials, such as cleaning cloth or cleaning liquid, into the air inlet or outlet of the equipment.

Maintenance of CPAP machine body

Should be placed in a dry and ventilated place to avoid direct sunlight.

It is strictly forbidden to flush with water or let water into the inside of the machine.

Clean regularly with non-dripping wet cotton cloth and neutral soap.

Beating and privately dismantling machines are prohibited.

Maintenance of mask

The mask should be placed in a dry and ventilated place when not in use.

After use, you can clean with a mild detergent.

Clean the head with dirt in time and use a neutral cleaner.

The mask is made of silicone, which can not get close to the high temperature and avoid sharp scratches.

Mask for consumables, use for a period of time found that oxidation hardening, inappropriate use should be replaced in time.

Maintenance of respiratory lines and pipe adapters

Pipes should be hung in a dry and ventilated place when not in use.

After using it for a period of time, it can be cleaned with a neutral cleaner.

The pipeline is made of plastic, which can not be close to the high temperature and avoid sharp scratches.

The pipeline is consumable and should be replaced in time if it is used for a period of time or if there is air leakage.

The use of filter cotton.

Filter cotton belongs to disposable consumables and can not be cleaned repeatedly.

It is recommended to remove the filter cotton every week and gently dust off the filter cotton.

According to the quality of the air, replace it according to the degree of dust on the filter cotton.

Because the air flow of the micro CPAP is much larger than that of normal breathing, filter cotton is very important.

Dust is not only seriously harmful to health, but also does great harm to the "heart" of micro CPAP-motor.

Maintenance of heating humidifier.

For heating humidifiers, pure water or cool boiled water is required to prevent scale.

It is recommended to change the pure water every day and pour out the water when it is not in use.

Check whether there is water in it before using the heating humidifier, and pay attention to the water level that should not be lower than the lowest or exceed the highest water level.

The humidifier water tank should be checked and cleaned frequently to prevent mildew and can be cleaned with detergent or detergent.

In the case of water in the heating humidifier, do not move the machine to prevent water from flowing back into the main engine, resulting in unnecessary losses.

CPAP & AUTO CPAP, Mini Cpap Machine and Buy Cpap Machinevisit our website for more details https://cpapeu.com/

1 note

·

View note

Text

Electric Actuated Valve Manufacturer in USA

SVR Global is a leading Electric Actuated Valve Manufacturer in USA. Electric Actuated valve is completely automated and has power and control signals which are connected internally to the motor. The internal controls operate the motors based on the control signals received as it is an apparatus that utilizes a single linear or circular motion to convert electrical energy into kinetic energy. To boost the effectiveness and complexity of the procedure, the valve is automatically closed. Depending on the functions they carry out inside the processes for which they were created, electric actuators come in a variety of sizes and shapes.

Electric Actuated Valve Manufacturer in USA provide valves that are not only cost-effective but also durable and corrosion resistant. An electric actuator valve has an electrical connection that connects to the signal for transmission, the supply cables for the actuator, and the motor commands to actuator.

Parts of Electric actuated valves

1.Valve body

2.Ball or disc

3.Stem

4.Seals

5.Actuator

6.Electrical control system

7.Accessories

Types of Electric actuated valve:

Electric actuated Ball valves: These valves have a spherical ball with a hole in the middle that allows or blocks flow when rotated. Electric actuated ball valves are commonly used in applications that require quick, quarter-turn on/off operation.

Electric actuated Butterfly valve: These valves have a disc or plate that rotates in the middle to regulate flow. Electric actuated butterfly valves are commonly used in applications where low profile and quick operation is required.

Electric actuated Globe valves: These valves have a plug that moves up and down to control flow. Electric actuated globe valves are commonly used in applications that require precise control of flow rate.

Electric actuated Gate valves: These valves have a gate that moves up and down to allow or block flow. Electric actuated gate valves are commonly used in applications where a tight seal is required.

Electric Actuated plug valve: An electric actuated plug valve uses an electric motor or actuator to control the movement of a tapered or cylindrical plug inside the valve body to regulate the flow of fluids.

Industries that use Electric Actuated Valves:

Mining

Chemical

Textile

Power Industries

Boiler industries

Farming and agricultural plants

Pulp and paper plants

Oil and gas

Applications:

Water and wastewater treatment: Electric actuated valves are used in water and wastewater treatment plants to control the flow of water, chemicals, and other fluids in various stages of the treatment process.

HVAC systems: Electric actuated valves are used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of hot and cold water in the system.

Process control: Electric actuated valves are used in various industrial processes to control the flow of fluids in pipelines, tanks, and vessels.

Chemical and petrochemical plants: Electric actuated valves are used in chemical and petrochemical plants to control the flow of corrosive and hazardous fluids.

Building automation: Electric actuated valves are used in building automation systems to regulate the flow of water and other fluids in various building systems such as plumbing, heating, and cooling.

Advantages :

Tight shutoff: Electric actuated plug valves provide tight shutoff, which means that they can effectively stop the flow of fluids through the valve. This is particularly important in applications where the fluid needs to be completely contained, such as in hazardous or corrosive environments.

High flow capacity: Electric actuated plug valves have a high flow capacity, which means that they can handle large volumes of fluid. This makes them suitable for use in applications that require high flow rates.

Simple design: Electric actuated plug valves have a relatively simple design, which means that they are easy to install and maintain. They also require minimal maintenance compared to other types of valves.

Quick and easy to operate

Provides tight seal service being an electric operated valve

Low failure Rate

Increased efficiency

Precise control

Consistent contol

Body material-Aluminium

Materials: CF8M, CF8, SS316, CF3M, WCB, and Stainless steel(SS304,

SS316,CF8M, SS316L, SS904L).

Class: 150 to 2500

Size: 1/2" to 80"

Pressure : PN6- PN450

End Connections: Flanged, Socket weld, Butt weld, Threaded, Wafer, Lug

Operation: Electric Actuator.

Electric actuator details-

Torque – 3 – 9 nm

Operating pressure- 8 Bar

Port Connection-NPT1.4”

Mounting Base-ISO5211

Temperature--20°C - +80°C

For more details, visit our website- https://svrglobal.net/products/electric-actuated-valve/

1 note

·

View note