#Waste oil storage and transfer systems

Explore tagged Tumblr posts

Text

Buy Heat Pump Hot Water System Today

The Smart Choice for Comfort and Savings Ever wonder why your water heater always seems to run out of hot water just when you need it most? Whether it’s a family member taking a marathon shower or your laundry demanding hot water, relying on traditional water heaters can feel like a gamble. It’s time to switch things up. Enter the heat pump hot water system—a game-changing solution that keeps your home running efficiently, no matter the season. If you’re ready to reduce energy costs and enjoy uninterrupted hot water, let’s dive into why you should buy a heat pump hot water system today.

What Makes a Heat Pump Hot Water System Different? A heat pump hot water system doesn’t work like traditional electric or gas water heaters. Instead of generating heat directly, it pulls warmth from the air and uses it to heat the water in your storage tank. Think of it as a more energy-conscious cousin of your air conditioner. While the old water heaters guzzle energy like an over-caffeinated office worker, a heat pump system sips energy with elegance, giving you hot water without running up your power bill.

If you’re tired of expensive energy bills creeping up each month, switching to a heat pump hot water system is a no-brainer. It offers lower operational costs while reducing your home’s carbon footprint—a win-win for your wallet and the planet.

Why You Should Buy a Heat Pump Hot Water System Now Waiting for your old water heater to fail before upgrading? That’s like waiting for your car to break down before changing the oil. Upgrading to a heat pump hot water system is one of the smartest decisions you can make today. Here’s why:

Government Incentives: Many areas in Australia offer rebates or tax credits for installing energy-efficient systems like heat pumps.

Future-Proofing: As energy prices rise, having a system that saves energy ensures you stay ahead of the curve.

Reduced Carbon Emissions: With climate-conscious choices becoming more important, a heat pump helps you contribute to a greener future.

Improved Home Value: Energy-efficient upgrades make your property more appealing, especially if you plan to sell.

With benefits like these, it’s clear that there’s no better time to buy a heat pump hot water system than right now.

How to Choose the Right System for Your Home Not all heat pumps are created equal, so selecting the right system requires a bit of research. Keep these key factors in mind:

Capacity: How much hot water does your household need? Families with multiple members should consider larger systems, like a 270L heat pump.

Efficiency Ratings: Look for models with higher energy star ratings for maximum savings.

Noise Levels: Some systems can be noisier than others. If you have sensitive ears (or light sleepers), check for a quiet model.

Installation Costs: Be sure to budget for installation by a certified professional, as a poorly installed system can underperform.

Choosing the right heat pump hot water system means balancing performance and budget. Luckily, with more models available, there’s a system to suit every household's needs.

Heat Pump Hot Water Systems vs. Traditional Water Heaters While both systems provide hot water, their operation and efficiency differ significantly. Traditional water heaters rely on constant energy input to maintain water temperature, which wastes energy during non-use periods. In contrast, heat pumps transfer heat from the environment, making them 2-3 times more efficient.

Imagine running a marathon and finding out your heat pump just jogged beside you with barely a sweat. That’s how these systems outperform traditional water heaters—they get the job done with far less effort (and energy).

Is a Heat Pump Hot Water System Suitable for All Climates? One common concern is whether a heat pump hot water system works efficiently in cooler climates. While it’s true that heat pumps perform best in moderate temperatures, modern systems are designed to operate effectively even when the mercury dips. For homes in cooler regions, installing the unit in a sheltered location or using a hybrid heat pump system ensures reliable performance year-round.

Australia’s diverse climate zones make heat pumps an ideal solution. They perform exceptionally well in warmer regions but can also be optimized for colder areas, ensuring that no matter where you live, you won’t have to suffer through cold showers.

Installation and Maintenance: Set It and Forget It Installing a heat pump hot water system isn’t rocket science, but it’s essential to hire a qualified professional for the job. A well-installed system operates efficiently and requires minimal maintenance. Routine checks, such as cleaning filters and monitoring the refrigerant, help keep the system running smoothly. Compared to traditional water heaters, heat pumps have fewer mechanical parts, which means fewer breakdowns and lower repair costs.

If the idea of dealing with another appliance breakdown sends chills down your spine, you’ll love the reliability of a heat pump. It's a "set it and forget it" solution—no more last-minute panics when guests arrive, only to find out the water heater quit.

Hot Water, Smarter The decision to buy a heat pump hot water system isn’t just about upgrading your home—it’s about making a future-forward investment. These systems offer a trifecta of benefits: lower energy costs, reduced environmental impact, and reliable hot water whenever you need it. With government incentives sweetening the deal and energy prices on the rise, there’s no better time to make the switch.

So, say goodbye to unpredictable water heaters and hello to a smarter, more efficient solution. If you’re ready to make your home more comfortable, explore the range of heat pump hot water systems today and discover which model best suits your needs.

Looking for the best heat pump hot water systems? Our next article dives into top-rated models and helps you choose the perfect fit for your home.

#heat pump hot water heater australia#heat pump hot water australia#best heat pump hot water#heat pump hot water system#heat pump hot water#buy heat pump hot water system

0 notes

Text

Explore the right-hand man in the industrial field-the oil suction gun

In the rapidly developing industrial field, efficient, safe and environmentally friendly production operations are the goals pursued by every enterprise. In this context, the oil suction gun, as a tool designed for liquid transfer, plays an indispensable role in mechanical maintenance, oil management, environmental protection cleaning and other aspects with its unique advantages. This article will explore the working principle, application field, advantages and characteristics and future development trend of the oil suction gun in depth.

Working principle of the oil suction gun The oil suction gun, as the name suggests, is a tool that absorbs and transfers oil Heavy Duty Pistol Grip Grease Gun or other non-corrosive liquids through a specific mechanism. It usually consists of a pump body, an oil suction pipe, a handle, a valve and other components. When working, the user drives the pump body manually or electrically to generate negative pressure, so that the air in the oil suction pipe is discharged to form a vacuum state. Subsequently, the oil suction pipe extends into the liquid to be transferred, and the difference between the atmospheric pressure and the negative pressure in the pump body is used to suck the liquid into the pump body, and the flow direction is controlled by the valve, and finally the liquid transfer process is completed.

Wide application fields Mechanical maintenance: In scenes such as automobile repair and engineering machinery maintenance, oil suction guns are often used to replace engine oil, gear oil and other operations, which greatly improves work efficiency and reduces oil waste. Oil management: In gas stations, oil depots and other places, oil suction guns are important tools for oil packaging and transfer, ensuring the safety and cleanliness of oil during storage and transportation. Environmental cleaning: When dealing with environmental protection tasks such as oil spills and oil pollution cleaning, oil suction guns can quickly absorb and transfer leaked oil pollution, reduce environmental pollution, and protect the ecological environment. Chemical production: In the chemical industry, oil suction guns are also widely used for precise measurement and transfer of non-corrosive liquids to ensure the stability and safety of the production process.

Advantages and characteristics Efficient and convenient: The oil suction gun is easy to operate and transfers liquid quickly, which greatly improves work efficiency. Safe and environmentally friendly: Through precise control, oil waste and environmental pollution are reduced, which meets the requirements of modern industry for green production. Durable and reliable: Made of high-quality materials, it has a compact structure, wear resistance and long service life. Versatility: It can be equipped with different specifications of oil suction pipes and valves according to different needs to meet various liquid transfer needs.

Future development trend With the continuous deepening of industrial automation and the increasing awareness of environmental protection, the oil suction gun industry is moving towards a more intelligent and environmentally friendly direction. In the future, we are expected to see more oil suction gun products with integrated sensors and intelligent control systems to achieve accurate monitoring and automatic adjustment of the liquid transfer process. At the same time, the application of environmentally friendly materials will further reduce the carbon footprint of oil suction guns during production and use, and contribute to sustainable development.

In short, as a powerful assistant in the industrial field, the importance of oil suction guns is self-evident. With the continuous advancement of technology and the continuous expansion of the market, we have reason to believe that oil suction guns will play a greater role in more fields and contribute more to the efficiency, safety and environmental protection of industrial production.

0 notes

Text

Safety Precautions while using Sodium Hydroxide Pellets

Sodium hydroxide pellets or also referred as caustic soda or lye are small and solid sodium hydroxide. They are white and odorless small pellet shaped material which is easily soluble in water and is strongly alkaline in nature. Sodium hydroxide pellets are essential in the manufacture of so many chemicals such as detergents, synthetic fabrics, and plastics. Soap making requires sodium hydroxide pellets to actually convert fats and oils into the solid soaps that are used in everyday life.

Personal Protective Equipment (PPE)

Sodium hydroxide pellets if not handled with precaution are usually dangerous and can cause severe injuries. Sodium hydroxide the solutions are alkalis and can burn the skin, eyes, and cause breathing problems. PPE is crucial to prevent direct contact with these risks as it provides a buffer between the user and risks and facilitates the reduction of accidents.

Types of PPE Required

Gloves: Ensure that the hands are protected from coming into direct contact with sodium hydroxide pellets through wearing chemical resistant gloves made of neoprene or nitrile.

Goggles: Use safety glasses to protect your eyes from splashes and flying debris.

Face Shields: Further to goggles, a face shield offers additional protection that covers the entire face.

Aprons: Take chemical-resistant aprons to avoid chances of getting your skin, and clothes stained by the chemical spills.

Safe Handling and Storage

Avoid Direct Contact: Sodium hydroxide pellets specifically come in the form of small pellets and can be strongly corrosive and can cause burns. It is advised to wear proper PPEs like gloves, goggles and wearing full sleeved clothes so as to avoid skin and eye contact. Use Tools: To minimize contact with the material, always use spatula, tongs, or special containers to transfer or to measure the pellets. This also helps to reduce chances of accidentally touching the containers or causing spills. Work in Well-Ventilated Areas: Make sure your environment at workplace should be adequately aerated so that your do not inhale dust or stinks that result from the pellets. Avoid exposure to gasoline because it poses a threat to your respiratory system and ensure to use fume hoods or work in well ventilated areas.

Storage Recommendations

Temperature Control: Sodium hydroxide pellets should be stored in a cool dry well ventilated area and should never be exposed to heat. At high temperatures, pellet materials degrade, and the presence of moisture in the air can cause dangerous situations. Humidity Management: Sodium hydroxide is a hygroscopic substance which means it has the property of taking up moisture from the air. Store the pellets in a sealed container in order not to attract moisture which in turn hinders the free flow of the pellets and they clump resulting to limited efficacy. Container Specifications: Employ containers of compatible materials including high density polyethylene (HDPE) or any other material that is not affected by corrosion. Make sure the containers are well labeled and that the lids are tightly sealed to minimize spillage or inter-mingling of contents.

Emergency Procedures

Spill Response

Evacuate the Area: Make sure that all the personnel evacuate the area of the spill so that they do not get in contact with the product.

Contain the Spill: Have barriers such as mats or spill Control kits to ensure that the pellet does not spread all over.

Neutralize the Spill: Use a weak acid solution such as dilute acetic acid or vinegar to neutralize the sodium hydroxide pellets. This facilitates the reduction of the alkaline effect of the substance in the body.

Clean Up Safely: When neutralized, it is advisable to use the right tools to scoop the residue sodium acetate and dump it in the chemical waste bins. Try not to get in direct contact with the substance during this stage of its application.

Ventilate the Area: It is necessary to ventilate the working area to prevent the spread of negative fumes in case of spillage.

First Aid Measures

Rinse Immediately: Wash the affected area with clean running water for not less than 15 minutes.

Remove Contaminated Clothing: Make sure that you do not touch any of the clothing that may have had contact with the pellets.

Seek Medical Attention: While rinsing, use cold water and one should immediately seek the help of a doctor for further tests and treatment.

Flush Eyes: Flush the eyes with warm water for at least 15 minutes with eyes wide open to allow proper washing.

Avoid Rubbing: The patient should avoid rubbing the eyes because such a move will only worsen the situation.

Get Medical Help: In the event of an abnormal sensation or observation, go to the emergency room as soon as possible after rinsing.

Move to Fresh Air: In case of an inhalation affect, remove the victim to an open air environment to allow for proper breathing.

Monitor Breathing: In case of the development of breathing problems, provide oxygen therapy, if possible and call the doctor at once.

It is extremely crucial to ensure the safety when it comes to handling sodium hydroxide pellets. Adopting these measures of safety is essential in preventing all risks that may be found in handling sodium hydroxide pellets and in ensuring that the workplace is safe. We would like to urge you to use these precautions to practice and to remain as safe as possible at all times. To learn more about sodium hydroxide pellets and to view the full Atlas Pellets product list, please click through to our website.

#sodium hydroxide pellet#atlas pellets industries#sodium hydroxide pellet exporters#caustic pellet#best sodium hydroxide pellet#caustic pellets#atlas pellet#sodium hydroxide pellets#sodium hydroxide pellets exporters#sodium hydroxide pellets manufacturer

0 notes

Text

Thermal Energy Storage Market Dynamics: Innovations and Opportunities

Introduction

Thermal energy storage (TES) refers to technologies that provide long-term storage of heat or cold for later use. Unlike conventional batteries, TES systems stock thermal energy by utilizing heat transfer between a storage medium and a heat sink or source. TES promises to deliver energy stability, address intermittency issues associated with renewable sources like solar and wind, and reduce peak demand on generation systems. Need and Applications of Thermal Energy Storage

There are several factors driving the need for widespread implementation of TES technologies. One key factor is the intermittent nature of renewable sources like solar and wind which produce energy only when the sun shines or wind blows. TES allows excess thermal energy generated from such resources to be stored for later use when the source may not be available. Secondly, TES helps address demand-supply mismatch problems as heat can be stored during off-peak generation periods and supplied when demand peaks. This helps shave peak loads on the electric grid and reduce transmission congestion. TES also finds applications in buildings for space cooling and heating by buffering energy from HVAC systems. Other notable uses include industrial process heating/cooling and production of chilled water for air conditioning. TES Materials and Methods

A variety of materials and technologies are used for TES depending on the temperature range and period of storage required. Sensible heat storage systems store energy by altering the temperature of a solid or liquid storage medium like water, molten salts, rocks or phase change materials. Latent heat storage utilizes the heat released or absorbed during phase transition of substances like paraffin wax or water for storage. Thermochemical storage relies on reversible endothermic chemical reactions to store energy in chemical bonds. Other methods include cryogenic storage using liquefied air or hydrogen and temperature gradient exchange using metallic foams. Each approach has its technical and economic viability depending on the application. Commercial Applications of TES

Several commercial TES systems are currently operational worldwide to support solar thermal power plants and process heating applications. Andasol, located in Spain, was one of the first commercial plants to use molten salt storage achieving over 7 hours of full-load energy generation after sunset. Solar One and Solar Two projects in USA demonstrated 10 hours molten salt storage coupled with solar power towers. Industrial process heating levers TES vastly for processes requiring steam or heat treatment. Buildings have begun integrating TES in form of borehole thermal energy storage to provide summer cooling and winter heating. Moving forward, cost reductions through economies of scale and material innovations will make TES increasingly viable across sectors. R&D Focus and Future Potential

Significant research continues to emerge new storage materials, designs targeting specific heat applications and system optimization. PCMs ranging from biobased oils to graphene-enhanced composites are being examined for high density storage. Thermochemical storage employing reversible hydrolysis/dehydration of salt hydrates shows promise at high temperatures. Researchers are also modeling hybrid thermal-electric systems leveraging complementary storage abilities. Government incentives and industry partnerships are supportingseveral large-scale pilot projects worldwide. If technology and installation costs keep declining, TES could emerge as a mainstream approach to store tens of gigawatt-hours of thermal energy in the future. Integrated with solar, waste heat and smart grids, it may play a transformative role in global energy management. Conclusion

In conclusion, thermal energy storage is an important technology that helps maximize renewable energy generation, address intermittency issues and reduce grid loads from peak demand. It enables shifting of thermal loads in time by decoupling energy generation from use through versatile heat storage approaches. With further innovation and cost reductions, diverse TES solutions could soon help transition energy systems towards greater sustainability, flexibility and resilience worldwide. Looking ahead, hybrid multi-applications of TES will undoubtedly maximize its overall techno-economic and environmental benefits.

#Thermal Energy Storage Market Growth#Thermal Energy Storage Market Size#Thermal Energy Storage Market Share

0 notes

Text

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a row x column matrix configuration to enable the delivery of a targeted range of voltage and current for a duration of time against expected load scenarios. Battery management systems do not have a fixed or unique set of criteria that must be adopted.The technology design scope and implemented features generally correlate with:The costs, complexity, and size of the battery packApplication of the battery and any safety, lifespan, and warranty concernsCertification requirements from various government regulations where costs and penalties are paramount if inadequate functional safety measures are in place.HOW BATTERY MONITORING SYSTEM WORK?Monitoring sensors are attached to each of the batteries. The sensor measures individual battery cell voltage charging and discharging current. These data are transferred to a monitoring system controller.Monitoring system controller is where the data are stored and then trended with the battery monitoring software.The software translates data into readable performance data.The controller alerts the user with alarm warnings via email and/or cell phone texts.The software allows user to access battery measurement data and historical data quickly and easily for trending analysis which can be viewed in PC.Identifying problems, performing predictive analysis, and generating simple and clear reports become easy with the help of the battery monitoring software.Our range of products include gauges, switches, transmitters, electric heaters, heat exchangers, flame arresters, rupture discs, rupture pin valves, safety relief valves, strainers, manual / automated valves, solenoid valves, positioners, gas regulators, choke valves, mist eliminators, vibration transmitters, vibration switches, dampers, expansion joints, pipes, tubes, fittings and many more.BMS is defined differently depending on the application. BMS, in general, refers to a management strategy that keeps an eye on, regulates, and improves a person’s performance or the performance of several battery modules in an energy storage system.BMS is used in automotive applications to manage energy at various system interfaces and to protect the system from dangers.BMS is composed of several useful structural components. The functional blocks of the BMS are linked to the batteries and every other element of the structured system, including controllers, a grid, and other dispersed resources.Bliss Flow Systems is a diversified supplier of Engineering products to Chemical, Petrochemical, Oil & Gas, Marine, Off-Shore Platform, Power Generation, Water and Waste Water industries, etc. We distribute the Measuring equipments, Heat transfer equipments, Safety devices, Filtration equipments, Valve automation systems, Condition monitoring systems, Pipes, Plates, Bars, Fittings, Pipeline components and many more …Battery monitoring, e-mobilityState-of-charge, state-of-healthPrototyping, development, test platformFunctional safety

0 notes

Text

Exploring the Benefits of Spring Return Hose Reels in Industrial Settings

Spring return hose reels are mechanical devices used in industrial settings to store and manage hoses efficiently. These reels are equipped with a coiled spring mechanism that automatically retracts the hose back into the reel after use, ensuring neat and organized storage. They are available in various configurations, including wall-mounted, ceiling-mounted, and portable options, and can accommodate hoses of different lengths and diameters. Spring return hose reels are designed to withstand the rigors of industrial environments and are commonly used in applications such as fluid transfer, pneumatic tools, lubrication systems, and firefighting equipment.

Importance of Spring Return Hose Reels Management in Industrial Settings:

In industrial settings, the management of spring return hose reels holds significant importance due to several key factors. These reels serve as crucial components in various operations, facilitating the safe and efficient handling of fluids such as water, oil, air, and chemicals. Proper management of spring return hose reels encompasses several aspects, each contributing to overall productivity, safety, and cost-effectiveness within industrial environments.

Effective management ensures the safety of workers and the integrity of the workplace. Spring return hose reels help prevent workplace accidents by minimizing tripping hazards and reducing the risk of injuries associated with tangled or misplaced hoses. Properly stored and maintained reels contribute to a clutter-free environment, promoting better visibility and organization on the shop floor. By implementing safety protocols and regular maintenance schedules, industrial facilities can mitigate potential risks and create a safer working environment for employees.

The management of spring return hose reels plays a crucial role in optimizing workflow efficiency and productivity. These reels facilitate quick and easy access to hoses, allowing workers to efficiently complete tasks without wasting time searching for or untangling hoses. By streamlining hose deployment and retraction processes, businesses can minimize downtime and maximize operational efficiency. Additionally, the versatility and flexibility offered by spring return hose reels enable their seamless integration into various industrial applications, from manufacturing and construction to automotive and agriculture.

Benefits of Spring Return Hose Reels in Industrial Settings

Spring return hose reels offer several benefits in industrial settings, making them essential equipment for various applications. Here are some key advantages:

Efficient Hose Management: Spring return hose reels provide a convenient and efficient way to store and manage hoses, preventing tangling, kinking, and damage. The automatic retraction feature ensures that hoses are neatly stored away when not in use, reducing clutter and minimizing tripping hazards in the workplace.

Enhanced Safety: By keeping hoses neatly stored and out of the way when not in use, spring return hose reels help improve workplace safety. They reduce the risk of accidents caused by loose hoses lying on the floor, such as trips, falls, and potential injuries from machinery running over hoses.

Extended Hose Lifespan: Proper hose storage provided by spring return reels helps extend the lifespan of hoses by preventing damage from exposure to elements, UV radiation, and abrasion. This can result in cost savings by reducing the frequency of hose replacements and maintenance.

Time and Labor Savings: Spring return hose reels facilitate quick and easy hose deployment and retraction, saving time and labor during setup, operation, and cleanup tasks. Workers can access hoses with minimal effort and without having to manually wind or unwind them, increasing productivity and efficiency.

Space Optimization: In industrial environments where space is limited, spring return hose reels help optimize space utilization by keeping hoses neatly stored in designated locations. Wall-mounted, ceiling-mounted, or portable reel options allow for flexible installation in various workspace configurations.

Versatility: Spring return hose reels are available in a wide range of sizes, configurations, and hose compatibility options, making them suitable for diverse industrial applications. Whether used for water, air, oil, chemicals, or other fluids, there are reel models designed to meet specific application requirements.

Weather and Environmental Protection: Many spring return hose reels feature weatherproof construction and materials, protecting hoses from damage caused by exposure to harsh environmental conditions such as rain, snow, sunlight, and chemicals. This ensures reliable hose performance and reduces the risk of downtime due to hose failure.

Regulatory Compliance: In industries where compliance with safety regulations and standards is critical, spring return hose reels help meet requirements related to hose management, storage, and safety practices. Employing these reels demonstrates a commitment to workplace safety and regulatory compliance.

Conclusion: Spring return hose reels offer numerous benefits in industrial settings, including efficient hose management, enhanced safety, extended hose lifespan, time and labor savings, space optimization, versatility, and weather resistance. By investing in high-quality spring return hose reels tailored to specific application requirements, industrial facilities can improve operational efficiency, mitigate risks, and ensure a safer working environment.

Frequently Asked Questions:

Can spring return hose reels handle high-pressure fluids? Yes, many spring return hose reels are designed to handle high-pressure fluids, but it's essential to choose a reel with the appropriate pressure rating for your specific application.

How do I determine the right hose length for my spring return hose reel? Measure the distance between the fluid source and the point of use, ensuring the hose length is sufficient to reach without excessive slack. Consider any obstacles or bends in the path.

Are spring return hose reels suitable for outdoor use? Yes, many spring return hose reels are designed for outdoor use and are constructed with weather-resistant materials to withstand exposure to the elements.

Do spring return hose reels require regular maintenance? Yes, like any equipment, spring return hose reels benefit from regular maintenance to ensure optimal performance and longevity. This may include lubricating moving parts, inspecting for wear, and replacing worn components as needed.

#industrialengineering#workplacesafety#productivity#efficiency#hosemanagement#safetyprotocols#industrialsolutions#equipmentmaintenance#springreturnhosereels

1 note

·

View note

Text

Harnessing the Power Process Gas and Flare Recovery Ejectors

In the industrial realm, efficiency and environmental responsibility are crucial. Ejectors, ingenious devices without moving parts, are increasingly recognized for their role in achieving both these goals within various processes. This article delves into the world of process gas ejectors and flare recovery ejectors, exploring their functionalities and the impactful benefits they offer.

Understanding Ejectors:

Ejectors, also known as jet pumps or eductor jets, operate based on the fundamental principle of Bernoulli's theorem. This principle states that an increase in the velocity of a fluid stream leads to a decrease in its pressure. Ejectors utilize a high-pressure "motive" fluid, typically steam, water, or gas, to entrain and compress a low-pressure "suction" fluid. This compressed mixture exits the ejector at an intermediate pressure, suitable for further processing or utilization.

Process Gas Ejectors:

Process gas ejectors play a vital role in various industrial applications. They offer numerous advantages:

Efficient Gas Mixing: Ejectors excel at mixing gas streams of varying pressures and compositions. This proves valuable in processes like gas blending, aeration, and reaction systems.

Vacuum Generation: Ejectors can create a vacuum at specific points within a process, enabling activities like material transfer, evacuation of vessels, and degassing operations.

Pressure Boosting: Ejectors can raise the pressure of low-pressure gas streams to meet specific process requirements. This eliminates the need for complex and energy-intensive mechanical compressors in certain situations.

Simple and Reliable Design: Ejectors have no moving parts, minimizing maintenance needs and enhancing operational reliability compared to traditional compressors.

Cost-Effective Operation: The absence of moving parts and lower energy consumption contribute to the overall operational cost-effectiveness of process gas ejectors.

Flare Recovery Ejectors:

In recent years, a growing emphasis has been placed on minimizing environmental impact and conserving valuable resources. Flare recovery ejector play a crucial role in achieving these goals:

Reduced Flaring: These ejectors capture low-pressure gas streams that would otherwise be combusted and wasted through traditional flaring. This recovered gas can be re-utilized within the process, reducing fuel consumption and emissions.

Environmental Benefits: By capturing and re-using gas, flare recovery ejectors significantly contribute to minimizing greenhouse gas emissions and air pollution.

Economic Advantages: Recovering previously flared gas translates to cost savings for companies as valuable resources are not wasted. Additionally, government regulations and emission trading schemes can incentivize companies to adopt flare recovery practices.

Applications:

Process gas ejectors find application in diverse industries, including:

Chemical Processing: Mixing reactants, creating vacuum in reactors

Food & Beverage: Aeration in fermentation processes, degassing liquids

Oil & Gas: Gas boosting, pressure maintenance in pipelines

Pharmaceuticals: Vacuum generation for drying operations

Flare recovery ejectors are particularly beneficial in:

Oil & Gas Production: Recovering gas from storage tanks, wellheads, and processing facilities

Petrochemical Plants: Capturing gas from various process units

Conclusion:

Ejectors, with their simple design, efficient operation, and environmental benefits, are emerging as a valuable tool for various industrial processes. From enhancing process efficiency to minimizing environmental impact, both process gas and flare recovery ejectors contribute to a more sustainable and cost-effective industrial future.

Visit: https://www.crystaltcs.com/ejector-vapour-recovery-unit.php

Contact: +91 253 2941600

0 notes

Text

Safety First: Essential Precautions for Using a Silent Diesel Generator at Home

While silent generators offer a reliable backup during power outages, their quiet operation can sometimes mask potential risks.

So, before you rely on these machines from trusted silent generator suppliers or DG sets suppliers, prioritise safety with these essential precautions:

Deadly Carbon Monoxide:

Silent Killer: Carbon monoxide (CO) is an odourless, colourless gas produced by diesel combustion. Even small amounts can be deadly.

Location, Location, Location: NEVER operate a generator indoors, in basements, garages, or near windows and doors. Always run it at least 15 feet away from your home and in a well-ventilated area, ensuring it's sourced from reputable silent generator suppliers for safety compliance.

Install a CO Detector: Equip your home with a battery-powered CO detector placed near bedrooms and living areas. Regularly check and replace batteries according to manufacturer's instructions.

Electrical Safety:

Professional Installation: Hire a qualified electrician to install your generator and connect it to your home's electrical system safely and according to local codes. Look for qualified professionals recommended by your chosen silent generator suppliers or DG sets suppliers.

Transfer Switch: Ensure a properly installed transfer switch isolates your generator power from the utility grid to prevent backfeeding and potential harm to line workers. Consult your silent generator suppliers for compatible transfer switch options.

Grounding is Crucial: Proper grounding protects against electrical shock. Never operate an ungrounded generator. Ensure your chosen silent generator suppliers provide grounded models for your safety.

Fuel Safety:

Store Fuel Safely: Store only the recommended amount of fuel in approved containers, away from heat sources and direct sunlight. Securely label and store fuel out of reach of children and pets. Silent generator manufacturers often offer fuel storage solutions; inquire about their recommendations.

Refuel with Care: Turn off the generator and let it cool completely before refuelling. Refuel outdoors using a safety funnel to prevent spills. Never smoke or use open flames near the generator or fuel.

Dispose of Waste Properly: Never dispose of used fuel or oil down drains or on the ground. Follow local regulations for proper disposal or recycling. Check with your silent generator suppliers for any specific waste disposal guidelines.

By following these essential precautions, you can harness the power of your silent generator for home, sourced from responsible silent generator suppliers or DG sets suppliers, with confidence. Remember, prioritise safety for yourself, your loved ones, and your property.

0 notes

Text

Maximize Cooking Oil Life In Your Namkeen Factory

Cooking oil is a crucial part of the Namkeen production process, and it is important to take important measures to prevent its deterioration from time to time which helps in reducing waste, expenses, and the possibility of producing food products with a poor flavour.

The frying oil tends to degrade over time due to various factors, such as exposure to heat, light, and air, and the accumulation of food particles and moisture. This degradation can result in the oil becoming awful and unhealthy, which can affect the quality of the namkeen and pose health hazards to consumers.

In this post, we will discuss how to extend the life of cooking oil in commercial frying machines and which company offers most affordable namkeen making machine price.

Because the degradation of oil is a serious problem, the namkeen fryer manufacturers must provide a machine that can help maintain oil quality.

When you are going to buy automatic namkeen fryers you should make yourself aware of various aspects of machines & their environmental requirements. You should choose the best namkeen fryer machine, choose the oil that is ideal for the frying system and product, and follow good oil management to maintain high oil quality.

How can oil go bad?

The deterioration of namkeen frying oil falls into three categories:

1. XEROSIS

Cooking oil and air coming into contact cause this. High temperatures, metal alloys, oil exposed to air over a large surface, sluggish rates of oil turnover, and UV light all catalyse the oxidation reaction. Antioxidants can be used to prevent excessive oxidation from starting and to extend the shelf life of products.

2. HYDROLYSIS

This happens when water and frying oil combine, giving the finished product a strange flavour. Many factors can accelerate hydrolysis, including acids, high temperatures, slow rates of oil turnover, increased number of heating and cooling cycles of the oil, particles in the oil, products of oxidation, caustic soda, metal alloys, and some emulsifiers.

3. POLYMERIZATION

When frying oil degrades, both volatile (or reactive) and non-volatile chemicals are produced as byproducts. The frying oil’s non-volatile chemicals are still there and can cause polymerization. On the oil surface and in other parts of the fryer, these molecules combine to create substantial clusters of various sizes. As they don’t dissolve, they produce foaming (such as when air gets trapped in the oil), raise the risk of hydrolysis, and are challenging to remove from the automatic namkeen fryer.

The selection of oil and its standards

The type of oil you are going to select for your namkeen-making industry will impact the final flavour. As a Namkeen Manufacturer, you are compelled by consumer choice to reduce the number of saturated fats in the finished product.

More oil instability would come from higher levels of unsaturated oils, which is a crucial factor to take into account when choosing continuous namkeen fryers.

Environmental standards are also quite important. Effective oil-handling performance along with appropriate oil storage and transfer equipment must be taken into account because some oils harden in ambient circumstances.

You need to make sure that the oil used is compatible with the way namkeen is fried. Namkeen manufacturers must also ensure that oil specifications are met.

You as a namkeen manufacturer must decide on what to consider to be a minimum standard for oil quality and make sure the supplied oil meets this need.

In countries like India, Bangladesh, Kenya, Uganda, Nigeria, UAE the namkeen machine prices are affordable and in premium quality.

Ways To Maximize Cooking Oil Life

Use high-quality oil

The quality of the oil used in the batch type namkeen fryer machine is critical to its lifespan. Using high-quality oil with low acidity and low moisture content will reduce the chances of the oil becoming rancid. It is recommended to use vegetable oils that are high in unsaturated fats such as sunflower, soybean, or canola oil.

Filter the oil

Filtering the oil regularly will help to remove food particles and other impurities that can contribute to the degradation of the oil. It is recommended to filter the oil daily or after every batch of namkeen snacks. This will not only extend the life of the oil but also improve the quality of the snacks along with affordable automatic sev making machine price.

Store the oil properly

Storing the oil properly is crucial in maximizing its life. The oil should be stored in a cool, dry place, away from heat and light. Exposure to heat and light can accelerate the oxidation process, leading to the oil becoming rancid quickly. It is also recommended to store the oil in a sealed container to prevent the entry of air and moisture.

Monitor the oil temperature

The temperature of the oil is another critical factor in its lifespan. Cooking oil should be maintained at a temperature between 160°C and 180°C. Cooking at higher temperatures will cause the oil to break down quickly, leading to faster degradation. It is recommended to use a thermometer to monitor the oil temperature during the frying process in an automatic namkeen fryer or bhujia maker machine.

Use antioxidants

Antioxidants such as citric acid or ascorbic acid can be added to the oil to slow down the oxidation process. These additives work by neutralizing the free radicals that cause the oil to become rancid. However, it is important to note that the use of antioxidants should be limited to the recommended dosage to avoid affecting the flavour of the snacks. In conclusion, maximizing the namkeen frying oil life in your namkeen-making factory is essential to producing high-quality and healthy snacks. Using the right continuous namkeen fryer, high-quality oil, filtering the oil regularly, storing the oil properly, monitoring the oil temperature, and using antioxidants are some of the ways to extend the lifespan of cooking oil. Economode offers affordable namkeen plant cost without even compromising the qualiy of final product.

0 notes

Text

The Solutions of Odor Removal From Fish Meal Plant

The fish meal processing of the fish meal factory is to use the scraps of aquatic products and some small fish and shrimp to make fish meal for feed through high-temperature steam cooking, pressing, drying, crushing and other processes. Malodorous gas is produced in many links in production, and the odor causes serious air pollution. In particular, some fishmeal production enterprises are generally small in scale, with less investment, relatively backward equipment and technology, irregular operation and management, and more obvious odor pollution.

1.The source of odor from fish meal processing

Organized emission sources: high-temperature cooking exhaust gas of wet drying furnace, drying exhaust gas of dryer;

Unorganized emission sources: raw material storage yard, waste water, waste water treatment station, raw material transfer in production, etc.

Among them, high-temperature cooking, raw material storage yard, and raw material transfer are the main sources of odor. The known components of fish meal odor are mainly acrolein, butyric acid and valeric acid, oil degradation products, hydrogen sulfide, ammonia, and trimethylamine. The concentration of trimethylamine in the waste gas discharged during the processing of fish meal can reach 600mg/m3, hydrogen sulfide can reach 30mg/m3, and the odor intensity is 4000~10000 (fresh fish processing). Up to more than 100,000.

2. Solutions for odor removal from fish meal processing

At present, the general fishmeal odor solution technology on the market can be roughly divided into the following points:

Combustion deodorization

adsorption deodorization

chemical deodorization

dissolution deodorization

biological deodorization

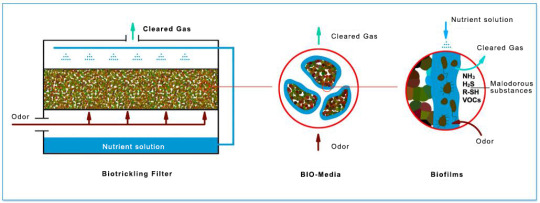

Today we mainly introduce the following biological trickle filter deodorization system launched by our company. Biological trickling filtration is a type of biological filtration. The difference is that biological trickling filtration is equipped with a spray system. Compared with ordinary biological filters, biological trickling filtration can treat higher concentrations of pollutants with higher efficiency.

Through the biofilm absorption and metabolism on the filler, the pollutants in the gas are degraded into odorless and harmless small molecular substances. Moisture and other nutrients required by microorganisms are provided by a circulating trickling filter device. Through the circulation of nutrient solution, the growth environment of microorganisms is controlled. The tunability of the growth environment of microorganisms is the distinguishing feature of biological trickling filtration from other biological filtration technologies.

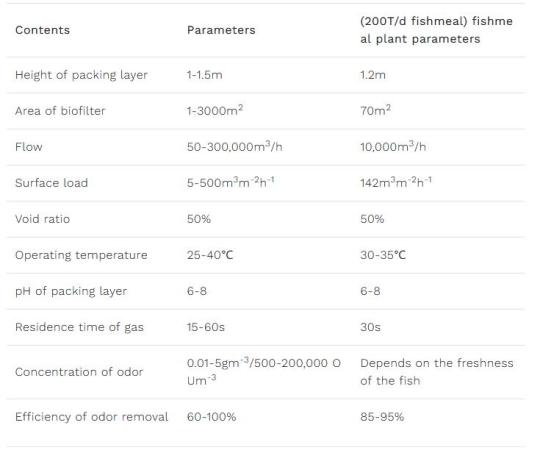

3. Practical application of biological trickling filtration in odor treatment of fishmeal factory

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fish meal and fish oil equipment production lines, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fish meal industry. Based on years of R&D and production experience of fish meal plant www.feedsmachinery.com production lines, Feeds Machinery has launched the Fish Meal Process (FMP), a wet-process fish meal production process, which is suitable for the production of fish meal with a raw material capacity of up to 15 tons/hour and above. The produced fish meal has better quality, high digestibility, low energy consumption and simple operation. If a complete fish meal and fish oil production and treatment system is used, the production capacity can be increased by 5% (the digestibility is increased by 3%), and at the same time, the whole process can be made pollution-free with the biological deodorization solution.

#fishmeal machine#fishmeal plant#fish meal#fish protein#fish oil#fishmeal dryer#fishmeal cooker#fishmeal equipment#fishmeal#fish oil separator

0 notes

Text

Suction Lances: Essential Tools for Efficient Liquid Extraction and Transfer

Suction lances are versatile and essential tools used in various industries for efficient liquid extraction and transfer. These devices are designed to extract liquids from containers, tanks, or reservoirs, and transfer them to other locations, making them a crucial component in many industrial processes. In this article, we will explore the design, functionality, and applications of suction lances, highlighting their importance in various industries.

Design and Construction of Suction Lances

Suction suction pipe are typically designed with a long, thin tube or pipe that is inserted into the liquid to be extracted. The tube is connected to a suction source, such as a pump or vacuum system, which creates a partial vacuum to draw the liquid up the tube. The lance is usually constructed from materials such as stainless steel, aluminum, or PVC, depending on the application and the type of liquid being extracted. The design of the suction lance can vary depending on the specific application, with some lances featuring adjustable lengths, angled or curved tubes, and specialized tips or nozzles.

Functionality of Suction Lances

The primary function of a suction lance is to extract liquids from a container or tank and transfer them to another location. The suction lance is inserted into the liquid, and the suction source creates a partial vacuum to draw the liquid up the tube. The liquid is then transferred to a storage tank, container, or other equipment for further processing or use. Suction lances can be used to extract a wide range of liquids, including water, oil, chemicals, and food products. The efficiency and effectiveness of the suction lance depend on various factors, including the design of the lance, the suction source, and the viscosity and density of the liquid being extracted.

Applications of Suction Lances in Various Industries

Suction lances have a wide range of applications in various industries, including oil and gas, chemical processing, food and beverage, pharmaceutical, and wastewater treatment. In the oil and gas industry, suction lances are used to extract crude oil and petroleum products from storage tanks and transfer them to pipelines or transportation vessels. In chemical processing, suction lances are used to extract chemicals and solvents from reactors and transfer them to storage tanks or other equipment. In the food and beverage industry, suction lances are used to extract ingredients and products from containers and transfer them to processing equipment or packaging lines.

Benefits and Advantages of Suction Lances

Suction lances offer several benefits and advantages, including efficient and effective liquid extraction, reduced spillage and waste, and improved safety. The use of suction lances can also reduce the risk of contamination and improve the overall quality of the extracted liquid. Additionally, suction lances can be designed to handle a wide range of liquids, including corrosive and abrasive materials. The benefits of suction lances are evident in various industries, where they have improved productivity, reduced costs, and enhanced overall system performance.

Challenges and Limitations of Suction Lances

Despite the benefits and advantages of suction lances, there are several challenges and limitations associated with their use. One of the primary challenges is the risk of clogging or blockage, which can occur when debris or sediment accumulates in the tube or suction source. Another challenge is the risk of liquid splash or spillage, which can occur when the lance is inserted or removed from the container. Additionally, suction lances can be prone to wear and tear, particularly when handling abrasive or corrosive liquids.

Maintenance and Troubleshooting of Suction Lances

Regular maintenance and troubleshooting are essential to ensure the optimal performance of suction lances. This includes inspecting the lance for signs of wear and tear, cleaning the tube and suction source to remove debris and sediment, and replacing worn or damaged components. Troubleshooting techniques, such as flow rate measurement and pressure drop analysis, can help identify issues with the lance or suction source. Regular maintenance and troubleshooting can help prevent clogging, blockage, and other issues that can impact system performance.

Conclusion

In conclusion, suction lances are essential tools for efficient liquid extraction and transfer in various industries. The design, functionality, and applications of suction lances make them a crucial component in many industrial processes. While there are challenges and limitations associated with the use of suction lances, regular maintenance and troubleshooting can help prevent issues and ensure optimal system performance. As the demand for efficient and effective liquid extraction and transfer continues to grow, the importance of suction lances will only continue to increase.

0 notes

Text

Waste Management - An Overview

Waste Management is one of the major concerns nowadays. There are many issues in relation to waste management and the result is that we are faced with a lot of waste which needs to be disposed. The waste can be categorized into two categories: organic and inorganic waste. These waste can be generated by different means; these include natural, chemical as well as biological means.

Waste management can be managed at the community level or it can also be managed at the governmental level. At the community level, there are waste management companies which provide complete waste management solutions at the neighborhood or area level. Waste Management can range from residential areas to big cities. These companies provide effective waste solutions to all such areas. However, most of the companies dealing in waste management prefer to deal at the neighborhood or area level.

Waste Management in the city can be dealt with effectively through the service provided by the Solid Waste Management Corporation (WWMC) in UK. The corporation manages and produces waste for both commercial and residential purposes. It is one of the leading service providers in the UK dealing in the management of waste. The main tasks of the company include the collection and storage of solid waste, removal of waste and recycling of waste.

Waste Management companies also provide environmental programs. In these programs, they ensure proper use of waste and disposal of waste. Programs can include water recycling or construction and environmental improvements.

The problems faced by the waste management sector are increasing due to the increase in the population and the growing needs of the people. The waste generated at the end of a manufacturing process can cause environmental pollution. Also, the waste generated in the manufacturing process can pollute the soil where the raw materials have been deposited. And, the waste generated at the plant can pollute the surrounding environment and affect the wildlife.

Waste management is not only limited to the treatment of waste that is generated at a waste site. They also deal with the disposal of waste that has been disposed of. This involves both household waste and industrial waste. The household waste that can be disposed of by the household includes food bags, paper bags, plastic bottles, etc. These can be used to manufacture different products. The industrial waste that can be disposed off by an industry includes oils, grease, thermometers, batteries, computers, electrical appliances, etc.

Waste management is important because it ensures a healthy environment. It helps in keeping the air clean and reduces the emission of waste into the environment. It also reduces the generation of waste in landfill sites and helps in saving energy. There are various waste management companies in the UK and internationally. The services provided by these companies help in keeping the environment clean and helps in saving the environment from the threats posed by environmental issues.

Companies providing waste management services also ensure that the waste is transported in an environmentally safe manner. They also ensure that the waste is packed in a hygienic and efficient manner so that no further environmental issues arise as a result of improper handling or transportation of waste. The waste management services also include installing closed systems for collecting the waste. These closed systems include container or buried ducts, vacuum bottles, and waste transfer devices.

Companies involved in the waste management process include large as well as small scale industries. These industries require timely and efficient service delivery. Moreover, they also face the threats of environmental issues. Therefore, they seek the aid of companies who specialize in environmental issues to handle their waste and environmental compliance issues.

Waste Management also involves recycling and demerits. It is one of the ways to reduce landfill waste and environmental hazards. Waste Management involves taking care of the waste that comes into the country. The waste management system includes collection, transportation, processing and disposal of the waste. Environmentalists consider that it is one of the most important ways of protecting the environment. Waste Management involves taking care of the waste that comes in the country.

The waste management methods help in preventing or reducing the generation of waste. They also help in reducing the generation of landfill waste and environmental hazards. These services are provided at different levels. Basic waste management methods include collection, transportation, processing and disposal. Advanced waste management services involve better understanding of the environment, creation of economic and legal solutions, involvement of business and voluntary action.

#Waste management#Bricks Waste Rubbish Removal#Concrete Waste Rubbish Removal#Soil Waste Rubbish Removal#Skip bins Melbourne#Skip bin provider#Bin hire Services#Skip bin Hire Services#Skip bin Services

1 note

·

View note

Text

Gateway

When you have every option available, you seek to close out those that don’t interest you.

Hauling cargo with the limited space inside this ship seems like a waste, but hauling information as a courier might suit it better. Heavy armor, added safety for those who want it with the firepower to match.

Idea proposed to the rest of the crew, flying colors, the boredom had settled in with the lack of combat or missions we had taken after retrieving the Phoenix. Like a well-oiled machine, Valkyrie and I took to the cockpit and plotted a course to the Empire capital.

Shipyard, designated as SY-2052, a branch of the larger portion carving its way across the planet. Thick mist forming as we approached the landing pad. Wheels down, engines off, we dismounted from the ship and took in the scene. Pad number 551, printed on the memory as the maintenance crew arrived.

“Welcome to Shipyard 2052, how may we assist?” Younger man, his face covered by a see through visor and a bright orange jumpsuit made sure you could not miss him.

“Refuel.”

“Understood, you have one free refuel curtesy of the Empress, after that you will have to buy the fuel like the rest of them.” The man explained as he tapped the order into his PDA. “Is there anything else I can help you with?”

“You have the map for this place?”

“Certainly, here you go.” Uploaded to my storage, the map showed the entire shipyard with several markers for utilities around.

“Thanks.”

“Have a nice day.” The man turned back to his work as I got back to Valkyrie and Nine.

Map shared, the landing pad connected to several of the areas services via an access corridor, engineering to our left, quarters to the front and transport hub to the right, the map showed a job station inside the hub, so we made our way there.

Greying walls with bright adverts blasted across them, the corridor was quiet but a constant flow of cargo moved by overhead on a rail, the markings unreadable from this distance. Scan my hand on the panel, the doors opened up into a large room with several monitors above kiosks of people buying and selling their goods, wherever to be transported or used here.

Scent of food, spices and cigarette smoke, I felt the looks on me as I walked through the crowd to an information desk and tapped my hand on it.

Overly happy greeting before a display showed up with a selection of jobs available.

Locked away from the higher paying ones, lacking the license and training for them, I picked out two jobs that payed out enough to refuel and rearm the gunship if required. Bullets are cheap, but autocannon shells aren’t.

Confirmed with the rest of the squad, a courier job for data and a small cargo run of medicines to a system close by. Gate connection up and running, I confirmed the job and filled the details. Easy to miss between the larger kiosks, a woman in rags sat behind a table covered in weapon parts. Burnt, damaged, unusable, many of the parts would pass as salvage to anyone without the tools to repair them. The woman glanced at me as I looked through the parts.

“See anything you like?” She leaned back against the wall and crossed her arms as the light hit her face, revealing a burn mark across it. “Most of the stuff is useless to the builders around here, too damaged.”

“Do you have a revolver cylinder?”

“A few, yes, what caliber?”

“.44.”

“Going with the classic, I see… Gimme a moment.” She turned around and dug around the cardboard box next to her, finally picking up a cylinder from it and placing it on the table before me.

“There, 50 credits and it’s yours.”

Mild scrapes, but otherwise fine. The Empire reward had contained a small amount of credits amongst everything else, the balance on my end sat around 250 after it had been shared to Valkyrie and Nine. Shake of hands, confirm the sale and credits transferred, I left with the cylinder in my pocket.

“Pleasure doing business.”

Back at the ship, the orange suited man had confirmed the loading of the cargo and fuel; all we had to do was get it to its destination in one piece. Cylinder secured in the armory with the gun, I sat down in the pilot’s seat and went through the preflight checks. Switches hot, the engines spooled up and the cooling systems kicked in, status showing up green on the HUD as we were given the all clear for takeoff.

Stick with the limited speed while in the access corridor; speed up once out of it, the instruments steady and the tank full as I pushed the throttle forward and felt the acceleration push me into the seat. Soon enough in orbit, the navigation systems made it easier to find the gate and know how far it actually was. The sense of scale gets messed up when you’re sitting in the pilot’s seat, everything looks small and close by but the distances are vast and everything is massive.

Hell, even this ship is larger than I think it is. The crew compartment in the back can sit around twelve passengers and the cargo bay fits an ATV along with the few crates we currently have in there.

Back to the task, we approached the gate, even while sitting at 10 kilometers away several larger ships paled in contrast. Signals crossing over everywhere, requests and adverts for those without the drives to get through the gate, the flight control guided us to the correct position for passing through as an electric mist formed between the gate segments.

The ship shook lightly as sparks formed amidst the mist, hit a few more switches on the panel above me and turn the key, Rapidly speeding up spooling from the drives, I lifted the safety cage off the button on my throttle and waited for the green light.

“Atlas, you’re cleared for gate travel. See you on the other side.”

Hit the button, sparks from the gate matched with the ship as it was pulled in. Spark in the dark, the acceleration was heavier than with the normal engines, but stabilized soon after we were in witch space.

Short flight through the darkness, dot of light approaching rapidly from it before the mist started forming around the ship again, the flash happened again and we were in the other system. Could have gone worse, the ship felt a bit heavy before I turned the drives off and switched us back to normal engines.

“Welcome to ZG-522, Atlas.”

“Thank you Control, Atlas resuming own navigation.”

“Skies are clear, safe travels.”

White star, the navigation panel showed a few targets; amongst them was our target, an outpost on nearby planet’s surface. Earthlike, breathing shouldn’t be an issue, we took the short time we had been in the black as enough for the day and headed to the surface.

Storms brewing.

Hi again. So it took me a while to regain my creativity after the last post, but now I have an idea on where to take this short act.

Thank you all for the follows and likes, see you in the next one. Harry

#logs of an android#scifi#science fiction#sci fi & fantasy#fantasy#cyber#cyberpunk#fiction#writing#story#stories

4 notes

·

View notes

Text

HVAC Service Contractors Near by in Vancouver

HVAC Service Contractors Near by in Vancouver

Pioneer Plumbing has built a reputation of honesty with our long time returning customers. We’ve found that “doing the right thing” in all aspects of our company has brought us to where we are today, and will continue to guide us into the future. Don’t hesitate to call and ask us any plumbing, heating, ventilation, or gas related questions. Chances are if you have a tricky issue, we can solve it.

We have a few goals for our clients. One is to be available for you. It is very uncommon that when you call us we are unable to make it within the same day. We give our repeat customers priority service so if you’ve used us before and you have an emergency, we are going to do what we need to, to get someone there.

Two is to be upfront and honest. From our quotes to our service techs on site, we don’t like to beat around the bush. We will let you know our concerns, our recommendations, and our opinions on how we would handle each situation as if it were our own residence where the problem occurred. We won’t tell you the job is only a 2 hour repair when we have had situations where it turned into an all day repair.

Three is to stand behind our installations and repairs. With mechanical work, it is very common for jobs to get larger or go sideways as you get into them. If we give you a quote we will stand true to the price, if we complete a job for you and you are unhappy with the finished product, we will come back and make it right. In return, all we ask is that you communicate with our office respectfully and honestly so that we can make sure at the end of the day you are happy with our services!

So next time you have a plumbing, heating, cooling, or gas question, repair, or installation you would like quoted, give us a call! Were here to help.

HVAC in Vancouver

Just how do you feel with regards to Electric Furnace Repair?

Heating Repair And Regular Maintenance Tips

There are many ways to maintain your furnace system. Odds are, during wintertime months your heater is on throughout the day attempting to keep the house warm. In fact, it is usually on more than it needs to be because it is unable to maintain an operable climate. When troubleshooting and optimizing the heating portion of your furnace system, there are several things to consider.

Change The Air Filter

This subject is what gets talked about the most in talks about furnace maintenance, but is sometimes overlooked. When there is a blockage, you either run the risk of not circulating heat adequately or possibly starting a fire.When the air conditioner filter gets dirty air will not flow through either which suggests the furnace must work overtime and could also mean a likelihood of fire. When the system works overtime, it is more expensive to run. You want eliminate any likelihood of fire. Neither circumstance is good for the pocket book or your well-being..

Try The Blower

Check the blower blades and clean them. A messy fan will work overtime to blow air around and naturally use more energy to preserve the thermostat level you set it at. This implies strain in your furnace system and your wallet since more energy is required to constantly run the blower.

Fire Damper Function

Next, look at the fire damper to make sure it is running the right way. The fire damper is self-explanatory so take note of this aspect.

Look For Holes In The Flex Duct

It is feasible that your ducts have become damaged throughout the years for a variety of reasons. If there are obstructions or the duct has flattened anywhere the furnace system will think the correct temperature has been reached, which can be wrong. Ultimately your equipment will be straining to keep your home cool as you keep on lowering the thermostat to reach cozy settings.

Band Insulation

It is easy to overlook the insulation, but is one of the most common reason for a system malfunctioning. Be sure to check the insulation and validate it has never become unfastened and prompted gaps between the ductwork and the outside. If this happens, your system will not reach ideal temperatures and will work too much to try and accommodate.

Ductwork Needs To Be Connected

Make sure the ductwork is hooked up everywhere to all sections. Disconnected ductwork will allow warm air to escape and naturally add to the running costs.

Check For Leaks In The Return Air Inlets And Zone Dampers

Be sure to make sure return air intakes are dirt free and in good shape or your system will be unbalanced. Look at the zone dampers to check if they are in the right position. Throughout the year we may change the position of the damper for a lot of reasons (i.e. getting into a tight space or arranging for storage). Check to notice that the dampers are in the correct position too.

If that is a tad too much to handle yourself, we suggest you hire an area plumbing business certified for furnace and heating repair. There will be a number of heating companies around you who can care for this all quite competently. The most sage advice we can offer is to establish yearly upkeep for this appliance.

https://www.google.com/maps?cid=16109373416364653742 https://vancouver-plumber.business.site/

https://www.pioneerplumbing.com/

Pioneer Plumbing & Heating Inc

626 Kingsway, Vancouver BC, V5T 3K4 Phone: (604) 872-4946

Business Hours: Sunday Open 24 hours Monday Open 24 hours Tuesday Open 24 hours Wednesday Open 24 hours Thursday Open 24 hours Friday Open 24 hours Saturday Open 24 hours

Types of Heating Systems

Central Heat

Furnaces

The majority of North American households depend on a central furnace to provide heat. A furnace works by blowing heated air through ducts that deliver the warm air to rooms throughout the house via air registers or grills. This type of heating system is called a ducted warm-air or forced warm-air distribution system. It can be powered by electricity, natural gas, or fuel oil.

Inside a gas- or oil-fired furnace, the fuel is mixed with air and burned. The flames heat a metal heat exchanger where the heat is transferred to air. Air is pushed through the heat exchanger by the “air handler’s” furnace fan and then forced through the ductwork downstream of the heat exchanger. At the furnace, combustion products are vented out of the building through a flue pipe. Older “atmospheric” furnaces vented directly to the atmosphere, and wasted about 30% of the fuel energy just to keep the exhaust hot enough to safely rise through the chimney. Current minimum-efficiency furnaces reduce this waste substantially by using an “inducer” fan to pull the exhaust gases through the heat exchanger and induce draft in the chimney. “Condensing” furnaces are designed to reclaim much of this escaping heat by cooling exhaust gases well below 140°F, where water vapor in the exhaust condenses into water. This is the primary feature of a high-efficiency furnace (or boiler). These typically vent through a sidewall with a plastic pipe.

New furnace standards are currently under development by the U.S. Department of Energy, and are due to be finalized in the spring of 2016. The current furnace standards have not been updated since 1987.

Heating system controls regulate when the various components of the heating system turn on and off. The most important control from your standpoint is the thermostat, which turns the system — or at least the distribution system — on and off to keep you comfortable. A typical forced air system will have a single thermostat. But, there are other internal controls in a heating system, such as “high limit” switches that are part of an invisible but critical set of safety controls.

The best gas furnaces and boilers today have efficiencies over 90%

The efficiency of a fossil-fuel furnace or boiler is a measure of the amount of useful heat produced per unit of input energy (fuel). Combustion efficiency is the simplest measure; it is just the system’s efficiency while it is running. Combustion efficiency is like the miles per gallon your car gets cruising along at 55 miles per hour on the highway.

In the U.S., furnace efficiency is regulated by minimum AFUE (Annual Fuel Utilization Efficiency). AFUE estimates seasonal efficiency, averaging peak and part-load situations. AFUE accounts for start-up, cool-down, and other operating losses that occur in real operating conditions, and includes an estimate of electricity used by the air handler, inducer fan, and controls. AFUE is like your car mileage between fill-ups, including both highway driving and stop-and-go traffic. The higher the AFUE, the more efficient the furnace or boiler.

Boilers

Boilers are special-purpose water heaters. While furnaces carry heat in warm air, boiler systems distribute the heat in hot water, which gives up heat as it passes through radiators or other devices in rooms throughout the house. The cooler water then returns to the boiler to be reheated. Hot water systems are often called hydronic systems. Residential boilers generally use natural gas or heating oil for fuel.

In steam boilers, which are much less common in homes today, the water is boiled and steam carries heat through the house, condensing to water in the radiators as it cools. Oil and natural gas are commonly used.

Instead of a fan and duct system, a boiler uses a pump to circulate hot water through pipes to radiators. Some hot water systems circulate water through plastic tubing in the floor, a system called radiant floor heating (see “State of the Art Heating”). Important boiler controls include thermostats, aquastats, and valves that regulate circulation and water temperature. Although the cost is not trivial, it is generally much easier to install “zone” thermostats and controls for individual rooms with a hydronic system than with forced air. Some controls are standard features in new boilers, while others can be added on to save energy (see the “Modifications by Heating System Technicians” section on the heating maintenance page).

As with furnaces, condensing gas-fired boilers are relatively common, and significantly more efficient than non-condensing boilers (unless very sophisticated controls are employed). Oil-fired condensing boilers are uncommon in the U.S. for several reasons related to lower latent heat potential, and potential for greater fouling with conventional fuel oil.

Heat Pumps

Heat pumps are just two-way air conditioners (see detailed description in the cooling systems section). During the summer, an air conditioner works by moving heat from the relatively cool indoors to the relatively warm outside. In winter, the heat pump reverses this trick, scavenging heat from the cold outdoors with the help of an electrical system, and discharging that heat inside the house. Almost all heat pumps use forced warm-air delivery systems to move heated air throughout the house.

A ground-source heat pump heats and cools in any climate by exchanging heat with the ground, which has a more constant temperature.

There are two relatively common types of heat pumps. Air-source heat pumps use the outside air as the heat source in winter and heat sink in summer. Ground-source (also called geothermal, GeoExchange, or GX) heat pumps get their heat from underground, where temperatures are more constant year-round. Air-source heat pumps are far more common than ground-source heat pumps because they are cheaper and easier to install. Ground-source heat pumps, however, are much more efficient, and are frequently chosen by consumers who plan to remain in the same house for a long time, or have a strong desire to live more sustainably. How to determine whether a heat pump makes sense in your climate is discussed further under “Fuel Options.”

Whereas an air-source heat pump is installed much like a central air conditioner, ground-source heat pumps require that a “loop” be buried in the ground, usually in long, shallow (3–6' deep) trenches or in one or more vertical boreholes. The particular method used will depend on the experience of the installer, the size of your lot, the subsoil, and the landscape. Alternatively, some systems draw in groundwater and pass it through the heat exchanger instead of using a refrigerant. The groundwater is then returned to the aquifer.

Because electricity in a heat pump is used to move heat rather than to generate it, the heat pump can deliver more energy than it consumes. The ratio of delivered heating energy to consumed energy is called the coefficient of performance, or COP, with typical values ranging from 1.5 to 3.5. This is a “steady-state” measure and not directly comparable to the heating season performance factor (HSPF), a seasonal measure mandated for rating the heating efficiency of air-source heat pumps. Converting between the measures is not straightforward, but ground-source units are generally more efficient than air-source heat pumps.

Direct Heat

Gas-Fired Space Heaters