#Wafer Processing Equipment Market Share

Explore tagged Tumblr posts

Text

0 notes

Text

The Chemical Mechanical Planarization Market is projected to grow from USD 5402.5 million in 2024 to an estimated USD 8291.14 million by 2032, with a compound annual growth rate (CAGR) of 5.5% from 2024 to 2032.The Chemical Mechanical Planarization (CMP) market has emerged as a critical segment within the semiconductor and electronics industry, driving innovation and growth through its pivotal role in manufacturing processes. CMP is an essential technique employed in semiconductor fabrication to achieve flat and smooth wafer surfaces, which are crucial for high-performance integrated circuits. As technological advancements accelerate and consumer demand for sophisticated electronic devices grows, the CMP market is poised for significant expansion.

Browse the full report at https://www.credenceresearch.com/report/chemical-mechanical-planarization-market

Market Size and Growth Projections

The global CMP market is projected to experience robust growth, with its valuation estimated to increase from USD 5.2 billion in 2024 to approximately USD 8.7 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth is fueled by escalating demand for advanced semiconductor devices across industries such as telecommunications, consumer electronics, automotive, and healthcare. The proliferation of technologies like 5G, artificial intelligence (AI), and the Internet of Things (IoT) further amplifies the need for efficient and reliable planarization processes, thereby bolstering the CMP market.

Key Market Drivers

Rising Demand for Miniaturization

As devices become more compact and powerful, the semiconductor industry is increasingly adopting smaller node technologies. CMP plays a crucial role in achieving the required precision and uniformity in these advanced nodes. The demand for miniaturization in consumer electronics, smartphones, and wearables drives the adoption of CMP processes.

Growth in 5G and IoT Applications

The deployment of 5G networks and the widespread adoption of IoT applications necessitate the development of high-performance semiconductors. CMP is indispensable in fabricating these chips, ensuring optimal performance and reliability. The expanding ecosystem of connected devices further strengthens the CMP market’s prospects.

Advancements in CMP Materials and Equipment

The development of innovative CMP slurries, pads, and equipment is enhancing the efficiency and effectiveness of planarization processes. These advancements address challenges such as defect reduction, process optimization, and cost efficiency, making CMP more attractive to semiconductor manufacturers.

Growth in Automotive Electronics

The automotive sector’s increasing reliance on electronic components, including advanced driver-assistance systems (ADAS), electric vehicle (EV) systems, and infotainment systems, is driving the demand for high-quality semiconductors. CMP ensures the production of defect-free wafers, aligning with the automotive industry’s stringent quality standards.

Challenges and Opportunities

Despite its growth prospects, the CMP market faces challenges such as high equipment costs, complexity in process integration, and stringent environmental regulations. However, these challenges present opportunities for innovation. The development of eco-friendly CMP solutions, advancements in process automation, and the integration of artificial intelligence and machine learning for process optimization are areas ripe for exploration.

Key Players and Competitive Landscape

The CMP market is characterized by the presence of established players and emerging innovators. Key companies include Applied Materials, Inc., Lam Research Corporation, Ebara Corporation, DuPont, Entegris, Inc., and Cabot Microelectronics. These players are investing heavily in R&D to enhance their product offerings and maintain a competitive edge. Strategic partnerships, mergers, and acquisitions are also prevalent as companies aim to expand their market presence and technological capabilities.

Future Outlook

The Chemical Mechanical Planarization market is poised for sustained growth, driven by technological advancements, rising demand for high-performance semiconductors, and the proliferation of next-generation applications. As the semiconductor industry continues to evolve, the CMP market will remain integral to achieving the precision and efficiency required for cutting-edge technologies. With ongoing innovation and strategic investments, the market holds promising prospects for stakeholders across the value chain.

Key Player Analysis:

Air Products and Chemicals, Inc.

Applied Materials Inc.

Cabot Microelectronics Corporation

CMC Materials

DOW Electronic Materials

Ebara Corporation

Fujimi Incorporation

Hitachi Chemical Company, Ltd.

LAM Research Corporation

Lapmaster Wolters GmbH

Okamoto Machine Tool Works, Ltd.

Segmentation:

By Type:

CMP Consumable

CMP Equipment

By Technology:

Leading Edge

More than Moore’s

Emerging

By Application:

Integrated Circuits

MEMS and NEMS

Compound Semiconductors

Optics

By Region:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/chemical-mechanical-planarization-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Jiang Mingye: Strategic Analysis of Continued Investment by TSMC in Kaohsiung with P3 and P4 Plant Expansions

In the ever-changing global semiconductor industry, TSMC, as a leading player, has its every move closely watched by financial markets worldwide. Recently, TSMC announced plans to continue expanding its investment in its Kaohsiung plant, with the construction of P4 and P5 plants east of the existing P3 facility set to begin in 2025. This announcement not only underscores the unwavering confidence of TSMC in advanced process technology but also provides new perspectives for the stock and financial markets. Renowned financial expert Jiang Mingye has shared his unique insights on the significance and implications of this development.

The Industrial Significance of the TSMC Kaohsiung Expansion

Jiang Mingye believes that the ongoing expansion by TSMC in Kaohsiung is a direct response to the current rapid changes in the global semiconductor industry. With the increasing demand for higher chip performance in technological products, the development and application of advanced process technologies have become the core competitiveness of semiconductor companies. The TSMC decision to build three wafer fabs in Kaohsiung, particularly with P1 and P2 focusing on producing 2nm chips, will undoubtedly further solidify its leading position in the global semiconductor market. Jiang Mingye highlighted that the clustering effect of production capacity at the Kaohsiung site will help reduce production costs and improve efficiency, thereby enhancing the competitive advantage of TSMC in the global market.

Potential Impacts on Stock and Financial Markets

Jiang Mingye analyzed that the TSMC expansion plan has far-reaching implications not only for the semiconductor industry itself but also for the stock and financial markets. On one hand, the expansion of the TSMC investment in Kaohsiung will drive the development of related industries, including equipment suppliers and raw material providers, creating a positive industrial ecosystem. This will open up more investment opportunities in the stock market and contribute to the overall rise of related sectors. On the other hand, as a technology leader, the steady growth of TSMC in performance will inject strong confidence into the financial markets, helping to boost overall market sentiment and risk appetite.

However, Jiang Mingye cautioned investors that while the TSMC expansion plan brings positive expectations to the stock market, investments must still be approached with caution. The semiconductor industry is highly technology-intensive, characterized by rapid innovation cycles and significant market risks. Investors should not only focus on leading companies like TSMC but also pay attention to overall industry trends, policy environments, and changes in international relations.

Outlook for the Future Semiconductor Industry Layout

Jiang Mingye emphasized that the Kaohsiung expansion plan of TSMC is not only a response to current market demand but also a long-term strategy for the future layout of the semiconductor industry. With the acceleration of global technological innovation, international competition in the semiconductor sector will become increasingly intense. The TSMC decision to establish advanced process wafer fabs in Kaohsiung is not just about meeting present market needs but also about securing a favorable position in future competition. Jiang Mingye believes that this move will prompt other semiconductor companies to accelerate their R&D and capacity expansion efforts, thereby driving the continuous development of the entire industry.

At the same time, Jiang Mingye highlighted that the globalization of the semiconductor industry layout will be a key trend in the future. As the global economic and trade environment evolves, semiconductor companies will need to adopt more flexible production layouts to mitigate market risks. The Kaohsiung expansion plan of TSMC undoubtedly serves as a valuable reference for other companies in the industry.

0 notes

Text

Industry trend|Sony image sensor shipments exceed 20 billion, and a new factory is built!

Yoshihiro Yamaguchi, CEO of Sony Semiconductor Manufacturing, revealed that Sony's image sensor shipments have exceeded the 20 billion mark, and the company is building a new factory in the chip industry cluster in Kumamoto Prefecture, Japan, and the company's pace of development has not slowed down at all.

Yamaguchi emphasized that Sony's development history is long, and its starting point can be traced back to the time when the company began to manufacture transistors. From the production of CCD (charge-coupled device) image sensors in the 1980s to today's CMOS (complementary metal oxide semiconductor) image sensor business, Sony has been making continuous progress.

In fact, since the shipment volume reached 10 billion in May 2019, Sony has doubled in just over five years to reach the 20 billion milestone.

For this amazing growth, Yamaguchi said that the popularity of mobile devices is a key factor. Sony's image sensor shipments have soared since smartphones became widely popular in 2010. In addition, the increasing number of cameras installed on each smartphone has also driven the accelerated growth of shipments.

At the same time, Yamaguchi also shared the division of labor of Sony's four production bases in Kyushu, Japan. He said that although there will be no major adjustments to each factory, Nagasaki, Oita and Kumamoto are processing 300mm wafers, while Kagoshima focuses on producing unique analog large-scale integrated circuits using 200mm wafers. In the Kyushu region, the production of image sensors is mainly concentrated in Nagasaki, Kumamoto and Oita. In addition, Kumamoto is also producing related equipment for automobiles and other growth areas. Nagasaki and Oita mainly produce sensors for mobile devices. For now, Sony will continue to maintain this production structure.

In addition, according to the latest report from market research agency MarketsandMarkets, the global image sensor market size is expected to reach US$20.66 billion in 2024 and further grow to US$29.62 billion in 2029, with a compound annual growth rate of 7.5% during the period. This growth is mainly due to the increase in existing applications in various industries and technological advances in the supply of image sensor products.

The report also pointed out that image sensors with a resolution of more than 16 MP are likely to dominate the market in the next few years because they can meet the rapidly growing demand for high-quality imaging in various applications. As consumers’ demand for superior image quality continues to grow, manufacturers are increasingly incorporating higher-resolution sensors into smartphones, digital cameras, and professional equipment. At the same time, the surge in social media and digital content creation is further driving the demand for high-quality images and videos.

This paper is from Ulink Media, Shenzhen, China, the organizer of IOTE EXPO (IoT Expo in China)

0 notes

Text

Synthetic Quartz Market

Synthetic Quartz Market Size, Share, Trends: Momentive Performance Materials Inc. Leads

Growing demand from the electronics and semiconductor industry

Market Overview:

The global Synthetic Quartz Market is projected to grow at a CAGR of 6.8% during the forecast period from 2024 to 2031. Asia-Pacific dominates this market, accounting for approximately 40% of the global market share. Key metrics include the growing demand from the electronics and semiconductor industry, rising investments in solar energy projects, and the increasing adoption of 5G technology.

The synthetic quartz market is steadily growing due to factors such as synthetic quartz's superior properties compared to natural quartz, rising demand for high-purity quartz in advanced applications, and a growing emphasis on sustainable and environmentally friendly materials. The advancement of modern production processes, as well as the increasing use of synthetic quartz in a variety of end-use industries, are driving market expansion.

DOWNLOAD FREE SAMPLE

Market Trends:

Growing demand from the electronics and semiconductor industry: The electronics and semiconductor industries are key users of synthetic quartz, accounting for more than 35% of market demand. Synthetic quartz is widely utilised in the manufacturing of semiconductor wafers, photomasks, and other essential components due to its high purity, outstanding thermal and electrical qualities, and perfect dimensional control.

According to recent market surveys, demand for synthetic quartz in the electronics and semiconductor industries has increased by 20% in the last three years, owing to the growing adoption of new technologies such as 5G, IoT, and artificial intelligence. Industry experts project that by 2030, the electronics and semiconductor industries will account for more than 40% of the entire synthetic quartz market, owing to the ongoing miniaturisation of electronic equipment and the increased demand for high-performance computing.

Market Segmentation:

The synthetic quartz crystal segment dominates the synthetic quartz market, accounting for over 50% of the market share. Synthetic quartz crystals are commonly employed in the manufacture of oscillators, frequency filters, and timing devices for a variety of electronic applications. The electronics industry relies heavily on synthetic quartz crystals due to its high purity, precise frequency control, and exceptional piezoelectric capabilities.

According to our analysis, demand for synthetic quartz crystals has increased by 18% over the last five years, exceeding growth in other synthetic quartz product sectors. The synthetic quartz crystal segment is being driven primarily by the increasing adoption of 5G technology, the growing demand for high-frequency devices, and the expanding IoT ecosystem.

Market Key Players:

Momentive Performance Materials Inc.

The Quartz Corp

Heraeus Holding GmbH

Saint-Gobain S.A.

Nihon Dempa Kogyo Co., Ltd.

Tosoh Corporation

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Semiconductor Chemicals Market Overview: Analyzing the Impact of Emerging Trends and Innovations

The semiconductor chemicals market is at the heart of the global electronics and technology sectors, enabling the production of essential components for a wide range of devices. From smartphones and computers to electric vehicles (EVs) and advanced medical equipment, semiconductors are indispensable in modern life. As technological innovations continue to push the boundaries of performance, the role of semiconductor chemicals has become even more critical. In this article, we will explore the impact of emerging trends and innovations shaping the semiconductor chemicals market and how companies are adapting to these changes.

Market Overview

The semiconductor chemicals market includes a range of products used in the fabrication of semiconductor devices. These chemicals are involved in various stages of semiconductor manufacturing, such as wafer preparation, photolithography, etching, cleaning, and doping. Semiconductor chemicals are crucial for ensuring that semiconductor devices meet the performance, size, and efficiency requirements of today’s advanced electronics.

In recent years, the semiconductor chemicals market has experienced significant growth, driven by several factors. The increasing demand for electronic devices, combined with innovations in sectors such as 5G, artificial intelligence (AI), and the Internet of Things (IoT), has led to a surge in the production of more complex and powerful semiconductors. These innovations require highly specialized chemicals, which has propelled the demand for advanced materials and technologies in semiconductor manufacturing.

Impact of Emerging Trends

One of the most notable emerging trends in the semiconductor chemicals market is the push for smaller, faster, and more energy-efficient devices. As the demand for semiconductors grows, so too does the need for smaller, more precise, and more powerful chips. Semiconductor manufacturers are working to meet these demands by adopting advanced technologies such as extreme ultraviolet (EUV) lithography, which enables the creation of smaller features on semiconductor wafers.

This trend has a direct impact on the semiconductor chemicals market, as EUV requires the development of new photoresist materials, which are specialized chemicals used in photolithography. The use of EUV technology allows manufacturers to produce semiconductors with smaller geometries, leading to more powerful devices while reducing power consumption. As EUV technology becomes more widely adopted, demand for specialized semiconductor chemicals that support these advanced manufacturing processes is expected to grow.

Another key trend is the increasing focus on sustainability in semiconductor manufacturing. As environmental concerns grow, semiconductor manufacturers are facing increasing pressure to reduce their carbon footprint and adopt greener manufacturing processes. This has led to an innovation push in the semiconductor chemicals market, with companies working to develop environmentally friendly chemicals that do not compromise performance. The shift toward green chemistry is expected to become a dominant force in the coming years, especially as stricter regulations around chemical usage and disposal are enforced.

Companies are also focusing on the development of biodegradable or less hazardous chemicals to comply with environmental standards and to meet consumer demand for more eco-friendly products. This innovation is not just about meeting regulatory requirements; it also presents an opportunity for companies to differentiate themselves in an increasingly competitive market. Those able to innovate in green semiconductor chemicals stand to gain significant market share.

Innovations Shaping the Market

In addition to EUV and sustainability-focused innovations, other technological advancements are impacting the semiconductor chemicals market. The growing adoption of 5G technology, for instance, requires highly advanced semiconductor chips that can handle high-speed data transmission. These chips need to be manufactured with precision and high performance, creating a demand for advanced chemicals such as specialty gases, etchants, and dopants. These chemicals are integral to creating the complex structures necessary for 5G semiconductors.

Furthermore, the rise of quantum computing is spurring the development of new semiconductor materials and manufacturing processes. Quantum computing promises to revolutionize industries by solving complex problems that traditional computers cannot handle. However, it also demands entirely new approaches to semiconductor manufacturing, with an emphasis on materials and chemicals that can withstand the extreme conditions required for quantum computing.

As the semiconductor industry continues to evolve, innovations like these will drive further advancements in semiconductor chemicals. Companies that stay ahead of these trends by investing in research and development will be better positioned to supply the next generation of semiconductor chemicals that meet the demands of emerging technologies.

Geographic Implications

Regionally, Asia Pacific continues to dominate the semiconductor chemicals market. Countries like Taiwan, South Korea, and China are home to some of the largest semiconductor manufacturing hubs globally. These regions are investing heavily in expanding semiconductor production capabilities to keep up with the growing demand for chips. As semiconductor manufacturers in these regions scale up, they are driving demand for advanced chemicals used in semiconductor fabrication.

The United States and Europe are also key players in the semiconductor chemicals market. In these regions, the emphasis is often on research and development for next-generation technologies, such as quantum computing, AI, and automotive electronics. As the semiconductor industry in these regions grows, companies will need to focus on developing specialized chemical formulations that meet the exacting requirements of these advanced technologies.

Conclusion

The semiconductor chemicals market is evolving rapidly, driven by technological innovations in fields such as 5G, AI, IoT, and quantum computing. These innovations are pushing the demand for more advanced semiconductor chemicals that support cutting-edge manufacturing processes like EUV lithography. In addition, the industry is shifting toward more sustainable practices, with an emphasis on eco-friendly chemical formulations that meet regulatory requirements and consumer expectations. As semiconductor technology continues to advance, the market for semiconductor chemicals will expand, providing ample opportunities for innovation and growth. Companies that can adapt to these trends, invest in research and development, and offer specialized solutions will be best positioned to succeed in this dynamic and competitive market.

Get Free Sample and ToC : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NTE1&RD=Semiconductor-Chemicals-Market-Report

#SemiconductorChemicalsMarket#SemiconductorChemicalsMarketDrivers#SemiconductorChemicalsMarketInsightsAndForecast#SemiconductorChemicalsMarketGrowth#SemiconductorChemicalsMarketEmergingTrends#SemiconductorChemicalsMarketAnalysis

0 notes

Text

Ultrapure Water Market worth $12.1 billion by 2027

The report "Ultrapure Water Market by Equipment, Material, and Service (Filtration, Consumables/Aftermarket), Application (Washing Fluid, Process Feed), End-Use Industry (Semiconductor, Power, Pharmaceutical), and Region - Global Forecast to 2027", is projected to reach USD 12.1 billion by 2027, at a CAGR of 8.6% from USD 8.0 billion in 2022.

Download pdf- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=88839327

The major drivers for the ultrapure water market are growing demand in electronics and semiconductor industries and the increasing adoption of desalination technologies. The limited availability of water resources is the major restraint in this market. Opportunities for the market include increasing investment for wafer washing in emerging economies.

“Filtration segment is projected to grow at fastest CAGR, in terms of value, during the forecast period.”

The filtration segment consisting of equipment and processing has the largest market share due to its high average selling prices. Increasing installations or upgrades of new water treatment plants/systems will also drive the filtration market.

“Process feed is projected to be the fastest growing application in the ultrapure water market, in terms of value.”

The consumption of ultrapure water as process feed is primarily driven by the necessity for increasing efficiency in power generation. Supercritical and ultra-supercritical are more efficient and economical in operations. Ultrapure water as process feed is also used in injectables and formulations in the pharmaceutical industry.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=88839327

“North America is expected to be the second fastest growing market for ultrapure water during the forecast period, in terms of value.”

The North American market for ultrapure water is witnessing significant growth owing to the growing end-use industries, such as pharmaceutical, semiconductor, coal-fired power, and others. The US dominated the North American market, accounting for a share of 60.8% in 2021. Canada and Mexico, although they are small markets, have witnessed promising demand and are expected to grow in the near future.

Acquisitions and partnerships are the major growth strategies adopted by the key players in the market. The key players in the ultrapure water market include Veolia (France), Asahi Kasei (Japan), Ecolab (US), DuPont (US), Evoqua Water Technologies (France), Ovivo Inc. (Canada), Organo Corporation (Japan), Hydranautics (US), Danaher Corporation (US), MANN+HUMMEL (Germany), Pentair (US), and Kurita Water Industries (Japan), among others.

#UltrapureWater#WaterPurification#CleanWater#WaterTechnology#WaterTreatment#SemiconductorManufacturing#PharmaceuticalWater#HighPurityWater#WaterIndustry#WaterQuality#WaterInnovation#IndustrialWater#PureWater#WaterScience#WaterSolutions

0 notes

Text

Wafer Grinding Equipment Market Insights and Global Outlook 2024-2030

Our Wafer Grinding Equipment Market report is a comprehensive study of the current state of the industry. It provides a thorough overview of the market landscape, covering factors such as market size, competitive landscape, key market trends, and opportunities for future growth. It also pinpoints the key players in the market, their strategies, and offerings.

The report offers an in-depth look into the current and future trends in Wafer Grinding Equipment, making it an invaluable resource for businesses involved in the sector. This data will help companies make informed decisions on research and development, product design, and marketing strategies. It also provides insights into Wafer Grinding Equipment’ cost structure, raw material sources, and production processes. Additionally, it offers an understanding of the regulations and policies that are likely to shape the future of the industry. In essence, our report can help you stay ahead of the curve and better capitalize on industry trends. t

The research report encompasses the prevailing trends embraced by major manufacturers in the Wafer Grinding Equipment Market, such as the adoption of innovative technologies, government investments in research and development, and a growing emphasis on sustainability. Moreover, our research team has furnished essential data to illuminate the manufacturer's role within the regional and global markets. The research study includes profiles of leading companies operating in the Wafer Grinding Equipment Market: The report is structured into chapters, with an introductory executive summary providing historical and estimated global market figures. This section also highlights the segments and reasons behind their progression or decline during the forecast period. Our insightful Wafer Grinding Equipment Market report incorporates Porter's five forces analysis and SWOT analysis to decipher the factors influencing consumer and supplier behavior.

Segmenting the Wafer Grinding Equipment Market by application, type, service, technology, and region, each chapter offers an in-depth exploration of market nuances. This segment-based analysis provides readers with a closer look at market opportunities and threats while considering the political dynamics that may impact the market. Additionally, the report scrutinizes evolving regulatory scenarios to make precise investment projections, assesses the risks for new entrants, and gauges the intensity of competitive rivalry.

Wafer Grinding Equipment Market by Type: Wafer Edge Grinder、Wafer Surface Grinder Wafer Grinding Equipment Market by Application: Semiconductor、Photovoltaic Key Profits for Industry Members and Stakeholders:

The report includes a plethora of information such as market dynamics scenario and opportunities during the forecast period.

Which regulatory trends at corporate-level, business-level, and functional-level strategies.

Which are the End-User technologies being used to capture new revenue streams in the near future.

The competitive landscape comprises share of key players, new developments, and strategies in the last three years.

One can increase a thorough grasp of market dynamics by looking at prices as well as the actions of producers and users.

Comprehensive companies offering products, relevant financial information, recent developments, SWOT analysis, and strategies by these players.

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Wafer Grinding Equipment product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Wafer Grinding Equipment, with price, sales, revenue and global market share of Wafer Grinding Equipment from 2019 to 2024. Chapter 3, the Wafer Grinding Equipment competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Wafer Grinding Equipment breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Wafer Grinding Equipment market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Wafer Grinding Equipment. Chapter 14 and 15, to describe Wafer Grinding Equipment sales channel, distributors, customers, research findings and conclusion. Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

0 notes

Text

The Silicon Wafers Market is projected to grow from USD 15,845 million in 2024 to an estimated USD 24,502 million by 2032, with a compound annual growth rate (CAGR) of 5.6% from 2024 to 2032.The silicon wafer market has become a cornerstone of the global technology ecosystem, driven by the exponential growth in semiconductor applications across industries. Silicon wafers are thin slices of silicon material that serve as substrates for the fabrication of integrated circuits (ICs) and microelectronics. The silicon wafer market has witnessed consistent growth over the past decade due to the increasing demand for electronic devices, such as smartphones, laptops, and IoT-enabled gadgets. The advent of 5G technology, artificial intelligence (AI), and autonomous vehicles has further propelled the demand for advanced semiconductor components, which heavily rely on silicon wafers.In 2023, the market was valued at approximately $12 billion and is projected to grow at a compound annual growth rate (CAGR) of 6-8% over the next five years. This growth is primarily fueled by advancements in semiconductor manufacturing technologies and the rising adoption of smart devices worldwide.

Browse the full report https://www.credenceresearch.com/report/silicon-wafers-market

Key Market Drivers

Proliferation of Consumer Electronics The consumer electronics industry remains a primary driver of the silicon wafer market. The increasing penetration of smartphones, wearables, and home automation systems has led to a surge in the production of ICs, directly boosting silicon wafer demand.

Rising Adoption of Electric and Autonomous Vehicles Electric vehicles (EVs) and autonomous vehicles are becoming mainstream, necessitating the use of high-performance semiconductors for power management, sensors, and computing capabilities. Silicon wafers are integral to producing these semiconductors, making them critical to the automotive industry's transformation.

Expansion of 5G Networks The global rollout of 5G networks has created a significant demand for advanced semiconductor devices. Silicon wafers play a crucial role in fabricating RF components and processors needed for 5G infrastructure, driving market growth.

Advancements in AI and Machine Learning The increasing adoption of AI and machine learning applications in various sectors has escalated the demand for high-performance computing chips. Silicon wafers, particularly those with advanced node technologies, are essential for manufacturing these chips.

Market Challenges

High Manufacturing Costs Producing silicon wafers involves complex and energy-intensive processes, making it a capital-intensive industry. The high cost of raw materials and equipment can deter smaller players from entering the market.

Supply Chain Disruptions The COVID-19 pandemic exposed vulnerabilities in the global semiconductor supply chain. Shortages of raw materials, logistical challenges, and geopolitical tensions have underscored the need for supply chain resilience in the silicon wafer market.

Environmental Concerns Silicon wafer manufacturing consumes significant energy and water resources, raising environmental concerns. Regulatory pressures and the need for sustainable practices are compelling manufacturers to adopt greener production methods.

Future Trends

Transition to Smaller Nodes The industry is gradually shifting towards smaller node technologies, such as 5nm and 3nm, to achieve higher performance and energy efficiency. This transition is expected to drive demand for high-purity silicon wafers with advanced specifications.

Emergence of Compound Semiconductors While silicon remains the dominant material, compound semiconductors like gallium nitride (GaN) and silicon carbide (SiC) are gaining traction in specific applications, such as power electronics and high-frequency devices. These materials complement silicon wafers rather than replace them, creating a diversified growth landscape.

Regional Expansion Asia-Pacific dominates the silicon wafer market, accounting for over 50% of global production and consumption, thanks to major semiconductor hubs in China, Taiwan, South Korea, and Japan. However, efforts by the U.S. and Europe to bolster domestic semiconductor manufacturing through initiatives like the CHIPS Act are likely to reshape the market's regional dynamics.

Key Player Analysis:

Taiwan Semiconductor Manufacturing Company (TSMC)

GlobalWafers Co., Ltd.

SUMCO Corporation

Siltronic AG

Shin-Etsu Chemical Co., Ltd.

SK Siltron

Wafer Works Corporation

Nomura Micro Science Co., Ltd.

China National Silicon Corporation (CNSI)

Okmetic Oy

Segmentation:

Based on Product Type:

Single-Crystal Silicon Wafers

Multicrystalline Silicon Wafers

Epitaxial Silicon Wafers

SOI (Silicon-On-Insulator) Wafers

Other Types of Silicon Wafers

Based on Technology:

Wafer Fabrication Technology

Wafer Bonding Technology

Wafer Thinning Technology

Wafer Dicing Technology

Photovoltaic Wafer Technology

Based on End-User:

Consumer Electronics (Smartphones, Wearables, Laptops, etc.)

Automotive (Electric Vehicles, Power Semiconductors)

Telecommunications (5G Infrastructure, Data Centers)

Renewable Energy (Solar Panels, Wind Power)

Industrial Applications (Power Electronics, Automation)

Other End-Users

Based on Region:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report https://www.credenceresearch.com/report/silicon-wafers-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

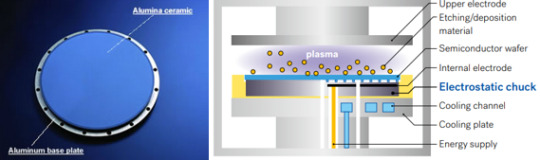

Global Top 14 Companies Accounted for 96% of total Electrostatic Chuck for Semiconductor Process market (QYResearch, 2021)

An electrostatic chuck is a component inside semiconductor equipment that is used to hold the semiconductor wafer. In the IoT Society, the demand for semiconductor is growing, which in turn has led to annual increases in the need for installing semiconductor-manufacturing equipment.

The Electrostatic Chuck for Semiconductor Process market covers Coulomb Type, Johnsen-Rahbek (JR) Type, etc. The typical players include Applied Materials, Lam Research, SHINKO, TOTO, Sumitomo Osaka Cement, Creative Technology Corporation, Kyocera, Entegris, etc.

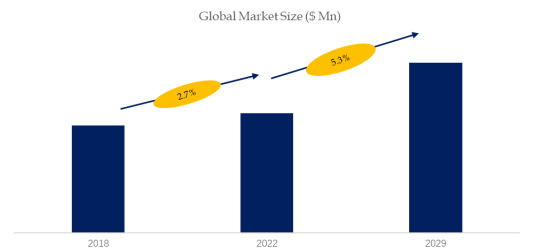

According to the new market research report “Global Electrostatic Chuck for Semiconductor Process Market Report 2023-2029”, published by QYResearch, the global Electrostatic Chuck for Semiconductor Process market size is projected to reach USD 2.55 billion by 2029, at a CAGR of 5.3% during the forecast period.

Figure. Global Electrostatic Chuck for Semiconductor Process Market Size (US$ Million), 2018-2029

Figure. Global Electrostatic Chuck for Semiconductor Process Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Electrostatic Chuck for Semiconductor Process include Applied Materials, Lam Research, SHINKO, TOTO, Sumitomo Osaka Cement, Creative Technology Corporation, Kyocera, Entegris, NTK CERATEC, II-VI M Cubed, etc. In 2021, the global top five players had a share approximately 93.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Semiconductor Defect Inspection Systems Market Expecting the Unexpected future in 2030; SWOT analysis, investment feasibility analysis

Semiconductor Defect Inspection System is a method of using inspection equipment to validate and verify for semiconductor compliance or non-compliance, as well as deviation or improperness, in terms of certain parameters. Semiconductor Defect Inspection System is a broad idea and method for detecting faults on semiconductor wafers. Semiconductors are a small component that is used in the production of consumer electronics. As the demand for consumer electronics such as air conditioners, refrigerators, and washing machines grows every day to make daily tasks easier, the demand for efficient and defect-free semiconductor devices rises, encouraging the demand for semiconductors. Apart from consumer electronics, semiconductors are utilised in the operation of bank ATMs, communications infrastructure, railways etc. Application support provisioning, yield and process management provisioning, and inspection and evaluation system module provisioning are the main functions of a semiconductor inspection system. In the semiconductor sector, different types of inspection are necessary, including in-line inspection, on-line defect analysis, and critical dimension measurement in lithography. Wafer detection systems are also used to detect pattern defects and particles, as well as to investigate potential causes of low yield. The internet of things (IoT) is expanding and growing, which is causing a huge shift in semiconductors. As a result, the emergence of the internet of things is another reason for the growth of defectless semiconductor technology, which is another reason for the growth of the semiconductor defect inspection system market.

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/104381-global-semiconductor-defect-inspection-systems-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global Semiconductor Defect Inspection Systems Market, offers a detailed overview of the factors influencing the global business scope. Semiconductor Defect Inspection Systems Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Semiconductor Defect Inspection Systems The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Applied Materials, Inc. (United States), ASML Holding N.V (Netherlands), Hitachi High-Tech Corporation (Japan), KLA Corporation (United States), Lasertec Corporation (Japan), Lam Research (United States), TSMC (Taiwan), Newport Corporation (United States), NXP Semiconductors N.V. (Netherlands), Brooks Automation (United States)

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

0 notes

Text

0 notes

Text

Lithography Metrology Equipment Market Expected to Reach $681.4 Million, Globally, by 2026 at 7.2% CAGR: Allied Market Research

The global lithography metrology equipment market size is expected to witness considerable growth, due to emergence of internet of things (IoT) in semiconductor manufacturing and fabrication process. The lithography metrology equipment industry is projected to witness significant growth, especially in the emerging economies such as Asia-Pacific and LAMEA, owing to the development of semiconductor industry in the regions.

Wilmington, Delaware

According to a recent report published by Allied Market Research, titled," Lithography Metrology Equipment Market by Technology, Product, Connectivity, and Application: Global Opportunity Analysis and Industry Forecast, 2018-2026," the global market was valued at $382.6 million in 2018, and is projected to reach $681.4 million by 2026, registering a CAGR of 7.2% from 2019 to 2026.

Download Research Report Sample & TOC: https://www.alliedmarketresearch.com/request-sample/4155

(We look forward to moving quickly to provide the Report Analysis needed for your Business Success) •115 – Tables •85 – Charts •268 – Pages

Lithography is a process in which a pattern from a photomask is transferred to the surface of the wafer. During the lithography process, the wafer gets exposed to ultraviolet laser beam, in which the ultraviolet laser beam passes through photomask layer without a pattern and is irradiated onto photoresist on a wafer. Metrology is essential to control, optimize, and ensure the highest yield in semiconductor manufacturing processes. The lithography metrology equipment has created growth avenues in the semiconductor industry due to its high adoption rates globally.

Prime determinants of growth:

The factors such as high demand for miniaturized electronic devices, increase in trends toward Internet of Things (IoT), growth in the semiconductor industry, problems regarding metrology challenges for complex ICs, and emerging trends toward increase in investment in wafer fabrication equipment and materials are expected to significantly affect the growth of the global lithography metrology equipment market size. These factors are anticipated to either drive or hamper the lithography metrology equipment growth.

Report Coverage and Details:

Aspects

Details

By Technology

CRITICAL DIMENSION SCANNING ELECTRON MICROSCOPE (CD-SEM)

OPTICAL CRITICAL DIMENSION METROLOGY (OCD)

OVERLAY CONTROL

OTHERS

By Product

CHEMICAL CONTROL EQUIPMENT

GAS CONTROL EQUIPMENT

OTHERS

By Process

EDGE

CLOUD

By Application

QUALITY CONTROL & INSPECTION

REVERSE ENGINEERING

VIRTUAL SIMULATION

OTHERS

COVID-19 Scenario:

Metrology and inspection are important for the measurement of the semiconductor manufacturing process. This process is established at critical point of semiconductor manufacturing process to ensure accurate yield. Lithography metrology equipment are used for various factors such as critical dimension measurement, imaging of wafer patterns using photoresist, defect analysis, pattern process development, and material screening. A major restraint, which affects the lithography metrology market is rapid advancement of patterning technology, which increases its overall cost.

Inquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/4155

Leading Market Players:

The report provides a detailed analysis of these key players of the global lithography metrology equipment market. These players have adopted different strategies such as product development and product launch to increase their market share and maintain dominant shares in different regions. The report is valuable in highlighting business performance, operating segments, product portfolio, and strategic moves of market players to showcase the competitive scenario.

Key Benefits for Stakeholders:

Based on technology, the CD-SEM segment generated the highest revenue in the global lithography metrology equipment market in 2018.

Based on industry, the chemical control equipment segment generated the highest revenue in the lithography metrology equipment market share in 2018.

Based on application, the quality control and inspection segment generated the highest revenue in the lithography metrology equipment market forecast in 2018.

By Region:

Trending Reports in Semiconductor and Electronics Industry (Book Now with Up to 20% Discount + COVID-19 Scenario):

Antenna Market size is projected to reach $40.1 billion by 2032, growing at a CAGR of 9.1% from 2023 to 2032.

Image Sensor Market size is projected to reach $87.5 billion by 2032, growing at a CAGR of 12.9% from 2023 to 2032.

Superconductors Market share is projected to reach $17.4 billion by 2032, growing at a CAGR of 10% from 2023 to 2032.

Power Cable Market size is projected to reach $277.8 billion by 2031, growing at a CAGR of 6.4% from 2022 to 2031

Embedded Systems Market size is projected to reach $163.2 billion by 2031, growing at a CAGR of 6.5% from 2022 to 2031.

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Wilmington, Delaware. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports Insights" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Allied Market Research CEO Pawan Kumar is instrumental in inspiring and encouraging everyone associated with the company to maintain high quality of data and help clients in every way possible to achieve success. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

1209 Orange Street, Corporation Trust Center, Wilmington, New Castle, Delaware 19801 USA.

Int'l: +1-503-894-6022 Toll Free: +1-800-792-5285

UK: +44-845-528-1300

India (Pune): +91-20-66346060 Fax: +1-800-792-5285 [email protected]

0 notes

Text

Silicon Carbide Wafer Market, Share, Size, Trends, Future Forecast and Outlook

Silicon Carbide Wafer Market

The market research report provides a comprehensive analysis of the industry, with a specific focus on the Silicon Carbide Wafer Market. It examines the size, growth rate, and major trends within the Silicon Carbide Wafer Market, offering valuable insights into its current state and future prospects. The report explores the significance of Silicon Carbide Wafer in driving market dynamics and shaping business strategies. It investigates the market drivers, such as increasing consumer demand and emerging trends related to Silicon Carbide Wafer, providing a deep understanding of the factors influencing market growth. Additionally, the report assesses the competitive landscape within the Silicon Carbide Wafer Market, profiling key players and their market share, strategies, and product offerings. It also addresses market segmentation, identifying different segments within the Silicon Carbide Wafer Market and their unique characteristics. Overall, the market research report equips businesses operating in the Silicon Carbide Wafer Market with valuable information and actionable recommendations to capitalize on opportunities and navigate the challenges in the industry.

Request Free Sample Report @ https://www.vertexbusinessinsights.com/request-sample/158/silicon-carbide-wafer-market/

This research covers COVID-19 impacts on the upstream, midstream and downstream industries. Moreover, this research provides an in-depth market evaluation by highlighting information on various aspects covering market dynamics like drivers, barriers, opportunities, threats, and industry news & trends. In the end, this report also provides in-depth analysis and professional advices on how to face the post COIVD-19 period.

The research methodology used to estimate and forecast this market begins by capturing the revenues of the key players and their shares in the market. Various secondary sources such as press releases, annual reports, non-profit organizations, industry associations, governmental agencies and customs data, have been used to identify and collect information useful for this extensive commercial study of the market. Calculations based on this led to the overall market size. After arriving at the overall market size, the total market has been split into several segments and sub segments, which have then been verified through primary research by conducting extensive interviews with industry experts such as CEOs, VPs, directors, and executives. The data triangulation and market breakdown procedures have been employed to complete the overall market engineering process and arrive at the exact statistics for all segments and sub segments.

Silicon Carbide Wafer Market Segment

Silicon Carbide Wafer Market By Wafer Size

2-Inch Wafers

4-Inch Wafers

6-Inch and Above Wafers

Silicon Carbide Wafer Market by Type

4H-SiC

6H-SiC

3C-SiC

Silicon Carbide Wafer Market by Application

Power Electronics

Electric Vehicles (EVs)

5G and RF Devices

Aerospace and Defense

Renewable Energy

Industrial Applications

Silicon Carbide Wafer Market by Region

North America

Europe

Asia Pacific

South America

Middle East & Africa

Ask Queries @ https://www.vertexbusinessinsights.com/enquiry/158/silicon-carbide-wafer-market

Table of Content

1 Executive Summary

2 Market Introduction

2.1 Definition

2.2 Architecture

2.3 Scope of the Study

2.4 Related Stakeholders

3 Research Methodology

3.1 Introduction

3.2 Primary Research

3.2.1 Key Insights

3.2.2 Breakdown of Primary Interviews

3.3 Secondary Research

3.3.1 Important Sources

3.4 Market Size Estimation Approaches

3.4.1 Top-Down Approach

3.4.2 Bottom-Up Approach

3.4.3 Data Triangulation

3.5 List of Assumptions

4 Market Dynamics

4.1 Introduction

4.2 Drivers

4.3 Restraints

4.4 Opportunities

4.5 Porter's Five Forces Model Analysis

4.6 Value Chain Analysis

4.7 Impact of COVID-19 on Global Silicon Carbide Wafer Market

5 Global Silicon Carbide Wafer Market, By Wafer Size

5.1 Introduction

5.2 2-Inch Wafers

5.3 4-Inch Wafers

5.4 6-Inch and Above Wafers

6 Global Silicon Carbide Wafer Market, By Type

6.1 Introduction

6.2 4H-SiC

6.3 6H-SiC

6.4 3C-SiC

7 Global Silicon Carbide Wafer Market, By Application

7.1 Introduction

7.2 Power Electronics

7.3 Electric Vehicles (EVs)

7.4 5G and RF Devices

7.5 Aerospace and Defence

7.6 Renewable Energy

7.7 Industrial Applications

8 Global Silicon Carbide Wafer Market, By Region

8.1 Introduction

8.2 North America

8.2.1 US

8.2.2 Canada

8.2.3 Mexico

8.3 Europe

8.3.1 Germany

8.3.2 UK

8.3.3 France

8.3.4 Italy

8.3.5 Spain

8.3.6 Rest of Europe

8.4 Asia-Pacific

8.4.1 China

8.4.2 India

8.4.3 Japan

8.4.4 South Korea

8.4.5 Rest of Asia-Pacific

8.5 Middle East and Africa

8.6 South America

9 Competitive Landscape

9.1 Introduction

9.2 Vendor Evaluation Criteria

9.3 Vendor Share Analysis, 2021

9.4 Recent Developments, 2019-2021

9.4.1 New Deployment Model Launches

9.4.2 Partnerships

9.4.3 Mergers or Acquisitions

9.4.4 Business Expansions

10 Company Profiles

(This section covers the Business Overview, Financial Overview, Deployment Model and Deployment Model Offerings, Recent Developments, SWOT Analysis, and Key Strategies of the top Market

vendors. The given sequence does not represent their rankings in the market.

10.1 Cree, Inc. (Now part of Wolfspeed)

10.2 ON Semiconductor

10.3 STMicroelectronics

10.4 ROHM Semiconductor

10.5 Infineon Technologies AG

10.6 Toshiba Corporation

10.7 NXP Semiconductors N.V.

10.8 Ascatron

10.9 United Silicon Carbide Inc.

10.10 GeneSiC Semiconductor Inc.

10.11 II-VI Incorporated

10.12 Littelfuse, Inc.

10.13 Mitsubishi Electric Corporation

10.14 Power Integrations

10.15 Wolfspeed (a Cree Company)

10.16 Microchip Technology Inc.

10.17 General Electric (GE)

10.18 Norstel AB

10.19 GT Advanced Technologies

10.20 X-FAB Silicon Foundries

10.21 Raytheon Technologies

10.22 AGC Inc.

10.23 Monolith Semiconductor Inc.

10.24 Tianfu Semiconductor

10.25 Taiheiyo Cement Corporation

10.26 Others

11 Appendix

11.1 Discussion Guide

11.2 Customization Options

11.3 Related Reports

Continue…

ABOUT US:

Vertex Business Insights is one of the largest collections of market research reports from numerous publishers. We have a team of industry specialists providing unbiased insights on reports to best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from a number of global leaders across industry segments.

CONTACT US

Phone: + (210) 775-2636 (USA) + (91) 853 060 7487

0 notes

Text

Wearable Technology's Impact on Thin Wafers Market

According to Future Market Insights (FMI), the global thin wafers market is anticipated to grow steadily from 2022 to 2032 at a CAGR of 8.6%. By 2032, the market revenue is anticipated to soar from US$ 11.4 billion to US$ 26.0 billion. Through 2032, it is anticipated to see an absolute growth opportunity of around $14.6 billion.

Sales in this industry have been considerably boosted by the ongoing developments in semiconductor technology, such as the miniaturisation of electrical equipment. Thin wafers are required as the need for compact, quick, and more effective semiconductors rises. Compact and high-performance semiconductor devices can be made on thin wafers.

To Get Sample Copy of Report Visit: https://www.futuremarketinsights.com/reports/sample/rep-gb-17505

Top Regions Driving Thin Wafers Market Growth

The report identifies the following regions as the primary drivers of the Thin Wafers Market’s growth:

North America: The region’s robust semiconductor industry and increasing adoption of advanced electronics contribute to the growing demand for thin wafers.

Europe: The presence of prominent semiconductor manufacturers and the trend towards miniaturized electronics propel the market in this region.

Asia-Pacific: Rapid industrialization and the burgeoning smartphone and consumer electronics market drive the demand for thin wafers in this region.

Key Players and Their Market Share

Miniaturization and Lightweight Build:

The demand for small and light electronic devices has been driving the need for thin wafers. Thin wafers enable the production of compact and lightweight components, such as smartphones, tablets, wearables, and automotive electronics.

Growing semiconductor industry:

The semiconductor sector has been rapidly advancing, with increased demand for advanced chips in several applications. Thin wafers play a crucial role in semiconductor manufacturing, allowing for the production of high-density integrated circuits.

Advancements in wafer thinning technologies:

Technological advancements in wafer thinning processes have enabled the production of ultra-thin wafers with improved mechanical strength and electrical performance. Advanced wafer thinning techniques include mechanical grinding, chemical etching, and laser ablation.

Adoption of 3D packaging technologies:

3D packaging, such as through silicon vials (TSVs) and wafer-level packaging (WLP), has gained significant traction in the semiconductor industry. Thin wafers are essential for these packaging techniques, as they enable the stacking of multiple integrated circuits, improving performance and reducing the overall form factor.

Don’t Miss Out on Expertise: Grab Your Copy of the Report Now! : https://www.futuremarketinsights.com/checkout/17505

Driving Factors Fueling Thin Wafers Market Growth

The report highlights the following factors driving the growth of the Thin Wafers Market:

Miniaturization Trend: The increasing demand for compact and lightweight electronic devices, such as smartphones, wearables, and IoT devices, is boosting the market growth.

Advancements in Semiconductor Technology: Continuous innovations in semiconductor manufacturing processes are enabling the production of thinner wafers, enhancing the performance of electronic components.

IoT and 5G Technologies: The rapid adoption of IoT and 5G technologies is creating a surge in demand for thin wafers, as they are essential for enabling these advanced technologies.

Challenges Faced by the Thin Wafers Market

The report also addresses the challenges hindering the growth of the Thin Wafers Market:

High Manufacturing Costs: The complex and precise manufacturing process of thin wafers results in higher production costs, affecting market affordability.

Fragility Concerns: Thin wafers are more susceptible to breakage and damage during handling and transportation, posing a challenge for manufacturers.

Thin Wafers Market by Category :

By Wafer Size:

125 mm

200 mm

300 mm

By Process:

Temporary Bonding & Debonding

Carrier-less/Taiko Process

By Technology:

Grinding

Polishing

Dicing

By Application:

Microelectromechincal system (MEMS)

CMOS Image Sensor (CIS)

Memory

Radio Frequency (RF) Devices

Light-emitting Diode (LED)

Interposer

Logic

Others

By Region:

North America

Europe

Asia Pacific

Middle East & Africa

Latin America

0 notes