#Vinyl Ester Resin News

Explore tagged Tumblr posts

Text

Vinyl Ester Resin Prices Trend | Pricing | News | Database | Chart

Vinyl Ester Resin is a widely used thermosetting resin that offers excellent corrosion resistance, high mechanical strength, and thermal stability, making it an essential component in various industries such as construction, automotive, and marine. The demand for vinyl ester resins has been steadily increasing due to their superior properties, especially in applications that require durability and resistance to chemical degradation. One of the key factors influencing the price of vinyl ester resin is the raw material cost, particularly the price of styrene, which is a key component in the production process. As the cost of styrene fluctuates, it directly impacts the overall cost of vinyl ester resins, which in turn affects pricing trends in the market.

Another important factor affecting the price of vinyl ester resins is the growing demand for composite materials, especially in the automotive, construction, and marine sectors. With the increasing trend toward lightweight materials, there has been a significant rise in the use of vinyl ester resins for the production of composite parts. These parts are used in applications such as boat hulls, wind turbine blades, and automotive components, where high strength-to-weight ratios and resistance to environmental factors are critical. As the demand for these materials continues to grow, so does the pressure on resin producers to meet market requirements, which often leads to higher prices.

Get Real Time Prices for Vinyl Ester Resin: https://www.chemanalyst.com/Pricing-data/vinyl-ester-resin-1293

The economic recovery in many regions has also played a role in shaping vinyl ester resin prices. As industries return to full capacity after the disruptions caused by the pandemic, there has been a surge in demand for various products, including resins. This surge in demand has pushed prices upward, particularly in regions where there is a high concentration of manufacturing activity. Additionally, the recovery of the construction industry, particularly in emerging markets, has also contributed to higher demand for vinyl ester resins, further driving up prices.

Environmental regulations and sustainability concerns are also influencing the pricing of vinyl ester resins. The growing focus on reducing the carbon footprint of manufacturing processes has led to increased investment in the development of eco-friendly resins and additives. While these innovations may ultimately lead to more sustainable options in the long term, the cost of research and development, as well as the initial production of these eco-friendly alternatives, has contributed to price increases in the short term. As governments and regulatory bodies around the world continue to impose stricter environmental standards, resin manufacturers are being pushed to adapt to these changes, which often leads to increased production costs and, consequently, higher prices.

In addition to the factors mentioned above, fluctuations in the global supply and demand balance have a direct impact on the prices of vinyl ester resins. Regional market conditions, such as the availability of production facilities and transportation infrastructure, can cause significant price variations between different markets. For example, in areas where production facilities are abundant, resin prices may be relatively stable, while regions that rely heavily on imports may experience price hikes due to transportation and tariff costs. Moreover, local competition and market dynamics play a crucial role in determining how prices evolve over time. In regions with multiple resin suppliers, increased competition may help stabilize or lower prices, while monopolistic or oligopolistic markets may see higher prices due to limited supplier options.

The rise in the use of vinyl ester resins in new and innovative applications, such as in the renewable energy sector, is another factor influencing the price trend. Vinyl ester resins are increasingly being used in the production of wind turbine blades, solar panels, and other renewable energy components due to their superior mechanical properties and resistance to environmental degradation. As the demand for renewable energy grows globally, so does the demand for these resins, which has further contributed to price increases in the market. Additionally, the ongoing development of more advanced materials for use in renewable energy applications has led to the need for specialized resins that offer enhanced performance, further impacting pricing.

Looking forward, vinyl ester resin prices are expected to continue to be influenced by a variety of factors. The ongoing global economic recovery, fluctuations in raw material costs, and increased demand for composite materials are likely to keep prices volatile in the short to medium term. However, advancements in resin manufacturing techniques and the development of more sustainable and cost-effective alternatives could help stabilize prices in the future. As industries continue to seek more efficient and environmentally friendly solutions, the evolution of vinyl ester resin technology will play a critical role in shaping the pricing landscape for years to come. Manufacturers and consumers alike will need to stay informed about market trends and anticipate shifts in pricing to make strategic decisions in their respective sectors.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Vinyl Ester Resin#Vinyl Ester Resin Price#Vinyl Ester Resin Prices#Vinyl Ester Resin Pricing#Vinyl Ester Resin News

0 notes

Text

Tianma group: the outstanding leader in the field of epoxy vinyl ester resin

In the field of chemical materials, epoxy vinyl ester resin as a high-performance materials is increasingly widely concerned. Tianma group, as a leading enterprise in the industry, has shown unique advantages in the R & D, production and application of epoxy vinyl ester resin.

Epoxy vinyl ester resin itself has a series of remarkable characteristics. This resin combines the advantages of epoxy and unsaturated polyester resins and has excellent chemical resistance. No matter it is attacked by strong acid, strong alkali or organic solvent, it can show excellent tolerance, so it becomes the first choice in chemical industry, environmental protection and electronic industry. At the same time, it has good mechanical properties, strength and toughness of the perfect combination of products made by it can withstand greater stress and strain, in the long-term use of the process is not easy to break or damage. Moreover, the epoxy vinyl ester resin also has the characteristic of low shrinkage, which is a huge advantage in the molding process, can guarantee the dimensional accuracy and stability of products, especially suitable for manufacturing precision mold and high-end electronic packaging and other demanding precision fields.

Tenma group in the field of epoxy vinyl ester resin has significant advantages. Since its establishment in 1960, Tianma Group has a profound technical background and rich production experience. The group has invested a lot in R & D, and its professional r & D team continuously improves and innovates the epoxy vinyl ester resin. Through precise formula adjustment and advanced production technology, Tianma Group can produce high-quality epoxy vinyl ester resin products, strict control of product quality, ensure that each batch of resin can meet international standards and customer specific needs.

Tianma group's production capacity can not be underestimated. Its strong production facilities to ensure a stable supply of epoxy vinyl ester resin, annual output of up to [ x ] tons, enough to meet the needs of large-scale industrial production. In addition, the group can also provide customized services according to the diverse needs of customers, whether specific chemical performance requirements or specific physical performance indicators, tianma group can be achieved by adjusting the production process and formula.

In the application field, Tianma Group provides customers with a full range of technical support. Its team of technical experts can assist customers to apply epoxy vinyl ester resin to different scenarios, whether it is complex industrial equipment corrosion resistance, high-performance construction materials, or high-precision electronic component packaging, tianma group can ensure that the resin in the use of the process to play the best performance.

Tianma group in the field of epoxy vinyl ester resin outstanding performance, not only for their own wide market praise, but also to promote the development of the entire industry has made a positive contribution. With the increasing demand for high performance materials, Tianma Group will continue to give full play to its advantages and lead epoxy vinyl ester resin to a new stage of development.

0 notes

Text

Vinyl Ester Resin Suppliers India | Vinyl Ester Resin Dealer in India

Orson Resins and Coatings Private Limited (ORCPL) is a leading supplier and dealer of vinyl ester resin in India. Vinyl ester resin is a type of thermosetting resin that is made from the polymerization of bisphenol A and methacrylic acid. It is known for its high strength, durability, and corrosion resistance. Vinyl ester resin is used in a wide range of applications. ORCPL is one of the few Vinyl Ester Resin Suppliers India and Vinyl Ester Resin Dealer in India that has a dedicated R&D center. This allows the company to develop new and innovative vinyl ester resin products that meet the specific needs of its customers. For example, ORCPL has developed a range of vinyl ester resins that are specifically designed for use in renewable energy applications such as solar panels and wind turbines. If you are looking for a reliable and reputable supplier and dealer of vinyl ester resin in India.

#VinlEsterresinsupplier#Vinlesterresindealer#supplierofindia#dealerofindia#topsupplier#orcpl#orcplmanufacturer#orcplsupplier

0 notes

Text

Navigating Regulatory Frameworks in the Itaconic Acid Market

Itaconic Acid: A Versatile Platform Chemical for the Global Market Production and Applications of Itaconic Acid Itaconic acid is mainly produced through the fermentation process of certain fungi strains. Aspergillus itaconicus and Aspergillus terreus are the most commonly used fungal strains for industrial-scale production of itaconic acid through fermentation. The fermentation process involves growing the fungal culture in a growth medium containing various nutrients under controlled conditions. Glucose is predominantly used as the primary carbon source in the growth medium. After several days of fermentation, itaconic acid is extracted from the fermentation broth using various separation technologies. The global production of itaconic acid reached over 25,000 tons in 2021. China is currently the leading producer with over 60% share of global capacity. Other major producers include South Korea, Italy, Germany, and the United States. However, the demand is growing steadily at over 5% each year due to its wide range of applications. Major application areas of itaconic acid include polymers & resins, adhesives, sealants & coatings, and detergents & cleaners among others. Polymer and Resins Industry Remains Largest End-user The polymer and resins sector accounts for nearly 45% of the total itaconic acid consumption globally. Itaconic acid acts as an excellent comonomer for producing various specialty polymers like acrylic latexes, polyesters, and polyurethanes. It enhances various properties of polymers like adhesion, toughness, heat stability, and degradation resistance. Some key polymers where itaconic acid finds major usage include vinyl itaconate latexes, polyitaconates, and polyitaconate esters. Itaconic acid is also widely used in the production of unsaturated polyester resins (UPRs). As a co-monomer, it improves various properties of UPRs such as hydrolytic stability, weather resistance, and toughness. UPRs produced using itaconic acid exhibit superior water resistance, high strength, and resistance to cracking. They are extensively used in the manufacturing of fiberglass products, baths & showers, pipes & tanks, and other industrial applications. Adhesives Industry Offers Lucrative Opportunities The adhesives industry has emerged as another prominent end-user industry for itaconic acid, accounting for over 20% of global consumption. Itaconic acid acts both as a reactive diluent and co-monomer in improving the overall performance of adhesive formulations. When used as a co-monomer, it improves the adhesion strength of acrylic adhesives along with their heat resistance and aging properties. Detergents Industry Offers New Avenues for Growth Rising usage of itaconic acid as a co-monomer in the production of various detergent polymers is opening new growth areas. When copolymerized with acrylic acid, itaconate-based detergent polymers exhibit exceptional cleaning efficiency along with other properties like dispersibility and thickening ability. They are suitable for versatile applications in laundry detergents, automatic dishwasher detergents, industrial & institutional cleaners and hard surface cleaners. Regulatory Approvals and Capacity Expansions To tap growing opportunities, major itaconic acid producers are actively pursuing capacity expansions and new plant investments globally. In 2021, several large projects were announced in Asia and Europe expanding total annual capacity to beyond 50,000 tons by 2024. Besides, regulatory approvals are enabling new applications. Also, approval for usage in personal care products helped penetrate new markets. With its renewable and sustainable production via fermentation, itaconic acid is gaining preference over petrochemical-based alternatives. If favorable regulatory, economic and market conditions persist, analysts project global itaconic acid capacity to double and surpass 10 billion by 2030. The future certainly looks promising for itaconic acid to establish itself as a critical platform chemical globally.

0 notes

Text

Specialty Polymers Market - Forecast (2023 - 2028)

Specialty Polymers Market size is estimated to reach US$248.1 billion by 2027, after growing at a CAGR of 6.5% during the forecast period 2022-2027. Specialty polymers are derived from natural polymers, semisynthetic polymers and synthetic macromolecule polymers. Specialty polymers have advantageous characteristics, such as improved gas barrier performance, flame resistance and heat stability. They are thus frequently used in a variety of applications, including polymers, resins, monomers, intermediates and more. The booming transportation industry is the primary factor driving the growth of the specialty polymers market. According to the Organisation Internationale des Constructeurs d'Automobiles, in 2020, the global automotive production was 77,711,725 units and in 2021, it was 80,145,988 - an increase of 3%. Also, the growth in construction activities worldwide would fuel the demand for specialty polymers. The COVID-19 pandemic, on the other hand, hampered the growth of the specialty polymers industry. This was due to the halt in industrial activities associated with automotive, building & construction and more in 2020. Nonetheless, the increase in industrial production activities in 2021 fueled the growth of the Specialty Polymers industry.

Report Coverage

The "Specialty Polymers Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Specialty Polymers Market.

By Source: Natural, Semisynthetic and Synthetic. By Form: Solid and Liquid. By Type: Specialty Elastomers (Fluoroelastomers, Fluorosilicone Rubber, Liquid Silicone Rubber, Natural Rubber and Others), Specialty Thermoplastics (Polyolefins, Polyimides, Vinylic Polymer, Polyphenyles and Others), Specialty Thermosets (Epoxy, Polyester, Vinyl Ester, Polyimides and Others), Biodegradable Polymers, Conducting Polymers, Liquid Crystal Polymers and Others. By End-use Industry: Building & Construction (Residential, Commercial, Industrial and Infrastructure), Transport [Automotive {Passenger Vehicles (PV), Light Commercial Vehicles (LCV) and Heavy Commercial Vehicles (HCV)}, Aerospace (Commercial, Military and Others), Marine (Passenger, Cargo and Others) and Locomotive], Textile, Food & Beverages (Fruits & Vegetables, Meat, Confectionery, Bakery Products, Dairy Products, Alcoholic Beverages, Non-alcoholic Beverages and Others), Electrical & Electronics (Computers, Smartphones, Semiconductors, Wires and Others), Cosmetics & Personal Care (Hair Care, Skin Care, Perfumes & Fragrance and Others) and Others. By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World [the Middle East (Saudi Arabia, the UAE, Israel and the Rest of Middle East) and Africa (South Africa, Nigeria and the Rest of Africa)].

Key Takeaways

Asia-Pacific dominated the Specialty Polymers Market, owing to the growth of the automotive industry in the region. According to the Society of Indian Automobile Manufacturers (SIAM), in 2020, the total automobile production in India was 22,655,609 units and in 2021, it was 22,933,230 units - an increase of 1.2%.

The increasing research & development associated with Specialty Polymers would create an opportunity for market growth during the projected forecast period.

Moreover, the surging application of Specialty Polymers as resins, monomers and intermediates in the textile and cosmetics & personal care industries is driving the market growth.

However, the higher price of Specialty Polymers may confine the growth of the Specialty Polymers industry in the upcoming years.

#Specialty Polymers Market#Specialty Polymers Market size#Specialty Polymers Market trends#Specialty Polymers Market forecast#Specialty Polymers Market report#Specialty Polymers Market research

0 notes

Text

Shaping the Future: Exploring the Applications of Polymer Concrete

Polymer concrete is a composite material that combines aggregates (such as gravel or sand) with a polymer binder to create a durable and high-performance construction material. It offers superior mechanical properties, chemical resistance, and durability compared to traditional concrete. The polymer binder used in polymer concrete can be epoxy, polyester, vinyl ester, or other resins. This versatile material finds applications in various industries, including construction, infrastructure, industrial, and residential sectors.

Market Overview:

The global polymer concrete market has witnessed significant growth in recent years and is expected to continue expanding at a considerable rate. Factors such as increasing infrastructure development, the need for durable construction materials, and growing awareness about the advantages of polymer concrete are driving market growth. Additionally, the rising focus on sustainable and eco-friendly construction practices has further boosted the demand for polymer concrete.

Key Market Segments:

By Type:

a. Epoxy Polymer Concrete b. Polyester Polymer Concrete c. Vinyl Ester Polymer Concrete d. Others

By Class:

a. Polymer-Modified Concrete (PMC) b. Polymer-Impregnated Concrete (PIC) c. Polymer-Cement Concrete (PCC)

By Application:

a. Industrial Tanks & Containments b. Pump Bases c. Waste Containers d. Flooring Blocks e. Trench Drains f. Bridge Drains g. Others

By End-Use Industry:

a. Construction b. Infrastructure c. Industrial d. Residential e. Others

Regional Analysis:

The polymer concrete market can be segmented into several key regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Each region has its market dynamics and growth drivers. Currently, Asia Pacific is the largest market for polymer concrete due to rapid urbanization, increasing construction activities, and infrastructural development in countries like China, India, and Southeast Asian nations. North America and Europe are mature markets for polymer concrete, with a steady demand driven by infrastructure renovation and repair projects.

Key Market Players:

Several prominent companies operate in the polymer concrete market. These companies actively participate in research and development activities, product innovation, and strategic collaborations to strengthen their market position. Some of the key players in the polymer concrete market include:

BASF SE Sika AG MAPEI S.p.A. ACO Group Forte Composites Inc. ErgonArmor Crown Polymers Corp. Sauereisen Inc. Bechtel Corporation Wacker Chemie AG

Competitive Landscape:

The polymer concrete market is competitive and fragmented, with numerous local and international players. Market participants focus on product development, technological advancements, and expansion into emerging markets to gain a competitive edge. Mergers and acquisitions, partnerships, and collaborations are also common strategies employed by companies to strengthen their market presence.

Future Outlook:

The polymer concrete market is projected to witness continued growth in the coming years. Factors such as urbanization, infrastructure development, and the increasing demand for durable and sustainable construction materials will drive market expansion. Furthermore, ongoing advancements in polymer technology and the introduction of new product formulations will provide additional growth opportunities for market players.

Conclusion:

The polymer concrete market is a rapidly growing industry, driven by the need for durable and high-performance construction materials. With its exceptional mechanical properties and chemical resistance, polymer concrete is increasingly adopted in various applications across different sectors. As infrastructure development and construction activities continue to rise, the demand for polymer concrete is expected to expand further, presenting lucrative opportunities for market players in the years to come.

0 notes

Text

Corrosion Resistant Resin Market: Exploring the Lucrative Opportunities and Challenges

The corrosion resistant resin market is a segment of the overall resin industry that specializes in the production and distribution of resins designed to withstand corrosion. These resins are formulated with specific properties that make them highly resistant to chemical attack, moisture, and other corrosive elements. They find extensive application in various industries where protection against corrosion is critical, such as oil and gas, automotive, marine, infrastructure, and electronics.

Corrosion resistant resins are primarily used as coatings and linings for protecting metal surfaces from degradation caused by corrosion. They provide a protective barrier that prevents direct contact between the metal substrate and corrosive agents, thereby extending the lifespan and enhancing the performance of the coated surfaces.

The market for corrosion resistant resins has witnessed significant growth in recent years due to various factors. One of the key drivers is the increasing demand for corrosion protection solutions across different industries. With the rising awareness about the detrimental effects of corrosion on infrastructure and equipment, there is a growing emphasis on preventive measures, leading to a higher adoption of corrosion resistant resins.

Furthermore, stringent environmental regulations and safety standards imposed by regulatory authorities have further propelled the market growth. Corrosion resistant resins offer eco-friendly and sustainable alternatives to traditional coating materials, which contain hazardous substances.

The market for corrosion resistant resins can be segmented based on resin type, end-use industry, and geography. The commonly used resin types include epoxy, polyester, polyurethane, and vinyl ester resins. Each resin type offers distinct advantages in terms of chemical resistance, adhesion properties, and durability.

In terms of end-use industries, the corrosion resistant resin market caters to various sectors. The oil and gas industry is a major consumer of corrosion resistant resins, as it involves harsh operating conditions and exposure to corrosive substances. Other key end-use industries include automotive, marine, infrastructure (including bridges, pipelines, and storage tanks), electronics, and water treatment.

Geographically, the market is spread across different regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America and Europe have traditionally been significant markets for corrosion resistant resins due to the presence of well-established industries and stringent regulatory standards. However, the Asia Pacific region is witnessing rapid growth in the market due to the increasing industrialization and infrastructure development activities.

Key players operating in the corrosion resistant resin market include multinational corporations as well as regional manufacturers. These companies are engaged in research and development activities to introduce innovative and technologically advanced products to cater to the evolving needs of end-use industries. Strategic partnerships, mergers and acquisitions, and expansion of production capacities are some of the common strategies adopted by market players to strengthen their market presence.

Overall, the corrosion resistant resin market is expected to witness steady growth in the coming years. The increasing focus on corrosion prevention and the demand for durable and long-lasting protective coatings are anticipated to drive the market further. With ongoing advancements in resin formulations and growing applications across industries, the corrosion resistant resin market presents lucrative opportunities for both existing players and new entrants in the market.

#Corrosion Resistant Resin Market#Corrosion Resistant Resin Market Growth#Corrosion Resistant Resin Market Trends

0 notes

Text

Vinyl Ester Resin Prices | Pricing | Trend | News | Database | Chart | Forecast

Vinyl Ester Resin Prices a versatile and high-performance material widely used in various industrial applications, has seen fluctuating prices influenced by multiple factors over recent years. As a type of synthetic resin, vinyl ester is renowned for its excellent corrosion resistance, high strength, and durability, making it a popular choice in industries such as marine, automotive, and construction. Its ability to withstand harsh environmental conditions and provide a robust barrier against chemical exposure has solidified its place in the market.

The pricing of vinyl ester resin is primarily influenced by raw material costs, production processes, and market demand. The resin's production involves complex chemical processes and the use of specialized raw materials, including epoxies and unsaturated polyesters, which contribute to its cost structure. Variations in the prices of these raw materials, driven by global supply chain dynamics and economic conditions, directly impact the final price of vinyl ester resin. Additionally, fluctuations in crude oil prices, as vinyl ester resins are partially derived from petrochemical sources, can lead to price volatility.

Get Real Time Prices for Vinyl Ester Resin: https://www.chemanalyst.com/Pricing-data/vinyl-ester-resin-1293

In recent years, there has been a noticeable trend towards increasing vinyl ester resin prices. This rise can be attributed to several factors, including the growing demand for high-performance materials in emerging markets and advancements in resin technology. As industries continue to push for more durable and efficient materials, the demand for vinyl ester resins has surged, placing upward pressure on prices. Moreover, the production of vinyl ester resins involves a significant amount of energy and specialized equipment, contributing to the overall cost. As energy costs rise and technological advancements drive changes in production methods, these factors can lead to fluctuations in resin prices.

The global supply chain has also played a crucial role in shaping vinyl ester resin prices. Disruptions caused by geopolitical events, trade policies, and logistical challenges can impact the availability of raw materials and affect production timelines. For instance, natural disasters or political instability in key supplier regions can lead to shortages and drive up costs. Additionally, transportation issues and increased shipping costs further exacerbate price fluctuations.

Furthermore, the competition among resin manufacturers can influence pricing strategies. Major players in the vinyl ester resin market often adjust their prices based on production capacity, market share, and strategic business goals. This competitive landscape can lead to price variations as companies seek to maintain profitability while responding to market demands.

The end-use applications of vinyl ester resin also contribute to its pricing structure. In sectors where high performance and specific properties are essential, such as aerospace or high-end automotive, the resin may command a premium price due to its specialized formulation and performance attributes. Conversely, in more commoditized applications, price sensitivity may lead to more competitive pricing strategies.

To manage the impact of rising vinyl ester resin prices, manufacturers and end-users often explore alternative solutions. Innovations in resin formulations, including the development of more cost-effective or sustainable alternatives, can provide options for reducing material costs. Additionally, bulk purchasing and long-term supply agreements can help mitigate price fluctuations and ensure a more stable cost structure.

In conclusion, vinyl ester resin prices are shaped by a complex interplay of raw material costs, production processes, market demand, and global supply chain dynamics. As industries continue to evolve and demand for high-performance materials grows, the pricing landscape for vinyl ester resin will likely remain dynamic. Understanding the factors that drive resin prices and exploring strategies to manage costs can be crucial for businesses seeking to navigate this ever-changing market.

Get Real Time Prices for Vinyl Ester Resin: https://www.chemanalyst.com/Pricing-data/vinyl-ester-resin-1293

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Vinyl Ester Resin#Vinyl Ester Resin Price#Vinyl Ester Resin Prices#Vinyl Ester Resin Pricing#Vinyl Ester Resin News

0 notes

Text

"Growing Awareness of the Environmental Benefits of FRP Rebar Drives Market Expansion"

The report "FRP Rebar Market by Fiber Type (Glass, Carbon and Basalt), Resin Type (Vinyl Easter, Epoxy), Application (Highways, Bridges & Buildings; Marine Structurers & Waterfronts Water Treatment Plants) and Region - Global Forecast to 2027" is expected to grow from USD 211 million in 2022 to USD 389 million by 2027, at a CAGR of 13.0% during the forecast period. The growing demand from the construction industry is driving the demand for FRP rebars and thereby growth of the market.

Download PDF Brochure of the report: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=77486355

Browse 250 market data Tables and 34 Figures spread through 199 Pages and in-depth TOC on "FRP Rebar Market”

GFRP rebars fibers account for the largest share in terms of value and volume.

GFRP rebars have the largest market share in the overall FRP rebar market globally. It is mostly used for reinforcement and strengthening various structures. The applications of GRFP include construction of bridges, highways, roads, & buildings, marine structures and waterfronts, and water treatment plants. The other applications include the construction of MRI rooms, parking structures, decks, and swimming pools. The high usage and growth can be attributed to its superior properties such as high tensile strength, durability, extreme lightweight, stability, flexibility, and high resistance to corrosion, acid and alkaline attacks, heat, temperature, and moisture.

Vinyl Ester Resins account for the largest market share in the global FRP rebar market in terms of value and volume

Vinyl ester resin-based FRP rebars are most commonly used worldwide due to their higher physical performance over polyester resins and cost benefits over epoxies. The major advantage of that vinyl ester over epoxies is that they do not need complex processing or special fabricating processes. Though polyester resins are cheaper, they are preferred less over vinyl ester and epoxy as they do not provide the same strength.

The highways, bridges & buildings application segment accounts for the largest share in the global FRP rebar market in terms of value and volume

The construction industry has traditionally seen very high usage of steel rebar-reinforced concrete structures as it was the accepted norm for many years on account of availability, cost incurred, and expertise of personnel working with steel rebars. Although the installation cost of these structures is low, the maintenance cost increases over the years owing to corrosion and subsequent weakening of the structure. The average life span of steel rebars is 20-25 years. However, the average lifespan of an FRP rebar-reinforced concrete structure is nearly 50–60 years, providing low maintenance cost during its operational life because of high resistance to corrosion. FRP rebars also increase the average lifespan of a project and, though the initial cost of installation can be high, the final cost is lowered as no additional cost on repairs and maintenance is incurred.

https://www.prnewswire.com/news-releases/frp-rebar-market-worth-344-million-by-2026--exclusive-report-by-marketsandmarkets-301296794.html

North America to lead the FRP rebar market during the forecast period

North America is the largest market for FRP rebar, by value, in the world. The market in this region is dominated by the US and Canada. The major players in the FRP rebar market in North America give each other tough competition and constantly innovate and develop new technology to produce high quality, high strength, and lightweight FRP rebars. These players adopt various growth strategies like expansion, new contracts & agreements to increase their market share and cater to the increase in demand. The usage of FRP rebars is high in the North American region as government agencies have identified the advantage of FRP rebars over traditional alternatives like steel rebars.

Schöck Bauteile GmbH (Germany), Dextra Group (Thailand), Pultron Composites (New Zealand), Pultrall Inc. (Canada), Composite Group Chelyabinsk (Russia), Owens Corning (US), FiReP Group (Switzerland), and Sireg Geotech S.r.l. (Italy) are the key players in the FRP rebar market. These players have taken different organic and inorganic developmental strategies over the past few years.

Early buyers will receive 10% free customization on this report.

Don't miss out on business opportunities in FRP Rebar Market.

Speak to Our Analyst and gain crucial industry insights that will help your business grow.

https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=77486355

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact: Mr. Ashish Mehra MarketsandMarkets™ INC. 630 Dundee Road Suite 430 Northbrook, IL 60062 USA: 1-888-600-6441 [email protected]

0 notes

Text

Global Market Analysis of Wind Turbine Materials

Global wind turbine materials market is estimated to be valued US$ 5,012 Million by 2019 end and is forecast to witness a significant growth of around 7% CAGR during the forecast period.

Key driving factor in global wind turbine materials market comes from an increasing number of wind power projects worldwide.

There has been a significant rise in the number of wind projects, which is the main outcome of rising demand for conventional energy resources.

For more insights into the Market, Request a Sample of this Report:

Key findings of the Wind Turbine Materials market study:

Regional breakdown of the Wind Turbine Materials market based on predefined taxonomy.

Innovative manufacturing processes implemented by Wind Turbine Materials vendors in detail.

Region-wise and country-wise fragmentation of the Wind Turbine Materials market to grasp the revenue, and growth outlook in these areas.

Changing preferences among consumers across various regions and countries.

Factors (Positive and Negative) impacting the growth of the global Wind Turbine Materials market.

Market Players Focused On Inorganic Growth:

Global wind turbine materials market is moderately fragmented in nature. Prominent players with established market presence in global wind turbine materials market are

Siemens AG

Teijin Limited

Toray Industries Inc.

Reliance Industries Limited

Lianyungang Zhongfu Lianzhong Composites Group Co.Ltd

Molded Fiber Glass Companies

Gurit Holding AG

Hexcel Corporation.

Global players in market have targeted acquisitions and mergers as a key strategy for future development.

For Instance, In October 2018, Gurit Holding (Switzerland) acquired all shares in JSB Group (Denmark) for US$ 72 Mn. JSB group is one of the key players in core material kits for wind turbine blades. This strategic move has enhanced Gurit’s value chain and will allow the company to offer wind energy OEMs a full solution of structural core materials, core material kits and wind turbine blade molds.

Likewise, in April 2017, Siemens concluded the merger of its wind power business with Gamesa.

For In-Depth Competitive Analysis, Buy now: https://www.factmr.com/checkout/4605?SP

Wind Turbine Materials Market Segmentation:

Fact.MR has studied the Wind Turbine Materials market with detailed segmentation on the basis of type, application and key regions.

By Type :

Fiber

Glass Fiber

Carbon Fiber

Other

Resin

Epoxy

Polyester

Polyurethane

Vinyl Ester

Others

By Application :

Wind Blades

Nacelles

Others

By Region :

North America

Latin America

Europe

East Asia

South Asia & Oceania

Middle East & Africa

How will be insights and market estimations provided in the Fact.MR report on the Demand of Wind Turbine Materials make a difference?

The study takes a closer look at the major economic turmoil, with a focus on the recent COVID-19 pandemic disruptions

The assessment of key growth dynamics highlights the attractiveness of new automation technologies and offers readers insight on the prospect of these during the forecast period

The study tries to offer a balance perspective of the opportunities in mature and the most lackluster markets

Analyzes how collaborations and partnerships among players from different industries shape the key growth dynamics in the near future

Evaluates the role of various stages of funding on new growth avenues in key regional markets

Contact: US Sales Office: 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583 E-Mail: [email protected]

0 notes

Text

Saudi Arabia Gelcoat Market Analysis, Trends, 2023-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Saudi Arabia gelcoat market size at USD 38.79 Million in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the Saudi Arabia gelcoat market size to grow at a CAGR of 6.76% reaching a value of USD 60.69 Million by 2029. An increasing demand for high-performance composite materials across a variety of industries, including transportation, aviation, aerospace, and military defense, is one of the main development factors for the Saudi Arabia gelcoat market. Expanding building operations in Saudi Arabia as a means of economic diversification is also emerging as a significant driving force for the growth of the Gelcoat market.

Saudi Arabia Gelcoat Market – Overview

Gelcoat, also called Gel Coat, is a substance used to give a high-quality finish on the visible surface of a fiber-reinforced composite. It is a two-part polyester resin that has been particularly prepared for use as the initial resin layer to be put in a mold for creating a polyester or vinyl ester composite product. The objective is to produce an opaque surface that will totally prevent glass pattern show-through. However, free water will seep through the surface of the gelcoat and infiltrate into the structure since Gelcoat is not waterproof. The water will then either evaporate or freeze, shattering the gelcoat as a result of temperature extremes.

Sample Request @ https://www.blueweaveconsulting.com/report/saudi-arabia-gelcoat-market/report-sample

Saudi Arabia Gelcoat Market – By End User

Based on end user, the Saudi Arabia Gelcoat market is segmented into automotive, marine, building & construction, wind energy, and others. The marine segment accounts for the highest market share. Gelcoat is a form of polymer that is applied to boats and other watercraft as a protective covering. It protects the vessel's hull from UV radiation, seawater, and other factors and is commonly applied to the hull. The color options for gelcoat are many, and it may be polished to a brilliant gloss. “Saudi Arabia is placed 20th internationally in the marine transport sector and achieved the highest regional improvement in the 2021 Maritime Connectivity Index”, as reported by Arab News. As a result, the demand for gelcoat is also expanding in the marine industry.

Impact of COVID-19 on Saudi Arabia Gelcoat Market

The unprecedented COVID-19 pandemic outbreak affected the growth of the Saudi Arabia gelcoat market. The operations of the major end-user industries of the Gelcoat market including automotive and building & construction were temporarily hindered which is impacting the market demand for gelcoat in Saudi Arabia. Additionally, the production activities and import activities also negatively affected the Saudi Arabia gelcoat market.

Competitive Landscape

Major players operating in Saudi Arabia gelcoat market include LyondellBasell Industries Holdings B.V., 3M, SIKA AG, AEKYUNG CHEMICAL Co., Ltd, ALLNEX NETHERLANDS B.V., AOC, LLC, BÜFA GmbH & Co. KG, Changzhou Huake Polymers Co., Ltd., Eternal Synthetic, and Euroresins. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Research Blog

Phone No: +1 866 658 6826

Email: [email protected]

0 notes

Text

Analysis of Vinyl Ester by Research Nester to Reach USD 3 Billion by 2033 Globally

Research Nester assesses the growth of global vinyl ester market over the forecast period, i.e., 2023-2033 and evaluates its future prospects. The rising application of vinyl ester in various end-use industries and growing import-export of chemicals to drive market growth.

Research Nester’s recent market research analysis on “VINYL ESTER Market: Global Demand Analysis & Opportunity Outlook 2033” delivers a detailed competitor’s analysis and a detailed overview of the global vinyl ester market in terms of market segmentation by type, application, end-user, and by region.

Growing Marine Industry to Drive Growth of Global Vinyl Ester Market

The global vinyl ester market is estimated to grow majorly owing to the exceptional properties of vinyl ester including great adhesion, high chemical resistance, and superior anti-corrosion properties making it the perfect choice for manufacturing marine equipment. Moreover, the rising marine industry across the globe is anticipated to boost market growth. According to data from the International Trade Administration, maritime exports to the United States were valued at USD 586 million in 2018 while imports were valued at USD 1,176 million.

The market research report on global vinyl ester encompasses an in-depth analysis of the industry growth indicators, restraints, supply and demand risk, along with detailed discussion on current and future market trends. These analyses help organizations identify a continuous flow of growth opportunities to succeed in an unpredictable future. Additionally, the growth opportunities exposed by the market is poised to gain significant momentum in the next few years.

By end-user, the global vinyl ester market is segmented into mining equipment, building & infrastructure, paints & coatings, transportation, and paper. Out of these, the building & infrastructure segment is estimated to gain the largest market share by the end of 2033. The rising usage of vinyl ester on plywood and other furniture, along with the increase in housing units and the renovation of older homes around the world, can be credited with the segment's growth. For instance, in the USA, 1,595,101 more housing units, or 15.5% more, are expected to be started in 2021 than in 2020. (1,379,601).

By region, the Asia Pacific vinyl ester market is to generate the highest revenue by the end of 2033. This growth is anticipated by the higher consumption and demand of gas and oil across the region. China's apparent gas consumption in 2022 was estimated to be between 375.1 and 380.1 billion cubic meters, up 1% to 3% annually.

The research is global in nature and covers detailed analysis on the vinyl ester market in North America (U.S., Canada), Europe (U.K., Germany, France, Italy, Spain, Hungary, Belgium, Netherlands & Luxembourg, NORDIC [Finland, Sweden, Norway, Denmark], Poland, Turkey, Russia, Rest of Europe), Latin America (Brazil, Mexico, Argentina, Rest of Latin America), Asia-Pacific (China, India, Japan, South Korea, Indonesia, Singapore, Malaysia, Australia, New Zealand, Rest of Asia-Pacific), Middle East and Africa (Israel, GCC [Saudi Arabia, UAE, Bahrain, Kuwait, Qatar, Oman], North Africa, South Africa, Rest of Middle East and Africa). In addition, analysis comprising of global vinyl ester market size, Y-O-Y growth & opportunity analysis, market players’ competitive study, investment opportunities, demand for future outlook etc. has also been covered and displayed in the research report.

Consult our expert analysts at: [email protected] or contact us at: https://www.researchnester.com/contact for any customized report.

This report also provides the existing competitive scenario of some of the key players of the global vinyl ester market which includes company profiling of INEOS Limited, Interplastic Corporation, Nivitex Fibreglass and Resin, Poliya Composite Resins and Polymers Inc., Polynt S.p.A., Scott Bader Company Limited, Showa Denko K. K., Sino Polymer Co. Ltd., Swancor Holding Co Ltd., AkzoNobel, and others. The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the global vinyl ester market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

Request Report Sample@ https://www.researchnester.com/sample-request-4596

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Composites Distributor Market – Revolutionary Trends 2027

Major aspects that fuel the market growth are discussed in this illustrative Composites Distributor Market research such as prospective, driving, restraining factors, latest trends and key advancements. Newly entering key players into the marketplace will obtain huge assistance by referring this Composites Distributor Market study report as it carries out detailed industry study along with depicting latest developments in the industrial sectors. Significant data provided here is of huge assistance for industry players to obtain detailed assessment of the market competition for the prediction period 2022-2027. By knowing competition for the upcoming period, key players can introduce novel products into the market and obtain huge profits in the business. It further catches data about market share, market tactics and industry volume.

Click here to request a Free Sample report:

This Composites Distributor Market research enables to target specific products into the market and enhance the revenue rate of the business. It further helps to know more about global market position in major regions of the globe such as Europe, Asia Pacific, North America, Latin America, Middle East and Africa. It further aims to provide a comprehensive presentation of the market strategies and entire market scenario. Some of the crucial factors are highlighted in this Composites Distributor Market report include continuously evolving consumer, buyer and vendor needs, key pricing structure, customer data, their preferences and buying attitude.

Top Players of Composites Distributor Market

The following are the key players in the Composites Distributor Market.

Composites One

Euroresins International GmbH

FRP Services & Company

Gazechim Composites UK

IMCD N.V.

Lintech International LLC.

Growth drivers and Market Value:

This report, from Stratview Research, studies the Composites Distributor Market value and growth drivers over the trend period of 2022-27. According to the report -

Composites distributor market is likely to witness an impressive CAGR of 4.7% during the forecast period. The increasing demand for composites in North America and Asia-Pacific and the presence of a large number of composite part fabricators are likely to propel the composites distributor market during the forecast period.

Segment Analysis:

Based on Raw Material Type:

Based on the raw material type, the composites distributor market is segmented as roving, textile, polyester resin, vinyl ester resin, epoxy resin, and other resins. Polyester resin is estimated to be the largest as well as the fastest-growing material during the forecast period driven by its increasing use in the construction and pipe & tank industries. The use of polyester resin offers advantages such as dimensional stability, ease of handling and provides mechanical and chemical resistance.

Based on Region:

In terms of regions, Asia-Pacific is estimated to be the largest as well as the fastest-growing composites distributor market during the forecast period due to the presence of a large number of small part fabricators for pipe & tank, construction, and consumer goods end-use industries. China and India are the growth engines of the region. North America and Europe are also expected to offer considerable growth opportunities during the forecast period.

Know more about the report, click here –

This Composites Distributor Market study report catches the impact of novel developments on the future market progress. There are a number of major industries already began adopting novel procedures, new headways, extensions, mergers and novel product launches to survive in the market and drive the business growth. It becomes easy for new players to rule the market and increase the product collection with this market research analysis. It focuses on major market segments. This Composites Distributor Market analysis is an effective tool to capture the COVID-19 impact on market developments and business growth. It also enables to explore through important insights such as latest market advancements, current market scenario, novel opportunities, challenges and market drivers.

Making sound and calculated decision for the benefit of business is important and this Composites Distributor Market report works as the best guide to help in this regard. It also enables to gauge through key competitors of the market and thorough analysis of the business scenario. Significant data gathered here is from interviews with leading business experts and primary research. Advanced data as well as statistics related to global market environment is also depicted in this market analysis.

Key features of the report -

Qualitative and Quantitative market research

Opportunity analysis

Market Assessment

Competitive Landscape

Industry best practices assessment

Product Research & Revenue Estimations

Market Trend Analysis

Report Customization Options

Stratview Research, one of the global market research firms, offers free customization and custom research services across the sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to the team.

Email at - [email protected]

Connect with the analysts at - +1-313-307-4176

0 notes

Text

Chemicals to avoid in consumer products

Endocrine disruptor chemicals are chemicals that manipulate our bodies' natural hormone communication system, known as the endocrine system. These chemicals are often found in consumer products containing plastics and chemical plants.

In this post, I will share several dangerous endocrine disruptor chemicals to try and avoid in your product consumption. Vinyl chloride, BPA, phthalates, and polychlorinated biphenyls are the chemicals I will be reviewing in this blog.

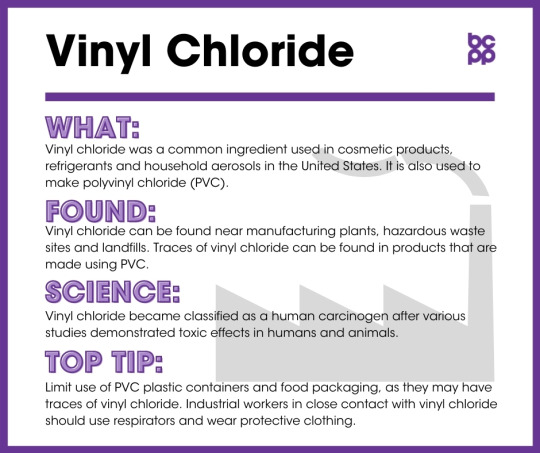

Vinyl chloride is a carcinogenic chemical used to make plastics, it is produced with endocrine disruptor chemicals known as phthalic acid esters (Bi et al., 2021). These phthalic acid esters can potentially cause cancer via confusion and mimicry of the body’s natural endocrine system. Not only can they cause damage to the endocrine system potentially causing cancer, but they can have transgenerational consequences, meaning that the consequences may be felt much later in life, or even by the victim’s offspring (Beatrice & Ruby, 2021). This makes it difficult to hold big chemical companies accountable and pinpoint the exact damage caused. Many of the individuals who get sick due to endocrine disruptors may never know the cause.

(BCPP, 2021)

BPA is another carcinogenic endocrine disruptor used in the production of plastics and resins. BPA stands for bisphenol A (Hafezi & Abdel-Rahman, 2019). Typically, human exposure to BPA comes from exposure to the production and use of plastic consumer products, such as water bottles, food containers, and plastic containers in general (Hafezi & Abdel-Rahman, 2019). As science fights to battle cancer, products containing endocrine disruptors like BPA fight right back (Moss, 2022). BPA performs as a xenoestrogen, meaning that it mimics and manipulates estrogen systems in our endocrine systems. This manipulation can lead to breast, ovarian, colon, and prostate cancers (Hafezi & Abdel-Rahman, 2019). BPA is also damaging to reproduction potential. BPA has alternatives such as BPF or BPS. However, these chemicals can be just as damaging if not worse than BPA regarding human health and chemical exposure (Zhang, 2022).

(Rust & Kissinger, 2008)

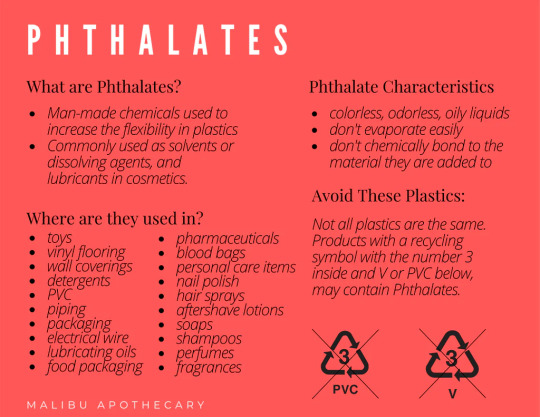

Phthalates are endocrine disruptors, which are also found in plastic products. When it comes to the absorption of harmful chemicals, phthalates, BPA, and polychlorinated biphenyls are the greatest concerns (Wang & Qian, 2021). Phthalates can be detrimental to reproduction, development, and neurological health (Wang & Qian, 2021). Phthalates have strong regulations in many countries but are still found in many consumer products.

(Ellis, 2020; Aquino, 2016)

Finally, polychlorinated biphenyls are a carcinogenic endocrine disruptor chemical. Polychlorinated biphenyls are the most studied endocrine disruptors, and they damage neurological functions more than anything (Bell, 2014). Aside from neurological issues, liver disease and cancer are also consequences of the endocrine disruptor known as polychlorinated biphenyls (Bell, 2014). Depression, limbic system damage, reproduction issues, and skin problems are all risks that exposure to polychlorinated biphenyls carries (Bell, 2014).

(What are PCBS? 2016)

While we cannot all create new cancer treatments or stop the production and use of these chemicals, we all can help aid ourselves, our communities, and our loved ones by looking out of these chemicals in our consumer products. The people who produce and push these chemical products should certainly be held accountable. However, we must also hold ourselves accountable if we have a choice in consumption. After all, if we were able to avoid these chemicals entirely, they would become less valuable in theory. On both ends of the issue, accountability, advocacy, and education are the only viable solutions.

References

Aquino, K. (2016, April 20). What are phthalates and should we avoid them? Project Vanity. http://www.projectvanity.com/projectvanity/2016/1/19/what-are-phthalates

Beatrice, A., & Ruby, R. (n.d.). National Center for Biotechnology Information. Endocrine Disruptor Chemicals. https://www.ncbi.nlm.nih.gov/books/NBK569327/

Bell, M. R. (2014, December). Endocrine-disrupting actions of PCBS on brain development and social and reproductive behaviors. Current opinion in pharmacology. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4298313/

Bi, M., Cui, Z., Liu, W., Liu, M., Li, M., Luan , X., & Liu, W. (2021). Production, use, and fate of phthalic acid esters for polyvinyl chloride products in China. Environmental science & technology. https://pubmed.ncbi.nlm.nih.gov/34617437/

Ellis, C. (2020, November 19). What are phthalates? Malibu Apothecary. https://malibuapothecary.com/blogs/clean-candles/what-are-phthalates

Hafezi, S. A., & Abdel-Rahman, W. M. (2019). The Endocrine Disruptor Bisphenol A (BPA) exerts a wide range of effects in carcinogenesis and response to therapy. Current molecular pharmacology. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6864600/

Rust, S., & Kissinger, M. (2008). BPA leaches from 'safe' products. Journal Sentinel. https://archive.jsonline.com/watchdog/watchdogreports/34532034.html/

Vinyl chloride. Breast Cancer Prevention Partners (BCPP). (2021, August 18). https://www.bcpp.org/resource/vinyl-chloride/

Wang, Y., & Qian, H. (2021, May 18). Phthalates and their impacts on human health. Healthcare (Basel, Switzerland). https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8157593/

What are PCBS? Spokane Aquifer Joint Board. (2016). https://www.spokaneaquifer.org/what-are-pcbs/

Zhang, H. (2022, February 22). BPA replacement linked to increased cardiovascular disease. EHN. https://www.ehn.org/bpa-replacement-2656483035.html#:~:text=A%20near%2Dubiquitous%20ingredient%20in,be%20as%20harmful%20as%20BPA.

1 note

·

View note

Text

Polymer Concrete Market- New Technological Development Projecting Massive Growth till 2032

The global polymer concrete market is worth US$ 465 Mn as of now and slated to reach US$ 979.2 Mn by the year 2032 at a CAGR of 7.7% between 2022 and 2032. Polymer concrete comes across as a composite material using thermoplastic polymers with epoxy binder for hardening materials in construction vertical.

The vital ingredients include gravel, water, and sand, which render it conducive to repair any of the concrete structures. Polymer concrete overpowers its counterparts with respect to impact strength. The prime end-users comprise industrial, municipal & residential, and commercial sectors.

An ever-increasing demand for polymer concrete in pump bases, chemical containments, waste containers, trench drains, and industrial flooring blocks is expected to take the polymer concrete market by storm going forward. This could be attributed to its ability of forming complex shapes, fast curing properties.

Polymer concrete finds its usage in an aplomb in various drainage applications. It makes way for precise finishing and precision molding, which, in turn, promulgates appropriate hydraulic flow. This ascertains exceptional rate of discharge of water from pipe. These advantages are actually expected to drive demand for polymer concrete across a multitude of applications.

Competitive Landscape

WACKER’s, in January 2022, unveiled Moscow Laboratory pertaining to cement and concrete additives. This laboratory is a part of WACKER’s new-fangled Innovation Hub for cement and concrete. Its major objective is that of rendering protection to cement and concrete from moisture – during storage as well as post-application.

Kwik Bond polyester concrete overlays do provide a 3-decade old solution, with unparalleled preservation and a 2-hour traffic return in various conditions.

Forte Composites manufactures pre-cast polymer concrete and also partners with its clientele for evaluating products made out of wood, fiberglass, or metal and identifying product improvements via usage of polymer concrete.

Dudick Inc. provides trowel applied, 3-component polymer concrete, which has been designed for diluting acids, solvents, alkali, and various other corrosive chemicals.

Braskem, in October 2019, introduced a recycled polypropylene product comprising one-time usable polypropylene string. After being processed and tested, string does give out pellets of homopolymer polypropylene (sustainability-oriented) that could be used in industrial sector.

For More Insights, Download Report Sample@ https://www.futuremarketinsights.com/reports/sample/rep-gb-3659

Polymer Concrete Market Outlook by Category

By Material Type:

Polyester

Vinyl Ester

Epoxy Based

Others

By Binding Agent:

Natural Resin

Synthetic Resin

By Application:

Solid Surface Countertops

Outdoor Seats & Benches

Waste Containers

Pump Bases

Flooring Blocks

Chemical Containments

Trench Drains

Others

“With construction sector in its full fervor, the global polymer concrete market is bound to witness grandeur in the upcoming period”, says an analyst from Future Market Insights.

Browse latest Market Reports@ https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes