#Vanadium Nox

Explore tagged Tumblr posts

Text

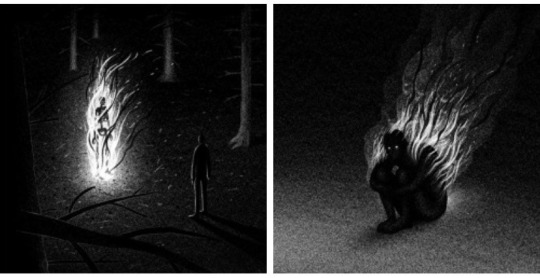

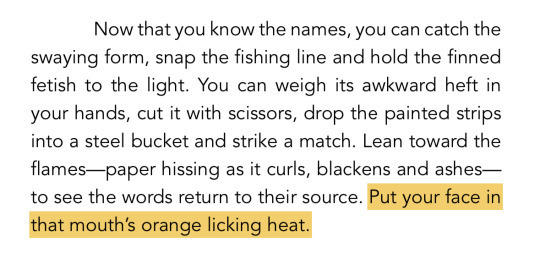

Vanadium 'Vengeance' Nox, a copy made to burn

would that i - hozier / Ada Limón, from “The End of Poetry”, The Hurting Kind / Czeslaw Milosz, New and Collected Poems: 1931-2001 / jen mazza / Elektra, Sophokles tr. Anne Carson / Skeleton & Demon, Brian Luong / hidden emotions, lia kimura / notes from a missing person - jennifer kwon dobbs / portrait of a lady on fire

5 notes

·

View notes

Text

#I’m kinda proud of this one 👉👈#It’s purposely fuzzy like that because of smoke#The hair blends with the flame on purpose yes yes#OC art#Vanadium Nox#Apex OC

3 notes

·

View notes

Video

youtube

In the incineration industry, catalysts are mainly used to reduce pollutant emissions and improve incineration efficiency. The following are the applications of catalysts in the incineration industry: 1. Reducing pollutants Denitrification catalyst (SCR): used to convert nitrogen oxides (NOx) into harmless nitrogen and water to reduce air pollution. Oxidation catalyst: used to oxidize organic pollutants such as carbon monoxide (CO) and volatile organic compounds (VOCs) to produce carbon dioxide and water. 2. Improving combustion efficiency Catalytic combustion: catalysts are used to reduce combustion temperatures, improve combustion efficiency, and reduce unburned residues. 3. Catalyst materials Common materials include precious metals (such as platinum and palladium) and metal oxides (such as vanadium and titanium). 4. Maintenance and replacement Catalysts need to be regularly inspected and replaced to maintain their activity and efficiency. By using catalysts, incineration plants can effectively reduce harmful emissions, comply with environmental regulations, and improve the economy and environmental performance of the combustion process. #scrcatalyst #catalyst#Engineering #Filtration #PelletizingPlant #Metallurgicalindustry #AirPollutionControl #CleanAir #Innovation #decarbonisation #fluegastreatment

0 notes

Text

Stationary Emission Control Market Research Analysis

Stationary Emission Control Market by Type (Palladium, Platinum, Rhodium), Application (Mobile sources (off road, and on road), and Stationary Sources), and Region (North America, Europe, Asia-Pacific, Middle East and Africa and South America)

The Stationary Emission Control market size is projected to reach a CAGR of 7.1% from 2022 to 2028.

The emissions are ejected by the vehicles or machines. If petrol or diesel is used for the operation of the machines then the emissions are usually carbon di oxide, carbon mono oxide, nitrogen oxide and various other unburnt hydrocarbons.

Surged demand due to the stringent policies by the government along with the increased production capacity from the thermal power plants are some of the factors that have supported long-term expansion for Stationary Emission Control Market.

Request Research Sample Pages: https://www.delvens.com/get-free-sample/stationary-emission-control-market-trends-forecast-till-2028

Regional Analysis

North America is the most rapidly growing market and offers a huge opportunity for the industry, whose growth is driven by the stringent governmental policies on pollution.

Key Players

BASF catalyst

Johnson Matthey

Umicore

Tenneco

Cataler

Heraeus

Bosal

Clean Diesel Technologies

Cormetech

DCL International Inc.

Hitachi Zosen Corporation

IBDIEN

Interkat

Kunming Sino-Platinum Metals Catalyst

Nett Technologies

NGK Insulators

Shell Global Sinocat

Make an Inquiry Before Buying: https://www.delvens.com/Inquire-before-buying/stationary-emission-control-market-trends-forecast-till-2028

Recent Developments

In 2021, BASF increased and expanded its production capacity of emission catalyst.

In 2019, ActivDPFTM diesel particulate filter (DPF) system was lunched by Johnson Matthey designed especially for stationary diesel engines.

Reasons to Acquire

Increase your understanding of the market for identifying the best and suitable strategies and decisions on the basis of sales or revenue fluctuations in terms of volume and value, distribution chain analysis, market trends and factors

Gain authentic and granular data access for Stationary Emission Control Market so as to understand the trends and the factors involved behind changing market situations

Qualitative and quantitative data utilization to discover arrays of future growth from the market trends of leaders to market visionaries and then recognize the significant areas to compete in the future

In-depth analysis of the changing trends of the market by visualizing the historic and forecast year growth patterns

Purchase the Research Report: https://www.delvens.com/checkout/stationary-emission-control-market-trends-forecast-till-2028

Report Scope

Stationary Emission Control Market is segmented into metal type, application, and region.

On the basis of Metal Type

Palladium based

Platinum based

Rhodium based

Others (vanadium, ruthenium, and irirdium)

On the basis of Application

Mobile sources (off road, and on road)

Stationary sources

On the basis of Catalytic Converter

Diesel oxidation catalyst

Selective catalytic reduction

Lean NOx trap

Three-way catalytic converter

Four-way catalytic converter

On the basis of Region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Read More:

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

0 notes

Text

NOX Scrubber Manufacturer & Supplier in India

A NOx scrubber is a device used to remove nitrogen oxides (NOx) from industrial emissions. NOx is a harmful air pollutant that is produced by combustion processes in industries such as power plants, refineries, and chemical plants.

NOx scrubbers work by converting NOx into less harmful compounds, such as nitrogen and water vapor, through a chemical reaction. This process is called selective catalytic reduction (SCR) and typically involves the use of a catalyst, such as vanadium oxide, to facilitate the reaction.

NOx scrubbers are an important technology for reducing air pollution and improving air quality. They are commonly used in large industrial facilities, particularly those that burn fossil fuels, to comply with environmental regulations and reduce their environmental impact.

In addition to reducing NOx emissions, NOx scrubbers can also help reduce other harmful pollutants, such as particulate matter and sulfur dioxide, from industrial emissions. However, NOx scrubbers can be expensive to install and maintain, which can be a barrier to their widespread adoption.

#NOX Scrubber#NOX Scrubber Manufacturer#NOX Scrubber Manufacturer in india#NOX Scrubber Manufacturer & Supplier

0 notes

Text

tagged by @hawkeshep to create some of my ships using dis picrew

Thank you for the tag!! I really enjoyed doin this <333

(forced affection between Din and Solas) (Ven's about to bite Witt moment)

A little fucky on the skintones, but ya

Anyone who wants to do this can!! I'm not sure who to tag that hasn't already heh

4 notes

·

View notes

Text

Javanese bondage

Javanese bondage

In the process of fertilization, nitrogen, ammonia, and other compounds in the atmosphere are converted to soil. Nitrogen in the atmosphere is usually bio-oxygen, an almost inactive molecule, and most of the organisms other than some microorganisms are not used in the digestive system. In organic-nitrogen bonds, some microorganisms, such as rhizobia, convert nitrogen into ammonia, which is used in the metabolism of other organisms.

Bonded nitrogen is essential for life because it requires inorganic nitrogen compounds such as nitric acid, amino acids, etc., which are essential for life. This is very important as the fertilizer cycle is part of the agricultural and fertilizer preparation. It is also indirectly needed for all chemical-based explosives, chemicals and chemical compounds used to make dyes. Fertilizers are synthesized by naturally occurring bioassays on soil such as azotobacter and aria. Some of the nitrogen-fixing bacteria have been found to coexist with bacteria (especially Dali plants). Some weaves and mushrooms also form bonds. The bond naturally forms NOx by electricity in the atmosphere.

All organic-nitrogen-fixing is possible by nitrogen. These enzymes usually contain molybdenum or vanadium with iron.

0 notes

Text

Global Catalyst Fertilizers Market

Global Catalyst Fertilizers Market was valued US$ 2.25 Bn in 2017, and expected to reach US$ 2.89 Bn by 2026, at a CAGR of 3.2 % during forecast period.

The objective of the report is to present a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, industry-validated market data and projections with a suitable set of assumptions and methodology. The report also helps in understanding global Catalyst Fertilizers market dynamics, structure by identifying and analyzing the market segments and project the global market size. Further, report also focuses on competitive analysis of key players by product, price, financial position, product portfolio, growth strategies, and regional presence. The report also provides PEST analysis, PORTER’s analysis, SWOT analysis to address questions of shareholders to prioritizing the efforts and investment in near future to emerging segment in global Catalyst Fertilizers market.

The major factors behind the growth of the global catalyst fertilizers market are growing need for efficient fertilizer production across the globe, and increasing need for control of emissions from fertilizers. However, long replacement period for catalyst membranes could restrain the growth of the global catalyst fertilizers market. Further, increasing demand for the organic fertilizer will hamper the growth of the catalyst fertilizers market.

High growth in R&D activity to improve the quality and functionality of catalyst will offer the tremendous opportunity for the manufacturers. Based on the Fertilizer production process, the Haber-Bosch process is projected to witness the fastest growth during the forecast period. Ammonia is one of the largest inorganic chemical produced across the globe through the Haber-Bosch process and approximately 80% of the entire ammonia produced by Haber-Bosch process. Further, the increasing emissions of NOX and N2O into the environment from ammonia production, emission controlling catalysts have also been developed and are increasingly adopted in conjunction with synthesis catalysts.

Based on the metal group, base metals segment are projected to witness the fastest growth in the catalyst fertilizer market during the forecast period. Catalysts are metal or organometallic compounds and are widely used in refinery and fertilizer applications. Nickel and vanadium pentoxide are widely used for sulfuric acid production in the Asia Pacific region. Raw materials occupy around 70% of the production cost, and since ammonia and phosphate fertilizer production is major in Asian countries, considering the developing economic conditions of these countries, cheaper catalysts would be determined to stabilize the fertilizer cost. Based on the application, the nitrogenous fertilizers segment dominated the catalyst fertilizer market in 2017, and it is expected to witness the faster growth in the catalyst fertilizers market. Nitrogen is considered to be the most important nutrient, and plants absorb more nitrogen than any other element. Nitrogen is vital to in making sure plants are healthy as they develop and nutritious to eat after they’re harvested. That’s because nitrogen is essential in the formation of protein, and protein makes up much of the tissues of most living things.

Geographically, The Asia Pacific region is expected to account for the largest share in the Catalyst Fertilizers market during the forecast period. The Asia Pacific catalyst fertilizers market is driven by the rising need to increase crop yield and growing production of fertilizers. With the growing population in countries such as China and India, the demand for food products continues to grow each year in the Asia Pacific region. Scope of Global Catalyst Fertilizers Market

Global Catalyst Fertilizers Market, by Fertilizer Production Process

• Haber - Bosch process • Contact Process Global Catalyst Fertilizers Market, by Metal Group

• Base Metals • Precious Metals Global Catalyst Fertilizers Market, by Fertilizer Application

• Nitrogenous • Phosphatic Global Catalyst Fertilizers Market, By Region

• North America • Europe • Asia Pacific • Middle East & Africa • South America Key Players Operating in Global Catalyst Fertilizers Market

• Clariant International • Dowdupont • Projects & Development India Limited (PDIL) • Lkab Minerals • Johnson Matthey • Quantumsphere Inc. • Haldor Topsoe • N.E.Chemcat • Quality Magnetite • Oham Industries

This Report Is Submitted By @Maximize Market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact Us:

Name: Lumawant Godage

Organization: MAXIMIZE MARKET RESEARCH

Email: [email protected]

Contact: +91 9607365656

0 notes

Text

Catalysis that neutralizes air-polluting NOx from power plant emissions

New research describes the mechanism behind catalysis that neutralizes air-polluting NOx from power plant emissions. Researchers used a High Field (HF) Nuclear Magnetic Resonance (NMR) spectrometer in conjunction with reaction studies to test three theories around titania-supported vanadium oxide. They found that tungsten oxide changes the structure of vanadium oxide from a less active form to a highly active form. Catalysis that neutralizes air-polluting NOx from power plant emissions syndicated from https://triviaqaweb.blogspot.com/

0 notes

Text

Artists it is my goal in life to commission someday when I have money:

grif

renepolumorfous

ari

bubbie

nox

cayzhuli

Thaaftwe

korppipoika

zeniak

The Laughing Star

houseteeth

limeypie

zweis

vanadium-and-circuitry

everyone who does snapper art

probably you, reading this

Keep doin’ what you doin, you inspire me.

2 notes

·

View notes

Text

Selective Catalytic Reduction (SCR) Reactors For Ships – Types, Working Principle, Advantages And Disadvantages

What is NOx and where does it come from??

NOx pollution occurs when nitrogen oxides are released as a gas into the atmosphere during the high-temperature combustion of fossil fuels.

These nitrogen oxides consist mainly of two molecules, nitric oxide (NO) and nitrogen dioxide (NO2) along with a few others that occur in much lower concentrations. These molecules- Nitrous oxides are a significant greenhouse gas that plays an important role in Global Climate Change.

Nitrogen oxides form when oxygen and nitrogen from the air interact during a high-temperature combustion event. These conditions occur in Internal Combustion Engines and fossil fuel-powered electricity plants.

Environmental and Health Concerns

NOx gases play an important role in the formation of smog. When exposed to the UV rays in sunlight, NOx molecules break apart and form ozone (O3). The problem is made worse by the presence of volatile organic compounds (VOC) in the atmosphere, which also interacts with NOx to form dangerous molecules. Ozone at the ground level is a serious pollutant, unlike the protective ozone layer much higher up in the stratosphere.

In the presence of rain, nitrogen oxides form nitric acid, contributing to the problem of acid rain.

Nitrogen oxides, nitric acid, and ozone can all readily enter the lungs, where they create serious damage to delicate lung tissue. Even short-term exposure can irritate the lungs of healthy people.

For those with medical conditions like asthma, just a short time spent breathing these pollutants have proved to be fatal. This air pollution can lead to respiratory diseases such as emphysema and bronchitis. NOx pollution can also worsen asthma and heart disease and is associated with elevated risks of premature death.

The International Shipping Industry is facing an increasingly tight regulatory environment, especially in terms of limits imposed upon emissions to air. And with the entry into force of the International Marine Organization’s (IMO) NOx Tier III limits on January 1st 2016, a part of MARPOL Annex VI, the regulations governing marine emissions became significantly tougher and stringent to follow.

As per MARPOL Annex VI, Regulation 13- Nitrogen Oxides (NOx), the Nitrogen oxides from diesel engines on board are to be controlled as follows

The NOx emission limits are set for diesel engines depending on the engine maximum operating speed (rpm), as shown in the above table, Tier I and Tier II limits are global, while the Tier III standards apply only in NOx Emission Control Areas.

There are two exceptions – engines used solely for emergencies and engines on ships operating solely within the waters of the state in which they are flagged. The latter exception only applies if these engines are subject to an alternative NOx control measure.

Emission Control Areas must comply with NOx “Tier III” emission limits which means that they must emit 80% less nitrous oxides than a “Tier I” complaint engine. Under these regulations, ships which are keel-laid after January 1st 2016 and operating in the United States/Canadian Emission Control Areas(ECAs) must comply with the new emission limits. These emission limits are applicable for engines with an output power of more than 130kW installed on ships with more than 5,000GT

Tier III standards are expected to require dedicated NOx emission control technologies. These mainly consist of two options.

1) Using Liquified Natural Gas (LNG) as a fuel in engines, using lean burn technology. e.g.- Win GD Engines-Winterthur Gas & Diesel Ltd. which burn LNG in their combustion chambers using a Low-Pressure LNG gas injection system for the reduction in NOx emissions.

2) Use of abatement technology such as various forms of water induction into the combustion process (with fuel, scavenging air(in-take air humidification), or in-cylinder), exhaust gas recirculation, or selective catalytic reduction.

This article throws light upon Selective Catalytic Reduction Reactors on Ships, it’s types, their basic working principle, components, its benefits, advantages and disadvantages.

Basic Working Principle

Selective Catalytic Reduction is a means of converting nitrous oxides in the exhaust with the help of a catalyst into diatomic nitrogen and water.

A reductant Anhydrous Ammonia (NH3), Aqueous Ammonia (Ammonium Hydroxide) or Urea (Carbamide) solution is added to a stream of exhaust gas and is adsorbed onto a catalyst. Carbon Dioxide (CO2) is a reaction product when urea is used as the reductant.

The chemical equation for the reaction using either anhydrous aqueous ammonia for the process is

4NO + 4NH3 + O2 = 4N2 + 6H2O 2NO2 + 4NH3 + O2 = 3N2 + 6H2O NO + NO2 + 2NH3 = 2N2 + 3H2O

The reaction for urea instead of anhydrous or aqueous ammonia is 4NO + 2(NH2)2CO + O2 = 4N2 + 4H2O + 2CO2 (in presence of catalyst)

Selective Catalytic Reduction

This exhaust gas after-treatment technology has a NOx abatement capability Of more than 80%. The SCR concept involves injecting a Urea-Water solution into the exhaust gas stream in combination with a special catalyst unit.

The SCR is considered as an additional and independent exhaust treatment system and as such does not interfere with the basic engine design or combustion process.

The process diagram below gives a better understanding of the SCR system wherein the urea interacts with nitrous oxides present in the incoming exhaust gas, in the presence of a catalyst, converting it into free nitrogen and water vapour.

The Maritime Environmental Protection Committee (MEPC) At The IMO has published guidelines for the certification of selective catalytic reduction (SCR) systems, referred to the “SCR Guideline”, namely IMO Resolution MEPC.198(62).

According to their configurations, SCRs can Be Classified into 2 Types- They can be either installed between The Exhaust Gas Manifold & The Turbocharger or between The Turbocharger and The Exhaust Gas Boiler.

1) High-Pressure SCR

In the High-Pressure SCR, the reactor is placed before the turbocharger. A sufficient exhaust

gas temperature is to be maintained between 300 to 400 deg Celsius, which might be challenging when the engine is running at low loads and manoeuvring.

Therefore, for two-stroke engines, the most likely location of the SCR unit is before the turbocharger in order to expand the active range of SCR operation. This has little to no effect on the engine combustion process.

It is possible to run high-pressure SCRs on Heavy Fuel Oil.

2) Low-Pressure SCR

In Low-Pressure SCRs, the reactor is placed after the turbine. Pre-heating of the exhaust gas stream may be necessary in order to achieve a sufficient temperature at the reactor inlet for the catalytic reaction. Some power generation may be needed for preheating.

Components of an SCR

Dosing Unit

The dosing unit consists of a compact external dosing system having a urea-water solution tank. The tank size depends upon how often the vessel enters NOx Tier III areas and how often the SCR is put in use. Urea Tank capacities range from 4 to 10 cub metres/MW for larger engines.

The area for marine use is usually dissolved in water having a concentration of 32%-40%. Urea is a non-toxic odourless solution considered safe to transport and store at ambient temperature & pressure. However special caution is required in winter temperatures in order to avoid crystallization.

The dosing handling system provides the reducing agent (urea solution) based on the dosing demand signal provided by the SCR and Engine control and monitoring system.

Vaporizer/ Mixing Unit

The urea from the dosing system is metered and injected into the vaporizer or mixing unit. The injected reducing agent (urea) will vaporise and mix with the incoming exhaust gas.

The mixing unit is in line with the exhaust manifold of the engine and its pipes are designed & constructed after complex flow calculations & intensive testing, to ensure a good mixture of the urea solution & hot exhaust gases. The mixing unit is usually 2 to 6 meters long and 500mm in diameter, however, size may vary as per Engine size.

Injection tubes from the dosing unit penetrate the vaporizer from the bottom, the top of the vaporizer is equipped with an electronic enclosure having a NOx measurement sensor to monitor nitrous oxides in the exhaust gas and Backpressure sensor.

SCR Reactor Chamber

This is where the conversion of NOx in exhaust gas into nitrogen and water takes place in the presence of catalyst material. The SCR reactor contains cassettes of the catalyst substrate material. The substrate elements work in limited temperatures, if exhaust gas temperature is too high, the elements get destroyed.

If the temperature is too low, SCR efficiency is reduced. Catalyst element contains Vanadium Pentoxide (V2O5) which helps the reaction process of converting the urea and exhaust gas into nitrogen and water vapour. The SCR reactor volume is usually 1.5-3 cub metres/MW installed power.

Fuel Oil Quality and SCR technology

The sulphur content in fuel oil and consequent SO2 concentration in the exhaust gas is a critical parameter which has to be observed while operating SCR systems. Urea temperature is to be controlled according to sulphur content in fuel.

A high sulphur content in presence of a low exhaust gas temperature (in case of manoeuvring) will require a higher temperature of urea solution to be injected as a condensation of exhaust gas could result in corrosion and catalyst substrate damage. A lesser content of sulphur in fuel will allow a lesser temperature of urea solution to be injected.

Condensation of water vapour in the presence of sulphur in the exhaust gas during low load operations can cause the formation of solid ammonium bisulphate. Thus, the exhaust inlet temperature is to be kept high enough to avoid condensation of ammonium bisulphate onto catalyst substrate elements.

Condensation would severely affect NOx reduction performance and cause clogging, increasing backpressure due to soot formation in the reactor.

Soot Blowing Unit

To prevent contamination of the reactor elements, a soot blowing system is installed. Soot blowing is done using compressed air of 7 bar.

SCR Control Sensor Unit

NOx sensors measure the NOx concentration before the SCR reactor and the turbocharger. The reactor chamber also contains outlet NOx sensors and outlet temperature sensors.

Venting System

The venting system vents the SCR reactor when the SCR is bypassed (i.e. when the engine is running in Tier-II mode) to avoid exhaust gas accumulation and soot formation in the reactor. The reactor is vented with Fresh Air during Tier II operation.

The Reactor Sealing Valve is used to seal the reactor during venting when the SCR is not in use.

Reactor Throttling Valve is located at the outlet of the reactor.

Reactor Bypass Valve is used to bypass the reactor for NOx Tier II operation or failure of the SCR.

The Cylinder Bypass Valve can be used while the engine runs at partial loads to bypass scavenge air towards the turbocharger to increase exhaust gas temperature.

The Cut-In Cut-Out settings of Auxiliary blowers are set slightly differently in case of engines fitted with SCRs. While cutting-in of auxiliary blowers at the time of reducing load, a slight delay is introduced so as to avoid a sudden drop in exhaust temperature.

Similarly, while cutting-out the auxiliary blowers, when engine load increases, the exhaust temperature tends to increase suddenly, to prevent this- the Cylinder Bypass Valve (CBV) opens first to gradually increase temperature, then the blowers cut out and the CBV later closes as per engine load.

Pros & Cons Of The SCR

To assure continuous NOx removal and avoid clogging, special considerations have to be observed with regard to exhaust temperatures.

Pros

● Tier III NOx compliance is achievable. ● Very efficient NOx removal for most engine loads (60-90%) ● SCRs have a widely growing reference base with over 300 installations

Cons

● Rather investment intensive ● Limited NOx removal at low engine loads ● In comparison to other solutions for NOx Tier III emissions, the use of urea requires the installation of urea tanks which may have to be replenished often (a costly affair) ● Can result in excess consumption of fuel (about 1%) ● Additional cost of Urea in ECA areas.

Maintenance

● Replacing NOx sensors- sensor life is approx. 2000hours ● Replacing the substrate catalyst elements in the SCR reactor (Lifetime-approx. 1000hours) The lifetime of the catalyst elements strongly depends upon the sulphur content of the fuel. For NOx Tier III compliance, NOx efficiency is to verified once a year. If NOx efficiency reduction < 70% all catalyst elements must be renewed as per manufacturer’s instructions. ● The Soot Blower consists of a compressed air bottle, soot blower diaphragm valves and pressure switches. All pressure hoses are to be checked and diaphragm valves to be maintained. ● The Dosing Unit consists of a urea solution tank, liquid filters, dosing pumps, nozzle assemblies, flowmeters, valves and pressure switches. Weekly maintenance includes cleaning of filters, monthly includes inspection of injectors. Proper inspection and working of all individual components are to be checked every 6 months.

Benefits For The Ship Owner/Operator

Installing NOx Tier III-compliant technology has been beneficial beyond just achieving compliance with emissions regulations. Demonstrating a company’s commitment to ensuring sustainable operations has become increasingly important. Some additional advantages include direct financial benefits, as major ports offer substantial discounts in harbour fees. One frequently used performance indicator for the environmental impact of shipping is the Environmental Shipping Index (ESI), which is used by major ports to calculate harbour fees. Installing Tier III-compliant technology, instead of Tier II-compliant technology, adds approximately five points on the ESI scale.

For example, the following reductions in harbour fees for operating on Tier III are given by these ports:

Los Angeles: $2,500 per call (ESI higher than 50) Hamburg: €1,500 per call (ESI higher than 50) Rotterdam: 20% reduction for Tier III Antwerp: 10% ESI higher than 31

Image credit: Cat Marine

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Report an Error

from Storage Containers https://www.marineinsight.com/tech/selective-catalytic-reduction-scr-reactors-for-ships-types-working-principle-advantages-and-disadvantages/ via http://www.rssmix.com/

0 notes

Text

Should You Buy An Electric Car Or a BS6 Car In 2020?

2020 brings a lot of latest issues. A brand new decade and new energy practice choices to call a couple. BS6 might be necessary from April 2020 and extra electrical car choices will make this an attention-grabbing 12 months for the car trade.

The two most complicated factor we as shoppers might need to take care of could be a selection between a BS6 compliant engine or an Electrically operated car. We will talk about how each of them work and the way they’ll problem one another within the Indian car market and do you have to select bs6 or electrical car. Let’s begin with BS6.

What is BS6 (Bharat Stage 6)?

BS6 or Bharat Stage 6 is an emission norm set by the federal government which makes it so the businesses should make an engine in a method specified by the federal government which can meet sure norms permitting for cleaner emission. The gas this engine will use is a bit totally different than what you’ll usually use in a BS4 engine. Let’s get into the working of a BS6 engine.

Tata harrier bs6 engine

Read More: Tata Nexon BS6 Variant Spotted

What are the internal machinations of BS6?

The engineering behind a BS6 is partly within the engine, and largely within the equipment that include it and the gas it makes use of. With the assistance of elements like SCR (Selective Catalyst Reduction), OBD (on-Board Diagnostics) and RDE(Real Driving Emissions) the polluting issue of IC engines might be diminished tenfolds.

What is SCR (Selective Catalytic Reduction)?

SCR makes use of the fundamental rule of chemistry, something which is a complicated construction might be damaged down into easy molecules until we get what we need. This is the working rule of Selective Catalytic Reduction (SCR). Using chemistry, it breaks dangerous pollution into innocent molecules. How innocent you ask? It makes NOx into Water.

How SCR works?

As to how SCR converts NOx into water will want a little bit of response finding out and it’s not sophisticated. We will stroll you thru it if it’s been too lengthy because you learn reactions and wish a little bit of a refresher. Before that, we have to know the development of SCR.

The Flow in SCR

What are the parts inside an SCR?

SCR has a chamber the place the response happens and the catalyst is current. Catalysts are chemical substances that assist in shifting a response within the route you need it to go. They additionally come out unhurt out of the response which supplies them a longer life.

This chamber has the catalyst that SCR requires which is chosen on the wants and the extent at which the automobile will normally function. Cheaper ones embody vanadium and tungsten which have decrease temperature withstanding skill. The excellent catalyst for vehicles is Zeolite Catalyst which may operate at pretty excessive temperatures and are additionally not as expensive as different alternate options.

The catalyst is within the partitions of the chamber. The response occurs within the chamber and that’s how an SCR is constructed. Now onwards to the working.

The working response inside a Selective Catalyst Reduction chamber

4NO + 4NH3 + O2 → 4N2 + 6H2O

NO is the factor we don’t want. It is extremely poisonous to each people and the setting. This response happens within the chamber. NH3 is ammonia which is added by the SCR together with oxygen molecule. This breaks it into nitrogen molecule and water and each of these are non-polluting.

Overall workings with a BS6 engine

As the petrol variant is just not that totally different from BS4 let’s contemplate the case of diesel BS6. With the brand new gas, and SCR working in tandem a 70% much less emission is the outcome, it’s effectively value each penny additional in comparison with BS4.

But how would you understand if it’s working ideally or not, as a result of in real-life circumstances the catalyst will begin to wear down and lose its effectivity? That’s why we’ve On-Board Diagnostics.

Popular Read: BS6 Compliant Toyota Yaris Launch Soon

What is OBD (On-board diagnostics)?

An automotive time period, in primary phrases it’s simply a device that helps technicians to collect information wanted to verify the right working of the car. So how does it assist with emission?

How does OBD work?

It screens the emission ranges leaving the exhaust which helps the ECU give out an error in your infotainment system if it’s not within the excellent spot the place it must be functioning. The different possibility is when a technician connects to it by way of an output which is contained in the hood and is simply accessible to computer systems that they use, it informs them how the car exhaust system is working and the place the error may lie.

Handheld OBD scanner

Why do you want of an On-Board Diagnostic?

As a client, it helps as a dangerous emission output may imply the engine is in jeopardy as a result of there’s some downside with the exhaust system. This helps each the individual guaranteeing they’ll experience the car for longer and the setting by releasing much less poisonous pollution.

Overall working with BS6

OBD informs when the exhaust system is beginning to fail or has already stopped working in the best way we’d like it to. This ensures that we don’t drive with a defective exhaust system for lengthy because it may end up in main harm to the engine.

Now that these two matters are lined, we have to look into how the businesses know the quantity of emission the car generate throughout real-life driving circumstances. Coincidentally, the subject we’re left inside BS6 is Real Driving Emissions (RDE).

Another Similar Read: BS6 Cars Might Get Expensive In 2020!

What does Real Driving Emissions do?

Real Drive Emissions exams a car for pollution resembling Nox. It helps car producers know if the car they made is as much as the norms set by the respective nation’s authorities or not.

A flowchart explaining how RDE works

Working of a Real Driving Emission take a look at

It entails utilizing a package known as Portable Emission Measuring System (PEMS). A PEMS is hooked up to the exhaust system of a car then it’s pushed on the street below circumstances it is going to undergo usually, not in a lab or a proving floor the place these circumstances are too good to be true for on a regular basis use. The PEMS is then hooked up to a pc the place it analyses the information and offers the suitable outcome.

Overall working with BS6

On the buyer finish, it does nothing, however earlier than the launch of a car, it ensures they’ll meet the emission norms and performance appropriately.

With all these adjustments to gas and new elements concerned, how does it fare towards the older emission norm?

What is the distinction between BS6 and BS4?

As lined earlier the petrol emission is just not that totally different however the distinction between BS6 and BS4 diesel is heaven and hell aside. It begins with gas. Adblue is utilized in BS6 which accommodates 10ppm sulphur as an alternative of 50 ppm in BS4 which when paired with SCR, RDE and OBD cut back the general emission of NOx to 30% of what BS4 used to work with.

BS6 compliant engines appear to be actually good for the setting as they cut back air pollution by a marginal issue however an electrical car gives extra possibility and releases zero emissions.

Electric vehicles | What’s all of the fuss about?

Electric cars are a godsend. With the federal government signalling that they need extra EV and developments exhibiting that individuals are beginning to want them too, they’ll see extra mild of day in 2020 with extra firms switching to electrical alternate options for his or her flagships and bestsellers, EV will solely rise from this 12 months ahead. So, how does it work and why do you have to contemplate it over BS6.

Sony’s Ev idea

How does an electrical car works?

With a battery powering an induction motor and an inverter managing totally different frequency of AC present it’s not powerful to know its working. Let’s take a have a look at the person a part of an EV and the way they work collectively to energy the way forward for the car trade.

What are the parts of an electrical car?

Compared to an IC engine, electrical vehicles have a lot much less quantity of shifting elements. Fewer elements imply much less weight and fewer weight means higher effectivity.

An EV’s drivetrain consists of an induction motor, a generator, a battery pack.

Read More: The Renault Zoe is the New EV in Town!

How does an Induction motor begin?

An induction motor works utilizing a easy legislation. Faraday’s legislation. It states that the motion of the magnetic subject creates a present in a route perpendicular to the magnetic circulate. Where do the magnetic fields come from although?

Induction Motor

They come from a three section AC present equipped to the motor coils. When this present reaches the coil and begins alternating they generate a rotating magnetic subject, which in flip generate induced present which rotates the output shaft thus producing torque for the car. It’s so simple as that.

Some benefits about an induction motor are that the pace of rotation relies upon upon the depth of present equipped which permits us to simply manipulate the pace of the car. It additionally has no brushes which guarantee low friction and lengthy motor life. Where does the present come from? The Battery pack in fact!

Battery pack, The powerhouse of the car!

The battery pack is one thing of a marvel, a small that nobody thought to do till somebody did. It makes use of AA batteries, sure AA the one you employ in your wall clock or your child’s toys, these ones. One of the businesses that do that is Tesla. As its extra attention-grabbing let’s speak about it. It makes use of AA batteries that they made themselves in a sequence and parallel mixture to get a actually excessive output. As they want cooling, it’s offered within the type of Glycol coolant. The battery pack is organized in such a method that it permits for even warmth distribution and cooling.

A Tesla battery pack

This battery pack generates DC energy which doesn’t enable Faraday’s legislation to work. So what occurs now? The inverter joins the fray!

Inverter; the mind of an electrical car

The inverter has two jobs, convert DC into AC and management the output offered thus controlling induction motor output successfully making it the mind (or coronary heart whichever you like) of an EV.

An EV invertor

Did somebody say extra options?

With some applied sciences, the EV will get even higher. Things like quicker response time to manage traction so your tires don’t slip and regenerative braking system, EV tries to make sure you have a easy and protected experience. Let’s see how Regenerative braking system and helps EV be extra environment friendly.

Consider Reading This: Why Scrap Your Old Car? Convert it to Electric, Here’s How!

Regenerative braking system | Simple but Effective

Law of conservation of power states that once you can’t destroy power and it solely adjustments types. once you transfer you get kinetic power and once you cease that power will get expended into some type of different power. In the case of vehicles its warmth and a little bit of sound. In EV although it’s within the type of electrical energy getting again into your battery. How does that occur?

Flowchart for a regenerative braking system

When you brake, the induction motor turns into a generator. This occurs as a result of the pace of the rotor is greater than the pace of the magnetic subject thus making it rotate in the other way. This generates a present in the other way which is then transferred to the battery pack successfully charging it.

I do know what you’re considering, this man is totally biased in the direction of EV and within the selection between bs6 or an electrical car he desires us to decide on EV. Let me present you why I obsess over EV and wish you to contemplate shopping for it.

BS6 or Electric car | An EV motor

How is an Electric Car higher than an Internal Combustion Engine?

The largest factor Ev has over IC engines is that there isn’t any emission. It actually generates zero carbon and different pollution that Ic generates.

The second level is energy era. IC engine generates a translatory movement i.e linear movement. This must be transformed into rotation movement. As a rule of thumb, the extra elements concerned the extra losses will happen. This is just not the case with an EV motor. The output is rotatory, to start with, and thus wants no additional elements to alter the movement route.

And the third level is IC engines are restricted within the vary of energy. They cant generate a extensive number of energy ranges. Induction motor doesn’t want to fret about that. It can generate power in a extensive spectrum with none limitations.

EV can’t be all that good proper? There should be some downsides.

BS6 or Electric car | A V6 engine

Why is an Internal Combustion Engine higher than an Electric Car?

IC is extra handy. The refuelling time is minimal and gas pumps are available.

IC can also be cheaper in comparison with EV with the identical applied sciences as it’s cheaper to make an engine than an EV motor system.

IC has extra different with hundreds of vehicles to select from whereas EV continues to be within the making and simply beginning to get extra variants.

Should I purchase a BS6 car or an electrical car in 2020?

If its comfort, cheaper choices and extra alternate options you need then BS6, with available gas stations and much less expensive in comparison with EV, it’s a sensible choice proper now. It may change sooner or later when EV takes the centre stage and cheaper applied sciences are launched. Although I’m positive that even when EV develop into the bulk BS6 nonetheless gained’t be affected however if you wish to put together for the longer term, you must contemplate getting an EV, its extra easy, extra environment friendly, smarter and environment-friendly.

As to what I’d advocate, EV all the best way! EVolution is coming be sure you are a a part of it!

0

Source link

The post Should You Buy An Electric Car Or a BS6 Car In 2020? appeared first on Carpost.

from Carpost https://www.carpost.net/should-you-buy-an-electric-car-or-a-bs6-car-in-2020/?utm_source=rss&utm_medium=rss&utm_campaign=should-you-buy-an-electric-car-or-a-bs6-car-in-2020

0 notes

Text

Catalysis that neutralizes air-polluting NOx from power plant emissions

New research describes the mechanism behind catalysis that neutralizes air-polluting NOx from power plant emissions. Researchers used a High Field (HF) Nuclear Magnetic Resonance (NMR) spectrometer in conjunction with reaction studies to test three theories around titania-supported vanadium oxide. They found that tungsten oxide changes the structure of vanadium oxide from a less active form to a highly active form. Latest Science News -- ScienceDaily https://www.sciencedaily.com/releases/2019/10/191024075009.htm

0 notes

Text

Catalysis that neutralizes air-polluting NOx from power plant emissions

https://sciencespies.com/environment/catalysis-that-neutralizes-air-polluting-nox-from-power-plant-emissions/

Catalysis that neutralizes air-polluting NOx from power plant emissions

We’ve known for decades that catalysts speed up the reaction that reduces harmful industrial emissions. And now, we know exactly how they do it.

A recent paper by Israel Wachs, the G. Whitney Snyder Professor of Chemical and Biomolecular Engineering at Lehigh University’s P.C. Rossin College of Engineering and Applied Science, describes the mechanism, and was the inside back cover story of the September 2, 2019, issue of Angewandte Chemie, a journal of the German Chemical Society.

Power plants are a major source of toxic emissions associated with climate change. When fossil fuels like coal and natural gas are burned, they produce dangerous contaminants, in particular, a group of harmful gases called nitrogen oxides (or NOx) that contribute to acid rain, ground-level ozone formation, and greenhouse gases.

“The combustion process to generate energy requires very high temperatures that cause molecular nitrogen (N2) and oxygen (O2) present in air to disassociate or crack,” says Wachs. “The N and O atoms then recombine and make NOx, which is considered the biggest pollution problem today because it’s very hard to control.”

Back in the 1970s, the Japanese developed a technology to control NOx emissions by reacting NOx with ammonia to form harmless nitrogen (N2) and water (H2O).

“It’s a beautiful chemical reaction, converting something very harmful to something very benign,” says Wachs, who directs Lehigh’s Operando Molecular Spectroscopy and Catalysis Research Lab.

NOx emissions are now strongly regulated and one common abatement strategy is the selective catalytic reduction (SCR) of nitrogen oxides by ammonia. Catalysts both speed up the SCR reaction and control the reaction products (such as forming N2 and H2O), meaning the catalyst ensures the reaction produces no undesirable harmful gases (hence “selective”).

One SCR catalyst widely used by power plants is titania-supported vanadium oxide.

“The catalyst consists of vanadium oxide and tungsten oxide dispersed on the surface of a titania (TiO2) support. The vanadium oxide is the active component performing the selective catalytic reduction towards N2 formation and not the undesirable reaction products that can be toxic,” says Wachs. “There’s been a big debate raging in the literature for 40 years, right from the beginning of the development of this technology, around the question of what exactly does the tungsten oxide component do?”

The research community knew from experience that tungsten oxide thermally stabilizes the titania support, which is vital as these catalysts can spend years at high temperatures during operation. They also knew that adding tungsten oxide makes the vanadium oxide much more active, which is also important as the more active a catalyst is the less of it you need. But why did tungsten oxide have such an effect on the reactivity of vanadium oxide?

Three theories have dominated over the years, says Wachs. One claimed that tungsten oxide has an acidic character that enhances the chemical reaction. The second said tungsten oxide was somehow sharing electrons with vanadium oxide, and the third stated that the tungsten oxide was changing the structure of the vanadium oxide.

Wachs and his collaborators used a cutting-edge instrument called a High Field (HF) Nuclear Magnetic Resonance (NMR) spectrometer in conjunction with reaction studies to test each theory.

“There are only a few of these HF NMR spectrometers in the world, and their magnetic fields are so sensitive that it gives all the subtle molecular details of what was going on in the material,” he says.

Those molecular details appear as signals that Wachs and his team then interpreted using theoretical calculations (Density Functional Theory).

“It turns out that the amount of vanadium oxide is very low in the catalyst making the vanadium oxide present as isolated species, or monomers,” says Wachs. “When you add the tungsten oxide, vanadium oxide changes from monomers to oligomers or polymers, so now all the vanadium oxide is connected as a chain or an island on the titania support. We performed independent studies and found that these oligomers of vanadium oxide are 10 times more active than in the isolated vanadium oxide sites. So the tungsten oxide really does change the structure of vanadium oxide, from a less active form to a highly active form.”

This fundamental understanding of how the catalyst works will help guide future designs of improved SCR catalysts, says Wachs, who was recently elected as a Fellow of the National Academy of Inventors and has been recognized internationally for his innovative contributions to fundamental catalysis that have been applied in the manufacture of chemicals and control of air pollution.

“Now that we know what’s going on, it won’t be trial and error in terms of making it better since we take a scientific approach to the catalyst design.”

And that will have huge ramifications for industry and air pollution control, he says.

“A more active catalyst has significant benefits. First of all, these systems are huge, almost the size of a small house, and a lot of these plants were built before this technology was mandated, so space at the plants is limited. So if you have a more active catalyst, you need a smaller footprint. They’re also expensive, so if the catalyst is more active, you don’t need as much. And finally, since we also think they’ll last longer, it will limit the amount of time a plant has to shut down to install a new catalyst.”

But for Wachs, the effect on public health is the most meaningful — and gratifying — result.

“Easily, 40,000 to 50,000 people in the United States die annually due to complications from poor air quality. So catalysis, and the research around it, has tremendous societal impact. It’s very satisfying when you’re able to solve a problem that’s been around for 40 years, that will improve the technology, and address these health issues.”

#Environment

0 notes

Link

Mobile emission catalyst helps in emission reduction from automotive and stationary engines from many vehicles such as cars, trucks, commercial vehicles and buses. It reduces emission of various gases such as carbon dioxide (CO2), carbon mono oxide (CO), hydrocarbons (HC), oxide of nitrogen (NOx) and other gases which are produced due to incomplete combustion of fuel. Mobile emission catalyst can also operate at high temperatures range. Mobile emission catalytic converter contains a substrate or core with a honeycomb structure coated with catalyst materials. Mobile emission catalyst is formulated either by single metals or a combination of various active metals such as vanadium, platinum, rhodium, zeolites, oxides of tungsten, titanium and molybdenum. Mobile emission catalyst is mainly use in gasoline engines, diesel engines, motorcycles engine and utility engines.

Request Sample Report@ https://www.persistencemarketresearch.com/samples/3718

Various mobile emission catalysts are diesel oxidation catalysts (DOC); catalyzed soot filters (CSF), selective catalytic reduction (SCR), SCRoF, lean NOx trap (LNT), premAir ozone reduction catalysts, natural gas catalysts, three-way conversion catalyst (TWC), FWC, motorcycle catalysts and small engine catalysts. Various regulations introduced by different countries for effective emission control to safeguard the ecosystem acts as a major driver for mobile emission catalyst market. New engine technologies and fluctuating precious metals prices are some of the key challenge for the growth of global mobile emission catalysts market. The demand of mobile emission catalyst is directly proportional automotives sales. Growing sales in automotive industry helps in the growth of mobile emission catalyst market.

Many global brands such as BASF and Clean Diesel Technologies offers most innovative mobile emission catalyst in the market with emphasis on latest technology and better quality which helps to enable clean air for a healthier environment. Growing investment over research and development on mobile emission catalyst and introduction of new technology further helps in the growth of mobile emission catalyst market.

In Asia Pacific region, China and India holds the largest share of mobile emission catalyst market. Asia Pacific is expected to witness fastest growth rates in mobile emission catalyst market during forecasted period 2014- 2020. Due to rising economy and increase in net income level the sales of automobiles is growing. This directly helps in the growth of mobile emission catalyst market. The European Union (EU) introduces strict limits on pollutant emissions for light road vehicles and commercial vehicles for emissions of nitrogen particulates and oxides. The Regulation includes measures concerning access to information on vehicles and their components. Introducing of such regulation leads to increase in the demand of mobile emission catalyst and replacement of emission technology is many vehicles further boost the mobile emission catalyst market. In North America, the U.S holds the largest market share in mobile emission catalyst market. The global mobile emission catalyst market is expected to grow in a double digit growth rate during forecasted period 2014- 2020.

Request TOC@ https://www.persistencemarketresearch.com/toc/3718

Some of the major companies operating in global mobile emission catalyst market are AeriNox, Inc., BASF, Clean Diesel Technologies, Inc. ,Clariant International Ltd., Cormetech Inc., Corning Incorporated, DCL International, Inc., Johnson Matthey Plc, Rhodia, Inc., Tenneco, Inc., Walker Exhaust Systems and Umicore SA

0 notes

Text

Diesel Exhaust Fluid Market by Component, Application, Vehicle Type and by Region-2022

The Diesel Exhaust Fluid Market was valued at USD 10.64 Billion in 2016 and is projected to grow at a CAGR of 13.06% during the forecast period. The base year considered for the study is 2016 and the forecast period is 2017 to 2022. Factors such as stringent emission regulations, increased penetration of selective catalytic reduction technology in diesel vehicles and the increasing average age of vehicles and miles driven are driving the growth of the diesel exhaust fluid aftermarket.

Don’t miss out on business opportunities in Diesel Exhaust Fluid Market. Speak to our analyst and gain crucial industry insights that will help your business grow: https://www.marketsandmarkets.com/speaktoanalyst.asp?id=155714937

The LCV segment is the largest segment of the diesel exhaust fluid OE market. According to MarketsandMarkets analysis, the number of LCVs equipped with SCR increased from 2.97 million units in 2015 to 3.08 million units in 2016. Other factors influencing the growth of the OE market are the higher tank capacity of LCVs as compared to passenger cars. Furthermore, the penetration of diesel engines and SCR systems is higher in LCVs as compared to passenger cars, as the amount of NOx emitted from LCV engines is more than that emitted from passenger car engines.

Asia-Oceania is estimated to be the largest diesel exhaust fluid OE market, owing to the increasing vehicle production in countries such as China and India. For instance, the vehicle production in China and India is expected to increase from 27.5 million units in 2016 to 39.4 million units by 2022, and 4.7 million units in 2016 to 6.8 million units in 2022 respectively. New stringent emission regulations, such as BS 4 and China 5, being implemented in India and China respectively, are expected to result in the increased penetration of SCR in vehicles in the region. This is consequently expected to fuel the growth of the diesel exhaust fuel market in the region.

Browse and in-depth TOC on "Diesel Exhaust Fluid Market"

103 - Tables

57 - Figures

180 - Pages

View more detailed TOC @

https://www.marketsandmarkets.com/Market-Reports/diesel-exhaust-fluid-market-155714937.html

The bulk supply mode segment is expected to be the largest segment of the diesel exhaust fluid aftermarket during the forecast period. Bulk supply modes which are directly supplied to the fleet are cheapest as compared to other supply modes. Owing to the bulk quantities, the price that the customer needs to pay is less. Customers in emerging regions such as Asia-Oceania and Row also prefer bulk supply mode than other supply modes, due to the lower price that they have to pay. Despite the expected increase in distribution of diesel exhaust fluid through dispensing pumps in the next 5 years, the bulk mode will always be the preferred mode by fleet owners than all the other supply modes of DEF.

The 80-100 HP segment is expected to be the largest segment of the diesel exhaust fluid market in construction equipment application of Off-highway vehicles owing to the reason that 80-100 HP construction equipment is the most widely used equipment type. Approximately 55%-60% of the construction equipment sold worldwide has a power output between 80-100 HP. Furthermore, the penetration of SCR systems in 80-100 HP and >400 HP power output construction equipment is high, due to the high NOx emitted by them as compared to other equipment types.

Request for Free Sample Report @ https://www.marketsandmarkets.com/requestsample.asp?id=155714937

The SCR catalyst component market is estimated to be the largest during the forecast period, owing to the high price of SCR catalyst compared to other components used in the selective catalytic reduction systems. Thus, the SCR catalyst component OE market in terms of value is the largest in the diesel exhaust fluid market by component. The SCR catalyst is made up of ceramic materials, such as titanium oxide or oxides of metals, such as vanadium, molybdenum, and tungsten, among others. Owing to the presence of such materials, the cost of SCR catalyst is higher which leads to the largest market size of the component.

The Diesel Exhaust Fluid Market ecosystem consists of DEF manufacturers such as Yara International (Norway), CF International Holdings, Inc. (U.S.), China Petrochemical Corporation (Sinopec) (China), Total S.A. (France), and Royal Dutch Shell (Netherlands). DEF is supplied to major OEMs in the automotive industry including Nissan (Japan), General Motors (U.S.), Honda (Japan), and others.

0 notes