#Valve Suppliers

Explore tagged Tumblr posts

Text

Gate Valves in the Petrochemical Industry: Key Applications

In the complex and demanding environment of the petrochemical industry, the selection of appropriate valves is critical to ensuring the efficiency and safety of operations. Among the various types of valves used, gate valves play a crucial role due to their unique characteristics and versatility. This article explores the key applications of gate valves in the petrochemical industry and highlights their importance, especially for those seeking reliable suppliers such as a Valve Stockist in the Dubai or renowned Valve Manufacturers globally.

Understanding Gate Valves

Gate valves are primarily used to either completely stop or allow the flow of a fluid through a pipeline. Unlike other valve types, gate valves operate by lifting a gate out of the path of the fluid. This mechanism is ideal for applications that require the valve to be either fully open or fully closed, making them unsuitable for flow regulation but perfect for on-off control.

Key Applications in the Petrochemical Industry

Isolation of Flow:

Gate valves are extensively used for isolating sections of pipelines during maintenance or emergencies. Their ability to provide a tight seal ensures that no leakage occurs, which is vital in handling hazardous fluids. This makes them indispensable in petrochemical plants where safety is paramount.

Handling High-Pressure Fluids:

The petrochemical industry often deals with high-pressure fluids, and gate valves are well-suited to handle such conditions. Their robust design and capability to withstand high pressures make them a preferred choice for critical applications. Valve Manufacturers in Spain are known for producing high-quality gate valves that can operate efficiently under extreme conditions.

Controlling Corrosive Media:

Petrochemical processes frequently involve corrosive media. Gate valves made from specialized materials, such as stainless steel or alloy, are used to resist corrosion and prolong the valve’s service life. For industries looking for specialized valves, engaging with a reputable Gate Valves Supplier is crucial to ensure durability and reliability.

Steam and Heat Transfer Systems:

In petrochemical plants, steam and heat transfer systems are integral to various processes. Gate valves are employed in these systems to manage the flow of steam and other high-temperature fluids. These valves can handle the thermal expansion and contraction that occur in such systems, making them a vital component of heat management.

Shutdown Systems:

In emergency shutdown systems, gate valves are often used due to their ability to quickly and completely stop the flow of hazardous fluids. This quick response capability is critical in preventing accidents and ensuring the safety of the plant and its personnel.

Sourcing the Right Gate Valves

For businesses in the petrochemical industry, sourcing the right gate valves from reliable suppliers is essential. A Valve Stockist offers a wide range of options, ensuring that industries can find the exact specifications they need. Moreover, working with a Ball valves Supplier, Globe Valves Supplier, or Butterfly valve supplier can provide comprehensive valve solutions for various applications.

Additionally, many industries are turning to international markets for their valve needs. Valve Manufacturers in Spain have earned a reputation for their quality and innovation, providing robust solutions for petrochemical applications. Engaging with such manufacturers ensures access to advanced technology and high-quality products.

Conclusion

Gate valves are indispensable in the petrochemical industry, serving critical functions across various applications. Whether isolating sections of a pipeline, handling high-pressure fluids, or managing corrosive media, these valves provide the reliability and safety that petrochemical plants demand. To ensure optimal performance and safety, it is crucial to source these valves from reputable suppliers, such as a Valve Stockist in UAE or leading Valve Manufacturers globally. Additionally, working with specialized suppliers like a Control valves supplier or Water Valves Supplier can further enhance the efficiency and safety of petrochemical operations

2 notes

·

View notes

Text

From Concept to Creation: The Journey of America's Premier Valve Manufacturer

Piping Projects is one of the leading Valve Manufacturers in USA. We manufacture our Valves using top-quality raw materials. We specialize in designing, producing, and distributing valves for various industries such as oil and gas, water treatment, power generation, and manufacturing. These valves are crucial components used to control the flow of liquids, gases, and slurries within piping systems.

Valve Manufacturer Pioneering Beginnings

Revolutionising an Industry

The story begins in the early 20th century when pioneers John Johnson and Robert Smith identified a need for superior Valve Manufacturers for machinery and industrial processes. They set out on a mission to revolutionise the valve manufacturing industry, aiming to create products that surpassed existing reliability, efficiency, and longevity standards.

Engineering Expertise

With a passion for engineering and a shared vision, Johnson and Smith established their first manufacturing facility in a small workshop in a quiet town. Drawing on their expertise and a commitment to quality, they meticulously designed and developed valves that outperformed anything available at the time. Their unwavering dedication soon caught the attention of industry experts, igniting the path to success for their company.

Growth and Expansion

Innovations and Advancements

As demand for their valves skyrocketed, America's premier valve manufacturer began investing heavily in research and development. Their talented engineers continuously introduced groundbreaking innovations that pushed the industry forward. Patented designs, advanced materials, and cutting-edge technologies became the hallmark of their products, cementing their reputation as leaders in Valve Manufacturers USA.

Increasing Market Reach

With a firm foothold in the domestic market, the company focused on expanding into international territories. Partnerships with distributors, collaborations with global industry giants, and strategic acquisitions of smaller Valve Suppliers enabled them to establish a strong presence across continents. This ambitious expansion solidified their position as the go-to choice for valves in various industries, from oil and gas to power generation.

Ethical Standards and Sustainability

Commitment to Ethical Practices

Throughout their journey, America's premier valve manufacturer has demonstrated an unwavering commitment to ethical business practices. They have cultivated long-term relationships with customers and suppliers by embracing fairness, honesty, and transparency. By adhering to strict quality control measures, they have established an excellent reputation that instils confidence in clients worldwide.

Embracing Sustainability

Recognising the importance of environmental responsibility, the company has incorporated sustainability as a fundamental pillar in its operations. They aim to minimise their ecological footprint through eco-friendly manufacturing processes, energy-efficient technologies, and the use of recycled materials. By setting an example for the industry, they inspire others to follow suit, protecting our planet for future generations.

List Of Our Products

Instrumentation Valves Manufacturers

Steel Wire Suppliers

Gasket Manufacturers in USA

Welding Electrode Manufacturers

Steel Pipe Sleeves

Embracing Digital Transformation

Harnessing the Power of Technology

In an ever-evolving world, America's premier valve manufacturer understands the importance of staying ahead of the curve. Embracing digital transformation, they have integrated state-of-the-art technologies into their manufacturing processes. Automation, machine learning, and real-time data analysis have enhanced productivity and allowed for predictive maintenance, reducing downtime and optimising performance.

Customer-Centric Approach

Beyond technological advancements, the company has leveraged digital platforms to enhance the customer experience. Their user-friendly websites, intuitive product configurators, and responsive customer support channels ensure seamless client interactions. By harnessing the power of technology, they have successfully built strong, long-lasting relationships with their valued customers.

Conclusion

From concept to creation, the journey of America's premier valve manufacturer is one of determination, innovation, and exceptional craftsmanship. Through their pioneering spirit, ethical practices, sustainability efforts, and embrace of digital transformation, they continue to shape the industry and inspire future manufacturers. As they forge ahead, propelled by their unwavering commitment to excellence, their story serves as a reminder that with vision and perseverance, anything is possible.

To Know More Visit us,

Product: Valve Suppliers in USA

Website: pipingprojects.us

0 notes

Text

#Online Retailers#Manufacturers#Industrial Supply Platforms#B2B E-commerce Platforms#Valve Suppliers

0 notes

Text

Forged Steel gate Valve Supplier Brazil

South American Valve is the largest forged steel gate valve supplier in Brazil. We supply to Rio de Janeiro, São Paulo and Salvador. A forged steel gate valve is a type of valve that is constructed using forged steel components. It is designed to control the flow of fluid by using a sliding gate or wedge mechanism that moves perpendicular to the direction of the flow. Gate valves are primarily used in applications where a full unobstructed flow is required or when the valve needs to be fully open or fully closed.

South American Valve is the largest forged steel gate valve supplier in Brazil .The body of a forged steel gate valve is made from forged steel, which provides strength and durability. It is typically a one-piece or two-piece construction with flanged or threaded ends for easy installation. Forged steel gate valves are commonly used in high-pressure and high-temperature applications, such as in oil and gas, petrochemical, and power industries. The forged steel construction ensures strength and resistance to corrosion, making them suitable for demanding environments.

Parts:

Body

Bonnet

Gate

Stem

Seat

Actuator

Applications:

Oil and gas pipelines: Gate valves are commonly used in oil and gas pipelines to control the flow of crude oil, natural gas, or other fluids under high pressure.

Water treatment plants: Gate valves are used in water treatment plants to control the flow of water through different stages of the treatment process.

Power generation: Gate valves are used in power generation plants to control the flow of steam or water in turbines and other equipment.

Chemical and petrochemical industries: Gate valves are used in chemical and petrochemical plants to control the flow of various chemicals and gases in different processes.

Mining: Gate valves are used in mining operations to control the flow of water, slurries, or other fluids in the processing of minerals.

HVAC systems: Gate valves are used in heating, ventilation, and air conditioning (HVAC) systems to control the flow of water in heating and cooling systems.

Marine and offshore: Gate valves are used in marine and offshore applications, such as oil rigs and ships, to control the flow of fluids and gases.

Advantages:

Full bore flow: Gate valves offer a full-bore flow path, which means that there is little resistance to flow, resulting in minimal pressure drop.

Strong and durable: Gate valves are designed to withstand high pressure and temperatures, making them ideal for use in demanding industrial applications.

Tight seal: The gate valve’s gate or wedge design allows for a tight seal when the valve is fully closed, which helps prevent leaks and reduces the risk of contamination.

Easy to operate: Gate valves are relatively easy to operate, typically requiring only a quarter-turn to fully open or close.

Long service life: Gate valves are constructed with high-quality materials and are designed for long service lifewith minimal maintenance.

Versatile: Gate valves can be used in a wide range of applications across various industries.

Description:

Available materials: Ductile Iron,SS306, SS904, SS316, Aluminum Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, CF8, CF8M, CF3, CF3M, WC1, Cast iron Carbon steel(WCB, WCC,WC6, LCB, LF2, WC9Size: 1/2″- 64”Class: 150 to 2500Nominal Pressure: PN10 to PN450Operations: Hand Wheel, Gear operated, Electric and Pneumatic, ActuatedEnds: Flanged, Buttweld, Socket weld, ThreadedStandards: ASME, API6D, API607, DIN, BS, ANSI, AWWA

Visit us: https://www.southamericanvalve.com/product-category/forged-steel-gate-valve/

0 notes

Text

Automating Efficiency: The Power of Valve Automation in Industrial Processes

In the industrial world, valve automation is a big deal! It helps make things work better and faster. By using smart systems and special devices, automated valves can control things precisely without needing people to do it manually. This means fewer mistakes and safer operations. It also saves money and makes work more efficient. With valve automation, industries can now do their jobs with less hassle and more success!

Introduction to Valve Automation:

Valve automation is a smart and efficient way to control valves in various industries. In simple terms, it means letting machines take care of the valve operations instead of relying on manual adjustments. This automation technology brings a host of benefits and has become a crucial part of modern industrial processes.

Automated valves play a significant role in regulating the flow of liquids, gases, or other substances within pipelines or equipment. They are used in a wide range of industries, including oil and gas, water treatment, chemical, pharmaceuticals, and manufacturing. By automating the valve control, businesses can streamline their operations, improve safety, and achieve better productivity.

Advantages of Automated Valves in Industrial Processes:

The use of automated valves offers numerous advantages to industries. Firstly, they provide precise control over the flow and pressure of fluids, ensuring that the right amount reaches the desired destination. This accuracy results in better product quality and reduces wastage, leading to cost savings.

Secondly, automated valves require minimal human intervention. Unlike manual valve control, where constant monitoring and adjustment are needed, automated systems can work independently once set up. This reduces the risk of human errors and frees up operators to focus on other essential tasks.

Furthermore, automated valves enhance safety in industrial settings. Accidents related to human error during valve operation can lead to hazardous situations. With automation, these risks are significantly reduced, making the workplace safer for employees.

Working Principles of Valve Automation Systems:

Valve automation systems consist of specialized components that work together to regulate the valve's position or flow. These systems use sensors to measure various parameters, such as pressure, temperature, or fluid levels. The information from these sensors is then processed by a control unit or computer program.

Based on the data received, the control unit sends signals to actuators, which are mechanical devices responsible for moving the valve. The actuators adjust the valve position, ensuring that the flow remains within the desired range.

In some cases, the valve automation system may use feedback loops to continuously monitor and adjust the valve position, maintaining the desired conditions. This closed-loop system helps maintain a steady flow or pressure even when external factors change.

Implementing Valve Automation: Best Practices and Considerations:

Implementing valve automation requires careful planning and consideration. Firstly, industries need to determine the specific requirements for their automation system. This includes understanding the flow characteristics, the type of fluids being handled, and the desired control parameters.

Choosing the right type of automated valve and actuator is crucial. Different applications may require different types of valves, such as ball valves, butterfly valves, or globe valves. Similarly, various actuators, such as electric, pneumatic, or hydraulic, offer different advantages depending on the application.

Proper installation and maintenance are essential for the reliable performance of valve automation systems. Regular inspections and servicing help identify and address any issues before they become major problems.

Future Trends and Innovations in Valve Automation Technology:

The future of valve automation looks promising, with ongoing advancements in technology. One of the significant trends is the integration of artificial intelligence (AI) and machine learning into valve automation systems. AI can optimize valve control by learning from past data and making real-time adjustments, leading to even more efficient operations.

Additionally, advancements in sensor technology will enable more precise and reliable monitoring of process conditions, further enhancing the performance of automated valves. These sensors may also facilitate predictive maintenance, where potential issues can be identified before they cause any disruption.

Wireless communication and the Internet of Things (IoT) are also likely to play a significant role in the future of valve automation. These technologies will enable seamless communication between valves, actuators, and control systems, allowing for more integrated and interconnected industrial processes.

Thus, valve automation has transformed the way industries handle fluid flow and pressure control. The benefits of automated valves, including increased precision, improved safety, and reduced human intervention, are driving their widespread adoption across various sectors. As technology continues to evolve, we can expect even more exciting innovations and improvements in valve automation, propelling industries toward greater efficiency and productivity.

Conclusion :

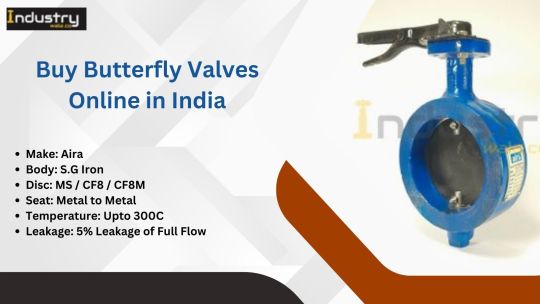

In conclusion, Aira Euromation's valve automation solutions offer precise flow control, enhanced safety, and improved efficiency for industrial processes. With cutting-edge technology and a dedication to excellence, Aira Euromation continues to be a trusted partner in the industry. Their commitment to innovation ensures a promising future of advanced automation, driving industries towards greater productivity and success.

0 notes

Text

The Impact of Valve Suppliers on Industrial Safety and Reliability

In the industrial sector, safety and reliability are of paramount importance. Every aspect of the manufacturing process needs to be carefully monitored and controlled to ensure the well-being of workers and the integrity of the equipment. One crucial component that plays a significant role in maintaining safety and reliability is valves. Valve suppliers have a direct impact on industrial safety and reliability by providing high-quality products, expertise, and support. In this article, we will explore the various ways in which valve suppliers contribute to industrial safety and reliability.

Industrial safety and reliability are fundamental considerations for any manufacturing operation. Valve suppliers play a crucial role in ensuring the smooth functioning of industrial processes by providing high-quality valves that meet industry standards and regulations. This article delves into the impact of valve suppliers on industrial safety and reliability, highlighting their contributions and the benefits they offer.

Understanding Valves and their Importance

Valves are mechanical devices used to control the flow of fluids or gases within a system. They play a vital role in regulating pressure, temperature, and flow rates, making them essential components in various industrial applications. Valves help maintain the stability and integrity of systems, ensuring efficient operations and preventing accidents or equipment failures.

The Role of Valve Suppliers in Ensuring Safety

Valve suppliers play a significant role in maintaining industrial safety. Here are three key ways in which they contribute:

Quality Assurance

Reputable valve suppliers prioritize quality assurance in their manufacturing processes. They adhere to stringent quality control measures to ensure that their valves meet or exceed industry standards. By providing high-quality valves, these suppliers help prevent malfunctions, leaks, and other safety hazards, reducing the risk of accidents or injuries in industrial settings.

Compliance with Industry Standards

Valve suppliers are well-versed in the relevant industry standards and regulations. They ensure that their products comply with these standards, such as ISO, API, ASME, or other applicable certifications. By adhering to these standards, valve suppliers contribute to the overall safety of industrial processes, providing customers with reliable and compliant valves.

Technical Expertise and Support

Valve suppliers possess extensive technical knowledge and expertise in their field. They offer valuable support to customers by providing guidance on valve selection, installation, and maintenance. This expertise helps industrial operators make informed decisions, ensuring that the valves are correctly installed and maintained for optimal performance and safety.

Enhancing Reliability with Valve Suppliers

Apart from safety, valve suppliers also contribute to the reliability of industrial operations. Here are three ways in which they enhance reliability:

Proactive Maintenance

Valve suppliers often offer maintenance services and programs to help customers proactively manage their valves. Regular inspections, repairs, and preventive maintenance can significantly extend the lifespan of valves and prevent unexpected failures. By partnering with valve suppliers, industrial operators can implement effective maintenance strategies, minimizing downtime and maximizing reliability.

Customization and Tailored Solutions

Different industrial processes have unique requirements. Valve suppliers understand this diversity and provide customized solutions to meet specific needs. Whether it's modifying valve designs or developing entirely new products, they work closely with customers to deliver tailored solutions that enhance reliability. Customized valves can optimize performance, increase efficiency, and improve overall system reliability.

Inventory Management

Maintaining an optimal inventory of valves is essential for uninterrupted operations. Valve suppliers can assist in inventory management by offering just-in-time delivery, consignment stock, or vendor-managed inventory solutions. By ensuring that the right valves are available when needed, suppliers help minimize downtime, streamline operations, and enhance overall reliability.

Case Studies: Real-Life Examples

To illustrate the impact of valve suppliers on industrial safety and reliability, let's examine a few real-life case studies. These examples highlight how collaboration with reputable valve suppliers has resulted in improved safety and enhanced reliability across different industries.

The Future of Valve Suppliers and Industrial Safety

As technology advances and industries evolve, valve suppliers will continue to play a vital role in ensuring industrial safety and reliability. With ongoing research and development, innovative valve solutions will emerge, further enhancing safety measures and optimizing industrial processes. The future of valve suppliers looks promising, with a focus on sustainability, digitalization, and continuous improvement.

Conclusion

Valve suppliers have a significant impact on industrial safety and reliability. Through their commitment to quality, compliance with industry standards, and technical expertise, they contribute to the prevention of accidents, injuries, and equipment failures. Moreover, their provision of customized solutions, proactive maintenance programs, and inventory management assistance enhance the overall reliability of industrial operations. By partnering with reputable valve suppliers, industries can prioritize safety, maximize efficiency, and achieve long-term success.

0 notes

Text

How Valve Suppliers Contribute to the Safety and Reliability of Industrial Systems

In this article, we will explore the vital role that valve suppliers play in ensuring the safety and reliability of industrial systems. Valves are essential components used in various industries, including oil and gas, power generation, water treatment, and manufacturing. They control the flow of fluids and glasses, enabling efficient and controlled operation of complex systems.

Importance of Valve Suppliers

Valve suppliers play a crucial role in the industrial sector by providing high-quality valves that meet specific requirements. Their expertise in valve design, manufacturing, and distribution ensures that industrial systems function optimally, preventing costly downtime and potential hazards.

Types of Valve Suppliers

Valve suppliers can be categorized into different types based on their specialization and scope of operations. They include original equipment manufacturers (OEMs), distributors, and specialized valve service providers. OEMs design and produce valves, while distributors procure and supply valves from various manufacturers. Specialized valve service providers offer maintenance, repair, and testing services.

Key Roles and Responsibilities

Valve suppliers have several key roles and responsibilities that contribute to the safety and reliability of industrial systems. They collaborate with engineers, consultants, and end-users to understand the specific requirements of each application. Based on these requirements, valve suppliers recommend suitable valve types, materials, and specifications to ensure optimal performance.

Quality Assurance

Maintaining strict quality control is essential for valve suppliers to deliver reliable products. They adhere to international standards and certifications, such as ISO 9001, to ensure that valves meet quality and performance criteria. Quality assurance processes include material testing, dimensional inspections, and pressure and leakage tests.

Safety Measures

Valve suppliers prioritize safety in industrial systems. They provide valves with built-in safety features, such as pressure relief valves, emergency shutdown valves, and fail-safe mechanisms. These safety measures prevent system failures, overpressure, and potential accidents, safeguarding both personnel and equipment.

Compliance with Standards

Valve suppliers ensure compliance with industry standards and regulations, such as API, ANSI, ASME, and ASTM. These standards define the design, manufacturing, and testing requirements for valves. Compliance guarantees that valves are suitable for specific applications and can withstand demanding operating conditions.

Collaborative Partnerships

Valve suppliers often collaborate with system integrators, engineering firms, and end-users to provide customized valve solutions. They actively engage in projects, offering technical expertise, support, and assistance throughout the lifecycle of the industrial system. Collaborative partnerships enable valve suppliers to deliver tailored solutions that meet specific industry needs.

Innovation and Technological Advancements

Valve suppliers embrace innovation and leverage technological advancements to enhance valve performance and reliability. They invest in research and development to improve valve design, materials, and manufacturing processes. Advanced technologies, such as smart valves with remote monitoring capabilities, contribute to predictive maintenance, increased efficiency, and improved system reliability.

Impact on Industrial Systems

Valve suppliers have a significant impact on the overall performance and safety of industrial systems. Their high-quality valves and expertise ensure efficient flow control, preventing leaks, pressure imbalances, and equipment failures. Reliable valve operation leads to uninterrupted production, reduced downtime, and increased productivity for industries.

Case Studies

Several case studies demonstrate the positive impact of valve suppliers on industrial systems. One example is the successful implementation of a valve solution in a petrochemical plant, which significantly reduced emissions and improved system efficiency. Another case study highlights how a valve supplier's technical support resolved a complex flow control issue in a water treatment facility, ensuring uninterrupted operation.

Future Trends

The valve industry is witnessing several trends that will shape its future. These include the increasing adoption of digitalization and IoT technologies for remote monitoring and predictive maintenance. Valve suppliers are also exploring sustainable materials and energy-efficient designs to align with environmental goals.

Conclusion

Valve suppliers are indispensable contributors to the safety and reliability of industrial systems. Their expertise, quality assurance processes, safety measures, and collaborative partnerships ensure that valves meet the specific requirements of diverse industries. By providing reliable flow control solutions, valve suppliers help optimize industrial operations, prevent accidents, and enhance productivity.

0 notes

Text

#electric ball valve#motorized ball valve#electric ball valve manufacturer and suppliers in saint clair#electric ball valve manufacturer in saint clair#motorized ball valve manufacturer and suppliers in saint clair#motorized ball valve suppliers in saint clair#missouri#usa

0 notes

Text

The Role of Pulp Valves in Wastewater Treatment and Slurry Handling

Pulp valves are essential for efficient wastewater treatment and slurry handling, offering superior durability, flow control, and clog-free operation. Their robust construction and advanced sealing mechanisms make them ideal for industries dealing with abrasive, high-solid-content fluids.

0 notes

Text

Double flanged type butterfly valves are a critical component across numerous industries. Their versatility, cost-effectiveness, and robust design make them a popular choice among water valve suppliers, ball valves suppliers, and control valves suppliers alike. Whether you’re looking for precision control in chemical processing or reliable performance in water treatment, these valves deliver unmatched value. Partnering with established European valve manufacturers ensures access to high-quality solutions that stand the test of time. Valvulasfevisa, is one of the leading butterfly valves suppliers and valve stockist in USA. They ensures optimal performance and long-term value.

0 notes

Text

UPVC ball valves are an excellent choice for industries and households looking for affordable, durable, and high-performance fluid control solutions. If you need a reliable UPVC ball valve at the best price, Petron Thermoplast offers a wide range of options tailored to your needs.

Visit Website - https://petronthermoplast.com/upvc-valves/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#upvcballvalve #upvcballvalvemanufacturer #upvcballvalvesupplier #upvcplasticballvalve

#UPVC Ball Valve#UPVC Valves#UPVC Plastic Ball Valve#UPVC Ball Valve Manufacturer#UPVC Ball Valve Supplier

0 notes

Text

0 notes

Text

Basket Strainers vs. Other Filtration Methods: Advantages in Valve Systems

In the world of industrial fluid control, effective filtration is essential to protect equipment and ensure smooth operations. Basket strainers have long been a popular choice for their efficiency and reliability. But how do they compare to other filtration methods, and what makes them ideal for various applications involving valves and steam traps? Let’s explore the advantages of basket strainers and their role in optimizing valve systems.

What are Basket Strainers?

Basket strainers are mechanical devices used to filter out debris from liquid or gas pipelines. They feature a perforated or mesh basket that traps particles, preventing them from flowing downstream and damaging sensitive components such as Ball Float Steam Traps, Actuated Butterfly Valves, and Float Steam Traps.

Advantages of Basket Strainers over Other Filtration Methods

High Debris Holding Capacity: Compared to Y-strainers and inline filters, basket strainers have a larger surface area, allowing them to capture more debris before requiring maintenance.

Easy Maintenance: The removable basket design simplifies cleaning and replacement, reducing downtime in industrial processes.

Versatility: Basket strainers can handle a wide range of flow rates and pressures, making them suitable for various applications, including steam distribution systems that rely on Ball Float Steam Traps and Float Steam Traps.

Minimal Pressure Drop: Due to their design, basket strainers create minimal pressure loss, ensuring that Actuated Butterfly Valves and other control valves operate efficiently.

Applications in Valve Systems

In complex fluid control systems, components such as Actuated Butterfly Valves and Float Steam Traps play critical roles in regulating flow and managing steam. Basket strainers complement these components by keeping the pipeline free of contaminants. This is especially important in systems with Ball Float Steam Trap, where debris can cause malfunction or inefficiencies.

Comparing Basket Strainers to Other Filtration Methods

Y-Strainers: While Y-strainers are compact and suitable for smaller pipelines, they have limited debris-holding capacity and are harder to clean compared to basket strainers.

Inline Filters: These are often used for finer filtration but can clog quickly, leading to higher maintenance demands.

For industries seeking efficient and reliable filtration, basket strainers stand out as a superior solution. Their ability to protect critical components like Ball Float Steam Traps, Actuated Butterfly Valves, and Float Steam Traps ensures the long-term efficiency and stability of valve systems. By investing in high-quality basket strainers, manufacturers can achieve better performance, reduced maintenance costs, and prolonged equipment lifespan.

When choosing a filtration method, consider the operational advantages of basket strainers and how they contribute to the seamless functioning of your valve systems.

0 notes

Text

Lubricated plug Valve Supplier in Mexico

South American Valve is a leading lubricated plug valve supplier in Mexico. A lubricated plug valve is a type of valve that utilizes a lubricant to reduce friction and facilitate smooth operation of the plug mechanism. It is commonly used in various industries, including oil and gas, chemical processing, and petrochemicals, where reliable shut-off and control of flow are required. The body of a lubricated plug valve is typically made of cast or forged steel. It provides the main housing for the valve components and is designed to withstand the operating pressures and temperatures.

South American Valve is a leading lubricated plug valve supplier in Mexico. Lubricated plug valves offer several advantages, including reduced operating torque, improved sealing performance, and extended service life due to reduced wear and friction. The lubricant helps minimize friction between the plug and the valve body, allowing for smooth operation and reducing the wear and tear of the valve components. Lubricated plug valves offer several advantages, including reduced operating torque, improved sealing performance, and extended service life due to reduced wear and friction. The lubricant helps minimize friction between the plug and the valve body, allowing for smooth operation and reducing the wear and tear of the valve components.

Parts

Body

Plug

Seat

Stem

Lubrication system

Applications

Oil and gas industry: Plug valves are widely used in the oil and gas industry for applications such as wellhead control, pipeline transport, refining, and processing. They are preferred for their high-pressure and high-temperature resistance, and their ability to handle abrasive fluids and slurries.

Chemical industry: The chemical industry uses plug valves for applications such as chemical processing, refining, and transportation. They are suitable for corrosive and abrasive fluids, and they can handle a wide range of temperatures and pressures.

Water treatment: Plug valves are used in water treatment facilities for applications such as water distribution, wastewater treatment, and desalination. They are suitable for handling a variety of fluids, including sewage and sludge.

Power generation: Plug valves are used in power generation plants for applications such as steam distribution, cooling water systems, and fuel handling. They are preferred for their reliability and ability to handle high-temperature and high-pressure fluids.

Pulp and paper industry: The pulp and paper industry uses plug valves for applications such as pulp processing, chemical recovery, and wastewater treatment. They are preferred for their ability to handle abrasive and corrosive fluids.

Advantages

Tight seal: Plug valves provide a tight seal, which minimizes the risk of leakage and ensures that the fluid flows through the valve in a controlled manner.

Simple design: Plug valves have a simple design that makes them easy to install, operate, and maintain. They also have fewer moving parts than other types of valves, which reduces the risk of mechanical failure.

High-pressure and high-temperature resistance: Plug valves are suitable for high-pressure and high-temperature applications, making them ideal for industries such as oil and gas, chemical, and power generation.

Abrasion and corrosion resistance: Some types of plug valves are designed to handle abrasive and corrosive fluids, making them suitable for applications where these conditions are present.

Throttling capability: Some types of plug valves, such as the eccentric plug valve, have a high degree of throttling capability, making them suitable for applications that require precise flow control.

Versatility: Plug valves can be used for a wide range of applications, including oil and gas, chemical processing, water treatment, and power generation.

Cost-effective: Plug valves are generally cost-effective, especially when compared to other types of valves that require more maintenance or have higher initial costs.

Description

Material: Carbon Steel, Iron, Duplex Steel, CF8, CF8M, WCB, CF3, CF3M, WC6, Ductile iron, WCC, LCB, LCC, SS304, SS316, Alloy 20

Class: 150 to 2500.

Pressure: PN10 to PN450.

Nominal Size: ½” to 24”

Ends: Flanged, Threaded, Socket weld, Buttweld

Operations – Gear operated, Electric actuated , Pneumatic actuated, Lever operated

Visit us: https://www.southamericanvalve.com/product-category/lubricated-plug-valve/

0 notes

Text

Trunnion ball valve suppliers & manufacturers in Dubai, UAE | Instruments Fittings

Dubai, the thriving business hub of the UAE, is home to a wide variety of industries requiring awesome components to maintain their operations. Among the critical components for diverse commercial applications are trunnion ball valves. These valves are designed for durability, performance, and reliability, making them vital in industries that include oil and gas, petrochemicals, water treatment, and production. This blog explores the leading trunnion ball valve providers, sellers, and manufacturers in Dubai-UAE, losing mild on why these valves are a favored preference for crucial operations.

What Are Trunnion Ball Valves?

Trunnion ball valves are specialized forms of ball valves that characterize a pivot or trunnion to aid the ball inside the valve. Unlike preferred ball valves, in which the ball is free to move, trunnion ball valves have a mechanical anchoring device that enhances their operational performance. This design is specifically useful for managing high-stress systems as it guarantees higher sealing, reduced put-on, and longer provider lifestyles.

The versatility and robust design of trunnion ball valves lead them to be perfect for traumatic programs in industries wherein reliability is non-negotiable. Whether it’s coping with the drift of oil and fuel or coping with corrosive chemicals inside the petrochemical area, trunnion ball valves providers in Dubai offer products that supply top-notch performance.

Leading Trunnion Ball Valve Manufacturers in Dubai-UAE

Dubai’s commercial landscape is exceedingly competitive, and corporations rely upon quality products to preserve their aspect. Trusted trunnion ball valve producers inside the region make certain their valves meet the very best standards of durability and overall performance. Here are a few key motives why deciding on local manufacturers advantages businesses:

Customised Solutions: Manufacturers in Dubai apprehend the precise demands of the location’s industries and provide tailored trunnion ball valves to meet precise desires.

High-Quality Standards: With a dedication to excellence, Dubai-primarily based trunnion ball valve manufacturers ensure their products adhere to global satisfactory standards.

Faster Turnaround: Choosing neighborhood manufacturers reduces delivery instances, making sure that organizations face minimal downtime.

Technical Support: Manufacturers in Dubai offer sturdy technical assistance, providing steerage on valve choice and renovation.

At Instrument Fittings, our aim is to offer pinnacle-notch additives, together with trunnion ball valves, that set new benchmarks for quality and sustainability within the fittings and fasteners industry.

Reliable Trunnion Ball Valve Suppliers in Dubai-UAE

For industries working in excessive stress and high-temperature environments, the reliability of their additives is important. This is where the position of trunnion ball valve suppliers in Dubai turns fundamental. Suppliers act as the bridge between manufacturers and cease-users, making sure seamless get-right of entry to first-rate products.

Key attributes of top trunnion ball valve providers include:

Wide Range of Products: Suppliers in Dubai offer an intensive stock, catering to numerous business packages.

Expertise and Knowledge: They are ready with in-depth know-how approximately trunnion ball valves, assisting clients pick the right valve for his or her wishes.

After-Sales Support: Leading suppliers provide splendid after-income offerings, ensuring the valves characteristically over time.

Competitive Pricing: Dubai’s trunnion ball valve sellers make sure that remarkable valves are to be had at competitive charges, making them available to agencies of all sizes.

Why Choose Trunnion Ball Valves?

Trunnion ball valves are the favored desire for industries requiring sturdy and dependable drift control answers. Here’s why:

Enhanced Sealing: The trunnion design guarantees better sealing even under high strain, making these valves ideal for essential programs.

Durability: Made from corrosion-resistant materials, trunnion ball valves are constructed to face up to harsh environments.

Ease of Operation: These valves provide easy operation, lowering put-on and tear over time.

Low Maintenance: With fewer moving parts and enhanced sealing, trunnion ball valves require minimal preservation, ensuring cost and financial savings.

The trunnion ball valve manufacturers and providers in Dubai always meet the stringent needs of various industries, presenting products that ensure safety, efficiency, and reliability.

Instrument Fitting New Standards

Instrument Fittings is dedicated to revolutionising the fittings and furnishings area with the aid of providing products that combine high-quality with sustainability. As a relied-on provider of trunnion ball valves, we ensure our products meet global standards, catering to the various wishes of our customers.

Our understanding lies in delivering fittings that assure seamless connections, making sure your operations run smoothly. By setting new benchmarks within the industry, we intend to create lasting relationships with our customers while specializing in a sustainable future.

Choosing the Right Trunnion Ball Valve Dealer

Selecting the proper trunnion ball valve dealers is vital for making sure the achievement of your industrial operations. Here are some elements to bear in mind whilst choosing a supplier in Dubai:

Product Range: Ensure the supplier gives a huge range of trunnion ball valves to satisfy your unique desires.

Reputation: Opt for sellers with a strong popularity for delivering tremendous products and first-rate customer service.

Certifications: Check if the provider’s products are licensed to fulfill international standards.

Experience: Look for dealers with years of experience in offering trunnion ball valves to diverse industries.

The Future of Trunnion Ball Valves in Dubai-UAE

As industries in Dubai continue to expand, the call for dependable components like trunnion ball valves is about to grow. Manufacturers and suppliers in the place are constantly innovating to meet this call for, specializing in sustainable and efficient solutions.

Trunnion ball valve producers, providers, and sellers in Dubai are well-placed to cater to the evolving needs of industries, supplying products that make certain operational efficiency and safety.

Conclusion

Trunnion ball valves are a cornerstone of business operations, imparting reliable glide-managed solutions for a variety of packages. Dubai’s trunnion ball valve manufacturers, providers, and dealers have mounted themselves as dependent on companions for industries throughout the UAE, making sure of great performance in every product.

Whether you’re in oil and gas, petrochemicals, or water treatment, deciding on the proper provider or manufacturer is important for seamless operations. With Instrument Fittings, you may rest assured that you’re getting the quality-in-elegance additives designed to decorate your approaches even as focusing on sustainability and innovation.

trunnion ball valve manufacturers

#Trunnion ball valve suppliers#Trunnion ball valves dealers#Trunnion ball valves manufacturers#Instruments Fittings#trunnion ball valves

0 notes

Text

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion

Ball valves are essential components in many industries, offering excellent control and reliability in fluid and gas handling systems. Their simple design, combined with a tight seal, makes them an ideal choice for various applications. Whether in oil and gas, water treatment, or pharmaceuticals, ball valves continue to play a crucial role in ensuring smooth and safe operations. As the demand for high-quality valves grows, ball valve manufacturers in India are playing a crucial role in supplying the global market with reliable and durable valves to meet diverse industry needs.

0 notes