#Vacuum Gas Oil Market Report

Explore tagged Tumblr posts

Text

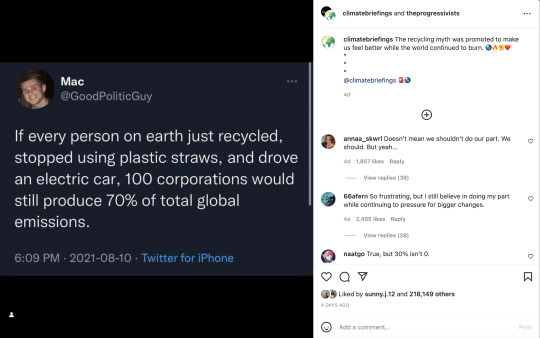

A specific piece of misinformation I'm responding to is the one originating from this headline:

(x)

spawning responses like

(x) which is... not entirely wrong

and

which is completely misunderstanding the original study - the Carbon Majors Database, CDP Carbon Majors Report 2017.

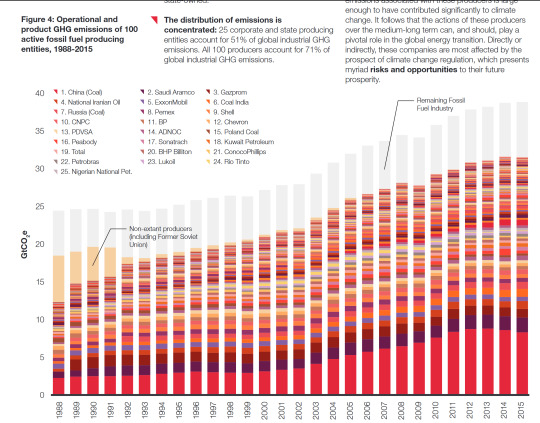

What this report absolutely does not say is "100 companies burn enough fossil fuels to produce 70% of emissions per year." It says something more like "70% of emissions since the 1988 can be traced back to extraction of fossil fuels by 100 producers." Those 100 producers include 36 state-owned companies, 7 state-owned producers, 41 public companies, and 16 private companies.

It also says that over half of industrial emissions since 1988 can be traced to just 25 producers. Of those 635 gigatons of emitted CO2, 59% come from state-owned producers, 32% from public companies, and 9% from private companies.

The largest shares here at the bottom of the graph are all state-owned producers: an aggregate of Chinese state-owned coal producers, Saudi Aramco (owned by the Saudi Arabian state), Gazprom (a Russian company with majority ownership by the state and partial public ownership), National Iranian Oil (unsurprisingly, nationally owned), and then finally we get to the first non-state-owned company (ExxonMobil).

The fraction is nearly identical for values for yearly emissions in 2015 - 59% of emissions since 1988 are tied to extraction by state-owned producers. Nonetheless:

"Emissions from investor-owned companies are significant: of the 30.6 GtCO2e of operational and product GHG emissions from 224 fossil fuel extraction companies, 30% is public investor-owned, 11% is private investor-owned, and 59% is state-owned."

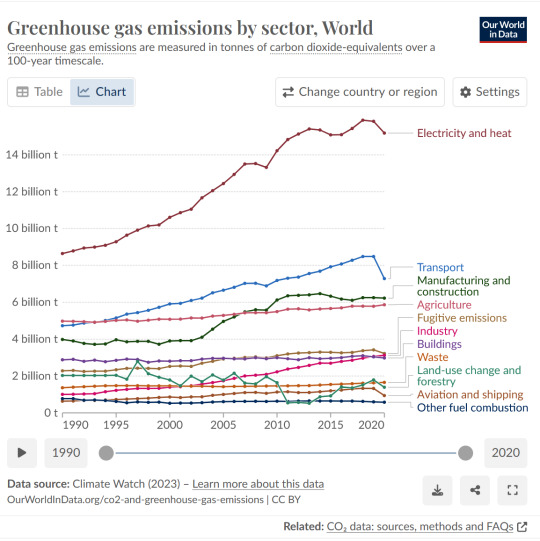

There is absolutely immense responsibility on producers for extracting, marketing, and selling fossil fuels, and for (in several notable cases) deliberately covering up anthropogenic climate change as an outcome of fossil fuel use. But that extraction doesn't occur in a vacuum - fuels are extracted and burned for heat, for electricity, for transport, for industry.

The tweet about nothing changing if people didn't drive and used plastic straws is exactly wrong: fossil fuels are valuable to extract because they're used for everything around us. In the US, transportation accounts for ~29% of greenhouse gas emissions, and 57% of that is from personal vehicles. In 2016, the average passenger car fuel efficiency in the US was 22.1 miles per gallon; an electric car can easily get > 100 miles-per-gallon-equivalent, some as high as 142 miles-per-gallon-equivalent. Magically substituting all gas cars in the US alone for electric would slash nationwide emissions by 13 percentage points even if all those vehicles were powered by electricity made from fossil fuels! (Clearly there are a lot of gross assumptions and approximations there.) (Also, yes, magic wand car swaps aren't a thing we can do in real life, but it's what the tweet said, so I wanted to toss it in there.)

Like, there's a lot of complexity to global emissions - who's responsible, what levers we have to move things in a better direction, what any individual can or can't do. But this specific piece of misinformation or at least misrepresentation really ought to be excised from the record.

#climate change#discourse#global warming#long post#effortpost#slightly more coherent version of the thing I was trying to poke at earlier

12 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Link

#market research future#vacuum pumps applications#vacuum pumps market types#vacuum pumps manufacturers#vacuum pumps market trends

0 notes

Text

Agricultural Fumigants Market - Industry Analysis, Market - Forecast(2025 - 2031)

Agricultural Fumigants Market Overview

Request Sample :

Such incidences result in a high demand for fumigants. The rising global population is driving the need for higher agricultural productivity which in turn is boosting the demand for fumigants to protect crops and ensure food security.

A major trend is the growing adoption of bio-based fumigants. Bio-based fumigants derived from natural sources are becoming popular due to rising environmental concerns and regulatory pressures to reduce chemical usage. These alternatives are seen as safer for the environment and human health. In January 2023, GroPro Corp. announced the successful trial of its bio-based nematicide in potato fields. Vigilance Nematicide is GroPro’s patented bio-nematicide providing fumigation and in-field application control for various crops such as potatoes, grapes, almonds, tomatoes, peppers, strawberries, citrus and more. Another trend is using precision agriculture. These technologies are transforming fumigation practices enabling more targeted and efficient application. By integrating sensors, drones and data analytics, farmers can optimize fumigant usage.

Report Coverage

The report “Agricultural Fumigants Market Report — Forecast (2024–2030)” by IndustryARC covers an in-depth analysis of the following segments of the Agricultural Fumigants market.

By Product: Methyl Bromide, Chloropicrin, Phosphine, 1,3-Dichloropropene, Metam Sodium, Carbon Disulphide, Ethylene dibromide (EDB), Methyl Chloroform and Others

By Form: Powder, liquid and gas

By Crop Type: Grains & Cereals, Fruits & Vegetables, Commercial Crops, Oil Seeds, Pulses and Others

By Pest Control Method: Vacuum Chamber Fumigation, Tarpaulin Fumigation, Structural Fumigation, Non-Tarp Fumigation and Others

By Method of Application: Soil and Warehouse

By Function: Nematicides, Insecticides, Fungicides, Herbicides and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Denmark, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia and New Zealand, Thailand, Indonesia, Malaysia, and Rest of Asia Pacific), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

For more details on this report — Request for Sample

Key Takeaways

APAC dominates the Agricultural Fumigants market on account of the heavy reliance on agriculture in the region.

Grains and cereals represent the largest crop type as more than 50% of world daily caloric intake is derived directly from cereal grain consumption.

The major opportunity for this market is harnessing the power of AI by using drones for fumigation.

Agricultural Fumigants Market- By Product

Phosphine is the largest segment in the Agricultural Fumigants, in terms of product due to its effectiveness and versatility in controlling a wide range of pests particularly in stored grains. Its ability to penetrate deeply into stored products without leaving harmful residues makes it a preferred choice among farmers and grain storage facilities. Additionally, phosphine is cost-effective and easy to apply. Its efficacy against resistant pests and its compliance with international trade standards also play significant roles in its widespread use. In January 2024, Degesch America, Inc. introduced U-Phos(R) Phosphine Fumigant in the U.S. market. This cylinderized fumigant is approved for use by the U.S. EPA and is currently in the approval process in several states.

Inquiry Before Buying:

Agricultural Fumigants Market- By Crop Type

Cereals and grains are the fastest growing segment in the Agricultural Fumigants market due to their role in ensuring food security. These crops are highly susceptible to pest infestations during storage and transportation. Based on estimates by the Food and Agriculture Organization of the United Nations (FAO), about 40% of global crop production is lost annually due to insect pests. Another FAO report estimates that insect pests cause 19–30% of global cereal losses. With the global demand for cereals and grains continually rising, there is an increasing need for effective fumigation to protect large quantities of stored produce from insects and rodents. Fumigants offer a reliable solution to ensure the quality and safety of these essential food sources.

Agricultural Fumigants Market- By Geography

The Asia Pacific region dominates the Agricultural Fumigants market with a share of 38% in 2023 owing to its large agricultural sector and the significant volume of food production and storage. Asian countries such as China, Indonesia, Thailand, Vietnam and India have substantial demand for fumigants to protect crops from pests and ensure food security. Additionally, the region exports a lot of its agricultural commodities which drives the need for higher agricultural productivity, further boosting the demand for fumigants. In May 2023, Cooperative Bulk Handling Ltd. (CBH Group), Australia’s largest grain exporter, announced that it signed a collaborative agreement with Universal Biosecurity Ltd. (UBL), to co-develop ethyl formate solutions for fumigation.

Schedule A Call:

Key Drivers

Growing Need for Food Security

The world population reached 8 billion people on 15 November, 2022, as per data from the United Nations (UN). According to the UN, by 2050, the world must feed 9 billion people. The demand for food will be 60% greater than it is today. To achieve this, agriculture has to become more productive. To ensure good yields, crops must be protected from pests both during the growing phase as well as post-harvest. Post-harvest solutions help farmers and other stake holders in managing the produce from tremendous losses due to biotic factors. Thus, the growing need for food security acts as a driver for the agricultural fumigants market.

Rising Incidences of Insect Infestation

The growing prevalence of insect infestations in agriculture is a significant driver for the agricultural fumigants market. Changes in climate such as warmer temperatures and increased humidity have led to a surge in pest populations. These outbreaks threaten crop yields globally. In June 2024, farmers in the Rostov region of Russia reported significant damage to their tomato crops due to an invasion of the tomato moth. The tomato moth poses a serious threat to crops due to its high fertility, one moth can lay up to 900 eggs. The moths have been flying en masse, damaging both the tomato fruits and the branches they grow on. This causes the stems to break leading to the tomatoes to fall to the ground and rot. Farmers are increasingly relying on fumigants to protect their crops and ensure food security. This rising threat of insect infestations, particularly in stored grains and cereals, underscores the critical role of fumigants in preventing economic losses, thereby driving demand for fumigants in agriculture.

Buy Now:

Key Challenges,

Side Effects of Certain Fumigants

A significant challenge in the agricultural fumigants market is the potential side effects associated with their use. Fumigants can pose risks to human health, non-target organisms and the environment. Exposure to certain fumigants can lead to respiratory issues, skin irritation and other health complications for workers handling these chemicals. For instance, studies have found that Methyl bromide, a widely used fumigant is an ozone depleting substance. Additionally, it is a highly toxic pesticide that causes acute or chronic toxicity to fumigators and related workers. Furthermore, the residue left behind by some fumigants can contaminate soil and water which leads to environmental pollution.

Key Market Players

Global Agricultural Fumigants top 10 companies include:

Bayer AG

BASF SE

Syngenta

Corteva

FMC Corporation

UPL

Valent BioSciences LLC

NuFarm Limited

Sumitomo Chemical Co., Ltd.

Isagro S.p.A.

For more Agriculture Market reports, please click here

#AgriculturalFumigation#CropProtection#PestControl#SoilFumigation#FarmSolutions#Agrochemicals#SustainableFarming#PostHarvestCare

0 notes

Text

Vacuum Priming Pumps Market Growth: Share, Value, Size, Trends, and Insights

"Vacuum Priming Pumps Market Size And Forecast by 2031

Global vacuum priming pumps market size was valued at USD 399.4 million in 2023 and is projected to reach USD 627.04 million by 2031, with a CAGR of 5.8% during the forecast period of 2024 to 2031.

the outlook for the Vacuum Priming Pumps Market remains optimistic, with significant opportunities for growth and innovation. The market’s competitive environment, shaped by leading companies and their strategies, underscores the importance of adaptability and foresight. With a focus on insights, trends, and data-driven analysis, this report serves as a comprehensive guide for stakeholders navigating the complexities of the Vacuum Priming Pumps Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-vacuum-priming-pumps-market

Which are the top companies operating in the Vacuum Priming Pumps Market?

The Top 10 Companies in Vacuum Priming Pumps Market are known for their strong presence and innovative solutions. These include industry leaders. Each of these companies has made significant contributions through cutting-edge products, strategic partnerships, and global reach. Their ability to adapt to market trends and consumer demands has helped them maintain leadership positions in the market, driving growth and setting industry standards.

**Segments**

- By Type: Liquid Ring Vacuum Priming Pumps, Dry Vacuum Priming Pumps, Rotary Vane Vacuum Priming Pumps, Others - By End-User: Chemical Industry, Food and Beverage Industry, Oil and Gas Industry, Pharmaceutical Industry, Water Treatment Plants, Others - By Distribution Channel: Direct Sales, Indirect Sales

The global vacuum priming pumps market is segmented based on type, end-user, and distribution channel. In terms of type, the market is categorized into liquid ring vacuum priming pumps, dry vacuum priming pumps, rotary vane vacuum priming pumps, and others. Liquid ring vacuum priming pumps are widely used across various industries due to their efficient performance and durability. On the other hand, dry vacuum priming pumps are gaining popularity for their low maintenance requirements. The end-user segmentation includes the chemical industry, food and beverage industry, oil and gas industry, pharmaceutical industry, water treatment plants, and others. Different industries have distinct requirements for vacuum priming pumps, leading to a diverse range of applications. Distribution channels in the market consist of direct sales and indirect sales, with manufacturers focusing on expanding their reach through both channels to cater to a wide customer base.

**Market Players**

- Gardner Denver - Atlas Copco - Pfeiffer Vacuum - ULVAC, Inc. - Busch Vakuumpumpen und Systeme - Graham Corporation - KNF Neuberger GmbH - Tsurumi Manufacturing Co. Ltd. - Aqseptence Group - EBARA CORPORATION

Key market players in the global vacuum priming pumps market include Gardner Denver, Atlas Copco, Pfeiffer Vacuum, ULVAC, Inc., Busch Vakuumpumpen und Systeme, Graham Corporation, KNF Neuberger GmbH, Tsurumi Manufacturing Co. Ltd., Aqseptence Group, and EBARA CORPORATION. These companies are actively involved in research and development activities to introduce innovative technologies and enhance their product portfolios. Collaborations, partnerships, and acquisitions are common strategies adopted by these players to strengthen their market presence and expand their foothold in the industry. With a focus on developing energy-efficient and sustainable solutions, market players are driving advancements in vacuum priming pump technologies to meet evolving customer demands and regulatory requirements.

https://www.databridgemarketresearch.com/reports/global-vacuum-priming-pumps-marketThe global vacuum priming pumps market is witnessing significant growth driven by several key factors. One of the primary drivers is the increasing demand for efficient and reliable vacuum technologies across various industries such as chemical, food and beverage, oil and gas, pharmaceutical, and water treatment plants. These industries require vacuum priming pumps for a wide range of applications, including degassing, distillation, crystallization, and sterilization, among others. The growing emphasis on process optimization, operational efficiency, and product quality is further fueling the adoption of advanced vacuum priming pump solutions.

Moreover, technological advancements in vacuum priming pump design and performance are also contributing to market growth. Market players are investing in research and development activities to introduce innovative features such as improved energy efficiency, reduced maintenance requirements, and enhanced durability. These advancements are enabling end-users to achieve higher productivity levels, lower operating costs, and improved operational safety. Additionally, the ongoing focus on sustainability and environmental regulations is driving the demand for eco-friendly vacuum priming pump solutions that minimize carbon footprint and energy consumption.

Furthermore, the rising trend of industry 4.0 and automation in manufacturing processes is creating opportunities for the integration of smart technologies in vacuum priming pumps. Market players are increasingly incorporating IoT (Internet of Things), AI (Artificial Intelligence), and data analytics capabilities in their pump systems to enable real-time monitoring, predictive maintenance, and remote control functionalities. These smart features enhance operational efficiency, optimize resource utilization, and enable proactive decision-making in industrial settings.

In terms of market competition, key players such as Gardner Denver, Atlas Copco, Pfeiffer Vacuum, ULVAC, Inc., and others are focusing on strategic initiatives to strengthen their market position. These initiatives include product launches, partnerships, collaborations, and acquisitions to expand their product portfolios, geographic presence, and customer base. Additionally, the market is witnessing a growing trend of customization and specialization in vacuum priming pump solutions to meet specific end-user requirements and application needs.

Overall, the global vacuum priming pumps market is poised for steady growth driven by the increasing demand for efficient vacuum technologies across diverse industries, technological advancements in pump design, the emphasis on sustainability and environmental regulations, the integration of smart technologies, and strategic initiatives by key market players. These factors are expected to shape the future trajectory of the market and offer opportunities for innovation, growth, and market expansion in the coming years.**Segments**

Global Vacuum Priming Pumps Market Segmentation: - **By Type:** Gas liquid Mixed, Water Ring Wheel, and Jet Type - **By Application:** Environmental Protection, Agriculture, Industrial, Others

The global vacuum priming pumps market is characterized by a diverse range of product types and applications. Gas liquid mixed, water ring wheel, and jet type pumps cater to different industrial needs, providing solutions for applications in environmental protection, agriculture, industrial processes, and various other sectors. The versatility of these pump types allows for flexible usage across multiple industries, driving the market's growth and adoption rates.

**Market Players**

- KSB SE & Co. KGaA (Germany) - Calpeda S.p.A. (Italy) - Lowara S.r.l. (Italy) - Xylem Inc. (U.S.) - BBA Pumps B.V. (Netherlands) - DLT Thurott S.r.l. (Italy) - PSG, a Dover company (U.S.) - Brown Brothers Engineers (NZ) Ltd. (New Zealand) - Cornell Pump Company (U.S.) - The Gorman-Rupp Company (U.S.)

The global vacuum priming pumps market is further enriched by the presence of key players such as KSB SE & Co. KGaA, Calpeda S.p.A., Lowara S.r.l., Xylem Inc., BBA Pumps B.V., DLT Thurott S.r.l., PSG, Brown Brothers Engineers, Cornell Pump Company, and The Gorman-Rupp Company. These market players contribute significantly to the industry through their innovative technologies, diverse product portfolios, and strategic initiatives aimed at market expansion and customer satisfaction. With a focus on quality, efficiency, and sustainability, these companies drive advancements in vacuum priming pump solutions, meeting the dynamic needs of various industries and applications.

The global vacuum priming pumps market is poised for continuous growth, propelled by the increasing demand for efficient and reliable pumping solutions across diverse sectors. As industries prioritize operational excellence, product quality, and environmental sustainability, the market players are stepping up their efforts to deliver cutting-edge technologies that address these requirements. The integration of smart features, advancements in pump design, and a focus on customization are key factors shaping the market landscape, offering enhanced performance, energy efficiency, and operational safety to end-users.

Moreover, the market's competitive landscape is characterized by robust strategies employed by key players to solidify their market positions. Collaborations, acquisitions, product launches, and geographic expansions are key tactics utilized by market players to stay ahead in the competitive arena. This dynamic environment fosters innovation, fosters healthy competition, and underscores the industry's commitment to meeting evolving market demands. Overall, the global vacuum priming pumps market is on a trajectory of continuous growth, driven by technological advancements, industry trends, and strategic partnerships that enhance product offerings and market reach.

Explore Further Details about This Research Vacuum Priming Pumps Market Report https://www.databridgemarketresearch.com/reports/global-vacuum-priming-pumps-market

Key Insights from the Global Vacuum Priming Pumps Market :

Comprehensive Market Overview: The Vacuum Priming Pumps Market is growing rapidly, driven by technological advancements and evolving consumer preferences.

Industry Trends and Projections: The market is expected to grow at a CAGR of X% over the next five years, with increasing automation and digitalization.

Emerging Opportunities: New market segments, such as sustainable and eco-friendly solutions, are creating significant growth prospects.

Focus on R&D: Companies are investing heavily in R&D to innovate and improve product offerings, ensuring market leadership.

Leading Player Profiles: Major player dominate the market with strong portfolios and strategic partnerships.

Market Composition: The market is diverse, with a mix of large enterprises and emerging startups driving competition and innovation.

Revenue Growth: The market has witnessed a steady increase in revenue, primarily driven by growing demand and product diversification.

Commercial Opportunities: There are considerable opportunities for business expansion in emerging regions and through technological innovations.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/zh/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/ar/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/pt/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/de/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/fr/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/es/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/ko/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/ru/reports/global-vacuum-priming-pumps-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Text

Metal Bellows Market Overview 2025 and Forecast till 2037

Research Nester assesses the growth and market size of the global drug delivery systems market which is anticipated to be on account of the rising requirement of metal bellows in the automobile industry and expanding oil & gas industry.

Research Nester’s recent market research analysis on “Metal Bellows Market: Global Demand Analysis & Opportunity Outlook 2037” delivers a detailed competitors analysis and a detailed overview of the global metal bellows market in terms of market segmentation by product types, material, end-use industry, application and by region.

Extensive Usage in Myriad of Industries and Increasing Awareness About Benefits of Metal Bellows to Promote Global Market Share of Metal Bellows Market

Request Free Sample Copy of this Report @ https://www.researchnester.com/sample-request-5748

The global metal bellows market is estimated to grow majorly on account of the increased industrialization across the globe and the rising application of welded metal bellows in the oil & gas industry. Moreover, the metal bellows are useful in the aerospace industry, automobile, semiconductor industry, and cryogenics. The manufacturers all across the globe are focusing on safeguarding the materials that have less effect on the operational processes. The major areas of use are vacuum sealing and vacuum valve stem seals. Other than this, there has been an increased need in the automobile industry for fuel delivery systems, suspension components, and exhaust systems. It has been estimated that by the year 2030, there will be almost 1.21 billion cars on the roads. On the back of the rising automobile industry, the global metal bellows market is projected to flourish during the forecasted period. Other than this, the growing welded metal bellows are also utilized in water treatment plants and wind energy generation. For instance, in the United States, there are almost 153,000 public water systems and more than 16,100 publicly owned waste water treatment. Also, in the year 2022, worldwide production of electricity through wind power is almost 900 GW. Hence, on the back of expanding number waste water treatments and rising demand of wind power plants, bolstering the demand of global metal bellows market is projected to garner remarkable growth.

Some of the major growth factors and challenges that are associated with the growth of the global metal bellows market are:

Growth Drivers:

Increasing Industrialization Across the Globe is Boosting the Growth of the Market

Widespread Use of Metal Bellows in Myriad of Industries

Challenges:

Risk of product failure and low quality product penetration, higher prices of metal bellows, and fluctuations in the raw materials prices are some of the major factors anticipated to hamper the global market size of global metal bellows market.

Request for customization @ https://www.researchnester.com/customized-reports-5748

By end-use industry, the global metal bellows market is segmented into aerospace & defense, automotive, power generation, water treatment, oil & gas refining, heavy manufacturing, and light manufacturing. Out of these, the aerospace & defense sector is projected to garner 60% of the market share. Metal bellows are essential for fuel systems, aircraft engines, and environmental control systems. The metal bellows are favored in defense applications for their ability to withstand harsh conditions.

By region, the Europe metal bellows market is to generate the highest revenue by the end of 2036. Europe is projected to exhibit steady growth on the back of the growing use of chemical manufacturing industries along with the rising use of welded bellows in the marine and aerospace industries. The growth can also be attributed to the rising investment in the defense sector.

This report also provides the existing competitive scenario of some of the key players of the global metal bellows market which includes company profiling of Technoflex Corporation, Duraflex Inc. EnPro Industries Inc. Meggitt PLC, MW Industries, Inc., USA Bellows Inc., BOA Holding GmbH, Freudenberg Group, Smith Group, Hyspan Precision Products Inc, Witzenmann GmbH, KSM Corporation, NOK CORPORATION, Nippon Steel Corporation, Mirapro Co., Ltd., Siemens Energy and others.

Access our detailed report @ https://www.researchnester.com/reports/metal-bellows-market/5748

About Research Nester-

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Industrial Salts Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

The Industrial Salts Market Report for 2024 provides a comprehensive overview of the Industrial Salts Market industry, presenting crucial data and insights into market dynamics, including growth drivers, challenges, and future potential. The report evaluates the Industrial Salts Market Components, focusing on significant opportunities and trends that could shape the industry's trajectory. Key stakeholders such as CEOs, global managers, traders, and analysts will find value in the SWOT analysis, which assesses the competitive strengths, vulnerabilities, opportunities, and threats impacting market players.

According to Straits Research, the global Industrial Salts Market market size was valued at USD 14.69 Billion in 2021. It is projected to reach from USD XX Billion in 2022 to USD 19.93 Billion by 2030, growing at a CAGR of 3.45% during the forecast period (2022–2030).

Get a Sample PDF/Excel of report starting from USD 995 :https://straitsresearch.com/report/industrial-salts-market/request-sample

Top Key Players of Industrial Salts Market :

Compass Minerals Limited

Cargill Inc.,

INEOS Enterprises

China National Salt Industry Corporation (CNSIC)

Tata Chemicals Limited

K+S Group

Morton Salt

Mitsui & Co. Ltd.

Rio Tinto PLC

Delmon Salt Factory Co. Ltd

Donald Brown Group

European Salt Company

and more....

Key Insights from the Industrial Salts Market Report

Market Size Overview: The report provides comprehensive estimates of the Industrial Salts Marketsize, including value and sales volume, for the period.

Market Trends and Dynamics: An analysis of the key drivers, opportunities, challenges, and risks shaping the Industrial Salts Market.

Global Economic and Regional Impact: Evaluation of the effects of global inflation and the Russia-Ukraine conflict on the Industrial Salts Market.

Trade Flow Analysis: Detailed examination of import and export volumes of Industrial Salts Marketacross major regions.

Industry Value Chain: Insight into the Industrial Salts Marketvalue chain, covering raw materials, suppliers, manufacturing processes, distributors, and downstream customers.

Industry News, Policies, and Regulations: Coverage of the latest developments, policies, and regulations impacting the Industrial Salts Market.

Regional Analysis for Industrial Salts Market:

The regional analysis section of the report offers a thorough examination of the global Industrial Salts Market market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Industrial Salts Market market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

Industrial Salts Market Segmentations:

By Source

Brine

Salt Mines

By Product

Rock Salt

Salt in Brine

Solar Salt

Vacuum Pan Salt

By Application

Chemical Processing

De-icing

Oil & Gas

Water treatment

Agriculture

Get Detail Market Segmentation :https://straitsresearch.com/report/industrial-salts-market/segmentation

Unit Economics must be known by C-suite professionals:

Cost of Goods Sold (COGS): Includes material, labor, and overhead costs in manufacturing.

R&D Costs: Investment in innovation and compliance with regulations.

Engineering and Design Costs: Resources for design, prototyping, and meeting technical standards.

Production Costs: Specialized manufacturing and quality control expenses.

Supply Chain Costs: Managing procurement and logistics for specialized components.

Testing and Quality Assurance: Costs for ensuring product safety and reliability.

SG&A Costs: Marketing, sales, and administrative expenses.

Revenue per Unit: Income from contracts, services, and licensing.

Gross Margin: Revenue minus COGS, showing unit profitability.

Break-even Analysis: Units or contracts needed to cover total costs.

Customer Acquisition Cost (CAC): Costs to secure new contracts.

Lifetime Value (LTV): Total revenue from a customer over time.

Capital Expenditure (CapEx): Investments in facilities and technology.

Economies of Scale: Cost reductions in larger production runs.

Profit Margin: Final profit after all expenses.

Top Reasons to Choose This Report

Access to Comprehensive Insights: Gain access to extensive analysis, research, and data that are often challenging to gather independently. This report provides valuable information, saving you significant time and effort.

Support for Informed Decisions: Enhance your decision-making process with in-depth insights into market trends, consumer behavior, and key industry factors. This report is essential for strategic planning, including investments, product development, and marketing strategies.

Gain a Competitive Edge: Stay competitive by understanding market dynamics and competitor strategies. The report provides detailed insights into competitor performance and market trends, helping you craft effective business strategies.

Cost-Effective Research Solution: Save on research costs by investing in this report, which offers a detailed and comprehensive analysis of the market. This cost-effective option eliminates the need for extensive independent research.

COVID-19 Aftermath and Geopolitical Influences: Russia-Ukraine Conflict and Middle East Crisis

The report explores the multifaceted impact of COVID-19 on the Industrial Salts Market market, covering both direct and indirect effects across global and local levels. It discusses market size, trends, and growth trajectories in the Industrial Salts Market , classified by type, application, and customer sector. Additionally, it provides a detailed evaluation of market development components before and after the pandemic, supported by a PESTEL analysis to assess key influencers and barriers to market entry. We offer the flexibility to customize the report based on specific regions, applications, or any other statistical details. Our goal is to align our analysis with your specific needs, ensuring a more complete market study. The final report will also examine the impact of the Russia-Ukraine War on the Industrial Salts Market market, assessing how these geopolitical events are influencing current market conditions and future opportunities.

This Report is available for purchase on :https://straitsresearch.com/buy-now/industrial-salts-market

About Us:

Straits Research is a leading research and intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & research reports.

Contact Us: email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: +1 646 905 0080 (U.S.) +91 8087085354 (India) +44 203 695 0070 (U.K.)

#Industrial Salts Market#Industrial Salts Market Share#Industrial Salts Market Size#Industrial Salts Market Research#Industrial Salts Industry#What is Industrial Salts?

0 notes

Text

Breather Vent Market Size, Share, Analysis and Opportunities by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Breather Vent Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Breather Vent Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Breather Vent Market?

The breather vent market is expected to grow at a CAGR of 7.8% during the forecast period of 2024 to 2032.

What are Breather Vent?

A breather vent is a specialized device designed to allow air to flow in and out of a sealed container or system, such as tanks, vessels, or pipelines, while keeping out contaminants, dust, and moisture. Its primary function is to equalize pressure changes that occur due to temperature variations, liquid transfers, or operational activities, thereby safeguarding the integrity of the container and its contents. Breather vents may include filters or check valves to enhance their effectiveness, ensuring that only clean air enters while allowing gases to escape safely. By maintaining proper pressure and preventing vacuum conditions, breather vents play a crucial role in the safe and efficient functioning of various industrial applications, including chemical storage, fuel tanks, and wastewater treatment systems.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1927

What are the growth prospects and trends in the Breather Vent industry?

The breather vent market growth is driven by various factors and trends. The breather vent market is witnessing consistent growth, propelled by the rising demand for effective pressure management solutions across various sectors, including oil and gas, chemical processing, and wastewater treatment. As regulations concerning safety and environmental protection tighten, companies are increasingly utilizing breather vents to maintain the integrity of their storage systems and prevent contamination. The market features a diverse range of products, including vents equipped with advanced functionalities such as filters, check valves, and automated monitoring systems that enhance both performance and reliability. Additionally, the growing emphasis on sustainable practices and the need for efficient resource management are contributing to market expansion. With ongoing technological innovations and heightened awareness of air quality and safety, the breather vent market is well-positioned for further growth, serving a variety of applications across multiple industries. Hence, all these factors contribute to breather vent market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Inline Breather Vent

Threaded Breather Vent

Bayonet Breather Vent

Customized Breather Vent

By Material:

Metal Breather Vent

Plastic Breather Vent

Composite Breather Vent

By End-Use Industry:

Automotive

Aerospace and Defense

Manufacturing

Oil and Gas

Chemicals and Pharmaceuticals

Electronics

Food and Beverage

Others

By Sales Channel:

Direct Sales

Distributor Sales

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Parker Hannifin Corporation

Donaldson Company, Inc.

MANN+HUMMEL GmbH

L. Gore & Associates, Inc.

Pall Corporation

Porvair Filtration Group

Eaton Corporation plc

SMC Corporation

Bosch Rexroth AG

Festo AG & Co. KG

Swagelok Company

Emerson Electric Co.

IMI plc

Camfil AB

WAMGROUP S.p.A.

View Full Report: https://www.reportsandinsights.com/report/Breather Vent-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Industrial Vending Machine Market Opportunities, Segmentation and Forecast Report 2024 - 2030

The global industrial vending machine market size was valued at USD 3.01 billion in 2023 and is anticipated to grow at a CAGR of 9.8% from 2023 to 2030.

The increasing demand is attributed to the growing trend toward lean manufacturing practices. As businesses strive to eliminate waste and improve efficiency, industrial vending machines are essential for managing and dispensing materials as needed. By supporting just-in-time (JIT) inventory practices, these machines help companies maintain minimal stock levels while ensuring that critical items are always available. This approach reduces storage costs and minimizes the capital tied up in inventory.

Another important driver is the rising adoption of customized and flexible manufacturing processes in sectors such as aerospace, automotive, and electronics, where production lines often need to adapt to different product specifications; industrial vending machines offer a flexible solution for managing a wide range of tools and components. These machines can be easily reconfigured to accommodate different items, enabling manufacturers to quickly adapt to changing production needs without disrupting operations. This flexibility is increasingly valuable as companies look to stay competitive in a market where customization and rapid product development are key differentiators. Industrial vending machines are provisioned to record inventory usage by tracking the type, time, and user identification, bringing transparency and accountability. Additionally, these machines improve the company's output by reducing the walk-around time and facilitating employee typicity. They also avoid hoarding various items.

Gather more insights about the market drivers, restrains and growth of the Industrial Vending Machine Market

Industrial Vending Machine Market Report Highlights

• The coil vending machine segment accounted for over 37.8% of the global revenue share in 2023, owing to its higher penetration across various end-use industries such as construction, manufacturing, and oil & gas

• The PPE segment accounted for the largest share in 2023 due to the increased use of protective items, including hard hats, safety goggles, and safety gloves, across various industries

• The manufacturing segment held the largest market revenue share in 2023. This is credited to the strong growth in the manufacturing sector worldwide, especially in emerging economies

• North America accounted for the largest regional share in 2023, owing to the strong presence of key players and distributors in the region, and high awareness about these machines across various industries

• Key players are opting for various strategies, including product development, expansion to new geographic locations, and joint ventures, to increase sales and improve market share

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global polymer filler market size was valued at USD 57.33 billion in 2023 and is projected to grow at a CAGR of 5.0% from 2024 to 2030.

• The global vacuum insulation panel market size was valued at USD 8.25 billion in 2023 and is projected to grow at a CAGR of 4.3% from 2024 to 2030.

Industrial Vending Machine Market Segmentation

Grand View Research has segmented the global industrial vending machine market based on type, product, end-use, and region:

Industrial Vending Machine Type Outlook (Revenue, USD Million, 2018 - 2030)

• Carousel Vending Machine

• Coil Vending Machine

• Cabinet Vending Machine

• Others

Industrial Vending Machine Product Outlook (Revenue, USD Million, 2018 - 2030)

• MRO Tools

• PPE

• Others

Industrial Vending Machine End-use Outlook (Revenue, USD Million, 2018 - 2030)

• Manufacturing

• Oil & Gas

• Construction

• Aerospace

• Others

Industrial Vending Machine Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

• Europe

o UK

o Germany

o France

o Italy

o Spain

• Asia Pacific

o China

o India

o Japan

o Australia

o South Korea

• Latin America

o Brazil

o Mexico

o Argentina

• Middle East & Africa (MEA)

o UAE

o Saudi Arabia

o South Africa

Order a free sample PDF of the Industrial Vending Machine Market Intelligence Study, published by Grand View Research.

#Industrial Vending Machine Market#Industrial Vending Machine Market size#Industrial Vending Machine Market share#Industrial Vending Machine Market analysis

0 notes

Text

Petrochemicals Market 2024- Business Planning Research and Resources, Revenue, and Forecasts 2030

Petrochemicals Industry Overview

The global petrochemicals market size was valued at USD 619.28 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.3% from 2024 to 2030.

The demand for the product is attributed to an increase in the demand for downstream products from various end-use industries such as construction, pharmaceuticals, and automotive, which is a major factor driving the growth. Petrochemical is a vital component for many industrial processes and hence forms the backbone of an industrial economy. Some of the products derived from petrochemicals include tires, industrial oil, detergents, plastics, etc. Basic plastic derived from the product act as a building block in the manufacturing of consumer goods.

Gather more insights about the market drivers, restrains and growth of the Petrochemicals Market

End-use industries evaluate the quality of products supplied from time to time and establish procurement agreements with suppliers to purchase petrochemical derivatives in bulk and ensure their stable and seasonal supply. An increasing number of product suppliers in petrochemicals market in U.S. has resulted in the high bargaining power of the buyers.

The industry is significantly affected by the prices of crude oil as it is a basic raw material used for the manufacturing of the product. The volatility in the prices and supply of crude oil has affected the production cost of petrochemicals, which, in turn, makes their production process costly. Factors such as the growing inclination of consumers in developed and developing regions toward environment-friendly products and the volatile prices of raw materials of petrochemicals are likely to hamper the market growth in the coming years.

The steam cracking process is one of the most commonly used processes for manufacturing petrochemicals from natural gas or crude oil. In this process, ethane, a derivative of natural gas or naphtha that is predominantly derived from crude oil, is used for the manufacturing of olefins. A steam cracker has equipment operating at pressure from near-vacuum to 100 atm and operating at temperatures from 100 K to 1400 K.

Moreover, the demand for petrochemicals and their derivatives for use in various applications such as tires, pharmaceuticals, high-tech materials, and paints across the U.S. is led by unprecedented success in the exploration and production of shale gas. The country is a major exporter of petrochemical products to Europe, as well as to countries such as China and India. There has been a significant resurgence in investments and petrochemical capacity expansions in the U.S. since 2014 owing to the reduction in feedstock prices and high demand for petrochemicals in aforementioned applications in the country.

Browse through Grand View Research's Petrochemicals Industry Research Reports.

• The global naphtha market size was valued at USD 189.5 billion in 2023 and is projected to grow at a CAGR of 4.3% from 2024 to 2030.

• The global diesel exhaust fluid market size was valued at USD 36.66 billion in 2023 and is projected to grow at a CAGR of 7.9% from 2024 to 2030.

Key Petrochemicals Market Company Insights

Some of the key players operating in the market include SABIC, ExxonMobil Corporation, and BASF SE.

SABIC, a global leader in petrochemicals, emphasizes on diversified product portfolio ranging from basic chemicals to specialty products. It focuses on innovation, sustainability, and operational excellence. SABIC often invests in R&D to enhance product quality, efficiency, and explore eco-friendly alternatives.

ExxonMobil is a leading player in petrochemical industry, with a focus on integrated downstream operations. Its strategy involves technological innovation, cost leadership, and commitment to sustainability. ExxonMobil continuously invests in advanced technologies to improve efficiency and reduce environmental impact.

Mitsubishi Chemical Holdings Corporation and Formosa Petrochemical Corporation are some of the emerging market participants in petrochemicals market.

Mitsubishi Chemical Holdings Corporation is an emerging player in the global petrochemicals market, emphasizing on innovation and sustainability. The company invests in R&D to create value-added products and reduce environmental impact. It also explores strategic collaborations to enhance its market position in a competitive market.

Formosa Petrochemical Corporation, an emerging player with a strong presence in Asia, focuses on expanding its petrochemical operations. Its strategy involves capacity expansions, technology upgrades, and a commitment to environmental responsibility. Further, it aims to meet increasing demand for petrochemical products in the region.

Key Petrochemicals Companies:

The following are the leading companies in the petrochemicals market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these petrochemicals companies are analyzed to map the supply network.

BASF SE

Chevron Corporation

China National Petroleum Corporation (CNPC)

China Petrochemical Corporation

ExxonMobil Corporation

INEOS Group Ltd.

LyondellBasell Industries Holdings B.V.

Royal Dutch Shell PLC

SABIC

Dow

Recent Developments

In November 2023, Dow announced invest of USD 8.9 billion for a net-zero petrochemical plant project in Alberta's Industrial Heartland, Canada. It is projected to produce around 3 million tons of low-emission ethylene and polyethylene derivatives. The construction of the project is set to start construction in 2024.

In July 2023, SABIC introduced its latest PCR-based NORYLTM portfolio to reduce carbon footprint by incorporating bio-based and recycled materials in petrochemical products, a step for making the chemical sector environment friendly.

In July 2023, ExxonMobil Corporation declared its agreement to acquire Denbury Inc. to expand its carbon capture and storage (CCS) solutions, and reduce carbon emissions for the petrochemical and energy industries.

In May 2023, Dow Corporate collaborated with New Energy Blue to produce bio-based ethylene from renewable residues of agriculture. Ethylene is a petrochemical-based raw material, and with its production Dow aims to initiate a sustainable approach to produce plastic.

In April 2023, INEOS Group Ltd. completed the acquisition of Mitsui Phenols Singapore Ltd. to enhance the production of petrochemical products including acetone, cumene, bisphenol A (BPA), phenol, and alpha-methylstyrene.

In March 2023, Chevron USA Inc. announced its collaboration with Bunge and Corteva Inc. to launch winter canola hybrids to produce plant-based oil with low carbon profile. This is an effective contribution to reduce carbon emissions in the energy and petrochemical sectors.

In February 2023, Royal Dutch Shell PLC completed its acquisition of Nature Energy Biogas A/S to create a RNG value chain to provide low carbon offerings to customers. The use of biogas will help Shell to produce renewable natural gas for the petrochemical manufacturing process.

In February 2023, China Petrochemical Corporation, also known as Sinopec, launched the largest green hydrogen-coal chemical project in Inner Mongolia to reduce carbon emissions in the petrochemical industry, and support green energy.

In November 2022, SABIC announced a joint project with Saudi Aramco to convert crude into petrochemicals in Ras Al-Khair, Saudi Arabia. The project is set to have a production capacity of producing 400,000 barrels of crude oil per day. The government initiative is being supported by development of a new port in the industrial city. This would help in efficient export of petrochemicals and help boost the economy as it is a leading petrochemicals producing country.

Order a free sample PDF of the Petrochemicals Market Intelligence Study, published by Grand View Research.

0 notes

Text

Technical Insulation Market worth $13.4 billion by 2028

The report "Technical Insulation Market by Material Type (Hot, Cold-Flexible, Cold-Rigid), Application (Heating & Plumbing, HVAC, Refrigeration, Industrial Process, Acoustic), End-use (Industrial & OEM, Energy, Transportation), and Region - Global Forecast to 2028", is projected to grow from USD 10.3 billion in 2023 to USD 13.4 billion by 2028, at a CAGR of 5.3% during the forecast period. Technical insulation has gained widespread acceptance across diverse industries, including industrial & OEM, energy, transportation, and commercial buildings. The industry is poised for growth due to stringent regulations governing the insulation of equipment and pipes, coupled with increasing demand in the oil & gas sector. These factors are anticipated to drive the expansion of related industries, thereby contributing to the overall growth of the technical insulation market.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=80630490

Hot Insulation segment is estimated to dominate the overall technical insulation market.

The category of hot insulation or man-made mineral fiber includes stone wool, fiberglass, cellular glass, calcium silicate, microporous insulation, aerogel, and vacuum insulated panels. It is anticipated to demonstrate the highest Compound Annual Growth Rate (CAGR) in terms of value from 2023 to 2028. This growth can be attributed to the efficient thermal insulation properties of man-made mineral fibers, contributing to decreased energy consumption, protection from hot surfaces, and stabilization of temperature fluctuations in both buildings and workplaces. Moreover, these materials offer acoustic insulation, reducing workplace noise and preventing issues such as hearing loss and noise pollution. Additionally, they exhibit minimal moisture absorption, reduced leachate, and sustained long-term insulation performance.

Industrial Processes is the largest market for technical insulation by applications.

Insulation materials play a crucial role in various industrial applications, including insulating piping, equipment, and tanks, as well as installing instrument tubing, steam tracing, and pre-insulated tubing. These applications are prevalent in industries such as refining, petrochemicals, power and energy, marine, and pulp and paper. The primary purposes of utilizing insulation in industrial processes are to manage surface temperatures for personnel safety, regulate and stabilize process temperatures, prevent condensation and potential corrosion on cold surfaces, enhance fire protection, and control noise and vibrations.

Industrial & OEM is the largest market for technical insulation by end-use industry.

A well-insulated industrial plant is essential for minimizing energy consumption and ensuring the durability of equipment. In industrial settings, high compressive strength insulation is utilized to maintain thickness during and after installation. Technical insulation materials must possess low thermal conductivity, low water absorption, effective noise reduction, and corrosion resistance. These properties are crucial for technical insulation, making the industrial sector the fastest-growing end-use industry from 2023 to 2028. The demand for insulation materials is driven by the industrial commitment to energy efficiency and sustainability. The emphasis on maintaining nominal thickness post-installation is vital for sustained effectiveness. Low thermal conductivity regulates temperatures, while minimal water absorption prevents moisture-related issues. Effective noise reduction enhances the working environment, meeting safety standards. Additionally, corrosion resistance protects equipment, contributing to overall durability. The integration of these properties underscores insulation's pivotal role in enhancing industrial efficiency and sustainability.

Sample Request-https://www.marketsandmarkets.com/requestsampleNew.asp?id=80630490

Asia Pacific is projected to be the largest technical insulation market.

The technical insulation market in Asia Pacific is projected to register the highest CAGR between 2023 and 2028. The Asia Pacific technical insulation market is segmented into key countries, including China, India, South Korea, Japan, Australia, and the Rest of Asia Pacific. This region is emerging as a lucrative market for technical insulation, driven by industrial development and improving economic conditions. With approximately 61% of the world's population, the Asia Pacific region is a major contributor to the growth of manufacturing, industrial, and processing sectors. The market's significance lies in the increasing demand for technical insulation in these sectors. As economies advance, the need for insulation materials for temperature control, energy efficiency, and safety purposes is on the rise. Overall, the Asia Pacific region plays a crucial role in the global technical insulation market, with its large population and growing industrial landscape shaping it into a key market for the industry's expansion.

#TechnicalInsulation#InsulationTechnology#EnergyEfficiency#IndustrialInsulation#ThermalInsulation#InsulationMaterials#SustainableInsulation#InsulationSolutions#HVACInsulation#AcousticInsulation#IndustrialSafety#FireProtection#EnergyConservation#ConstructionIndustry#BuildingMaterials

0 notes

Text

Powder Metallurgy Market - Forecast(2024 - 2030)

Powder Metallurgy Market Overview

Request Sample Report :

COVID-19 Impact

The onset of Covid-19 in the entire nation had a negative impact on the automotive industry. There was an overall revenue impact across the automotive industry. The pandemic also impacted all the stakeholders present in the value chain for the short as well as medium term. Shortage of raw material, shifting of production to other countries, liquidity crunch to delays in availability of models, deferred launches, and shrinkage in consumer demand were some of the main issues faced by the automotive stakeholders, owing to which the production and demand of automobiles had significantly fallen. For instance, according to the China Passenger Car Association (CPCA), China’s passenger car sales in June fell 6.5% year on year to 1.68 million units. The unstable automotive production and demand have significantly impacted the market of powder metallurgy as the demand for powder metal was also uncertain during the period. A prolonged truncation of consumer demand due to the lockdown has significantly affected auto manufacturers’ revenues and cash flows. Even after the restriction is eased in 2021, with discretionary spending taking a backseat, further declines in the market for passenger vehicles are expected.

Powder Metallurgy Market Report Coverage

The report: “Powder Metallurgy Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the powder metallurgy Industry.

By Material: Ferrous (Iron, Steel, and Stainless Steel), Non-Ferrous (Copper, Aluminium, Cobalt, Tin, Nickel, Magnesium, Zinc, Titanium, Molybdenum, and Others By Process: Conventional Process, Metal Injection Moulding, Hot Isostatic Pressing, and Metal Additive Manufacturing By Application: Porous Products, Bearing and Bushes, Filters (Ceramic Filter, Fiber Metal Filter, and Others), Refractory Metal Composites, Electric Motors, Cemented Carbides, Machinery Parts (Gears, Sprockets, Rotors, and Others), Tungsten Wires, Medical Implants, Magnetic Materials, Cutting Tools and Dies, and Others By End-Use Industry: Medical & Healthcare, Automobile (Transmission, Engine Parts, and others), Oil & Gas, Electrical and Electronics (Refrigerators, Vacuum Cleaners, Circuit Breakers, Electric Motors, Sewing Machines, and Others), Industrial (Hydraulics, Motors/Controls, and Others), Aerospace (Aero-engine, Land-based Gas Turbine, Airframes, and Others), Household Appliances, Recreation and Leisure, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the powder metallurgy market, owing to the increasing demand and production of lightweight vehicles in the region. For instance, according to OICA, the production of passenger cars has increased by 2.6 % in Malaysia in 2019.

There are many cases in which powder metallurgy over casting has a strong benefit. The benefits of the powder metallurgy process are particularly apparent when dealing with high-value and high-melting-point materials, owing to which there is increasing adoption of powder metallurgy over die casting, which will propel the market growth.

There are growing interests in producing customized medical implants using additive manufacturing and in producing porous implant structures (to match bone stiffness and to aid osteointegration) by powder metallurgy processing, which may boost the market growth.

For More Details on This Report — Request for Sample

Powder Metallurgy Market Segment Analysis — By Material

The ferrous segment held the largest share in the powder metallurgy market in 2020. Ferrous powdered metals such as iron, steel, and more offer the highest level of mechanical properties. Ferrous metal powders are also known for their extensive characteristics such as durability, hardness, tensile strength, lower costs, broad flexibility, and more. The ferrous powdered metal is largely employed in the automotive industry for designing bearings, gears, or other auto parts, owing to its good strength and flexibility. Furthermore, ferrous metals are also widely utilized in various other end-use industries such as construction, piping, aerospace, electronics, and more. Thus, it is anticipated that these extensive characteristics and wide applications of ferrous powder metallurgy are the major factors driving its demand during the forecast period.

Powder Metallurgy Market Segment Analysis — By Application

The bearings segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 7.4% during 2021–2026, owing to its self-lubricating property. Bearings that are made from powder metallurgy are known as self bearings of sintered metal. They are economical, suitable for high production rates, and precision tolerances can be produced. The majorities of porous-metal bearings consist of either bronze or iron with pores that are interconnected. These voids take up 10 percent of the total volume to 35 percent. In operation, lubricating oil is deposited in these voids and feeds to the bearing surface through the interconnected pores. Sintered-metal self-lubricating bearings are widely used in home appliances, small motors, machine tools, aircraft, and automotive accessories, business machines, instruments, and farm and construction equipment, owing to which it holds a prominent share in the powder metallurgy application segment.

Schedule A Call :

Powder Metallurgy Market Segment Analysis — By End-Use Industry

The automotive segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 8.6% during 2021–2026. Powder metal parts display excellent controlled porosity and self-lubricating properties that allow gases and liquids to be filtered. Powder metallurgy is also a strongly recommended method in the manufacture of components involving complex bends, depressions, and projections. Flexibility in the development of mechanical parts of different compositions, such as metal-non-metal and metal-metal hybrids, allows high dimensional precision in the production of automobile parts and ensures consistent properties and measurements with very little scrap and waste of material. The most popular vehicle parts that are manufactured through the method of powder metallurgy are the bearings and gears. A variety of metals, including ferrous, and non-ferrous are used in automotive components including chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake disc, and more. The powder metallurgy is often used in these components as it improves the net shape, utilizes heat treatment, enhances surface treatment, and improves the precision of these components. Thus, the demand for powder metallurgy in the automotive sector is growing due to such factors.

Powder Metallurgy Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the powder metallurgy market in 2020 up to 45%, owing to the increasing automotive manufacturing coupled with population growth in the region. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile production to reach 35 million by 2025. In 2019, according to OICA, the automotive production in Malaysia and Vietnam has increased up to 571632, and 250000, i.e., 1.2%, and 5.5%. India’s annual production in 2019 was 30.91 million vehicles, according to Invest India, compared to 29.08 million in 2018, recording a healthy 6.26 percent growth. Also, by 2026, the US$118 billion Indian car industry is projected to cross US$300 billion. The increasing automation production in the Asia Pacific will eventually boost the demand for powder metallurgy to manufacture various automobile components, which will likely influence the growth of the powder metallurgy market in the APAC region.

Powder Metallurgy Market Drivers

Flourishing Aerospace Industry

Powder metallurgy is used extensively in aerospace, because of its advantages of high strength/weight ratio, high heat capacity, and high modulus of elasticity. Within aerospace, powder metallurgy finds its most significant application in turbine engines, compressors, fan sections, discs, airframes, fasteners, and landing gear. Tungsten metallurgy based tungsten carbide has received considerable attention in the aerospace industry because of its high strength at very high temperatures. Tungsten carbide is sintered through a selective laser sintering process based on the additive manufacturing process. In 2019, China was the second-largest civil aerospace and aviation services market in the world and one of the fastest-growing markets, according to the International Trade Administration (ITA). China will need 7,690 new aircraft over the next 20 years, valued at US$1.2 trillion, according to Boeing (Commercial Market Outlook 2018–2037). China also currently accounts for 15 percent of the world’s commercial aircraft fleet, and it will be almost 20 percent by 2037. According to Boeing, the demand for 2,300 airplanes worth US$320 billion is projected in India over the coming 20 years. Boeing’s current market outlook (BMO) forecasts demand for 2,520 new aircraft in the Middle East by 2030. With the flourishing aerospace industry, the demand for aircraft components will also gradually increase, which will drive the market growth.

Buy Now :

Expanding Electrical and Electronics Sector

The powder metallurgy method offers the opportunity to cost-effectively produce net form components from a variety of materials. A market segment that has exhibited the ability to take advantage of powder metallurgy’s flexibility has been in electromagnetic applications such as household appliances, industrial applications, and more. Magnetic materials are essential elements in the electronic industry in recent times. From the motors and turbines that provide the power for the industry to the high-frequency transformers that power computers, magnetic materials are becoming increasingly important for consumers. The electronic sector is booming in various regions, which will further drive the market growth as there is an increasing demand for powder metallurgy from the electrical and electronics sector. For instance, the consumer electronics and appliances sector in India is expected to become the fifth-largest in the world by 2025, according to Invest India. India could create an US$800 billion to US$1 trillion digital economy by 2025, and India’s digital economy could fuel 18–23 percent of overall economic activity by 2025. According to the Government of Canada, revenues in the ICT sector reached an estimated US$210 billion in 2019. ICT sector revenues grew from US$158 billion to US$200 billion from 2013 to 2018, a 26.9 percent increase.

Powder Metallurgy Market Challenges

Various Drawbacks Associated with Powder Metallurgy

The cost of metal powders compared to the cost of raw material used for casting or forging a component is relatively higher. At the time the cost of tooling and equipment is also higher. When production volumes are limited, this is especially a limitation. Also, low melting point metal powders such as zinc, tin, and cadmium give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point. Furthermore, large or complex-shaped parts, and uniformly high — density products are difficult to produce by the powder metallurgy process. Without any degradation, a few powders are also difficult to store. All these drawbacks associated with the powder metallurgy may hinder the market growth during the forecast period.

Powder Metallurgy Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the powder metallurgy market. Major players in the powder metallurgy market are Arcam AB, Carpenter Technology Corp., ExOne GmbH, GKN Plc, Höganäs AB, Materialize NV, Melrose Industries PLC, Sumitomo Electric Industries, Ltd., and Hitachi Chemical Co., Ltd.

Acquisitions/Technology Launches

In May 2019, Epson Atmix Corp. installed a new production line at its Kita-Inter Plant in Japan for producing amorphous alloy powder. The company invested around ¥800 million (USD 7.43 million) for the installation of a new line and it plans to further increase its production capacity in stages and reach 6,000 tons per year by 2023.

In October 2019, GKN Powder Metallurgy a leading metal powder and parts manufacturers acquired specialist polymer 3D printing service provider Forecast 3D. The acquisition presents a significant expansion of GKN powder metallurgy’s additive capabilities.

Relevant Reports

Powder Coatings Market — Forecast (2021–2026)

Report Code: CMR 0113

Ferromanganese Market — Forecast (2021–2026)

Report Code: CMR 0382