#United States Tank Trucking Market size

Explore tagged Tumblr posts

Text

0 notes

Link

0 notes

Text

0 notes

Text

0 notes

Text

Armored Vehicle Market to enjoy 'explosive growth' to 2030

Latest business intelligence report released on Global Armored Vehicle Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Armored Vehicle market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis: Oshkosh Corporation (United States), UralVagonZavod (Russia), Ukroboronprom (Ukraine), General Dynamics Corporation (United States), BAE Systems plc (United Kingdom), NORINCO (China), Rheinmetall AG (Germany). Download Free Sample PDF Brochure (Including Full TOC, Table & Figures) @ https://www.advancemarketanalytics.com/sample-report/1792-global-armored-vehicle-market-1 Brief Overview on Armored Vehicle: The armored vehicle is a vehicle that is guarded by means of armor plate. The major companies are adding more proven technologies systematically and strategically in the Asia Pacific, Africa and the Middle East owing to increasing political pressure, hostile activities, and terrorism in this region. Moreover, growing defense spending by governments globally is likely to support the growth of the armored vehicles market. For instance, BAE Systems received a contract worth USD 376.0 million from the US Government for the development, engineering, and manufacturing of mobile protected firepower vehicles for use across the spectrum of terrains and operations. Key Market Trends: Technological Developments and Improvements towards Reducing the Weight and Size of Armored Vehicles Opportunities: Increasing Demand for Modular Armored Vehicles

Rising Demand from the Developing Economies

Market Growth Drivers: Increasing Incidences of Cross-Border Conflicts

Emphasizing On Military Modernization Plans

Challenges: Absence of OEMs in Emerging Economies Segmentation of the Global Armored Vehicle Market: by Platform (Combat Vehicles (Main Battle Tanks (MBTs), Infantry Fighting Vehicles (IFVs), Armored Personnel Carriers (APCs), Armored Amphibious Vehicles (AAVs), Others), Combat Support Vehicles (Armored Supply Trucks, Armored Command and Control Vehicles, Repair and Recovery Vehicles, Others), Unmanned Armored Ground Vehicles), Mobility (Wheeled (4x4, 6x6, 8x8, Others), Tracked), System (Engines, Drive Systems, Ballistic Armor, Composite Armor, Explosive Reactive Armor, Electric Armor, Others) Purchase this Report now by availing up to 10% Discount on various License Type along with free consultation. Limited period offer. Share your budget and Get Exclusive Discount @: https://www.advancemarketanalytics.com/request-discount/1792-global-armored-vehicle-market-1 Geographically, the following regions together with the listed national/local markets are fully investigated: • APAC (Japan, China, South Korea, Australia, India, and Rest of APAC; Rest of APAC is further segmented into Malaysia, Singapore, Indonesia, Thailand, New Zealand, Vietnam, and Sri Lanka) • Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe; Rest of Europe is further segmented into Belgium, Denmark, Austria, Norway, Sweden, The Netherlands, Poland, Czech Republic, Slovakia, Hungary, and Romania) • North America (U.S., Canada, and Mexico) • South America (Brazil, Chile, Argentina, Rest of South America) • MEA (Saudi Arabia, UAE, South Africa)Furthermore, the years considered for the study are as follows: Historical data – 2017-2022 The base year for estimation – 2022 Estimated Year – 2023 Forecast period** – 2023 to 2028 [** unless otherwise stated] Browse Full in-depth TOC @: https://www.advancemarketanalytics.com/reports/1792-global-armored-vehicle-market-1

Summarized Extracts from TOC of Global Armored Vehicle Market Study Chapter 1: Exclusive Summary of the Armored Vehicle market Chapter 2: Objective of Study and Research Scope the Armored Vehicle market Chapter 3: Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis Chapter 4: Market Segmentation by Type, End User and Region/Country 2016-2027 Chapter 5: Decision Framework Chapter 6: Market Dynamics- Drivers, Trends and Challenges Chapter 7: Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile Chapter 8: Appendix, Methodology and Data Source Buy Full Copy Armored VehicleMarket – 2021 Edition @ https://www.advancemarketanalytics.com/buy-now?format=1&report=1792 Contact US : Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 201 565 3262, +44 161 818 8166 [email protected]

#Global Armored Vehicle Market#Armored Vehicle Market Demand#Armored Vehicle Market Trends#Armored Vehicle Market Analysis#Armored Vehicle Market Growth#Armored Vehicle Market Share#Armored Vehicle Market Forecast#Armored Vehicle Market Challenges

0 notes

Text

The Story of Chevron Corporation’s Rise to the Top

Chevron Corporation is one of the largest and most recognized corporations in the United States, with a long and storied history. From its humble beginnings as a small oil company in California, it has grown into a global leader in energy production, distribution, and services. But how did Chevron come to be the powerhouse that it is today? Let’s take a look at Chevron’s untold story.

Storage Tanks of the Standard Oil Company, circa 1910 - Whiting, Indiana. Photo by Steve Shook. Flickr.

The Early Days of Standard Oil Company

Chevron traces its roots back to the Standard Oil Company, which was founded by John D. Rockefeller in 1870. At its height, Standard Oil controlled up to 90 percent of all U.S. refineries and pipelines, giving Rockefeller an almost monopolistic grip on the nation’s oil production market. In 1911, following a landmark Supreme Court ruling that declared Standard Oil an illegal monopoly, the company was broken up into 34 smaller companies—one of which was California-based Standard Oil Company (California). The Birth of Chevron In 1926, Standard Oil Company (California) merged with another former arm of Standard Oil called Gulf Oil Corporation. This merger created what is now known as Chevron Corporation. Initially called Caltex Petroleum Corporation, it changed its name to Chevron Corporation in 1984 after acquiring Texaco Inc., a move that more than doubled its size and scope. Following this acquisition, Chevron became one of the world’s largest integrated energy companies with operations spanning more than 180 countries around the globe. Expanding Beyond Oil Production Chevron is no longer just an oil company; it is a major player in natural gas production as well as renewable energy sources like solar and wind power. It also operates convenience stores across North America under its brand name "Chevron ExtraMile." The company continues to invest heavily in research and development with a focus on sustainability initiatives such as alternative energy sources and cleaner burning fuels for cars and trucks. These investments have helped cement Chevron's reputation as one of the most innovative energy companies in the world today.

Chevron gas station in San Francisco, California. Photo by Cool Caesar. Wikimedia.

Chevron’s Acquisition Strategy

In 1901, SOCAL reorganized itself under the name Standard Oil of California (SOCONY) and began acquiring other oil companies throughout the United States. Over time, SOCONY expanded its reach even further when it acquired interests in Venezuela, Indonesia, South Africa, Angola, Gabon, Nigeria, Thailand, and Mexico. By 1929 SOCONY had become one of the largest oil producers in the world. Chevron's Acquisition Philosophy Chevron views acquisitions as an important part of its growth strategy. The company seeks out opportunities that will increase its geographic presence, expand its operations, and improve its competitive position in the market. By doing so, it can leverage existing assets and resources to gain a competitive edge over other players in the industry. Chevron the Deal Maker Chevron Corporation also looks for deals that are value-accretive, meaning they will add value to the company on an ongoing basis. This means that when evaluating potential acquisitions, Chevron looks for businesses that have strong management teams, high-quality products or services, and demonstrated potential for future growth. This focus on long-term value creation helps ensure that any acquisitions will provide returns for years to come. How Chevron Executes Its Acquisitions Once a potential target has been identified, Chevron enters into negotiations with the target company’s owners or shareholders to purchase their shares or assets. Often these negotiations are complex due to differing interests between both parties but ultimately result in an agreement based on fairness and mutual benefit. Once an agreement is reached, it must then be approved by regulators before it can be finalized. Once all conditions are met, the transaction is closed, and ownership transfers from one party to another.

Chevron El Segundo Refinery, California. Photo by Pedro Szekely. Flickr.

Chevron Today and Tomorrow

With an estimated market capitalization of nearly $200 billion, Chevron is a powerhouse in energy production, exploration, refining, and marketing. But what does the future hold for Chevron beyond 2023? Let’s take a closer look at this giant of the industry and its potential role in the economy after 2023. Chevron's Current Position Currently, Chevron operates more than 3400 service stations across the US, has indirect operations in over 80 countries worldwide, and produces roughly 2 million barrels of oil per day. In addition to producing oil and gas products, Chevron also refines petrochemicals such as lubricants, waxes, and solvents. Despite its size and presence on the global stage, Chevron has had to face many challenges due to changing environmental regulations as well as technological advances that have seen other energy sources becoming more popular than ever before. The Future of Chevron Despite these challenges, Chevron Corporation remains committed to its core mission of providing reliable energy resources to power America’s economy. As part of this commitment, it has announced plans to invest heavily in clean energy projects over the next few years. This includes investing $100 million into renewable energy projects and up to $3 billion into low-carbon technologies such as electric vehicles and carbon capture technology by 2023. This commitment demonstrates that despite external factors affecting the oil and gas industry today, Chevron remains focused on serving customers around the world with quality products while also taking steps toward reducing emissions from its operations.

Chevron Corporation uses digitization and AI at the pump. Photo by Rafael Castillo. Flickr.

Digitalization for Future Proofing

Chevron has made substantial investments in digitalization efforts to maintain its competitiveness in an ever-changing landscape. These investments encompass a wide range of technologies, including autonomous robots for data collection and pipeline monitoring, AI-powered analytics platforms, predictive maintenance software, digital twin technology, cloud computing services, advanced drone surveillance systems, cybersecurity measures, AI, ML, NLP, blockchain, big data analytics platforms, RPA, VR simulations, AR visualizations, geospatial imagery analysis software, mobile app development tools, and 3D printing for materials testing. These forward-thinking investments position Chevron for long-term success beyond 2023, distinguishing it from competitors still transitioning from traditional business models to digital solutions.

Conclusion:

Chevron Corporation has come a long way since its beginnings as a small oil company in California nearly 140 years ago. Through strategic acquisitions, it has become one of America's largest corporations with operations all over the world. Its success story serves as an inspiration for American businessmen who are looking to achieve similar heights through hard work and smart moves. With its impressive track record, Chevron looks set to remain at the top for many more years to come! Sources: THX News & Chevron. Read the full article

#Chevroncorporation#Cleanenergyinitiatives#digitaltransformation#Energyproduction#FutureofChevron#Globaloperations#Marketacquisitions#Oilindustryhistory#RenewableEnergyInvestments#Sustainablepractices

0 notes

Text

Fire Truck Market to Scale New Heights as Market Players Focus on Innovations 2023 – 2028

Latest study released by AMA Research on Global Fire Truck Market research focuses on latest market trend, opportunities and various future aspects so you can get a variety of ways to maximize your profits. Fire Truck Market predicted until 2027*. The fire truck is an emergency vehicle which helps for firefighting operation. This vehicle is also used to rescue people from fire hazards. The term fire truck and fire engine are interchangeably in a different department. There are many types of a fire truck in market few are like Pumper Fire Apparatus, Quint Fire Apparatus, Foam, and Water Tenders and many more. Fire truck is also available according to water tank size, ladder size. Some of Key Players included in Fire Truck Market are:

W.S. Darley & Co. (United States)

Oshkosh Corporation (Japan)

Rosenbauer International AG (Austria)

Magirus GmbH (Germany)

Morita Holdings Corporation (Japan)

E-one (United States)

HME, Inc (United States)

Spartan Motors, Inc (United States)

Jon's Mid America Fire Apparatus (United States)

Boise Mobile Equipment Inc (United States)

Drivers: Increasing Fire Hazard

Opportunities: Usage of Electricity Increasing Day by Day

The titled segments and Market Data are Break Down by Type (Fire Fighting, Elevating, Special, Rescue, Mini Tanker), Application (Municipal Fire, Industrial Fire, ARFF)

Presented By

AMA Research & Media LLP

0 notes

Text

Container Shipping Market Will Hit Big Revenues In Future | Biggest Opportunity Of 2022

Latest added Container Shipping Market research study by AMA Research offers detailed outlook and elaborates market review till 2027. The market Study is segmented by key regions that are accelerating the marketization. At present, the market players are strategizing and overcoming challenges of current scenario; some of the key players in the study are

Maersk (Denmark)

CMA CGM (France)

COSCO Container Lines (China)

Evergreen Line (Taiwan)

Mediterranean Shipping (Switzerland)

APL (United States)

China Shipping (China)

Hamburg Sud (Germany)

Hanjin Shipping (South Korea)

Hapag-Lloyd (Germany)

Containers are basically used to transport the objects from one place to another. In container shipping, the containers are of various standard sizes that is 20 foot (6.09 m), 40 foot (12.18 m), 45 foot (13.7 m), 48 foot (14.6 m), and 53 foot (16.15 m), they are used to load, transport, and unload the objects or goods. As a result, then, containers can be moved by ships, trains, and trucks. Containers are generally made up of steel, and aluminum. The type and size built of each container comply with the regulations and specifications formulated by the International Organization for Standardization (ISO). Currently, the rising number of manufacturing units and factories has driven the growth of the global container shipping market.

Influencing Trend: Growth of Intermodal Shipping Transportation

Challenges: Tariff or Tax Levied On the Goods

Difficult To Transport Under Slack (Partially Full) Conditions

Opportunities: Government Associations are also Boosting Growth of the Global Container Shipping Market

Market Growth Drivers: Increasing Demand for Transportation Services

Growing Demand for Cost-Effective Shipping Solution

The Global Container Shipping segments and Market Data Break Down by Type (Dry Storage Container, Flat Rack Container, Open Top Container, Open Side Storage Container, Refrigerated ISO Containers, ISO Tanks, Half Height Containers, Others), End-users (Food & Beverages, Automobile, Healthcare, Consumer Goods, Electronics, Others), Size (Small Feeder, Feeder, Feedermax, Panamax, Post-Panamax, New Panamax and Ultra-large)

Presented By

AMA Research & Media LLP

0 notes

Text

Container Shipping Market Is Likely to Experience a Tremendous Growth in Near Future

Latest study released by AMA Research on Global Container Shipping Market research focuses on latest market trend, opportunities and various future aspects so you can get a variety of ways to maximize your profits. Container Shipping Market predicted until 2027*. Containers are basically used to transport the objects from one place to another. In container shipping, the containers are of various standard sizes that is 20 foot (6.09 m), 40 foot (12.18 m), 45 foot (13.7 m), 48 foot (14.6 m), and 53 foot (16.15 m), they are used to load, transport, and unload the objects or goods. As a result, then, containers can be moved by ships, trains, and trucks. Containers are generally made up of steel, and aluminum. The type and size built of each container comply with the regulations and specifications formulated by the International Organization for Standardization (ISO). Currently, the rising number of manufacturing units and factories has driven the growth of the global container shipping market. Some of Key Players included in Container Shipping Market are

Maersk (Denmark)

CMA CGM (France)

COSCO Container Lines (China)

Evergreen Line (Taiwan)

Mediterranean Shipping (Switzerland)

APL (United States)

China Shipping (China)

Hamburg Sud (Germany)

Hanjin Shipping (South Korea)

Hapag-Lloyd (Germany)

Market Trends: Growth of Intermodal Shipping Transportation

Drivers: Increasing Demand for Transportation Services

Growing Demand for Cost-Effective Shipping Solution

Challenges: Tariff or Tax Levied On the Goods

Difficult To Transport Under Slack (Partially Full) Conditions

Opportunities: Government Associations are also Boosting Growth of the Global Container Shipping Market

The titled segments and Market Data are Break Down by Type (Dry Storage Container, Flat Rack Container, Open Top Container, Open Side Storage Container, Refrigerated ISO Containers, ISO Tanks, Half Height Containers, Others), End-users (Food & Beverages, Automobile, Healthcare, Consumer Goods, Electronics, Others), Size (Small Feeder, Feeder, Feedermax, Panamax, Post-Panamax, New Panamax and Ultra-large)

Presented By

AMA Research & Media LLP

0 notes

Note

Is this basically what it looks like when an engine goes shopping? Or is it a more involved process?

That depends - for smaller machines this is basically accurate. The concept of a "drive thru store" was a very beneficial invention, and can be applied to vehicles ranging from automobiles all the way up to trains and small aircraft. Drive thru stores like this still usually employ attendants, but some movement has been made to automate the process in some countries - Japan being the most successful, with Lawson's markets unveiling a combination of automatic vending machines and programmable conveyor belts that dispense product without human interaction, an innovation that was later rolled out by their competitors. (Unsurprisingly, this has also proven to be a popular feature with Japan's human citizens as well.)

(This North American store caters mostly to humans, however it is also capable of serving small to mid-sized vehicles. Large ground vehicles such as over the road trucks and busses can be served in the parking lot by attendants.)

-

All that being said, serving individuals on a scale larger than that of railway locomotives is an incredible pain, and is done rarely outside of certain organizations and population groups:

Commercial airliners often joke that they still live in the 1960's, as the vast majority of their commerce takes place through mail-order catalogs, as few stores are capable of supporting them. Those stores that do support them are few and far between, usually operated by local airport authorities. Outside of those operations, family stores, usually set up during the early days of transcontinental flight or leftovers from World War Two, operate from a single location, with their clientele flying to them. Among the more notable stores includes Berlin's last remaining Intershop, which was built by the East German government along the Berlin Wall as a way to showcase their increased "machine rights" record, and survives today as the shop of choice for almost every Airbus ever made; Australia's Coober Pedy International Market, which features hangar lodging inside a disused opal mine (Which is more than capable of giving an A380 a claustrophobia-induced panic attack); and South Dakota's Wall Drug, which features a 19,000 foot dirt runway for airborne customers, a railroad spur and drive through operations for ground based craft, and a permanent 35% discount for any ship who manages to get to the store under their own power.

Commercial shipping works mostly off of mail-order catalogs as well as "mobile stores", where smaller ships or even helicopters make pre-arranged deliveries as well as offering goods for sale to anyone who can flag them down. While most of these operations are reputable, price gouging is known to occur, especially in less-reputable parts of the world. Some attempts have been made to create drive thru or otherwise land-based stores, but due to the nomadic nature of ships as well as their immense size, the concept has not caught on outside of captive ecosystems like the Suez and Panama Canals, Lake Baikal, and the Great Lakes.

That last point, however, does ignore one noted exception to the rule: the patient, diligent, and totally ignored staff of the United States Department of Defense's combined retail sales organizations.

The DoD's retail arms, which include: The Defence Commissary Agency, the Army & Air Force Exchange Agencies, and the Navy Exchange, do more work in the support for machine accessibility than the next ten organizations combined. They do it not because they want to, nor because they care - they do it because they have to.

The madate of these agencies is simple: serve the retail needs of the men and women of the United States military.

What is less simple is the fact that the "men and women" of the US Military are not just humans, but also Tanks, Humvees, Transport Aircraft, Jeeps, Trains, Hovercraft, Helicopters, Airships, Zeppelins, Trucks, Armored Personnel Carriers, NASA's Space Shuttle fleet, any retired vehicles who may have served the US Military in the past, and several hundred active duty warships ranging in size from 30-foot tugboats and Civil War era Ironclad ships all the way to Nimitz-Class aircraft carriers.

The logistical challenges these organizations face on an annual basis is so substantial that it often seen as hyperbole during annual budget appropriation hearings.

#ask response#ttte#sentient vehicle headcanon#headcanon#worldbuilding#sentient trains#sentient vehicles#background info

37 notes

·

View notes

Text

Collection Report Part 2: Widmer Brothers Brewing Company Records, 1984-2013

Previously, I posted about the collection pick up and the collection description. Today I'm going to tell you about the Widmer Brothers Brewing Company company!

Read Jeff Alworth's book The Widmer Way. It's way better than this post.

Check out the whole guide to the collection.

The Widmer Brothers Brewing Company was founded in 1984 in Portland, Oregon by Kurt and Rob Widmer.

Portland is known as the locus of a local beer scene. The Cartwright Brewing Company founded there in 1980, four years later the Bridgeport Brewing Company and Widmer Brewing followed. Not everyone was keen to try the unfamiliar beers and the brothers struggled to get taverns to offer them. They only sold beer in kegs, believing flavor was degraded by the bottling process, so they were dependent on draft sales. To increase awareness and promote their beers, they formed the "Widmer Designated Drinker" program; the brothers and their friends rented vans (driven by nondrinkers) and traveled to bars where they ordered large amounts of Widmer beer. Fortunately, in future years they sold more than their friends and families consumed.

Kurt was introduced to a wide variety of beer styles while living in Germany in the 1970s, and brewed his own beer after he returned to the United States. He used a traditional strain of yeast obtained from the Brewing Research Institute in Weihenstephan, Bavaria, and later returned to Germany to fine-tune his craft at a brewery in Dusseldorf. The brothers wanted to open a brewery and raised more than $50,000 from family members and an outside investor. With their father Raymond, they set about assembling a small brewery at 1405 NW Lovejoy Street, in an industrial part of NW Portland now known as the Pearl District. At the time, the brewing industry was comprised of large, industrial-sized breweries, which meant this smaller microbrewery had to be creative when acquiring equipment. They purchased used dairy and restaurant equipment (a dairy tank turned mash tun and shrimp cooker turned whirlpool), and by fall began running test batches.

The first Widmer offering, Altbier (German for "old beer"), was offered for sale in early 1985, and the richly flavored brew was soon joined by Weizenbier, a lighter variety filtered wheat beer. They marketed the beer to taverns and pubs, often delivering kegs in the red 1970 Datsun pickup truck they borrowed from their dad. Their first year production totaled 400 barrels. The Dublin Pub was their first longtime account and served both Altbier and Weizenbier; in 1986, owners Carl Simpson and Katie Bullard wanted them to make a third beer. This was a challenge because they only had two fermenters and couldn’t afford to buy another. They decided to leave the Weizenbier unfiltered, use Cascade hops, and put it directly into kegs. The result was a uniquely cloudy beer, the first American-style Hefeweizen or Hefe, which translated from German means "yeast wheat." This style of "American Hefeweizen" and the custom of serving wheat beers with a slice of lemon spread widely. Also in 1986, the brewery released Festbier, a seasonal "winter warmer" beer brewed for winter months.

Annual production increased each year. By 1989, they reached maximum capacity on their brewing equipment and had to turn away new business. They bought two adjoining historic buildings in North Portland that were slated for demolition and planned to renovate them for a new brewery. The 100-year-old Smithson and McKay Buildings had Italianate and Romanesque Revival brickwork, a cast-iron storefront, and were on the National Register of Historic Places. The extensive interior work meant renovation costs were significantly higher than constructing a new facility from scratch. They increased production dramatically, but demand grew even faster. In 1992, they laid out plans for an expansion adjacent to the brewery that would, once again, double production. They continued to only distribute their beer in kegs, but in 1996, decided to begin bottling.

In 1995, they opened a pub and restaurant, the Widmer Gasthaus, and began work on the brewery expansion. In spring of 1996, the new $20 million brewery opened and its brewing vessels and utilities were connected to the older one through under-the-street tunnels. At that time, Widmer produced 11 different beers; this included year-round production of Hefeweizen, Widberry Weizen, Blackbier, Amberbier, Altbier, and Weizen and seasonal beers Doppelbock, Oktoberfest, and Winternacht. In 1997, they introduced new beers, including Widmer Vienna and Czech Pilsner, as well as a hard cider. They made seven year-round brews and the seasonals Golden Bock, Sommerbrau Kolsch, and Hop Jack Pale Ale. In early 2000, they unveiled redesigned packaging, which emphasized the "W" initial in the firm's name and featured more colorful graphics. In 2003, they started brewing Hefeweizen at the New Hampshire RedHook Ale Brewery plant. In 2004, they introduced a seasonal brew called Snowplow Milk Stout, which had been developed by the Oregon Brew Crew, a home brewers club to which the brothers belonged. In 2005, they launched the “W Series,” which showcased their brewmaster’s most innovative and creative recipes.

In 1997, they sold a 27% stake to Anheuser-Busch InBev for $18.25 million in order to gain access to their distribution network and strengthen the company financially at a time when many craft brewers were struggling. Anheuser-Busch InBev had already purchased a stake in Seattle's RedHook Ale Brewery. In 2007, RedHook and Widmer Brothers announced plans to formally merge, forming a new company called the Craft Brewers Alliance, It was renamed Craft Brew Alliance in 2012. By 2013 was composed of five beer and cider brands: Widmer Brothers Brewery, RedHook Ale Brewery (founded in 1981 in Seattle, Washington), Kona Brewing Company (founded in 1994 in Kona, Hawaii), Omission Beer (developed in 2012 in Portland), and Square Mile Cider (launched in 2013).

Kurt Widmer retired in 2016, the Gasthaus closed in 2019, and Anheuser-Busch InBev acquired the company in 2020.

#widmer brothers brewing#jeff alworth#beer history#oregon beer#oregon hops and brewing#widmer archives

2 notes

·

View notes

Text

0 notes

Text

March 10, 2020: 3:56 pm:

I just returned from an errand expedition in Dystopia, Meford Oregon.

Sometimes I have to go to Medford.

There is a billing terror going on with my account at the place I went to. The billing at that place has never been correct, is always manipulated, and the manipulations are such that the billing amounts, in dollars, on the bills, and with consideration of how often, and how many bills are sent, or payment at time of service, speak as if the numerals are words. The billing is coded in every way that it can be coded and used for terror communication. Today, no billing was talked about, there was no demand for payment at time of service. What’s more, is that no payment demand at time of service would usually be considered as normal business for the kind of services provided there, however, that place is not normal, and for about five years, the billing has been demanded at the time of service, until today.

At the place I went to run the errand, there were none of the familiar faces, with exception of two people. All but two of the normal people that I encounter there have been changed. Both of the familiar people were part of the service I received privately.

There was a set of circumstance in the form of communication made with objects and vehicles all along the route to Medford, and the return trip home. I am not going to spell out the communication components unless I am somehow compelled to elaborate. I will say what the communication amounts to, as follows:

A number of objects:

A number of chairs made of rubber balls filled with air.

A stretch limousine, forty feet long, hummer, black.

Many balloons shaped like balls, about two-feet in diameter, attached to new cars for sale at the Mazda dealership.

A triple truck trailer, Oak Harbor Freight, parked on the overpass at Eagle Point/Central Point exit.

A video of a sea turtle being set free on Twitter news story, and a car in the parking lot at the place I went to, are connected with an electrical trailer connection (very difficult to make this observation, is a big deal)

A sign at the Chadwick’s Pub at the Biddle Road Freeway onramp, says: “Dishwasher Wanted” on a marquee in large lettering.

All of those things and more, are about the “Corona Virus” attack on USA. and other parts of the world, happening now. The “Dishwasher Wanted” at the Chadwick’s is the glue that puts it all together. Without that, the comm would not mean anything other than “a hair ball”.

Add the Dishwasher at Chadwick’s and it becomes a #SAGClubMed announcement about production of “Mold Spores”, and that is what Corona Virus is made from. SDA terror soldiers produce airborne gasses that are made of mold spores. Those gasses are released into areas where people gather, and many of those people will become sick. Many will seek medical attention, and others may go to a hospital, some may die, because mold spores made by SDA terror soldiers can be lethal to people who are very young, or, very old, and those who suffer from other immune system ailments.

The hospitals and medical clinics are all hijacked by the #SAGcoup, so, when people go to seek help, from exposure to the mold spore airborne gas, they will be told they have “Corona Virus”. Family members will be told the bad news and come to the hospital, or other mandatory confinement area, and the whole fa,ily is killed there. Impostors come out, two weeks later, using the names of those who were killed, and the Corona Virus is only a news media and US State run terror tool used as an excuse to blame many thousands of deaths on. Realty is that the people are killed, mass murdered,by news media who are the driving force of the Corona Virus attack scenario.

That is only one of the ways people will be murdered with Corona Virus Attack on USA, and other parts of the world. The way News Media is running the attack, it’s like a “Pot Luck” at a church gathering, everyone brings a dish to the diner. News stories on Twitter, are the ideas presented in bulk, and become part of the Church Pot Luck Dinner, where terror soldiers in the cities and towns can adopt different stories, that are presented in coded language on Twitter from all of the SAG News Media networks, as murder scenarios. When the terror soldiers choose from the Twitter Pot Luck Menu, they are assured that the murder attack plan they have chosen, is an approved one, that will be supported by the terror soldiers who are the impostor police, and other “authorities”. The authorities know what is on the menu, and the terror soldiers also know what is on the menu, in that way, all of the murderers know what to do, how to behave, where and who to attack and kill, and a lot of other information, as long as the terror soldiers choose a method from the Pot Luck, then, the authorities already will know what is going on, and how to assist the terror soldiers in completing the ,ass murder scenarios they have chosen to carry out from the menu, on Twitter.

This is happening now. And in Medford Oregon, they will be running a Mold Spores Gas terror play scenario that will make people sick, and they will seek medical attention at one of the many hospitals that were overtaken by #SAGClubMed.

On the way home from Medford, I saw one of the vehicles that carries the machine that grinds human beings up into a liquid. It was blue in color, large, looks similar to a cement mixing truck, or a large mulch/aggregate materials delivery truck with conveyor belt attached. The truck said: “CAD” painted on the door. That truck was preceded, North Bound I-5 at Rogue River Oregon at about 3:30 pm, by a forty foot trailer on a big rig containing extruded metal in a “Channel Metal” configuration. Very long, and shiny metal, and a lot of it. That truck was preceded by “Amazon Prime” blue colored forty foot trailer. That truck was accompanied by “Knife River Construction” truck, a specialty custom made truck, with a liquid hauling tank on board, about 1,000 gallon size, and also had an onboard boxy looking compartmentalized unit behind the liquid hauling tank. I think that vehicle contains the liquefied human remains of victims that were put into the one marked “CAD”. Those vehicle also were traveling with a dark blue Prius, and a Fiat.

That is the killing carnival. They expose people to Nitrous Oxide gas, and then carry them to the truck with the machine the grinds people into liquid. they add water, and some seeds, and then make a profit by selling that product back to teh federal government as “Erosion Abatement”. They spray the hillsides with the human remains of mass murdered Americans, and bill the government for the work of Erosion Prevention. ODOT Contractors do this. Knife River is an ODOT Contractor, there were many Knife River Trucks on the road today. They are extreme bad news.

Victims of the Knife River attack happen at road construction detours that don’t lead anywhere, the detours lead to a dead end, where the people are forced out of their cars at gunpoint, and put into that giant size grinding machine.

Victims are also taken at super market parking lots, and anywhere that large groups of people gather.

End terror reporting:4:58 pm.

2 notes

·

View notes

Text

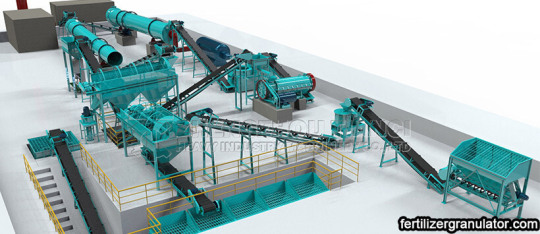

How to choose fertilizer manufacturing process plant

Fertilizer promotes the development of ecological agriculture, and the demand is huge. Investment in building fertilizer plants has become a popular project. Some investors want to build small-scale fertilizer manufacturing process to save costs, while some investors in fertilizer plants are going to build large-scale fertilizer plants to save unit production costs.

So what should we pay attention to when purchasing fertilizer manufacturing process plant? Here are some notes.

1. Determine the type of fertilizer and producton site. Determining whether to produce organic fertilizer or compound fertilizer affects the choice of site. If organic fertilizer is produced, it should not be too far from the farm where raw materials are provided. The type of fertilizer determines whether compound fertilizer equipment or organic fertilizer equipment is needed. Different types of fertilizer equipment also have differences.

2. Determine the fertilizer granulator machine. Granulation is the key link in fertilizer production and plays an important role in the quality of manufactured fertilizer. Fertilizer granules are cylindrical, spherical and flat spherical in shape. The granules produced by granulators of different shapes are different. The choice of granulator is related to the scale of fertilizer plant construction and local market. Fertilizer factories have different investment scales, different production processes, and different supporting equipment.

If a small fertilizer plant is to be built, it is suggested to configure simple machinery and equipment to reduce investment in equipment. The small fertilizer production line is composed of crusher, mixer, granulator, drum screener and automatic packing machine. If organic fertilizer fermentation is needed, it can be carried out with batten fermentation and windrow turning machine. The advantages are that they are more in line with the principle of aerobic fermentation. It is not easy to form anaerobic fermentation. The fermentation is full and complete, and the fermentation speed is fast. Forklift trucks can also be used instead of turner (the effect is not as good as turner), which can be adopted in terms of saving investment. According to the local environmental protection requirements, choose dust removal settings, where environmental protection requirements are high, choose heavy dust settings to meet the local emission quality standards.

Investment in large and medium-sized fertilizer plants, fertilizer production equipment can choose turning machine, automatic batching system, loader feeding hopper, crusher, mixer, granulator, dryer, hot stove, cooler, feeder, screener, cyclone dust collector, packing machine, etc. Increase mechanical automation, save manpower and cost. Organic fertilizer tank fermentation, can choose simple compost turning machine, double screws compost turning machine (suitable for large yield).

3. Determine the manufacturer of fertilizer manufacturing process plant. Several fertilizer machine manufacturers were inspected, and the strength, scale and reputation of the manufacturer of fertilizer equipment were fully understood. It is better to inspect the production workshop, finishing workshop and assembly workshop of the enterprise, to know the product quality, processing equipment, production process of the enterprise, and whether the fertilizer equipment produced by the manufacturer is professional. Referring to the customer cases that the manufacturer has completed, on-site test machine, the production site can best show the real operation of the equipment. Looking for fertilizer equipment suppliers with perfect after-sales service, suppliers provide professional technicians to guide customers to install and debug equipment, so that the equipment can operate normally, and provide corresponding training services.

4. Determine the safety performance of fertilizer manufacturing process plant. Safety is the first, before purchasing, we need to consider whether the production line has safety devices, whether the machine design is reasonable, whether safety factors are taken into account, whether the parts are not welded properly, whether the bolts are tightened, whether there is pollution, and so on. In addition, whether the overall operation of the equipment is smooth and whether the design of the production line is reasonable are also matters needing attention, because it relates to the efficiency and quality of the operation of the equipment. With the permission of the manufacturer, the operator can try to operate it in practice and feel its state conveniently.

Powerful organic fertilizer production equipment enterprises can customize their own equipment configurations for different customers according to their needs, and users can choose their own equipment according to their own needs. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. We provide customers with process design, equipment manufacturing, installation and commissioning, with full one-stop services. We are a leading agricultural equipment manufacturer in China, has strong technical strength in fertilizer machines. We have exported to many countries, India, Korea, Vietnam, Pakistan, Malaysia, Kenya, Sudan, Egypt, Algeria, Russia, Ukraine, Turkey, Spain, etc. Any question, welcome to contact us.

1 note

·

View note

Text

Toyota Land Cruiser Customer's Guide

First manufacturing Toyota 4x4 energy, geared up with a B-series engine and also a three-speed transmission. Makes use of a grille with 9 upright slots, normally has no doors, has headlights installed behind steel guards on level fenders. Similar in look to early Jeeps, yet bigger. Assigned Land Cruiser name in 1954. 1951 - 1955

Land Cruiser (20 Collection).

Basic 20 Series car is an utility 4x4 outfitted with a soft or metal top.Land Cruiser BJ25s were outfitted with B-series engines,FJ25s with F-series engines.Both feature a grille with four horizontal slots between the headlights and use square, upright designing that means what the timeless FJ40 will certainly resemble.Readily available in several kinds,consisting of as a long wheelbase with a soft top (BJ28),fire truck (FJ24JA) and a hardtop with lengthy wheelbase (FJ28V).1955 - 1960.

Land Cruiser (40 Collection).

The timeless Land Cruiser 40 Series in its FJ40 kind,with its looks and also unified percentages.2 doors with a hard or soft top, folding windshield,F-series engine and two-speed transfer instance.The roofs of the hardtops are repainted white,and all hardtops had wrap-around rear windows. instead of straight grille slots,the grille contains a mesh aspect in between the two headlights.Square turn signals were placed atop each front fender.Available in numerous types,including a somewhat longer wheelbase permanent top (FJ45V) as well as a pick-up (FJ45).

Land Cruiser (55 Series).

A long-wheelbase four-door energy wagon with 40-Series running equipment. Designing remains really square-edged,but down-sloping front fenders with vestigial level tops somewhat integrated into the front clip. Square directional signal were placed atop the front fenders.Carburetor air intake grilles are high above,and also somewhat aft of, the front wheel wells.Hood is a lot more a flat panel than was the 40 Series hood.Grille includes horizontal ports between the fronts lights. The taillights are high-mounted as well as rectangle-shaped.The interior is much more complete and also incorporated than previously, with a cushioned dash top.1967 - 1979.

Land Cruiser (60 Series).

Land Cruiser wagon,the logical extension of the 55 Series,remains square for outstanding application of space however the sides are softer and also more rounded.The grille includes four horizontal bars as well as 5 horizontal slots.Fenders are completely incorporated into front clip.The front turn signals are incorporated right into the front fascia,immediately outboard of each headlight.Rear directional signal are rectangle-shaped and also upright,inset right into the body's sheet steel just over the rear bumper.The back door can be a single lift gateway,a solitary swing-out or a pair of swing-outs.Interior is currently styled,with an automotive-type dash.1980 -1989.

Land Cruiser (70 Collection).

Square-bodied Land Cruiser energy 4x4 two-door with steel doors as well as leading, inclined windscreen. The front-clip designing continues to be much like that of the 40 Series. The grille can be mesh or can include three horizontal bars.Both have three extra straight ports in a solitary line under the grille.Front turn signals are square with triangular white lens aspects underneath,as well as are fastened to the vertical edge of the front clip above the fenders and just outboard of each headlight.The top can be hard or soft.The doors are hard,with roll-up home windows.Taillights are long, upright rectangular shapes inset reduced right into the back bodywork.Rear doors are paired swing-outs.Windscreens of some armed forces versions will fold up atop hood. Available in several kinds,including a pickup (FJ75P) and a four-door,long wheelbase energy wagon (FJ77HV).1984 -present.

Land Cruiser (80 Collection).

Land Cruiser wagon with upright,rounded designing.Hood has a wide power lump, front fenders reveal character lines that mean the 55 Collection 'front fenders as well as stream the length of the car's body.Front fenders are fully incorporated right into the front clip and have sheet metal flares.Turn signals are thin,straight systems installed just below headlights. Grille is egg-crate mesh in between rectangular fronts lights. Back doors can be either swing-out side-openers or a tailgate/lift gate mix.Taillights are vertical rectangular shapes inset into the bodywork simply over the rear bumper.The interior is currently very contemporary,tending toward high-end, with a control panel inset under a curved brow in very early (broad) as well as late (much less large) styles. Springs are currently coils,as opposed to leafs,at each corner.1990 - 1997.

Land Cruiser (90 Series).

Called the Prado and developed from the 70 Series,the very first Land Cruiser to utilize independent front suspension.Was not marketed in the U.S.in this iteration.90 Series is somewhat smaller sized than 60 Collection and 80 Series,as well as offered with 2 or 4 doors.Grille is made up of 11 vertical bars in between styled headlamps,with additional air conditioning slots below the grille,in the bumper.1993 - 2001.

Land Cruiser (100 Collection).

Land Cruiser wagon with a high greenhouse, independent front suspension and 4.7 L V8. Some variations sold outside the U.S. get a solid front axle (101 Series). Power lump on large,flat hood much less obvious than formerly; front fenders reveal unique sheet-metal flare. Grille contains three horizontal bars in between incorporated and styled headlamps. An extra narrow straight air conditioning consumption is located listed below the grille, in the front bumper. A bump strip runs size of body below belt-line. Noticable flare around back wheel wells. Back door is a lift-gate. Taillights are huge ribbed systems that are partially built right into the lift gate and also twist around the rear edges of the vehicle to be noticeable from the side as well as from the rear. The dashboard is very modern with a cockpit console under its very own eyebrow and with HVAC as well as sound controls, as well as several Air Conditioning vents, in a different central panel. 100 Collection is offered just as a four-door. 1998 - 2007.

Land Cruiser (120 Series).

In 2002 the Land Cruiser Prado was revised as 120 Collection Prado,or in some markets, just the Land Cruiser.Seen in the United States as the Lexus GX 470.Body has 60 percent extra torsional strength as well as extremely advanced electronic grip controls for enhanced off-as well as on-road efficiency,lower noise and also far better quality. Center of mass was reduced, making sure far better stability.Along with a Torsen limited-slip main differential,Energetic Grip Control and also Vehicle Security Control offer superior movement on practically any kind of surface.2002 - Present.

FJ Cruiser (120 Collection).

Toyota's 2007 FJ Cruiser uses the 120 Collection frameworks layout created in 2002 as well as more enhanced in 2005 for this application.Optimization consists of increased fuel-tank clearance,32-inch tires and even more suspension articulation than on various other versions of the 120 Series.It includes a wide,flat hood with rounded sides as well as a mesh grille between two round white headlights,per FJ40.Flat,upright windshield, roof covering,wrap-around back home windows,brief front/rear overhangs,angular wheel openings,off-center back license plate,all per FJ40. 2006 as a 2007 version.

Land Cruiser (200 Collection).

A high-end 4x4 with fine-tuned, upright bodywork as well as styling for excellent area usage.A broad,flat hood contains character lines,as well as moves right into the beltline as well as into the horizontal,four-slatted grille - a theme that echoes the 60 Collection Used Toyota Land Cruiser For Sale In Europe - and also unitized straight headlights.Fender bulges and a three-dimensional rocker mark the vehicle's side facet,and a rear liftgate which contains part of the 200 Collection' taillights notes the back.Integrated bumper covers coincide shade as the bodywork.Power is provided by 3UR-FE 5.7 L DOHC engine as well as a six-speed automatic transmission.The full time four-wheel drive system includes an advanced traction-control system as well as a two-speed transfer case with a Torsen center differential with locking function.Inside includes three rows of seats with locations for eight guests.Instruments are included under a control panel eyebrow and also HEATING AND COOLING,sound and also offered navigation controls lie in a center binnacle.200 Collection readily available just as a four-door.2007 to present.

1 note

·

View note

Text

Grypmat Reviews

You may risk putting them down on some part of the aircraft that’s close to to the duty, however there’s all the time the hazard of marking or damaging surfaces. That’s improbable whenever you may be that individual and when it aligns together with your vision for your life. The Grypmat is the world’s best non-slip device tray that’s available on the market proper now. Since premiering on SharkTank, Grypmat has doubled its workforce and gross sales, has landed partnerships with leaders in the instrument truck business, and not too long ago, has been named one among TIME magazine’s Greatest Inventions of the Year. Starting his pitch by stating that he's an F16 mechanic in the United States Air Force, he tells them that he runs into issues “time and time again” throughout his work. After promoting his home and a lot of his belongings to afford to take his invention to EAA AirVenture for the primary time in 2015, he was finally capable of share his invention with the aviation world. Grypmats have been a big vendor in the military and industrial aerospace markets and the final aviation group. Elaborating, he tells them that they’re about to move from the aviation to the automotive industry.

Any advice I would give is that there is no such thing as a “big break”, there are “breaks” — but don’t assume that one break means you have to cease working. For every working man and woman, their instruments are vital to them performing their job efficiently. I was bored with my instruments slinging off the aircraft and probably not having a place to set them,” he says. The Bigger GrypMat 12" x 22" is for the heavy obligation GA Mechanic who wants extra; extra devoted area and more group, identical to having an additional set of arms on site with you. Whether or not you're engaged on a sizzling engine, a high-wing airplane, or on the inside of a marine vessel, The Grypmat offers a protected area so that you can set your instruments. We found that Grypmats follow any floor we tried them on-body, glass, the intake manifold, even inside carpeting-whereas still permitting easy placement and removing if you lift up an edge. We've got discovered the massive Grypmat to be an excellent instrument caddy/platform when performing maintenance on helicopters. GrypMat works the place other tool trays wont, such because the curved surfaces discovered on aircraft wings and our bodies.

Burden was creating the first prototypes of the Grypmat when he was accepted into Wisconsin-based mostly seed fund and mentoring program Ideadvance. It was absolutely funded in the primary 10 hours,” Burden says. The first hybrid of its sort, the bilevel equalizer successfully combines the excessive efficiency of an lively equalizer with the low cost of the passive equalizer. It may appear a little bit dear, especially contemplating the simplicity of the design, however a non-slip tray that won’t mark up a paint job is probably value its weight in gold. You may be able to complete the job on-time with out breaking a sweat. Keep your instruments shut and get the job completed right. Plus, the extremely visible orange shade presents a pleasant, stark distinction to monochromatic instruments and fasteners, which improves visibility. To suit a wide range of wants, the vivid orange Grypmat is on the market in three sizes: giant, medium and small. To resolve this problem he explains, he invented the Grypmat.

Respect Your Workflow With Grypmat you’ll expertise an entire new workflow. The GrypMat by Grypshon Industries is made from a rubberized, flexible, non-marring, non-slip, anti-static material. Kickstarter efforts. Grypshon developed a proprietary mix of polymers and silicon rubber which is utilized in all Grypmats and which supplies them unique properties. In the future, Tom was riding along with his Mother and noted a bit rubber pad on her automotive's dashboard. Sooner or later he seen his mothers sticky sprint-board phone holder mat and he knew he had an concept to keep his instruments from sliding. The large Grypmat is designed for extra involved jobs, the place a handful of tools just won't cut it. MEASUREMENT SYSTEM: The big and medium Grypmats include a built in ruler. Until you watch ABC’s Shark Tank, of course, which provided a huge financial enhance and nationwide publicity grypmat to propel Grypmat development after Burden’s product was featured on the popular tv present. Sarit Bhaduri, PhD, professor of mechanical, industrial and manufacturing engineering, led improvement of a brand new, moldable bone substitute that fills gaps in bone and encourages new bone progress in difficult fractures that can’t heal on their very own.

1 note

·

View note