#Under Voltage Relay

Explore tagged Tumblr posts

Text

Buy Under Voltage, Over Voltage, Start-Stop, Photocell, Liquid Level Relays in Dubai, UAE

Discover a wide range of high-quality relays in Dubai, UAE. Shop under voltage relays, over-voltage relays, start-stop relays, photocell relays.Order now for fast delivery!

#Phase Failure Relays#Over Voltage Relay#Photocell Relay#Under Voltage Relay#Under Current Relay#Phase Protection Relay

0 notes

Text

Ship Current Monitoring Relay (over/ under current monitoring relay on ship electrical system)

Ship overcurrent relays are used to protect sensitive equipment against over or under current conditions. By using current transformers (CTs), these protective relays monitor large AC currents common to large motor starters, circuit breakers, and transformers. Ship current transformers CT which steps down the monitored current to a secondary (output) range of 0 to 5 amps (AC) to power the…

View On WordPress

#current monitor relay#current monitor relay on ship#current transformer#inder voltage relay#over current relay#ship monitor relay#ship over current relay#ship under current relay#under current relay

5 notes

·

View notes

Text

Under Voltage Relay Manufacturers

Aditya India is one of the best Under Voltage Relay Manufacturers and suppliers in India. Our company is well-known for producing Under Voltage Relay, which are used to prevent damage from transient blackouts and brownouts to gensets, pumps, motors, shunt caps, transformers, and other electrical equipment. They are also used for auto start-stop functions on AMF panels, where a changeover signal is generated by a low or high in any phase. For more details, Visit the website.

Address -RZ -445/15, Tughlakabad Extension, Tughlakabad, New Delhi, Delhi 110019

Contact US - 08061859680

0 notes

Text

Failsafe software has been installed to Spamgon without issue.

The failsafe software creates pop-up messages when a piece of code is run on Spamgon. These will pop-up under three circumstances; action override, biological override, or pain override. For example, if someone were to hit Spamgon (please do not), the pain override failsafe would not activate. He would feel pain as normal. Failsafes can only be triggered by running code directly on Spamgon. There are workarounds, and it is not perfect. But for the purpose of double checking each and every function I personally run on him, this will work.

The process of testing the failsafe was tedious. For each type of override, I ran a small piece of code that should trigger a pop-up. I had Spamgon relay the pop-up to me, then deny it. This then repeated, but instead he accepted it. For the action override, his spun slowly for a few seconds, and the pop-up would read for him as "functional override, rotation of head segment, 5 rpm, proceed?". For the biological override, his left arm segment would turn green for a few seconds, displaying the pop-up "biological override, recolor left arm segment, hex value #3d8c40, duration 3 seconds, proceed?" For the pain override, a small shock would be delivered to his right arm segment, displaying the pop-up "pain override, shock to right arm segment, 5 kV, proceed?" We also repeated with a faster rpm, a different hex value, and a lower voltage to ensure the readings on the pop-up were correct.

The failsafe appears successful, however I will be staying here overnight and asking that he stays in the lab as well, in case there are any issues.

I do... feel bad about testing the pain override. The shocks were at such a low voltage that it should be no more than a carpet shock from static electricity, but it made him jump. Spamgon appeared uncomfortable when I asked him to select "yes" for the pop-up. In the long term, I know this is important. If there is ever more significant pain caused by running code, we know the failsafe will trigger and stop it before it happens. I still can not help but feel terrible. Watching him jump at the sudden shock, it felt cruel. Maybe there was a way to save him the pain. Maybe I should have tried harder.

He is putting his trust into me, and I am fearful it may all come crashing down. I hope this works. For his sake, I will do everything I can.

@ask-spamton-gpory-spamgon

9 notes

·

View notes

Text

Arteche Relays for Error-Free Operation: Protecting Power Transformers and Circuit Breakers

In the high-stakes world of power systems, ensuring the safety and reliability of critical equipment is paramount. Power transformers and circuit breakers form the backbone of electrical infrastructure, handling massive loads and enabling smooth power distribution. However, these vital components are susceptible to faults, overloading, and other hazards. Arteche relays, particularly their trip and lockout relays, have become a trusted solution to safeguard such equipment, offering reliability, speed, and durability in demanding environments.

The Role of Relays in Power Systems

Relays serve as protective devices in electrical circuits, detecting anomalies such as overcurrent, short circuits, and other fault conditions. When an issue is detected, relays promptly isolate the affected section to prevent further damage. This protective mechanism is critical for power transformers and circuit breakers, as failures in these systems can lead to costly repairs, extended downtime, and potential safety hazards.

Arteche, a globally recognized leader in relay manufacturing, has been at the forefront of developing high-performance relays for over 60 years. Their trip and lockout relays are specifically designed to meet the rigorous demands of modern power systems, ensuring error-free operation and long-term reliability.

Arteche’s Trip and Lockout Relays: Key Features

Arteche’s trip and lockout relays are purpose-built for high-voltage environments, such as substations, power generation plants, and industrial facilities. Here are some standout features that make these relays indispensable:

High-Speed Operation

Arteche relays boast a rapid response time, typically between 3 and 20 milliseconds, depending on the model. This swift action minimizes the risk of cascading failures and ensures that faults are isolated before they can escalate.

Latching Mechanism

The latching design of Arteche’s lockout relays (LOR - ANSI 86) ensures that once a trip occurs, the relay remains in a locked position until it is manually or electrically reset. This feature prevents inadvertent re-energization of faulty equipment, enhancing overall safety.

High Breaking Capacity

Arteche relays are engineered to handle high fault currents without compromising performance. Their robust construction guarantees reliable operation even under extreme fault conditions.

Compliance with International Standards

Arteche relays meet stringent standards such as IEC 61000, IEC 60947, IEC 60255, and ANSI C37.90. This compliance ensures compatibility and reliability across diverse power systems worldwide.

Wide Voltage Range

Arteche offers relays with a broad spectrum of auxiliary voltage options, making them suitable for various applications and environments.

Durability in Harsh Environments

Designed to withstand seismic conditions, vibrations, and extreme temperatures, Arteche relays are ideal for deployment in demanding operational environments.

Protecting Power Transformers

Power transformers are crucial for voltage regulation and power transmission in electrical grids. They operate under high stress and are prone to issues like overheating, oil leaks, and insulation failures. Arteche relays provide several layers of protection for transformers:

Fault Isolation: Arteche’s trip relays rapidly disconnect transformers from the grid in case of overcurrent or short circuits, preventing further damage.

Preventing Re-Energization: The lockout feature ensures that a transformer cannot be re-energized until the fault is rectified and the relay is manually reset. This eliminates the risk of additional damage from unresolved issues.

Monitoring Critical Parameters: Arteche relays integrate seamlessly with monitoring systems, enabling real-time tracking of key transformer parameters like temperature, gas pressure, and oil levels. This proactive approach enhances reliability and reduces maintenance costs.

Enhancing Circuit Breaker Reliability

Circuit breakers play a pivotal role in interrupting fault currents and protecting electrical circuits. Arteche relays enhance their operation in several ways:

Precise Command and Control: Arteche’s high-speed relays ensure that circuit breakers receive accurate and timely trip commands, minimizing response times during fault conditions.

Long Wiring Support: The high-burden configuration of Arteche relays prevents false trips caused by transient signals or long wiring distances. This feature is particularly beneficial in large substations where relay-to-breaker connections can span significant distances.

Durability and Longevity: Arteche’s relays are built to last, ensuring consistent performance over decades of operation. Their robust design minimizes the risk of relay failure, which could otherwise compromise circuit breaker functionality.

Meeting the Demands of High-Voltage Substations

High-voltage substations are complex environments where reliability and safety are non-negotiable. Arteche’s relays are specifically designed to address the challenges of such settings:

Handling High Fault Currents: Arteche relays are equipped to manage the high fault currents typical of HV substations, ensuring seamless operation during fault conditions.

Seismic and Vibration Resistance: Arteche relays are tested to withstand seismic activity and mechanical vibrations, making them suitable for installations in earthquake-prone regions.

Error-Free Operation Under Transients: Arteche’s compliance with ESI 48-4 standards ensures that their relays operate reliably even under transient conditions, minimizing the risk of nuisance trips.

Arteche’s Legacy of Excellence

With over six decades of experience, Arteche has earned a reputation for producing high-quality electromechanical relays. Millions of their relays are in service worldwide, safeguarding critical power equipment in diverse applications. Here are some reasons why Arteche continues to lead the industry:

Uncompromising Quality: Arteche’s relays undergo rigorous testing to ensure they meet the highest standards of performance and reliability.

Innovative Designs: Arteche’s commitment to innovation is evident in features like high-speed operation, latching mechanisms, and high-burden configurations.

Global Reach: Arteche’s relays are trusted by utilities, industrial plants, and power generation facilities across the globe, thanks to their adaptability and compliance with international standards.

Case Studies: Arteche Relays in Action

Substation Safety in Europe: A high-voltage substation in Europe implemented Arteche trip and lockout relays to enhance equipment safety. The relays’ rapid response and high-breaking capacity significantly reduced downtime during fault incidents, saving the utility millions in repair costs.

Transformer Protection in Asia: A power generation company in Asia relied on Arteche relays to protect its fleet of transformers. The relays’ real-time monitoring capabilities helped identify potential issues before they escalated, improving overall system reliability.

Industrial Facility in North America: An industrial plant in North America integrated Arteche relays into its control systems to ensure seamless operation of circuit breakers. The relays’ durability and precision were key factors in minimizing production losses due to electrical faults.

Conclusion

Arteche relays are a cornerstone of modern power systems, offering unmatched reliability, speed, and durability. Their ability to protect vital equipment like power transformers and circuit breakers ensures that electrical grids and industrial facilities operate smoothly and safely. Whether it’s preventing the re-energization of faulty equipment, handling high fault currents, or enduring harsh environmental conditions, Arteche’s trip and lockout relays consistently deliver error-free performance.

For power systems where safety and reliability are paramount, Arteche relays provide the peace of mind that comes with over 60 years of engineering excellence. As the demands on power infrastructure continue to grow, Arteche remains a trusted partner in safeguarding the critical components that keep the lights on and the world running.

At Digital & Smart Grid Enterprises, we pride ourselves on delivering cutting-edge solutions, including reliable Arteche relays, to ensure the safety and operational efficiency of your power systems. Our expertise spans comprehensive testing, commissioning, and monitoring services tailored to safeguard your critical power equipment, such as power transformers and circuit breakers.Contact us today at +917021624024 or email [email protected] to learn more about how we can support your power system's reliability and safety. Click here to explore our Relay Protection and Maintenance Services.

#PowerSystemSafety#ElectricalInfrastructure#ArtecheRelays#TransformerProtection#CircuitBreakerReliability#HighVoltageSolutions#RelayProtection#EnergyEfficiency#ElectricalSafety#SubstationAutomation#IndustrialPowerSolutions#FaultDetection#GridReliability#ElectricalEngineering#SmartGridSolutions

0 notes

Text

GF1115P PROGRAMMABLE AC LOAD UNIT

GF1115P three phase programmable AC load unit is mainly used as the load for on-site verification of electric vehicle AC charging pile. The on-site detection process of AC charging pile can be realized by cooperating with our GF1115 AC charging pile on-site test set. The whole detection process meets the requirements of relevant national detection standards and measurement standards JJG 1148-2018 verification regulation of electric vehicle AC charging pile. The internal motherboard of the resistance load box adopts the processor chip of armcortex-m4 core architecture, which automates the workflow of the whole resistance load box, reduces manual participation and saves operation time. The internal structure adopts multi-channel high-power resistance parallel connection, which is connected through high-quality relay control. Multiple gear switching can be realized through the control relay. The whole process is fully automated without manual participation. Forced air cooling is adopted, and the circuit structure is simple without too much maintenance, saving the heat dissipation cost. Internal temperature detection is set to monitor the working temperature in the box in real time, ensuring the safety and reliability of the load in use. Two national standard AC charging gun sockets are installed on the box to facilitate user cascade and increase load power.

FEATURES ■ Forced air cooling; ■ Remote control via CAN bus or serial port; ■ With insulation grounding protection inspection function; ■ The load box has the function of automatic resistance shift; ■ The equipment can be powered supply by mains AC supply or charging pile; ■ It has the functions of emergency stop protection, overcurrent, overvoltage and short circuit protection; ■ Under the rated voltage, the minimum current step is 4.5mA, the minimum power step is 1W, and all have 8192 gears; ■ Realize the power verification points required in JJG 1148-2018 verification regulation for AC charging piles of electric vehicles; ■ Support a variety of working modes, constant current mode, constant voltage mode, constant resistance mode, constant power mode; ■ The box body is equipped with 2 metering sockets meeting the safety requirements, and the loads are controlled through CAN bus; ■ With advanced control algorithm and DSP digital control implementation, it is suitable for various load regulation requirements with high precision, high speed and high stability; ■ The equipment is equipped with voltage and current calibration and correction function, which can calibrate and correct the measured value of the instrument at any time, so as to ensure the measurement accuracy of the instrument used for a long time; ■ Built in temperature sensor, when the temperature in the box is too high, it will actively disconnect the load for high temperature protection, and send out an alarm at the same time. In addition, it can try to monitor the temperature in the box through the communication port;

APPLICATION ■ Electrical laboratory; ■ EV & Charging pile factory; ■ Metrological service center; ■ Laboratories of power utilities; ■ Third party testing organization; ■ Electricity power bureau & power company; ■ National Metrology and testing department; ■ Charging pile operation and maintenance organization;

1 note

·

View note

Text

High voltage commissioning is a crucial step in ensuring the safe and efficient operation of electrical systems

High voltage commissioning is one of the most critical phases in the lifecycle of electrical systems, laying the groundwork for their safe and efficient operation. As modern industries increasingly rely on robust electrical infrastructure, proper commissioning becomes essential to mitigate risks and enhance performance. This process involves a series of systematic tests and inspections to ensure that high voltage equipment functions as intended, adheres to safety regulations, and meets operational standards.

Understanding High Voltage Commissioning

High voltage commissioning is the entire process that is carried out when new electrical installations, such as switches, transformers, and cabling systems, are connected to the power grid. This process is multifaceted, covering the verification of installations, electrical earthing system, system configurations, and safety protocols. Each step in commissioning serves to validate that the equipment will operate effectively within its designated parameters.

Key Aspects of High Voltage Commissioning

1. Visual and Physical Inspection A visual inspection is conducted before any electrical testing can be done. This inspection checks the quality of installation, mechanical integrity, and adherence to design specifications.

2. High Voltage Cable Testing: One of the major parts of a commissioning activity is the testing of high voltage cables. These tests include insulation resistance testing, which tests the integrity of the insulation material; megger testing, where the insulated part of a cable is applied with high voltage to detect any faults; and high potential, or hi-pot, tests to ensure that the cable can withstand operational voltages.

3. Functional Testing. After cable testing, functional testing is performed on all elements of the system-the circuit breakers, protective relays, and control systems-by confirming that every element works correctly with other parts of the electrical system.

4. Verification of Electrical Earthing System: In high voltage installations, the electrical earthing system is an essential safety measure. It ensures that fault currents have a direct path to the earth and hence prevents electrical shocks and equipment damage. In commissioning, the earthing system should be tested for resistance and functionality to ensure it will perform as needed during low-resistance fault conditions.

5. Performance Testing: After individual components are tested, performance testing is implemented to evaluate the entire system's behavior under various operational scenarios. This may include load testing, which simulates real operating conditions, and transient analysis to assess the system's response to sudden changes in load.

Importance of High Voltage Maintenance

High voltage maintenance is of utmost importance after successful commissioning to maintain the safety and efficiency of electrical systems. Regular maintenance, which includes inspections, testing, and repairs, ensures that equipment remains in optimal condition. Preventive maintenance, coupled with predictive analytics, can identify issues before they lead to system failures, thus safeguarding investment and enhancing reliability.

Moreover, continued maintenance supports the high voltage commissioning work as it ensures that the initial testing and verification processes are maintained throughout the lifetime of the facility. Higher efficiency can reduce operational costs and increase system life.

High voltage commissioning is not a mere regulatory checkbox. It is the process that guarantees the integrity, reliability, and safety of electrical systems. From rigorous cable testing to the validation of electrical earthing systems, every step of the commissioning process is essential to ensure high voltage installations perform as expected.

As technology advances, and the need for efficient energy systems continues to grow, a strong commissioning and maintenance approach will be necessary. It is essential for companies to consider these processes so that they are able to protect their assets, as well as those who may work with or around high voltage equipment. Finally, investing in thorough commissioning and reliable on-going maintenance means that not only will safety standards be met but also that it will open doors to sustainable energy management in this modern world.

#electrical earthing system#electrical test equipment#electrical testing services#cable fault location

0 notes

Text

Is a Protection Relay Essential for Safeguarding Your Electrical System?

A protection relay is an essential component in electrical systems, providing critical protection for equipment from electrical faults and hazards. But how exactly does a protection relay work, and why is it crucial for safeguarding your system? Let's explore its role and importance in ensuring the safety and longevity of your electrical infrastructure.

1. What is a Protection Relay?

A protection relay is a device designed to detect abnormalities or faults in electrical circuits, such as overcurrent, short circuits, or ground faults. It works by monitoring the current and voltage levels in the system and triggering a disconnect if these levels exceed safe limits. Protection relays are essential for preventing damage to electrical equipment and ensuring that the system operates reliably under varying conditions.

2. How Does a Protection Relay Protect Your System?

Fault Detection: Protection relays continuously monitor the electrical system for fault conditions. If a fault such as a short circuit or an overload is detected, the relay immediately activates, isolating the affected part of the system to prevent further damage.

Minimizes Damage to Equipment: By disconnecting faulty circuits quickly, protection relays reduce the risk of equipment failure, overheating, or even fires caused by electrical faults. This ensures that expensive components like transformers and motors remain safe.

Ensures System Stability: Protection relays also help maintain the overall stability of your electrical system by quickly isolating issues and preventing them from spreading across the network, which could cause widespread outages or even catastrophic failures.

3. Why Should You Consider a Protection Relay for Your Electrical System?

Enhanced Safety: Protection relays provide an extra layer of safety by detecting and isolating faults before they cause harm to the system, operators, or the surrounding environment. This makes them critical for ensuring a safe working environment, especially in industries with high-risk electrical setups.

Reduced Downtime: When a fault occurs, a protection relay quickly isolates the affected circuit, ensuring minimal disruption to the rest of the system. This reduces downtime and keeps the system running smoothly.

Cost Savings: Installing protection relays can help save costs in the long run by preventing major equipment damage. The cost of replacing damaged equipment or dealing with the aftermath of a system failure can be far more expensive than investing in reliable protection relays.

Compliance with Standards: Many industries require the use of protection relays to meet safety standards and regulations. By implementing these devices, you ensure that your system is in compliance with safety and operational guidelines.

4. How to Choose the Right Protection Relay for Your Needs

Selecting the right protection relay for your electrical system depends on several factors, including:

The type of electrical faults you want to protect against (overcurrent, undercurrent, ground faults, etc.)

The size and complexity of your electrical network

Specific industry requirements and standards

By carefully evaluating these factors, you can choose the most suitable protection relay for your system and ensure maximum protection.

Discover More About Protection Relays and Enhance Your System’s Safety

For more information on how protection relays can enhance the safety and reliability of your electrical setup, visit Schneider Electric’s Protection Relays page. Choose the best protection for your system today!

0 notes

Text

Electromagnetic compatibility (EMC) testing plays a crucial role in ensuring the safety and reliability of electronic devices. The EFT (Electrical Fast Transient) test is a vital component of EMC testing that assesses the immunity of electronic equipment to fast transients and electrical disturbances. This paper focuses on the detailed analysis of EFT testing using the LISUN EFT61000-4 EFT Immunity Measurement system. Key aspects such as the equipment setup, test procedures, technical specifications, and data interpretation are discussed. The study provides a comprehensive understanding of the EFT test and its significance in maintaining the operational integrity of electronic devices. Introduction Electromagnetic compatibility (EMC) testing is essential for ensuring that electronic equipment can operate without interference in its intended environment. One of the critical tests in EMC is the EFT (Electrical Fast Transient) test, which is used to evaluate the immunity of equipment against fast transient disturbances. These disturbances are typically caused by switching inductive loads, relay operations, or other similar sources. The EFT test is vital for assessing the robustness of electronic devices and systems in real-world conditions. The LISUN EFT61000-4 EFT Immunity Measurement system is a state-of-the-art device designed specifically for EFT testing. It conforms to international standards and provides accurate, repeatable results that are essential for product development and compliance verification. This paper delves into the functionality of the LISUN EFT61000-4, highlighting its specifications, testing procedures, and practical applications in the field of EMC testing. Equipment Overview: LISUN EFT61000-4 EFT Immunity Measurement System The LISUN EFT61000-4 EFT Immunity Measurement system is engineered to perform EFT tests in compliance with IEC/EN 61000-4-4 standards. This equipment is widely used in industries such as automotive, electronics manufacturing, and consumer electronics, where EMC compliance is critical. Key features of the LISUN EFT61000-4 include: • Pulse Voltage Range: The equipment supports a wide range of pulse voltages, typically from 100V to 4.5kV, making it suitable for testing a variety of devices. • Repetition Frequency: The system allows adjustment of pulse repetition frequencies from 1kHz to 100kHz, providing flexibility in simulating real-world transient conditions. • Burst Duration: Adjustable burst durations enable detailed analysis of the equipment’s response to transients. • Coupling/Decoupling Network (CDN): The built-in CDN allows for efficient coupling of test pulses onto power lines, minimizing signal distortion and enhancing test accuracy. EFT61000-4_EFT Immunity Measurement Below is a table summarizing the key specifications of the LISUN EFT61000-4: Parameter Specification Pulse Voltage Range 100V – 4.5kV Pulse Repetition Rate 1kHz – 100kHz Burst Duration 0.75ms – 300ms Output Impedance 50Ω Rise Time 5ns ± 30% Polarity Positive/Negative Coupling Modes Direct, Line to Line, Line to Ground Standard Compliance IEC/EN 61000-4-4 EFT Test Procedure The EFT test procedure using the LISUN EFT61000-4 system involves several steps to ensure accurate and repeatable results: • Test Setup: The equipment under test (EUT) is placed on a non-conductive surface, and connections are made as per the testing standard. The LISUN EFT61000-4 is connected to the EUT via the built-in CDN. • Parameter Configuration: Test parameters such as pulse voltage, repetition rate, burst duration, and coupling mode are configured based on the specific test requirements. These parameters are critical for simulating the desired transient conditions. • Test Execution: The test is initiated, and the EFT pulses are injected into the EUT. The equipment monitors the EUT’s response to the transients, including any functional disturbances or failures. • Data Collection and Analysis: Data is collected during the test, including information on the EUT’s performance under transient conditions. Analysis of the data helps identify the susceptibility of the EUT to EFT disturbances. • Reporting: A detailed report is generated, documenting the test conditions, results, and any observed anomalies. This report is essential for compliance documentation and product improvement. Test Results and Analysis A typical EFT test result will include the EUT’s response to various levels of transient disturbances. The LISUN EFT61000-4 allows for precise control of test parameters, enabling a thorough evaluation of the EUT’s immunity. Below is a sample data table from a test conducted on an industrial control unit: Test Condition Pulse Voltage (kV) Repetition Rate (kHz) Burst Duration (ms) EUT Response Test Condition Pulse Voltage (kV) Repetition Rate (kHz) Burst Duration (ms) EUT Response Condition 1 0.5 5 15 No disturbance Condition 2 1 5 15 Minor functional glitch Condition 3 1.5 10 30 System reset observed Condition 4 2 50 75 Intermittent shutdown Condition 5 3 100 150 Complete system failure From the data, it can be observed that as the pulse voltage and repetition rate increase, the susceptibility of the EUT also increases. Condition 5 represents the critical failure point, indicating the maximum transient level the device can withstand without complete malfunction. Importance of EFT Testing EFT testing is essential for identifying vulnerabilities in electronic systems, especially those operating in environments prone to electrical disturbances. The results from EFT tests guide engineers in designing more robust systems by improving shielding, grounding, and filtering techniques. Compliance with EFT standards is not only a regulatory requirement but also a crucial factor in product reliability and customer satisfaction. Conclusion The EFT test, facilitated by advanced systems like the LISUN EFT61000-4 EFT Immunity Measurement, is a vital aspect of EMC testing. It ensures that electronic devices can endure the fast transients they may encounter during their operation. This paper provides a detailed look into the EFT test procedures, highlighting the capabilities of the LISUN EFT61000-4 in performing precise and reliable assessments. Through careful configuration of test parameters and analysis of results, the EFT test helps manufacturers improve product designs, ensuring that they meet EMC standards and perform reliably in real-world conditions. As technology continues to evolve, the importance of rigorous EFT testing will only grow, reinforcing its role in the development of safe and dependable electronic equipment. Read the full article

0 notes

Text

7 Essential EMC Tests for Electric Vehicles

As electric vehicles (EVs) become more popular, it's crucial to ensure they are reliable and safe. A key part of this is making sure they work well with other electronic devices, which is where electromagnetic compatibility (EMC) comes in. EMC testing checks that EVs don't interfere with other electronics and can resist external electromagnetic interference (EMI). Let us look at seven important EMC tests for electric vehicles. These tests help manufacturers create high-quality, compliant products.

Radiated Emissions

Radiated emissions testing measures the electromagnetic energy emitted by the vehicle into its surroundings. This test ensures that the emissions stay within acceptable limits to prevent interference with other electronic devices, like radios, GPS systems, and mobile phones. Testing is typically conducted in an anechoic chamber, a room specially designed to absorb reflections of electromagnetic waves, isolating the vehicle from external noise and ensuring accurate measurements. Maintaining low radiated emissions is crucial for minimizing potential disruptions to communication and navigation systems both inside and outside the vehicle.

Radiated Immunity

Radiated immunity testing evaluates how well the vehicle can withstand electromagnetic interference (EMI) from external sources. It simulates real-world scenarios where the vehicle might encounter high levels of EMI, such as near broadcast towers or powerful transmitters. Ensuring strong radiated immunity is essential for the reliable operation of critical vehicle systems, including navigation, braking, and communication. Vehicles that pass this test are better equipped to handle electromagnetic disturbances without affecting their performance or safety.

Conducted Emissions

Conducted emissions testing focuses on the electromagnetic energy conducted through the vehicle's power lines and wiring harnesses. This test ensures that emissions remain within permissible limits, preventing interference with the vehicle's own systems and external electrical infrastructure. Effective conducted emissions testing helps preserve the integrity of the vehicle's electrical components and ensures compliance with regulatory standards, ensuring safe operation and reducing the risk of interference with other vehicles or electrical devices.

Harmonics Emissions

Harmonics emissions testing evaluates the distortion of electrical current within the vehicle's power system. Harmonic distortion can lead to excessive heating in electrical components and reduce the efficiency of the power system. By identifying and mitigating harmonic emissions, manufacturers can enhance the reliability and efficiency of electric vehicles. Minimizing harmonic distortions contributes to longer-lasting components and improved overall performance, ensuring that the vehicle operates efficiently and reliably over its lifespan.

Flicker Emissions

Flicker emissions testing assesses variations in voltage caused by the vehicle's electrical loads. Rapid changes in voltage can result in flickering lights and disruptions in the power supply, affecting both the vehicle and connected infrastructure. This test ensures that electric vehicles maintain a stable and consistent electrical environment, minimizing the potential for power quality issues. By reducing flicker emissions, manufacturers enhance the overall user experience and ensure reliable operation of electrical systems within and around the vehicle.

EFT/Burst Immunity

Electrical Fast Transient (EFT) or burst immunity testing evaluates the vehicle's ability to withstand sudden, high-frequency bursts of electrical energy. These bursts can occur due to switching operations, relay contacts, or other abrupt changes in the vehicle's electrical system. Ensuring strong EFT immunity is essential for protecting sensitive electronic components and maintaining reliable operation under real-world conditions. Vehicles that pass this test demonstrate robust resilience against transient disturbances, ensuring consistent performance and longevity of critical systems.

Surge Immunity

Surge immunity testing examines the vehicle's capacity to endure high-energy surges, such as those caused by lightning strikes or power line switching. These surges can pose a significant threat to electronic components and disrupt the vehicle's operation. By validating robust surge immunity, manufacturers safeguard critical systems and enhance the safety and reliability of electric vehicles in extreme conditions. Vehicles that withstand surge tests effectively are better equipped to handle unpredictable electrical events, ensuring uninterrupted operation and protecting both passengers and equipment.

About RF Electronics

RF Electronics is your one-stop shop for all RF-related needs, offering a comprehensive range of products and services to support your EMC testing requirements. From high-quality components and advanced test equipment to expert technical support and custom solutions, RF Electronics is dedicated to helping you achieve the highest standards of performance and compliance in your electric vehicle projects.

Ensuring the electromagnetic compatibility of electric vehicles is essential for their safe and reliable operation. By focusing on these seven essential EMC tests, manufacturers can deliver high-quality, compliant vehicles that perform well in real-world conditions. With the right tools and expertise, you can navigate the complexities of EMC testing and achieve success in the rapidly evolving electric vehicle market.

0 notes

Text

Testing and commissioning a substation is a critical process to ensure that the electrical infrastructure operates safely and efficiently. Here’s a step-by-step guide to help you through the process:

Step 1: Pre-Commissioning Preparation

Review Design Documentation:

Ensure you have the latest drawings, specifications, and manuals for all equipment.

Create a Commissioning Plan:

Develop a detailed plan outlining the scope of testing, timelines, resources, and responsibilities.

Gather Tools and Equipment:

Ensure that all necessary testing equipment (e.g., insulation resistance testers, power quality analyzers, etc.) is available and calibrated.

Safety Protocols:

Establish safety procedures and ensure all personnel are trained on them.

Step 2: Visual Inspection

Inspect Equipment:

Check all equipment for physical damage, correct installation, and cleanliness.

Verify Connections:

Ensure all electrical connections are tight and correctly configured.

Check Grounding:

Verify the grounding system for integrity and continuity.

Step 3: Functional Testing

Control Systems:

Test control panels and automation systems for proper operation.

Relay Testing:

Conduct relay functional tests to ensure they respond correctly to simulated fault conditions.

Circuit Breakers:

Perform tests on circuit breakers, including tripping and operational tests.

Transformer Testing:

Test transformers for insulation resistance, winding resistance, and turns ratio.

Protection Schemes:

Verify that all protection schemes function as intended during fault simulations.

Step 4: Performance Testing

Load Testing:

Conduct load tests to verify performance under actual or simulated operating conditions.

Power Quality Analysis:

Measure voltage, current, harmonics, and other power quality parameters to ensure compliance with standards.

Temperature Monitoring:

Monitor temperatures of critical components during load testing to ensure they remain within safe limits.

Step 5: Documentation

Record Results:

Document all test results, including any anomalies and corrective actions taken.

Update As-Built Drawings:

Modify any drawings to reflect changes made during installation and testing.

Compile Commissioning Report:

Prepare a comprehensive report summarizing all tests, findings, and recommendations.

Step 6: Final Review and Handover

Review with Stakeholders:

Conduct a review meeting with all stakeholders to discuss findings and address any concerns.

Handover to Operations:

Officially transfer responsibility to the operations team, ensuring they have all necessary documentation.

Training:

Provide training for operations personnel on the equipment and systems.

Step 7: Post-Commissioning Support

Monitor Performance:

Continue monitoring the substation's performance for a defined period to ensure stability.

Address Issues:

Be prepared to address any operational issues that arise during the initial operation period.

Regular Maintenance:

Schedule regular maintenance and testing to ensure ongoing reliability.

0 notes

Text

We are one of the top producers and providers of under-voltage relays in India. If you are looking for the best Under Voltage Relay Manufacturers and Suppliers in New Delhi, India. So you have come to the right location. Visit Aditya India. Our company is well-known for manufacturing Under Voltage Relays, which are used to shield transformers, gensets, pumps, motors, shunt caps, and other electrical equipment against damage caused by momentary blackouts and brownouts. They are also utilized in AMF panels' auto start-stop features, which produce a changeover signal in response to a low or high in any phase. Go to the website for further information.

Address -RZ -445/15, Tughlakabad Extension, Tughlakabad, New Delhi, Delhi 110019

Contact US - 08061859680

1 note

·

View note

Text

Top Electrical Solutions in Sharjah - Limit Switches, Timers & More

Looking for reliable electrical solutions in Sharjah? We offer a variety of products, from limit switches to multifunction timers. Here’s a quick overview of our key offerings:

Limit Switches

Essential for automation, limit switches detect the presence or absence of objects. Explore our Limit Switches in Sharjah.

Multifunction Timers

Versatile multifunction timers manage multiple timing functions. Learn more about our Multifunction Timers in Sharjah.

Process Controllers

Crucial for monitoring, process controllers ensure smooth operations. Check our Process Controllers in Sharjah.

Signal Splitters

Signal splitters divide signals for various outputs. Discover our Signal Splitters in Sharjah.

Split Core CTs

Used for AC current measurement, split core CTs are easy to install. Find out more about our Split Core CTs in Sharjah.

Under Voltage Relays

Under voltage relays protect equipment from low voltage. Explore our Under Voltage Relays in Sharjah.

Wago PLCs & Connectors

Reliable Wago PLCs and splicing connectors enhance automation. Learn more about our Wago PLCs and Wago Connectors in Sharjah.

Conclusion

At Creative Automation, we provide top-quality electrical solutions in Sharjah. For more information, contact us at +971 55 761 2347.

0 notes

Text

VNI4140K Load Handling Capabilities

The VNI4140K is an integrated power driver designed to manage high-power loads in various industrial and automotive applications. Its load-handling capabilities make it a highly efficient and reliable solution for driving multiple outputs simultaneously. Below is an overview of its key features and load-handling abilities:

1. High Current Capability

The VNI4140K is capable of handling output currents of up to 0.7A per channel. This makes it suitable for driving inductive and resistive loads such as motors, relays, and lamps. With four independent channels, it can control multiple loads at once, offering versatility in a wide range of applications.

2. Integrated Protection Features

To ensure safe operation under challenging conditions, the VNI4140K is equipped with several protection mechanisms:

Overcurrent Protection: Limits the current in case of short circuits or overloading to protect both the IC and the load.

Overtemperature Shutdown: Protects the device from damage by automatically shutting down when a critical temperature threshold is exceeded.

Undervoltage Lockout (UVLO): Ensures that the system operates only when the input voltage is within safe limits, protecting against low-voltage conditions.

3. Wide Operating Voltage Range

The VNI4140K supports a wide supply voltage range from 8V to 36V, allowing it to handle loads in both low-voltage and higher-voltage systems. This flexibility makes it ideal for automotive systems that require 12V or 24V power supplies, as well as industrial applications with varied power requirements.

4. Robust Load Switching

The VNI4140K utilizes high-side MOSFET switches to control the connected loads. These switches are capable of fast and efficient switching with minimal heat generation, making the device well-suited for applications where heat management is crucial.

5. PWM and Diagnostics

For precise load control, the VNI4140K supports Pulse Width Modulation (PWM), which allows for fine-tuning the power delivered to the load. It also features diagnostic feedback that provides information about the load status (e.g., open load, short to ground) for better control and system diagnostics.

Applications

The VNI4140K can handle a wide variety of loads in different environments, including:

Automotive lighting systems (e.g., headlights, indicators)

DC motors for industrial and automotive applications

Solenoids and valves in fluid control systems

Resistive loads such as heaters and lamps

Conclusion

The VNI4140K's load-handling capabilities make it an excellent choice for high-power applications requiring multiple, independent output channels. Its ability to handle up to 0.7A per channel, combined with advanced protection and diagnostic features, ensures reliable and efficient performance across a wide range of industrial and automotive systems.

0 notes

Text

Get top-notch testing services at PESVS

Testing is an integral part of ensuring your electrical systems are safe and available. However, the industrial, commercial, or residential sector to which you may belong, top-notch testing services make a difference. Comprehensive testing services at PESVS guarantee integrity to your electrical installations. Our team is specialized in various testing methods, including earth testing services, protection relay testing, site acceptance testing, and transformer testing, that will meet all your needs.

Why Testing Matters

Electrical systems form the backbone of all your operations. Failure or malfunction might come with expensive repairs, significant downtime, and even safety risks. Therefore, compliance on testing by regulatory means translates into proactive protection of your assets; PESVS offers a customized testing approach designed to detect issues before they become problems in the achievement of smooth operations.

Earth Testing Services

Grounding or earthing is very essential to protect electrical systems from sudden surges and faults. Our earth testing services check your grounding systems for you to have all safety assurances in place and meeting all the right local safety requirements and standards. PESVS uses the newest technology and techniques in its testing procedures, including Earth Resistance Testing, which determines your earthing configuration's resistance.

Risk of protection and damage to equipment due to electrical shock are taken off when you take our earth testing services. Service recommended by our trusted experts will be equipped with detailed reports and recommendations so that you can make sure that your grounding systems are reliable and efficient.

Protection Relay Testing

Protection relays form a very important part of electrical systems. Electrical currents and voltages are sensed to detect faults, and thus the faulty equipment is automatically removed from the system. PESVS provides protection relay testing in all its variants to ensure proper operation of such vital components.

Advanced testing techniques, including functional testing and calibration of protection relays, guarantee that your relays behave as they are expected to respond under fault conditions. And so, we avoid the hazards of operational dangers and equipment damage that may lead to expensive downtimes. Let PESVS take care of ensuring proper operation of your protection relays by keeping them safe and reliable in all your electrical installations.

Site Acceptance Testing SAT

Typically, new installations or major upgrades would require site acceptance testing at commissioning. All the systems would have to perform as desired in the operational environment. Our SAT services by PESVS seek validation that your system satisfies the requirements to operate safely according to the established guidelines.

Our team performs a series of tests that test equipments' performance, system integration, and safety compliance. In this manner, we assist you in identifying what is lacking before complete operation so that these may be corrected in due time. PESVS Site Acceptance Testing further strengthens the reliability of your systems and fills you with confidence in their performance.

Transformer Testing

Transformers are major equipment within electrical distribution, and the testing provided should ensure that these are operating correctly as well as long-lived. PESVS offers transformer testing facilities specifically designed according to the company's needs, and such services include insulation resistance testing, winding resistance testing, and power factor testing among others.

Our skilled technicians use sophisticated diagnostic equipment to conduct diagnostic inspection and testing that will provide us with information concerning the operational health of your transformers. That way, we prevent untimely breakdowns and costly repair jobs by catching problems such as breakdowns in insulation or faults at the winding stage early.

PESVS ensures that the quality of service provided in testing is excellent in terms of protection of the employees from probable risks and efficiency. Our company caters to earth testing services, protection relay testing, site acceptance testing, and transformer testing services. Choose PESVS today and experience testing services-you're also investing in peace of mind in knowing that your electrical systems are in excellent hands.

That is, don't let the safety and dependability of your electrical systems linger in the dark. Contact us at PESVS today for superb testing services which can ascertain that your operations are safe, compliant, and efficient.

#electrical earthing system#electrical test equipment#electrical testing services#cable fault location#earth testing#lightning protection system#site acceptance testing#electrical test equipment hire#factory acceptance testing#electrical commissioning & testing

0 notes

Text

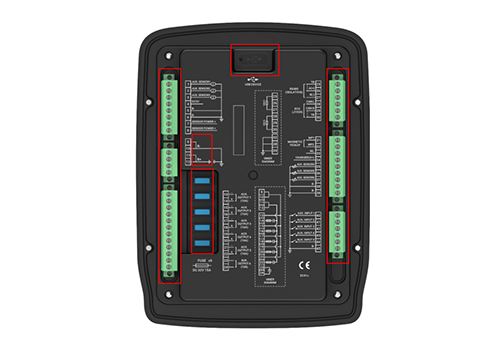

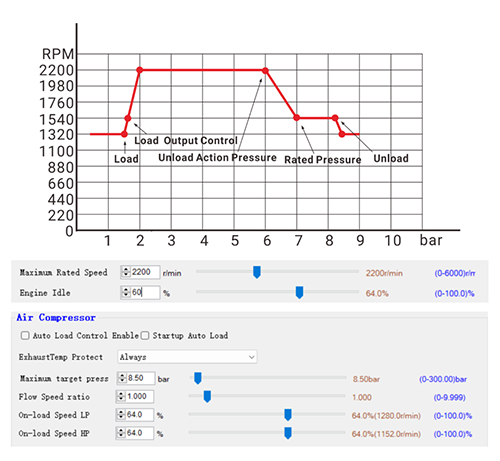

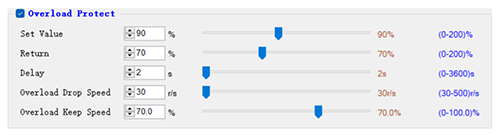

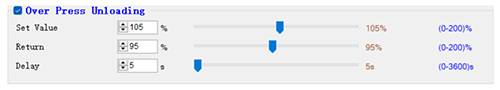

SmartGen | ACC5100 Controller Rolled Out

ACC5100 Diesel Air Compressor Controller is used for air compressor with diesel-driven engine to realize start/stop, data measurement, maintenance, alarm protection and “Three Remotes” functions. It can automatically adjust speed based on the discharge pressure of air compressor, and control various ECU or non-ECU diesel air compressors.

Functional Features

• Five active relay outputs connect with the positive and negative directly, no need to extend external relays with 15A capacity

Five digital inputs can be configured as active under high level or low level, which is highly flexible

Six analog sensor inputs, three of them can be configured as general resistance/current/voltage type sensor inputs

Manual DPF regeneration function supports non-road Stage IV engines

Control functions of heater, cooler, fuel pump and screw oil cooler

Real time clock, Event log (200), Maintenance (10) and ECU information display

With CANBUS port, it can collect the data, protect and control the ECU engines

With RS485 communication port, it can realize “Three Remotes” function

Advantage I: Colorful large screen, HD display

3.5-inch color LCD display, 320x240 pixel resolution, with adjustable backlight brightness

Smart LCD heating system allows it to work normally under low temperature of -40°C

Optional languages of Chinese, English and Russian, which supports custom languages

The description bar in the controller main screen can be configured, which contains ten letters/digits, or five Chinese characters

The analog parameter display area in the controller main screen can be configured, which can display different analog parameters

Advantage II: Highly integrated, installation design without fixed on cabinet

· Front panel integrates power on/off switch knob, high/low pressure switch knob, and emergency stop button to save the customer’s cost · The connection wires between ports and components are reduced to be installed flexibly, which improves space efficiency and overall appearance · Equipped with waterproof and dustproof screws installation · With cover for the emergency stop button, it can avoid the touch by mistake

Advantage III: Reliable design for using safely

· It adopts 15A plug-in automotive blade fuses for easy maintenance · Plastic sealing gasket is designed for back enclosure, which has great dustproof performance and allows it to work in extreme environment · General Type-C port with dust cover ensures high IP level · Connection terminals with flange structure makes the harnesses be fixed tightly · Dual wires of B+ and B- meet the requirement of power input

Advantage IV: Smart control of engine speed for variable need

Engine speed can be automatically adjusted based on the discharge pressure of air compressor

Advantage V: Smart control for high automation level

Speed down control when overloaded: ①When the load rate is too high, the speed will be automatically reduced to the stable speed ②When the load rate gets normal, the speed will return to the rated speed ③The speed down rate and delay value can be adjusted

Auto standby control: ①It can realize automatic control of standby and shutdown based on the discharge pressure ②It can be correlated with discharge pressure sensor and other auxiliary sensors

Auto unload control when overpressure: It can realize automatic control of unloading based on the discharge pressure

Overall Dimensions

For more product details, please contact SmartGen business personnel in your region. Welcome your order! SmartGen, Making Control Smarter!

www.smartgen.cn

0 notes