#UV master batch manufacturer

Explore tagged Tumblr posts

Text

They produce the best white, black and coloured masterbatches at affordable prices. They are the preferred choice for the following reasons

Because they use top-notch spectrophotometers and strict quality controls, their company produces colour masterbatches with outstanding quality and colour matching.

Their masterbatches have all important features- safety, reliability and longevity.

They also provide a variety of colours to suit unique requirements. They are highly experienced professional manufacturers of masterbatches. They have the perfect team of skilled experts who are well-versed in providing high-quality products as per everyone’s requirements.

Clients won't have to be concerned about the colour of their items fading or shifting over time. When used as directed, Sumiran Masterbatch masterbatches quality and pigment will last for many years.

Ask them for a quote right now to submit your purchase as soon as possible and save needless delays. Go with them as they are the to masterbatch manufacturer in Ahmedabad.

#black masterbatches manufacturer#black masterbatch#masterbatch manufacturer in ahmedabad#additive masterbatch#masterbatch supplier#black masterbatch manufacturer#masterbatch manufacturer#color masterbatch#white masterbatch#black masterbatch supplier#sumiran Masterbatch#black pp granules#uv master batch

0 notes

Text

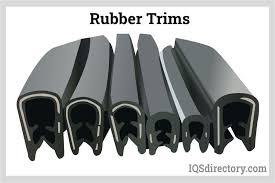

What Are The Key Advantages Of Rubber Extrusion Profiles?

Regarding manufacturing and engineering. Rubber extrusion profilesare gaining popularity. Many industries show interest in them. They are especially common in the automotive and construction sectors. These profiles have unique benefits.

In this article, we delve into the advantages of rubber extrusion profiles. We will explore why they’re favored in manufacturing. We will discuss how they are beneficial for your projects.

What Are Rubber Extrusion Profiles?

Let’s first clarify what these profiles are. The process involves forcing rubber material through a die. This creates continuous shapes. Shapes possess specific cross-sections. This is what the rubber extrusion process achieves. It allows manufacturers to produce

various products. These include seals and gaskets. They also make tubing and custom shapes. Shapes are tailored to specific needs.

Key Features of Rubber Extrusion Profiles

Customizability: One standout feature is their ability to be customized. Manufacturers can create custom profile extrusions. They meet precise specifications for different applications.

Diversity in Materials: Various types of rubber can be used in the extrusion process. This includes natural rubber and silicone. Also, neoprene and more. This diversity allows for tailored properties. Properties such as temperature resistance and flexibility. Also durability.

The Incredible Benefits of Rubber Extrusion Profiles

Design Flexibility That Defies Imagination

The most exceptional advantage is almost limitless design potential. Manufacturers can create custom-designed rubber components. These would be impossible or very expensive through other manufacturing methods whether a complex seal with multiple inner channels is needed. Or a unique profile with differing wall thicknesses. Extrusion makes it achievable.

Picture yourself designing a rubber seal that needs to fit perfectly. It should fit into an automotive engine compartment. This seal should have precise curves. Also, tight tolerances. Specialized functional features must be included. Custom rubber extrusionallows engineers to bring these designs to life. They can do so with remarkable accuracy.

Cost-Effectiveness at Scale

Large-volume production is the domain of rubber extrusion. It becomes incredibly economical. Initial die creation is necessary. After that, producing thousands, maybe even millions, of rubber profiles becomes cost-effective. The continuous nature of the extrusion process eliminates material waste. Rapid production speeds become possible.

For businesses that seek to create specialized components, cost-effectiveness means lower per-unit costs. Faster time-to-market becomes a reality. It’s almost like having a rubber profile production superhighway. It’s efficient. It’s quick. It’s precise.

Material Versatility

Rubber isn’t uniform. Extrusion technology grasps this perfectly. Different rubber compounds feature in this understanding. These range from natural rubber to specialized synthetic elastomers. They all can play a role in the extrusion process. This allows manufacturers to choose materials with specific properties. These properties include the following:

High-temperature resistance

Chemical compatibility

UV resistance

Flexibility across different environmental conditions

Specific durometer (hardness) requirements

Exceptional Consistency and Quality Control

Some production processes display substantial variations across production runs. This is not the case with rubber extrusion. This process delivers astonishing uniformity. Today’s extrusion lines boast state-of-the-art sensors and checks. This technology ensures that each profile meets precise requirements.

This process is akin to a master chef. This chef crafts identical pastries, batch after batch. Just like the chef, each rubber profile emerges from the line. It looks and functions like its predecessor. This uniformity is essential in critical sectors. Sectors such as aerospace medical devices and auto manufacturing. Where exactness is key.

Complex Cross-Sectional Geometries

One of the most impressive benefits of these profiles is the ability to create complex

cross-sectional shapes. Other manufacturing methods might find it challenging or impossible to do. They include:

Hollow sections

Multi-layered profiles

Profiles with internal channels

Intricate sealing lips

Profiles with varying wall thicknesses

Rapid Prototyping and Development

New rubber parts are developed much faster and cheaper now due to advancements in extrusion technologies. Techniques of computer-aided design (CAD) and cutting-edge

die-making methods are used. Engineers can now change from mere concept to the creation of a finished product with much more ease.

For companies that require custom extrusions, it means that innovation cycles speed up. These companies now have the ability to adapt promptly to market demands. They can also respond quickly to complex engineering issues.

Enhanced Performance Characteristics

Rubber extrusion is not only about forming a shape. It is about scientifically crafting a performance. Through the careful selection of compounds, manufacturers can create rubber components with:

Superior sealing capabilities

Reduced friction

Enhanced wear resistance

Improved thermal stability

Specific compression and rebound characteristics

Real-World Applications

Appreciation of these profiles is better by understanding their advantages. Let’s delve into some intriguing real-world applications.

Automotive Industry: Weather stripping, window seals, engine gaskets

Medical Devices: Specialized tubing, precision seals

Construction: Expansion joint seals, window and door weatherproofing

Electronics: Protective gaskets, vibration dampening components

Aerospace: Specialized sealing solutions for extreme environments

Conclusion

Rubber extrusion profiles encapsulate a merging of material science engineering accuracy and production innovation. These profiles tackle intricate design hurdles. Simultaneously they bring about remarkable adaptability, evenness, and efficiency.

In the next instance, you encounter a precisely engineered rubber component. Pause for a moment. Consider the astonishing technology associated with its genesis, whether it’s the smartphone within your grasp. Or the vehicle you operate, it is likely you reap benefits from the wonder of rubber extrusion. We are Custom Rubber Extrusions. Today. Reach out today. Call our expert team. Dial at (647) 294-5240. Alternatively, send us an email. Our email address is [email protected].

#advantages-of-rubber-extrusion-profiles#rubber-extrusion-profiles#custom-profile-extrusions#custom-rubber-extrusion

0 notes

Text

Looking for Top Masterbatch Supplier Company in Russia?

Perfect Colourants & Plastics Pvt. Ltd is a leading Master Batch manufacturer in Russia with a comprehensive range of colours and pigments. We adhere to stringent quality control measures to develop highly concentrated Black, white, colour, and special effect MB, making us the Russia's largest Masterbatch manufacturer. So, if you are looking for UV, conductive, Masterbatches for injection moulding, or special effect Masterbatch, color Masterbatch Supplier has got you covered! Check our E-shade card and contact today!

#Master Batch manufacturer in Russia#Masterbatch manufacturer#Masterbatch manufacturer in Russia#Russia's largest Masterbatch manufacturer#Master Batch company in Russia#Masterbatch in Russia#top Masterbatch manufacturer#Masterbatch Supplier#Masterbatch producer

0 notes

Text

Capital Colours: A Leading Master Batch Manufacturer in India

In the rapidly evolving plastic industry, masterbatches play a vital role in enhancing the quality, aesthetics, and functionality of plastic products. As a trusted Master Batch Manufacturer in India, Capital Colours stands out for its expertise, innovation, and commitment to delivering high-quality masterbatches that meet the needs of a diverse range of industries. With a focus on performance, customer satisfaction, and sustainability, Capital Colours has earned a reputation as a leading supplier of masterbatches for plastic manufacturers across the country and beyond.

What is a Masterbatch?

A masterbatch is a concentrated mixture of pigments, additives, and other materials that are incorporated into polymers during the manufacturing process to modify their properties. Masterbatches are used in various applications, from improving the color of plastic products to enhancing their durability, heat resistance, UV protection, and more. Depending on the requirements, masterbatches can be designed to address specific needs, including color masterbatches, black and white masterbatches, additive masterbatches, and functional masterbatches.

As a Master Batch Manufacturer in India, Capital Colours specializes in producing a wide range of masterbatches that help businesses meet specific performance and aesthetic goals in their plastic products.

Why Choose Capital Colours as Your Master Batch Manufacturer in India?

High-Quality Products Capital Colours is committed to providing superior-quality masterbatches that meet international standards. By using the best raw materials and state-of-the-art technology, the company ensures that its masterbatches deliver consistent color, performance, and quality. Rigorous quality control processes are implemented throughout the production cycle, ensuring that every batch is free from defects and meets customer specifications.

Customization and Versatility One of the key strengths of Capital Colours is its ability to offer customized masterbatches tailored to specific customer needs. Whether it’s a unique color shade, specific performance characteristics, or particular additives, Capital Colours works closely with its clients to deliver bespoke solutions that meet their precise requirements. This ability to provide tailored masterbatches makes Capital Colours a preferred choice for a wide range of industries, from packaging to automotive and textiles.

Wide Range of Masterbatches Capital Colours offers an extensive variety of masterbatches to cater to the diverse needs of different industries. These include:

Colour Masterbatches: Vibrant and consistent colors for plastic products, ranging from standard shades to customized Pantone colors.

Additive Masterbatches: Functional additives to enhance properties like UV protection, anti-bacterial resistance, flame retardancy, and more.

Black & White Masterbatches: High-quality black and white masterbatches for products requiring uniform coloration and opacity.

Specialty Masterbatches: Unique formulations for specific applications, such as transparent, metallic, or glow-in-the-dark masterbatches.

Sustainability and Eco-Friendly Solutions In today’s environmentally conscious world, sustainability is paramount. Capital Colours understands this and offers eco-friendly masterbatches that comply with global environmental regulations. The company uses non-toxic materials, recyclable resins, and efficient manufacturing processes to minimize waste and reduce its carbon footprint. This commitment to sustainability ensures that their masterbatches are safe for both the environment and end consumers.

Timely Delivery and Competitive Pricing Capital Colours ensures that its customers receive their orders on time, helping businesses maintain their production schedules without unnecessary delays. The company’s efficient manufacturing process and well-established supply chain enable it to offer timely delivery, even for large-scale orders. Additionally, Capital Colours offers competitive pricing, making its high-quality masterbatches accessible to businesses of all sizes while helping them optimize production costs.

Applications of Masterbatches

Masterbatches produced by Capital Colours are used in a wide range of industries, including:

Packaging: Masterbatches are extensively used in the packaging industry to enhance the appearance, functionality, and durability of packaging materials. Color masterbatches, as well as additive masterbatches, are used for food packaging, pharmaceutical packaging, and other consumer goods.

Automotive: The automotive industry relies on high-performance masterbatches to enhance the aesthetics and durability of plastic components like dashboards, bumpers, and trims.

Textiles: In the textile industry, masterbatches are used to achieve vibrant, consistent colors in synthetic fabrics and fibers.

Consumer Goods: From household items to electronics and toys, masterbatches help in achieving precise color and desired properties in plastic products.

Agriculture: Masterbatches, including UV stabilizer masterbatches, are used in agricultural films, nets, and other products to enhance durability and provide protection from harsh environmental conditions.

Conclusion

As a leading Master Batch Manufacturer in India, Capital Colours continues to be at the forefront of innovation in the masterbatch industry. With a focus on high-quality products, customization, sustainability, and timely delivery, the company has earned a reputation for delivering solutions that meet the ever-evolving needs of its clients. Whether you require color, additives, or specialty masterbatches, Capital Colours is committed to providing the perfect solution for your plastic manufacturing needs. By choosing Capital Colours, businesses can ensure enhanced product quality, improved processing efficiency, and competitive advantage in the market.

0 notes

Text

Manufacturing Process of Masterbatch: How is Masterbatch Made?

Masterbatches are vital components in the realm of plastic products. They play a pivotal role in imparting colour and functionality to thermoplastics. In this blog, we explore the complex manufacturing process of masterbatches, providing a comprehensive view of how these innovative pigments are created.

What is a Masterbatch?

Masterbatches are granular materials that are composed of carrier resin and various additives. The carrier resin is compatible with the main plastic, which is later blended during molding while imparting colour and functionality to the end product. The manufacturing process of masterbatch plays a pivotal role in determining the end products' properties and quality.

Manufacturing Process of Masterbatch: What is Needed?

When it comes to how is masterbatch made, it is a complex process that needs careful selection of suitable raw materials and equipment to create high-quality masterbatches.

Ingredients:

The master batch manufacturer in India uses top-quality ingredients to formulate precise MBs. Here are some key ingredients needed to manufacture masterbatches:

Base Resin: The base resin acts as the foundation of the masterbatch’s properties. These base resins comprise polymers like PP, PE, PS, and other plastics. This determines the compatibility with end products and processing conditions.

Additives & Pigments: These active ingredients add colours and functional and desired characteristics like UV protection, anti-slip, anti-fog or anti-bacterial.

Carrier Resin: The carrier resins help to disperse the additives within the master batch. It ensures uniform dispersion, resulting in consistent color, texture, and properties.

Equipment

The top master batch company in India uses various equipment to achieve consistency and quality in the final product.

Mixer or Compounder: This equipment is used to mix the base resin, pigments & additives, and carrier resins to get a homogeneous mixture. The mixer ensures uniform dispersion of additives and pigments.

Extruder: It is used to melt and process the compounded resin mixture. The extruder transforms the blended resin mixture into a high-quality melt that can be easily pelletized.

Pelletizing Machines: This equipment gives the molten resin mixture uniform pellets. This allows ease of handling, transportation and storage.

Quality Control Devices: Devices like spectrophotometer, rheometer and other equipment are used for testing quality and ensuring the masterbatch meets the desired specifications.

Perfect Colourants & Plastics Pvt. Ltd uses suitable high-quality ingredients and state-of-the-art equipment to produce masterbatches for different industries with consistent quality and tailored properties.

The Masterbatch Manufacturing Process

Developing a masterbatch involves various intricate manufacturing processes. This process needs careful attention to detail to ensure consistent quality and performance of the MB.

Formulation & Compounding: The formulation involves deciding the the accurate ratio of base resin, pigments, carrier resins, and desired additives. This determines the final colour, functionality, and compatibility with the end product.

Mixing of Ingredients: After the formulation is ready, the ingredients are put into a mixer or compounder. This equipment blends the base resin, pigment, and additives to create an even homogenous mixture. This mixing step ensures that pigment and additives are evenly dispersed throughout the mixture.

Extrusion: The compounded mixture is put into an extruder that melts and processes the resin blend. In the extruder equipment, the mixture is exposed to controlled pressure and temperature to form into a consistent molten form. This process breaks down any cluster to ensure a uniform distribution of pigments and removes any moisture or air.

Pelletization: In this process, the molten resin is put through a pelletizing unit to shape the resins into granular or pellets.

Quality Control & Testing: Various equipment and devices are used for quality control and testing. Spectrophotometers and rheometers are used to check the colour, lightfastness, dispersion, and other characteristics to ensure the masterbatches meets the specific requirements and performance standards.

Wrapping Up

After the masterbatch meets the standards, it is packed and stored under controlled conditions to preserve its quality. At PCPPL, we offer an array of products like colour, white, black, additive, and liquid masterbatches. Developed using hi-tech equipment and precise formulation, it delivers exceptional dispersion, is cluster-free, and high performance. We provide tailored solutions to meet your specific requirements. Contact us today to transform your plastic products.

Visit:- How to Import Quality Masterbatches in Your Country?

#How is Masterbatch Made#Manufacturing Process of Masterbatch#Master Batch Manufacturer in India#Master Batch Company in India#Liquid Masterbatches

0 notes

Text

Bagrecha Polymers Leads the Way in High-Quality Master Batches for Plastics

In the realm of plastics manufacturing, the quality and consistency of master batches play a critical role in achieving vibrant colors, uniformity, and durability in plastic products. Bagrecha Polymers emerges as a leading name in the industry, renowned for being top-tier master batch manufacturers in India and black master batch manufacturers in Ahmedabad. Our commitment to excellence, innovation, and customer satisfaction sets us apart as a reliable partner for industries seeking premium master batch solutions tailored to their specific requirements.

As premier master batch manufacturers in India, we take pride in our ability to deliver a diverse range of master batches that meet the stringent quality standards of the industry. Our master batches are formulated with precision and expertise to ensure optimal dispersion, color accuracy, and performance in a wide variety of plastic applications. Whether you're in the packaging, automotive, or consumer goods sector, our master batches are designed to enhance the visual appeal and functionality of your plastic products.

Why Bagrecha Polymers is the Top Choice for Color and Black Master Batches

Bagrecha Polymers also excels as black master batch manufacturers in Ahmedabad, offering specialized solutions that cater to the unique needs of industries requiring deep, rich black tones in their plastic products. Our black master batches are formulated to provide excellent coverage, UV resistance, and consistent color dispersion, ensuring that your products maintain their aesthetic appeal and structural integrity over time.

When it comes to plastic color masterbatch manufacturers, Bagrecha Polymers stands out for its comprehensive range of vibrant and customizable color options. Our plastic color masterbatch are formulated using high-quality pigments and additives to deliver brilliant hues, exceptional light fastness, and excellent heat stability. Whether you need standard colors or custom formulations, our team is dedicated to creating master batches that meet your exact specifications and elevate the visual impact of your products.

Additionally, as plastic master batch manufacturers in Ahmedabad, Bagrecha Polymers leverages state-of-the-art technology and rigorous quality control measures to ensure that our master batches meet the highest standards of performance and consistency. We understand the importance of precision in plastic processing and are committed to delivering master batches that enhance the quality and appeal of your end products.

#plastic master batch manufacturers in Ahmedabad#plastic color masterbatch manufacturers#black master batch manufacturers in Ahmedabad#master batch manufacturers in India

0 notes

Text

Mastering Darkness: BS Masterbatch's Excellence in Black Masterbatch Manufacturing in India

In the vast canvas of plastics manufacturing, black masterbatches stand as the embodiment of elegance, versatility, and sophistication. Among the array of manufacturers specializing in this domain, BS Masterbatch emerges as a shining example of excellence, crafting black masterbatch solutions that redefine industry standards. Let's delve into the realm of black masterbatch manufacturing in India and uncover the artistry and expertise behind BS Masterbatch's leadership in this domain.

Understanding the Essence of Black: Black masterbatches are not merely about color; they symbolize depth, richness, and timeless appeal. BS Masterbatch recognizes the significance of black as a design element and approaches black masterbatch manufacturing as a form of art. With an understanding of color theory, polymer science, and market trends, BS Masterbatch meticulously formulates black masterbatches that achieve the perfect balance of opacity, dispersion, and aesthetics. Whether it's for packaging, automotive, consumer electronics, or construction applications, BS Masterbatch's black masterbatches elevate products with a touch of sophistication and class.

Precision and Consistency: Consistency is paramount in black masterbatch manufacturing, and BS Masterbatch excels in delivering products that meet the highest standards of precision and reliability. Through state-of-the-art manufacturing facilities and rigorous quality control measures, BS Masterbatch ensures that every batch of black masterbatch maintains uniformity in color, dispersion, and performance. This unwavering commitment to precision and consistency instills confidence in customers, allowing them to achieve predictable results and superior product outcomes.

Customization and Flexibility: BS Masterbatch understands that each application has its unique requirements, and therefore offers a high degree of customization and flexibility in its black masterbatch solutions. Whether it's adjusting the shade of black, enhancing UV stability, or incorporating special additives for specific functionalities, BS Masterbatch collaborates closely with customers to develop bespoke formulations tailored to their precise needs. This customer-centric approach not only ensures optimal results but also fosters long-term partnerships built on trust, understanding, and mutual success.

Innovation and Technology: Innovation lies at the core of BS Masterbatch's black masterbatch manufacturing process, driving the company to explore new technologies, materials, and processes to push the boundaries of what is possible. By leveraging advanced pigments, dyes, and additives, BS Masterbatch develops black masterbatch formulations that offer superior color intensity, lightfastness, and weatherability. Moreover, BS Masterbatch continually invests in research and development to optimize production techniques, reduce environmental impact, and enhance product performance, ensuring that its black masterbatches remain at the forefront of the industry.

Sustainability and Responsibility: As a responsible corporate citizen, BS Masterbatch is committed to sustainability and environmental stewardship in its black masterbatch manufacturing operations. The company actively seeks to minimize its environmental footprint by incorporating recycled materials, reducing waste generation, and optimizing energy usage in its production processes. Moreover, BS Masterbatch offers eco-friendly black masterbatch formulations that comply with regulatory standards and support customers' sustainability goals, helping to create a more sustainable future for the plastics industry.

Global Reach, Local Presence: While BS Masterbatch's roots are firmly planted in India, its reach extends far beyond national borders. Through strategic partnerships, distribution networks, and international collaborations, BS Masterbatch serves customers in diverse markets worldwide. By establishing a localized presence in key regions, BS Masterbatch ensures prompt delivery, efficient logistics, and personalized service, further strengthening its position as a global leader in black masterbatch manufacturing.

In conclusion, BS Masterbatch's excellence in black masterbatch manufacturing in India is a testament to its unwavering commitment to quality, innovation, and sustainability. With its precision, customization, and customer-centric approach, BS Masterbatch continues to redefine the standards of excellence in the industry, driving progress and innovation in the world of plastics. As the demand for high-quality black masterbatch solutions continues to grow, BS Masterbatch remains poised to lead the way, empowering manufacturers worldwide to achieve their goals with confidence, integrity, and excellence.

0 notes

Text

KAIAO Rapid Prototyping CNC Machining: Advancing Innovation and Solving User Problems

In today’s fast-paced and competitive business environment, innovation is the key to success. As a leader in rapid design development services for over 26 years, KAIAO has been at the forefront of revolutionizing product development and manufacturing. With a wide range of cutting-edge services, including CNC rapid precision machining, SLA rapid prototyping, rapid silicone mould, and vacuum casting, among others, KAIAO has served more than 10,000 satisfied customers across various industries. In this article, we will delve into the technical aspects of KAIAO’s services and explore how they provide innovative solutions to address user problems effectively.

CNC Rapid Precision Machining

CNC (Computer Numerical Control) rapid precision machining is a crucial service offered by KAIAO, enabling the rapid production of high-quality prototypes and final parts. This technology involves using computer-controlled machines to remove material from a workpiece with extreme accuracy and precision. By utilizing advanced CAM (Computer-Aided Manufacturing) software and a variety of cutting tools, KAIAO can quickly transform digital designs into physical objects. This process is ideal for creating complex geometries and fine details that other traditional manufacturing methods might struggle with.

The benefits of CNC rapid precision machining include shorter lead times, cost-effectiveness for small-batch production, and the ability to make design iterations efficiently. For users seeking to streamline their product development process and quickly bring ideas to life, this service is a game-changer.

SLA Rapid Prototyping

SLA (Stereolithography) rapid prototyping is another core service offered by KAIAO. SLA utilizes an additive manufacturing process to create 3D models layer by layer using liquid photopolymer resins. A UV laser selectively cures the resin, solidifying each layer, and building the prototype from the ground up. This method allows for the production of highly detailed and accurate prototypes with smooth surface finishes.

For innovators looking to validate their designs before committing to mass production, SLA rapid prototyping is invaluable. It enables users to assess the physical appearance, fit, and functionality of their product in a cost-effective and time-efficient manner. Any necessary modifications can be made swiftly, reducing the risk of costly mistakes during mass production.

Rapid Silicone Mould & Vacuum Casting

KAIAO’s rapid silicone mould and vacuum casting services offer an efficient way to produce small-batch parts with the same quality as injection-moulded components. The process begins with creating a master pattern using SLA rapid prototyping or CNC machining. A silicone mould is then produced from the master pattern, which allows for the reproduction of multiple parts.

This technique is particularly advantageous for users who require functional prototypes or limited production runs. It provides a bridge between rapid prototyping and full-scale manufacturing, offering a cost-effective solution without compromising on quality.

Rapid Reaction Injection Molding

Rapid Reaction Injection Molding (RIM) is a technology that enables the production of plastic components with characteristics similar to those of injection-moulded parts but with faster turnaround times. KAIAO’s RIM process involves combining two reactive liquid components under low pressure in a mould. The mixture rapidly polymerizes and solidifies to form the desired part.

This service is ideal for users who need high-quality, low-volume plastic parts in a short time frame. RIM offers a wide range of material options, making it suitable for various applications across industries.

Rapid Plastic Injection Molding

For users requiring larger quantities of plastic parts with consistent quality, KAIAO’s rapid plastic injection molding service is the solution. Injection molding is a well-established manufacturing process in which molten plastic is injected into a mould under high pressure, taking the shape of the cavity.

By employing advanced tooling and automated processes, KAIAO ensures that each part is accurately replicated. With fast cycle times and the ability to handle a range of thermoplastic materials, rapid plastic injection molding is a cost-effective way to produce large quantities of components.

Rapid Pressure Die Casting

Rapid pressure die casting is an efficient method for producing high-integrity metal parts with excellent surface finishes. This process involves injecting molten metal into a steel mould, under high pressure, to create intricate shapes and thin-walled parts.

KAIAO’s rapid pressure die casting service is suitable for various metals, including aluminum, zinc, and magnesium alloys. It is a preferred option for users seeking lightweight, yet durable, metal components for their products.

Post Production Finishing

In addition to their outstanding manufacturing capabilities, KAIAO excels in post-production finishing, ensuring that each part meets the highest standards of quality and aesthetics. Finishing processes such as sanding, polishing, painting, and plating are meticulously performed to achieve the desired surface texture and appearance.

By providing comprehensive post-production finishing services, KAIAO delivers end products that are ready for market, saving users valuable time and resources.

Quality Control & Assurance

At KAIAO, quality control and assurance are of paramount importance. Their state-of-the-art quality management systems ensure that every step of the manufacturing process meets rigorous standards. From material inspection to final product evaluation, KAIAO employs a range of testing and inspection techniques to maintain consistency and reliability.

By prioritizing quality control, KAIAO ensures that users receive products that not only meet their specifications but also exceed their expectations.

SLA/SLS Manufacturer

As a leading manufacturer of SLA and SLS (Selective Laser Sintering) parts, KAIAO provides users with a wide range of additive manufacturing solutions. SLS, in particular, allows for the production of functional, end-use parts using various powdered materials, such as plastics, metals, and ceramics.

The versatility and flexibility of SLA/SLS manufacturing make it an ideal choice for users seeking innovative solutions for complex geometries, custom designs, and low-volume production.

KAIAO’s rapid prototyping CNC machining services have transformed the way products are developed and manufactured. With their diverse range of cutting-edge technologies and unwavering commitment to quality, they have successfully served thousands of satisfied customers across various industries.

Whether it’s CNC rapid precision machining for complex prototypes, SLA rapid prototyping for quick design validation, or rapid pressure die casting for lightweight metal components, KAIAO’s services provide innovative solutions to address user problems effectively.

In today’s rapidly evolving market, the ability to bring ideas to life quickly and efficiently is crucial for staying ahead of the competition. With KAIAO’s technical expertise and dedication to excellence, users can confidently navigate the product development journey and turn their visions into reality.

0 notes

Text

Innovative PVC Compounding Technology: Shriram Polytech's Cutting-Edge Solutions for Quality and Efficiency

Introduction:

PVC (Polyvinyl Chloride) is a widely used thermoplastic material known for its versatility, durability, and cost-effectiveness. It finds applications in various industries, including construction, automotive, electrical, and healthcare. Shriram Polytech, a leading provider of PVC compounds, has emerged as a pioneer in innovative PVC compounding technology. With a strong focus on quality and efficiency, Shriram Polytech offers cutting-edge solutions that meet the evolving needs of the market.

Understanding PVC Compounding:

PVC compounding involves the process of combining PVC resin with various additives and modifiers to create tailored formulations that exhibit specific properties. The compounding process plays a crucial role in enhancing the performance, appearance, and processing characteristics of PVC. Shriram Polytech has mastered the art of PVC compounding through continuous research, advanced manufacturing techniques, and a commitment to delivering top-notch products.

Advanced Formulation Development:

Shriram Polytech's innovative approach to PVC compounding starts with extensive formulation development. The company's team of experts works closely with customers to understand their specific requirements and challenges. They leverage their in-depth knowledge of PVC and its additives to create custom formulations that precisely address the desired properties and performance characteristics.

From impact resistance and flame retardancy to UV stabilization and weatherability, Shriram Polytech formulates PVC compounds with a wide range of functionalities. The company's cutting-edge technology allows for precise control over the formulation, resulting in compounds that exhibit consistent and reliable performance across different applications.

Quality Assurance and Testing:

Shriram Polytech has established stringent quality assurance measures to ensure that its PVC compounds meet the highest industry standards. The company follows a comprehensive testing protocol that covers various parameters such as physical properties, chemical resistance, thermal stability, and mechanical strength. By conducting rigorous testing, Shriram Polytech guarantees the quality, reliability, and consistency of its PVC compounds.

Furthermore, Shriram Polytech's state-of-the-art testing facilities are equipped with advanced equipment to perform specialized tests, including color matching, UV stability testing, and weatherability analysis. These tests help to assess the long-term durability and performance of the PVC compounds, ensuring they can withstand demanding environmental conditions.

Enhancing Efficiency through Process Optimization:

In addition to ensuring top-notch quality, Shriram Polytech focuses on optimizing the compounding process for enhanced efficiency. The company has invested in cutting-edge manufacturing equipment and technology to streamline the production process, reduce waste, and improve productivity.

Shriram Polytech's manufacturing facilities are equipped with automated compounding lines that enable precise control over the compounding parameters, such as temperature, mixing speed, and pressure. This level of control ensures the consistent production of PVC compounds with minimal batch-to-batch variations.

Moreover, the company employs advanced melt filtration systems that effectively remove impurities and contaminants, resulting in PVC compounds with excellent purity and uniformity. The efficient filtration process not only enhances the quality of the compounds but also contributes to the overall sustainability of the manufacturing process.

Application-Specific Solutions:

Shriram Polytech understands that different industries have unique requirements when it comes to PVC compounds. To cater to diverse applications, the company offers a wide range of specialized solutions. Whether it is flexible PVC for wire and cable insulation, rigid PVC for pipe and profile extrusion, or specialty PVC compounds for specific industries, Shriram Polytech has the expertise to deliver tailor-made solutions.

The company's dedicated R&D team continuously explores new formulations and additives to expand its product portfolio and address emerging industry trends. Shriram Polytech stays at the forefront of PVC compounding technology, ensuring that its customers have access to the latest advancements and breakthroughs.

Partnership and Customer Support

Shriram Polytech values long-term partnerships and strives to provide exceptional customer support. The company believes in building strong relationships with its customers, working closely with them to understand their specific needs and challenges. Shriram Polytech's dedicated team of professionals offers prompt assistance, from product selection to technical guidance. The company's commitment to customer satisfaction extends beyond the initial sale, as they provide ongoing support and ensure that customers receive the necessary assistance throughout their PVC compounding journey. Shriram Polytech believes that strong partnerships and excellent customer support are the keys to mutual growth and success.

Conclusion:

Shriram Polytech's innovative PVC compounding technology has revolutionized the industry by offering cutting-edge solutions for quality and efficiency. With a focus on advanced formulation development, stringent quality assurance, and optimized manufacturing processes, Shriram Polytech delivers PVC compounds that meet the diverse needs of various industries. The company's commitment to customer satisfaction, long-term partnerships, and exceptional customer support sets it apart in the market. By continuously pushing the boundaries of PVC compounding technology and staying at the forefront of industry advancements, Shriram Polytech remains a trusted and reliable partner for businesses seeking high-quality PVC compounds.

0 notes

Link

0 notes

Text

Sumiran Masterbatch Pvt. Ltd. is a leading manufacturer of black masterbatches in India, located in Ahmedabad, Gujarat. Their black masterbatches are Generally used in the plastic industry to impart black color to vibrant plastic products. These masterbatches typically contain a high concentration of carbon black, up to 50%, making them suitable for applications demanding high jetness, UV stability, and resistance to high temperatures.

#white masterbatch#additive masterbatch#black masterbatch#black masterbatches manufacturer#color masterbatch#black masterbatch supplier#masterbatch manufacturer in ahmedabad#masterbatch supplier#black pp granules#uv master batch

0 notes

Text

Different Types of Tarps Cover Materials

To cover an outer surface or things, tarpaulins are a specific type of fabric. A large sheet of strong, flexible, water-resistant, or waterproof material is known as a tarp or Tarpaulin Sheet. Tarpaulins, often known as "tarps," are adaptable, simple to set up, and, depending on the quality of the material used to make them, have a long lifespan.

When you wish to protect your work site from various elements, tarpaulins are utilized as a barrier or cover. But you need to be sure the tarp you're using is made of good materials. Additionally, the supplier or manufacturer you select will have a significant impact on the quality of the tarpaulin you purchase. Tarps can provide protection from severe storms such as wind, rain, and sun. The main use of a tarp is to protect items from dampness or mud.

Types of Tarpaulin Cover Material

Canvas

This material is resistant to water but not completely waterproof. They might not be affected by a small amount of water, but when water cannot quickly drain from a canvas tarpaulin sheet, it begins to drip. They can assist in hiding or protecting machinery while also preventing condensation because they are ventilated and robust.

Features

long-term and powerful

Custom choices are offered.

weather-resistant construction

suitable for construction and agriculture

Clear Tarpaulin

The Clear Tarpaulins are simple to store and roll up. It will fit in your shed, where you may keep it. They might be used for your barns and garage. They are excellent at keeping the rain outside and out of your house.

Feature

This kind of tarpaulin is created using premium UV master batches, color master batches, and virgin raw materials.

This item is rot-proof, waterproof, leak-proof, weatherproof, and oil-proof.

UV protection on both sides for extended life even in direct sunlight.

LDPE Tarpaulin

Low-density polyethylene (LDPE) tarpaulin would be a polymer created by compressing the monomers of ethylene gas in a tubular reactor or autoclave to promote polymerization.

Features

The best reprocessed polymer granules are used to make LDPE tarpaulins.

High-density polyethylene and cutting-edge technologies were employed in the design of such a product to shield the objects from water damage.

LDPE tarpaulins seem to be more resilient to UV radiation as compared to HDPE and PVC tarpaulins.

eco-friendly and fully recyclable product

Vinyl Tarpaulin

PVC-made tarpaulin sheets are stronger than their polyethylene counterparts and are therefore intended for heavy-duty applications. These are highly durable and abrasion-resistant. These tarps are made of heavy-duty tarpaulin, which is frequently used in the construction sector as roof tarpaulin. Vinyl sheets are used in trucks, farming, building, and other industrial fields. Grain covers and truck tarpaulins are two more frequent uses.

Polyethylene Tarpaulin

The most popular type of tarpaulin is made of polyethylene because it is extremely durable and completely waterproof. These tarps are constructed of polyethylene, an ethylene-based plastic polymer, as their name would imply. They are naturally lightweight, flexible, and extremely tensile. The simplicity with which multiple colors may be manufactured into the plastic has also made it a vibrant and readily available cover for many businesses.

#clear tarp#glass clear tarps#glass clear tarpaulin#glass clear tarp#Clear Tarpaulins#Clear Tarpaulin#Clear Tarps#buy tarpaulins#buy tarpaulins uk#tarpaulin cover#tarpaulin covers#tarpaulin sheets#tarpaulin sheet#tarpaulins sheets#tarpaulins sheet#waterproof tarpaulins#tarpaulins#tarpaulin#tarp#tarps#tarps sheet#uk#heavy duty tarps#canvas tarps

0 notes

Text

Looking for Top Masterbatch Supplier Company in China?

Perfect Colourants & Plastics Pvt. Ltd is a leading master batch manufacturer in China with a comprehensive range of colours and pigments. We adhere to stringent quality control measures to develop highly concentrated Black, white, colour, and special effect MB, making us the China's largest masterbatch manufacturer. So, if you are looking for UV, conductive, masterbatches for injection moulding, or special effect masterbatch, color masterbatch supplier has got you covered! Check our E-shade card and contact today!

#master batch manufacturer in China#masterbatch manufacturer#masterbatch manufacturer in China#China's largest masterbatch manufacturer#master batch company in China#masterbatch in China#top masterbatch manufacturer#masterbatch supplier#masterbatch producer

0 notes

Link

Manufacturing plastic products is not as easy as it is depicted or is perceived by the world and only the manufacturing companies understand the technical difficulties which they face while manufacturing plastic products.

#Filler Masterbatch Manufacturer#UV Masterbatches#Master Batch Manufacturer in Ahmedabad#Master Batch Manufacturers in Gujarat#Masterbatch Company#Masterbatch Supplier#Plastic Master Batch Manufacturers in India#Plastic Master Batch Manufacturers

0 notes

Text

Black Masterbatch Manufacturers in Gujarat - Bagrecha Polymers Setting New Standards

In the realm of plastics and polymers, the significance of masterbatch cannot be overstated. As a key player in the industry, Bagrecha Polymers stands out as a leading force, setting new benchmarks as premier master batch manufacturers in India. With an unwavering commitment to excellence and innovation, Bagrecha Polymers has emerged as a prominent provider of black masterbatch manufacturers in Gujarat and plastic color masterbatch manufacturers.

The Indian market for masterbatches is thriving, with several manufacturers and suppliers vying for prominence. However, Bagrecha Polymers distinguishes itself through a combination of quality, expertise, and a diverse range of offerings. As a testament to their standing, they have garnered attention both nationally and internationally as top-tier plastic master batch manufacturers.

Bagrecha Polymers has earned a stellar reputation for its unmatched expertise in manufacturing high-quality masterbatches. Their impressive line of products includes black masterbatch, color masterbatch, additive masterbatch, and special effect masterbatch, positioning them as a go-to source for superior quality masterbatches. This comprehensive product portfolio showcases their dedication to meeting the diverse needs of the industry with precision and excellence.

Spearheading Quality as plastic color masterbatch manufacturers in Gujarat

The company's commitment to innovation is evident in its cutting-edge manufacturing processes. By leveraging advanced technologies and industry best practices, Bagrecha Polymers ensures that their masterbatches exhibit exceptional color dispersion, UV stability, and heat resistance, setting a new standard for plastic color masterbatch manufacturers.

In an industry that demands continual evolution, Bagrecha Polymers remains ahead of the curve by providing future-ready solutions that align with market demands. Their relentless pursuit of excellence and their ongoing efforts to refine and expand their product offerings further solidify their position as front runners among plastic master batch manufacturers in India.

Bagrecha Polymers exemplifies unwavering quality, innovation, and reliability in the realm of masterbatch manufacturing. With a steadfast commitment to excellence and a proven track record of delivering exceptional products, Bagrecha Polymers continues to elevate industry standards as leaders among master batch manufacturers in India.

#master batch manufacturers in India#black masterbatch manufacturers in Gujarat#plastic color masterbatch manufacturers#plastic master batch manufacturers

0 notes

Text

Overview-types of master batch and What is the process of master batch

Masterbatch is a concentrated mixture of pigments, additives, or other materials that are used to color or modify plastics during the manufacturing process. There are several types of masterbatch, including:

Black Masterbatch: Used to add black color to plastics, black masterbatch can also provide UV protection and other additives to the plastic.

White Masterbatch: White masterbatch is used to add opacity and brightness to plastics. It can also be used to mask the color of underlying pigments.

Color Masterbatch: Color masterbatch is used to add specific colors to plastics. It can be used to match specific brand colors or to create custom color combinations.

Additive Masterbatch: Additive masterbatch is used to add performance-enhancing properties to plastics. Examples of additives include UV stabilizers, flame retardants, and anti-static agents.

The process of masterbatch manufacturing involves several steps, including:

Raw Material Selection: The first step in the process is to select the raw materials for the masterbatch. These may include pigments, additives, and carrier resins.

Weighing and Mixing: The raw materials are weighed and mixed together in precise amounts to create the desired color or additive concentration.

Extrusion: The mixed materials are then fed into an extruder, which heats and melts the materials to form a homogenous mixture.

Pelletization: The melted mixture is then extruded into a pelletized form, which can be easily transported and stored.

Quality Control: Finally, the masterbatch pellets undergo quality control testing to ensure that they meet the desired specifications.

Visit : Color Masterbatch to knowmore !

0 notes