#Tube and Pipe Bending Machines in UAE

Explore tagged Tumblr posts

Text

Introducing our latest addition – LM-50 Series CNC Precision Leveling Machine. Explore your metalworking precision with this advanced technology.

#Steel fabrication machines in UAE#Best Industrial Steel Fabrication Machines in UAE#Laser Marking Machines in UAE#Tig Brush Cleaning Machine in UAE#Welding rotator in UAE#Tube and Pipe Bending Machines in UAE

1 note

·

View note

Text

Steel Fabrication Machinery Suppliers in the UAE: Powering the Nation’s Infrastructure

The steel fabrication industry plays a crucial role in the development and growth of infrastructure across the UAE. From the towering skyscrapers that define the skyline of Dubai to the vast industrial plants and oil refineries, steel fabrication is at the heart of construction and manufacturing in the region. The demand for high-quality, precise, and efficient steel fabrication machinery is paramount to meet the rigorous standards of the industry. This article delves into the world of steel fabrication machinery suppliers in UAE, highlighting the significance of their offerings and the impact they have on the country's infrastructure.

The Role of Steel Fabrication in the UAE

Steel fabrication is the process of cutting, bending, and assembling steel to create various structures and components. It is a critical component of construction, manufacturing, and industrial projects. The UAE, with its rapidly growing economy and ambitious construction projects, relies heavily on steel fabrication for everything from residential buildings to complex industrial facilities.

In the UAE, the construction sector alone is a significant contributor to the nation's GDP. The demand for steel products, such as beams, columns, trusses, and custom-fabricated components, is ever-growing. This demand is met by a network of steel fabrication companies that rely on advanced machinery to deliver precision-engineered products.

The Importance of High-Quality Machinery

Steel fabrication is a precise and intricate process that requires the use of advanced machinery. The quality of the machinery directly affects the quality of the final product. In the UAE, where construction standards are among the highest in the world, the need for top-notch machinery cannot be overstated.

The machinery used in steel fabrication includes cutting machines, bending machines, welding machines, and various other tools designed to manipulate steel into the desired shapes and sizes. Each piece of equipment must be capable of handling the specific demands of the project, whether it's creating intricate designs or ensuring the structural integrity of large steel components.

Types of Steel Fabrication Machinery

Steel fabrication machinery encompasses a wide range of equipment, each designed for specific tasks within the fabrication process. Some of the most commonly used machines include:

Cutting Machines: These machines are used to cut steel plates, beams, and other components to the required dimensions. Types of cutting machines include plasma cutters, laser cutters, and oxy-fuel cutters. Precision and efficiency are key in this stage, as accurate cuts are essential for the integrity of the final product.

Bending Machines: Bending machines are used to shape steel into various forms, such as angles, curves, and tubes. These machines are vital for creating components like beams, pipes, and structural elements. CNC (Computer Numerical Control) bending machines are particularly popular due to their precision and ability to handle complex bending tasks.

Welding Machines: Welding is a critical process in steel fabrication, as it joins steel components together to form the final structure. Welding machines come in various types, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding machines. Each type of welding machine is suited for different applications, depending on the material thickness and the required strength of the weld.

Drilling and Punching Machines: These machines are used to create holes and notches in steel components, allowing for the assembly of structures. Precision drilling and punching are essential for ensuring that components fit together correctly and that the final structure is secure.

Shearing Machines: Shearing machines are used to cut large sheets of steel into smaller, more manageable sizes. These machines are particularly useful for preparing materials for further processing, such as bending or welding.

Roll Forming Machines: Roll forming machines are used to create long, continuous shapes, such as beams and channels, by passing steel through a series of rollers. This process is ideal for producing large quantities of uniform components quickly and efficiently.

The Significance of Local Suppliers

In the UAE, sourcing steel fabrication machinery from local suppliers offers several advantages. Local suppliers are more attuned to the specific needs of the region’s industries, and they can provide machinery that is tailored to the unique requirements of projects in the UAE. Additionally, local suppliers often offer better after-sales support, including maintenance services and the availability of spare parts, which is crucial for minimizing downtime and ensuring the longevity of the machinery.

Another advantage of local suppliers is their ability to offer training and support to operators. Operating complex steel fabrication machinery requires specialized skills, and local suppliers can provide training to ensure that operators are proficient in using the equipment. This not only improves the efficiency of the fabrication process but also enhances the safety of the workplace.

Challenges Faced by Steel Fabrication Machinery Suppliers

While the demand for steel fabrication machinery in the UAE is strong, suppliers face several challenges in meeting the needs of their customers. One of the primary challenges is keeping up with technological advancements. The steel fabrication industry is constantly evolving, with new technologies and techniques being developed to improve efficiency and precision. Suppliers must stay ahead of these trends to provide their customers with the latest and most advanced machinery.

Another challenge is the need to balance cost and quality. While customers in the UAE demand high-quality machinery, there is also pressure to keep costs down. Suppliers must carefully select the machinery they offer to ensure that it meets the required standards while remaining cost-effective.

Future Trends in Steel Fabrication Machinery

The steel fabrication industry in the UAE is poised for further growth, driven by ongoing infrastructure projects and the development of new industrial sectors. As the industry grows, so too will the demand for advanced steel fabrication machinery. Several trends are expected to shape the future of the industry:

Automation: The adoption of automation in steel fabrication is expected to increase, with more companies investing in CNC machines and robotic systems. Automation can significantly improve the efficiency and precision of the fabrication process, reducing the need for manual labor and minimizing errors.

Sustainability: As sustainability becomes a greater focus in the construction industry, there will be a growing demand for machinery that is energy-efficient and capable of working with sustainable materials. Suppliers will need to offer machinery that meets these requirements to stay competitive.

Customization: The ability to customize machinery to meet the specific needs of a project will become increasingly important. Suppliers who can offer flexible solutions and tailor their machinery to the unique requirements of their customers will have a competitive edge.

Integration with Digital Tools: The integration of digital tools, such as Building Information Modeling (BIM) and advanced software for design and planning, will become more prevalent. Suppliers will need to offer machinery that can seamlessly integrate with these tools to enhance the overall fabrication process.

Conclusion

Steel fabrication machinery suppliers in UAE play a vital role in supporting the nation's construction and industrial sectors. Their ability to provide high-quality, advanced machinery is essential for ensuring that projects are completed to the highest standards. As the industry continues to evolve, suppliers will need to stay ahead of trends and challenges to meet the growing demands of their customers. By focusing on innovation, quality, and customer support, steel fabrication machinery suppliers in the UAE will continue to power the nation’s infrastructure and contribute to its ongoing development.

0 notes

Text

Pipe and Tube Bending Machine Market Size,Volume,Revenue Trends Analysis Report 2024-2030

"Pipe and Tube Bending Machine" 2024 Breakdown, Data Source, Secondary Sources, Primary Sources, Research Report delivers leading competitors strategic analysis, with micro and macro-economic factors, market trends, future growth scenarios, with pricing analysis. This report provides a holistic overview on Market Current Situations, Key Collaborations, Merger & Acquisitions along with Trending Innovations and New Business Development Policies. A detailed professional report focusing on primary and secondary growth drivers, regional segments, growth share, and geographical analysis of top key players. Pipe and Tube Bending Machine trend analysis with historical data, estimates to 2024 and Compound Annual Growth Rate (CAGR) forecast to 2030.

Top Key Players Covered in Market Report 2024-2030:BLM GROUP、Crippa、Winton Machine、AMOB、Unison Ltd、Schwarze-Robitec、SMI、UNIT PLUSsroPlzeň、EUROMAC SpA、YLM Group、Akyapak、SOCO Machinery、MASSARO GROUP、CSM Machinery、Chiyoda Kogyo Co., Ltd、Criterion Machinery、Numalliance、Hines Bending Systems、Horn Machine Tools、OPTON.Co.Ltd、CML International(Ercolina)、Transfluid Maschinenbau GmbH、Schind Machines、Macri Italia、COMCO CORPORATION、Herber Engineering AB、Taiyo Corporation、NISSIN PRECISION、Foshan Deyi

Short Description of the Pipe and Tube Bending Machine 2024-2030: Market Overview of Global Pipe and Tube Bending Machine: According to our latest research, the global Pipe and Tube Bending Machine looks promising in the next 6 years. As of 2024, the global Pipe and Tube Bending Machine was estimated at USD Million, and it’s anticipated to reach USD Million in 2030, with a CAGR during the forecast years. This report covers a research time span from 2019 to 2029, and presents a deep and comprehensive analysis of the global Pipe and Tube Bending Machine, with a systematical description of the status quo and trends of the whole market, a close look into the competitive landscape of the major players, and a detailed elaboration on segment markets by type, by application and by region. Global and Regional Analysis: North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

Market Segmentation Pipe and Tube Bending Machine report provides an exhaustive 360-degree analysis, by utilizing both primary and secondary research techniques. The research gained comprehensive insights into current market dynamics, pricing trends, developments, supply-demand and evolving consumer behaviors.

On the basis of product type, this report displays the production, revenue, price, market Electric Driven Hydraulic Driven Hybrid Driven

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each Automotive Commercial Vehicles Ship Building Architectural Industrial

Inquire or Share Your Questions If Any before Purchasing This Report https://www.globalinforesearch.com/contact-us Our method for estimating market size is holistic and multifaceted. We assess vital industry trends, regulatory landscapes, and segment-specific dynamics, evaluating their potential influence on demand projections. Key macroeconomic factors, including price fluctuations, demographic shifts, and changes in demand patterns, are integrated into our calculations. To discover market value, we not only delve deep into the profiles of prominent players and their global market shares but also rely on our frequently updated internal database, enriched with insights and announcements from pivotal market stakeholders.

Some of the Key Questions Answered in this Report:

What is the Pipe and Tube Bending Machine size at the regional and country level

What are the key drivers, restraints, opportunities, and challenges of the Pipe and Tube Bending Machine, and how they are expected to impact the market

What is the global (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa) sales value, production value, consumption value, import and export of Pipe and Tube Bending Machine

Who are the global key manufacturers of the Pipe and Tube Bending Machine? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)

What are the Pipe and Tube Bending Machine opportunities and threats faced by the vendors in the Pipe and Tube Bending Machine?

Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application?

What focused approach and constraints are holding the Pipe and Tube Bending Machine?

What are the different sales, marketing, and distribution channels in the global industry?

What are the key market trends impacting the growth of the Pipe and Tube Bending Machine?

Economic Impact on the Pipe and Tube Bending Machine and development trend of the Pipe and Tube Bending Machine

What are the Pipe and Tube Bending Machine opportunities, market risk, and market overview of the Pipe and Tube Bending Machine

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Hydrogen Bromide product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Hydrogen Bromide, with price, sales, revenue and global market share of Hydrogen Bromide from 2019 to 2024. Chapter 3, the Hydrogen Bromide competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Hydrogen Bromide breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2022.and Pipe and Tube Bending Machine forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Hydrogen Bromide. Chapter 14 and 15, to describe Hydrogen Bromide sales channel, distributors, customers, research findings and conclusion. Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Tube and Pipe Bending Machines

The United Arab Emirates (UAE) has experienced unprecedented growth in various industries, including construction, oil and gas, and manufacturing. Among the key players contributing to this economic surge are tube and pipe bending machines, essential tools that have undergone significant evolution over the years. This article explores the journey of tube and pipe bending machines in the UAE, their role in shaping the industrial landscape, and the technological advancements driving this sector forward.

Historical Perspective:

The UAE's industrial development traces back to the early days of oil discovery in the region. The need for efficient methods to handle and transport oil and gas prompted the establishment of advanced manufacturing processes. Tube and pipe bending machines emerged as crucial tools in fabricating pipelines, oil rigs, and various infrastructure components.

Initially, manual bending techniques were prevalent, requiring skilled artisans to shape tubes and pipes according to project specifications. However, as industrial demands grew, the need for automation became apparent.

Automation Revolution:

The late 20th century witnessed a revolution in manufacturing processes globally, and the UAE was quick to adopt advanced technologies. CNC (Computer Numerical Control) tube and pipe bending machines emerged as game-changers, offering precise, efficient, and repeatable bending processes. This automation not only improved accuracy but also increased production speed, a critical factor in meeting the demands of the burgeoning construction and oil industries.

Key Technological Advancements:

CNC Technology: Computer-controlled bending machines allowed for highly accurate and complex bending operations. This technology became a cornerstone in enhancing efficiency and reducing waste in material usage.

3D Bending: With the advent of 3D bending machines, manufacturers gained the capability to create intricate and multi-dimensional bends. This was particularly beneficial in projects where unconventional pipe configurations were required.

Hydraulic and Electric Benders: The shift from traditional hydraulic benders to electric benders marked another milestone. Electric benders are known for their energy efficiency, reduced maintenance, and quieter operation, contributing to a more sustainable and cost-effective industrial landscape.

Current Landscape:

In the present day, the UAE boasts a sophisticated tube and pipe bending machinery sector, with local manufacturers and international suppliers catering to diverse industries. The machines available are equipped with state-of-the-art features, including advanced control systems, real-time monitoring, and predictive maintenance capabilities.

The demand for tube and pipe bending machines in the UAE remains robust, fueled by ongoing infrastructure projects, oil and gas exploration, and the rapid expansion of manufacturing capabilities. Moreover, the emphasis on sustainability has led to the adoption of eco-friendly technologies within the sector.

Conclusion:

The evolution of tube and pipe-bending machines in the UAE reflects the nation's commitment to technological advancement and industrial excellence. From manual craftsmanship to CNC precision, these machines have played a pivotal role in shaping the infrastructure that defines the UAE today. As the country continues to embrace innovation, the tube and pipe-bending machinery sector is poised to contribute significantly to its future industrial landscape.

0 notes

Link

Hydraulic pipe benders have become an essential tool in the plumbing, construction, and manufacturing industries in the UAE. These machines are used to bend pipes of various sizes and shapes to fit specific requirements of different applications. They are popular because of their high efficiency, accuracy, and ease of use. In this blog, we will discuss the benefits of hydraulic pipe benders in the UAE.

One of the main advantages of hydraulic pipe benders is their ability to handle different pipe materials, including steel, copper, and aluminum. The machines come with different bending dies that can accommodate different pipe sizes and shapes, making them versatile and suitable for a wide range of applications.

Read more about Welding rotator in UAE

Hydraulic pipe benders are also very efficient in terms of time and labor. They can bend pipes quickly and accurately, reducing the amount of time and effort required to complete a project. In addition, these machines are relatively easy to use and require minimal training, making them accessible to a wide range of users.

0 notes

Text

Detailed Information about Steel Fittings

Pipe fittings involve rerouting the water supply via tees, elbows, and other pipe components. Reducing tees, reducers, and similar pipe fittings are used to modify pipe sizes. In addition to the countless variations of coupling, there are

ASME B16.9 bend

Schedule 40 ASME B16.9 bend Producer Steel Tubing Curves It is usual to have the pipe's diameter, wall thickness, and pressure contained within its program. The ASME B16.9 standard, for instance, applies to pipe and fitting diameters between 1/2 inch and 48 inches.

Steel Hollow Section

Tubular sections made from steel that have had their interiors hollowed down are called hollow steel. In addition to "structural steel tubes" and "Hollow Structural Sections," these terms can also be used interchangeably (HSS). steel hollow section suppliers are often used as beams in welded frames and columns because of their many advantages in building and mechanical applications.

Pipe Clamps

Pipe clamps, also known as pipe clips or saddle clamps, are standard, straightforward fixtures used in various do-it-yourself and professional installation scenarios. pipe clamps suppliers are channel support systems frequently used in HVAC, plumbing, and electrical installations.

Forged Fittings

Pipe fittings constructed from forged carbon steel, stainless steel, or high nickel alloys are known as "forged steel fittings." That's why Forged Fittings suppliers in uaeproductsso helpful to have a method of making sturdy fittings that forges steel.

Branch Fittings

Pipes that cross each other can be joined with branch fittings. T-fittings and 45- and 60-degree wyes are the two most common types of pipe produced by Branch Fittings suppliers. Considering the necessary sweep when choosing a branch suited for a specific sector is essential.

Heat Exchanger Tubes

One common type of tube produced by Heat exchanger tubes suppliers in UAE is the shell-and-tube type. It is the standard heat exchanger used in oil refineries and other large-scale chemical processes because it can withstand greater pressure.

Steel Angle

In most cases, hot-rolled carbon steel or high-strength low-alloy steel is used to create steel angle, also known as angle iron or Steel Angle supplier’sbar. It has an L-shaped section with two legs that can be the same length or different lengths, and the angle would be 90 degrees.

Sanitary Fittings

Cleanable tubing connections, known as Sanitary Fittings, are fitted in process piping systems to provide a germ-free environment. Sanitary Fittings suppliers in UAE like regular fittings, are used to regulate the flow of fluid by connecting different sections of piping systems.

Welding Electrode

Electrical arc welding requires electrodes and lengths of wire linked to a welding machine. A high amount of heat is generated by the arc created when current flows through this wire to melt and fuse metal for welding electrode suppliers in uae.

Fasteners

A mechanical tool or element, a Fasteners suppliers in UAE, firmly binds multiple items together. The pins can take apart or reassemble the parts without any problems. But they can also serve as fixed connections.

Conclusion

Tube fittings connect tubing segments to one another or to other tubes, pipes, hoses, or other components in various configurations, including in-line, offset, multi-port, and mounting. The straight components of a system are joined together by fittings, which are couplings and joints made from specialised materials.

2 notes

·

View notes

Video

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD https://www.carsai-precisionparts.com/ Whatsapp&WeChat: +8615212743691 email: [email protected] --------------------- Chinese 2040wood cutting carpentry cnc router woodworking carve model custom wood design logos factory carving stone suppliers near me,fruit carving services near me,bending machine supplier malaysia,bending supplier in cebu,carving supplies canada,carving manufacturers india,carving cnc,jade carving service,pipe bending suppliers in chennai,custom wood carving services near me,bending near me,bending machine supplier in uae,bending supplier singapore,bending machine supplier in penang,cnc wood carving services near me,v carving machine,stone carving service,carving furniture manufacturers in hyderabad,carving ice supplier,3d carving service,v-carving software,steel bending machine suppliers in uae,v carving cnc,wood carving manufacturers,teak wood carving manufacturer,wood carving service singapore,bending flat stock,z bending tool,v carving aluminum,cnc wood carving service,u bending sheet metal,pipe bending supplier in malaysia,cnc carving machines,pipe bending supplier,rebar bending supplier,wood carving services,tube bending supplier,service-carving manual,rebar bending machine supplier philippines,stone carving manufacturers,gemstone carving service,cnc stone carving services,service carving synchronization,carving tools supplier in abu dhabi,wood carving services near me,bending machine supplier in pakistan,wire bending supplier,carving tool sharpening service,gunstock carving service,carving service definition,pumpkin carving service,rod bending supplier,service carving evpn,carving services delhi,pipe bending supplier in uae,carving suppliers,cnc wood carving machine service,marble carving service,3d wood carving service uk,carving stone suppliers canada,wood carving machine suppliers,bending machine supplier in cebu,pipe bending suppliers in bhosari,wood carving service,carving cnc machine,bend angle sheet metal,pipe bending supplier in penang,free cnc v carving software,wood carving suppliers near me,carving temple manufacturer,foam carving manufacturer,carving serviceberry,pipe bending suppliers in coimbatore,carving knife manufacturers,service-carving manual primary,tube bending suppliers,indian wood carving manufacturers,carving stone supplier,z bend sheet metal,carving kit manufacturers,bending suppliers,wood carving supplier,tree carving service,carving wood suppliers uk,carving stone suppliers,cnc carving service,cnc machine wood carving service,carving board manufacturers,bending machine supplier philippines,v carving tool,bending supplier philippines,v carving,carving services meaning,bending machine supplier,carving wood suppliers,carving wood supplier,pipe bending supplier in faridabad,bending machine supplier in manila,carving knife sharpening service,service-carving hrw

0 notes

Text

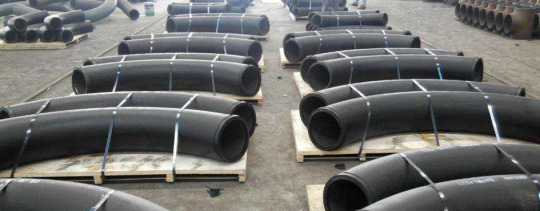

Long Radius Pipe Bend manufacturers in Chennai

Mesta INC is a manufacturer and exporter of Stainless Steel Long Radius Bend with low carbon content. We, Mesta INC are Long Radius Pipe Bend Manufacturers in Chennai. Hence, this renders exceptional formability and weldability, annealed and fabricated to enhance better performance, high strength against rupture making them suitable for irrigation and agriculture covering heavy fluid flow. ANSI ASTM ASME B16.9 SS Long Radius Bend allow purport insertion of pipes due to its long bodies and Keene so room for leakage and also help in maximizing drainage of waste. Mesta INC is Long Radius Pipe Bend Supplier in Chennai, India. Also, it provides cleaning and hygiene for food-related processing. Our SS 304 Long Radius Bend and SS 316 Long Radius Bend have high demand over the international market. Long Radius Pipe Bend / LR Pipe Bends / Piggable Bends are available at Mesta INC in Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Monel, Special Metals. We are manufacturers of 2d pipe bend, 2.5D Pipe Bend, 3D Pipe Bend, 4D Pipe Bend, 5D Pipe Bend, 6D Pipe Bend, 7D Pipe Bend, 8D Pipe Bend, 9D Pipe Bend, 10D Pipe Bend, 12D Pipe Bend, 22D Pipe Bend, Mitered Pipe Bend and Hot Pipe Bend in Chennai. We are reputed and well-known supplier of Long Radius Bend in Chennai, India.

Specifications of Long Radius Pipe Bend -

· Long Radius Pipe Bend Size: 15NB to 900NB

· Long Radius Pipe Bend Width: 500 - 2500 mm

· Long Radius Pipe Bend Length: 500 - 10000 mm

· Long Radius Pipe Bend Type: Seamless Pipe Bend / Welded Pipe Bend / Fabricated Pipe Bend

About Long Radius Pipe bend

This Long radius pipe bend is widely found applications in different industries such as Long Radius Pipe Bend for shipbuilding, Long Radius Pipe Bend for power plants, Long Radius Pipe Bend for water treatment plants, Long Radius Pipe Bend for refineries and Long Radius Pipe Bend for petrochemical industries. Long Radius Pipe Bend are accessible in various size, class, type and schedule according to the needs of the client's. We are Long Radius Pipe Bend Manufacturers in Chennai. Mesta INC is one of the main maker of value item that is ANSI/ASME Long Radius Pipe Bend. We guarantee the quality item will be conveyed in the market. With the times of involvement, we offer high caliber with lower cost and the best service. long radius bends - Bending is used to change the direction of run of pipe and tubes. The bend consists of various types such as 3D, 5D, hot bend, LR bend, piggable bend available in various materials of alloys & Nickel Alloys. Pipe bending is now available in an easy way by using the right machine, tool, material and lubrication. There is a little difference in bend and elbows, bend is usually used in changing the direction of the piping while elbows have limitations to size, angle and bend radius. Common materials used for pipe bending are carbon steel Long Radius Pipe Bend, stainless steel Long Radius Pipe Bend and alloy steel Long Radius Pipe Bend.

Long Radius Pipe Bend Applications and Uses-

· Long Radius Pipe Bend are ideal to use in the drainage pipe systems as their longer bodies help in cleansing the waste inside the pipe and controlling the formation of clogs.

· Easy to fit, our long radius bend promotes flexibility sufficient enough for expanding and decreasing the pipelines.

· Long Radius Pipe Bend made of Inconel give oxidation resistance and resistance to biofouling.

Long Radius Pipe Bend Manufacturers Exporters in Chennai - Mesta INC

Mesta INC are Exporters of Long Radius Pipe Bend in Kuwait, Long Radius Pipe Bend exporter in UAE, Long Radius Pipe Bend exporter in Bahrain, Long Radius Pipe Bend exporter in USA, Long Radius Pipe Bend exporter in Saudi Arabia, Long Radius Pipe Bend exporter in Qatar, Long Radius Pipe Bend exporter in Singapore, Long Radius Pipe Bend exporter in China, Long Radius Pipe Bend exporter in Mexico, Long Radius Pipe Bend exporter in Dubai, Long Radius Pipe Bend exporter in Turkey, Long Radius Pipe Bend exporter in Iran, Long Radius Pipe Bend exporter in Brazil and more than 90+ other countries. Mesta INC is also well-known Chennai's Manufacturers, Supplier, and Dealer. We have our sales offices in different cities of Chennai. Our head office is located in Mumbai and we provide Long Radius Pipe Bend to all major cities of India and export to more than 160+ countries from Mumbai. we are a leading Long Radius Pipe Bend manufacturer in Chennai.

Visit us: https://www.mestainc.net/long-radius-pipe-bend-manufacturer-chennai.php

For more products: https://www.mestainc.net/steel-piping-spools-flanged-pipes-pipe-fittings-manufacturer-in-india.php

0 notes

Text

Exploring the Types of Bending Machines in UAE

Exploring the Types of Bending Machines in UAE

Bending machine in UAE has an important role in shaping metals and other materials for different kinds of applications across industries like construction, manufacturing, automotive, and more. These machines are essential for achieving precise bends in various materials, ranging from pipes and tubes to sheets and profiles. In this article let us discuss about types of bending machines commonly used in the UAE:

1. CNC Pipe Bending Machines

CNC (Computer Numerical Control) pipe bending machines are highly advanced and automated tools used to bend pipes and tubes accurately. These machines offer hi precision and efficiency, making them ideal for handling industries like HVAC (Heating, Ventilation, and Air Conditioning), automotive, and aerospace. In the UAE, CNC pipe bending machines are widely used to create complex pipe configurations with minimal error.

2. Press Brake Machines

Press brake machines are essential for bending sheet metal into various shapes and sizes. They use a hydraulic or mechanical press to exert force on the metal, allowing for precise bending according to specified angles and dimensions. Press brake machines are extensively used in the fabrication of components for construction, electronics, and furniture industries in the UAE.

3. Roll Bending Machines

Roll bending machines, also known as plate bending machines, are used to curve or roll metal sheets and plates into cylindrical or conical shapes. These machines operate through a series of rollers that apply continuous pressure to the metal, gradually shaping it into the desired form. Roll bending machines are vital for manufacturing pipelines, tanks, and structural components in industries such as oil and gas and marine engineering.

4. Profile Bending Machines

Profile bending machines are designed to bend various profiles and sections of metal, including beams, channels, and angles. They employ different bending techniques, such as three-roll and four-roll bending, to achieve precise curvatures without deforming the material. Profile bending machines are indispensable in architectural metalwork, structural steel fabrication, and shipbuilding industries across the UAE.

5. Tube Bending Machines

Tube bending machines are specialized equipment used to bend tubes and pipes into specific shapes and configurations. These machines utilize different bending methods, such as mandrel bending and rotary draw bending, to maintain the integrity of the tube during the bending process. Tube bending machines are widely employed in industries like furniture manufacturing, automotive exhaust systems, and hydraulic piping in the UAE.

In conclusion, the UAE's industrial sector depends on a variety of bending machines to meet the demands of modern production processes. From CNC pipe bending machines to profile and tube bending machines, each type plays a crucial role in enhancing efficiency, productivity, and precision across different industries. As technology continues to evolve, the use of advanced bending machines will further revolutionize the manufacturing landscape in the UAE, driving innovation and growth in key sectors.

#Bending machines in UAE#Hydraulic Press Brakes in UAE#Universal Bender in UAE#Welding tables and accessories in UAE#Pu foam gasket machine in uae#Stainless steel Weld & Tank Cleaning Machines in UAE#Weld and Tank Cleaning Machines in UAE#Welding Fumes Extractor in UAE

0 notes

Text

Hydraulic Pipe Benders in the UAE: An In-Depth Look at Their Role and Benefits

In the fast-evolving industrial landscape of the UAE, hydraulic pipe benders have become indispensable tools in manufacturing and construction sectors. These machines are renowned for their efficiency, precision, and ability to handle complex bending tasks with ease. As the UAE continues to invest in infrastructure and industrial development, understanding the significance and advantages of hydraulic pipe benders in UAE is crucial for businesses and industries reliant on pipe fabrication and metalworking.

Understanding Hydraulic Pipe Benders

Hydraulic pipe benders are specialized machines designed to bend pipes and tubes into various angles and shapes using hydraulic pressure. They are essential in industries where metal pipes are used extensively, such as in construction, automotive, aerospace, and oil and gas. These machines utilize hydraulic force to apply pressure to the pipe, allowing it to be bent without compromising its structural integrity.

The key components of a hydraulic pipe bender include:

Hydraulic Cylinder: Generates the necessary force to bend the pipe.

Die Set: Contains the specific shapes and angles required for bending.

Mandrel: Supports the inside of the pipe during bending to prevent kinking.

Control System: Allows operators to set and adjust bending parameters for precision.

The Role of Hydraulic Pipe Benders in UAE

The UAE's rapid growth in infrastructure and industrial projects has amplified the demand for hydraulic pipe benders. These machines play a pivotal role in several key areas:

Construction Industry: Hydraulic pipe benders are used to fabricate custom metal pipes for building frameworks, structural supports, and architectural elements. Their precision ensures that pipes fit perfectly within complex building designs, contributing to the structural integrity of construction projects.

Automotive Sector: In the automotive industry, hydraulic pipe benders are crucial for producing exhaust systems, roll cages, and custom components. They enable manufacturers to create precise bends and shapes that are essential for vehicle performance and safety.

Aerospace Industry: Aerospace applications require high precision and durability. Hydraulic pipe benders are used to fabricate components for aircraft, including fuel lines, hydraulic systems, and structural elements. Their ability to handle high-strength materials and maintain accuracy is vital in this industry.

Oil and Gas Industry: The oil and gas sector relies on hydraulic pipe benders for producing pipes and tubing used in drilling and extraction operations. These machines ensure that the pipes can withstand high pressures and harsh environments while maintaining their functionality.

General Manufacturing: Hydraulic pipe benders are also used in general manufacturing for creating various metal parts and assemblies. Their versatility makes them suitable for a wide range of applications, from furniture manufacturing to machinery production.

Advantages of Hydraulic Pipe Benders

Hydraulic pipe benders offer several advantages over traditional bending methods, making them a preferred choice in many industries:

Precision and Accuracy: Hydraulic pipe benders provide exceptional accuracy in bending angles and dimensions. This precision is crucial for applications where exact measurements are required to ensure proper fit and function.

Efficiency and Speed: These machines are designed for high-speed operation, allowing for rapid production of bent pipes. This efficiency is particularly beneficial in high-volume manufacturing environments where time is of the essence.

Versatility: Hydraulic pipe benders can handle a wide range of pipe sizes and materials, including various metals and alloys. Their ability to perform multiple bending operations makes them versatile tools for diverse applications.

Consistency: The hydraulic system ensures consistent bending force and results, reducing the risk of defects and variations in the final product. This consistency is important for maintaining quality standards in production.

Reduced Material Waste: By bending pipes accurately and efficiently, hydraulic pipe benders minimize material waste. This not only helps in cost savings but also contributes to more sustainable manufacturing practices.

Operator Safety: Modern hydraulic pipe benders are equipped with safety features to protect operators from accidents and injuries. These features include automatic shut-off systems, safety guards, and user-friendly controls.

Key Considerations for Selecting Hydraulic Pipe Benders

When choosing a hydraulic pipe bender, several factors should be considered to ensure that the machine meets specific needs and requirements:

Pipe Size and Capacity: Assess the maximum pipe size and bending capacity required for your projects. Hydraulic pipe benders come in various sizes and capacities, so selecting one that aligns with your needs is essential.

Bending Radius and Angle: Consider the required bending radius and angle for your applications. Different machines offer varying bending capabilities, so choose one that can achieve the desired results.

Material Compatibility: Ensure that the hydraulic pipe bender can handle the types of materials you will be working with, such as steel, aluminum, or stainless steel. Some machines are designed for specific materials, while others offer greater flexibility.

Automation and Controls: Evaluate the control system and automation features of the machine. Advanced controls and automation can enhance precision and ease of use, improving overall efficiency.

Maintenance and Support: Consider the availability of maintenance services and support for the machine. Regular maintenance is crucial for ensuring the longevity and optimal performance of hydraulic pipe benders.

Budget and Cost: Determine your budget and compare the cost of different hydraulic pipe benders. While it is important to find a machine that fits within your budget, investing in high-quality equipment can lead to long-term benefits and cost savings.

The Future of Hydraulic Pipe Benders in the UAE

As the UAE continues to advance in industrial and infrastructure development, the role of hydraulic pipe benders is expected to grow. Innovations in hydraulic technology, automation, and digital controls are likely to enhance the capabilities and efficiency of these machines. The integration of smart technologies and data analytics may also lead to more precise and efficient bending operations.

Additionally, as industries in the UAE place increasing emphasis on sustainability and environmental impact, hydraulic pipe benders will play a role in reducing material waste and improving resource efficiency. The ongoing evolution of hydraulic pipe bender technology will contribute to the UAE's goals of achieving excellence in manufacturing and construction.

Conclusion

Hydraulic pipe benders are indispensable tools in the UAE's industrial and construction sectors, offering precision, efficiency, and versatility for a wide range of applications. Their ability to produce accurate and consistent bends makes them essential for manufacturing and infrastructure projects. As the UAE continues to invest in technological advancements and industrial growth, hydraulic pipe benders will remain at the forefront of innovation, supporting the country's development and contributing to its economic success.

Read More pipe welding rollers in UAE

0 notes

Text

Pipe And Tube Bending Market to Incur Meteoric Growth During 2017 - 2025

Global Pipe and Tube Bending Machine Market: Introduction

Growth in construction and automotive industry has led to higher adoption of machines, such as pipe and tube bending machines in the market. Pipe and tube bending machines are generally used to bend pipes and tubes to produce finished parts. This machine consists of a guidance wheel device, driving device, pre-pressing device, clamping head device, rocker arm, hydraulic system and intermediate frequency power supply. Among these, the rocker arm is the main part of the bending machine as its function is to bend the pipe into a required radius.

Pipe and tube bending machines are generally available in two types: CNC (Computer Numerically Controlled) bending machines and hydraulic bending machines. CNC bending machines are highly preferred by end-use industries owing to their various advantages, such as cost efficiency, accuracy and consistency.

Request For Report Sample@ https://www.persistencemarketresearch.com/samples/22216

Global Pipe and Tube Bending Machine Market: Dynamics

Drivers:

Increasing construction and automotive industries are expected to be major factors expected to drive the growth of the pipe and tube bending machine market in near future. Moreover, pipe and tube bending machines are highly cost effective as they do not require any welded fitting. This is expected to drive the growth of the pipe and tube bending machine market over the forecast period. Furthermore, CNC (Computer Numerically Controlled) bending machines produce a high level of accuracy, repeatability and consistency. Such improvements in technologies will also bring traction to the pipe and tube bending machine market in near future. That apart, increasing efficiency and advancements in technology in pipe and tube bending machines will encourage the end-user industries to purchase machines, which will further add to the growth of the market.

Restraints

Pipe and tube bending machines have few drawbacks. These machines demand high maintenance cost, which is anticipated to be a major factor hampering the growth of pipe and tube bending machine in near future. Moreover, pipe and tube bending machines require qualified technicians and labor to manage machines, which will further act as a restraining factor for the growth of pipe and tube bending machine market over the forecast period.

Global Pipe and Tube Bending Machine Market: Region-wise Outlook

Europe is anticipated to be closely followed by Asia Pacific throughout the forecast period. Both of these markets are expected to witness massive growth in the pipe and tube bending machine market due to the growth in construction sector in emerging economics, such as China and India. Owing to high demand for pipe and tube bending machines from various end-use industries in the region, North America is estimated to grow at a substantial CAGR during the forecast period. Latin America, in particular, is projected to support growth in the pipe and tube bending machine market due to growing shift in the preference of consumer towards automated products in the region. Japan and Middle East and Africa are expected to support the growth of tempered glass market over the forecast period owing to growing construction activity in countries, such as UAE, Saudi Arabia, etc.

Request For Report Table of Content (TOC): https://www.persistencemarketresearch.com/toc/22216

Global Pipe and Tube Bending Machine Market: Key Participants

Some of the market participants identified across the value chain of the global pipe and tube bending machine market include:Electropneumatics,Wonsten Group,CML USA, Inc.,Shuz Tung Machinery Industrial Co., ,td.,Tube & Pipe Bending Machines Ltd.,Baileigh Industrial, Inc.,SOCO Machinery Co., Ltd.,Promau S.r.l.,Van Sant Enterprises, Inc.,AMOB,SweBend,PHI,Chiao Sheng Machinery Co., Ltd.,Thorson Industries,Sharpe ,roducts,Chiyoda Kogyo Co., Ltd.,Pines Technology,

0 notes

Link

0 notes

Text

How does one go about selecting an excellent fabricator?

It's not always easy to find a metal fabrication company that can fulfil your needs. In truth, many businesses have difficulty finding a trustworthy supplier that is reasonably priced and able to satisfy their needs. As a company owner, it is your duty to choose the most competent fabricator to maximize your profits. When selecting a choice, it's important to weigh several factors.

When asked what they specialize in, what do they say?

Many people have specialized knowledge in metalworking. Everyone is quite distinct from the last. As you consider potential service providers, check to see whether the services you need are readily accessible. Alloy steel valve suppliers has the finest results. This may need discussing not just the manufacturing process, but also the finishing options available. The most common areas of expertise are shearing, laser cutting, and stamping. Stainless Steel Round Bar suppliers in UAE has been doing well.

Some companies also provide supplementary services including shaping and punching, and even tube rolling. You might add value to your business by providing sheet rolling, tube bending, and welding services. Stainless Steel 316 Round Bar suppliers has the finest results.

The following are some examples of supplementary services you may want to look for from specialized businesses: -Stamping -Powder Coat -Wet Spraying -CNC Machining -CNC Turning -Glass Beach Blasting -Sand Blowing -Paint Sanding -Silk Screens

Beyond the firm's actual skill, you should think at things like who they are and what they can do to keep costs down. SS 304 Hex Bar suppliers are top-notch.

Essential Traits of Reliable Businesses

Look for a company that has been around for a while and has a history of consistently delivering excellent products. You can easily find Carbon Steel Pipe Fittings suppliers in UAE. Unfortunately, when working with a constrained budget, it's not uncommon to have to compromise on aspects of accuracy and prowess. The products from Stainless Steel Flat Bar suppliers are the best.

It is possible to find businesses that have a track record of providing high-quality service at affordable prices. One should be sure to look for both. In most cases, ASTM A276 Round Bar suppliers are the preferred choice.

A Quote Request

When it comes to fabricating metal, getting a quotation is always a smart idea. Before you commit to a contract with a company, most will provide you a free estimate and sometimes even a sample to evaluate. Stainless Steel Pipe Fittings suppliers in UAE will help you. Think on the price, the service's ability to meet your needs, and the product's quality. Then, narrow down your choices depending on each firm's track record and the services you're looking for. The quality of Carbon Steel Round Bar suppliers is exceptional.

There is a significant need for metal fabrication services. But it's not enough to take the firm at its word. Instead, it's best to go further and find out whether they have experience in the specific area you need help with, whether it's specialized labor, transport, coloring, or anything else. brass valve suppliers in UAE are the best.

0 notes

Text

Pipe and Tube Bending Machine Market Size to Expand Significantly by the End of 2025

Global Pipe and Tube Bending Machine Market: Introduction

Growth in construction and automotive industry has led to higher adoption of machines, such as pipe and tube bending machines in the market. Pipe and tube bending machines are generally used to bend pipes and tubes to produce finished parts. This machine consists of a guidance wheel device, driving device, pre-pressing device, clamping head device, rocker arm, hydraulic system and intermediate frequency power supply. Among these, the rocker arm is the main part of the bending machine as its function is to bend the pipe into a required radius.

Request to Sample of Report- https://www.persistencemarketresearch.com/samples/22216

Pipe and tube bending machines are generally available in two types: CNC (Computer Numerically Controlled) bending machines and hydraulic bending machines. CNC bending machines are highly preferred by end-use industries owing to their various advantages, such as cost efficiency, accuracy and consistency.

Global Pipe and Tube Bending Machine Market: Dynamics

Drivers:

Increasing construction and automotive industries are expected to be major factors expected to drive the growth of the pipe and tube bending machine market in near future. Moreover, pipe and tube bending machines are highly cost effective as they do not require any welded fitting. This is expected to drive the growth of the pipe and tube bending machine market over the forecast period.

Furthermore, CNC (Computer Numerically Controlled) bending machines produce a high level of accuracy, repeatability and consistency. Such improvements in technologies will also bring traction to the pipe and tube bending machine market in near future. That apart, increasing efficiency and advancements in technology in pipe and tube bending machines will encourage the end-user industries to purchase machines, which will further add to the growth of the market.

Restraints

Pipe and tube bending machines have few drawbacks. These machines demand high maintenance cost, which is anticipated to be a major factor hampering the growth of pipe and tube bending machine in near future. Moreover, pipe and tube bending machines require qualified technicians and labor to manage machines, which will further act as a restraining factor for the growth of pipe and tube bending machine market over the forecast period.

Request Report for TOC @ https://www.persistencemarketresearch.com/toc/22216

Global Pipe and Tube Bending Machine Market: Segmentation

The global pipe and tube bending machine market can be segmented on the basis of product and end-use industry.

By product type, the pipe and tube bending machine market can be segmented into:

CNC Bending Machine

Hydraulic Pipe Bender

Single Head Hydraulic Pipe Bender

Double Head Hydraulic Pipe Bender

By end-use industry, the pipe and tube bending machine market can be segmented into:

Power Construction

Public Railway Construction

Boilers

Bridge

Ships Furniture

Global Pipe and Tube Bending Machine Market: Region-wise Outlook

Europe is anticipated to be closely followed by Asia Pacific throughout the forecast period. Both of these markets are expected to witness massive growth in the pipe and tube bending machine market due to the growth in construction sector in emerging economics, such as China and India. Owing to high demand for pipe and tube bending machines from various end-use industries in the region, North America is estimated to grow at a substantial CAGR during the forecast period. Latin America, in particular, is projected to support growth in the pipe and tube bending machine market due to growing shift in the preference of consumer towards automated products in the region. Japan and Middle East and Africa are expected to support the growth of tempered glass market over the forecast period owing to growing construction activity in countries, such as UAE, Saudi Arabia, etc.

For more information about this Report visit @ https://www.persistencemarketresearch.com/market-research/pipe-and-tube-bending-machine-market.asp

Global Pipe and Tube Bending Machine Market: Key Participants

Some of the market participants identified across the value chain of the global pipe and tube bending machine market include:

Electropneumatics

Wonsten Group

CML USA, Inc.

Shuz Tung Machinery Industrial Co., Ltd.

Tube & Pipe Bending Machines Ltd.

Baileigh Industrial, Inc.

SOCO Machinery Co., Ltd.

Promau S.r.l.

Van Sant Enterprises, Inc.

AMOB

SweBend

PHI

Chiao Sheng Machinery Co., Ltd.

Thorson Industries

Sharpe Products

Chiyoda Kogyo Co., Ltd.

Pines Technology

0 notes

Text

Hydraulic Pipe Benders in UAE: An Indispensable Tool for Modern Industry

The United Arab Emirates (UAE) is known for its rapid industrialization and infrastructural development, playing a significant role in the Middle East's economic landscape. Key to these advancements are the tools and machinery that drive the construction and manufacturing sectors. Among these essential tools are hydraulic pipe benders, which have become indispensable for various industries. This blog explores the importance, functionality, types, and applications of hydraulic pipe benders in UAE, emphasizing their contribution to the country's industrial growth.

What Are Hydraulic Pipe Benders?

Hydraulic pipe benders are specialized tools designed to bend pipes and tubes to precise angles and shapes without compromising their structural integrity. Utilizing hydraulic pressure, these machines provide a powerful and efficient means to manipulate metal pipes, making them essential in industries where precision and durability are paramount.

Importance in the UAE's Industrial Sector

In the UAE, the demand for hydraulic pipe benders in UAE is driven by several key sectors:

Construction: The construction boom in cities like Dubai and Abu Dhabi requires precise bending of pipes for plumbing, electrical conduits, and structural components.

Oil and Gas: The UAE's significant oil and gas industry relies heavily on pipelines, necessitating precise bends to ensure efficient flow and safety.

Manufacturing: Factories and production lines often require customized pipe shapes for machinery and equipment, making hydraulic pipe benders crucial.

How Do Hydraulic Pipe Benders Work?

Hydraulic pipe benders operate by using hydraulic fluid to generate force. This force is applied through a piston that bends the pipe around a die. The key components of a hydraulic pipe bender include:

Hydraulic Cylinder: Provides the necessary force to bend the pipe.

Die: A tool that shapes the pipe to the desired angle.

Clamp: Holds the pipe securely in place during the bending process.

The process involves positioning the pipe in the machine, setting the desired bend angle, and activating the hydraulic system. The pipe is then bent around the die, resulting in a precise and uniform bend.

Types of Hydraulic Pipe Benders

Several types of hydraulic pipe benders are available, each suited for different applications and materials. The main types include:

Manual Hydraulic Pipe Benders: These are operated by hand and are suitable for small-scale projects and thinner pipes. They are portable and ideal for on-site work.

Electric Hydraulic Pipe Benders: These use electric motors to power the hydraulic system, offering greater power and precision. They are suitable for larger pipes and more demanding tasks.

CNC Hydraulic Pipe Benders: Computer Numerical Control (CNC) benders offer the highest level of precision and automation. They are used in advanced manufacturing processes where complex bends and high volumes are required.

Applications of Hydraulic Pipe Benders in UAE

The versatility of hydraulic pipe benders makes them applicable in various industries across the UAE:

Construction and Infrastructure: Used for bending pipes in plumbing, HVAC systems, and structural components.

Oil and Gas: Essential for creating bends in pipelines that transport oil, gas, and other fluids.

Automotive: Used in the manufacturing of exhaust systems, roll cages, and other automotive components.

Shipbuilding: Vital for bending pipes used in the construction of ships and marine vessels.

Aerospace: Used in the fabrication of aircraft components where precise bends are critical.

Advantages of Using Hydraulic Pipe Benders

Hydraulic pipe benders offer several advantages that make them preferable over other bending methods:

Precision: Hydraulic benders provide accurate and consistent bends, crucial for applications requiring high precision.

Efficiency: They allow for faster bending processes, increasing productivity in industrial settings.

Versatility: Suitable for various materials, including steel, aluminum, and copper, making them adaptable to different industry needs.

Safety: Hydraulic systems reduce the physical effort required, minimizing the risk of injury to operators.

Cost-Effective: By reducing material wastage and labor costs, hydraulic pipe benders offer long-term economic benefits.

Choosing the Right Hydraulic Pipe Bender

Selecting the appropriate hydraulic pipe bender depends on several factors:

Pipe Material and Size: Consider the material and diameter of the pipes you will be bending.

Bend Radius: Determine the required bend radius and ensure the machine can accommodate it.

Volume and Frequency: Assess the volume of work and how frequently the machine will be used to choose between manual, electric, or CNC options.

Portability: For on-site work, a portable manual bender may be more suitable, whereas a stationary electric or CNC bender is ideal for factory settings.

Budget: Balance the cost of the machine with its features and capabilities to ensure a cost-effective investment.

Maintenance and Care

Proper maintenance is essential to ensure the longevity and performance of hydraulic pipe benders:

Regular Inspection: Conduct routine inspections to identify and address any wear or damage.

Lubrication: Keep moving parts well-lubricated to reduce friction and wear.

Hydraulic Fluid: Regularly check and replace hydraulic fluid to maintain optimal performance.

Cleaning: Keep the machine clean and free from debris that could interfere with its operation.

Training: Ensure operators are well-trained in using and maintaining the equipment to prevent misuse and accidents.

Conclusion

Hydraulic pipe benders play a crucial role in the UAE's industrial landscape, supporting various sectors with their precision, efficiency, and versatility. As the UAE continues to grow and develop, the demand for reliable and advanced pipe bending solutions will remain strong. By understanding the functionality, types, and applications of hydraulic pipe benders, businesses can make informed decisions to enhance their operations and contribute to the country's ongoing industrial success.

Read More pipe welding rollers in UAE

0 notes