#Thermal Conductive Gap Filler

Explore tagged Tumblr posts

Photo

Thermal Conductive Electrical Insulator is a flexible material mixed with glass fabric as reinforcement. Thermal Conductive Gap Filler has good thermal conductivity and strong cutting resistance. This material is commonly used in electronic industries due to its high performance.

1 note

·

View note

Text

The fabric could reach 100 dB in the shielding effectiveness and 0.005-0.008O/sq in the surface resistivity, and this is the lowest resistivity fabric in the JINAN.

Website: http://www.emishielding.com.cn

Tel: 86-531-81901321

Fax: 86-531-81901321

Email: [email protected]

Add: 1-301,XINGFULIANCHENG LASER PARK, KEJIA ROAD, JINAN, CHINA

0 notes

Text

0 notes

Text

Thermal Interface Materials | Thermal Management Solutions - Techni3

Thermal Interface Materials

What are Thermal Interface Materials?

Successful thermal management of high-power electronic components (single chips, multi-chip modules, integrated circuits, etc.) with high heat dissipation ratings requires careful design engineering. The most important goal in electronic cooling is to maintain junction temperature from rising above prescribed levels. Junction temperature is good predictor of the useful life of the component. Thermal interface materials bridge the interface between hot components and a chassis or heat sink assembly. Heat transfer is increased, and components are kept cooler. An example is a gap filler pad transferring heat between two or more solid surfaces.

How do they work?

Materials formulated in the lab are manufactured and inserted between parts to enhance the thermal coupling. Most applications involve dissipating heat. When two surfaces are interfaced, rough surfaces create insulating air gaps between them. These gaps create thermal barriers to heat transfer due to the low thermal conductivity of air. Heat will transfer and be removed more rapidly because of the presence of an engineered material that has significantly higher thermal conductivity than the air in the interface. Thus, the material helps minimize the resistance of heat flow into, through, and out of an interface.

What are Common Uses?

● Gap Filler Pads – These materials can offer a unique combination of extremely high thermal conductivity and softness. The combined features reduce mechanical stress while maintaining thermal performance. Several offerings are free of silicone, an ideal situation for some applications, Some feature no oil bleed. An example is a gap filler pad transferring heat in a densely packed PCB.

● Dispensable Gap Fillers – Examples include liquid putty gap fillers, thermal pastes, gels, and greases. They are generally non-electrically conductive. Putty is used for filling in gaps that are present between irregular or unusual surfaces or those that do not touch one another. A popular application ofliquid gap fillers is handheld gaming systems. Fragile components, design density, and high operating temperatures are common issues to be resolved.

● Phase Change – Components within servers and computers of all types achieve increased processing speeds and overall functionality and reliability improvements with phase change materials. They take advantage of latent heat of fusion to absorb heat, but they change phase only once to allow for the material to fill up all nooks and crevices. Screen-printable formulations deliver the reliability and performance of a phase change material with the low-cost handling of thermal grease.

● Automation Support – Through advancements in robotic motion control, users can now automate the application of all forms of thermal interface materials. These pioneering applications add speed, reliability, and rapid ROI to any application process while lowering overall costs.

● Electrically Insulating -Electrical isolation can be a critical design consideration in numerous applications. Electrically insulating products offer solutions whenever reliability, cut-through resistance, and thermal conductivity are critical factors. Military and aerospace applications are examples.

● Thermally Conductive PCB -Thermal management can be designed directly into PCBs. Design teams can desire systems which eliminate costly, secondary thermal management components, seeking to drastically reduce system size.

0 notes

Text

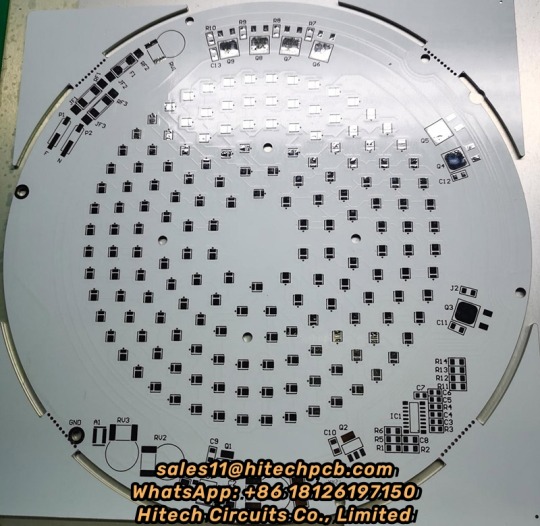

Aluminium PCB

1. What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Aluminum LED PCB with White Solder Mask

The retail price of Aluminum LED lights has dropped dramatically in recent years, while the energy efficiency and brightness of LED lights have improved. These technological advances have led some to predict annual growth of 45% over the next five years. With the development of the LED industry, the demand for LED PCBS and solder masks is also increasing. Solder shield is a protective coating applied to exposed printed circuit boards. The exposed PCB board is covered with a mask to prevent accidental solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green, and are expected to withstand the high temperatures that occur in reflow soldering, as different colors such as blue, red, or black will occasionally appear. Increased production of Hitch Aluminum LED PCB requires increased whiteness and color stability of the mask. Aluminum LED PCB commonly used LPI welding color is white and black, of which white welding color is the most commonly used to achieve high brightness and perfect light reflection. White Aluminum LED PCB ensures no darkening and will not affect the color temperature of LED smd. At the same time, it also helps to increase the life of LED applications. Looking for reliable Aluminum LED PCB suppliers, Hitech is a good choice.

6. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

7. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

8. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

9. Technical requirements for Aluminum LED PCB

The main technical requirements are:

1. Dimensional requirements: including panel size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delimitation, aluminum oxide film, etc.

2. Performance requirements, including peel strength, surface resistively, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

10. Special test method for Aluminum-based copper clad plates

One is the measurement method of dielectric constant and dielectric loss factor. It is the series resonance method with variable Q value. The sample and tuned capacitor are connected to the high-frequency circuit in series to measure the Q value of the series circuit.

The other is the measurement method of thermal resistance, which is calculated by the ratio of temperature difference and heat conduction between different temperature measurement points.

11. The Aluminum LED PCB manufacturing process in Hitechpcba

(1)Substrate cutting

a. cutting process: material → cutting

b. Note: ① Check the size of the first piece; ② Pay attention to Aluminum surface scratching and copper surface scratching; ③ Pay attention to the layering of the board edge and the tip.

(2)Plate drilling

a, drilling process: pin → drilling → inspection plate

b, matters needing attention: ① check the number of drilling holes, the size of the empty chestnut chain; ② Check the plate burr, hole deviation; ③ Avoid scratching the substrate; ④ Check and replace the drill nozzle.

(3) Imaging transfer

a, graphic imaging process: grinding plate → film → exposure → development

b, precautions: ① Check whether there is an open circuit after development; ② Pay attention to the poor line caused by the board wipe; ③ There can be no air residual exposure to prevent poor exposure; ④ Whether there is deviation in developing counterpoint; ⑤ After exposure, the development should be done at rest for more than 15 minutes.

(4)Solder mask and Silkscreen process

a, kill row silk printing resistance welding, character process: screen printing → pre-baking → exposure → development → character

b, matters needing attention: ① Check whether there is foreign body on the board; ② Pay attention to the cleaning of the net board; ③ Pre-bake for more than 30 minutes after screen printing, to avoid bubbles in the line; ④ Pay attention to the thickness and uniformity of screen printing; ⑤ After the pre-baked plate to completely mutual cooling, avoid touching film or damage to the ink surface gloss.

(5)E-test or flying probe test

a, test process: line test → withstand voltage test

b, precautions: ① How to distinguish after the test how to store qualified and unqualified products.

(6)FQC, FQA, packaging, shipping

a. Process: FQC→FQA→ Packaging → shipping

b. Note: ① FQC should pay attention to the confirmation of the appearance of the finished Aluminum LED PCB in the process of eye inspection and make a reasonable distinction; ② FQA does spot check and verify the inspection standards of FQC; ③ We should confirm the number of packages to avoid mixed plates, wrong plates and package

12. Application of Aluminum LED PCB

1. Audio devices: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier.

2. Power Supply: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

3. Communication electronic equipment: high frequency amplifier, filter, transmitter circuit

4. Office automation equipment: motor drive, etc

5. Automobile: electronic regulator, ignition device, power controller, etc.

6. Computer :CPU board, floppy disk drive, power equipment, etc.

7. Power module: converter, solid relay, rectifier bridge, etc

8. Lamps and lighting: A variety of colorful LED energy-saving lamps are well received by the market, and Aluminum LED PCB used in LED lights has also begun to be applied on a large scale.

13. Aluminum LED PCB Storage Conditions

Aluminum LED PCB are generally stored in a dark and dry environment. Most Aluminum LED tube lighting metal core pcb are prone to dampness, yellowing, and blackening. Generally, they should be used within 48 hours after opening the vacuum package.

14. Specification for the manufacture of Aluminum LED PCB

a. Aluminum LED PCB is often used in power devices, power density is high, so the copper foil is thicker. If copper foils over 3oz are used, the etching of thick copper foils requires engineered line width compensation, otherwise the line width will be out of tolerance after etching.

b. The aluminum base surface of aluminum substrate must be protected by protective film in advance during PCB processing, otherwise, some chemicals will etch the aluminum base surface, resulting in appearance damage. And the protective film is easy to be hurt, resulting in gaps, which requires the whole PCB processing process must be inserted.

c. The hardness of the milling cutter used by the glass fiber board gong board is relatively small, and the hardness of the milling cutter used by the aluminum substrate is large. In the process of manufacturing glass fiber board milling cutter speed, while the production of aluminum substrate is at least two thirds slower.

d, computer milling glass fiber board is just the use of the machine's own cooling system, but the processing of aluminum substrate must be in addition to alcohol heat dissipation for the gong head.

15. Aluminum LED PCB circuit fabrication

(1) Mechanical processing: Drilling of aluminum substrate can be done, but no burr is allowed on the edge of the inner hole after drilling, which will affect the pressure test. Milling the shape is very difficult. And punching shape, need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After shape punching, the edge should be very neat, without any burr, and do not hurt the welding resistance layer on the edge of the plate. Usually the use of soldier die, hole from the line, shape from the aluminum surface, circuit board punching force is cut down, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

(2) The whole production process is not allowed to wipe the aluminum base surface: aluminum base touch, or by a certain chemical will produce surface discoloration, blackening, which is absolutely unacceptable, re-polishing aluminum base some customers do not receive, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base plate. Some enterprises use passivation process, some in hot air leveling (spray tin) before and after each pasted protective film.

(3) Over-high voltage test: the aluminum base board of the communication power supply shall be tested at 100% high voltage. Some customers require direct current or alternating current. The voltage shall be 1500V or 1600V, and the time shall be 5 seconds or 10 seconds. Dirt on the board, holes and aluminum edge burr, line saw tooth, damage to any little insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board stratification, foaming, are rejected.

1 note

·

View note

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

7. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

0 notes

Text

Horiaki's Pioneering Approach: Elevating Industries with Thermal Conductive Materials

In the ever-evolving landscape of modern technology and industry, efficient thermal management is a crucial aspect of ensuring optimal performance and reliability. Horiaki, a frontrunner in manufacturing excellence, stands out with its innovative approach to Thermal Conductive Materials Manufacturers, offering solutions that redefine standards in heat dissipation across diverse applications.

Thermal conductive materials play a pivotal role in dissipating heat from electronic components, machinery, and various industrial systems. Horiaki's commitment to pushing the boundaries of thermal management is evident in its range of advanced materials designed to meet the stringent requirements of modern industries.

At the heart of Horiaki's thermal conductive materials is a meticulous selection of high-performance substances. The company employs cutting-edge materials such as thermal interface pads, gap fillers, and phase change materials, each chosen for its specific thermal conductivity properties. This strategic material selection ensures that Horiaki's thermal conductive solutions excel in efficiently transferring and dissipating heat, contributing to enhanced performance and reliability in applications ranging from electronics to automotive systems.

Precision engineering is a hallmark of Horiaki's thermal conductive material manufacturing process. The company leverages advanced techniques to create materials with consistent thermal conductivity characteristics, ensuring reliable performance across a broad spectrum of operating conditions. This precision not only contributes to the effectiveness of the materials but also extends the lifespan of the systems they serve.

Horiaki's customer-centric philosophy is reflected in its thermal conductive material solutions. The company collaborates closely with clients, understanding the unique thermal challenges of their applications, and offering customized materials that address specific needs. This tailored approach has positioned Horiaki as a trusted partner, providing tThermal Conductive Materials Manufacturers that contribute to the efficiency and longevity of diverse industrial processes.

In conclusion, Horiaki's thermal conductive materials stand as a testament to the company's dedication to innovation and excellence. As industries continue to demand superior thermal management solutions, Horiaki remains at the forefront, delivering materials that set new benchmarks in efficiency, reliability, and adaptability. In the dynamic world of thermal management, Horiaki's commitment to advancing technology and industry is evident, making them a key player in the evolution of heat dissipation solutions.

0 notes

Text

0 notes

Text

Thermal Interface Materials Market Report Analysis, Regional Outlook and Supply Chain by 2030

The thermal interface materials (TIM) market refers to the industry involved in the manufacturing and distribution of materials used for improving thermal conductivity between two surfaces. These materials are primarily used to enhance heat dissipation and transfer between electronic components, such as microprocessors, integrated circuits, power electronic devices, and heat sinks. The thermal interface materials play a crucial role in managing and controlling heat generated by electronic devices, thereby improving their overall performance and reliability.

Here is some information about the thermal interface materials market:

Market Overview:

The thermal interface materials market has been witnessing significant growth due to the increasing demand for electronic devices and the need for efficient heat management. The market includes a wide range of materials, such as thermal greases, thermal adhesives, thermal pads, phase change materials, and thermal tapes.

Key Drivers:

Several factors drive the growth of the thermal interface materials market, including:

Increasing Demand for Electronic Devices: The growing use of electronic devices, such as smartphones, tablets, laptops, gaming consoles, and automotive electronics, has fueled the demand for thermal interface materials. These materials are essential for maintaining optimal operating temperatures and preventing thermal throttling or overheating issues.

Technological Advancements: The continuous advancement in electronic component design and miniaturization has resulted in the generation of more heat within smaller spaces. This necessitates the use of advanced thermal interface materials that offer higher thermal conductivity and improved heat dissipation properties.

Growing Awareness of Thermal Management: Manufacturers across various industries are becoming more aware of the importance of thermal management for improving the lifespan and reliability of electronic devices. This awareness has increased the adoption of thermal interface materials to optimize heat dissipation.

Increasing Focus on Energy Efficiency: With the rising demand for energy-efficient devices, the need for effective heat management becomes crucial. Thermal interface materials help in reducing energy consumption by improving thermal conductivity and reducing heat resistance.

Types of Thermal Interface Materials:

The thermal interface materials market offers various types of materials suitable for different applications:

Thermal Greases: These are viscous compounds containing a combination of thermally conductive fillers and a silicone or non-silicone base. Thermal greases provide excellent thermal conductivity and conformability, making them ideal for applications where there are slight surface irregularities.

Thermal Adhesives: These materials offer both thermal conductivity and bonding properties. Thermal adhesives are used to attach heat sinks or other cooling components to electronic devices. They provide mechanical support while ensuring efficient heat transfer.

Thermal Pads: These are soft, compressible pads made from materials like silicone or elastomers. Thermal pads fill the air gaps between surfaces and provide a low thermal resistance pathway for heat transfer. They are commonly used in applications with moderate temperature requirements.

Phase Change Materials (PCMs): PCMs are substances that absorb and release heat during phase transitions. They change from solid to liquid or vice versa, enabling efficient heat dissipation. PCMs are particularly useful in applications where temperature fluctuations occur.

Thermal Tapes: These tapes consist of thermally conductive materials with adhesive properties on both sides. They are easy to apply and provide a reliable bonding solution while ensuring efficient heat transfer.

Regional Market Analysis:

The thermal interface materials market is geographically diverse, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific dominates the market due to the presence of major electronic manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. The region's robust electronics industry and the increasing adoption of thermal management solutions contribute to its market dominance.

Key Market Players:

Several prominent players operate in the thermal interface materials market. These include:

Henkel AG & Co. KGaA Dow Inc. 3M Company Parker-Hannifin Corporation Laird Performance Materials Momentive Performance Materials Inc. Shin-Etsu Chemical Co., Ltd. Bergquist Company (A Henkel Company) Indium Corporation Fujipoly America Corporation

These companies focus on research and development activities, product innovations, collaborations, and strategic acquisitions to strengthen their market position and cater to the growing demand for thermal interface materials.

Overall, the thermal interface materials market is witnessing steady growth due to the increasing demand for efficient heat management solutions in various industries. The advancements in electronic devices and the need for improved thermal conductivity are expected to drive further market expansion in the coming years.

0 notes

Text

Thermal Interface Materials Market Size, Growth Analysis Report, Forecast to 2032

Between 2022 and 2032, the global thermal interface materials market is anticipated to grow at a CAGR of 11.2%. The market will be worth USD 2.05 billion in 2022 and is expected to grow to USD 5.33 billion by 2032.

Thermal interface materials are usually inserted between two components or surfaces in order to improve the thermal coupling and heat flow between the two surfaces or components. Nowadays, electronic assemblers know the importance of thermal interface materials and use them in almost every application where heat flow is a critical part of operation.

These materials are used primarily due to the uneven, rough, and wavy surfaces of machined parts, which lead to few actual points of contact between the two joined components. These rough surfaces form air gaps when joined, resulting in insulation, and act as a thermal barriers for small scale power applications.

Thermal interface materials help eliminate air gaps and increase the heat conductance between the joined surfaces. These materials are available in several forms; however, their selection depends on several factors. Thermal conductivity is the primary selection criteria. Besides thermal conductivity, ease of usage during assembly, ability to rework, and long term stability are also important in selecting these materials for high-end applications.

Download Sample Copy@ https://www.futuremarketinsights.com/reports/sample/rep-gb-15462

Global Thermal Interface Materials Market Key Players

Network Medical Products Ltd., Olympus, Lohmann & Rauscher, Meril Life Sciences Pvt Ltd., FABCO, Aegis Lifesciences, Summit Health, Smith & Nephew, Stryker Corporation, Medtronic plc.

Thermal Interface Materials Market by Segmentation

By Product Type:

Tapes and films

Elastomeric Pads

Greases and adhesives

Phase change materials

Metal-Based

Others

By Application Outlook:

Telecom

Computer

Medical devices

Industrial machinery

Consumer durables

Automotive electronics

Others

Recent Developments in Global Thermal Interface Materials Market

Lately, 3M stretched its operations in Clinton, Tennessee by investing around USD 470 million and adding around 600 new jobs by 2025 at its plant in Clinton, Tennessee.

In 2022, Ray Techniques Ltd introduced an innovative technology for nanodiamonds manufacturing or laser ablation. The nanodiamonds obtained through this technology have high purity and homogeneity.

Henkel AG & Co. KGaA launched a new TIM Bergquist Gap Filler TGF 7000. It is used for various applications, such as automotive ADAS systems, power conversion systems, electric pumps, and others. With this launch, the company strengthens its product portfolio in the TIMs market

Browse latest Market Reports@ https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

The Key to Electronic Success: Thermal Interface Materials for Efficiency and Reliability

Thermal Interface Material come in various forms, each tailored to specific applications and needs:

Thermal Greases and Compounds: These are semi-liquid materials that fill gaps effectively, ensuring intimate contact between surfaces. They are typically used in applications with irregular surfaces, such as CPU installations.

Thermal Pads: These are solid, pre-formed pads with good conformability. They are ideal for applications where the even distribution of pressure is crucial.

Phase Change Materials: These materials change phase from solid to liquid during operation, ensuring optimal contact. They are well-suited for applications requiring minimal pump-out and a consistent interface.

Thermal Adhesives: In addition to their thermal properties, these materials offer adhesive qualities, making them ideal for applications that require both heat dissipation and component fixation.

Thermal Gap Fillers: These are highly compressible materials, perfect for applications with varying gap distances. They conform to surface imperfections and provide excellent thermal conductivity.

Read more blog : Unlocking the Secret World of Thermal Insulation: Click to Learn More

#thermal gap pads#thermal interface materials market#thermal management#thermal graphite sheet#books#energikey#thermal adhesive#thermal products company#silica grease#thermal gap filler#thermal insulator

0 notes

Link

0 notes

Text

HALA Contec GmbH & Co. KG - Gap Filler, Heatpipes, Phase Change Material and more

The HALA Contec GmbH & Co. KG is one of the leading companies when it comes to thermal interface material, phase change material, gap filler and heat pipes. They also offer a wide variety of silicone caps, thermally conductive foils and grease, graphite foils, PSA insulating tape, adhesives and potting gels.

HALA Contec GmbH & Co. KG

Siemensstr. 5, 85521 Ottobrunn

+498966547783

https://www.hala-tec.de/

Linkedin

1 note

·

View note

Text

Consumer Electronics - Techni3

We deliver the most innovative, reliable and scalable solutions in effective EMI mitigation and thermal management for consumer and portable electronic applications. Laird’s broad product portfolio covers a wide range of EMI and thermal solutions along with multi-functional solutions incorporating a single process design. Laird’s advanced materials and multifunctional layers allow miniaturization of components and enable zero air gap in portable devices. Our high performance thermal and EMI shielding materials help device and system manufacturers solve escalating temperature and EMI issues caused by the increasing functionality of consumer electronic devices.

Laird’s best-in-class co-engineering expertise in simulation, modeling, rapid prototyping and lab testing during early design stages speeds our customers on the path to achieving compliance. These efforts bring products to market more quickly. Our global manufacturing footprint enables Laird to consistently and efficiently fulfill customers’ demands in different regions. We are proven, reliable and strong partners to many of the world’s leading brands.

Laptop and Tablet

Design challenges inherent in laptops and tablets include increasing demands for ever higher performance, more compelling multi-functional capabilities, miniaturization, and energy efficiency. To support the work of design engineers, Laird delivers expert solutions in EMI mitigation, thermal management, power efficiency improvement and the integration of multifunctional layers. In addition, we are flexible in creating product designs to meet our customer’s security requirements, in-line inspection and cosmetic standards.

Computer Peripherals and Printers

Computer peripheral equipment and printer systems expand capabilities of computers and laptops. More functions continue being integrated into single devices. In them, our magnetic ceramic components suppress unwanted noise or improve system power efficiency in power converting. Our advanced thermal interface materials transfer heat away from hot ICs or components on the PCB to the enclosure. Our EMI shielding materials protect your equipment sensing elements and help to meet compliance.

Game Consoles

Each year, next generation game consoles promise to be slimmer, faster and more powerful. These increasing demands for higher performance produce design challenges in thermal management, EMI mitigation and device reliability. Increasing power density drives the need for higher thermal conductivity material and developing added thermal management innovation. Tighter integration into smaller spaces leads to a need for ultra-soft thermal materials and process improvements through automation. At a device design level, the heat generated from more powerful devices is one problem. Waste energy or EMI “noise” is another. Laird provides innovative solutions to mitigate EMI while also effectively transferring unwanted heat in a tight, shrinking spaces.

Augmented Reality and Virtual Reality Headsets

Soon, Augmented Reality (AR) and Virtual Reality (VR) systems and headsets are expected to introduce astonishing new experiences into our everyday lives. The massive data transfer of image and video requires high speed data links and ever greater processing power. Meanwhile, AR and VR headsets require lightweight, longer battery life and tighter integration, all within smaller spaces. A holistic approach is required to understand EMI mitigation and thermal issues at the system level. Those issues must be addressed and resolved at the same time and most important, in an early design stage. Laird’s extensive portfolio includes high performance thermal interface materials, liquid gap fillers, fabric-over-foam gaskets, board level shields and multi-functional solutions, all engineered to enable design engineers to help create more immersive experiences in AR and VR.

WiGig, the new Wi-Fi standard, will benefit AR and VR by multi-gigabits per second data speeds using the uncongested 60 GHz frequency band. Laird’s innovative thermoplastic absorbers provide excellent absorption and isolation at 60GHz for WiGig technology.

Mail

Mobile

+44 (0)29 2125 2100

Service Area

Unit 4B Caerphilly Business Park Caerphilly CF83 3GS

0 notes

Video

youtube

Performance test of thermal conductive silicone pad / thermal gap filler...

14 notes

·

View notes

Text

Key characteristics of thermal interface materials

In order to meet the heat dissipation needs of electronic products, there are also a wide variety of thermal interface materials. The commonly used thermal interface materials on the market are: Thermal Pad, Electrically Insulating Thermal Sheet, Thermal Conductive Gap Filler, Thermal Grease, Thermally Conductive Potting Encapsulant, Thermally conductive phase change materials, etc. Today, thermal interface material manufacturers will come to tell you what are the key characteristics of thermally conductive interface materials?

One. Thermal characteristics 1, Thermal impedance Thermal resistance is equal to R=d/k. This equation shows that thermal resistance is inversely proportional to thermal conductivity k and directly proportional to material thickness. In other words, the thermal conductivity of the material is a constant, and the thermal resistance is only related to the thickness of the material. The thicker the thickness, the greater the thermal resistance, and vice versa. The contact thermal resistance can be controlled manually, and the appropriate thermal interface material is selected according to the contact surface. In this way, the total thermal resistance can be controlled.

2, Thermal conductivity Thermal conductivity is a sign that determines the thermal conductivity of thermal interface materials. The greater the thermal conductivity, the better the thermal conductivity.

Two. Electrical characteristics

1, breakdown voltage The measurement of breakdown voltage is how much voltage the thermally conductive material can withstand under certain conditions. This value indicates the electrical insulation capability of the thermal interface material. This value will be affected in humid and high temperature environments, because the thermal interface material absorbs moisture in the air.

2, Volume resistivity

Volume resistivity is used to measure the volume electronic resistance per unit volume of a material. The volume resistivity is the ability of the thermal interface material to guide the current leakage between the energized component and the metal heat sink. Like the breakdown voltage, it will also be affected by humidity and high temperature and will also decrease the volume resistivity.

Three. elastomer characteristics 1, Compression set Compression deformation refers to the resultant force applied during deflection. When a compressive load is applied, the elastomer material deforms, but the volume of the material remains unchanged. The compression deformation characteristics may vary depending on the geometry of the part, the deflection rate, and the size of the probe.

2, Stress relaxation When pressure is applied to the thermal interface material, after the initial deformation, a relaxation process will occur slowly, and then the pressure will be removed. This process will continue until the pressure load and the intrinsic strength of the material reach a balance.

3, Compression deformation Compression deformation is the result of stress relaxation. If the thermal interface material endures the pressure load for too long, part of the deformation will become a longer deformation, which cannot be recovered after the load is reduced.

Source of information:http://www.aok-technologies.com/, Shenzhen Aochuan Technology Co., Ltd. Professional team of Thermal Interface Material Manufacturer in China . If you want to reprint, please specify.

1 note

·

View note