#Temperature cycle test chamber

Explore tagged Tumblr posts

Text

𝑾𝑰𝑷 𝑾𝒆𝒅𝒏𝒆𝒔𝒅𝒂𝒚!! ♥

wow! i'm on time this week!!

thank you to the lovely @dirty-bosmer @your-talos-is-problematic and @skyrim-forever for the tags!!

tagging the amazing @archangelsunited @orfeoarte @thana-topsy @gilgamish @saltymaplesyrup @thequeenofthewinter @viss-and-pinegar and @changelingsandothernonsense !

this week i'm cheating a little and posting a large portion of the (now published) rewrite of chapter 4 from Cycle of the Serpent! i've posted up to chapter 6's rewrites thus far, and should have 7 and 8 rewritten and updated soon. this chapter features the trio heading to Bleak Falls Barrow, from Emeros' point of view <3

The road twisted narrowly from the bridge, angled and sloping, lined with strange stones. Some appeared intentionally arranged and stuck in their ways, watching the young elves through every crack in their worn surfaces. Some were more incidental, shrugging off the weather. Some appeared to be severed off from old pillars, smoothed by the many years gone by and wondering where their extra heights had gone. Emeros kept an eye on the greenery, on the land that gradually grew more and more distant, the town that faded from view as the three marched up the pathway. The gradual drop in temperature intensified itself the further they got from Riverwood, the dusting of snow that cropped up at the tops of new and unfamiliar trees still preserved this far into Last Seed, and by the looks of the powdery texture, had fallen not too long ago. The pathway in its drastic angles took on more danger, as ice collected at the bases of the evergreens. Meticulous with their footing, the three carried themselves up the path to the barrow, careful to examine each stone they pressed their boots against. Emeros had been in various ruins for any number of purposes over the years. He'd adventured into Ayleid ruins in his earliest days in Cyrodiil, never leaving the first chamber if he could help it, collecting samples of the mosses and fungi that grew within. Sometimes, he'd find an interesting vine, or a plant he hadn't recognized from the surface world. He'd take great pains to preserve them until he could examine them safely, testing new potions and properties, inspiration his guide in every experiment. If he combined this amount of imported trama root with this amount of the unidentified fungi, placed it in an already known potion recipe, how would it change the effects? Would it create something to heal, or to harm? What new concoctions could he make with the native flora of Skyrim? And maybe, if luck was on his side, would he find something previously unknown in this ancient place?

The trio trudged onward, the wind whipping at their faces, brushing flakes of snow like tiny spears against their skin. The cold was one factor all of them wished they'd prepared more thoroughly for, but if they were going to explore this place and bring back the claw, then they had to keep going. Day had long since crest the mountains, rising above them in a lustrous sheen of blue, light bleaching the landscape before them a harsh, eye-pulsing white. As they turned their eyes to the top of the mountain, a strange stone tower came into view. Weathered by the ages and capped with snow, the sight alone sent shivers through the Bosmer. Emeros hissed for the others to get down, snagging the other two by their tunics, hidden behind a massive stone. When Wyndrelis was about to quietly protest, Emeros pressed a finger to his own lips and then gestured to the tower. The other two Mer looked. A figure marched the slim, dreadful bridge from the tower to the mountain, back and forth at an easy pace. Bandits. And they'd almost walked right into their line of sight. "What do we do?" Athenath asked in a hushed tone, partially unsheathing their newly acquired sword. Wyndrelis pressed his spine to the rock they huddled behind, with the spare, occasional glance to the figure. "Emeros, you have a bow. Can you use it?" Wyndrelis asked in a hush, Emeros already nocking an arrow. "I've been hunting in Valenwood since my childhood," he answered, taking aim. He shut one eye, lined up his shot, and stilled his breaths. "Not yet!"

Emeros startled at Athenath's hard whisper, grip on the arrow tighter. He slid it forward, letting the string go slack. He cursed under his breath as he turned to Athenath, brow quirked and eyes narrow. The Altmer pressed palms to the sides of Emeros' head, and as the alchemist was about to protest, his eyes landed on a detail he'd missed. Up the incline, pacing back and forth before them, a bandit that no one else had seen. Two targets, then. He looked to his companions, then to the bandit. This would come down to timing, by his own analysis. If he took one out without the other noticing at first, it would give him a few seconds to get another arrow and put the last one down. Then, they could safely traverse the mountainside. He gave Athenath one last look, this time the slightest gleam of a grin on his lip, not daring to speak too much. He knelt in the snow, nocked his arrow, and waited. When the bandit at the fortress had their back turned, he fired. This arrow pierced through a weak spot in the incline-bandit's armor, injuring them, stunning for a moment before Emeros got another arrow through their neck. He shifted his attentions to the fortress-bandit, who dashed to the crumpled body of their companion. He fired, and this shot went clean through the torso, spearing the upper chest, likely a lung, if he guessed from here. "I think that's all of them." Wyndrelis rose from behind the stone, wiping the snow from his trousers as he grabbed his belongings. The three rushed to the bodies, and as they confirmed that the bandits were dead, Athenath began to rifle through the pockets of the corpses. Emeros sputtered protests, but as the Altmer produced some gold, some new arrows, and a set of leather gauntlets, he found himself complaining much less. They handed the leather gauntlets to Emeros, then stood and stretched. Wyndrelis thought something over for a moment. Then, he knelt, slowly undoing the fastens and buckles of the much warmer-looking armor the bandits wore.

"What in Oblivion are you doing?" Emeros hissed, Wyndrelis looking up at the other momentarily before returning to his task. Athenath joined in, helping Wyndrelis lift the fur-lined piece from the first body before they descended on the second. "It's not like they need it, and we can't run around looking like soldiers forever," Athenath retorted. Wyndrelis agreed, pulling the first set of armor to himself. He shifted his gaze to Athenath, brow knit. "Tell me, why did he get the gauntlets?" Athenath shrugged as they looked up to Emeros momentarily, before handing over a soul gem they'd dug out of a bandits pack Dunmer, who tucked it into his pocket. "Archers usually need them, right? Something about the string?" Emeros gave a small, apprehensive nod, and even though his features were marred with the shock of the pair descending upon the dead like carrion birds, he figured that they had a point. It wasn't like any of them could afford to buy armor right now, and none of them needed to run around dressed as Imperial soldiers in potentially-hostile land. He donned the gauntlets. The leather fit well over his fingers, and most importantly, they were warm. The other two bundled up fur and leather armors, before they stepped into the tower, nudging their steps with extra caution over the frail bridge. Rifling through drawers gave them more gold and a place to toss the Imperial armor without much worry. They'd have to hurry, though. Taking too much time here meant that they were both wasting time they could be using to get in and out of the barrow, and meant that it gave the bandits more time to come find them, and the bodies of their compatriots. Once Athenath and Wyndrelis had donned the bandit armor - "Well, you didn't seem to want it," Wyndrelis shuffled the explanation awkwardly out - the three inched back to the stability of the mountain, the wind whipping furiously around them. The steep pathway lead further upwards, to the enormous stone arches and sharp angles of the ancient ruins. Stairs slick with ice rose up to a gigantic platform, the air thick with worry. Something innate gnawed at Emeros, the warnings of old friends from northern High Rock not to head into similar structures rumored to line the furthest reaches of the province murmuring in the back of his mind. He shook them away. This was not the same. This was something he'd said he'd do, and he would bloody do it.

"We should be on our guard. Two bandits means there's probably more, and if we're not careful, we'll walk right into a trap." "Or another ambush." Wyndrelis joked dryly. Emeros rolled his eyes, but still, he laughed. "Or another ambush." He repeated, grinning. The dark, snow-covered stone gathered in points towards the sky. They made a calculated approach, the three in a line as they focused on any potential movement from the structure. When bandits emerged from the shadows of the ancient, high-arched ruins, the caution came in handy. One of them fired arrows down at the three, barking at them to leave with their lives or they'd gut them like a purse. Athenath flinched and dodged the barrage, Wyndrelis holding up a ward, magicka pouring into his fingertips, collected in arching light. He pushed forward, Emeros using the ward's cover as a shield to fire his own arrows behind. This time, it took several shots, moving as he fired at a simultaneously moving target. He cursed and hissed as he fired at the figure until he saw them kneel, then another, then down. A second bandit charged with a war axe, Wyndrelis using his other hand to fire a bolt of lightning that struck through the middle, jarring the bandit enough to give Athenath an opening. The Altmer charged, bashing the hilt of their sword into the back of the bandits head, hoping they'd only knocked them out. The final bandit rushed Emeros, nearly swiping their blade into him. The Bosmer ducked down by an inch, bringing his own sword from its hilt and striking them through the chest, pushing it as deep as he could muster in the moment. The armor gave way as the bandit struggled to block, a fight that lasted mere seconds and ended just as quickly. The three caught their breaths, snow now pelting down at them from the pale clouds above their heads. Whatever world they'd just ambled into gave them one hell of a welcome. Better than the one they'd all received at the border, Emeros thought as he tugged his cowl tighter, thefurious winds knocking the fabric off his head every time he attempted to right it. Grumbling, he left it around his neck as a scarf, and trudged up the final stairs to the doorway of Bleak Falls Barrow. Adrenaline throttled their veins. The Mer looked between one another. Then, Emeros slowly pushed open the door to the barrow, into the dim chamber that would seal their decision. No going back from here, the decision decreed. No turning back.

#tesblr#wip wednesday#skyrim#the elder scrolls#tes fic#skyrim fic#tes v fanfic#bishop.txt#writeblr#ficblr#cycle of the serpent#oc ; emeros#oc ; wyndrelis#oc ; athenath#my writing

23 notes

·

View notes

Text

Proba-3 will constantly measure Sun's energy output

Proba-3 is such an ambitious mission that it needs more than one single spacecraft to succeed. In order for Proba-3's Coronagraph spacecraft observe the sun's faint surrounding atmosphere, its disk-bearing Occulter spacecraft must block out the fiery solar disk. This means Proba-3's Occulter ends up facing the sun continuously, making it a valuable platform for science in its own right.

The sunward side of the Occulter therefore hosts a dedicated instrument that will maintain a continuous measurement of the sun's total energy output, known as the total solar irradiance, which is a essential variable for climate studies.

The shoebox-sized Davos Absolute Radiometer, DARA, has been supplied to the mission by the Physical Meteorological Observatory Davos, PMOD, in Switzerland.

"Researchers used to talk about the 'solar constant' but in fact it is always changing slightly," explains Wolfgang Finsterle, DARA Principal Investigator at PMOD. "And it's essential to keep track of the total solar irradiance, because it is the dominant energy input to the surface of the Earth.

"It amounts to something like 99.978% of the energy available on Earth, including the conserved solar energy stored in coal and oil. It drives all the dynamic processes of Earth's climate, so even the tiniest variations are hugely significant."

The mountain-based PMOD has been studying total solar irradiance for more than a century, initially with ground-based instruments and then from the 1970s deploying space-based radiometers to acquire a continuous dataset. The World Meteorological Organization has mandated PMOD as the World Radiation Centre to calibrate radiation measurements across global UN monitoring programs.

Wolfgang adds, "Total solar irradiance varies along with the 11-year cycle of solar activity, and one of the most obvious ways to look for long-term energy drift is to compare total solar irradiance between consecutive solar minimia.

"This requires a long time-series of data, ideally coming from multiple instruments because single radiometers will undergo degradation in sensitivity from the hard ultraviolet in the sun's rays they are continuously exposed to. That said any degradation is very gradual: the radiometer aboard the ESA-NASA SOHO solar observatory for instance, which was launched in back 1995, is still working satisfactorily."

DARA's basic operating principle is simple. The radiometer possesses a 5-mm diameter cavity made from black-painted silver, possessing low temperature emissivity. For 15 seconds at a time, sunlight warms the interior of the cavity, then a shutter blade automatically closes at its entrance.

For the next 15 seconds, electric heat maintains the cavity's previous temperature—and the energy needed to maintain this temperature is extrapolated to the unit of total solar irradiance, which is watts per meter squared.

This process continues for the entire lifetime of the instrument—the actuated shutter design employed in DARA has been tested for millions of openings and closings in PMOD's vacuum chamber.

"DARA is an improvement on previous radiometer designs with an optimized cavity design to minimize unwanted straylight and a multi-channel measuring system for self-calibration," adds Wolfgang. "This generation of instrument also possesses a fully digital control loop, allowing the possibility of experimenting with higher frequency observations.

Two versions of this radiometer design have already flown, notes Werner Schmutz of PMOD, who oversaw its development: "A compact version called CLARA flew on Noway's NorSat-1 CubeSat in 2017, remaining operational to this day, while a previous DARA is serving aboard the Chinese FY-3E weather satellite, launched in 2021. So we have high confidence in the design, which can operate whenever the Proba-3 Occulter is pointed at the sun within half a degree of accuracy."

The main difference between Proba-3's DARA and previous radiometers will be its very elongated orbit, which will carry it 60 000 km above Earth's surface. DARA can automatically adjust to slight changes in the size of the solar disk based on how far it is away—which are also due to Earth's yearly elliptical orbit around the sun. All the radiometer needs to know is its position in space and its data gathering compensates for the shift.

3 notes

·

View notes

Text

What is an environmental test chamber and what products does it include

#Environmental test chamber#Climatic test chamber#Temperature test chamber#Humidity test chamber

An environmental test chamber is a device or system used to simulate and control specific environmental conditions. It is widely used in scientific research, engineering testing, product development and quality control.

The environmental test chamber can simulate various environmental conditions, such as temperature, humidity, air pressure, light, vibration, vibration, climate, etc. They usually consist of a closed box, and the environmental conditions inside the box can be precisely regulated and monitored by a control system. The environmental test chamber usually has functions and equipment such as temperature controller, humidity controller, sensor, data logger, etc.

By using environmental test chambers, researchers, engineers, and manufacturers can test and evaluate materials, products, or systems under controlled conditions. For example, they can use test chambers to simulate material properties under extreme temperature conditions, product stability under high humidity, and the reliability of electronic devices under different climatic conditions. These tests can help them understand how the material or product will behave in the context of actual use and make necessary improvements and optimizations.

Environmental test chambers have a wide range of applications, covering many industries, including aerospace, automotive, electronics, pharmaceuticals, food, environmental science, etc. They play an important role in product development, quality control and compliance testing to improve product reliability, stability and adaptability.

There are many different types of products on the market to meet the needs of different fields and applications. Here are some common environmental test chamber products:

Temperature test chamber: used to simulate the test environment under different temperature conditions, can provide low temperature, high temperature or temperature cycle functions.

Humidity test chamber: used to simulate the test environment under different humidity conditions, can achieve high humidity, low humidity or humidity cycle.

Thermal shock test chamber: A combination of temperature and humidity functions is used to simulate the environment of rapid temperature and humidity changes to test the heat and cold resistance of the product.

Vibration test chamber: used to simulate the test environment under different vibration conditions, which can realize sinusoidal vibration, random vibration or shock vibration.

Salt spray chamber: used to simulate the salt spray corrosion environment, often used to test the corrosion resistance of materials and coatings.

Dust test chamber: Used to simulate dust and particulate environments, often used to test the sealing performance of electronic devices and packages.

Climate test chamber: combined with temperature, humidity, light and other environmental factors, used to simulate the test environment under real climate conditions.

ESS Chamber:ESS Chamber can simulate the operation of the product under various environmental stress conditions such as temperature, humidity, vibration and shock. It provides a fast and efficient method for screening products for possible failures and reliability issues during actual use

Uv Testing Chamber:UV testing chamber is a device used to simulate the UV radiation environment and test the weather resistance of materials. It is usually composed of ultraviolet light source, temperature control system, humidity control system, transparent sample rack, etc., which can simulate ultraviolet light exposure in the natural environment, high temperature and high humidity and other conditions for evaluating the weather resistance and durability of materials.

If you want to know more about the relevant products of environmental reliability testing equipment, you can visit Environmental test chamber manufacturer,JOEO ALI testing. They are a professional manufacturer and sales of environmental test chamber and vibration test system in China. Guangdong ALI Testing Equipment Co,. Ltd. specializes in temperature and humidity testing and mechanical vibration testing systems, and is a leader in the field of environmental and reliability testing.

4 notes

·

View notes

Text

who: @meredythrowan where: one of the many maesters chambers within a wing of dedicated care and treatment in the castle of highgarden

the echoing footsteps of the lady of the arbor bounced off the towering marble walls, bathed in the colours of the illuminating stained glass windows. the sun was sinking beneath the currents of the mander outside, and she was based in hues of orange and red alongside the new princess of the westerlands - whilst they painted her golden, she only saw meredyth as blue. her footsteps paced and paced back and forth the end of a bed; a part of her wishing she had just summoned a maester to the florent apartments and yet during their evening walk in the gardens, the very same thing had occurred.

the spreading of numbness in her knees, feeling as she suddenly could hardly see the world around her for the way it blurred and smoothed so quickly. this time she had managed to sit herself amongst a bed of roses, no doubt looking somewhat peculiar to the guests that walked through the sunset that illuminated the gardens of highgarden. the maester's wing was closer than returning to the florent apartments, and whilst lucrezia insisted she would return there and call upon a maester, meredyth rowan had insisted on them going directly to the wing and seeing a maester immediately.

apparently her face had gone strikingly white, all too suddenly; whilst coloured had returned to her cheeks now, there was sudden moments where she felt as though she could not feel anything below the soles of her feet.

the maester had asked her multiple questions, inspected her condition and her temperature; sending a septa to inspect her bust and her hips, asking questions that were more personal in details. questions regarding her cycle, when she had last bled. the questions made it clear what was being suggested, though she were surprised; perhaps as a result of seeing her mother's struggle with pregnancies, carrying and becoming, she did not think such a thing would happen so soon. still, it could only be confirmed should the test carried out upon bags of wheat and barley show any evidence, something the maester was overseeing and inspecting now.

she was thankful meredyth was here, looking over at the woman who sat on the edge of her bed. as lucrezia did her buisness on the opposite side of the divide, meredyth was there to help provide her some relief during the tense moment where she felt her hands were clammy. and now, she waited for what the maesters would determine, looking over at mimi whilst she paced back and forth. "do you think this will take long?" she asked, moving a strand of her chestnut coloured hair from her face.

3 notes

·

View notes

Text

Unveiling the Versatility of High-Temperature Furnaces: Spotlight on the Muffle Furnace 1400 Degree

High-temperature furnaces play a pivotal role in advancing both scientific research and industrial processes. Among the various options available, the Muffle Furnace 1400 Degree stands out as a benchmark of reliability, precision, and efficiency. With its ability to perform under extreme conditions, this furnace is an indispensable asset for laboratories, research facilities, and manufacturing units worldwide. In this comprehensive guide, we explore the features, applications, and unparalleled benefits of the Muffle Furnace 1400 Degree to showcase why it remains a preferred choice.

What Sets the Muffle Furnace 1400 Degree Apart?

The Muffle Furnace 1400 Degree is not just another high-temperature furnace; it is a meticulously engineered device designed to handle processes requiring extreme heat with utmost accuracy. Its ability to reach temperatures as high as 1400°C ensures that it can accommodate a vast array of applications, ranging from material testing to advanced research experiments. Its design incorporates modern technologies to deliver exceptional results while maintaining the integrity and purity of the samples being processed.

Salient Features of the Muffle Furnace 1400 Degree

Extreme Heat Capability: Achieving a maximum temperature of 1400°C, this furnace supports intricate high-temperature operations such as sintering, annealing, and calcination.

Enhanced Insulation: The use of cutting-edge insulation materials minimizes heat loss, ensuring energy efficiency and consistent performance.

Accurate Temperature Control: Advanced digital controllers equipped with programmable settings offer precise temperature regulation, essential for repeatable outcomes.

Robust Construction: Built from durable and high-grade materials, the furnace withstands the rigors of demanding industrial environments without compromising functionality.

User-Friendly Interface: Modern designs include intuitive control panels and safety features, making operation simple and secure for users of all experience levels.

How is the Muffle Furnace 1400 Degree Used?

The versatility of the Muffle Furnace 1400 Degree allows it to cater to a wide variety of applications across industries. Some of its prominent uses include:

Thermal Analysis: Understanding the behavior of materials when subjected to high temperatures, enabling advancements in materials science.

Ash Content Testing: A critical process in industries such as food, fuel, and polymers, where determining residual ash is essential.

Heat Treatment: Improving the mechanical properties of materials like metals and alloys by controlled heating and cooling cycles.

Sintering Processes: Creating solid objects by compacting and heating powders, widely applied in ceramics, metallurgy, and additive manufacturing.

Calcination Studies: Decomposing chemical compounds to analyze their fundamental components, useful in geology and chemical industries.

Glass and Ceramics Production: Essential in the creation of high-quality glassware and ceramics, ensuring uniformity and structural integrity.

Benefits of Choosing the Muffle Furnace 1400 Degree

Consistency and Reliability: The furnace ensures uniform heat distribution, resulting in consistent and dependable outcomes for all applications.

Enhanced Safety: An isolated heating chamber reduces exposure to high temperatures, safeguarding both users and samples.

Energy Efficiency: By utilizing advanced insulation and efficient heating elements, the furnace minimizes energy consumption without sacrificing performance.

Adaptability: Its multifunctional nature makes it suitable for both routine and complex procedures, addressing diverse needs in research and production environments.

Long Service Life: The robust design and use of premium materials ensure that the furnace offers a prolonged operational lifespan, making it a cost-effective investment.

Why Invest in a Muffle Furnace 1400 Degree?

For professionals in fields that demand precision, durability, and high performance, the Muffle Furnace 1400 Degree is an invaluable tool. Its modern design, coupled with its ability to deliver exceptional results across a multitude of applications, makes it a must-have for anyone seeking advanced heating solutions. Whether you are conducting experiments in a laboratory or managing industrial processes, this furnace offers unparalleled support and functionality.

Final Thoughts

The Muffle Furnace 1400 Degree exemplifies excellence in high-temperature technology, making it an indispensable asset for scientific and industrial applications alike. With its robust design, advanced features, and energy-efficient performance, it has set a new standard in high-temperature furnaces. For reliable, top-of-the-line muffle furnaces, Bionics Scientific is your trusted partner. Known for their commitment to innovation and quality, Bionics Scientific provides state-of-the-art solutions tailored to meet the specific needs of researchers and industry professionals. Choose Bionics Scientific for equipment that delivers excellence and empowers progress.

0 notes

Text

Environmental Test Chamber Manufacturers

Roch Mechatronics is a trusted name in the manufacturing of high-quality environmental test chambers, designed to meet the rigorous demands of various industries. Specializing in advanced engineering and innovation, the company offers a wide range of test chambers that cater to diverse testing needs, including temperature, humidity, vibration, and thermal cycling tests.

Environmental test chambers are essential for simulating real-world conditions to evaluate the performance, reliability, and durability of products across industries such as automotive, electronics, aerospace, and pharmaceuticals. Roch Mechatronics stands out by delivering precision-engineered chambers that ensure accurate and consistent results.

The company takes pride in its state-of-the-art manufacturing processes, which combine cutting-edge technology with industry expertise. Roch Mechatronics emphasizes energy efficiency, user-friendly designs, and customizability to meet specific client requirements. Their chambers are equipped with advanced control systems, enabling precise monitoring and adjustment of environmental parameters.

Roch Mechatronics also prioritizes customer satisfaction by offering comprehensive support, from consultation and design to installation and after-sales service. Their team of skilled professionals works closely with clients to understand their unique needs and deliver tailored solutions.

By maintaining stringent quality standards and staying ahead of technological advancements, Roch Mechatronics has earned a reputation as a reliable partner for businesses seeking dependable environmental test chamber solutions. Whether you are testing prototypes or ensuring product compliance, Roch Mechatronics provides the expertise and tools to help you succeed in today's competitive market.

For more details contact us 701165465 [email protected]

#Environmental Test Chamber Manufacturers#Environmental Test Chamber Suppliers#Environmental Test Chamber in India#Environmental Test Chamber in Ghaziabad#Best Environmental Test Chamber in India#Top Environmental Test Chamber Company in India#Environmental Test Chamber Manufacturer in India

0 notes

Text

Lithium-ion battery testing standards by UL and IEC ensure safety in modern applications. Battery test standards address risks like overheating, with methods such as thermal resistance and temperature cycling validating compliance. Meeting every battery test standard builds trust and reliability. ESPEC’s cutting-edge chambers help streamline this process. Contact us today to explore how our solutions can support your safety and compliance goals.

1 note

·

View note

Text

Introduction The importance of environmental testing has grown exponentially as industries seek to ensure the durability and reliability of their products. One of the most commonly used equipment for such testing is the temperature humidity test chamber, which replicates various climatic conditions to determine how materials and products perform under stress. Among these, the LISUN GDJS-015B Temperature Humidity Chamber, also known as a thermal chamber, stands out for its versatility in testing a wide range of products under extreme temperature and humidity conditions. This article delves into the functionality of the LISUN GDJS-015B temperature humidity test chamber and its application in simulating different climatic environments, including high and low temperature, as well as humidity fluctuations. The importance of these tests for different industries, from electronics to automotive parts, will also be explored in detail. The Functionality of the LISUN GDJS-015B Temperature Humidity Test Chamber The LISUN GDJS-015B is a highly sophisticated temperature humidity test chamber designed to test products under simulated climatic conditions, such as high and low temperatures, high humidity, and temperature cycling. The device can control both temperature and humidity, allowing users to create a broad spectrum of environmental conditions. Key Features: • Temperature Range: The chamber operates within a wide temperature range, from -70°C to +150°C, enabling it to test products under both extreme heat and freezing conditions. • Humidity Control: The humidity range spans from 20% to 98% RH, offering comprehensive testing of product durability in moist environments. • Programmable Cycles: The GDJS-015B is equipped with programmable cycles that simulate temperature and humidity variations over time. This allows for testing how materials and components react to prolonged exposure to harsh conditions. The ability to simulate these varied conditions makes the temperature humidity test chamber a critical asset in sectors such as electronics, lighting fixtures, automotive components, and other fields where product reliability is essential. Simulation of Climatic Conditions A temperature humidity test chamber like the LISUN GDJS-015B can simulate a broad range of climatic conditions. By adjusting the temperature and humidity, the chamber mimics extreme environments that products might encounter in real-world applications. Below are some of the most common climatic conditions simulated in such chambers: 1. High-Temperature Testing One of the most basic functions of a temperature humidity test chamber is simulating high-temperature conditions. Products are exposed to elevated temperatures to assess their behavior when subjected to heat. This is critical for materials such as plastics, metals, and electronics, which can degrade under excessive heat. Test Condition Temperature (°C) Time Duration (hours) Humidity (%) High Temp Test 120°C 8 hours 50% RH High-temperature tests are essential for products intended for use in hot climates, industrial environments, or near heat sources like motors and electronics. 2. Low-Temperature Testing In contrast, low-temperature testing simulates environments where products are exposed to freezing or sub-zero conditions. Low-temperature tests are vital for materials and components used in cold climates or applications where freezing temperatures are common, such as outdoor electronics or automotive parts. Test Condition Temperature (°C) Time Duration (hours) Humidity (%) Low Temp Test -40°C 10 hours 30% RH Low-temperature tests help determine whether products remain operational under freezing conditions and whether their structural integrity is affected by extreme cold. 3. Humidity Testing Humidity can have a significant impact on the durability and functionality of products, particularly electronics and materials prone to corrosion. The GDJS-015B temperature humidity test chamber is capable of simulating environments with high moisture content, providing a way to test how products respond to moisture over long periods. Test Condition Temperature (°C) Time Duration (hours) Humidity (%) Humidity Test 40°C 24 hours 98% RH Excess moisture can lead to oxidation, corrosion, and degradation of materials. Therefore, these tests are essential for industries like aerospace, electronics, and automotive, where product longevity is critical. 4. Temperature Cycling Temperature cycling involves exposing products to alternating high and low temperatures over a period of time. This test simulates the effects of temperature fluctuations that materials may experience in real-world settings, such as outdoor environments where daytime temperatures rise and nighttime temperatures fall. Cycle Stage Temperature (°C) Time Duration (hours) Humidity (%) Cycle 1 80°C 4 hours 60% RH Cycle 2 -30°C 4 hours 50% RH This type of testing is particularly important for products that experience frequent environmental changes, such as vehicles, outdoor electronics, and other equipment exposed to the elements. GDJS-015B Temperature Humidity Chamber | Thermal Chamber Applications of the LISUN GDJS-015B Temperature Humidity Test Chamber The temperature humidity test chamber finds widespread applications across several industries. Below are some key areas where the LISUN GDJS-015B plays a crucial role: 1. Electronics Testing Electronic devices, especially consumer products like smartphones, tablets, and computers, require rigorous testing under varying environmental conditions to ensure long-term reliability. The LISUN GDJS-015B can simulate the heat and humidity experienced by these devices during use or storage in different regions, ensuring that they operate effectively without overheating or malfunctioning. 2. Automotive Industry Automotive components are constantly exposed to a wide range of environmental conditions, from extreme heat in engine compartments to freezing temperatures in colder climates. By testing these components in the temperature humidity test chamber, manufacturers can guarantee that their products will perform reliably in all weather conditions. This includes testing everything from electrical systems to plastics, rubbers, and metals. 3. Aerospace Components Aerospace components undergo extreme temperature variations during flight, requiring materials that can withstand both high and low temperatures. The LISUN GDJS-015B provides an ideal platform for simulating these harsh environments, ensuring that materials meet the stringent standards required by the aerospace industry. 4. LED and Lighting Testing LED lighting fixtures are often exposed to varying temperature and humidity levels, particularly when used in outdoor environments. The GDJS-015B temperature humidity test chamber ensures that these lighting products can withstand the conditions they will face in real-world installations, ensuring performance and longevity. Conclusion The LISUN GDJS-015B temperature humidity test chamber is an essential tool for simulating a variety of climatic conditions. Its ability to perform high and low-temperature tests, humidity tests, and temperature cycling allows manufacturers to evaluate the durability and reliability of their products in different environmental conditions. Industries ranging from electronics to aerospace and automotive greatly benefit from the insights provided by these tests, enabling them to deliver products that meet the highest quality standards. By understanding how products behave under extreme heat, cold, and humidity, manufacturers can enhance their designs and produce more durable goods. In today’s competitive market, the LISUN GDJS-015B temperature humidity test chamber offers the precision and versatility needed to ensure product success in a wide range of applications Read the full article

0 notes

Text

Introduction The importance of environmental testing has grown exponentially as industries seek to ensure the durability and reliability of their products. One of the most commonly used equipment for such testing is the temperature humidity test chamber, which replicates various climatic conditions to determine how materials and products perform under stress. Among these, the LISUN GDJS-015B Temperature Humidity Chamber, also known as a thermal chamber, stands out for its versatility in testing a wide range of products under extreme temperature and humidity conditions. This article delves into the functionality of the LISUN GDJS-015B temperature humidity test chamber and its application in simulating different climatic environments, including high and low temperature, as well as humidity fluctuations. The importance of these tests for different industries, from electronics to automotive parts, will also be explored in detail. The Functionality of the LISUN GDJS-015B Temperature Humidity Test Chamber The LISUN GDJS-015B is a highly sophisticated temperature humidity test chamber designed to test products under simulated climatic conditions, such as high and low temperatures, high humidity, and temperature cycling. The device can control both temperature and humidity, allowing users to create a broad spectrum of environmental conditions. Key Features: • Temperature Range: The chamber operates within a wide temperature range, from -70°C to +150°C, enabling it to test products under both extreme heat and freezing conditions. • Humidity Control: The humidity range spans from 20% to 98% RH, offering comprehensive testing of product durability in moist environments. • Programmable Cycles: The GDJS-015B is equipped with programmable cycles that simulate temperature and humidity variations over time. This allows for testing how materials and components react to prolonged exposure to harsh conditions. The ability to simulate these varied conditions makes the temperature humidity test chamber a critical asset in sectors such as electronics, lighting fixtures, automotive components, and other fields where product reliability is essential. Simulation of Climatic Conditions A temperature humidity test chamber like the LISUN GDJS-015B can simulate a broad range of climatic conditions. By adjusting the temperature and humidity, the chamber mimics extreme environments that products might encounter in real-world applications. Below are some of the most common climatic conditions simulated in such chambers: 1. High-Temperature Testing One of the most basic functions of a temperature humidity test chamber is simulating high-temperature conditions. Products are exposed to elevated temperatures to assess their behavior when subjected to heat. This is critical for materials such as plastics, metals, and electronics, which can degrade under excessive heat. Test Condition Temperature (°C) Time Duration (hours) Humidity (%) High Temp Test 120°C 8 hours 50% RH High-temperature tests are essential for products intended for use in hot climates, industrial environments, or near heat sources like motors and electronics. 2. Low-Temperature Testing In contrast, low-temperature testing simulates environments where products are exposed to freezing or sub-zero conditions. Low-temperature tests are vital for materials and components used in cold climates or applications where freezing temperatures are common, such as outdoor electronics or automotive parts. Test Condition Temperature (°C) Time Duration (hours) Humidity (%) Low Temp Test -40°C 10 hours 30% RH Low-temperature tests help determine whether products remain operational under freezing conditions and whether their structural integrity is affected by extreme cold. 3. Humidity Testing Humidity can have a significant impact on the durability and functionality of products, particularly electronics and materials prone to corrosion. The GDJS-015B temperature humidity test chamber is capable of simulating environments with high moisture content, providing a way to test how products respond to moisture over long periods. Test Condition Temperature (°C) Time Duration (hours) Humidity (%) Humidity Test 40°C 24 hours 98% RH Excess moisture can lead to oxidation, corrosion, and degradation of materials. Therefore, these tests are essential for industries like aerospace, electronics, and automotive, where product longevity is critical. 4. Temperature Cycling Temperature cycling involves exposing products to alternating high and low temperatures over a period of time. This test simulates the effects of temperature fluctuations that materials may experience in real-world settings, such as outdoor environments where daytime temperatures rise and nighttime temperatures fall. Cycle Stage Temperature (°C) Time Duration (hours) Humidity (%) Cycle 1 80°C 4 hours 60% RH Cycle 2 -30°C 4 hours 50% RH This type of testing is particularly important for products that experience frequent environmental changes, such as vehicles, outdoor electronics, and other equipment exposed to the elements. GDJS-015B Temperature Humidity Chamber | Thermal Chamber Applications of the LISUN GDJS-015B Temperature Humidity Test Chamber The temperature humidity test chamber finds widespread applications across several industries. Below are some key areas where the LISUN GDJS-015B plays a crucial role: 1. Electronics Testing Electronic devices, especially consumer products like smartphones, tablets, and computers, require rigorous testing under varying environmental conditions to ensure long-term reliability. The LISUN GDJS-015B can simulate the heat and humidity experienced by these devices during use or storage in different regions, ensuring that they operate effectively without overheating or malfunctioning. 2. Automotive Industry Automotive components are constantly exposed to a wide range of environmental conditions, from extreme heat in engine compartments to freezing temperatures in colder climates. By testing these components in the temperature humidity test chamber, manufacturers can guarantee that their products will perform reliably in all weather conditions. This includes testing everything from electrical systems to plastics, rubbers, and metals. 3. Aerospace Components Aerospace components undergo extreme temperature variations during flight, requiring materials that can withstand both high and low temperatures. The LISUN GDJS-015B provides an ideal platform for simulating these harsh environments, ensuring that materials meet the stringent standards required by the aerospace industry. 4. LED and Lighting Testing LED lighting fixtures are often exposed to varying temperature and humidity levels, particularly when used in outdoor environments. The GDJS-015B temperature humidity test chamber ensures that these lighting products can withstand the conditions they will face in real-world installations, ensuring performance and longevity. Conclusion The LISUN GDJS-015B temperature humidity test chamber is an essential tool for simulating a variety of climatic conditions. Its ability to perform high and low-temperature tests, humidity tests, and temperature cycling allows manufacturers to evaluate the durability and reliability of their products in different environmental conditions. Industries ranging from electronics to aerospace and automotive greatly benefit from the insights provided by these tests, enabling them to deliver products that meet the highest quality standards. By understanding how products behave under extreme heat, cold, and humidity, manufacturers can enhance their designs and produce more durable goods. In today’s competitive market, the LISUN GDJS-015B temperature humidity test chamber offers the precision and versatility needed to ensure product success in a wide range of applications Read the full article

0 notes

Text

Ensuring Battery Safety and Performance: A Comprehensive Guide to Lithium-Ion Cell Testing Machines

In today’s rapidly advancing world of electric vehicles (EVs), consumer electronics, and renewable energy systems, lithium-ion batteries have become the cornerstone of modern technology. Their high energy density, lightweight design, and longevity make them a preferred choice across industries. However, ensuring the safety, reliability, and performance of these batteries is crucial. This is where lithium-ion cell testing machines play a vital role.

Why is Lithium-Ion Battery Testing Essential?

Lithium-ion batteries are known for their efficiency, but they can pose safety risks if not tested properly. Issues like thermal runaway, capacity degradation, and inconsistent performance can result in catastrophic failures. Comprehensive testing ensures that:

Battery cells meet safety standards.

Performance metrics are consistent and reliable.

The risk of hazards like short circuits or overheating is minimized.

By investing in state-of-the-art cell testing equipment, manufacturers can enhance product quality and build customer trust.

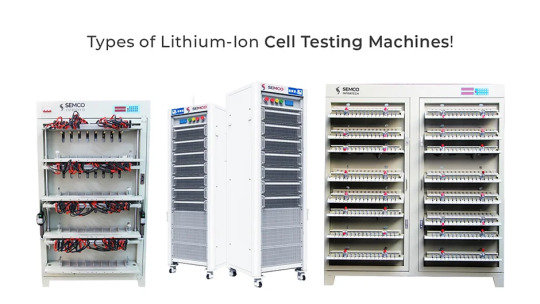

Types of Lithium-Ion Cell Testing Machines

A wide array of testing machines is available to cater to different testing needs. Here are some of the most commonly used ones:

1. Battery Cycle Testers

These machines test the charge and discharge cycles of a battery to assess its longevity and efficiency. Cycle testing is essential for understanding how a battery will perform over time.

2. Cell Sorting Machines

Lithium-ion cell sorting machines are used to categorize cells based on their voltage, capacity, and internal resistance. Accurate sorting ensures that only high-quality cells are used in battery packs.

3. Battery Pack Testers

These devices evaluate the performance of a complete battery pack. They simulate real-world conditions to ensure the pack’s durability and reliability.

4. Environmental Test Chambers

These chambers simulate extreme conditions, such as high temperatures, humidity, or vibrations, to assess a battery’s resilience and safety under various scenarios.

5. Impedance Testers

Impedance testers measure the internal resistance of a cell, which is a key indicator of its health and performance.

Key Features to Look for in Lithium-Ion Cell Testing Machines

When selecting a lithium-ion cell testing machine, it’s important to consider the following features:

Accuracy and Precision: High-quality testing equipment provides accurate and consistent results.

Automation: Automated machines improve efficiency and reduce the chance of human error.

Data Logging: Advanced machines offer robust data analysis and reporting capabilities.

Safety Standards: Ensure the equipment complies with global safety certifications like UL, CE, or ISO.

Benefits of Using Lithium-Ion Cell Testing Machines

Investing in reliable cell testing equipment offers multiple benefits:

Enhanced Product Safety: Comprehensive testing minimizes the risk of battery failures and accidents.

Improved Performance: Testing ensures that batteries deliver optimal performance in real-world applications.

Regulatory Compliance: Proper testing helps manufacturers meet industry standards and regulations.

Cost Efficiency: Identifying and eliminating defective cells reduces long-term operational costs.

Future Trends in Lithium-Ion Cell Testing

With advancements in technology, battery testing machines are becoming smarter and more efficient. Key trends include:

AI Integration: Artificial intelligence is enabling predictive analytics and more precise defect detection.

Faster Testing: New methods are reducing testing times without compromising accuracy.

Sustainability Focus: Eco-friendly testing solutions are gaining popularity to align with green manufacturing practices.

Conclusion

As the demand for lithium-ion batteries continues to soar, ensuring their safety and performance is more critical than ever. High-quality lithium-ion cell testing machines are indispensable tools for achieving this goal. By integrating these advanced systems into the production process, manufacturers can deliver safer, more reliable, and high-performing batteries that meet the needs of a rapidly evolving market.

Invest in the right battery testing equipment today and take a step towards a safer, greener future.

#electric vehicles#energy storage system#lithium ion batteries#lithium ion cell testing machines#cell testing equipment#testing machines#cycle testing#lithium ion cell sorting machines#battery testing machines

0 notes

Text

How Sarok Chemicals Maintains Industry Standards in Product Testing

Product testing forms the backbone of safe chemical manufacturing. Testing labs catch quality issues before they impact production lines. In pigment manufacturing, strict testing prevents common problems like color inconsistency and particle size variations. Labs check for impurities that could affect the final shade. Sarok Chemicals tests the Quality Assurance of Pigment Alpha Blue for each batch through multiple quality checkpoints. These tests examine particle distribution, color strength, and chemical purity. When pigments fail tests, manufacturers face production delays and financial losses. Testing helps maintain standards and keeps manufacturing processes running smoothly.

Why Product Testing Matters in the Chemical Industry

Manufacturing flaws in pigments can trigger chain reactions of production problems. Untested Alpha Blue batches might contain oversized particles that clog spray nozzles. Impure pigments react unexpectedly with base materials, causing color shifts mid-production. Testing catches these issues early through readings and analysis.

Paint manufacturers lose millions when pigments fail quality checks. Testing labs measure dispersion stability under different temperatures and pH levels. Quality control prevents costly recalls and material waste. Modern testing equipment detects trace contaminants down to parts per million.

Without proper testing, manufacturers risk batch rejections and production line shutdowns. Chemical testing protects both equipment and end products from contamination.

Key Testing Processes at Sarok Chemicals

Chemical labs run multiple tests to validate Alpha Blue pigment quality. X-ray diffraction confirms crystal structure purity in each batch. Light fastness testing exposes samples to UV rays, measuring color stability. Temperature cycling tests check pigment behavior from -20°C to 180°C.

Quality checks start with particle size distribution analysis. Labs use laser diffraction to spot oversized particles. Rheology tests measure flow behavior in different base materials. pH testing confirms acid-base balance for stable dispersion.

Environmental testing tracks emissions during processing. Labs monitor wastewater for metal traces and organic compounds. Air quality sensors detect dust particles during powder handling. Specialized filters capture and measure environmental release levels.

Performance testing simulates real manufacturing conditions. Paint samples undergo accelerated weathering in salt spray chambers. Heat stability tests run for 100 hours at peak temperatures. Dispersion tests in various solvents check compatibility ranges. Color strength measurements use calibrated for accuracy. Each test builds a complete picture of pigment performance.

Meeting Global Industry Standards

Exporting Alpha Blue pigments to diverse markets requires meeting strict global standards. Each country and industry has unique certification needs, creating complex challenges for manufacturers. Sarok Chemicals ensures every batch aligns with these requirements through careful planning and testing.

European clients demand REACH compliance to meet environmental and safety standards. For the U.S. market, FDA-approved testing is necessary for materials used in food packaging. South Korean regulations emphasize precise particle size documentation, while Germany requires rigorous dispersion stability checks.

Sarok Chemicals also adapts to specific industry needs. Pharmaceutical companies expect high purity levels, while paint manufacturers prioritize UV stability under extreme conditions. Customized quality certificates match exact client specifications, ensuring smooth imports and exports.

Innovations in Testing Technology

Modern labs face the challenge of balancing speed and accuracy in testing. Sarok Chemicals addresses this by combining advanced technology with practical techniques. Accurate colorimeters ensure precise color values in seconds, supporting consistent batch quality. Computerized particle analyzers track size variations efficiently, preventing production delays.

Automation reduces human errors during testing. Systems like automated sample handlers process multiple batches simultaneously, saving time. Real-time monitoring alerts labs to potential inconsistencies before they escalate. Temperature-controlled chambers provide stable conditions, delivering accurate results year-round.

Data management is equally important. Electronic lab records store testing histories, aiding compliance and analysis. Advanced software identifies trends, helping predict potential issues early. These innovations ensure that Sarok maintains reliable quality across every batch, meeting customer expectations worldwide.

Conclusion

Product testing is not just a step in manufacturing—it’s necessary to get quality, reliability, and trust. For Sarok Chemicals, ensuring the Quality Assurance of Pigment Alpha Blue that goes beyond meeting just the clients expectations. It’s about delivering consistency and upholding a reputation made by years of hard work. By embracing advanced testing technologies and adapting to global certification requirements, Sarok Chemicals minimizes risks and ensures smooth operations for manufacturers worldwide.

Through meticulous testing and compliance with international standards, Sarok Chemicals plays a vital role in helping industries avoid costly errors and maintain their competitive edge. Every test performed reflects their commitment to quality, ensuring Alpha Blue pigments meet the expectations of customers across industries and borders.

0 notes

Text

Protecting Products from Corrosion: The Role of Pacorr's Salt Spray Chamber in Quality Control

Comprehensive Guide to Salt Spray Chamber – Ensuring Corrosion Resistance Testing

Introduction

In today's competitive industrial landscape, product durability and quality assurance are paramount. Corrosion, a persistent issue in manufacturing, can compromise the lifespan and performance of products. To combat this, industries employ advanced testing instruments like the Salt Spray Chamber. At pacorr.com, we offer state-of-the-art Salt Spray Chambers designed to test and ensure the corrosion resistance of materials under simulated environmental conditions. This article explores the functionality, benefits, and applications of the Salt Spray Chamber.

What is a Salt Spray Chamber?

A Salt Spray Test Chamber is a specialized testing instrument used to evaluate the corrosion resistance of coatings, paints, metals, and other materials. It simulates a saline environment by creating a controlled atmosphere of salt fog, mimicking real-world conditions that materials face over time. The results help manufacturers ensure that their products can withstand corrosive environments.

Features of Pacorr’s Salt Spray Chamber

Pacorr’s Salt Spray Chamber offers cutting-edge features that make it a preferred choice for manufacturers across industries:

1. Durable Construction

Built with corrosion-resistant materials, ensuring longevity and consistent performance.

2. Advanced Temperature Control

Equipped with precise temperature regulation for accurate simulation of environmental conditions.

3. User-Friendly Interface

Intuitive controls and digital displays make it easy to set up and monitor test parameters.

4. Compliance with Standards

Conforms to international standards like ASTM B117, ISO 9227, and JIS Z 2371, ensuring reliable results.

Benefits of Using a Salt Spray Chamber

The Salt Spray Chamber offers several advantages to industries seeking quality assurance:

1. Enhanced Product Durability

Identifies potential weaknesses in coatings and materials before products reach the market.

2. Cost Savings

Detects flaws early in the production cycle, reducing costly recalls and replacements.

3. Improved Customer Satisfaction

Guarantees high-quality, corrosion-resistant products that meet consumer expectations.

4. Regulatory Compliance

Helps manufacturers comply with global quality standards, boosting market reputation.

Applications of the Salt Spray Chamber

The Salt Spray Chamber is a versatile instrument used in various industries:

1. Automotive

Tests the corrosion resistance of vehicle parts like chassis, bumpers, and fasteners.

2. Electronics

Ensures protective coatings on electrical components can withstand harsh conditions.

3. Aerospace

Validates the durability of materials exposed to extreme weather conditions.

4. Construction

Examines the resistance of metal fixtures, hardware, and structural elements.

Why Choose Pacorr’s Salt Spray Chamber?

At pacorr.com, we are committed to delivering testing solutions that meet the highest standards of quality and reliability. Our Salt Spray Chambers Price are trusted by leading manufacturers to ensure superior product performance. By integrating advanced features and robust designs, Pacorr provides an invaluable tool for industries striving for excellence in quality assurance.

Conclusion

The Salt Spray Chamber is an indispensable instrument for evaluating the corrosion resistance of materials. Its ability to simulate real-world conditions helps manufacturers produce durable, high-quality products. At pacorr.com, we understand the importance of precision and reliability in testing equipment. Explore our range of Salt Spray Chambers to elevate your quality assurance processes and ensure your products stand the test of time.

0 notes

Text

Copper Testing Machine| Tech Trivial

Introducing our cutting-edge Copper Testing Machine, meticulously engineered by Tech Trivial. Experience precision and efficiency in analyzing copper materials like never before.

• A Programmed Timer automatically controls the UV & Condensation cycles of the UVCON &

programming.

• Temperature is measured & controlled by a solid state circuit. A PT-100 Sensor is

mounted in a black aluminum panel on the specimen rack.

• The temperature is set by the Operator & monitored by Digital panel meter on the

Control Panel. Note:- This version is with UV lamps but Xenon Arc (ISO 4892-2) is also available on request.

The instrument Generally comprises:-

• A Double Walled Chamber for sample burning with front glass door

• A Burner settable 0- 90 o angle and precise gas control system including gas regulator

• Microprocessor control Burner Moving system

• Sample Holding System (adjustable both vertically and horizontally)

• Digital Timer for flame application (can be preset for 1 to 99 sec)

• Digital timer for flame observation after flame is removed.

For more information contact us.

0 notes

Text

Environmental test chamber test standards

The test standards of the environmental test chamber usually cover the performance of the equipment, test methods, environmental conditions and safety requirements. The following are some common environmental test chamber related standards:

International standards IEC 60068 Series: Environmental test standards published by the International Electrotechnical Commission (IEC), including various environmental test methods such as temperature, humidity, vibration and shock. ISO 9022: Standard for the testing of electrical and electronic equipment under environmental conditions, including climatic, mechanical and chemical environmental effects.

National standards GB/T 2423 series: Chinese national standard, covering different methods of environmental testing, such as: GB/T 2423.1: High temperature test. GB/T 2423.2: Low temperature test. GB/T 2423.3: wet heat test. GB/T 31485: Environmental test standard specifically for lithium-ion batteries, including temperature, humidity, cycle life and other test requirements.

Industry standards MIL-STD-810: United States military standard for testing equipment performance in extreme environments for military and aerospace applications. AEC-Q100: Test standard for automotive electronic components, covering environmental adaptability and reliability testing.

Product standards IEC 62133: Standard for safety and performance testing of portable sealed batteries, for lithium batteries, etc. UL 2054: Safety standard for batteries and battery components, primarily for the North American market.

Test method Temperature and humidity test: Set the temperature and humidity conditions in the test box according to the relevant standards for testing. Vibration and shock testing: Mechanical vibration and shock testing is performed according to standards to assess the product's tolerance. Salt spray testing: Used to assess the corrosion resistance of materials, especially in Marine or chemical environments.If you need more models about our test equipment, please reference our https://www.chamber-testing.com/#climate-chamber-manufacturers

1 note

·

View note

Text

The Quadra Growth Chamber: A Game Changer for Controlled Environmental Research and Horticulture

Introduction

In the world of scientific research, agriculture, and horticulture, controlled environments play a pivotal role in ensuring optimal growth conditions for plants, testing agricultural products, and conducting experiments. One such innovative solution is the Quadra Growth Chamber manufacturer, designed to offer highly precise and customizable environments for plant growth and experimentation. As a leading manufacturer of growth chambers, Quadra is at the forefront of providing advanced, reliable, and versatile growth chamber solutions for a wide range of applications.

What is a Quadra Growth Chamber?

A Quadra Growth Chamber is a sophisticated piece of equipment used to simulate various environmental conditions for plant growth, research, and agricultural testing. The chamber is equipped with advanced controls for temperature, humidity, light intensity, CO2 levels, and other factors critical for plant development. This precision allows researchers, horticulturists, and agricultural professionals to study plant growth under highly controlled and reproducible conditions, free from the fluctuations and uncertainties of the outside environment.

Manufacturers like Quadra have engineered these growth chambers to cater to the evolving needs of industries focused on plant science, crop research, climate control, and product testing. Quadra growth chambers are ideal for applications in agricultural research, biotechnology, botanical research, and horticultural development.

Visit Also:- Understanding Humidity Test Chambers: Features, Types, and Uses

Key Features of Quadra Growth Chambers

Customizable Environmental Control The most significant feature of the Quadra Growth Chamber is its ability to precisely control a variety of environmental factors. These factors can include:

Temperature: The growth chamber allows users to set and maintain specific temperatures (ranging from ambient to extreme conditions) to simulate different seasons or climates.

Humidity: Adjustable humidity levels ensure that plants experience the optimal moisture conditions required for their growth cycle.

Lighting: LED lighting systems can be customized to simulate day/night cycles, adjusting light intensity and wavelength for different types of plants.

CO2 Levels: Some chambers are equipped with CO2 regulation systems to simulate different levels of atmospheric CO2 concentrations, crucial for studying photosynthesis.

Energy Efficiency and Sustainability Quadra Growth Chambers are designed with energy efficiency in mind, ensuring that the chambers provide optimal environmental conditions while minimizing energy consumption. This helps reduce operating costs and environmental impact, especially in long-term research setups.

Advanced User Interface and Controls Quadra growth chambers are often equipped with easy-to-use touchscreens or remote-access interfaces, allowing users to monitor and adjust environmental settings. This intuitive interface also includes data logging features that can track the conditions over time, which is crucial for scientific accuracy and experimentation.

Multi-Stage Climate Control Some models offer multi-stage temperature control, providing researchers with the ability to simulate day-night cycles, seasonal temperature fluctuations, or even the changing climate conditions expected in specific geographic regions.

Compact and Modular Design Quadra growth chambers are designed to be space-efficient without compromising on capacity. The modular design allows for easy expansion, with the possibility of linking multiple chambers together for larger-scale experiments or broader environmental tests.

Applications of Quadra Growth Chambers

Agricultural Research In agriculture, research into crop growth and development under controlled conditions is essential for improving yield and resilience. Quadra growth chambers help researchers simulate various climate conditions, such as temperature fluctuations, seasonal changes, or drought, enabling better predictions for crop behavior in different environments.

Biotechnology and Genetic Engineering For biotechnologists, growth chambers offer a controlled setting to experiment with genetically modified organisms (GMOs) or hybrid plants. These controlled environments are crucial when working with genetically altered crops that require consistent conditions to thrive.

Horticultural Development Horticulturists use these chambers to study plant species, optimize cultivation practices, and accelerate the breeding of new plant varieties. Whether growing delicate ornamental plants, vegetables, or fruits, the ability to control environmental factors ensures better results in terms of growth and quality.

Climate Simulation and Environmental Research Quadra growth chambers are invaluable for climate researchers who want to simulate and study the effects of climate change on plant life. This technology can replicate different environmental stressors like increased heat, drought, or excessive rainfall, allowing scientists to better understand how plants react under such conditions.

Seed Germination and Propagation For nurseries, agriculturalists, and researchers, Quadra growth chambers help optimize conditions for seed germination and early plant growth. With precise control over light, humidity, and temperature, seeds can be germinated more efficiently, ensuring healthy plants for the next stage of growth.

The Advantages of Choosing Quadra Growth Chamber

Precision and Reliability The hallmark of Quadra growth chambers is their precision in controlling critical environmental variables. This allows researchers to carry out consistent, reproducible experiments with high levels of accuracy.

Durability and Low Maintenance Built with high-quality materials and components, Quadra growth chambers are designed to be durable and require minimal maintenance. This makes them a cost-effective solution for long-term use in research facilities, universities, or agricultural testing sites.

Support and Service Quadra, as a manufacturer, offers exceptional customer support and maintenance services. Their expertise in the design and operation of growth chambers ensures that customers can access guidance when needed and keep their systems running optimally.

Customization and Scalability Quadra understands that each research facility or agricultural operation has unique needs. As such, they provide customizable solutions, allowing users to select specific features and functionalities to meet their exact requirements.

Global Presence With a strong reputation in the market, Quadra growth chambers are in use across the world. From research labs in universities to large-scale agricultural projects, Quadra has a proven track record of providing dependable equipment for diverse applications.

Visit Also:- Understanding Stability Test Chambers: Features, Types, and Applications

Conclusion

The Quadra Growth Chamber represents the pinnacle of innovation and technology in environmental control. With its advanced features, reliability, and versatility, Quadra continues to lead the way in providing solutions that support a wide range of applications in plant science, agriculture, biotechnology, and environmental research. Whether you're a researcher looking to understand plant behavior under controlled conditions or a horticulturist seeking to optimize plant growth, investing in a Quadra Growth Chamber ensures that your work will be done under the most precise and optimal conditions available today.

By leveraging the capabilities of a Quadra Growth Chamber, industries can expect accelerated advancements in research, crop development, and environmental sustainability.

#QuadraGrowthChamber#PlantGrowthChamber#ControlledEnvironment#AgricultureInnovation#HorticultureTech#PlantResearch#GrowthChamberTechnology#AgriculturalEquipment#EnvironmentalControl#PlantScience#ClimateControlledGrowth#CropResearch#IndoorFarming#ResearchChamber#SustainableAgriculture#PrecisionFarming#BiotechResearch

0 notes

Text

The Role of Muffle Furnace Manufacturers in Advancing Laboratory Efficiency

In modern laboratories, the demand for precision and reliability is paramount. Among the essential tools enabling such accuracy is the muffle furnace, a piece of equipment that is indispensable for applications ranging from material testing to ashing and heat treatment. At the heart of the innovation in this sector are muffle furnace manufacturers, who continuously refine their designs to meet the dynamic needs of science and industry.

What Makes Muffle Furnaces Essential?

Muffle furnaces are compact, high-temperature furnaces that use an insulated chamber to isolate the sample from direct exposure to heat sources. This unique design ensures uniform temperature distribution, making them suitable for tasks like calcination, annealing, sintering, and loss-on-ignition tests. These furnaces are essential in fields such as metallurgy, ceramics, pharmaceuticals, and environmental analysis, where precise thermal processing is critical.

By shielding samples from direct flame and gases, muffle furnaces maintain the purity and integrity of materials, making them the preferred choice for sensitive experiments. Reliable muffle furnace manufacturers ensure these essential qualities are met with precision, durability, and safety in every product they deliver.

Innovations by Leading Muffle Furnace Manufacturers

In the competitive arena of laboratory equipment, muffle furnace manufacturers are pushing boundaries with innovative technologies. Advances such as:

Programmable Controllers: Modern furnaces feature highly intuitive interfaces with advanced programmable settings, allowing users to define precise temperature profiles for complex procedures.

Energy Efficiency: Manufacturers now focus on using high-grade insulation materials and eco-friendly components to minimize energy consumption while ensuring superior performance.

Rapid Heating and Cooling Rates: Many manufacturers are optimizing heating elements and chamber designs to achieve faster temperature cycles, reducing downtime for laboratories.

Enhanced Safety Features: Auto-shutoff mechanisms, overheat protection, and low-emission designs ensure that both the equipment and the operator remain safe during operations.

These innovations not only improve the operational efficiency of laboratories but also extend the life and reliability of the equipment.

How Muffle Furnace Manufacturers Address Industry-Specific Needs

Different industries have unique thermal processing requirements. For instance:

In Metallurgy: Muffle furnaces are used for heat treatment processes such as hardening, annealing, and tempering.

In Environmental Science: These furnaces aid in testing the combustion properties of materials and determining their organic or inorganic content.

In Research Laboratories: They are used for experiments that require clean, controlled environments, such as chemical decomposition and crystallography.

By offering tailored solutions, muffle furnace manufacturers help their clients achieve optimal results, regardless of the industry. Customization options such as chamber sizes, temperature ranges, and control systems further add value.

Why It’s Crucial to Choose the Right Manufacturer

Choosing the right muffle furnace manufacturer is as important as selecting the furnace itself. A trusted manufacturer ensures not just superior product quality but also provides post-purchase support, including installation, maintenance, and troubleshooting. Additionally, they adhere to international quality and safety standards, offering customers peace of mind.

Future Trends in Muffle Furnaces

The future of muffle furnaces lies in increased automation, IoT integration, and enhanced data analytics. Manufacturers are exploring how to integrate remote monitoring, predictive maintenance, and cloud-based controls to provide seamless operation. As technology evolves, muffle furnace manufacturers are likely to adopt AI-powered systems for even greater precision and efficiency in thermal processing.

Conclusion

The advancements driven by muffle furnace manufacturers are a testament to their commitment to precision, reliability, and innovation. Whether you're operating in a research laboratory or an industrial setting, investing in a high-quality muffle furnace can transform your workflow.

For those seeking top-notch solutions, Bionics Scientific stands out as a trusted name, offering state-of-the-art muffle furnaces tailored to meet modern laboratory demands. Their expertise and dedication to quality make them a preferred choice among professionals.

0 notes