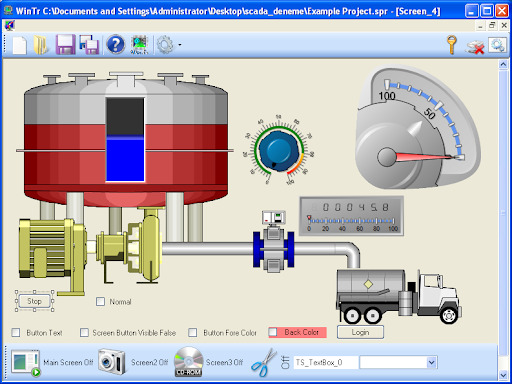

#Supervisory Control and Data Acquisition Industry

Explore tagged Tumblr posts

Text

#SCADA#Supervisory Control And Data Acquisition#SCADA software#software#WinTr#industrial#industrial engineering#webcore#old web#techcore#cybercore

8 notes

·

View notes

Text

Battery-operated Remote Terminal Units Market Research, Size, Share, Analysis, Overview and Regional Outlook Study 2017 – 2032

The market for Remote Terminal Units (RTUs) that are battery-operated allows them to function in isolated or off-grid regions where access to a reliable power supply is restricted. RTUs are electronic devices used to monitor and manage remote equipment and processes in many different industries, such as oil and gas, water and wastewater management, power distribution, and telecommunications. Here is a summary of the market for battery-operated RTUs, including information on demand:

Market Overview: Due to a number of circumstances, the market for battery-operated RTUs has been expanding. The need for battery-operated RTUs has been fueled by the necessity for remote monitoring and control capabilities in various industries, particularly in places with weak power infrastructure. These devices enable efficient monitoring and control of remote assets without the requirement for a continual external power source thanks to their dependable and autonomous operation.

Demand Drivers:

1. Real-time monitoring and control of assets: situated in remote or isolating locations are necessary in many businesses. Without the requirement for a sizable power infrastructure or reliance on cable connections, battery-operated RTUs allow for effective data gathering, monitoring, and control of these assets.

2. Applications Off-Grid: In off-grid applications where access to a dependable power supply is restricted or nonexistent, battery-operated RTUs are widely used. Examples include remote water pumping stations in rural areas, environmental monitoring stations, remote weather monitoring stations, and remote oil and gas wellheads.

3. Emergency and Temporary Installations: Whereas immediate deployment is necessary, battery-powered RTUs are also used in emergency and temporary installations. When catastrophe recovery, building projects, or temporary infrastructure installations are taking place, these machines can instantly provide remote monitoring and control capabilities.

4. Environmental Monitoring: Data collection from remote weather stations, air quality sensors, and water quality sensors are all important aspects of environmental monitoring that battery-operated RTUs play a key role in. Continuous monitoring is made possible in remote or environmentally delicate locations by these equipment.

5. IoT Connectivity: The need for battery-operated RTUs has increased as the Internet of Things (IoT) is becoming more widely used in a variety of businesses. These devices are essential parts of IoT networks because they provide seamless data transmission, communication, and control between remote assets and central management systems.

Here are some of the key benefits for Stakeholders:

Remote Monitoring and Control

Flexibility and Mobility

Cost-Effective Deployment

Resilience to Power Outages

Integration with IoT and Smart Grids

Increased Data Accessibility

Environmental Monitoring and Compliance

Rapid Deployment for Emergency Response

Redundancy and Reliability

Scalability and Future-Proofing

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/battery-operated-remote-terminal-units-market/10333/

Market Segmentations:

Global Battery-operated Remote Terminal Units Market: By Company • SIEMENS • SENECA • Omniflex • King Pigeon Communication Co.,Limited • Servelec Group • TEKBOX • Micro Sensor Co., Ltd. • Hitachi Group • Remsdaq Ltd Global Battery-operated Remote Terminal Units Market: By Type • GPRS • GSM • Modular • Others Global Battery-operated Remote Terminal Units Market: By Application • Power Industry • Government and Utilities • Industrial Global Battery-operated Remote Terminal Units Market: Regional Analysis The regional analysis of the global Battery-operated Remote Terminal Units market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Battery-operated Remote Terminal Units market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Battery-operated Remote Terminal Units in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Battery-operated Remote Terminal Units in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: TheAsia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Battery-operated Remote Terminal Units in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Battery-operated Remote Terminal Units in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/battery-operated-remote-terminal-units-market/10333/

Reasons to Purchase Battery-operated Remote Terminal Units Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Battery-operated Remote Terminal Units#RTU Market#Remote Monitoring#Wireless RTU#Industrial Automation#Battery-powered RTU#IoT (Internet of Things)#Energy Efficiency#Data Collection#Telemetry#Remote Control#Battery-powered Sensors#SCADA (Supervisory Control and Data Acquisition)#Energy Management#Off-grid Applications#Renewable Energy#Battery Technology#Remote Sensing#Communication Protocols#Edge Computing#Connectivity Solutions#Remote Data Acquisition#Condition Monitoring#Asset Management.

0 notes

Text

PLC, SCADA, and AVEVA: How They Work Together in Automation

PLC :- programmable logic controller

SCADA:- Supervisory Control and Data Acquisition

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#PLC#AVEVA#industry#SCADA#scada systems#blog#google#solutions#software#human machine interface#machinery

3 notes

·

View notes

Text

Automation and Digital Monitoring in Anaerobic Wastewater Treatment Systems

As the global focus intensifies on sustainability, energy efficiency, and environmental compliance, wastewater treatment technologies are evolving rapidly. One area experiencing transformative advancements is anaerobic wastewater treatment, a process favored for its low energy consumption and biogas generation potential. Traditionally considered complex and operator-dependent, anaerobic systems are now increasingly leveraging automation and digital monitoring to improve reliability, scalability, and performance.

This integration of intelligent technologies is enabling plant operators to maintain optimal biological activity, reduce operational risks, and comply with stringent anaerobic wastewater treatment discharge norms—all while maximizing resource recovery.

Understanding Anaerobic Wastewater Treatment

Anaerobic wastewater treatment is a biological process that breaks down organic matter in the absence of oxygen, producing biogas (primarily methane and carbon dioxide) and treated effluent. It's particularly suited for treating high-strength wastewater from industries such as food and beverage, dairy, pulp and paper, petrochemicals, and pharmaceuticals.

Key Advantages:

Energy efficiency: No aeration is required.

Resource recovery: Generates biogas, which can be used for heating or electricity.

Lower sludge production: Compared to aerobic systems.

Smaller footprint: High-rate systems like UASB (Upflow Anaerobic Sludge Blanket) or EGSB (Expanded Granular Sludge Bed) reactors offer compact solutions.

Despite these benefits, anaerobic wastewater treatment is sensitive to operational conditions such as temperature, pH, hydraulic load, and nutrient balance. Without proper monitoring and control, performance fluctuations and system failures can occur. This is where automation and digital monitoring come in.

The Role of Automation in Anaerobic Wastewater Treatment

1. Real-Time Process Control

Modern anaerobic systems are equipped with Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems that continuously monitor critical process parameters such as:

pH and alkalinity

Temperature

Oxidation-reduction potential (ORP)

Gas composition (CH₄, CO₂, H₂S)

Hydraulic retention time (HRT)

Organic loading rate (OLR)

Real-time feedback allows operators to fine-tune operations instantly. For example, if methane content drops or hydrogen sulfide levels spike, automatic alerts and control actions (e.g., adjusting feed rates or chemical dosing) can prevent system upset.

2. Automated Feed Control

To maintain microbial stability, automated dosing systems are used to regulate influent loading based on preset thresholds. These systems use flow meters, chemical sensors, and predictive analytics to adjust feed volume and composition in real time.

This is particularly valuable in industries where wastewater characteristics can vary throughout the day or week. By automating feed and nutrient dosing, treatment performance remains consistent without operator intervention.

3. Gas Handling Automation

Anaerobic reactors produce biogas as a valuable byproduct. Automation plays a key role in gas flow regulation, pressure monitoring, and flare control. Advanced systems also integrate biogas upgrading units, converting raw gas into pipeline-quality biomethane.

Automation ensures safe, continuous biogas handling—minimizing energy losses and maximizing energy recovery.

Digital Monitoring: Visibility, Insight, and Optimization

Beyond traditional automation, digital tools provide a new layer of intelligence and decision support.

1. IoT Sensors and Cloud Platforms

Internet of Things (IoT)-enabled sensors are now standard in anaerobic wastewater treatment facilities. These wireless devices transmit real-time data to cloud-based platforms, allowing operators and managers to:

Access plant status remotely

Compare multi-site performance

Identify trends and anomalies

Automate data logging and regulatory reporting

Cloud dashboards with visual analytics make it easy to track KPIs like COD removal efficiency, biogas yield, and uptime metrics.

2. Predictive Maintenance

One of the most significant advantages of digital monitoring is predictive maintenance. By analyzing sensor data and equipment performance trends, AI algorithms can anticipate failures in components such as:

Pumps and mixers

Heating systems

Membrane units in AnMBRs

Gas compressors and storage tanks

Early detection of wear or fouling allows for proactive service, reducing costly downtime and extending equipment life.

3. AI-Driven Process Optimization

Machine learning (ML) models can correlate thousands of data points to recommend optimal operating conditions. For instance, they can suggest adjustments in:

Organic loading rate (OLR)

Buffer dosing (e.g., bicarbonate)

Temperature or mixing intensity

This results in higher methane yield, better effluent quality, and lower operating costs over time.

Compliance and Reporting Automation

In many regions, regulatory bodies require detailed operational data from anaerobic treatment systems. Digital solutions now enable automated compliance reporting, including:

Effluent discharge logs (BOD, COD, TSS)

Sludge production volumes

Energy generation and consumption

Maintenance records and incidents

Automating compliance helps facilities avoid penalties, maintain certifications (e.g., ISO 14001), and build stakeholder trust.

Use Cases in Industry

1. Food and Beverage Plants

Facilities handling dairy, beer, or meat waste are increasingly installing smart anaerobic digesters to recover biogas and meet ZLD targets. Automation ensures consistent output despite fluctuating waste loads.

2. Textile and Pulp & Paper

Industries producing complex effluents benefit from advanced control to prevent biomass washout and maintain stable methane production under varying conditions.

3. Municipal WWTPs

Larger cities now integrate AnMBRs and automated digesters in centralized plants to handle sewage with minimal energy input and enhanced sludge stabilization.

Challenges and Considerations

Despite their benefits, automated and digitalized systems face certain barriers:

High upfront costs for smart sensors, SCADA, and cloud integration.

Data overload can be overwhelming without proper analytics.

Cybersecurity risks in connected environments.

Skilled workforce required to interpret and act on insights.

However, as the cost of technology drops and digital literacy improves, these challenges are increasingly being mitigated.

The Road Ahead

The future of anaerobic wastewater treatment is undeniably digital. Advances in AI, IoT, and machine learning are making it possible to operate highly efficient, self-optimizing treatment systems with minimal manual intervention. Furthermore, integration with Enterprise Resource Planning (ERP) and Environmental, Social, and Governance (ESG) frameworks allows for comprehensive sustainability reporting and resource planning.

Expect to see a growing adoption of containerized, AI-managed anaerobic systems in remote areas and developing economies, where infrastructure may be limited but digital networks are expanding.

Conclusion

Automation and digital monitoring are redefining how anaerobic wastewater treatment systems are operated, maintained, and optimized. By enabling real-time control, predictive analytics, and remote visibility, these technologies turn conventional treatment plants into smart, efficient, and sustainable systems. For industries and municipalities aiming to meet environmental goals while reducing costs, the digital transformation of anaerobic treatment offers a compelling path forward.

1 note

·

View note

Text

Enhancing Water Network Efficiency in Municipal Supply Systems Using Pressure Reducing Stations

Urban and semi-urban areas rely on extensive water distribution networks to deliver consistent water supply across residential, commercial, and industrial zones. One of the biggest challenges in these networks is managing fluctuating water pressure caused by elevation changes, demand variations, and pumping dynamics. To combat these inconsistencies, Pressure Reducing Valves (PRVs) and complete Pressure Reducing Stations (PRS) have become vital tools for municipalities aiming to enhance network performance, minimize leakage, and optimize supply.

The Problem of High and Unstable Pressure

In municipal water distribution, water is often pumped at high pressure to overcome long distances and elevation gradients. However, this high upstream pressure, if left unregulated, can cause burst pipelines, excessive leakage, and water hammer effects. The situation worsens in low-lying areas or during periods of reduced consumption, when pressure naturally spikes.

Without proper pressure control mechanisms, municipal utilities face higher operating costs, frequent maintenance needs, and increased non-revenue water (NRW)—a significant problem in aging water infrastructures.

Role of Pressure Reducing Stations in Water Distribution

A Pressure Reducing Station (PRS) is a specialized setup designed to control and stabilize water pressure before it enters distribution zones or supply branches. It typically includes:

Pressure Reducing Valves (PRVs)

Bypass lines for maintenance or emergencies

Isolation valves

Strainers and filters

Instrumentation (gauges, transmitters, flow meters)

Flow control or surge protection equipment

These stations are strategically placed across the pipeline network, especially near elevation drops, zone boundaries, or critical supply junctions. By dividing the system into pressure-managed zones, PRSs allow for better control, fewer system failures, and optimized water usage.

Maintaining Consistent Flow and Supply

One of the biggest advantages of PRVs is their ability to maintain a constant downstream pressure, regardless of fluctuations in upstream pressure. This means consumers at various elevations receive consistent water pressure, improving service quality while reducing the risk of pipeline fatigue or bursts.

For instance, in a hilly municipality, PRVs prevent excess pressure from building up in low-lying areas while ensuring adequate flow to elevated neighborhoods. The result is a balanced and equitable water supply that supports both residential and commercial usage.

Reducing Non-Revenue Water (NRW)

Non-Revenue Water—water lost through leaks, theft, or unmetered usage—is a serious concern for municipalities. High-pressure zones are more prone to leakage, as old pipes and joints are not designed for prolonged overpressure. By reducing pressure to optimal levels, PRVs decrease leakage volumes and extend pipeline lifespan.

Studies have shown that even a 10% pressure reduction can result in over 30% reduction in leakage rates. Over time, this leads to cost savings, improved water accountability, and a more sustainable water supply model.

Automation and Remote Monitoring

Modern PRV stations can be equipped with smart controllers and actuators that allow dynamic pressure adjustments based on time of day, demand, or remote operator input. Integration with SCADA (Supervisory Control and Data Acquisition) systems offers real-time monitoring of pressure trends, flow rates, and valve performance.

In case of emergency conditions such as pipeline ruptures or backflow risks, automated stations can respond instantly—closing valves or reducing pressure to protect the system. These automated responses eliminate delays and reduce the risk of large-scale water losses.

Long-Term Reliability and Easy Maintenance

PRVs designed for municipal systems are often pilot-operated, providing precise regulation and smooth operation even under variable flow conditions. Their robust construction, corrosion-resistant bodies, and easily serviceable components ensure years of reliable operation with minimal maintenance.

Periodic inspections, calibration, and flushing keep the stations in top condition—ensuring that the city’s water infrastructure performs optimally despite growing demand and aging assets.

Conclusion

Pressure Reducing Stations are indispensable for modern water supply networks. They do more than manage pressure—they protect infrastructure, reduce water losses, improve service quality, and lay the foundation for smarter, more resilient cities.

By investing in well-designed, automated PRV systems, municipalities not only enhance operational efficiency but also move closer to the goal of sustainable, equitable, and accountable water distribution.

0 notes

Text

PC Based Automation Market Size Driving the Next Generation of Industrial Intelligence

As industries continue to evolve toward smarter, data-driven operations, the PC Based Automation Market Size stands out as a pivotal enabler of intelligent manufacturing. These systems combine the power of personal computers with advanced control technologies to provide superior flexibility, processing power, and integration capabilities across a broad range of industrial applications.

Overview

According to Market Size Research Future, the PC Based Automation Market Size was valued at USD 36.7 Billion in 2023 and is projected to reach USD 59.4 Billion by 2030, growing at a compound annual growth rate (CAGR) of 7.25% from 2024 to 2030.

PC based automation systems are widely adopted across manufacturing, energy, transportation, and utilities. Their ability to centralize control, interface with multiple devices, and run complex algorithms gives them an edge over traditional programmable logic controllers (PLCs) in high-performance and scalable environments.

Market Size Segmentation

The PC Based Automation Market Size is segmented based on Offering, Component, Industry, and Region.

By Offering:

Hardware

Software

Services

By Component:

Human Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Programmable Automation Controllers (PAC)

Industrial PCs

Input/Output Devices

By Industry:

Automotive

Oil & Gas

Chemicals

Pharmaceuticals

Energy & Power

Aerospace & Defense

Food & Beverage

Water and Wastewater Treatment

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Market Size Trends

1. Rise of Smart Factories and Industry 4.0

PC based automation is integral to Industry 4.0 initiatives, enabling real-time data processing, AI-based analytics, and seamless cloud integration. Manufacturers are adopting these systems to achieve predictive maintenance, process optimization, and operational efficiency.

2. Convergence of IT and OT

The integration of Information Technology (IT) and Operational Technology (OT) is accelerating, with PC based systems serving as the bridge. They support open architecture, multiple operating systems, and connectivity standards like OPC UA and MQTT.

3. Increased Focus on Edge and Cloud Computing

Industrial PCs are increasingly being deployed at the edge for faster response times. Simultaneously, PC based systems are supporting hybrid models with cloud integration for centralized monitoring and analytics.

4. Demand for Open and Scalable Systems

Unlike proprietary PLC systems, PC based automation offers open platforms that are easier to upgrade and expand. This flexibility makes it ideal for dynamic environments with evolving operational needs.Segment Insights

Automotive Industry

PC based automation systems manage robotic assembly lines, material handling, and quality inspection systems in automotive manufacturing. Their precision and adaptability are essential in EV production and custom configurations.

Energy & Power

These systems monitor and control turbines, generators, and energy distribution networks. Integration with smart grid systems enables predictive analytics and efficient load balancing.

Pharmaceuticals

In pharma manufacturing, PC based automation ensures accurate mixing, dosage control, and regulatory compliance (such as FDA and GMP standards). They also support electronic batch records and audit trails.

Water and Wastewater

Water treatment plants use PC based SCADA systems to monitor pH levels, flow rates, and chemical dosing in real time. Automation ensures efficient resource usage and compliance with environmental regulations.

End-User Insights

Small and Medium Enterprises (SMEs)

With their modular design and cost-effectiveness, PC based automation systems are increasingly accessible to SMEs looking to digitize their production lines without heavy upfront investment.

Large Enterprises

Enterprises with multiple facilities use centralized PC based systems for real-time coordination, performance benchmarking, and remote troubleshooting across global operations.

System Integrators and OEMs

Automation integrators prefer PC based platforms for their programming flexibility and compatibility with custom applications, sensors, and industrial protocols.

Key Players

The PC Based Automation Market Size includes established automation giants and emerging players delivering robust, scalable solutions. Key companies include:

Siemens AG

Rockwell Automation, Inc.

ABB Ltd.

Advantech Co., Ltd.

Beckhoff Automation GmbH & Co. KG

Mitsubishi Electric Corporation

Schneider Electric SE

Bosch Rexroth AG

Omron Corporation

General Electric Company

These players are focusing on innovations such as AI-enabled industrial PCs, cybersecurity integration, and seamless cloud connectivity to enhance their offerings.

Conclusion

The PC Based Automation Market Size is transforming industrial operations by bridging the gap between traditional automation and digital intelligence. Its scalability, high computing power, and real-time processing capabilities make it an essential pillar of smart manufacturing and digital transformation strategies.

As global industries gear up for more autonomous and data-centric operations, PC based automation will continue to provide the backbone for agile production, resilient infrastructure, and intelligent decision-making.

Trending Report Highlights

Stay updated with emerging technologies and transformative sectors with these insightful reports:

Gyroscope Market Size

BLE Beacons Market Size

Audio IC Market Size

Microcontroller Unit (MCU) Market Size

Digital Mobile Radio (DMR) Market Size

Factory Automation Sensor Market Size

Mining Automation Market Size

USB Devices Market Size

AI-Powered Storage Market Size

Quantum Dots Market Size

Industrial Radiography Market Size

P2P Antennas Market Size

0 notes

Text

Best Industrial Automation Courses in 2025

Introduction

Industrial automation is becoming a vital part of modern manufacturing and production. In 2025, as industries move towards smarter technologies, learning automation skills has become important for students, engineers, and technicians. If you are planning a career in this field, choosing the right course is the first step toward success.

What is Industrial Automation?

Industrial automation involves using machines, control systems, and software to operate processes with minimal human involvement. This includes the use of PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), robotics, and sensors. These systems help improve efficiency, safety, and productivity in industries.

Why Learn Industrial Automation in 2025?

In today’s competitive job market, industries are looking for professionals who understand automation systems. Companies are shifting to smart factories and using advanced tools to monitor, control, and improve their operations. Learning industrial automation gives you the skills needed for jobs in manufacturing, production, maintenance, and system design.

Top Course Features to Look For

When choosing an industrial automation courses in 2025, here are the key features to consider:

1. Beginner to Advanced Levels

Look for a course that suits your experience level. Beginners can start with the basics of PLC programming, wiring systems, and sensors. Advanced learners should look for topics like SCADA systems, robotics, and industrial IoT.

2. Hands-on Training

Good courses offer practical sessions using real or simulated automation systems. These labs help you understand how automation works in real-life industrial settings.

3. Industry-Relevant Tools

Make sure the course includes popular software and tools used in the industry such as Siemens TIA Portal, Allen Bradley PLCs, HMI design, and robotic arms.

4. Flexible Learning Options

Courses that are available in online, offline, or hybrid formats are best suited for different learning needs. Online courses are great for self-paced learning, while classroom sessions offer better interaction and direct support.

5. Certifications and Placement Support

Courses that provide a certificate of completion or industry-recognized credentials can help boost your resume. Some institutes also offer placement assistance or internship opportunities.

Who Should Enroll?

Diploma or engineering students interested in electrical, mechanical, or instrumentation fields

Working professionals looking to upgrade their skills

Anyone interested in the future of smart manufacturing

Conclusion

2025 is the perfect time to learn industrial automation as industries continue to evolve with new technologies. Choose a course that matches your learning goals and provides hands-on experience with real-world tools. By gaining the right skills and knowledge, you can build a strong career in the growing field of industrial automation.

0 notes

Text

Integrated Automation System (IAS) Market, Industry Recent Developments and Latest Technology 2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Integrated Automation System (IAS) Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Integrated Automation System (IAS) Market Share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Integrated Automation System (IAS) Market?

The integrated automation system (IAS) market is expected to grow at a CAGR of 5.6% during the forecast period of 2024 to 2032.

What are Integrated Automation System (IAS)?

An Integrated Automation System (IAS) is an advanced technological solution engineered to unify and enhance diverse industrial processes within a single integrated framework. Through the integration of control systems, sensors, actuators, and software applications, IAS enables smooth communication and coordination among various components and subsystems, facilitating efficient monitoring, management, and control of activities such as production, logistics, and quality assurance. With its capacity to consolidate data, offer real-time insights, and automate repetitive tasks, IAS boosts productivity, lowers operational expenses, and enhances overall efficiency across a broad spectrum of industrial operations.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1880

What are the growth prospects and trends in the Integrated Automation System (IAS) industry?

The integrated automation system (IAS) market growth is driven by various factors. The market for Integrated Automation Systems (IAS) is experiencing swift expansion, fueled by the growing demand for efficient industrial automation and streamlined operational workflows. With businesses increasingly prioritizing enhanced productivity and cost-effectiveness, IAS solutions have become indispensable across diverse sectors such as manufacturing, energy, automotive, and healthcare. These systems offer seamless integration of control mechanisms, sensors, and software applications, facilitating optimized production, logistics, and quality control processes. Moreover, the increasing adoption of Industry 4.0 principles and the Internet of Things (IoT) further accelerates the IAS market growth, as organizations acknowledge the benefits of centralized data management, real-time monitoring, and predictive maintenance capabilities provided by these sophisticated automation systems. Hence, all these factors contribute to integrated automation system (IAS) market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Component:

Hardware

Software

Services

Type:

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

Supervisory Control and Data Acquisition (SCADA)

Human Machine Interface (HMI)

Others

Industry Vertical:

Manufacturing

Oil and Gas

Energy and Utilities

Automotive

Aerospace and Defense

Chemicals

Pharmaceutical and Healthcare

Food and Beverage

Others

End User:

Small and Medium Enterprises (SMEs)

Large Enterprises

Application:

Process Automation

Discrete Automation

Connectivity:

Wired

Wireless

Functionality:

Plant Automation

Machine Automation

Deployment:

On-premises

Cloud-based

End-Use:

Industrial

Commercial

Solution:

Control Systems

Robotics

MES (Manufacturing Execution System)

Industrial IoT (Internet of Things)

Others

Service:

Consulting

Integration and Implementation

Maintenance and Support

Industry 4.0 Enabler:

Big Data Analytics

Artificial Intelligence

Industrial Cybersecurity

Cloud Computing

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

India

Japan

South Korea

Australia

New Zealand

ASEAN

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA.

Who are the key players operating in the industry?

The report covers the major market players including:

Siemens AG

Schneider Electric SE

Emerson Electric Co.

Honeywell International Inc.

Rockwell Automation Inc.

Mitsubishi Electric Corporation

Yokogawa Electric Corporation

Omron Corporation

Bosch Rexroth AG

General Electric Company

Johnson Controls International plc

Fanuc Corporation

Schneider Electric SE

Hitachi Ltd.

View Full Report: https://www.reportsandinsights.com/report/Integrated Automation System (IAS)-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Programming Techniques for PLC Controllers in Complex Industrial Processes

Introduction to PLC Controllers in Industrial Automation

Programmable Logic Controllers (PLCs) play a foundational role in industrial automation, offering precise, real-time control over machinery and systems. Their robust design and programming flexibility make them essential in complex industrial environments, from manufacturing lines and HVAC systems to chemical plants and packaging facilities. PLCs are capable of managing intricate, multi-step processes with minimal human intervention, improving productivity, consistency, and operational safety.

Structured Programming for Enhanced Flexibility

One of the core programming approaches in modern automation is structured programming. Built on the IEC 61131-3 standard, PLCs support multiple programming languages, including Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST). These languages enable engineers to develop modular code—functions or routines that can be reused, tested independently, and scaled as needed.

Structured programming improves clarity, simplifies troubleshooting, and makes large automation projects more manageable. In applications where control logic must adapt to different conditions or production stages, this modular approach allows for flexible logic definition and efficient system updates.

Integration with Frequency Converters for Optimized Control

Modern industrial processes often rely on motors that must operate at variable speeds. By integrating PLC controllers with frequency converters, also known as inverters or VFDs (Variable Frequency Drives), engineers can fine-tune motor control based on real-time requirements. PLCs send commands to adjust speed, torque, or acceleration according to changing system loads, environmental conditions, or product flow.

This integration enhances process stability, reduces energy usage, and prevents unnecessary mechanical wear. For example, in HVAC systems or conveyor lines, the ability to ramp motors up or down smoothly reduces strain on both the equipment and power infrastructure.

Advanced Communication Protocols for Seamless System Integration

In large-scale automation networks, connectivity between components is crucial. PLCs must communicate with devices such as sensors, actuators, Human-Machine Interfaces (HMIs), and Supervisory Control and Data Acquisition (SCADA) systems. To enable this, modern PLCs support communication protocols like Modbus, CANopen, EtherCAT, and RS485.

These protocols facilitate real-time data exchange across systems, allowing centralized control, monitoring, and data logging. With seamless integration, operators can visualize process states, remotely adjust settings, or trigger maintenance alerts—all from a single interface. Communication-enabled PLCs also support cloud integration and IoT-based monitoring, making them a key part of Industry 4.0 environments.

Precision and Real-Time Responsiveness in Complex Applications

For high-speed or critical operations, real-time responsiveness is essential. PLCs are designed with fast scan cycles and deterministic logic execution, enabling them to react within milliseconds. This capability ensures that time-sensitive tasks—such as synchronizing a robotic arm, detecting faults on a packaging line, or managing pressure in a chemical reactor—are executed reliably and safely.

In addition to digital signals, PLCs also handle analog inputs and outputs, which are vital in processes that require precise measurement and control of variables like temperature, pressure, or flow rate. Their ability to manage these signals with minimal latency ensures that systems remain responsive under varying conditions.

Robust Design for Harsh Industrial Conditions

Industrial environments are often harsh, featuring high levels of dust, moisture, vibration, or electromagnetic interference. PLC controllers are engineered with rugged components and protective features to ensure long-term operation under these demanding conditions. Features such as reinforced casings, temperature-resistant electronics, and EMI shielding enable PLCs to maintain stable performance in environments where conventional computers or microcontrollers might fail.

This robustness minimizes unplanned downtime and reduces maintenance frequency, making PLCs a reliable choice for mission-critical systems.

Scalability for Expanding Automation Needs

As industrial operations evolve, the ability to scale control systems becomes a major advantage. PLCs are inherently modular—supporting expansion with additional I/O modules, communication interfaces, and memory capacity. Engineers can add new sensors, actuators, or logic routines without replacing the core controller.

This scalability ensures that a system can grow alongside the business. Whether upgrading machinery, increasing production capacity, or integrating new technologies, PLCs provide a future-ready solution that supports both current needs and long-term innovation.

Conclusion: Building Smarter Automation with Advanced PLC Programming

Advanced programming techniques for PLC controllers are essential for managing the increasing complexity of industrial automation. Structured, modular programming, real-time integration with motor drives, robust communication, and hardware designed for tough environments all contribute to highly responsive and efficient control systems.

By leveraging these programming practices, engineers can create scalable, reliable, and intelligent automation frameworks that reduce costs, improve safety, and optimize performance. As industry trends continue toward digitalization and smart manufacturing, the role of well-programmed PLC systems will only grow in significance—serving as the core intelligence behind the machines that drive modern industry.

0 notes

Text

Industrial Automation Market Size, Share, Growth, Trends, Demand and Opportunity Analysis

Industrial Automation Market Segmentation, By Components (Sensors, Industrial Robots, Industrial PC, Machine Vision, Industrial 3D Printing, Human-Machine Interface (HMI), Field Instruments, Control Valves, and Others), Mode of Automation (Semi-Automation and Fully-Automation), Systems (PID, Model Based Control, and Others), Solution (Programmable Logic Controller (PLC), Distributed Control System (DCS), Supervisory Control and Data Acquisition (SCADA), Enterprise Level Controls, Programmable Automation Control (PAC), Plant Asset Management (PAM), Digitalization, Functional Safety, and Emission Control), Type (Programmable Automation, Fixed or Hard Automation, Integrated Automation, and Flexible or Soft Automation), End User (Process Industries and Discrete Industries) - Industry Trends and Forecast to 2032

The global industrial automation market size was valued at USD 196.94 billion in 2024 and is expected to reach USD 372.70 billion by 2032, at a CAGR of 8.30% during the forecast period.

The base year for calculation in Industrial Automation Market business report is taken while the historic year which will tell how the market will perform in the forecast years by informing what the market definition, classifications, applications, and engagements are. This report is also all-embracing of the data which covers market definition, classifications, applications, engagements, market drivers and market restraints that are based on the SWOT analysis. The large scale Industrial Automation Market report is a comprehensive study about the market which tells about the market status in the forecast period .

An excellent Industrial Automation Market research report can be generated only with the leading attributes such as highest level of spirit, practical solutions, committed research and analysis, innovation, talent solutions, integrated approaches, most up-to-date technology and dedication. Hence, all the above aspects are firmly followed by DBMR team while building this market report for a client. Furthermore, influencing factors such as market drivers, market restraints and competitive analysis is studied with the SWOT analysis which is the most established tool when it comes to generate market research report. With Industrial Automation Market report, build a strong organization and make better decisions that take business on the right track.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Industrial Automation Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-industrial-automation-market

Industrial Automation Market Overview

**Segments**

- On the basis of component, the global industrial automation market is segmented into hardware, software, and services. The hardware segment includes programmable logic controller (PLC), supervisory control and data acquisition (SCADA), distributed control system (DCS), human-machine interface (HMI), and others. The software segment consists of enterprise asset management, warehouse management system, predictive maintenance, manufacturing execution system, and others. Additionally, the services segment comprises training, maintenance, consulting, and others. - Based on industry, the market is classified into automotive, electrical and electronics, aerospace, oil and gas, pharmaceuticals, food and beverage, chemicals, and others. The automotive sector is expected to witness significant growth due to the increasing adoption of automation technologies in manufacturing processes to improve efficiency and productivity. The electrical and electronics industry is also projected to surge as automation helps in enhancing quality control and reducing production costs. - Regarding geography, the global industrial automation market is analyzed across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is anticipated to dominate the market share owing to the rapid industrialization in countries like China and India, coupled with the growing demand for automation solutions to streamline manufacturing operations. North America and Europe are also expected to exhibit substantial growth due to the presence of key players and technological advancements in the region.

**Market Players**

- Some of the major market players in the global industrial automation market include ABB Ltd., Siemens AG, Emerson Electric Co., Rockwell Automation, Inc., Schneider Electric, Mitsubishi Electric Corporation, General Electric, Yokogawa Electric Corporation, Honeywell International Inc., and Bosch Rexroth AG. These companies are focusing on strategic initiatives such as partnerships, acquisitions, and product launches to strengthen their market position and expand their customer base. Additionally, constant innovation in technologies and solutions is a key strategy adopted by these players to stay ahead in the competitive landscape.

The global industrial automation market is witnessing a significant transformation driven by technological advancements and the increasing demand for enhancing operational efficiency across various industries. One of the emerging trends in the market is the integration of artificial intelligence (AI) and machine learning capabilities into automation systems, enabling predictive maintenance, autonomous decision-making, and optimization of production processes. This integration is poised to revolutionize the industrial landscape by enabling real-time data analytics, proactive maintenance strategies, and improved resource utilization. Companies are increasingly investing in AI-powered automation solutions to gain a competitive edge and meet the evolving demands of the market.

Another key trend shaping the industrial automation market is the proliferation of collaborative robots, also known as cobots. These robots are designed to work alongside human operators, enhancing the flexibility and agility of manufacturing operations. Cobots are being utilized in various industries, including automotive, electronics, and consumer goods, to perform tasks that require precision, such as assembly and material handling. The rise of cobots is driving efficiency gains, reducing the need for complex safety systems, and enabling companies to quickly adapt to changing production requirements.

Moreover, the industrial automation market is witnessing an increased focus on cybersecurity measures to safeguard critical infrastructure against potential cyber threats. With the growing connectivity of industrial systems and the adoption of Industrial Internet of Things (IIoT) technologies, the risk of cyber attacks has heightened. As a result, organizations are prioritizing the implementation of robust cybersecurity protocols, including network monitoring, encryption, and access control, to mitigate risks and ensure the integrity of automation systems.

In terms of market dynamics, the global industrial automation market is anticipated to experience steady growth in the coming years, driven by the expanding manufacturing sector, the integration of advanced technologies, and the focus on operational excellence. The adoption of automation solutions is poised to increase across industries such as automotive, aerospace, pharmaceuticals, and food and beverage, as companies seek to improve process efficiency, product quality, and compliance with regulatory standards. Additionally, the ongoing trend towards smart manufacturing and the Industrial Internet of Things (IIoT) is expected to drive further advancements in industrial automation, enabling real-time data monitoring, predictive maintenance, and enhanced production capabilities.The global industrial automation market is undergoing a significant transformation due to technological advancements and the increasing demand for operational efficiency enhancement across various industries. One of the emerging trends in the market is the integration of artificial intelligence (AI) and machine learning capabilities into automation systems. This integration allows for predictive maintenance, autonomous decision-making, and optimization of production processes, leading to real-time data analytics, proactive maintenance strategies, and improved resource utilization. Companies are investing in AI-powered automation solutions to gain a competitive edge and cater to the evolving market demands.

Another noteworthy trend shaping the industrial automation market is the rise of collaborative robots, or cobots. These robots are designed to work alongside human operators, increasing the flexibility and agility of manufacturing operations. Cobots find applications across industries like automotive, electronics, and consumer goods to perform precision tasks such as assembly and material handling. The adoption of cobots drives efficiency gains, reduces the need for complex safety systems, and enables quick adaptation to changing production requirements, enhancing overall operational capabilities.

Furthermore, cybersecurity measures are becoming increasingly critical in the industrial automation sector to protect critical infrastructure against cyber threats. With the growing connectivity of industrial systems and the adoption of Industrial Internet of Things (IIoT) technologies, the risk of cyber attacks has escalated. Organizations are focusing on implementing robust cybersecurity protocols like network monitoring, encryption, and access control to mitigate risks and ensure the integrity of automation systems.

Looking ahead, the global industrial automation market is poised for steady growth driven by the expanding manufacturing sector, technological advancements, and a focus on operational excellence. Automation solutions are expected to witness increased adoption across various industries like automotive, aerospace, pharmaceuticals, and food and beverage to enhance process efficiency, product quality, and compliance with regulatory standards. The industry's shift towards smart manufacturing and the Industrial Internet of Things (IIoT) is anticipated to drive further advancements in industrial automation, enabling real-time data monitoring, predictive maintenance, and enhanced production capabilities. Key players in the market are likely to continue focusing on innovation and strategic partnerships to maintain a competitive edge and cater to the evolving needs of the industry.

The Industrial Automation Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-industrial-automation-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Pointers Covered in the Industrial Automation Market Industry Trends and Forecast

Industrial Automation Market Size

Industrial Automation Market New Sales Volumes

Industrial Automation Market Replacement Sales Volumes

Industrial Automation Market By Brands

Industrial Automation Market Procedure Volumes

Industrial Automation Market Product Price Analysis

Industrial Automation Market Regulatory Framework and Changes

Industrial Automation Market Shares in Different Regions

Recent Developments for Market Competitors

Industrial Automation Market Upcoming Applications

Industrial Automation Market Innovators Study

Browse More Reports:

Global Body Butter Market Global Aliphatic Thinners Market Asia Pacific Single Board Computer Market Asia-Pacific Plastic Surgery Devices Market Global Vacuum Packaging Market Asia-Pacific Whole Exome Sequencing Market Global Elastomeric Coating Market Global Polyglycolic Acid Market Global Garden Tools Market Global RegTech Market Europe Stroke Market Asia-Pacific Pest Control for Livestock Market Asia-Pacific Skin Tightening Market Global Alcoholic Psychosis Treatment Market Global Concealed Weapon Detection Systems Market Global Phytonutrient Ingredients Market Global Structural Core Market Global Poultry Feed Anticoccidials Market Global Air Separation Plant Market Global Myocarditis Disease Market Global Silicone film Market Global Lever Handles Market Asia-Pacific Massive Open Online Courses (MOOCS) Market Middle East and Africa Projection Mapping Market Global Water Quality Monitoring Market Global Aarskog Syndrome Treatment Market Global Solar Panel Recycling Market North America Nerve Regeneration and Repair Market Europe Nerve Regeneration and Repair Market Asia-Pacific IgG4-Related Disease Market Global Rhabdomyolysis Treatment Market Global Wastewater Treatment Market Global Bio Based Polytrimethylene Terephthalate (PTT) Market Global Anastomosis Device Market Global Rubber Conveyor Belts Market Global Fluid and Lubricant Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

"

0 notes

Text

Automation is the future — and SCADA (Supervisory Control and Data Acquisition) systems are at its core.

From monitoring remote assets to managing entire plants, SCADA integrates sensors, software, and control systems to ensure efficiency, safety, and intelligent decision-making.

📚 In this detailed article, you’ll learn: ✔️ What SCADA is and how it works ✔️ Key components: RTUs, PLCs, HMIs, servers ✔️ Real-world applications in energy, water, and manufacturing ✔️ Major benefits and future trends

📘 Powered by: ECAAICO – Smarter and Green Engineering

#automation#instrumentation#sensors#renewable#renewable resources#plc#batteries#renewable energy#solar cells#solar panels

0 notes

Text

Predictive Maintenance in Heavy Steel Industries: Boost Productivity

Predictive maintenance (PdM) is becoming a key option in the demanding heavy steel industries. There are equipment failure can lead to significant financial losses, safety hazards, and unscheduled downtime. Predictive maintenance in steel industries; provides a clever, data-driven method to preserve equipment health, and optimizes operations. As these industries deal with mounting pressure to cut expenses and boost productivity.

Why Predictive Maintenance is Crucial for Heavy Steel Industries

Extreme circumstances, such as high temperatures, enormous weights, and continuous vibration, are present in steel plants.

To reach productions targets, the sector depend on enormous gear such metal furnaces, rollers, conveyors, and casting equipment that must run constantly.

Any unplanned equipment failure has the potential to stop the entire production line, resulting in significant losses.

Here are some reasons; why this industry benefits greatly from predictive maintenance:

Minimizes unplanned downtime can avoid production interruptions by scheduling repairs during scheduled outages by anticipating failures in advance.

In a hazardous situation, preventing equipment failure lowers the chance of accidents.

Labor, equipment, and materials are saved by concentrating maintenance efforts just; where they are required.

Frequent condition monitoring prolongs the life of machinery by spotting small problems before they become serious ones.

Overall factory efficiency rises with fewer disruptions and more effective machinery.

Technologies Behind Predictive Maintenance

A variety of cutting-edge technologies are using in the heavy steel industry to monitor, analyze, and interpret machine data when PdM is used. Important elements consist of:

Real-time data on temperature, vibration, pressure, lubrication, and other variables is gathered via sensors and IOT devices.

AI models examine both live and historical data to find trends and anticipate potential malfunctions.

Large amounts of data are processed and stored via cloud-based platforms. So, they enable remote monitoring from different locations.

To aid in problem diagnosis and maintenance scenario testing, virtual copies of actual assets replicate current conditions.

PdM tools, including shaft alignment services, are integrated with Supervisory Control and Data Acquisition (SCADA) systems to provide centralized monitoring.

Common Use Cases in Steel Plants

Numerous crucial pieces of machinery and procedures in the production of steel can benefit from predictive maintenance:

Tracking temperature and vibration aids in the early detection of wear or misalignments.

Temperature and pressure sensors in blast furnaces can notify operators of anomalies before harm is done.

Electrical sensors in electric arc furnaces (EAFs) identify erratic current flow as a sign of electrode deterioration or malfunction.

Condition monitoring keeps mechanical breakdowns and motor burnout at bay.

Challenges in Implementation

Predictive maintenance has several advantages. However, there are drawbacks to its application in the heavy steel sector:

Sensors, software, and integration must be purchasing in advance when setting up PdM systems.

Custom solutions or modifications may be necessary; if legacy equipment is incompatible with contemporary IoT platforms.

Expertise in equipment monitoring and data processing is crucial yet frequently absent.

Strategic planning, leadership support, and training are necessary to transition from a traditional maintenance culture to a predictive model.

Real-World Impact and ROI

Remarkable gains in operational and financial performance get reporting by steel producers who have used predictive maintenance. For example, after putting PdM systems in place, multinational steel companies reported up to 30% lower maintenance expenditures, 40% less downtime, and 20% longer asset lifespans.

Final Remarks

Predictive maintenance is a calculated investment in the heavy steel industry’ future, not only a technical advancement. Steel producers need to implement more intelligent, flexible maintenance techniques as competition heats up.

Thus, predictive maintenance allows to less risk, cut expenses, and maintain the smooth operation of the steel production process by using real-time data.

So, our team also deals in many Laser Alignment Services, including Windmill Laser Alignment Services, EOT Crane Alignment, and other Geometrical Alignment Services.

0 notes

Text

SCADA Market Insights on Technological Advancements and Emerging Applications in Manufacturing and Utilities

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global SCADA Market Size, Share & Trends Analysis Report By Offering (Hardware, Software, Services), Component (Programmable Logic Controller, Remote Terminal Unit, Human-Machine Interface), End User (Process Industries, Discrete Manufacturing, Utilities), Region, Market Outlook And Industry Analysis 2031"

The global SCADA market is estimated to reach over USD 25.21 billion by 2031, exhibiting a CAGR of 11.6% during the forecast period.

Get Free Access to Demo Report, Excel Pivot and ToC: https://www.insightaceanalytic.com/request-sample/2123

The SCADA (Supervisory Control and Data Acquisition) system, which integrates both hardware and software, allows industrial organizations to monitor, collect, and analyze real-time data across various domains. It also facilitates local or remote control of industrial operations and supports the management of log files, as well as communication with devices, sensors, valves, pumps, and motors.

The global SCADA market is experiencing growth, driven by the increasing adoption of mobile SCADA systems and the ongoing Industry 4.0 transformation in the manufacturing and processing sectors. Furthermore, the rapid advancement of cloud computing technology is positively influencing the expansion of the SCADA market. However, challenges such as high installation and maintenance costs, along with the rising threat of industrial network intrusions, may hinder market growth. Conversely, the continued development of wireless sensor networks is expected to present significant opportunities for the SCADA market throughout the forecast period.

List of Prominent Players in the SCADA Market:

Rockwell Automation,

Schneider Electric,

Emerson Electric,

Siemens,

ABB,

General Electric,

Honeywell International,

Omron,

Yokogawa Electric

ABB (Switzerland)

Azbil Corporation (Japan)

Capula Ltd. (UK)

ELYNX TECHNOLOGIES LLC (US)

Emerson Electric Co. (US)

Enbase LLC, Ing. (US)

Fuji Electric Co. Ltd. (Japan)

GENERAL ELECTRIC (US)

Hitachi Ltd. (Japan)

Honeywell International,

Inductive Automation LLC (US)

Mitsubishi Electric Corporation (Japan)

OMRON corporation (Germany)

Progea srl (Italy)

Rockwell Automation Inc. (US)

Schneider Electric (France)

Schweitzer Engineering Laboratories Inc. (US)

Siemens (Germany)

TOSHIBA CORPORATION (Japan)

Valmet (Finland)

Willowglen Systems (Canada)

Yokogawa Electric Corporation (Japan)

Expert Knowledge, Just a Click Away: https://calendly.com/insightaceanalytic/30min?month=2025-02

Market Dynamics:

Drivers:

The increasing development of smart buildings in emerging economies is expected to significantly contribute to the overall growth of the SCADA market. Moreover, the rising adoption of smart devices and the expanding number of internet users further bolster market expansion. Additionally, the integration of big data analytics and cloud computing enhances service delivery across various sectors, positively impacting the market. Ongoing research and development (R&D) efforts are also advancing the capabilities of supervisory control and data acquisition (SCADA) hardware and software solutions, supporting overall market growth.

Challenges:

Conversely, factors such as fluctuations in oil prices and the high installation and maintenance costs of SCADA systems are likely to impede market growth. Furthermore, the increasing threat of cyberattacks poses a significant challenge for the SCADA market during the forecast period.

Regional Trends:

The Asia-Pacific region currently dominates the global SCADA market, driven by its role as a manufacturing and technology hub that supports the widespread adoption of SCADA applications. Countries such as South Korea, China, and Japan are leading providers of advanced SCADA solutions. In contrast, North America is expected to present substantial growth opportunities over the forecast period, driven by rapid technological advancements and the adoption of innovative solutions.

Recent Developments:

In July 2020, Schneider Electric, a leading name in energy management and automation, unveiled Power SCADA Operation 2020, the newest iteration of its acclaimed EcoStruxureTM software. The most recent version is intended to function as an open platform rather than just a SCADA system for power networks, with high-speed control capabilities and the most recent cybersecurity improvements.

Unlock Your GTM Strategy: https://www.insightaceanalytic.com/customisation/2123

Segmentation of SCADA Market-

By Offering-

Hardware

Software

Services

By Component-

Programmable Logic Controller

Remote Terminal Unit

Human-Machine Interface

By End-User-

Process Industries

Discrete Manufacturing

Utilities

Telecommunications

By Region-

North America-

The US

Canada

Mexico

Europe-

Germany

The UK

France

Italy

Spain

Rest of Europe

Asia-Pacific-

China

Japan

India

South Korea

South East Asia

Rest of Asia Pacific

Latin America-

Brazil

Argentina

Rest of Latin America

Middle East & Africa-

GCC Countries

South Africa

Rest of the Middle East and Africa

Read Overview Report- https://www.insightaceanalytic.com/report/scada-market/2123

About Us:

InsightAce Analytic is a market research and consulting firm that enables clients to make strategic decisions. Our qualitative and quantitative market intelligence solutions inform the need for market and competitive intelligence to expand businesses. We help clients gain competitive advantage by identifying untapped markets, exploring new and competing technologies, segmenting potential markets and repositioning products. Our expertise is in providing syndicated and custom market intelligence reports with an in-depth analysis with key market insights in a timely and cost-effective manner.

0 notes

Text

How SCADA, HMI & PLC work together

SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interface), and PLC (Programmable Logic Controller) work together as key components in industrial automation and control systems.

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#rockwell automation#allen bradley#plc#hmi#scadatraining#scada

2 notes

·

View notes

Text

Unleashing Efficiency: The Rise of Industrial Automation Software Solutions

In the age of digital transformation, industrial sectors across the globe are undergoing a fundamental shift. One of the most significant developments driving this evolution is the rise of Industrial Automation Software Solutions. These intelligent systems are redefining how industries operate, streamline processes, and respond to real-time data — all while reducing human error and maximizing productivity.

Industrial automation is no longer just a competitive advantage; it’s quickly becoming a necessity for modern manufacturing, logistics, energy, and production-based businesses. At the core of this transformation lies powerful software designed to integrate machinery, manage workflows, and monitor operations with precision and efficiency.

One of the key strengths of Industrial Automation Software Solutions is their ability to centralize control over complex industrial processes. From programmable logic controllers (PLCs) to supervisory control and data acquisition (SCADA) systems, this software enables seamless communication between machines, sensors, and operators. The result is a smarter, more connected operation that can adapt quickly to changing demands.

Beyond basic automation, these solutions offer deep analytics capabilities. Using machine learning and AI, the software can detect patterns, predict equipment failures, and recommend proactive maintenance — ultimately helping businesses avoid costly downtime. This predictive approach not only increases reliability but also extends the lifespan of expensive equipment.

Flexibility is another crucial advantage. Most modern Industrial Automation Software Solutions are highly customizable and scalable, allowing companies to tailor systems to their unique needs and expand functionality as they grow. Whether an organization is automating a single production line or an entire facility, the right software can be scaled appropriately without significant disruptions.

In today’s globalized economy, remote access and cloud integration are more important than ever. Many automation platforms now offer web-based dashboards and mobile apps, giving managers and technicians the ability to monitor and control systems from virtually anywhere. This level of accessibility promotes faster response times and better decision-making, even across multiple locations.

Security, too, has become a top priority. As more industrial systems connect to the internet, they become more vulnerable to cyber threats. Industrial Automation Software Solutions are now being developed with robust cybersecurity features, including encrypted communication, multi-layered access control, and real-time threat monitoring.

These solutions also play a key role in sustainability efforts. By optimizing energy usage, reducing waste, and ensuring consistent product quality, industrial automation supports greener operations. Businesses not only improve efficiency but also meet environmental standards more effectively.

As industries continue to adopt smart technologies and prepare for Industry 4.0, the demand for reliable and intelligent automation software is set to grow exponentially. Investing in Industrial Automation Software Solutions is no longer just about keeping up with competitors — it's about laying the foundation for a resilient, future-ready operation.

Whether it's enhancing productivity, improving safety, or driving innovation, automation software is reshaping what’s possible in the industrial world. The future of manufacturing and production isn’t just automated — it’s intelligent, adaptive, and incredibly powerful.

#Traceability Software Great Lakes Region#Machine Vision Integration Great Lakes#Great Lakes Industrial Marking Solutions#Factory Monitoring Software Great Lakes Region#Lean Manufacturing Solutions Great Lakes#Automated Data Collection Systems Great Lakes#Industrial Traceability Solutions Detroit#Machine Vision Systems Detroit#Detroit Barcode Verification Services#Laser Marking Services Detroit MI#Production Management Software Detroit#Detroit Manufacturing Systems#product traceability software Detroit#industrial marking systems Detroit#Laser Marking Services Auburn Hills#Industrial Traceability Solutions Michigan#Barcode Verification Systems Auburn Hills#Machine Vision Systems Michigan#Auburn Hills Laser Part Marking#Industrial Marking Solutions Michigan#Traceability Software Auburn Hills#Turnkey Laser Systems Michigan#Auburn Hills Barcode Reader Solutions#Advanced Laser Marking Auburn Hills MI#laser marking systems#laser marking machine#laser part marking#uv laser marking machine#uv laser marking#dot peen marking machine

0 notes

Text

Automation and Control Industry Insights Opportunities, Key Applications & Market Dynamics

The automation and control market USD 136.64 Billion in 2024 to USD 273.32 billion by 2032, exhibiting a compound annual growth rate CAGR of 9.05% during the projected period 2024 - 2032.Growing as industries seek efficient, reliable, and cost-effective ways to improve operational performance. These systems streamline processes, reduce human error, and increase productivity across manufacturing, energy, and transportation sectors.

Market Segmentation

By Product

Programmable Logic Controllers

Distributed Control Systems

Supervisory Control and Data Acquisition

Human Machine Interface

By Application

Manufacturing

Energy and utilities

Automotive

Building automation

By Region

North America, Europe, Asia-Pacific, Latin America, Middle East and Africa

Market Trends

Rise of Industry automation and smart factories

Integration with AI, machine learning, and IoT

Adoption of cloud-based control systems

Emphasis on cybersecurity for industrial networks

Segment Insights

PLC and SCADA systems are extensively used in manufacturing and energy sectors. HMI interfaces are gaining traction for real-time data visualization and control.

End-User Insights

Manufacturers use automation for precision and speed. Utility providers leverage it for monitoring and managing grids. Smart buildings employ control systems for energy management and security.

Key Players

Siemens AG

ABB Ltd

Schneider Electric

Rockwell Automation

Honeywell International Inc.

Emerson Electric Co.

Opportunities and Challenges

Opportunities

Industry transformation through digitalization

Adoption of robotics and advanced control

Challenges

Complex implementation and integration

High upfront investment

Trending Report Highlights

Kids Tablet Market

Fluorescent Lighting Market