#Super Duplex S32750/S32760 Flanges Manufacturers in India

Explore tagged Tumblr posts

Text

#Super Duplex S32750/S32760 Flanges Manufacturers in India#Super Duplex S32750/S32760 Flanges Suppliers in India#Super Duplex S32750/S32760 Flanges Stockists in India#Super Duplex S32750/S32760 Flanges Exporters in India

0 notes

Text

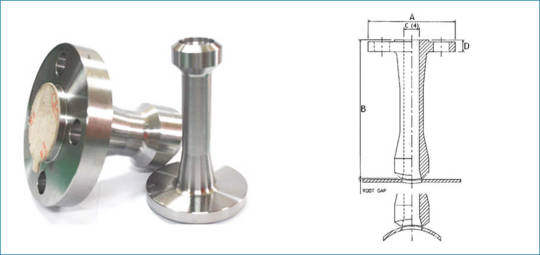

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182 Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. Size: 1/2" (15 NB) to 48" (1200NB) Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

12 notes

·

View notes

Text

Duplex 2205 | Super duplex 2507 | Sheet, Plate, Coil, Pipes & tubes - Calicometal

Duplex 2205 | Super duplex 2507 | Sheet, Plate, Coil, Pipes & tubes - CalicometalCalico Metal Alloys LLP is one of the main Manufacturers, Suppliers and Exporters of top notch Duplex 2205, UNS S31803, UNS S32205, UNS S32750, UNS S32760, Duplex 2202, Duplex 2304 pipe, Tube, sheet, plates, Coil, Shim Sheet flanges, fasteners in India at low price.

1 note

·

View note

Text

Super Duplex Stainless Steel Grades With Astm Specification

Super Duplex Stainless Steel is a special type of stainless steel known for its strength and high resistance to corrosion. It’s used in industries like oil and gas, chemical processing, and marine applications where harsh conditions demand a tough material.

Super Duplex Stainless Steel is a metal that combines the benefits of two different types of stainless steel- austenitic and ferritic. It performs well in tough environments, like where there’s exposure to salty water or harsh chemicals. The word “super” refers to its superior performance when compared to regular stainless steel, especially in environments that cause other metals to corrode or fail.

ASTM Standards for Super Duplex Stainless Steel

The ASTM (American Society for Testing and Materials) sets important standards for materials like Super Duplex Stainless Steel. These standards ensure the metal meets certain requirements, like chemical composition, mechanical properties, and strength, so it can be used safely in different applications.

Here are some common ASTM standards for Super Duplex Stainless Steel:

ASTM A182: Covers fittings, flanges, and other parts made of Super Duplex Stainless Steel, used for high-temperature applications.

ASTM A240: Sets the standards for sheets and plates made from stainless steel, including Super Duplex grades.

ASTM A789: Covers tubing made from Super Duplex Stainless Steel, commonly used in heat exchangers and other applications that need strong, corrosion-resistant tubes.

Common Super Duplex Stainless Steel Grades

There are different types of Super Duplex Stainless Steel, each suited for particular jobs. Here are some common grades:

UNS S32750: This is a very popular grade, known for being strong and resistant to rust, especially in environments with saltwater or chemicals. It’s often used in the oil and gas industry, as well as in chemical processing.

UNS S32760: This grade offers higher corrosion resistance, particularly in chloride-rich environments making it perfect for subsea pipelines and offshore oil rigs where exposure to saline solutions and extreme conditions is common. For example, in desalination plants and shipbuilding due to its ability to withstand pitting and stress corrosion cracking.

UNS S32550: Another grade of Super Duplex, it offers good performance at a lower cost. It’s often chosen when top-level corrosion resistance isn’t needed, but strength is still important.

Why Super Duplex is So Special?

Super Duplex Stainless Steel is valued for two main reasons: its strength and its resistance to corrosion. Compared to regular stainless steel, Super Duplex is about twice as strong. This means thinner walls can be used in pipes and fittings, reducing costs without losing durability.

Its resistance to corrosion, especially in environments that contain chlorides, is much higher than regular steel. This makes it ideal for industries that work with chemicals, water, or high-pressure systems.

Where is Super Duplex Stainless Steel Used?

Super Duplex Stainless Steel is a favourite in industries that face tough conditions:

1. Oil and Gas: Offshore platforms and undersea pipelines use Super Duplex because it can handle the pressure and exposure to corrosive elements.

2. Chemical Processing: Super Duplex is used in tanks, reactors, and piping systems that must withstand harsh chemicals without corroding.

3. Marine Applications: Ships, desalination plants, and underwater equipment rely on Super Duplex to avoid rusting in salty environments.

We are the premium suppliers of Super Duplex Stainless Steel products and other top-quality forged pipe fittings in India. Our extensive range of products adheres to the highest Pipe Fittings Manufacturing Standards and Types, ensuring durability and performance across a wide variety of industrial applications.

Online Fittings offers raw materials for industrial fittings straight from the manufacturer at unbeatable factory prices. With fast global shipping and reliable post-sales support, you can trust us to deliver the best value with a seamless, secure buying experience.

0 notes

Text

Super Duplex Globe Valve Manufacturer in India

Specialityvalve is a leading Super Duplex Globe Valve Manufacturer in India. We supply to France, Australia, Mexico and Turkey.

Description:

Available Materials: SS2328, SAF 2507(UNS S32750, F53), S32760( F55), UNS S32550, F61

Size: 1/8″- 24”

Class: 150 to 2500

Nominal Pressure: PN6 to PN300

Operations: Gear operated, Handwheel operated, lever operated, pneumatic actuated, electric actuated

Ends: Flanged, socket Welded, Buttweld, wafer, lug.

0 notes

Text

Super Duplex steel valve manufacturer in India

Specialityvalve is the top Super Duplex steel valve manufacturer in India. Super Duplex steel valve is a type of valve made from a high-performance alloy known as Super Duplex steel. This alloy is a combination of austenitic and ferritic stainless steels, which provides it with excellent corrosion resistance, high strength, and good toughness.

Super Duplex steel valves are commonly used in applications where high resistance to corrosion and erosion is required, such as in the oil and gas industry, chemical processing, and offshore and marine applications. These valves can withstand high pressures and temperatures and are suitable for use in harsh environments.

Specialityvalve is a well-known Super Duplex Valve Manufacturer in India which provides quality valves in different materials and design. All the products are tested according to requirements and standards.

Available Materials: Super Duplex (SS2328, SAF 2507(UNS S32750, F53), S32760( F55), UNS S32550

Size: 1/8″- 24”

Class: 150 to 2500

Nominal Pressure: PN6 to PN300

Operations: Gear operated, Handwheel operated, lever operated, pneumatic actuated, electric actuated

Ends: Flanged, socket Welded, Buttweld, wafer, lug

1 note

·

View note

Text

Super Duplex steel valve manufacturer in India

Specialityvalve is the top Super Duplex steel valve manufacturer in India. Super Duplex steel valve is a type of valve made from a high-performance alloy known as Super Duplex steel. This alloy is a combination of austenitic and ferritic stainless steels, which provides it with excellent corrosion resistance, high strength, and good toughness. Super Duplex steel valves are commonly used in applications where high resistance to corrosion and erosion is required, such as in the oil and gas industry, chemical processing, and offshore and marine applications. These valves can withstand high pressures and temperatures and are suitable for use in harsh environments.

Specialityvalve is a leading Super Duplex Valve Manufacturer in India which provides quality valves in different materials and design. All the products are tested according to requirements and standards.

Types of super duplex steel valves: Ball Valves Gate Valves Globe Valves Check Valves Butterfly Valves

Advantages of super duplex steel valve: Toughness: Super Duplex steel valves have good toughness and can resist impact and fatigue, which helps to extend their service life.

Cost-effective: Super Duplex steel valves offer a cost-effective solution for applications where high-performance valves are required, as they have a long service life and require minimal maintenance.

Versatility: Super Duplex steel valves are available in various types and can be customized to meet specific requirements, making them suitable for a wide range of applications.

High Temperature Resistance: Super Duplex steel valves are capable of withstanding high temperatures, which makes them ideal for use in applications where high-temperature fluids or gases are present.

Improved Corrosion Resistance in Acidic Environments: Super Duplex steel valves are particularly useful in environments with high chloride concentrations or acidic conditions where conventional stainless steel valves would corrode.

Industry of super duplex steel valve: Oil and Gas Chemical Processing Power Generation Water Treatment Marine Aerospace

Available Materials: Super Duplex (SS2328, SAF 2507(UNS S32750, F53), S32760( F55), UNS S32550 Size: 1/8″- 24” Class: 150 to 2500 Nominal Pressure: PN6 to PN300 Operations: Gear operated, Handwheel operated, lever operated, pneumatic actuated, electric actuated Ends: Flanged, socket Welded, Buttweld, wafer, lug https://www.specialityvalve.com/product-category/super-duplex-valves/

0 notes

Text

What are Flanges and their types?

Flanges are an essential component of any piping system, as they provide a secure and leak-free connection between two pipes or valves. As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP understands the importance of choosing the right type of flange for your application.

In this blog post, we will cover everything you need to know about flanges, including their types, materials, and applications.

Before we dive into the details, let's start with the basics!

Introduction

Flanges are mechanical connectors used to join two pipes or valves. They are usually made of steel, and their main purpose is to provide a tight and leak-free seal between the two parts. Flanges come in various types and sizes, and choosing the right type of flange is essential for the safety and efficiency of your piping system.

Types of Flanges?

Flanges come in several types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Each type has its unique characteristics and applications, and selecting the right one will depend on several factors, such as pressure ratings, temperature ratings, size, material compatibility, and cost.

● Weld Neck Flanges

Weld neck flanges are the most common type of flange, known for their high durability and strength. They are welded to the pipe or valve, making them ideal for high-pressure and high-temperature applications.

● Slip-On Flanges

Slip-on flanges are easy to install and remove, making them ideal for applications that require frequent maintenance. They slide over the pipe or valve and are then welded or bolted in place.

● Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges, but they are welded only on the outer side of the flange, leaving the inner side free of welding marks. They are ideal for smaller-sized pipes and low-pressure applications.

● Lap Joint Flanges

Lap joint flanges are used when a piping system requires dismantling frequently. They are also ideal for applications that require easy access to the pipe or valve.

● Threaded Flanges

Threaded flanges are designed to be screwed onto the pipe or valve, making them ideal for applications that require easy installation and removal. They are commonly used in low-pressure applications.

● Blind Flanges

Blind flanges are used to seal the end of a pipe or valve. They are commonly used for pressure testing and maintenance purposes.

Materials & Grades Available In Flanges with Bullion Pipes & Tubes LLP

Flanges can be made of various materials & Grades, such as,

● Stainless Steel - 904L Flanges, 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 Flanges

● Hastelloy Flanges - C22, B2 Flanges, C276 Flanges

● Carbon Steel Flanges - ASTM A350 15LF1, LF2 CL1/CL2, LF3 CL1/CL2 Carbon Steel Flanges

● Nickel Alloy - 200/201

● Duplex Steel Flanges - Duplex UNS S32205/31803 Flanges

● Alloy Steel Flanges - P5, P9, P11, P12, P22, P91 Flanges

● Super Duplex Steel - UNS S32750/S32760 Flanges

● Titanium Alloys - Gr 2 Flanges, Gr 5 Flanges, Gr 7 Flanges

● Aluminium Flanges - 5052 Reducing Flanges, 5082 Flanges, 5082 Flanges, 6063 SORF Flanges, 6082 Blind Flanges, 2024 Aluminum Weld Neck Flanges, and 5052 Threaded Flanges.

● Tantalum Flanges - ASTM B521 Tantalum Flanges, Spectacle Blind Flanges, Orifice Flange, Ta-10W Flanges, Tantalum UNS R05200 Flanges, ASTM B365 Ta2.5W Flanges

● Monel Flanges - Monel K500 Flanges, Monel 400 Flanges

● Alloy 20 Flanges - Alloy 20 RTJ Flange, Alloy 20 WNRF Flanges, Alloy UNS N08020 Pipe Flanges, Alloy 20 Weld Neck Flange, Alloy 20 Nipo Flanges, ASTM B462 Alloy Threaded Flanges, Alloy 20 Spectacle Blind Flanges, Alloy 20 Industrial Flanges, and UNS N08020 Alloy 20 Forged Flanges

● SMO 254 Flanges

● Inconel Flanges - Inconel 718, 600, 601 and 625 Flanges

● Incoloy Flanges - 825, 800/800H/800HT Flanges

Choosing the right material for your flange will depend on several factors, such as the application's temperature, pressure, and corrosion resistance requirements.

Factors to Consider When Selecting Flanges

Selecting the right flange for your application can be challenging, as there are several factors to consider, such as pressure ratings, temperature ratings, size, material compatibility, and cost. At Bullion Pipes & Tubes LLP, we can help you choose the right flange for your application, ensuring safety and efficiency.

Flange Standard Ratings

Flanges come in various standard ratings, such as ANSI, API, DIN, and JIS. These ratings determine the flange's pressure-temperature rating and its compatibility with other components in the piping system.

Flange Installation

Proper flange installation is essential for the safety and efficiency of your piping system. It involves several steps, such as preparation of the piping system, installation of the flanges, flange tightening process, flange alignment, and testing and inspection.

Maintenance and Repair of Flanges

Maintaining and repairing flanges is critical for the longevity and safety of your piping system. Regular inspections, leak checks, and maintenance can help detect any potential issues before they become a more significant problem.

Applications of Flanges

Flanges have a wide range of applications in various industries, including:

● Oil and Gas Industry

● Petrochemical Industry

● Chemical Industry

● Power Generation Industry

● Water Treatment Industry

They are used in various applications, including HVAC systems, plumbing, and firefighting systems.

Why Choose Bullion Pipes & Tubes LLP for Flanges?

As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP offers a wide range of flanges made from high-quality materials. We provide customized solutions to meet our customers' specific needs, and our flanges are available in various sizes, ratings, and materials.

We have been providing high-quality flanges to various countries, such as Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany, and our products are known for their durability, reliability, and safety.

Conclusion

Flanges are a critical component of any piping system, and selecting the right type of flange for your application is essential for safety and efficiency. Choosing a reliable and trustworthy supplier like Bullion Pipes & Tubes LLP can ensure that you get high-quality flanges that meet your specific requirements.

0 notes

Text

API Flanges by Flangesnuts

Nickel Alloy API Flanges, API Blind Flanges, API Slip on Flanges, Best Deals on Raised Face API Flanges, Carbon Steel API Flange, API Class 300 Flanges, API Raised Face Flange, Stainless Steel API Flange dealer in India.

Large Selection of Inconel API Flanges, API 150 LBS Forged Flange, Alloy Steel API Flanges, Hastelloy API Flange Dealer, High Quality Duplex Steel API Flanges, Monel API Pipe Flanges, Class 1500 API Flanges, SS API Flanges, Class 600 API Flange Exporter.

About Flanges And Nuts

Flanges nuts Is An ISO 9001:2015 licensed enterprise And Has A song file Of providing A wide variety Of Piping solution At Very competitive prices. In a totally brief time period, we've gained An tremendous national And international popularity.

Headed through Mr. Ronak Bhansali (Director) And Supported by way of Our committed, expert team, we are able to fulfill The needs Of Our customers In A timely And Systematic manner. The Profound know-how And wealthy experience Of our crew within the Respective arena Of metal merchandise Has Assisted The business enterprise To gather outstanding role Amidst The reliable chrome steel, Pipe fitting In India.

we're Counted most of the nice manufacturer, Exporter Stockist & provider. We Export 60% Of Our range Of Flanges, shops, Pipe Fittings And solid Fittings To many nations Like u.s.a., united kingdom, Italy, Malaysia, Gulf and so on. we'd admire To Get Your Esteemed Enquires And look ahead to The delight Receiving Your precious response. we're often supplying these objects To Many main industrial gadgets inclusive of : ship constructing, Petrochemical flora, metallic flowers, Refineries, chemical substances, Fertilizers, electricity Plant, Pharmaceutical, Ports, Oil & gas, Railway, Mining, Cement vegetation, Paper mills, Sugar generators, Fabrication units and so on.

TO KNOW MORE ABOUT OUR PRODUCTS YOU CAN VISIT OUR WESITE

www.flangesnuts.com

0 notes

Text

The Metals Factory

The Metals Factory is an ISO certified and PED approved professional and international manufacturer, supplier and exporter of stainless steel, aluminium, nickel alloys, carbon steel and alloy steel products. With a collective experience of over 30 years, we have emerged as one of the largest just in time exporter of steel and aluminum products. Our range of products includes steel plates, rods, bars, angle, channels, steel pipe and tube, forged flange and fittings, elbow, tee, reducer, stub end, gaskets, fasteners, valves etc. We are devoted to provide the best solutions for steel materials and industrial equipment for our respected customers. We have manufacturing set up, sales and export offices in both India and China to meet the immediate and long term steel and aluminium product requirements across the globe.

Our stainless steel pipe and carbon steel pipe products are designed and manufactured in compliance with international standards and are appreciated for their sturdiness, precise dimensions, durability, finish and corrosion resistance. They are available in distinguished sizes, dimensions and thicknesses to cover the requirements of various industries like power plants, automobile, heavy engineering, offshore and chemical.

In addition to being a manufacturer of seamless pipes and welded steel pipes, we are also one of the biggest stainless steel plate and aluminum plate processing center in India. We are a leading stockholder, processor and supplier of high quality stainless steel plates, stainless steel sheets, stainless steel coils, stainless steel strips, alloy steel plates, special alloy plates, mild steel plates, mild steel coils, hot rolled coils, hot rolled plates, cold rolled coils.

We supply not only commonly used carbon steel and stainless steel materials (SS304/L, SS316/L, SS321), but also duplex and super duplex steel 1.4547, 1.4462, 1.4410 (S31254, S31803, S32750, S32760), and special austenite stainless steel such as 310S, 347H, 317L, 904L.

Some of our important & key products include the following:

1) Aluminium sheets, plates and coils in size range of 0.2mm to 350mm in Alloys 1050, 1060, 1070, 1080, 1100, 1200, 3003, 3105 and 8011. We are also one of the leading suppliers of 5052, 5083, 5086, 6061, 6082 and 7075 plate, and sheet products. Other products available in Aluminium alloys include bar and rods, seamless tubes, buttweld fittings, flanges and aluminium blocks for CNC machining.

2) Stainless steel sheets, plates and coils in size range of 0.2mm to 80mm in SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L. We offer stainless steel products in various forms including stainless steel pipes, stainless steel rods, stainless steel forgings, stainless steel large diameter pipes, stainless steel pipe fittings and flanges.

3) Carbon steel plates are available for sale in size range of 6mm to 200mm in custom widths and lengths, especially boiler quality plates, pressure vessel steel plates, abrasion resistant steel plates, and high tensile plates.

4) Stainless steel flexible hose pipes and bellows in sizes from 1/4” to 12” in custom lengths with various types of end connections such as flanges, female or male nuts, nipples, adaptors, camlock couplings, quick release couplings etc.

5) Carbon steel seamless pipes available in size range of 1/2’’~24’’NB, carbon steel ERW pipes available in sizes 1/2’’~40’’NB, while LSAW and Spiral welded steel pipes are available in size range of 18’’~72’’NB

6) Stainless steel pipes are available in various grades such as SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L, Stainless steel seamless pipes are available in size range of 1/2’’~24’’NB, while stainless steel ERW and Fabricated pipes are available in sizes 1/2’’~40’’NB.

Various piping system related pipes fittings, fasteners, gaskets and flanges are available in carbon steel, stainless steel, nickel alloys and alloy steel grades. We manufacture and supply buttweld pipe fittings, forged fittings and flanges in size ½” to 60”.

1 note

·

View note

Text

Applications of High Pressure Forged Fittings - SPP Metal & Alloys

Forged steel fittings are used to connect several pieces of plumbing equipment. Their diameters range from 2 to 4 inches and they come in a variety of shapes. Forged steel fittings are used in many industries for a variety of high-pressure applications, particularly for threaded connections. It is commonly used to move high-pressure liquids and gases between locations at high temperatures.

With SPP Metals and Alloys you will find a wide range of forged pipe fittings such as 90 and 45-degree elbows, flow tees, Coupling, Union, end caps, nipples, reducers, etc. As SPP Metals and Alloys is one of the well-known - forged fittings manufacturers and suppliers in India.

These forged pipe fittings are available in various international standards such as B16.11, MSS SP43, and MSS SP75 to complete the client's requirements. Moreover, the products with SPP Metals & Alloys are made of high-strength forged metal and incredibly robust and resistant to environmental influences.

Forged pipe fittings.

High-pressure forged fittings are a type of piping component used in high-pressure and high-temperature applications. These fittings are typically made from materials such as carbon steel, stainless steel, and alloy steel, and are designed to withstand high pressure and temperature conditions.

Additionally, they are typically used to connect pipes and other components in a piping system and come in various shapes and sizes, such as elbows, tees, and reducers, to meet the specific needs of the application. High-pressure forged fittings are known for their strength and durability and are often used in conjunction with other high-pressure piping components, such as valves, flanges, and pipes, to create a complete piping system.

Types of Forged Fittings.

45 Deg Elbow

90 Deg Elbow

Tee

Couplings

Unions

Cap

Plug

Nipple

Benefits of High Pressure Forged Pipe Fittings.

High-pressure forged pipe fittings have several benefits that make them well-suited for high-pressure and high-temperature applications:

Corrosion Resistance

Cost-effective

Higher strength and durability

Customization

Easy to Install

Leak-tightness.

Grades in which forged fittings are available.

Super Duplex: S32750/S32760/F55/F53

Duplex: S31803/S32205/SMO 254

Nickel Alloys: Alloy 400, 625, 800, 825

Stainless Steels: 304, 316L, 310S, 321, 904L, etc

Carbon Steel: A105

LTCS: LF2

Alloy Steel: F9/F11/F12/F22/F91

Standards in which these forged pipe fittings grades are available.

B16.11

MSS SP43

MSS SP75

Applications of High Pressure-Forged fittings

High-pressure forged fittings can be used in a variety of applications and are produced from the finest raw materials. With its high level of consistency and dependability, forged fittings guarantee a long lifespan, high pressure, and no faults. High-pressure fittings are used in almost all industrial applications where a complex threaded connection is required. Additionally, it could be used to evaluate submerged structures.

In chemical fertilizer industries, instrumentation, nuclear thermal industries, heat exchanger, oil gas industries, pharmacy surgical industries, water gas-piping systems, and refineries petrochemicals seem to be just a few of the industries using these forged pipe fittings.

Forged pipe fittings can be used to change the direction of a piping system, and therefore the direction of a stream. The durability, leak-free operation, precise dimensioning, and smooth finish of such pipe fittings make them quite popular. In heavy-duty operations, where a line must be completely sealed, such long-lasting products are useful.

Final Thoughts.

If you are looking to purchase high-pressure forged fittings for an upcoming project which requires high strength, then you need to check out the best place which supplies the high-quality forged pipe fittings that will suit and fulfill your project requirements. In such case, you can visit, SPP Metals and Alloys the most well-known forged fittings manufacturers and suppliers in the Indian market. As supply a wide range of high-pressure forged fittings at the most competitive price all across India.

0 notes

Photo

Application and Uses Of Pipe fitting

Top quality Pipe Fittings Manufacturer

Bhansali Steel is a significant Pipe Fittings Manufacturer in India. We supply high-quality Stainless Steel and Carbon Steel Pipe Fittings to a variety of industries all around the world. With many years of experience in this industry, we as a Pipe Fittings Manufacturers have been able to achieve several things such as providing best-quality products, delivering the ordered products on time, inspecting the quality of materials regularly and providing the best available services to our customers.

We manufacture Pipe Fittings in a variety of thicknesses, specifications, grades, and dimensions. Pipe fittings are available to us in Stainless Steel, Carbon Steel, Mild Steel, Inconel, Monel and other grades, with ASTM, ASME, ANSI, UNS, DIN, and other standards

Pipe Fittings - Specifications

Type of Pipe Fitting: Elbow, Tee, Cross, Reducer, End Caps, Bends, Stub Ends - Lap Joint, Nipples, Outlet Fittings

Size: ½ NB to 48NB.

Type: Seamless / ERW / Welded / Fabricated.

Grade

Titanium: Titanium 6-4, Gr 1, Gr 2, Gr 3, Gr 4, Gr 5, Gr 7, Gr 9, 5-2.5, 6-2-4-2, 6-4 ELI, 6-6-2

Hastelloy: C22, C276, X, B-2.

Monel: 400, K500.

Monel: Nickel 200 Nickel 201, Alloy 20, Alloy 286, Alloy 218 (Nitronic 60), Nitronic 50 (XM-19).

Cupro Nickel: Cu 90-10 (C70600,CW352H), Cu 70-30 (C71500, CW354H).

Inconel: 601, 625, 660A, 718, X-750, 825, 925, 608.

Nimonic Alloy: 75, 80A, 81, 86, PE16, PE12.

Duplex / Super Duplex: D S31803, D S32205, SD S32750, SD S32760, SD S32950.

Chromium Molybdenum Steel: A387 Gr 2, A387 Gr 12, A387 Gr 11, A387 Gr 22, A387 Gr 22L, A387 Gr 7, A387 Gr 21, A387 Gr 21L, A387 Gr 9, A387 Gr 91.

Pipe Fittings - Types of Pipe Fittings

Elbow Fittings

Tee Fittings

Cross Fittings

Reducer Fittings

End Caps Fittings

Bend Fittings

Stub End Fittings

Nipple Fittings

Applications and Uses of Pipe Fittings

Pipe Fittings used in the Oil and Gas Industry.

Pipe Fittings used in ShipBuilding Industry.

Pipe Fittings used in Power and Telecom Industry.

Pipe Fittings used in Food, Beverage, and Dairy

Pipe Fittings used in Municipal and Utility.

Pipe Fittings used in Mining and Construction.

What are considered pipe fittings?

Pipe Fittings are defined as the piping components that help in pipe routing for directional changes, size changes, and branch connections. Piping Elbows, Piping Reducers, Tee Connections, Olet Connections, Caps, Crosses, etc are pipe fittings and widely used in both the piping and plumbing industry.

For More Details

Mail Us: [email protected]

Website: https://bhansalisteels.com

Product Sources: Pipe Fittings Manufacturer In India and Flanges Manufacturer India

#pipe fittings manufacturers#pipe fittings manufacturer in India#ms pipe fitting#SS pipe fitting manufacturer#stainless steel pipe fitting manufacturer

0 notes

Text

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Groove & Tongue Flanges by Flangesnuts

Best Deals on Raised Face Groove & Tongue Flanges, Nickel Alloy Groove & Tongue Flanges, Carbon Steel Groove & Tongue Flange, ASME B16.5 Raised Face Groove & Tongue Flange, ANSI B16.5 Groove & Tongue Flanges, ASME / ANSI B16.5 Groove & Tongue Flanges, Class 300 Groove & Tongue Flanges, Stainless Steel Tongue and Groove Flange deaker in India

DIMENSIONS OF GROOVE & TONGUE FLANGES

About Flanges And Nuts

Flanges nuts Is An ISO 9001:2015 licensed enterprise And Has A song file Of providing A wide variety Of Piping solution At Very competitive prices. In a totally brief time period, we've gained An tremendous national And international popularity.

Headed through Mr. Ronak Bhansali (Director) And Supported by way of Our committed, expert team, we are able to fulfill The needs Of Our customers In A timely And Systematic manner. The Profound know-how And wealthy experience Of our crew within the Respective arena Of metal merchandise Has Assisted The business enterprise To gather outstanding role Amidst The reliable chrome steel, Pipe fitting In India.

we're Counted most of the nice manufacturer, Exporter Stockist & provider. We Export 60% Of Our range Of Flanges, shops, Pipe Fittings And solid Fittings To many nations Like u.s.a., united kingdom, Italy, Malaysia, Gulf and so on. we'd admire To Get Your Esteemed Enquires And look ahead to The delight Receiving Your precious response. we're often supplying these objects To Many main industrial gadgets inclusive of : ship constructing, Petrochemical flora, metallic flowers, Refineries, chemical substances, Fertilizers, electricity Plant, Pharmaceutical, Ports, Oil & gas, Railway, Mining, Cement vegetation, Paper mills, Sugar generators, Fabrication units and so on.

TO KNOW MORE ABOUT OUR PRODUCTS YOU CAN VISIT OUR WESITE

www.flangesnuts.com

0 notes

Text

Ring Spacer Flanges by Flangesnuts

ASME B16.5 Raised Face Ring Spacer Flange, Nickel Alloy Ring Spacer Flanges, ASME / ANSI B16.5 Ring Spacer Flanges, Carbon Steel Ring Spacer Flange, ANSI B16.5 Ring Spacer Flanges, Best Deals on Raised Face Ring Spacer Flanges, Class 300 Ring Spacer Flanges, Stainless Steel Ring Spacer Flange Supplier in India.

About Flanges And Nuts

Flanges nuts Is An ISO 9001:2015 licensed enterprise And Has A song file Of providing A wide variety Of Piping solution At Very competitive prices. In a totally brief time period, we've gained An tremendous national And international popularity.

Headed through Mr. Ronak Bhansali (Director) And Supported by way of Our committed, expert team, we are able to fulfill The needs Of Our customers In A timely And Systematic manner. The Profound know-how And wealthy experience Of our crew within the Respective arena Of metal merchandise Has Assisted The business enterprise To gather outstanding role Amidst The reliable chrome steel, Pipe fitting In India.

we're Counted most of the nice manufacturer, Exporter Stockist & provider. We Export 60% Of Our range Of Flanges, shops, Pipe Fittings And solid Fittings To many nations Like u.s.a., united kingdom, Italy, Malaysia, Gulf and so on. we'd admire To Get Your Esteemed Enquires And look ahead to The delight Receiving Your precious response. we're often supplying these objects To Many main industrial gadgets inclusive of : ship constructing, Petrochemical flora, metallic flowers, Refineries, chemical substances, Fertilizers, electricity Plant, Pharmaceutical, Ports, Oil & gas, Railway, Mining, Cement vegetation, Paper mills, Sugar generators, Fabrication units and so on.

TO KNOW MORE ABOUT OUR PRODUCTS YOU CAN VISIT OUR WESITE

www.flangesnuts.com

0 notes