#Styrenic Block Copolymer Market Growth

Explore tagged Tumblr posts

Text

The global styrenic block copolymer market has reached $8.2 Billion in 2023. IMARC Group forecasts it to grow to $11.8 Billion by 2032, exhibiting a 3.9% CAGR. This video breaks down the key drivers and trends fueling this growth. Stay tuned and subscribe for more market insights.

0 notes

Text

#Styrenic Block Copolymer Market to Build Excessive Revenue at Healthy CAGR Growth Rate Up to 2028 |#Versalis#Eastman#LG Chem#Asahi Kasei#intellectualmarketinsights

0 notes

Text

Styrene-Butadiene-Styrene (SBS) Copolymer Block Market: Enhancing Electronics and Electrical Equipment

The Styrene-Butadiene-Styrene (SBS) copolymer block market has experienced significant growth and transformation over the years. This versatile material, known for its excellent properties such as elasticity, durability, and resistance to environmental factors, plays a crucial role in various industries. From adhesives and sealants to asphalt modification and footwear, SBS copolymers have established themselves as a cornerstone of modern manufacturing and construction. In this comprehensive analysis, we will explore the current state of the SBS copolymer market, recent innovations, emerging trends, and the future outlook for this remarkable material.

The SBS Copolymer Block: A Brief Overview

SBS copolymer blocks market are a type of thermoplastic elastomer, which means they exhibit both rubber-like elasticity and plastic-like processability. They are synthesized through the copolymerization of three monomers: styrene, butadiene, and styrene. The unique arrangement of these blocks within the polymer chain results in their distinct properties.

One of the key strengths of SBS copolymer blocks is their ability to undergo repeated deformation and return to their original shape. This property, known as "shape memory," makes SBS copolymers an ideal choice for products that require flexibility, resilience, and the ability to withstand mechanical stresses. It's no wonder they find applications in numerous industries.

Current Market Dynamics

The SBS copolymer market has witnessed steady growth over the past few years. This growth can be attributed to several factors, including the rising demand for lightweight, durable materials in automotive and construction industries, as well as the increasing popularity of sustainable and eco-friendly products.

Automotive Industry: SBS copolymers are widely used in the automotive sector for applications such as bumpers, door trims, and weatherstripping. As the automotive industry continues to focus on reducing vehicle weight and improving fuel efficiency, SBS copolymers have gained prominence due to their lightweight yet sturdy nature.

Construction Industry: In the construction sector, SBS copolymers are often used to modify asphalt and improve the performance of roads and roofing materials. They enhance durability and resistance to temperature fluctuations, thus prolonging the lifespan of the structures.

Footwear: SBS copolymers are an essential component in the manufacturing of sports shoes, sneakers, and other footwear. Their flexibility and cushioning properties make them ideal for comfortable and long-lasting shoe soles.

Adhesives and Sealants: SBS copolymers find application in the formulation of adhesives and sealants, where their ability to provide strong bonds and resistance to environmental factors is highly valued.

Recent Innovations in SBS Copolymer Applications

Innovations in SBS copolymer applications have expanded the market's reach and introduced new possibilities for various industries. Some of the notable innovations include:

Sustainable Alternatives: With the growing emphasis on sustainability, manufacturers have been exploring the development of bio-based SBS copolymers. These eco-friendly alternatives reduce the environmental impact of SBS production.

3D Printing: SBS copolymers are increasingly being used in 3D printing due to their excellent mechanical properties. This has opened up opportunities for rapid prototyping and customized product manufacturing.

Medical Devices: SBS copolymers are being employed in the production of medical devices and components, thanks to their biocompatibility and flexibility.

Emerging Trends in the SBS Copolymer Market

Several trends are shaping the SBS copolymer market trend and are likely to influence its trajectory in the coming years:

Smart Infrastructure: The integration of SBS-modified materials in infrastructure projects is expected to rise. These materials can enhance the durability and longevity of roads, bridges, and other structures.

Circular Economy: The adoption of circular economy principles is gaining momentum. SBS copolymers can be recycled and repurposed, aligning well with this sustainability trend.

Customized Formulations: Manufacturers are increasingly offering tailored SBS copolymer formulations to meet the specific needs of various industries, further expanding the market's scope.

Future Outlook

The future of the SBS copolymer block market appears promising, with continued growth on the horizon. As industries demand more versatile and eco-friendly materials, SBS copolymers are well-positioned to meet these requirements. The market is expected to witness innovation in terms of product formulations, applications, and manufacturing processes.

The automotive and construction sectors are likely to remain major consumers of SBS copolymers, driven by the need for lightweight and durable materials. Additionally, the emergence of advanced technologies, such as 3D printing, may further boost demand in other industries.

As sustainability and circular economy principles continue to gain traction, the market will also witness a shift toward more environmentally friendly practices and materials. Bio-based SBS copolymers and increased recycling efforts will contribute to this transformation.

In conclusion, the Styrene-Butadiene-Styrene (SBS) copolymer block market has shown remarkable resilience and adaptability, positioning itself as a cornerstone of various industries. With continuous innovation and the growing focus on sustainability, the future of this market is bright, offering new possibilities and applications in the ever-evolving world of materials science.

#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Share#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Growth#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Demand

0 notes

Text

"Hygiene Adhesives Market Expected to Rise from $3.9 Billion in 2024 to $7.2 Billion by 2034, at a 6.2% CAGR"

Hygiene Adhesives Industry encompasses the production and distribution of adhesive products specifically designed for hygiene applications, including diapers, feminine care products, and adult incontinence solutions. This sector is driven by innovations in adhesive technologies that ensure efficiency, comfort, and reliability. Key trends include the growing demand for eco-friendly adhesives, advancements in bonding techniques, and the expansion of the personal care market globally, which collectively underscore significant growth opportunities within the industry.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10630 &utm_source=SnehaPatil&utm_medium=Article

The Hygiene Adhesives Industry is experiencing robust growth, propelled by rising demand for personal care products and innovations in adhesive technologies. The baby diapers segment leads the market, driven by increasing birth rates and improved living standards globally. Feminine hygiene products emerge as the second-highest performing sub-segment, reflecting heightened awareness and acceptance of modern hygiene solutions. Geographically, Asia-Pacific dominates the market, benefiting from a large population base and rapid urbanization. North America follows closely, with significant contributions from the United States, where consumer awareness and technological advancements drive demand. Within Europe, Germany stands out due to its strong manufacturing base and focus on sustainable product development. These regions benefit from strategic collaborations and investments in research and development, which enhance product efficacy and environmental compliance. The industry’s growth is further supported by evolving consumer preferences towards eco-friendly and skin-sensitive products, creating lucrative opportunities for market players.

Market Segmentation

Type: Hot Melt Adhesives, Water-Based Adhesives, Solvent-Based Adhesives, Pressure Sensitive Adhesives, Reactive Adhesives

Product: Baby Diapers, Adult Incontinence Products, Feminine Hygiene Products, Medical Adhesives

Application: Disposable Hygiene Products, Medical and Surgical, Packaging

Technology: Nonwoven Technology, Spray Technology, Slot Die Technology

Material Type: Polyurethane, Polypropylene, Ethylene Vinyl Acetate, Styrenic Block Copolymers

End User: Healthcare, Personal Care, Household, Industrial

Form: Liquid, Solid

Component: Base Resin, Additives

Functionality: Bonding, Sealing, Coating

Process: Extrusion, Lamination

In 2023, the Hygiene Adhesives Industry reported a market volume of 1.2 billion metric tons, with projections indicating a rise to 1.8 billion metric tons by 2033. The personal care adhesives segment commands the largest market share at 45%, followed by medical adhesives at 30%, and industrial adhesives at 25%. Growth in personal care adhesives is driven by increasing demand for hygiene products in emerging markets. Key players such as Henkel AG, 3M Company, and H.B. Fuller Company dominate the market, leveraging advancements in adhesive technology and sustainable product offerings.

Competitive dynamics are shaped by these industry leaders through strategic mergers and acquisitions, enhancing their global footprint and product portfolios. Regulatory frameworks, particularly in the EU and North America, emphasize eco-friendly and non-toxic adhesive formulations, influencing market trajectories. Future projections highlight a 10% annual increase in R&D investments, focusing on biodegradable and high-performance adhesives. The industry outlook remains robust, with technological innovations and rising consumer awareness fostering growth. Challenges include compliance with stringent regulations and the need for continuous innovation to maintain competitive advantage.

#HygieneAdhesives #PersonalCareProducts #EcoFriendlyAdhesives #AdhesiveTechnology #BabyDiapers #FeminineHygiene #SustainableProducts #NonwovenTechnology #GlobalMarketTrends #HealthcareAdhesives #InnovationInAdhesives #ConsumerAwareness #RisingDemand #EmergingMarkets #TechnologicalAdvancements

0 notes

Text

Thermoplastic Elastomer Market Overview: Key Drivers and Challenges

The global thermoplastic elastomer market size was USD 26,856.8 million in 2019 and is projected to reach USD 39,424.6 million by 2027, exhibiting a CAGR of 5.7% during the forecast period. The rising demand for lightweight, durable, and recyclable materials is fueling market expansion, with innovations in material development further driving adoption.

The report offers?

The report on the thermoplastic polyurethane market uncovers excellent insights into the market, systematic data with detailed analysis, market dynamics & aspects demonstrating development and growth, meticulous information about vital players in the market, and procured statistics about dominant regions.

Get a Free Sample Report - https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/thermoplastic-elastomer-tpe-market-104515

Key Market Drivers

Growth in Automotive Industry

Increasing use of TPEs in automotive applications such as seals, gaskets, interior components, and bumpers to enhance fuel efficiency by reducing vehicle weight.

Rising Demand for Eco-Friendly Materials

Growing awareness of sustainability is pushing manufacturers to develop recyclable and bio-based TPEs.

Expansion in Medical Applications

TPEs are widely used in medical devices, tubing, and wearable devices due to their flexibility, biocompatibility, and ease of sterilization.

Versatility Across Industries

TPEs’ ability to replace traditional materials in footwear, construction, and consumer goods applications is driving market growth.

Advancements in Material Technology

Development of high-performance TPE grades with enhanced thermal, mechanical, and chemical properties is opening new application areas.

Thermoplastic Polyurethane Market Segmentation

By Type of TPE

Styrenic Block Copolymers (SBCs)

Widely used in adhesives, sealants, and coatings.

Thermoplastic Polyolefins (TPOs)

Primarily used in automotive applications for impact resistance and durability.

Thermoplastic Polyurethanes (TPUs)

Preferred in footwear, medical devices, and consumer electronics for their abrasion resistance and flexibility.

Thermoplastic Vulcanizates (TPVs)

Used in automotive and industrial applications due to their high heat resistance.

Copolyester Elastomers (COPEs)

Known for their high strength and chemical resistance, ideal for engineering applications.

Others (Nylon-based, Bio-based TPEs)

Emerging materials with niche applications in sustainable and specialty markets.

By End-Use Industry

Automotive

The largest application segment, driven by the need for lightweight and durable materials.

Building & Construction

TPEs are used in roofing membranes, sealants, and insulation materials.

Medical

Includes applications in tubing, catheters, and wearable devices.

Footwear

Growing demand for lightweight and comfortable shoes is boosting TPE use in soles and uppers.

Consumer Goods

Includes applications in electronics, toys, and household items.

Others

Includes industrial and agricultural applications.

By Region

North America

Strong demand from the automotive and medical sectors.

Europe

Focus on sustainability and high-quality materials drives market growth.

Asia-Pacific

The largest and fastest-growing region due to rapid industrialization and a booming automotive industry.

Rest of the World

Moderate growth, with opportunities in emerging markets.

Regional Insights:

Expanding Infrastructure to Fuel Growth in APAC

High rates of growth and development and population growth and industry consolidations have resulted in innovation and development, establishing APAC as a global industrial powerhouse. In addition, the expanding infrastructure and increasing product demand in the construction industry will improve the prospects of the market in the forthcoming years. The growing need for high-performance materials is propelling the TPU market in Asia Pacific to new heights. Moreover, the high demand for polyester-based thermoplastic polyurethane from the electronics sector is driving the rise in North America. Furthermore, increased demand for footwear due to increased disposable income would drive market expansion in this region. The fast-developing automobile sector in nations like Germany, France, and the United Kingdom will boost market expansion in Europe.

Emerging Trends

Sustainability and Bio-Based TPEs

Increasing development and adoption of bio-based and recyclable TPEs to reduce environmental impact.

Growing Adoption in 3D Printing

Use of TPE filaments in additive manufacturing is opening new avenues for customization and rapid prototyping.

Advancements in Automotive Applications

Increasing use of TPEs in electric vehicles (EVs) for weight reduction and energy efficiency.

Miniaturization in Medical Devices

Demand for TPEs is growing in wearable and minimally invasive medical devices.

Increased Focus on Customization

Development of tailor-made TPE grades for specific applications across industries.

Source- https://www.fortunebusinessinsights.com/thermoplastic-elastomer-tpe-market-104515

Competitive Landscape

The thermoplastic elastomer market is highly competitive, with key players focusing on R&D and strategic collaborations to expand their market presence. Leading companies include:

BASF SE

SABIC

Dow Inc.

Kraton Corporation

LG Chem Ltd.

Covestro AG

Asahi Kasei Corporation

Mitsubishi Chemical Corporation

Arkema S.A.

Teknor Apex Company

These companies are driving innovation in bio-based and high-performance TPEs to meet the evolving demands of various industries.

Future Outlook

The thermoplastic elastomer market is poised for steady growth, driven by advancements in material science, increasing demand for lightweight and durable materials, and expanding applications in emerging markets. The Asia-Pacific region is expected to lead in growth, while North America and Europe will remain key innovation hubs.

Conclusion

The thermoplastic elastomer market is transforming industries with its unique combination of flexibility, durability, and sustainability. As industries move toward lightweight, high-performance, and eco-friendly solutions, TPEs will play a pivotal role in shaping the future of manufacturing and product design.

0 notes

Text

Hot Melt Adhesives

Global Hot Melt Adhesives Market Overview

The global market for hot melt adhesives (HMAs) was valued at over USD 9.3 billion in 2019 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% during the forecast period, presenting significant revenue opportunities for industry stakeholders.

Key Market Drivers

Hot melt adhesives are gaining traction across various industries due to their low emissions of volatile organic compounds (VOCs) and superior shelf life compared to solvent-based adhesives. This sector is outpacing the growth of the broader chemical industry, driven by the rising demand for high-performance solutions in heavy industries. As competition intensifies, manufacturers are prioritizing product innovation and patent acquisitions to solidify their market presence.

Innovations and Developments

Leading companies are implementing strategic initiatives to enhance revenue and brand visibility. Notably, in 2015, Eastman Chemical Company introduced Aerafin Polymer A, a new polyolefin specifically designed for hot melt adhesives. Jowat also launched a polyurethane (PUR) hot melt adhesive tailored for window profile wrapping. The focus on patenting innovations has been evident since 2010, with Bostik, Inc. receiving a patent in 2013 for a high-styrene SBS hot melt adhesive, while H.B. Fuller patented a hot melt pressure-sensitive adhesive incorporating vegetable wax. This trend is expected to persist throughout the forecast period (2018-2028).

Market Segmentation

By Product Type:

Ethylene-Vinyl Acetate (EVA)

Polyolefins

Styrene Block Copolymers (SBC)

Polyurethane (PUR)

Hot Melt Pressure Sensitive Adhesives

Others

By Application:

Packaging

Electronics

Automotive

Hygiene Products

Construction

Furniture

Textiles

Others

Market Analysis by Product

The polyolefin-based hot melt adhesives segment is anticipated to achieve the fastest growth, with a CAGR of 6.1% during the forecast period. These adhesives are known for their excellent bonding capabilities and rapid setting speed, making them essential across various industries. The rise of smart factories is expected to further boost the demand for polyolefin-based HMAs.

Application Insights

Packaging is the leading application for hot melt adhesives, accounting for 24% of the global market share in 2019. With the packaging industry valued at USD 550 billion and experiencing rapid growth, this segment presents vast opportunities for hot melt adhesive manufacturers.

Regional Market Dynamics

Asia Pacific dominated the market, holding an estimated 45% share in 2019, with China being the largest contributor. Many leading companies have established production facilities in China due to lower manufacturing costs and supportive government policies. Additionally, China is recognized as the world's largest market for packaging and consumer electronics, driving substantial demand for HMAs. The Chinese hot melt adhesives market was valued at over USD 2.1 billion in 2019, with packaging accounting for 27% of this revenue.

The competitive landscape in China features over 210 active suppliers, predominantly small-scale firms operating on a contract basis. Key players such as Henkel, Tex Year Fine Chemical, Bostik, and H.B. Fuller continue to lead the high-end market due to robust supply chains and a strong focus on product innovation.

In mature markets like Europe and North America, companies are leveraging inorganic growth strategies. In Western Europe, the UK, Germany, and France are projected to hold a combined market share of 69% in the hot melt adhesive sector.

Competitive Landscape

To maintain a competitive edge and maximize returns on investment (ROI), industry participants are prioritizing product innovation.

Key Players in the Hot Melt Adhesives Market:

Adhesive Technologies, Inc.

Worthen Industries Inc.

American Chemical, Inc.

3M

Jowat SE

Evans Adhesive Corporation Ltd.

Avery Dennison Corporation

Tex Year Industries Inc.

Bostik Inc.

Capital Adhesives & Packaging Corp.

LORD Corporation

Costchem srl

Daubert Chemical Company, Inc.

Ashland Global Holdings Inc.

Dow Corning Corporation

Alfa International Corporation

H.B. Fuller Company

Henkel AG & Co. KGaA

Sika AG

0 notes

Text

Anticipated Size of Styrenic Block Copolymer Market: $9.22B by 2032, 4.6% CAGR

Leading market research and consulting organization Polaris Market Research is excited to announce the release of its latest research report titled Styrenic Block Copolymer market. The report highlights the current state and growth potential of the Styrenic Block Copolymer market. It delves into various aspects of the market, including market share, market size, top trends, and recent developments. Also, it sheds light on the major operating strategies used by market participants to stay competitive in the market. Besides, a thorough analysis of all the major segments and sub-segments has been included in the study.

The research report includes Porter’s Five Forces analysis to examine the competitive landscape within the market. Both quantitative and qualitative analyses have been used in the study to offer an in-depth market comprehension. Also, the report makes use of pictorial representations like graphs and charts to help readers understand the key stats and other information easily. The report is a must-read for anyone looking to make strategic and informed business decisions.

Global Styrenic Block Copolymer Market size and share is currently valued at USD 6.41 billion in 2024 and is anticipated to generate an estimated revenue of USD 9.22 billion by 2032, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 4.6% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2024 - 2032

Top key players: Asahi Kasei Corporation, China Petrochemical Corporation (Sinopec), Denka Company Limited, Dynasol Group, INEOS Styrolution Group GmbH, JSR Corporation, KRATON CORPORATION, Kuraray Co., Ltd., LCY Group, LG Chem, TSRC, ZEON CORPORATION

Market Dynamics

This section of the research study examines the key forces that affect the performance and behavior of the market. These include:

Supply and Demand: The research study examines the fluctuations in supply and demand and their impact on pricing signals.

Technological Advancements: An examination of all the major technology advancements and innovations and how they are driving market growth have been examined in the study.

Regulatory Changes: The study assesses all the major regulatory changes, policies, and initiatives and how they are influencing market demand.

Consumer Preferences: The impact of consumer behavior and preferences on Styrenic Block Copolymer market sales has been detailed in the research report.

Economic Trends: The sheds light on all the major economic trends worldwide that can affect the market dynamics.

Browse Full Insights:

Market Segmentation

This section of the research study divides the market into meaningful subgroups based on common characteristics. The Styrenic Block Copolymer market segmentation is primarily based on type, application, end-use, and region. By understanding market segmentation, businesses can create effective targeted advertising and promotions that resonate with every group. Also, it can help save time and money by avoiding mass marketing techniques that may not be effective for specific groups. Besides, businesses can collect valuable feedback from every group to improve their products/services. What’s more, segmental analysis can improve business focus by enabling them to make better decisions about location, inventory, and hiring.

Competitive Landscape

The competitive landscape examines the current state of competition in the market. It assesses all the major companies that compete with a specific company for customers. Also, it examines the options available to customers instead of the company’s products/services. Competitive landscape analysis includes several factors, including the number of competitors and their market share, product offerings, and pricing strategies. Also, it sheds light on the level of competition and major Styrenic Block Copolymer market trends. By going through the competitive landscape section, businesses can identify potential opportunities and avoid costly mistakes. Furthermore, it can assist stakeholders in capitalizing on new ideas and improving their customer journey.

Regional Analysis

Regional analysis involves the study of specific geographic regions in the Styrenic Block Copolymer market. It helps examine the impact of social, physical, and economic variables in a regional context. Also, it assists businesses in understanding consumer behavior, economic trends, and competitive landscapes. Regional analysis is important for stakeholders, businesses, analysts, and policymakers to assess the market state in various market regions and sub-regions across the globe.

The key regions and sub-regions covered in the research report are:

North America (US, Canada)

Europe (France, Germany, UK, Italy, Netherlands, Spain, Russia)

Asia Pacific (Japan, China, India, Malaysia, Indonesia. South Korea)

Latin America (Brazil, Mexico, Argentina)

Middle East & Africa (Saudi Arabia, UAE, Israel, South Africa)

The Report Answers Questions Such As:

What is the current market size and forecast market value?

What is the estimated CAGR for the market over the forecast period?

Which region is projected to witness substantial Styrenic Block Copolymer market growth?

Which segment is anticipated to lead the market?

What are the emerging business opportunities for market players?

What can strategic developments take the market in the upcoming years?

More Trending Latest Reports By Polaris Market Research:

Skin Care Products Market

Space propulsion market

North america Automated Breach And Attack Simulation Market

U.S. Metaverse Market

Anomaly Detection Market

0 notes

Text

Global Low VOC Adhesives Market Overview : Size, Share, and Future Trends Forecast

Global Low VOC Adhesives Market Industry ,Trends & Analysis

The Low VOC Adhesives Market research report offers an in-depth analysis of market dynamics, competitive landscapes, and regional growth patterns. This comprehensive report provides businesses with the strategic insights necessary to identify growth opportunities, manage risks, and develop effective competitive strategies in an ever-evolving market.

According to Straits Research, the global Low VOC Adhesives Market market size was valued at USD 51.96 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 87.71 Billion by 2031, growing at a CAGR of 5.99% during the forecast period (2023–2031).

Request a Sample Report Today @ https://straitsresearch.com/report/low-voc-adhesives-market/request-sample

Global Low VOC Adhesives Market Segmental Analysis

As a result of the Low VOC Adhesives market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Technology

Water-Based

Hot Melt

Pressure Sensitive

Reactive

By Resin

Polyvinyl Acetate

Acrylic

Polyurethane

Ethylene-Vinyl Acetate

Epoxy

Styrenic Block Copolymer

Others

By End-User

Paper and Packaging

Building and Construction

Furniture

Automotive and Transportation

Leather and Footwear

Consumer and DIY

Medical Devices

Others

You can check In-depth Segmentation from here @ https://straitsresearch.com/report/low-voc-adhesives-market/toc

Why Invest in this Report?

Leverage Data for Strategic Decision-Making: Utilize detailed market data to make informed business decisions and uncover new opportunities for growth and innovation.

Craft Expansion Strategies for Diverse Markets: Develop effective expansion strategies tailored to various market segments, ensuring comprehensive coverage and targeted growth.

Conduct Comprehensive Competitor Analysis: Perform in-depth analyses of competitors to understand their market positioning, strategies, and operational strengths and weaknesses.

Gain Insight into Competitors' Financial Metrics: Acquire detailed insights into competitors' financial performance, including sales, revenue, and profitability metrics.

Benchmark Against Key Competitors: Use benchmarking to compare your business's performance against leading competitors, identifying areas for improvement and potential competitive advantages.

Formulate Region-Specific Growth Strategies: Develop geographically tailored strategies to capitalize on local market conditions and consumer preferences, driving targeted business growth in key regions.

List of Top Leading Players of the Low VOC Adhesives Market -

3M

Henkel

Sika

H.B. Fuller

Arkema (Bostik)

Dow

Mapei

Chemence

Infinity Bond

Parker LORD

PPG Industries

Beacon Adhesives

Dymax

Huntsman International

Ashland

Delo

DuPont

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

Regional Analysis Low VOC Adhesives Market

The regional analysis section of the report offers a thorough examination of the global Low VOC Adhesives market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Low VOC Adhesives market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

To Understand How Covid-19 Impact Is Covered in This Report @ https://straitsresearch.com/buy-now/low-voc-adhesives-market

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Low VOC Adhesives Market#Low VOC Adhesives Market Share#Low VOC Adhesives Market Size#Low VOC Adhesives Market Research#Low VOC Adhesives Industry#What is Low VOC Adhesives?

0 notes

Text

Non-woven Adhesives Market Outlook to 2031

The Insight Partners recently announced the release of the market research titled Non-woven Adhesives Market Outlook to 2031 | Share, Size, and Growth. The report is a stop solution for companies operating in the Non-woven Adhesives market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Non-woven Adhesives Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, The Insight Partners is helping brands unlock revenue opportunities in the Non-woven Adhesives market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Non-woven Adhesives market research has all that you need.

What are Key Offerings Under this Non-woven Adhesives Market Research?

Global Non-woven Adhesives market summary, current and future Non-woven Adhesives market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Non-woven Adhesives Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Non-woven Adhesives Market?

Non-woven Adhesives market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Non-woven Adhesives market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Non-woven Adhesives market share.

Report Attributes

Details

Segmental Coverage

Technology

Hot-melts

Others

Type

Styrenic Block Copolymers

Amorphous Poly Alpha Olefin

Ethylene Vinly Acetate

Application

Baby Care

Feminine Hygiene

Adult Incontinence

Medical

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Avery Dennison Corporation

Cattie Adhesives Solutions LLC.

Celanese Corporation

Eastman Chemical Company

Itw Dynatec Americas

Klebstoffwerke Collodin Gmbh

Michelman Inc.

Nordson Corporation

Palmetto Adhesives Company Inc.

Sika Ireland Ltd.

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Non-woven Adhesives market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The The Insight Partners offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Non-woven Adhesives market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

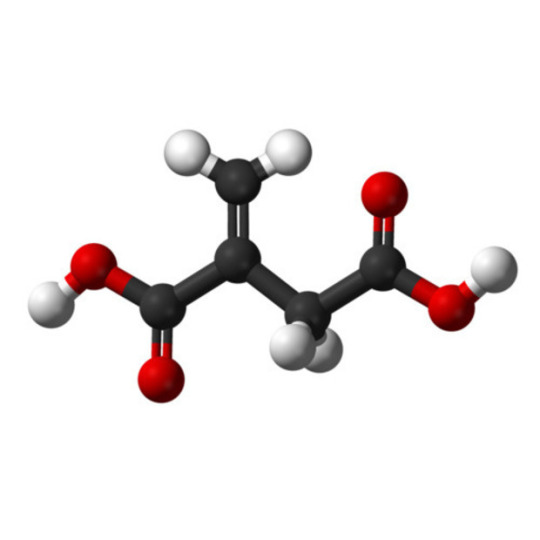

Exploring the Biomedical Applications of Itaconic Acid in Drug Delivery and Biomaterials

Itaconic Acid: A versatile platform chemical gaining significance Production and Applications of Methylenesuccinic Acid Itaconic acid is produced through fermentation of carbohydrates like glucose, sucrose or molasses by fungi species Aspergillus itaconicus or Ustilago maydis. The process involves fungi growth in aqueous medium containing nutrients and sugars followed by acidification to extract methylenesuccinic acid. The medium is then filtered and purified using ion-exchange or crystallization to achieve high purity methylenesuccinic acid. Some key players involved in commercial production of methylenesuccinic acid include Itaconix Corporation, Qingdao Kehai Biochemistry Co., Ltd. and Zhejiang Guoguang Biochemistry Co., Ltd. Current global production capacity of methylenesuccinic acid stands at over 50,000 tons per year. Uses in Polymers and Specialty Chemicals Manufacturing Being a dicarboxylic acid, methylenesuccinic acid serves as an important building block chemical for polymers and specialty chemicals. It finds significant usage in manufacturing of synthetic latex, superabsorbent polymers, chelating agents and copolymers for diverse applications. As a comonomer for acrylate or methacrylate polymers, methylenesuccinic acid improves water-absorbency and acid-base properties. Its copolymers with acrylates and styrene are used in paper coatings, adhesives, thickeners and dispersants. Methylenesuccinic acid also acts as a complexing agent for heavy metal ions and is used in industrial and agricultural chelating formulations. Potential in Novel Therapeutic Applications Novel applications of itaconic acid are being researched in the medical field as well. Some studies have revealed its anti-fungal, antibacterial and anti-viral properties. Research is in progress to develop itaconate derivatives with enhanced bioactivity against multi-drug resistant pathogens. Methylenesuccinic acid is also known regulate inflammatory responses in human body by inhibiting certain enzymes. This makes it a potential candidate for developing novel anti-inflammatory pharmaceuticals. Exploratory trials indicate it may assist in managing conditions like diabetes, neurodegeneration and cancer. Though in early stages, these therapeutic applications open up completely new frontiers for methylenesuccinic acid if successfully commercialized in future. To conclude, with its unique structural attributes and bio-based origin, methylenesuccinic acid has emerged as a very important specialty platform chemical with broad scope across industries. Backed by steady growth in end-use markets and rising sustainability emphasis, the methylenesuccinic acid industry is rightly positioned for significant expansion globally in the coming years. Ongoing R&D and commercial initiatives also point towards novel product concepts and applications further accentuating the industrial relevance of this multifaceted organic acid.

0 notes

Text

Styrene Block Copolymer (SBC) Market Assessment: Current Status and Outlook

Styrene Block Copolymers (SBCs) have established themselves as versatile materials in the realm of polymers, offering a unique combination of properties that cater to diverse applications across industries. This blog delves into the dynamics of the global Styrene Block Copolymer market, exploring its demand drivers, applications, emerging trends, and future prospects.

Understanding Styrene Block Copolymers (SBCs):

Styrene Block Copolymers thermoplastic elastomers composed of styrene and diene monomers arranged in a block structure. This distinctive molecular arrangement imparts SBCs with characteristics of both thermoplastics and elastomers, including flexibility, resilience, and processability, making them ideal for various applications.

Demand Drivers:

Adhesive and Sealant Industry: SBCs serve as key ingredients in adhesive and sealant formulations, offering excellent adhesion, tackiness, and cohesion properties, driving demand in the construction, automotive, and packaging sectors.

Footwear and Textiles: The footwear industry extensively utilizes SBCs in the production of shoe soles and components due to their cushioning, durability, and abrasion resistance. Additionally, SBCs find applications in textile coatings, providing waterproofing and abrasion resistance.

Medical and Healthcare: SBCs are increasingly used in medical and healthcare applications, including medical adhesives, wound dressings, and drug delivery systems, benefiting from their biocompatibility and flexibility.

Consumer Goods Manufacturing: SBCs are integral in the manufacturing of consumer goods such as toys, sporting goods, and household products, owing to their versatility, durability, and aesthetic appeal.

Applications Across Industries:

Adhesives and Sealants: Construction, automotive, packaging.

Footwear and Textiles: Shoe soles, textile coatings.

Medical and Healthcare: Medical adhesives, wound dressings, drug delivery.

Consumer Goods: Toys, sporting goods, household products.

Market Trends:

Focus on Sustainability: The SBC market is witnessing a shift towards sustainable solutions, with an increasing demand for bio-based and recyclable SBCs to meet environmental concerns and regulatory requirements.

Customization and Specialty Grades: Manufacturers are offering specialized SBC formulations tailored to specific industry needs, incorporating additives and modifiers to enhance performance characteristics and address niche applications.

Technological Advancements: Ongoing research and development efforts focus on improving SBC processing techniques, exploring novel applications, and enhancing product performance to meet evolving market demands.

Future Prospects:

The global Styrene Block Copolymer market is poised for significant growth, driven by its versatility, adaptability, and increasing demand across industries. As industries continue to prioritize performance, sustainability, and innovation, SBCs are well-positioned to meet the evolving needs of diverse applications.

Conclusion:

Styrene Block Copolymers have emerged as indispensable materials in various industries, offering a unique blend of properties that address a wide range of application requirements. Navigating the global SBC market requires a deep understanding of market dynamics, emerging trends, and the evolving needs of industries. With a promising future shaped by sustainability initiatives and technological advancements, SBCs stand as versatile solutions paving the path for innovation in polymer applications worldwide.

#MarketResearch#SustainableMaterials#MarketTrends#AutomotiveApplications#PackagingMaterials#ChemicalIndustry#PolymerIndustry#StyreneBlockCopolymer

0 notes

Text

Styrene-Butadiene-Styrene (SBS) Copolymer Block Market: Insights into Regional Growth Patterns

Styrene-Butadiene-Styrene (SBS) Copolymer Block Market: Driving Forces and Future Trends

The Styrene-Butadiene-Styrene (SBS) copolymer block market is witnessing significant growth and transformation in recent years. SBS is a versatile synthetic rubber with a wide range of applications across various industries. This article explores the driving forces behind the expansion of the SBS copolymer block market and provides insights into future trends that are likely to shape the industry.

Understanding SBS Copolymer Blocks Market

Before delving into the market dynamics, it's essential to understand what SBS copolymer blocks are and why they are significant. SBS is a thermoplastic elastomer produced by copolymerizing styrene and butadiene. This unique combination of properties makes SBS an attractive material for a multitude of applications.

SBS copolymer blocks are known for their exceptional elasticity, durability, and resistance to temperature extremes. They can be processed through various methods, including extrusion, injection molding, and blow molding, making them suitable for diverse manufacturing processes. The ability to modify SBS copolymer blocks to achieve specific properties, such as improved tensile strength or enhanced chemical resistance, further enhances their appeal across industries.

Driving Forces Behind the Growth of SBS Copolymer Block Market

Several factors are driving the growth of the SBS copolymer block market:

1. Growing Demand in Construction and Infrastructure The construction and infrastructure sectors have been key drivers of SBS copolymer block consumption. SBS-modified bitumen is widely used in roofing and pavement applications due to its excellent weather resistance and flexibility. As urbanization continues to rise globally, the demand for durable construction materials like SBS copolymer blocks is expected to surge.

2. Automotive Industry Advancements The automotive industry is another significant consumer of SBS copolymer blocks. SBS is used in manufacturing various automotive components, including tires, gaskets, seals, and interior parts. With the continuous development of electric and autonomous vehicles, there is a growing need for lightweight materials that offer noise reduction and vibration damping characteristics, making SBS an attractive choice.

3. Advancements in Medical Devices The medical device industry has witnessed a surge in the use of SBS copolymer blocks for applications like tubing, seals, and gaskets. SBS's biocompatibility, sterilizability, and flexibility make it ideal for medical device manufacturing. As healthcare technologies advance, the demand for SBS in this sector is expected to increase further.

4. Consumer Electronics Consumer electronics, including smartphones, tablets, and wearables, require materials that provide shock absorption and impact resistance. SBS copolymer blocks are being increasingly used in the manufacturing of protective cases and shock-absorbing components, contributing to their market growth.

5. Sustainability and Recycling Sustainability is a significant driver in the modern materials industry. SBS copolymer blocks are recyclable and can be processed into various products, reducing environmental impact. The emphasis on sustainability and the circular economy has encouraged the adoption of SBS in various applications.

Future Trends in the SBS Copolymer Block Market

As the SBS copolymer block market continues to evolve, several trends are likely to shape its future:

1. Research and Development Ongoing research and development efforts are expected to result in new formulations of SBS copolymer blocks with enhanced properties, such as improved flame resistance, UV resistance, and electrical conductivity. These innovations will open up new application opportunities in industries like aerospace and electronics.

2. Sustainable Practices Environmental regulations and consumer demand for sustainable products are pushing manufacturers to explore more eco-friendly production methods and raw materials. This trend is likely to lead to the development of bio-based SBS copolymer blocks and improved recycling processes.

3. Increased Use in Healthcare The healthcare industry's reliance on SBS copolymer blocks is expected to grow further, with advancements in medical devices, drug delivery systems, and biotechnology. Customized SBS formulations designed for specific medical applications will become more prevalent.

4. Infrastructure Investments As governments invest in infrastructure projects to support economic growth, the demand for SBS-modified bitumen in road construction and roofing applications is projected to rise, creating opportunities for manufacturers in the construction sector.

In conclusion, the Styrene-Butadiene-Styrene (SBS) copolymer block market demand is poised for continued growth due to its versatility and adaptability across various industries. The driving forces behind this expansion include its use in construction, automotive, healthcare, and consumer electronics. Future trends in the market are likely to be shaped by research and development, sustainability initiatives, increased healthcare applications, and infrastructure investments. Manufacturers and industry stakeholders should keep a close watch on these developments to capitalize on the opportunities presented by the evolving SBS copolymer block market.

#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Share#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Growth#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Demand

0 notes

Text

Styrene Butadiene Styrene Rubber Market Size, Scope, Growth Opportunities, Trends by Manufacturers And Forecast to 2030

The global styrene butadiene styrene rubber market is valued at US$ 5.5 Million in 2023 and is projected to reach US$ 6.3 Million by 2030, growing at a CAGR of 4.90% from 2023 to 2030. SBS rubber is a synthetic rubber that is produced by the copolymerization of styrene and butadiene. It is a versatile material with a wide range of properties, including good abrasion resistance, low heat resistance, and good elasticity. SBS rubber is used in a variety of applications, including tires, footwear, adhesives, and sealants.

Styrene-butadiene-styrene is the name of a thermoplastic elastomer composed of butadiene and styrene. A different kind of block copolymer comprises a long chain of polystyrene and a middle chain of polybutadiene. Because styrene-butadiene-styrene possesses qualities of both rubber and polymers, its market demand is rising. Although polybutadiene offers flexibility, styrene-butadiene-styrene polystyrene offers excellent strength and durability. The diverse applications of styrene-butadiene-styrene in a range of industries, including electrical and electronic equipment, shoe soles, and many more, contribute to the rise in demand for this material on the global market.

Get your Sample Report with Latest Market Information! https://absolutemarketresearch.com/Global-Styrene-Butadiene-Styrene-Rubber-Market/1792/request-sample

Styrene butadiene styrene rubber (SBS) is a type of thermoplastic elastomer (TPE) that is made from the copolymerization of styrene and butadiene. The styrene units in SBS provide the material with its hardness and stiffness, while the butadiene units give it its elasticity and resilience. The ratio of styrene to butadiene in the polymer can be varied to control the properties of the material. For example, a higher styrene content will produce a harder, more rigid material, while a higher butadiene content will produce a softer, more elastic material.

SBS is typically synthesized by a free radical polymerization process in which styrene and butadiene monomers are heated in the presence of a free radical initiator. The initiator breaks down into free radicals, which then attack the monomers and initiate the polymerization reaction. The polymer chains grow by adding monomers to the ends of the chains. The ratio of styrene to butadiene in the polymer depends on the relative amounts of the monomers and the reaction conditions.

SBS is a block copolymer, which means that it is made up of alternating blocks of styrene and butadiene units. The styrene blocks are more rigid and glassy, while the butadiene blocks are more flexible and rubberier. The alternating arrangement of the blocks gives SBS its unique properties.

The growth of the market is driven by several factors, including:

Increased demand from the automotive industry: SBS rubber is used in a variety of automotive components, such as tires, seals, and hoses. As the automotive industry continues to grow, the demand for SBS rubber is expected to increase.

Growing demand from the adhesives and sealants industry: SBS rubber is used in a wide variety of adhesives and sealants, due to its good adhesion and elasticity. As the construction and packaging industries continue to grow, the demand for SBS rubber is expected to increase.

Rising demand from the medical device industry: SBS rubber is used in a variety of medical devices, such as catheters, tubing, and implants. As the medical device industry continues to grow, the demand for SBS rubber is expected to increase.

Key Takeaways:

The global styrene butadiene styrene rubber market is valued at US$ 5.5 Million in 2023 and is projected to reach US$ 6.3 Million by 2030, growing at a CAGR of 4.90% from 2023 to 2030.

The growth of the SBS rubber market is being driven by the increasing demand for thermoplastic elastomers (TPEs) in various industries, including automotive, construction, and consumer goods.

The automotive industry is the largest end-use sector for SBS rubber, accounting for over 40% of the global market in 2023.

The Asia Pacific region is the largest market for SBS rubber, accounting for over 50% of the global market in 2023.

Regional Outlook:

Asia Pacific is the largest market for SBS rubber, accounting for over 50% of the global market in 2023. The growth of the SBS rubber market in Asia Pacific is being driven by the rapid growth of the automotive and construction industries in the region.

Europe is the second largest market for SBS rubber, accounting for over 30% of the global market in 2023. The growth of the SBS rubber market in Europe is being driven by the increasing demand for TPEs in the automotive and construction industries.

North America is the third largest market for SBS rubber, accounting for over 15% of the global market in 2023. The growth of the SBS rubber market in North America is being driven by the increasing demand for TPEs in the automotive and construction industries.

Key Players:

Dow Chemical Company

Asahi Kasei Corporation

Kumho Petrochemical Co., Ltd.

LG Chem

Sinopec Styrene Butadiene Rubber Co., Ltd.

Segmentation:

By type, the market is segmented into:

Block styrene-butadiene-styrene (SBS)

Random styrene-butadiene-styrene (SBS)

Hydrogenated styrene-butadiene-styrene (HSBS)

By application, the market is segmented into:

Automotive

Construction

Consumer goods

Industrial goods

By region, the market is segmented into:

Asia Pacific

Europe

North America

South America

Middle East and Africa

0 notes

Link

Growing demand in road pavement and waterproofing sheets is projected to drive the market growth of styrene butadiene styrene (SBS) block copolymer in the...

#adroit market research#sbs block copolymer#sbs block copolymer 2019#sbs block copolymer trend#sbs block copolymer share

0 notes

Text

The hot melt adhesive (HMA) market is expected to witness market growth at a rate of 7.55% in the forecast period of 2021 to 2028

#Hot Melt Adhesive (HMA) Market#Hot Melt Adhesive (HMA) Market Share#Hot Melt Adhesive (HMA) Market Size#Hot Melt Adhesive (HMA) Market Growth#Hot Melt Adhesive (HMA) Market Trends#Hot Melt Adhesive (HMA) Market Players

0 notes

Text

Hot Melt Adhesives

The global market size of hot melt adhesives is estimated to surpass USD 9.3 billion in 2019, with a projected compound annual growth rate (CAGR) of 5.4% during the forecast period, creating significant revenue opportunities for industry stakeholders.

Hot melt adhesive (HMA) has garnered widespread adoption across various industries due to its low emission of volatile organic compounds (VOC) and prolonged shelf life compared to solvent-based adhesives. This sector has exhibited robust growth, outperforming the overall chemical industry, driven by the escalating demand for high-performance solutions across heavy industries. The competitive landscape of the industry has intensified, prompting players to focus on product innovation and securing patents to fortify their market presence.

Several leading companies have undertaken strategic initiatives to enhance revenue and establish a prominent brand presence. For example, in 2015, Eastman Chemical Company introduced Aerafin Polymer A, a novel polyolefin for hot melt adhesives, while Jowat introduced PUR hot melt adhesive for window profile wrapping. Furthermore, there has been a notable surge in patent registrations post-2010, indicating a sustained trend of innovation within the industry.

Global Hot Melt Adhesives Market Size and Forecast: By Product

The market for polyolefin-based hot melt adhesives is projected to witness the fastest growth, with a CAGR of 6.1% during the forecast period. These adhesives offer superior adhesive properties and rapid setting speeds, finding extensive applications across diverse industries.

Global Hot Melt Adhesives Market Size and Forecast: By Application

Packaging emerges as the largest end-use market for hot melt adhesives, expected to account for 24% of the global share in 2019. The burgeoning USD 550 billion packaging industry presents substantial growth opportunities for hot melt adhesive manufacturers.

Global Hot Melt Adhesives Market Size and Forecast: Regional Analysis

Asia Pacific is anticipated to command a significant market share, accounting for 45% in 2019, with China leading the regional market. The region's robust market presence can be attributed to its cost-effective production capabilities, favorable government policies, and extensive demand generated by its thriving packaging and consumer electronics sectors.

Global Hot Melt Adhesives Market Size and Forecast: Competition Landscape

Industry players are prioritizing product innovation to maintain competitiveness and drive returns on investment.

Key Hot Melt Adhesives Players Include:

Adhesive Technologies, Inc.

Worthen Industries Inc.

American Chemical, Inc.

3M

Jowat SE

Evans Adhesive Corporation Ltd.

Avery Dennison Corporation

Tex Year Industries Inc.

Bostik Inc.

Capital Adhesives & Packaging Corp.

LORD Corporation

Costchem srl

Daubert Chemical Company, Inc.

Ashland Global Holdings Inc.

Dow Corning Corporation

Alfa International Corporation

H.B. Fuller Company

Henkel AG & Co. KGaA

Sika AG

Industry Segmentation:

By Product Type:

EVA

Polyolefins

Styrene Block Copolymers (SBC)

Polyurethane (PUR)

Hot Melt Pressure Sensitive Adhesives

Others

By Application:

Packaging

Electronics

Automotive

Hygiene Products

Construction

Furniture

Textile

Others

0 notes