#Steel Round Bars Market

Explore tagged Tumblr posts

Text

Stainless Steel Round Bar Market: Innovations Driving Industrial Applications

0 notes

Text

Stainless Steel Round Bar Market was valued at US$ 3.19 Billion in 2023. Defense and aerospace is one of the segments reviewed in the MMR report dominating the global Stainless Steel Round Bar market

0 notes

Text

Stainless Steel Round Bar Market Size, Share, Analysis, Growth, Key Players, Trend and Forecast to 2034

In 2023, the global Stainless Steel Round Bar market was estimated at around 31 million tonnes. The market is expected to experience steady growth, with a projected Compound Annual Growth Rate (CAGR) of 4.2% during the forecast period through 2034.

Introduction:

Stainless steel round bars are essential components in various industrial applications due to their remarkable strength, corrosion resistance, and versatility. In South Africa, the demand for these robust materials is on the rise as industries seek durable and high-performance solutions. This article explores the dynamics of the Stainless Steel Round Bar Market in South Africa, highlighting its applications, market trends, and impact on industrial development.

Industrial Applications and Demand:

Stainless steel round bars are used extensively across multiple industries, including construction, automotive, manufacturing, and aerospace. Their superior mechanical properties make them ideal for applications requiring durability, precision, and resistance to harsh environments. The increasing industrialization and infrastructural development in South Africa drive the demand for stainless steel round bars in various sectors.

Click Here: https://www.chemanalyst.com/industry-report/stainless-steel-round-bar-market-4172

Construction Industry:

In the construction industry, stainless steel round bars are utilized for structural support, reinforcement, and fabrication of components such as beams, columns, and railings. Their strength and corrosion resistance make them suitable for both indoor and outdoor applications, ensuring long-lasting performance. As South Africa invests in building and infrastructure projects to support urbanization and economic growth, the demand for stainless steel round bars is expected to increase significantly.

Automotive Sector:

The automotive industry relies on stainless steel round bars for manufacturing critical components like axles, engine parts, and fasteners. These bars offer high strength, durability, and resistance to wear and tear, making them ideal for vehicle parts that require long-term reliability. With South Africa's automotive sector focusing on innovation and sustainability, the adoption of high-quality materials like stainless steel round bars is anticipated to rise, supporting the production of more efficient and durable vehicles.

Manufacturing and Heavy Industries:

Stainless steel round bars play a crucial role in manufacturing and heavy industries, including machinery, equipment, and tool production. Their versatility allows for precise machining and fabrication, making them indispensable in creating components that demand exact specifications and high performance. The expansion of South Africa's manufacturing base, driven by both domestic demand and export opportunities, fuels the growth of the stainless steel round bar market.

Aerospace and Defense:

In the aerospace and defense sectors, stainless steel round bars are used for producing high-strength, corrosion-resistant parts and components. Their reliability under extreme conditions is critical for aerospace applications, including aircraft frames, landing gear, and engine components. As South Africa aims to enhance its aerospace capabilities, the demand for advanced materials like stainless steel round bars is set to grow, contributing to the sector's development and innovation.

Market Trends and Growth Drivers:

The Stainless Steel Round Bar Market in South Africa is influenced by several trends and growth drivers. These include the increasing need for durable and high-performance materials in industrial applications, advancements in production technologies, and the push for sustainable and eco-friendly solutions. The growing focus on infrastructure development, automotive innovation, and industrial modernization also drives the adoption of stainless steel round bars across various sectors.

Click Here: https://www.chemanalyst.com/industry-report/stainless-steel-round-bar-market-4172

Significant players in the Global Stainless Steel Round Bar market are Universal Stainless & Alloy Products, Carpenter Technology Corporation, Tsingshan Holding Group, ThyssenKrupp Materials, Shri Bhagavati Bright Bars, Dongbei Special Steel, Crucible Industries, J. H. Stainless, ArcelorMittal, Garelick Steel, WalsinLihwa, ATI Allvac, Outokumpu, and Others.

Challenges and Strategies:

Despite its advantages, the Stainless Steel Round Bar Market in South Africa faces challenges such as fluctuating raw material prices, competition from alternative materials, and technical complexities in production. To address these challenges, strategic initiatives such as investing in research and development, enhancing local production capabilities, and fostering partnerships with global suppliers are essential. These strategies can help stabilize supply, reduce costs, and drive innovation in the market.

Conclusion:

The Stainless Steel Round Bar Market in South Africa represents a vital component in the country's industrial and infrastructural development. With its exceptional properties and wide-ranging applications, stainless steel round bars support key sectors like construction, automotive, manufacturing, and aerospace. By leveraging market opportunities, addressing challenges, and fostering innovation, South Africa can harness the full potential of the Stainless Steel Round Bar Market, driving industrial growth, technological advancement, and economic development in the region.

0 notes

Text

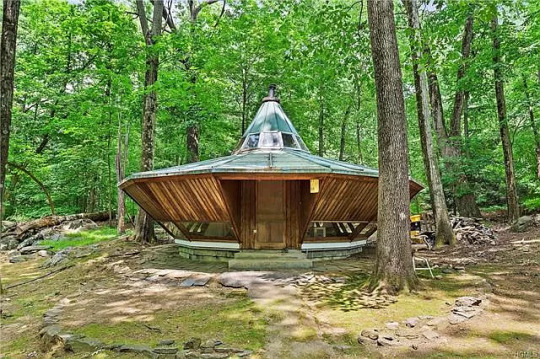

I don't know why, but they took this 1959 Flying Saucer house in Cortlandt Manor, New York, off the market. It was owned by the late comedic actor Jackie Gleason (You know, Ralph, on The Honeymooners). 5bds, 5ba, $1,679,300.

Wow, look at the millwork! This was some amazing house in the 1950s. Looks like a dance floor here.

This kitchen is incredible. And it's in perfect condition.

Spacey stainless steel with lighted cabinets.

Look at this. It's built-in, but it's as big as a bed. Hmmm.

A game room. Wonder if the games convey.

There's also a beautiful fireplace and bar.

Everything is rounded. Even the shower doors. The sink is cool, elevated by thin legs.

I don't know what this is, but it's by the dining room. It has seats, closets, and cabinets. I don't think it's the primary bedroom, b/c it's open. Maybe it is, though.

Beautiful dining room right outside the kitchen. Look at the built-in counter and seat. Has a bar, too.

A cool built-in home office.

The grand stairway.

The black marble bath looks so well-kept.

Nice sun room is quite a large space.

Looks like this was a well-used area.

This stone guest house is beautiful inside, too.

Oh, I would definitely rent this out.

The main house has a beautiful patio and pool.

Decks and patios go around the house.

Think that's the guest house behind that cluster of trees.

8.49 acres of property.

https://www.zillow.com/homedetails/196-Furnace-Dock-Rd-Cortlandt-Manor-NY-10567/2129892550_zpid/?

#celebrity homes for sale#unique homes#unusual homes#mid century modern homes#MCM architecture#houses#house tours#home tour

290 notes

·

View notes

Text

Bass Hall, Ft. Worth

The pain is excruciating. Anne takes a shallow breath, her eyes roving over the wide imperial staircase twenty feet ahead. Martin stands at the first landing with the Donaldson family, laughing against the tapestried backdrop. He glances at her and nods tightly.

She makes her way carefully, stepping between huddled couples and groups of young men drinking too quickly. The bannister is thick, curved and oiled, and she likes how it feels under her hand. She grasps it and trains her eyes to Martin.

“Here she comes,” he says, smiling. The group stops talking and looks at her, nodding hellos.

Her toes ache, crumpled in black heels a half a size too small. She teeters, and prays it was unnoticeable.

Martin descends a few steps and takes her arm.

“Remember, darling, as charming as ever,” he says. “Smile.”

Anne knows there’s something too stiff, too careful in her walk. She swallows against the pain and grips his arm. Two more steps. They exchange pleasantries with the Donaldsons and she fights disassociation. There, a guéridon table. There, a mission chandelier. There, French Rococo armchairs.

“Anne?” Mrs. Donaldson waves her mauve-tipped fingers in front of her face. “Are you ok, dear?”

Martin squeezes her arm.

“Yes,” Anne says. “I’m sorry. Just getting a blister.”

Mrs. Donaldson nods and gestures to her feet. “These are killing me. Let’s find our table and send the men for a drink.”

The group moves along the brightly lit hallway to a high-ceilinged room. The orchestra plays on a raised platform. The bar is crowded. Almost every table is full. The sheer noise startles her. Competing voices and too-loud laughter and lively music. Martin stops and mingles with various groups, talking about the weather, the markets, the opera they’ve just left. The Donaldsons are already at the table, and Anne is sure Mrs. Donaldson has slipped off her shoes under the table and has sent her little husband off for a glass of something.

They’re hailed by a short, dark haired man at the end of the bar. Anne strains to see him better. Christian Hensely. Oh, and his wife. Stephanie or Jennifer or –

“Martin! It’s been too long,” Christian says. The men shake hands.

“It’s good to see you,” Martin says and he turns to the woman. “Heather, hello.” He kisses her cheek and she smiles, squeezing his shoulders.

“Hello, Anne,” Christian turns to her. “It’s nice to see you. How are you feeling?”

“Good, thank you, Mr. Hensely,” Anne replies. “Hello, Mrs. Hensely.”

The older woman smiles at her. “You look wonderful tonight, Anne. Doesn’t she, Christian?”

He watches her closely. “She does.”

“Thank you,” Anne says.

“Should we find our seats?” Martin leads the way through the maze of chairs and bodies.

Mrs. Hensely takes Anne’s hand and they follow the men.

“Is she wearing it?” Christian asks Martin quietly.

Martin nods. The two couples take seats around the large round table and Martin introduces everyone to the Donaldsons. He motions to the server.

“Who’s wearing what?” Mrs. Donaldson asks.

Anne stares at the tablecloth. Martin takes her hand and squeezes.

“Anne wears a special bra that I designed for her, hm, maybe a year ago,” Martin says and glances at his wife. “It’s fitted just for her, very snug, and the interior is studded with steel spikes.”

Mrs. Donaldson takes a sharp breath. “Oh, my.”

“Isn’t it marvelous?” Mr. Hensely’s eyes shine. He turns to Anne. “It must be torture. Anne, are you suffering terribly?”

Anne looks up at him. “Yes, I am.”

Mr. Hensely glances around the table and settles back on Martin. “And then this one, absolute devil, he brings her to the opera and to the parties and has her socialize…”

“That’s delightful,” Mr. Donaldson says. “What a thing, Martin.”

“Doesn’t she bleed?” Mrs. Donaldson asks.

“Not much,” Martin says. He pauses while the table orders drinks. He kisses Anne on her cheek and takes care to press against her breasts. “In any case, the bra is thick. What she really hates are the clamps on her nipples. Don’t you, dear?”

“Yes,” Anne whispers.

“We have to find a quiet corner every forty-five minutes or so,” Martin goes on, “to remove the clamps for a bit, let the blood flow. I think taking them off is the most painful.”

“My God,” Mrs. Donaldson says, shivering. “I just love it. But how can she stand it?”

“She has to.”

The woman leans forward in her chair. She lowers her voice. “Do you like it? Even a little bit?”

“No, I don’t,” says Anne.

“What would be the point if she did?” Martin says. He takes a long drink. “Christian, why don’t you take her for a dance. Careful, her shoes are a little small and she keeps tripping–hold her tightly.”

Mr. Hensely stands, eager. “Anne?” He extends his hand.

“Alright,” she says. She rises to meet him and he leads her to the floor.

“You do look beautiful,” he says. He pulls her tightly against him. Anne tries, gently, to maintain a space between their bodies but he keeps a strong arm around her waist.

“Painful?” he asks.

“Yes.”

“Good,” he says. “It's good to see you suffer. Oh – no, keep your eyes on me, please.”

A few more slow steps and Christian slides his arm a couple inches higher, pulling her harder against him, her breasts pressed into the front of his tuxedo jacket. Sweat breaks out on her forehead.

“Easy, please,” she says. “People will see…”

“No, it’s fine, Anne. They’ll see a couple dancing. They’d never think of anything else.”

He pulls her tight, eases up, pulls her tight again. She makes a high whining sound and he smiles into her hair.

“That really hurts doesn’t it? Of course it does, poor thing. You’re trembling. Careful, your husband is watching and you’re squirming. Let’s move over here to the side…”

He dances her to an open spot in the corner. Anne’s face stays impassive but she whimpers softly and writhes against him.

“Please let me go,” she says.

“No, Anne. Keep dancing. Keep hurting. Do you remember last month at the lake house and Martin had you try on your new bra for us?”

“Mhm.”

Christian laughs. “He had you lie on your stomach almost all day, just hurting and being fucked and rubbing against the floor. God – wasn’t that a perfect weekend? Anne?”

“Yes, Mr. Hensley,” she whispers.

“I’ll bet Mr. Donaldson will want to dance next. Or maybe take a walk in the garden.” He slides a hand between their bodies to finger the clamps on her nipples. She shakes.

“It’s agony, isn’t it? I could come right here. Do you want that?”

She shakes her head no.

“I want to hold you a little tighter but I’m afraid you’ll scream,” he whispers.

The song fades away and a new one begins. Couples pull apart, adjust to the new tempo.

“Ah,” he sounds disappointed. “Maybe we’ll have time for another dance in a bit. Come on, Martin looks impatient.”

58 notes

·

View notes

Text

Boozehounds - I

Summary: King Aegon II and his courtiers halt at a tavern in White Harbour on their lengthy journey to Winterfell. What ensues when they encounter an audacious barmaid who disrespects the king's authority?

Warnings: Contains sensitive themes, including implied sexual violence, namecalling, as well as depictions of sexual harassment. The story contains explicit language and mature themes, including substance abuse and addiction. Authors Note: This was inspired by my beloved Ser Brienne of Tarth. Word Count: 1k Series: i

It was the hour of the wolf, and the pregnant moon’s silver beams glinted off the freshly driven snow. Yet, glowing white in the northern tundra, Barrowtown sat wide awake with no dream of settling. As the north wind whistled its bone-aching chill, the streets turned a quilted tapestry, each patch a drunkard, vendor or whore. But no establishment held a flickering candle to the Wandering Wolf, a small tavern carved into the frozen hill of the Great Barrow.

King Aegon Targaryen, the Second of His Name, sat comfortably in a corner by the roaring fire wrapped in his lynx fur coat, his legs wide, a glass of Harbor Red in his bejewelled, pudgy-fingered grasp. The snow that once covered the circlet of Valyrian steel and square-cut rubies he called a crown had now melted, and his silver hair sat damp like a stray dog’s fur pelted by rain. Behind his chalice was his drooping nose and plump lips stained berry red.

The king's drunken stupor began and ended as it always did, with tall tales. As the brew flowed as did his words, tales of his unwavering bravery, his valiance, his cock. Only when the fibs of the army of bastards he had sired tumbled from his wine-stained mouth did the barmaid behind the counter grow jaded.

She hiked up the tattered grey tunic that hung onto her frame and squatted with a wince. Her feet ached as she had been on that all eve. The war brought soldiers, and soldiers brought coin, and coin kept her fed, but gods, did she hate this wretched work. Her slender fingers brushed past the various barrels under the bar in search of one, in particular, a strong mead from Bear Island.

“Load of horseshite…” She murmured, setting the bronze jug of piss-gold liquid down on the slate counter.

The horde of drunken men, a bewildering mix of northern bannermen, southern knights and sellswords, turned statued; their eyes widened, and their mouths cemented shut.

Aegon turned his head towards her, a crooked crown to match the crooked grin on his flushed, cherubic face.

“I beg your pardon?” he laughed, arching his brow.

Y/N straightened from her hunched-over position and wiped her hands, back and front, on her dingy apron.

“I said it’s a load of horseshite.” she turned to him, deadpan.

Aegon's tightened red fist of fury came down on the round table with a thud. And his party rubbernecked between the pair, the popping and sputtering of the deep rust and scarlet hearth filling the heavy silence.

“She can’t speak to me that way!” he turned to The Hand.

Ser Criston Cole was sat cleaning his longsword, an ugly grey thing, the ugliest weapon Y/N had ever laid her eyes on. Though its blade was sharp, its pommel was discoloured and black, no doubt from ceaseless use. There were no carvings, no figures, no personality. It was just as dull and lifeless as its owner she imagined, although tanned and dornish, the man's features sat quite plainly on his face which always held such a bored expression.

The woman leaned against one of the wooden beams that kept the tavern standing and snorted.

“What are you laughing at?” Aegon barked with wide lilac eyes.

The barmaid stifled another laugh as his face began to resemble the ripened tomatoes that sat plump on the vegetable wagon at the market.

Y/N slipped from behind the tavern counter, filling a wooden mug to its brim with bubbling mead. Her fingers pulled out a rickety stool before she sat, crossed her legs at her ankles and took a long, slow sip. She hummed. Her dark lashes kissing her cheeks as she greedily gulped.

“Was laughin’ at you Your Grace,” she jested after rubbing her sleeved arm against her plush, wet lips.

“One of the mad ones?” whispered Fern, another barmaid with flaming red hair.

“Aye, every time one of these silver haired fucks is born the gods flip a coin.” she mumbled.

Y/N and Fern were the only women in Barrowtown lacking just enough sanity to waitress at The Wandering Wolf, a place known for stiff drinks and the most unsavory of characters. In their defence, it was that or the pleasurehouse, which chambered a darkness even Y/N feared.

Fern cackled along with most of the Northmen that filled the space, almost spilling the bucket of discoloured, soapy water in her calloused grasp.

Aegon’s mouth was agape.

“This is the highest of treasons!” his fist hit the table again, knocking the Arbor Red in his chalice clean over the round table’s edge.

Y/N rolled her dark eyes while Fern groaned.

“I just scrubbed that bloody floor…” she sighed.

Aegon eyed his Kingsguard, “Are you hearing this?! Why are you just stand there?!”

The knights shifted in their armor.

“And what might you have us do Your Grace?” Ser Criston Cole sighed.

“S-Something! Seize them!” He commanded with wild eyes.

The Dornishman nodded, rising to his feet.

“Aye!" Y/N's hand flew out in front of her, "How about a wager?" she hummed, "If the King can outdrink me, he may lie with me till morning cometh,” Y/N smirked, “But if he cannot, he must make knight before the old gods and the new.”

Ser Criston stiffened, his coppered complexion paling.

The tavern erupted into howls of laughter.

“A knight?! A bloody knight?! that’s your wager?” Aegon threw his head back in laughter, “If you wanted to fuck me you could have simply asked,” tears formed in his lilac eyes.

“Your Grace-” Ser Criston began.

The king raised his leather-gloved left hand.

“No, no, you had your chance Dornishman. I’ll make the bitch a knight… When the moon is made of cheese!” He sniggered.

Y/N’s eyes narrowed.

“Craven...” She sighed with arms folded under her chest.

He turned to face her with a look she had never seen on him, earnestness.

“I am no craven.”

The woman shrugged.

“Who’s to say really?"

"All I see is a craven king who dares not enter a bet with a lowborn tavern maid…” she hummed.

The room was so silent one could hear the dire wolves howling in the distance.

Aegon eyed her skepticism before his usual smirk returned to his lips.

“You shall have your wager tavern wench. For your sake I hope you've long lost your maidenhead," he chuckled, “My prick leaves whores bow legged.”

#house of the dragon#game of thrones#a song of ice and fire#aegon targaryen#aegon targaryen x black reader#poc fanfiction#aegon targaryen x reader#ser criston cole#aegon ii#fanfic#fanfiction#king aegon#aegon fanfiction#aegon x reader#aegon x you#aegon targaryen x black!reader#aegon targaryen angst#angst

64 notes

·

View notes

Text

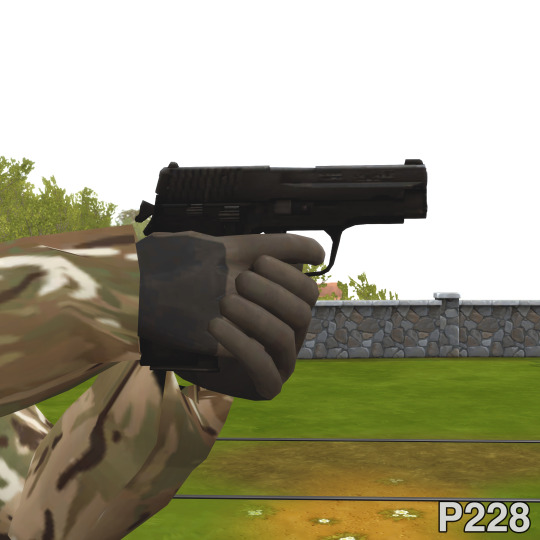

SIG-Sauer Pistols CC Collection

Began in 1975, with an aquisition of a German arms factory of J.P Sauer und Sohn GmbH by the Swiss SIG AG, SIG-Sauer produces many variants of pistols including :

SIG P220

The very first patent since the joint of these two companies. Launched in 1975 to fill the position of the police issue sidearm. Also this model is a principle of the next SIG-Sauer pistol designs.

SIG P226

Issued in 1985 as a development of P220 with advanced features. Actually participated in US DoD's XM9 program, but instead the Beretta 92F was chosen. Later acquired by the US Navy as M11. One of Original "Wonder 9" Member who Successfully toppled the Revolver's Domination during 1980s inside Law Enforcement and Military alike.

SIG P228/P229

A compact variant of P226 basically some length was chopped from the barrel and slide, as well as from the grip. The P229, was developed especially for the US market and is assembled in the USA using both German and US-made parts. It’s identical to the P228 except for a heavier slide. The P229 slide is made by machining a bar of steel as opposed to stamping and forming from sheet steel. The heavier slide on the P229 is necessary because of the comparatively more powerful calibers used in this pistol.

SIG Pro

Sig Sauer's Attempt on Modernizing their Sig Sauer Series to make it relevant for current Polymer frame Pistol Trend and stay relevant in Military Industries. The SIG Pro is a series of semi-automatic pistols developed by SIG Sauer in Exeter, New Hampshire. It became the first polymer-frame handgun from SIG Sauer and one of the first pistols to feature a built-in universal accessory rail and interchangeable grips. Offerings in the series are chambered in .40 S&W, .357 SIG, or 9×19mm Parabellum. As of March 2020, only the SP 2022 variant is still listed on the SIG Sauer website. The SIG Pro was marketed as a lightweight. and compact alternative to the "legacy" SIG Sauer handguns in an increasingly competitive and budget-oriented law enforcement market. SIG P320 (M17 And M18 )

A further development of previous model SIG P250 which issued by SIG Arms Inc. USA. Released in 2014 as a SIG participation in the US DoD's XM17 next sidearm program. After some evaluation, this model won the contract and acquired as M17 in the US Army in 2017. US Marine Corps acquired it's compact variant known as M18. The full-sized model was designated the M17, and the shorter length carry model, the M18. The guns have subsequently been adopted by the Army, Navy, Marine Corps, Air Force, and Space Force. The pistol replaces the Beretta M9, as well as several other handguns across the services. There are two color variants, coyote brown and black, for both the M17 and M18, though almost all have been produced in brown.

The SIG Sauer P365

Modern Derringer is here.. with superior compact size over the smallest modern Handgun that ever known, Glock 42 (5.8 inch on P365 Vs 5.94 inch on Glock 42) also the Best Seller on "Concealed Carry" Category in United States. perfect for anyone who looking for smaller Pistol as Third Sidearms or Perfect pistol for Political Assassination 3:)

SIG Sauer P365 is a striker-fired subcompact semi-automatic pistol manufactured by SIG Sauer, intended for everyday carry. It is offered with Tritium XRAY3 Day/Night Sights and two 10-round magazines; one flush fit and the other with an extended finger tab, and a stainless steel frame with polymer grip module. It is primarily chambered in 9×19mm Parabellum and is rated for +P (higher pressure) ammunition while utilizing offset double-stack magazines. A variant chambered in .380 ACP was introduced in February 2022. The P365, which replaced the P290RS, is produced in Newington, New Hampshire. In both 2018 and 2019, it was the best selling handgun in the United States.

Shoutout To @honeyssims4 & @r-jayden For M17 Pose...

@ts4-poses @ts4-poses-masterlist @cctreasuretrove

DOWNLOAD LINK:https://www.patreon.com/posts/63376609

#thesims4#the sim#the sims 4#the sims#the sims 4 gun#ts4cc#ts4acc#The Sims military#Ts4 military#The sims 4 Weapon#TS4Weapon#ts4 custom content#ts4 cc#ts4 cas#ts4military#ts4 accessories#ts4gun#ts4#the sims 4 custom content#the sims 4 cc#ts4cc download#ts4 gun

86 notes

·

View notes

Text

Why Virat Special Steels ?

The Leading Company VIRAT SPECIAL STEELS PVT. LIMITED, INDIA, A name of trust, synonymous with quality's , keeping in view the global markets and expanding business operations of the Company.

We are largest Importer, Exporter and Stockiest of Die Blocks (DIN 1.2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades fulfill all the requirements pertaining to highly specialized steels.

The visionaries incorporated another company under the name & style of Virat Special Steels Pvt. Ltd., with offices at #GURGAON, #LUDHIANA, #PUNE & #CHENNAI to provide efficient business services to the Industrial undertaking at the location in #India. We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

A team of professional has been appointed all the concerned at all levels. For more information visit https://www.viratsteel.in/special-steel-supply-networks/

Size Range in Forged / Rolled Bars: Rounds: 13mm Dia to 1500mm Dia Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm

Connect with us today ! 🌐https://www.viratsteels.com 📩[email protected] 📲+91-98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#chennai#chandigarh#db6 steel#h13steel#h13steelbarexporter#h11steels#d2steel#m2steels#hss#din2738#din 2714

2 notes

·

View notes

Text

Introducing VMO Steel - The Perfect Grade for Hot Work Applications!

Virat Special Steels is thrilled to bring you the highly specialized VMO steel grade, also known as ABNT VMO.

This exceptional steel is ideal for hot work applications, especially in forging dies for high-performance drop hammers. Discover the unmatched strength and durability of VMO Steel for your demanding projects.

Trust in Virat Special Steels for top-quality steel solutions. Virat Special Steels is bringing a highly specialized and valuable steel grade to the market! The VMO steel grade, also known as ABNT VMO, is indeed well-regarded for its use in hot work applications, particularly in forging dies for high-performance drop hammers. Its robust chemical composition and mechanical properties make it ideal for such demanding environments.

Why Choose VMO Steel? Superior Strength & Toughness: Ideal for demanding environments. High Performance: Perfect for high-temperature applications. Reliable Quality: Trusted by industry professionals.

Key Features: Chemical Composition: Carbon 0.57%, Silicon 0.25%, Manganese 0.70%, Sulfur 1.10%, Chromium 0.50%, Molybdenum 1.65%

Upgrade your tools and dies with the best in the industry!

Contact us today to learn more about how VMO steel can enhance your operations.

Contact us today to learn more! https://www.viratsteel.in/products/vmo-steel-supplier-in-india/

Any further queries feel free to contact us : 🌐https://wwww.viratsteels.com 📬 [email protected] ☎+91 98140-21775

#iso9001#chandigarh#pune#delhi#mumbai#maharashtra#aurangabad#walujindustry#toolsteelsupplier#ahmedabad#VMOSteel#HotWorkApplications#ForgingDies#SpecialSteel#ToolSteel#DieSteels#ABNT

2 notes

·

View notes

Text

Monel K500 Round Bar Exporters

Are you searching for top-notch corrosion-resistant materials in India? Look no further than Monel K500 Round Bars, the ultimate solution for your demanding industrial needs. Monel K500 is a high-performance alloy renowned for its exceptional corrosion resistance, making it the ideal choice for critical applications in various industries.

Unmatched Corrosion Resistance: Monel K500 is primarily composed of nickel and copper, with small additions of aluminum and titanium. This unique alloy composition offers extraordinary resistance to a wide range of corrosive environments, including seawater, acids, alkalis, and more. In India's diverse climate and industrial landscape, Monel K500 Round Bars ensure your equipment and structures remain robust and reliable for years to come.

Excellent Mechanical Properties: Beyond its corrosion resistance, Monel K500 offers outstanding mechanical properties. Its high tensile strength and durability make it suitable for a multitude of applications, from marine components to chemical processing equipment. Whether you're operating in the bustling cities of Mumbai or Chennai or the rugged terrains of the Himalayas, Monel K500 Round Bars are engineered to withstand the toughest conditions.

Exceptional Thermal Stability: Monel K500 retains its mechanical integrity even at elevated temperatures, making it perfect for high-temperature applications. Whether you're in the steel industry of Jamshedpur or the textile industry of Coimbatore, you can trust Monel K500 Round Bars to perform reliably in your specific environment.

Cost-Effective Solution: While Monel K500 Round Bars offer premium performance, they also provide long-term cost savings. Their extended service life and reduced maintenance requirements ensure that your investment pays off over time, allowing your business to thrive in the competitive Indian market.

Customized Solutions: We understand that every project is unique, which is why we offer customizable Monel K500 Round Bars to suit your exact specifications. Whether you require specific sizes, shapes, or quantities, we can deliver tailor-made solutions to meet your needs.

Compliance and Quality: Our Monel K500 Round Bars adhere to international quality standards, ensuring you receive a product of unmatched quality and consistency. We prioritize safety and reliability, making us the trusted choice for businesses across India.

In conclusion, Monel K500 Round Bars are the ideal choice for industries across India, offering unparalleled corrosion resistance, exceptional mechanical properties, thermal stability, cost-effectiveness, and customized solutions. Elevate your projects, enhance your equipment's longevity, and ensure the success of your business with Monel K500 Round Bars. Contact us today and experience the excellence of Monel K500 for yourself.

4 notes

·

View notes

Text

Inconel 625 Round Bars in Rocket Engine Manufacturing

Rocket engine manufacturing requires materials that can withstand extreme conditions, including high temperatures, pressure, and corrosive environments. Inconel 625 round bars have emerged as a preferred choice for aerospace and rocket engine components due to their exceptional strength, oxidation resistance, and superior weldability.

Why Inconel 625 Round Bars Are Used in Rocket Engines?

High-Temperature Strength: Inconel 625 retains its mechanical strength even at extreme temperatures, making it ideal for combustion chambers and exhaust nozzles.

Corrosion and Oxidation Resistance: The presence of nickel, chromium, and molybdenum provides excellent resistance to oxidation, corrosion, and carburization in rocket engine environments.

Superior Fatigue Strength: Rocket components undergo intense mechanical and thermal stress cycles, and Inconel 625 offers outstanding fatigue and creep resistance.

Weldability and Fabrication: Inconel 625 round bars can be easily welded and fabricated into intricate designs, reducing production time and improving efficiency.

Cryogenic Applications: The material maintains its toughness even at extremely low temperatures, making it suitable for liquid-fuel rocket applications.

Applications of Inconel 625 in Rocket Engine Manufacturing

Rocket nozzles

Combustion chambers

Turbine blades

Exhaust ducts

Heat shields

Fuel system components

Inconel 625 Round Bar Price and Availability

The Inconel 625 round bar price varies depending on factors like size, thickness, and market demand. For those looking for bulk purchases, understanding the Inconel 625 price per ton is crucial. Prices can fluctuate based on raw material costs, production techniques, and availability from major manufacturers.

Trusted Inconel 625 Suppliers in the UK

If you're searching for reliable Inconel 625 suppliers UK, Amardeep Steel Centre LLP is a trusted name in the industry. We provide premium-quality Inconel 625 round bars with international certifications and competitive pricing. Our materials meet aerospace and defense industry standards, ensuring the highest level of performance and durability.

Why Choose Amardeep Steel Centre LLP?

High-quality Inconel 625 products

Competitive pricing

Fast global delivery

Large inventory, including Inconel 625 STOCIKEST products

Customization options available as per specifications

Conclusion

The use of Inconel 625 round bars in rocket engine manufacturing continues to grow due to their unparalleled properties. With the demand for high-performance materials increasing in aerospace applications, sourcing from a reliable supplier is crucial. Contact Amardeep Steel Centre LLP today for the best Inconel 625 round bar price and superior quality products.

0 notes

Text

The Greatest Round Bar Suppliers in India

As a major force in the steel business, Nippon Alloys Inc. is a round bar supplier in India that is globally recognized for its exceptional goods. Round bars are critical structural and equipment components that are widely utilised in the industrial, automotive, and construction industries. To fulfil the diverse demands of clients worldwide, our exporters provide a wide choice of round bars manufacturer of alloy steel, carbon steel, and stainless steel.

Round bars are long, cylindrical products utilised in many different industries, such as infrastructure development, heavy machinery, automotive manufacturing, and construction. These round bars are made from a variety of materials, such as copper, alloy steel, carbon steel, and stainless steel. Because of their strength, resilience, and versatility, round bars are essential in modern manufacturing and construction.

Another significant market for round bars is the automotive industry. India, one of the world's largest automakers, has experienced an exponential surge in demand for quality round bars for use in axles, chassis, and engine parts. A large quantity of round bars was also required for the construction of train stock, signalling equipment, and rails in the country's developing railway network.

For More Detail

Website: nipponalloys.com

Product: Round Bar Exporter in India

Other Product: Alloy Round Bar Supplier in India.

#Round bar Supplier in India#Round bar Supplier#Round bar#Alloy Round Bar Supplier in India#Monel Round Bar Importer in India

0 notes

Text

Best Duplex Steel F51 Round Bars Manufacturer in India

Shashwat Stainless Inc. is the largest Duplex Steel F51 Round Bars Manufacturer in India. These Din 1.4462 Round Bars are available in a variety of sizes, shapes, and dimensions, and may also be customized to fit our customers' specifications. To satisfy the needs of various industrial sectors, we offer these things in the proper amount and with all customized choices. Several metals contribute to the high strength, superior quality, and extended life of these Duplex Steel F51 Round Bars Supplier in India.

Duplex Steel F51 Round Bars Manufacturers offer significant cost advantages due to their durability and longevity. The combination of strength and corrosion resistance means that components made from F51 are one of our most popular products in the Metal Market. can often be designed with thinner walls, reducing material usage without compromising performance. We are also known as the largest Suppliers of Super Duplex Steel 32760 Round Bars, Super Duplex Steel 32750 Round Bars and more.

Duplex Steel F51 Round Bars Suppliers are often called “corrosion-resistant steel” – they trust, stain, or corrode as easily as standard carbon steel and other metal materials in the Metal Market. Duplex Steel F51 Round Bars products are well suited for different environments and temperatures. We provide a variety of formable and strong steels, as well as boron and waterproof steels.

Other Product: Round Bars Manufacturers in India

#Duplex Steel F51 Round Bars#Duplex Steel F51 Round Bars Manufacturer#Duplex Steel F51 Round Bars Manufacturer in India

0 notes

Text

Why the Best Quality Steel Matters for Large-Scale Projects

When it comes to large-scale projects, the quality of materials used can make or break the entire structure. Among these materials, steel plays a pivotal role due to its unmatched strength, durability, and versatility. Selecting the best quality steel is not just a necessity but a priority for architects, engineers, and builders who aim to deliver safe, long-lasting, and efficient structures. Let’s explore why premium steel products are crucial for large-scale projects and how A One Steel Group ensures top-notch materials for every need.

Strength and Durability

Large-scale projects demand materials that can withstand significant stress and external forces over time. High-quality steel, such as cold rolled steel, ensures enhanced strength, uniformity, and a smooth finish, making it ideal for applications where precision and durability are essential. The longevity and resistance to corrosion offered by premium-grade steel products minimize maintenance costs, ensuring the structure remains robust for decades.

Versatility for Different Applications

Large projects often involve diverse applications, ranging from structural frameworks to intricate plumbing systems. For example, copper tubes are frequently used for efficient water and gas transportation due to their anti-corrosive properties and high thermal conductivity. Additionally, metal bars and steel round bars provide essential support in reinforced concrete structures, ensuring stability and strength. The adaptability of these materials makes them invaluable in meeting the varying requirements of large-scale constructions.

Cost-Effectiveness and Value

While the initial cost of premium steel might be slightly higher, it proves to be cost-effective in the long run. High-quality materials reduce repair costs, downtime, and the need for frequent replacements. Staying updated on the TMT steel price per kg today and TMT saria price ensures that builders can make informed decisions without compromising on quality. With A One Steel Group, you can access reliable pricing and superior steel products to enhance the efficiency of your projects.

Safety and Compliance

In large-scale projects, safety is non-negotiable. Inferior steel can lead to structural failures, putting lives and investments at risk. Quality steel, such as TMT bars, is engineered for superior tensile strength and ductility, ensuring it withstands seismic activity and other stressors. Keeping track of the TMT rate today and opting for the best-rated materials helps ensure compliance with safety standards, reducing risks and enhancing the overall reliability of the structure.

Market Awareness and Pricing

In today’s competitive construction landscape, keeping an eye on the market is crucial. Builders and contractors should stay updated on the today steel rate, including fluctuations in TMT steel price per kg. This not only ensures budget alignment but also helps in sourcing materials at the right time and price. A One Steel Group offers transparent pricing and premium materials, ensuring you get the best value for your investment.

CONCLUSION:

For large-scale projects, the importance of using the best quality steel cannot be overstated. From enhancing structural integrity to ensuring long-term value and safety, premium steel products like cold rolled steel, copper tubes, TMT bars, and metal bars are indispensable. By choosing trusted suppliers like A One Steel Group, builders can guarantee quality, durability, and cost-effectiveness in every aspect of their construction.

0 notes

Text

0 notes

Text

Round Bar Supplier in India That Redefines Quality Standards

In the world of manufacturing, construction, and engineering, round bars play a pivotal role. They are versatile and reliable, and form the backbone of numerous applications across diverse industries. There are many round bar suppliers in India, Pipex stands tall as a brand that redefines quality standards, catering to both domestic and international markets with unparalleled excellence.

Round Bar Supplier in India

When it comes to sourcing round bars, the stakes are high. Quality, consistency, and compliance with industry standards are non-negotiable factors. We have emerged as a leading round bar supplier in India, renowned for its unwavering commitment to delivering top-notch products.

1. Premium Quality Materials

Pipex sources high-grade raw materials to manufacture round bars, ensuring durability, strength, and corrosion resistance. Whether it’s stainless steel, carbon steel, alloy steel, or other specialised materials, our guarantees products that meet and exceed expectations.

2. State-of-the-Art Manufacturing Facilities

The company’s advanced manufacturing units are equipped with the latest technology, enabling precise production processes. From melting to machining and finishing, every stage is meticulously monitored to ensure the highest quality standards. This technological edge has solidified Pipex’s reputation as a premier round bar supplier.

3. Extensive Product Range

We offer an extensive range of round bars in various sizes, grades, and finishes to cater to diverse industrial needs. Whether you require round bars for construction, automotive, aerospace, or marine applications, we have a solution tailored to your requirements.

4. Stringent Quality Control

We adhere to rigorous quality control protocols at every stage of production. Each round bar undergoes thorough testing to ensure it meets the desired specifications, including dimensional accuracy, tensile strength, and surface finish. This commitment to quality has earned us recognition as a trusted round bar exporter in India.

Pipex: A Trusted Round Bar Supplier in India

India’s manufacturing sector has gained global prominence, and we have been at the forefront of this evolution. As a leading round bar exporter, Pipex has successfully established a robust presence in international markets, delivering products that align with global standards.

1. Global Reach

We export round bars to numerous countries across Asia, Europe, the Middle East, and the Americas. The company’s ability to fulfil bulk orders while maintaining quality and timely delivery has made it a preferred partner for clients worldwide.

2. Certifications and Compliance

Our products comply with international standards such as ASTM, EN, and DIN, among others. These certifications underscore the company’s commitment to excellence and have cemented its position as a reliable round bar exporter in India.

3. Customized Solutions

Every industry has unique requirements, and we understand the importance of customisation. The company offers tailor-made solutions to meet specific client needs, be it in terms of dimensions, materials, or finishes. This flexibility has further strengthened Pipex’s standing as a versatile round bar supplier.

Applications of Round Bars from Pipex

The versatility of round bars makes them indispensable across various industries. We cater to a wide array of sectors, including:

Construction and Infrastructure: Round bars are extensively used in reinforcing concrete structures and fabricating frameworks.

Automotive Industry: Precision-engineered round bars are crucial for manufacturing engine components, shafts, and fasteners.

Aerospace: The high strength-to-weight ratio of round bars makes them ideal for critical aerospace applications.

Oil and Gas: Round bars are used in drilling rigs, pipelines, and offshore platforms, where durability and corrosion resistance are paramount.

Marine Industry: With superior resistance to saltwater corrosion, round bars are indispensable in shipbuilding and marine equipment.

Industrial Machinery: Round bars serve as raw materials for manufacturing gears, rollers, and other machinery components.

Commitment to Sustainability

In addition to quality, Pipex is deeply committed to sustainability. The company employs eco-friendly manufacturing practices, minimizes waste, and ensures efficient energy usage. By choosing us, clients not only benefit from premium products but also contribute to a greener planet.

Consumer-First Method

Pipex's success as a leading round bar supplier in India and round bar exporter stems from its customer-first philosophy. The company emphasizes clear communication, responsive support, and seamless logistics to ensure a hassle-free experience for its clients. Whether you are a small business or a large multinational corporation, Our team is dedicated to addressing your needs with the utmost professionalism.

When it comes to finding a reliable and high-quality round bar supplier in India, We stand out as the go-to choice. With its commitment to excellence, state-of-the-art facilities, and customer-centric approach, we have redefined quality standards in the industry. Its reputation as a trusted round bar exporter in India further underscores its dedication to delivering value to clients worldwide.

For More Detail

Website: pipex.ai.

1 note

·

View note