#Steel Prefabricated Warehouses

Explore tagged Tumblr posts

Text

0 notes

Text

EPACK Prefab offers customized solutions for Industrial Factory Buildings, delivering durable, cost-effective, and efficient structures. Designed with precision using advanced pre-engineered techniques, our factory buildings ensure optimal functionality and space utilization.

✅ Key Features:

Quick construction with PEB technology

High-quality steel ensuring strength and durability

Energy-efficient designs with insulated panels

Custom layouts to suit specific industrial needs

👉 Contact EPACK Prefab today for innovative factory building solutions tailored to your requirements!

#Industrial Factory Building#Factory Building Construction#Pre-Engineered Buildings#PEB Structures#Industrial Construction Solutions#Steel Factory Buildings#Warehouse Construction#Prefabricated Industrial Buildings#Durable Factory Buildings#Custom Industrial Structures#EPACK Prefab#Modern Industrial Construction#Factory Building Design#Turnkey Construction Solutions#Industrial Building Manufacturers#Energy-Efficient Buildings#Steel Structures for Factories#Fast Construction Solutions#Prefab Industrial Structures#Reliable Factory Buildings

0 notes

Text

Warehouse Construction Company in India – Kaizen PEB

Kaizen PEB, Top Warehouse construction Company in India, is at the forefront of the industry with its outstanding skills and unique solutions. Kaizen has built its reputation as a dependable and customer-focused partner by delivering high-quality PEB warehouses. They cater to different project requirements with the latest technology and a competent crew, ensuring timely and cost-effective delivery. Whether it’s a small-scale storage facility or a major distribution centre, Kaizen PEB commitment to excellence shines through in every project they take on, making them the chosen choice for warehouse construction needs in India.

To know more information about our cold shrink cable joints and terminations, you can directly contact us at +91-9810048397 or visit our official website: https://www.kaizenpeb.com/warehouse-construction-company-india/

#Warehouse Construction Company in India#Warehouse Construction Cost in India#Industrial Shed Manufacturer in India#Steel Building Manufacturer#Prefabricated Modular Building Structure Manufacturer#Prefabricated Modular Building Structure Company India#Pre Engineered Metal Building Manufacturers

1 note

·

View note

Text

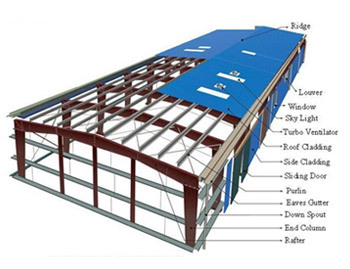

Steel frame prefabrication long span warehouse building prefabrication workshop

0 notes

Text

How do PEB Structures protect the Environment?

The traditional method of construction has been accepted norm for a long time. The word traditional means conventional, customary, and established by its very definition. In traditional construction foundations are laid, walls are built, roofs are added and then the interior of the building begins to be created. Finally, before being handed over to the customer, the snag-list is drawn up and tackled – all those minor issues and tasks that need addressing. Then, and only then, is the building officially complete. Modular construction, on the other hand, revolutionizes everything, from cutting time to changing attitudes.

Here we are discussing how Traditional Construction methods degrade our environment?

A mandatory aspect of any construction project is to ensure the preservation of the surrounding environment. In India, it is tough to maintain soil erosion and degradation. The reason is mainly floods, droughts, soil alkalinity, aridity, and salinity. Besides air and water pollution levels are still not within controllable limits in the country. Urbanization in major cities has decreased the soil quality, impacting the environment. Building construction contributes 23% to pollution of the air, 40% to drinking water pollution, and 50% to landfill waste. For a deeper understanding of this topic, let’s dig deeper into the details.

1. Atmosphere

When it comes to air pollution, every action matters as the production of dioxide gases is one of the main factors causing global warming. The construction sector is responsible for 39% of energy and process-related carbon dioxide emissions.

2. Biodiversity

Think about how construction impacts animals. The first few things that probably came to your mind are loud machines or working on construction sites at night. Noise and light pollution heavily impact wildlife, especially bats, badgers, and birds, by disturbing their natural day cycle.

3. Waste

Traditional construction methods require extra materials because it relies on fast, cheap solutions that need to be replaced every year or even every few months which leads to increased waste.

Different construction processes generate a great deal of this waste. It’s our responsibility to adopt the right tools and technologies to reduce this waste.

Luckily, prefabricated buildings can reduce this pollution percentage and waste.

We believe that the future of construction is sustainable, which is why now is a perfect time to change our approach and take responsibility for our actions. You might not know that these buildings are constructed from factory-made components or units that are transported and assembled on site.They take very little construction time and reduce waste by up to 52%, which helps us protect the environment. Additionally, they often use recycled building materials for their internal walls, insulation, and roofs, making them very eco-friendly. We are MultiDecor India Pvt. Ltd., a leading manufacturer of modular buildings in India, produces all sorts of prefabricated structures, such as prefabricated labour accommodation, prefabricated site offices, portacabins, modular homes, and farmhouses.

Multi Decor India Pvt. Ltd is a top leading pre-engineered buildings manufacturer in India established in the year 1992. We manufacture, design, and deliver a wide range of customized PEB structures constructed specifically per the customer’s requirements. We provide every commercial requirement and being a leading PEB structure manufacturer, guarantee a high-quality construction with quick installation.

Our concept is designed to provide a complete building envelope system that is airtight, energy efficient, optimum in weight, and above all, designed to fit user requirements like a well-fitted glove. PEB (Pre Engineered Buildings ) means that all the components are manufactured at the factory site and shipped to the location site to be assembled and erected at the site with the nuts bolts and anchor bolts. These types of buildings are also known as Pre Engineered Steel Buildings.

Check more at:

#laborcolonies#porta cabin manufacturer#peb manufacturers#prefabricated steel buildings#prefabricatedbuildings#prefabricated warehouse

0 notes

Link

Prefabricated Commercial Steel Buildings | Commercial Metal Building & Warehouse Construction - Coastal Steel Structures

Prefabricated Commercial Steel Frame Buildings from Coastal Steel Structures are the perfect solution for businesses looking for an affordable, high-quality steel building. Our pre-engineered steel buildings are designed to meet the highest standards of quality and durability, and are perfect for a variety of commercial applications, including warehouses, retail stores, and office buildings. Our commercial steel frame buildings are constructed with heavy-duty steel framing and can be customized to meet your exact needs. We also offer commercial metal building construction.

Know More: https://coastalsteelstructures.com/uses/commercial-metal-buildings-retail/

#Prefabricated Commercial Steel Buildings#Commercial Metal Building#Commercial Steel Frame Buildings#Commercial Steel Buildings#Commercial Warehouse Construction

0 notes

Text

Prefab Steel Buildings and also Custom-made Construction

Prefab steel buildings are preferred options in business construction due to the fact that they decrease, though possibly not remove, specific frustrations that commonly crop up. Prefab steel buildings could even be more effective for personalized tasks despite there being no noticeable economic situation of range. Nonetheless, it takes prudence, strong funding, and effective procedure to take the fullest benefit of this strategy.

Steel buildings are normally prefab when the style provides the specialist with significant challenges, such as the broad and high spaciousness required for aircraft hangars and comparable frameworks. Hence, assistance beam of lights frequently need to be eliminated lest they disrupt ordinary procedures, and tolerances are normally tighter, demanding persistance and also accuracy. Specialists that possess the devices and workers in their look for managing the awareness of such tough layouts are thus offered with an internal benefit.

Not all projects making use of metal framing are appropriate for prefabrication or pre-engineering, as well as good specialists need to be experienced at making such analyses. For example, the layout may not be advanced enough to justify the additional costs of accuracy developing as well as carrying finished framing to the website. Occupant improvement projects or any type of circumstances including modification of existing facilities (possibly while remaining to be occupied) are not suitable to be prospects for prefabrication strategies.

Also for garages or similar frameworks where the prefab approach appears noticeable, there is an option about just how to finest approach their building and construction, as well as one requires to carry out a cost/benefit evaluation. We have already described what is involved in pre-engineering the framework, building it in a shop, and after that carrying the constructed frameworks to the last site. The other choice is to carry out all jobs onsite, going back to square one and sticking to the specs laid out in the plans.

There are a lot of aspects to be considered for the option to be scampered the cuff. One of the most essential aspect is the general nature of the project, as ramifications after that tend to form. We devote the remainder of this post on examining job kinds that fit to use metal buildings effectively.

Possibly the most familiar type, one we currently discussed, is the airplane hangar with its requirement to accommodate both a high ceiling and also a huge open location. The implication is that messages as well as beam of lights are lacking, which in turn suggests that the structure needs adequate toughness and also honesty in and of itself to conquer the stress and anxieties put on it from wind shear and various other pressures. Comparable framework needs are additionally required in other transportation applications, and also prefabrication is therefore a big favorite.

Open areas are common in several industrial and commercial applications; some likewise need high ceilings to suit things like cranes, whereas others do not have this requirement. Recycling facilities, food handling plants, as well as producing assembly lines are examples of this type. Prefab steel is not always the best means to go here, yet may be.

An intriguing circumstance develops for warehouse and storehouses, which have huge open spaces and also thus are typically developed from steel. Application-specific equipment can use up a lot of this space, and also a resolution may need to be made as to whether the framework or devices obtains positioned initially. This in turn points to whether offsite prefab is also possible or whether framing needs to be erected around the equipment.

For owners of big rented out structures, such as shopping malls, the essential question is generally what needs to happen when renters alter. New residents often tend to desire enhancements and may expect the proprietor to accommodate them. Right here, steel framework, prefab or not, gives the owner with much more adaptability.

What we have actually been reviewing locations high demands on both proprietor and also professional, mostly due to the fact that it is custom-made job. Choice of product as well as choices relating to strategy need to be straightened out well beforehand. In the end, there is a clear relationship in between prefab steel buildings and also customized building and construction.

www.facilitybuilders.com

youtube

2 notes

·

View notes

Text

Warehouse Manufacturer In Uttar Pradesh

Creative Building Solutions: The Best Pre-Engineered Steel Building Manufacturer in Uttar Pradesh

Pre-engineered steel buildings (PEBs) are a popular choice for a variety of applications, including factories, warehouses, , retail stores, and even homes. PEBs offer large number of advantages over traditional building methods, including speed of construction, energy efficiency.and durability

If you are looking for a pre engineered steel building manufacturer in Uttar Pradesh, Creative Building Solutions is the best option for you. Creative Building Solutions has been in the business of manufacturing PEBs for over 12 years, and they have a proven track record of quality and customer satisfaction.

Why Choose Creative Building Solutions?

There are many reasons why you should choose Creative Building Solutions for your next PEB project. Here are just a few reasons

Quality

: Creative Building Solutions uses only the highest quality materials in their PEBs. Their steel is sourced from reputable suppliers, and their manufacturing process is strictly controlled to ensure that every building meets their exacting standards.

Durability

PEBs are built to last. They are designed to withstand even the harshest weather conditions, and they are virtually maintenance-free.

Energy Efficiency

PEBs are very energy efficient. Their steel construction helps to keep them cool in the summer and warm in the winter, and they can be easily insulated to further improve their energy efficiency.

Speed of Construction

: PEBs can be constructed much faster than traditional buildings. This is because they are prefabricated in a factory, and they can be assembled on-site in a matter of weeks.

Affordability:

PEBs are a very affordable option for many businesses and homeowners. The initial cost of a PEB may be higher than a traditional building, but the long-term savings on energy costs can make them a very cost-effective choice.

Creative Building Solutions' Services

Creative Building Solutions offers a wide range of PEB services, including:

Design:

Creative Building Solutions' engineers can help you design the perfect PEB for your needs. They will work with you to determine the size, layout, and features of your building.

Manufacturing

: Creative Building Solutions' factory uses state-of-the-art equipment to manufacture your PEB to the highest standards.

Construction:

Creative Building Solutions' team of experienced construction professionals will assemble your PEB on-site in a matter of weeks.

Maintenance:

Creative Building Solutions offers a comprehensive maintenance program for your PEB. This program will help to ensure that your building remains in good condition for many years to come

.

Here are some additional benefits of choosing Creative Building Solutions:

Expertise:

Creative Building Solutions has a team of experienced engineers and construction professionals who are experts in the design and construction of PEBs.

Flexibility

: Creative Building Solutions can customize your PEB to meet your specific needs. They offer a wide range of sizes, layouts, and features to choose from.

Warranty

: Creative Building Solutions offers a comprehensive warranty on their PEBs. This warranty will protect you against defects in materials and workmanship.

If you are looking for a quality, affordable, and reliable pre engineered steel building manufacturer in Uttar Pradesh, then Creative Building Solutions is the clear choice. Contact them today to get started on your next project.

2 notes

·

View notes

Text

Buy RS Joist in Gwalior – The Backbone of Strong and Durable Structures

When it comes to construction, structural integrity is paramount. Every building, bridge, or infrastructure project needs a strong foundation to withstand the test of time and external forces. One of the critical elements that contribute to the overall strength and stability of a structure is the RS (rolled steel) joist. If you're considering a construction project in Gwalior, whether residential, commercial, or industrial, buy RS Joist in Gwalior is a smart choice for ensuring durability and reliability.

In this blog post, we will explore the importance of RS Joists in construction, their benefits and applications, and why Gwalior is the ideal place to purchase them. Whether you're a contractor, builder, or project manager, understanding the value of RS Joists will help you make informed decisions for your construction needs.

What is an RS Joist?

An RS Joist is a type of structural steel member used primarily in construction for framing, supporting, and reinforcing various parts of a building or infrastructure. It is a rolled steel shape with a distinctive I-beam or H shape. RS Joists are known for their high strength-to-weight ratio, making them suitable for load-bearing applications in various construction projects. These joists are created through a rolling process, which makes them cost-effective while still maintaining high durability and structural integrity.

RS Joists are widely used in large and medium-sized projects like residential buildings, warehouses, factories, and bridges. They are also crucial in the creation of industrial frameworks, which require materials that can bear heavy loads.

Why Buy RS Joist in Gwalior?

Gwalior, a prominent city in Madhya Pradesh, has seen rapid growth in the construction industry in recent years. Whether you're constructing a commercial complex, residential building, or industrial facility, the need for strong, durable materials is essential. Buy RS Joist in Gwalior offers several advantages, from local availability to quality assurance. Here’s why you should consider it for your construction project:

1. Strength and Durability

The most significant advantage of using RS Joists in construction is their incredible strength and durability. These joists are engineered to withstand heavy loads, making them ideal for supporting roofs, floors, and bridges. When you buy RS Joist in Gwalior, you ensure the structural stability of your building or infrastructure. Whether your project involves residential buildings or commercial complexes, RS Joists provide the necessary support to keep everything intact over time.

The high strength of RS Joists also makes them resistant to environmental challenges such as wind, rain, and seismic activity, ensuring that your structure remains stable in various conditions.

2. Cost-Effectiveness

RS Joists are cost-efficient in comparison to other structural materials like reinforced concrete or timber. They offer a high strength-to-weight ratio, meaning fewer materials are needed to achieve the desired level of support. This not only reduces the material costs but also minimizes labor and transportation costs. When you buy RS Joist in Gwalior, you get an affordable and reliable option for your construction needs.

Moreover, RS Joists require less maintenance compared to other materials. Their corrosion resistance and ability to withstand heavy loads without deformation contribute to a longer lifespan, reducing the need for frequent repairs and replacements.

3. Ease of Fabrication and Installation

One of the main reasons construction professionals prefer RS Joists is their ease of fabrication and installation. These joists are prefabricated and can be easily customized according to the dimensions of the project. Whether it’s for a small building or a large-scale infrastructure project, RS Joists can be cut, welded, and assembled with minimal effort.

In Gwalior, you will find suppliers who offer ready-to-use RS Joists, making it easy for builders to access and implement these essential components without delays. The straightforward installation process also helps speed up construction timelines, enabling you to complete your project on schedule.

4. Environmental Benefits

Sustainability is becoming an essential factor in modern construction, and RS Joists offer several environmental benefits. RS Joists are made from recycled steel, which is a renewable resource. Using recycled materials helps reduce the carbon footprint of construction projects, making RS Joists an eco-friendly choice.

Additionally, since RS Joists are highly durable, they contribute to reducing the overall waste generated by construction projects. Structures that utilize RS Joists require fewer replacements and repairs, which means fewer resources are consumed over time.

5. Local Availability and Quick Delivery

One of the main reasons why buy RS Joist in Gwalior makes sense is the availability of suppliers in the region. Gwalior, with its growing industrial and commercial sectors, is home to several construction material suppliers, making it easy to find RS Joists at competitive prices. Local availability ensures that you can quickly access the materials you need, reducing delays in the procurement process.

Moreover, local suppliers often provide delivery services, ensuring that RS Joists are delivered directly to the construction site. This eliminates the need for long transportation times and ensures that materials are available when needed.

Applications of RS Joist in Construction

RS Joists are widely used in a variety of construction projects due to their strength, flexibility, and cost-effectiveness. Below are some of the most common applications of RS Joists in construction:

1. Flooring Systems

RS Joists are frequently used in the flooring systems of both commercial and residential buildings. These joists provide the necessary support to floors, ensuring that they can bear the weight of furniture, people, and equipment. By using RS Joists for flooring, construction projects can achieve strong and stable floors without the added weight of solid beams or concrete.

2. Roof Support

The roofing system of a building is crucial to its structural integrity. RS Joists are often used to support the roof of a building by serving as the main beams. They ensure that the roof remains stable under extreme weather conditions, such as heavy snowfall or strong winds.

3. Bridges and Overpasses

RS Joists are a vital component in the construction of bridges and overpasses. They provide the strength needed to support heavy loads from traffic, ensuring that the structure remains intact and safe. RS Joists are used in the framing of bridges, with additional reinforcements added to enhance their load-bearing capacity.

4. Industrial Buildings

In industrial buildings and warehouses, RS Joists are used for framing and supporting heavy machinery, equipment, and storage systems. The high strength of RS Joists makes them perfect for large, open spaces that require substantial support without compromising on floor area.

5. Structural Reinforcement

RS Joists can be used to reinforce existing structures that may have weakened over time. Whether it’s for reinforcing columns, beams, or foundations, these joists provide additional support to improve the overall stability and safety of a structure.

Conclusion

If you're planning a construction project in Gwalior, buy RS Joist in Gwalior is one of the smartest decisions you can make. With their unmatched strength, durability, cost-effectiveness, and ease of installation, RS Joists are the backbone of robust, long-lasting structures. Whether you're building a residential home, a commercial complex, or an industrial warehouse, RS Joists will provide the support and stability necessary to ensure the success of your project.

Moreover, with local suppliers in Gwalior offering RS Joists at competitive prices, you can be assured of a quick and hassle-free procurement process. These joists are a reliable choice for construction professionals looking to complete their projects on time and within budget.

Investing in RS Joists for your construction project is an investment in quality, longevity, and safety. So, don’t hesitate to buy RS Joist in Gwalior and take the first step toward building strong and durable structures.Bottom of Form

0 notes

Text

"Say Goodbye to Traditional Buildings – Metal is the Future”

For centuries, wood, brick, and concrete have been the go-to materials for constructing homes, businesses, and storage spaces. However, the construction industry is evolving rapidly, and metal buildings are taking center stage. With superior durability, cost-effectiveness, and sustainability, metal structures are proving to be the future of construction. Millennium Buildings specializes in high-quality metal buildings designed to meet diverse needs, from residential and commercial spaces to agricultural and industrial applications.

The Advantages of Metal Buildings:

1. Unmatched Durability

One of the biggest advantages of metal buildings is their longevity. Traditional materials like wood are susceptible to rot, termites, and warping, while brick and concrete can crack over time. In contrast, steel buildings are resistant to extreme weather conditions, including hurricanes, heavy snow, and earthquakes. Millennium Buildings’ metal structures are engineered to withstand harsh environments, ensuring they last for decades with minimal maintenance.

2. Cost-Effectiveness

Building a structure is a significant investment, but metal buildings offer long-term savings. Compared to traditional construction, metal buildings reduce labor and material costs. The prefabricated nature of Millennium Buildings’ structures means they are easy to assemble, cutting down on labor expenses and project timelines. Additionally, their durability leads to fewer repairs and lower insurance premiums, making them a financially wise choice.

3. Eco-Friendly and Sustainable

Sustainability is a growing concern in the construction industry, and metal buildings are an eco-friendly alternative to traditional structures. Steel is one of the most recyclable materials on the planet, reducing waste and environmental impact. At Millennium Buildings, we use high-quality, eco-friendly steel that minimizes carbon footprints while maximizing efficiency. Furthermore, metal buildings are often designed to accommodate solar panels, rainwater collection systems, and other green technologies, making them a smart choice for environmentally conscious consumers.

4. Versatility and Customization

Gone are the days when metal buildings were only used for warehouses and barns. Today, they serve various purposes, including homes, offices, workshops, garages, and even churches. Millennium Buildings offers a wide range of customizable options, including different roof styles, colors, and layouts. Whether you need a small storage shed or a large commercial facility, metal buildings provide limitless design possibilities tailored to your needs.

5. Energy Efficiency

Metal buildings can be designed to be incredibly energy efficient. With proper insulation, these structures maintain comfortable indoor temperatures year-round, reducing heating and cooling costs. Additionally, reflective roofing options can help deflect sunlight, keeping interiors cooler in the summer. Millennium Buildings ensure that all our metal structures are designed with energy efficiency in mind, helping owners save on utility bills while maintaining a comfortable environment.

6. Low Maintenance Requirements

Traditional buildings require frequent maintenance, such as repainting, termite treatments, and roof repairs. In contrast, metal buildings require minimal upkeep. Steel does not warp, crack, or attract pests, and high-quality coatings prevent rust and corrosion. With Millennium Buildings, you get a long-lasting structure that remains in excellent condition with little effort.

The Future of Construction is Here

The shift from traditional buildings to metal structures is gaining momentum. As more individuals and businesses recognize the benefits of metal buildings, the demand for these innovative solutions continues to rise. Millennium Buildings is at the forefront of this transformation, providing top-tier metal structures that combine strength, affordability, and sustainability.

Whether you need a new home, a commercial space, or a durable storage solution, metal buildings offer a future-proof alternative to traditional construction. Say goodbye to outdated building materials and embrace the strength and innovation of metal – the future starts with Millennium Buildings.

Get Started with Millennium Buildings Today!

Looking to invest in a high-quality metal building? Contact Millennium Buildings today to explore our customizable options and find the perfect solution for your needs. Our team is ready to help you build a structure that lasts a lifetime!

0 notes

Text

Pre Engineered Buildings | Fast & Cost-Effective | Kamdhenu

Revolutionize your construction process with Kamdhenu's pre-engineered buildings (PEBs). We specialize in designing, manufacturing, and erecting high-quality, cost-effective PEB solutions for a wide range of applications, including warehouses, factories, industrial sheds, commercial complexes, and more. Our PEBs offer significant advantages over conventional construction methods, including faster construction times, reduced costs, superior structural strength, and design flexibility. Kamdhenu's experienced engineers utilize advanced technology and high-grade steel to ensure the durability and longevity of your PEB. Choose Kamdhenu for your next project and experience the benefits of efficient, sustainable, and reliable pre-engineered building solutions.

0 notes

Text

Sri Surya Constructions: Leading Steel Building Construction Company in Coimbatore

The demand for strong, durable, and cost-effective buildings is increasing, and Sri Surya Constructions, a trusted steel building construction company in Coimbatore, is at the forefront of delivering high-quality steel structures. With unmatched durability, faster construction, and modern designs, steel buildings are now the preferred choice for residential, commercial, and industrial projects.

Why Steel is the Best Choice for Construction

Exceptional Durability: Steel buildings can withstand extreme weather, fire, and pests, ensuring a long lifespan.

Lightweight Yet Strong: High strength and lightweight properties reduce the structural load and foundation costs.

Low Maintenance: Unlike traditional materials, steel structures do not rot, crack, or degrade over time.

Key Advantages of Steel Buildings

Faster Construction: Prefabricated steel structures allow for quick assembly, reducing project completion time.

Flexible Design Options: Suitable for warehouses, offices, and residential spaces with various customisation possibilities.

Spacious Interiors: Fewer supporting columns create open spaces ideal for industries, retail spaces, and large halls.

Cost-Effective and Eco-Friendly Solution

Energy Efficiency: Steel buildings offer superior insulation, reducing heating and cooling costs.

Sustainable Construction: 100% recyclable steel ensures minimal environmental impact.

Long-Term Savings: Lower maintenance and repair costs lead to a higher return on investment.

Applications of Steel Structures

Industrial and Warehouses: Factories, logistics centres, and manufacturing units benefit from the durability and scalability of steel.

Commercial Buildings: Offices, malls, and retail outlets leverage steel’s strength and modern design.

Event and Public Spaces: Marriage halls, exhibition centres, and auditoriums use steel for structural stability and flexibility.

Conclusion: Build a Stronger Future with Sri Surya Constructions

With expertise in modern construction, Sri Surya Constructions, a leading steel building construction company in Coimbatore, provides durable, efficient, and cost-effective building solutions. Steel structures offer unmatched strength, faster completion times, and minimal maintenance, making them the perfect choice for various applications.

Know More:

#construction company#construction#coimbatore#building construction#constructions#builders#best builders in coimbatore

0 notes

Text

Understanding EPS Panels: A Comprehensive Guide for Commercial Construction Projects

In the rapidly evolving construction industry, efficiency, durability, and sustainability are no longer optional—they are essential. For businesses and organizations looking to optimize their commercial construction projects, EPS Panel Construction has emerged as a game-changing solution. Whether you’re constructing a warehouse, industrial shed, cold storage facility, or even a metro station, EPS Panels offer a versatile and cost-effective alternative to traditional building methods.

This blog dives deep into what EPS Panels are, their benefits, and why they should be a top consideration for your next commercial project. We’ll also explore how EPACK Prefab, a leading provider of prefabricated and pre-engineered building solutions, can help you leverage this innovative technology.

What Are EPS Panels?

EPS Panels, or Expanded Polystyrene Panels, are lightweight, prefabricated building materials used in EPS Panel Construction. These panels consist of an EPS core sandwiched between two layers of durable materials, such as steel, aluminum, or cement boards. The result is a robust, insulated, and easy-to-install building component that is ideal for a wide range of commercial applications.

EPS Wall Panels, a specific type of EPS Panel, are widely used for constructing walls in industrial and commercial buildings. They are known for their thermal insulation properties, structural strength, and quick installation process.

Why Should You Consider EPS Panels for Your Next Project?

1. Speed of Construction

One of the most significant advantages of EPS Panel Construction is the speed at which buildings can be erected. Since EPS Panels are prefabricated, they arrive at the construction site ready to be assembled. This drastically reduces construction time, allowing businesses to operationalize their facilities faster. For example, a warehouse or factory building that would traditionally take months to construct can be completed in a matter of weeks using EPS Panels.

2. Energy Efficiency

India’s extreme weather conditions, from scorching summers to chilly winters, make energy efficiency a critical factor in building design. EPS Panels provide excellent thermal insulation, reducing the need for artificial heating or cooling. This not only lowers energy consumption but also translates to significant cost savings over the building’s lifespan.

3. Cost-Effectiveness

When compared to traditional construction methods, EPS Panel Construction is more cost-effective. The lightweight nature of EPS Panels reduces the need for heavy machinery and labor, while the prefabricated design minimizes material wastage. Additionally, the energy savings achieved through better insulation further enhance the cost benefits.

4. Durability and Strength

Despite being lightweight, EPS Panels are incredibly strong and durable. They are resistant to fire, moisture, and pests, making them ideal for a variety of commercial applications, including cold storage buildings, clean rooms, and industrial enclosures. Their structural integrity ensures that the building remains safe and functional for decades.

5. Sustainability

As businesses increasingly prioritize sustainability, EPS Panels offer an eco-friendly alternative to traditional construction materials. EPS is 100% recyclable, and the energy-efficient nature of these panels contributes to a lower carbon footprint. This aligns with India’s growing focus on green building practices and sustainable development.

Applications of EPS Panels in Commercial Projects

EPS Panels are incredibly versatile and can be used in a wide range of commercial projects. Here are some examples:

Industrial Buildings: Warehouses, factory buildings, and industrial sheds benefit from the quick installation and durability of EPS Panels.

Cold Storage Facilities: The excellent thermal insulation properties of EPS Panels make them ideal for cold storage buildings.

Infrastructure Projects: Metro stations, railway sheds, and airport terminal buildings can be constructed efficiently using EPS Panels.

Healthcare and Education: Hospitals, school buildings, and laboratories require structures that are safe, durable, and energy-efficient—qualities that EPS Panels deliver.

Commercial Complexes: Shopping malls, exhibition halls, and office buildings can be constructed faster and at a lower cost with EPS Panels.

India-Relevant Data and Trends

According to a report by the India Brand Equity Foundation (IBEF), the Indian construction industry is expected to reach $1.4 trillion by 2025. This growth is driven by increased infrastructure development and industrial expansion.

The Indian government’s push for sustainable construction practices, such as the Energy Conservation Building Code (ECBC), has created a demand for energy-efficient building materials like EPS Panels.

The cold storage market in India is projected to grow at a CAGR of 14.8% from 2021 to 2026, driven by the increasing demand for perishable goods. EPS Panels are a preferred choice for cold storage construction due to their insulation properties.

Why Choose EPACK Prefab for EPS Panel Solutions?

At EPACK Prefab, we specialize in providing end-to-end solutions for prefabricated and pre-engineered buildings. With years of experience and a commitment to quality, we are one of the leading EPS Panel Manufacturers and EPS Panel Suppliers in India. Our expertise spans a wide range of commercial projects, including:

Warehouses and industrial sheds

Cold storage buildings and clean rooms

Airport terminal buildings and metro stations

Hospitals, schools, and office buildings

We understand the unique needs of commercial projects and offer customized solutions to ensure that your building is constructed to the highest standards. Whether you need a complete prefabricated building or specific components like EPS Wall Panels, we have the expertise and resources to deliver.

Conclusion

EPS Panel Construction is revolutionizing the way commercial buildings are designed and constructed. From faster construction times and cost savings to energy efficiency and sustainability, the benefits of EPS Panels are undeniable. For businesses and organizations looking to optimize their construction projects, EPS Panels offer a practical and innovative solution.

If you’re planning a commercial project and want to explore the advantages of EPS Panels, EPACK Prefab is here to help. With our extensive experience and commitment to quality, we can provide the perfect solution for your needs. Contact us today to learn more about our EPS Panel offerings and how we can assist you in building a better future.

Contact EPACK Prefab:

Website: https://www.epack.in/eps-panels

Email: [email protected]

Phone: +918130444466

Let’s build smarter, faster, and more sustainably with EPS Panels!

#EPSPanelConstruction#EPSPanels#EPSWallPanels#PrefabBuildings#SustainableConstruction#EnergyEfficientBuildings#CommercialConstruction#IndustrialBuildings#ColdStorageSolutions#GreenBuilding#EPACKPrefab#ConstructionInnovation#BuildingMaterials#IndiaConstruction#PrefabricatedStructures#ThermalInsulation#CostEffectiveConstruction#EcoFriendlyBuilding#WarehouseConstruction#InfrastructureDevelopment

0 notes

Text

Peb Industrial Shed | New Life Steel

PEB industrial sheds by New Life Steel are designed to meet diverse industrial needs with durability and precision. Our pre-engineered buildings offer cost-effective and customizable solutions, perfect for warehouses, factories, and storage facilities. Crafted from high-grade steel, our sheds ensure structural stability and quick installation https://www.newlifesteel.com/peb-industrial-shed/

Pre-engineered buildings (PEBs) have transformed the construction landscape, offering efficient and innovative solutions for industrial sheds. These structures are designed with precision, fabricated in controlled environments, and assembled on-site, providing unparalleled advantages over conventional construction methods.

Key Characteristics of PEB Industrial Sheds

Structural Versatility PEB industrial sheds are highly flexible, catering to varied needs such as warehouses, manufacturing units, and workshops. Their modular nature allows for expansion or modifications with minimal effort and cost.

Durable and Weather-Resistant Made primarily from steel, these sheds are engineered to withstand harsh weather conditions, including heavy rain, strong winds, and even seismic activity. Protective coatings further enhance their longevity by preventing rust and corrosion.

Quick Installation Since components are prefabricated off-site, the time required for construction is significantly reduced. On-site assembly is straightforward, ensuring faster project completion compared to traditional methods.

Energy Efficiency Advanced insulation materials used in PEB sheds help regulate indoor temperatures, reducing energy consumption for heating or cooling. Additionally, features like skylights and efficient ventilation systems enhance natural lighting and airflow.

Cost-Effective Solutions With optimized material usage, reduced construction time, and minimal maintenance, PEB industrial sheds offer significant cost savings. This makes them an economically viable option for businesses looking to scale operations.

Advantages Over Conventional Construction

Sustainability: PEBs generate less construction waste, and materials used are often recyclable, making them an eco-friendly choice.

Customization: They can be tailored to meet specific operational needs, whether for large-scale manufacturing or small storage facilities.

Minimal Maintenance: High-quality materials and precise engineering ensure that these structures require less upkeep over time.

Scalability: The modular design of PEB sheds allows for seamless expansion as business needs evolve.

Applications of PEB Industrial Sheds

Warehouses: Ideal for storage and inventory management due to their expansive and unobstructed spaces.

Manufacturing Facilities: Designed to support heavy machinery, overhead cranes, and other industrial equipment.

Workshops: Custom layouts and durable construction make PEBs suitable for various industrial activities.

Agricultural Storage: Frequently used for storing crops, fertilizers, and equipment.

Cold Storage Units: With appropriate insulation, PEBs serve as effective cold storage solutions for perishable goods.

Why Choose PEB for Industrial Sheds?

PEBs offer a strategic advantage for businesses aiming to optimize costs and enhance operational efficiency. Their quick construction time allows businesses to start operations sooner, while their durability ensures long-term reliability. Moreover, the aesthetic appeal of PEB sheds, with sleek designs and modern finishes, adds value to industrial spaces.

Conclusion

PEB industrial sheds are an excellent representation of modern engineering, providing solutions that combine durability, efficiency, and sustainability. Their adaptability across industries makes them a preferred choice for businesses seeking robust infrastructure. As the demand for cost-effective and eco-friendly construction grows, PEBs stand out as a forward-thinking approach to meeting these challenges.

By leveraging the advantages of pre-engineered building systems, industries can focus on growth while ensuring their infrastructure supports operational success.

0 notes

Text

The Advantages of Choosing PEB Structures for Your Next Project

When it comes to construction projects, selecting the right structure is paramount to ensure success. In recent years, Pre-engineered buildings (PEBs) have gained significant popularity, thanks to their numerous advantages over traditional construction methods. PEB structures offer benefits such as cost-effectiveness, accelerated construction timelines, design flexibility, and sustainability. we will dive into these advantages in detail and explore why PEB structures are an excellent choice for your next project and why you should choose MDIPL for the Best PEB Structures.

#light gauge steel framing manufacturers in india#temporary office structures#Precast Concrete Godown Wall#prefabricated warehouse#warehouse godown

0 notes

Text

Prefabricated steel structures manufacturers

Prefabricated steel structures manufacturers specialize in designing and fabricating steel components that are pre-engineered and assembled at construction sites. These structures are widely used for industrial buildings, warehouses, factories, and commercial spaces due to their durability, strength, and cost-effectiveness. Prefabricated steel structures are customizable, quick to install, and environmentally friendly, as they generate minimal construction waste. Trusted manufacturers focus on delivering high-quality materials and innovative designs to meet diverse project requirements, ensuring efficient and long-lasting building solutions.

1 note

·

View note