#Steel Beams

Explore tagged Tumblr posts

Text

Steel composition.

By Matti Merilaid.

#photographers on tumblr#original photographers#artists on tumblr#street photography#color#matti merilaid#steel#steel beams#composition

118 notes

·

View notes

Text

699,000 €

172 m² / 1851 ft²

La Rochelle, Charente-Maritime, Nouvelle Aquitaine, France.

#beautiful french house#wooden#kitchen#bedroom#bathroom#cement tiles#stairs#staircase#interior window#bricks#loft#steel beams#fireplace#modern#french#la rochelle#charente-maritime#poitou charentes#nouvelle aquitaine#france

7 notes

·

View notes

Text

Box Frame or Goal Posts?

The use of steel is essential in all structural modifications. Its use allows Structural Engineers and Builders to achieve Clients requirements of spanning across openings. Sometimes adding a steel beam is not sufficient which means the project needs a steel box frame or goal posts. This page tries to answer frequently asked questions regarding the use of a box frame or goal posts during the structural modification of masonry structures and buildings (residential, commercial and industrial).

A box frame or a goal post?

Clients and contractors often ask this question. When removing a substantial part of an external wall, there is more to consider than just the vertical loads. For example, many homeowners want to knock down as much of the rear wall as possible to create an open-plan kitchen-diner when building a rear extension. As structural failures are not only caused by vertical forces, it is important to consider resistance to lateral loads such as wind. Traditional masonry houses have cross walls or shear walls. The party walls have “buttressing” walls that provide lateral stability which are the front/rear walls and a cross wall in the middle. The masonry can this way transmit wind and lateral loads in all directions safely to the ground. Homeowners carrying out structural modifications to their properties may inadvertently strip their property (and neighbouring properties) of this “lateral stiffness”. It is important to carry out these works in a safe and compliant manner, as otherwise it could lead (in the worst scenario) to the collapse of the party wall and may contribute to the collapse of a whole block of flats or a terrace of houses like a “house of cards”.

Compliance and Building Regulations

To ensure masonry buildings maintain the required lateral stiffness, the Building Regulations Approved Document A sets some conditions on openings in structural walls. Approved Document A limits the amount of external or buttressing wall that can be removed and insists that the corners or returns of these walls are substantial. The guidance states that no more than 66% of an external or buttressing wall can be removed and that a min of a 550mm (665 external measured from the centreline of the party wall or external wall) return is maintained. Please refer to Diagram 12 in Approved Document A of the Building Regulations. If this guidance can’t be achieved a portal or a box frame is required. We encourage clients interested to refer to Document A of the Building Regulations or to LABC technical guidance.

Why you need a Structural Engineer?

Structural Engineers can design steel box frames (picture frames) or steel portal frames (goal posts). Our designs allow homeowners to comply with Building Regulations and achieve an architectural layout that suits the aspirations of modern lifestyle of maximum openness and ease of movement. Below is a description of the main three structural options available to any homeowner undertaking a rear extension or converting a rear reception into a kitchen diner. If you have any question regarding the information provided below, please do not hesitate to contact us to seek advice. We are happy to explain to you the technical, regulatory and cost impacts of each option.

Option 1: Use of a steel beam supported on masonry returns

If the client or the contractor is able to retain a minimum return of 550mm either side of the opening, then this would be the right choice. A steel beam would support the loads from above. This steel beam is rests on pad-stones that are spread the loads to the masonry returns preventing the crushing of the relatively soft masonry. The beam width matches the width of the supported wall and takes into account whether there is any moisture.

The Structural Engineer would produce a design and a drawing for the use of the builder who is pricing and carrying out the works. The design and drawing also form part of an application to Building Control to ensure compliance with the Building Regulations Approved Document A.

Advantages: minimum demolition, short construction time, less expensive than other options. The return of the wall is conveniently similar to a kitchen counter width. Disadvantages: the opening achieved does not give the maximum openness that some homeowners may want.

Option 2: Use of portal frame (goal posts)

The opening is as wide as possible because the clients intends to remove the whole of the rear wall between the two flank walls (party walls). The builder secures the first floor and the wall above using adequate temporary supports. Following the securing of the property, the contractor inserts a steel portal frame. The steel frame refers to two columns and a top beam. The top column transfers the loads to the two columns using moment/rigid connections. The two columns transfer loads to new foundation cast at the edges next to the flank wall. The columns would be at the edge of these new foundations. The frame columns provide lateral stability to the masonry walls so the contractor needs to use chemical fixings to attach the steel columns to the masonry walls to compensate for the lost lateral stiffness.

Advantage: the client can have the maximum opening. Steel columns can be H section 152x152mm to 254x254mm depending on the opening span and loads from above (as well as sway forces from wind).

Disadvantage: the main disadvantage is the need for new foundations. Columns are at the edge of the foundations, causing eccentric loading so foundations size could be quite large to counteract the eccentric loading and to spread the load without over-stressing the soil. Option 2 requires a higher budget and a longer construction time than option 1.

Option 3: Use of box frame (picture frame)

Description: the opening is as wide as possible. The whole of the rear wall between the two flank walls (party walls) would require removal (obviously after the builder secures the first floor and the wall above using properly chosen temporary supports). The contractor would need to insert a steel box frame (a top steel beam on two steel columns sitting in turn on a bottom steel beam). The bottom beam is encased in concrete and supported on the old corbelled brickwork foundation that lies underneath the removed wall. The connections between the columns and the beams are moment/rigid connections and we provide the details and design for them. Alternatively the fabricator may have an in-house Structural Engineer to undertake the design and detailing based on the forces from the Structural Engineer.

Advantage: this options results in a maximum opening. Steel columns can be H section 152x152mm to 254x254mm depending on the opening span and loads from storeys above (as well as sway forces from wind). The use of the corbelled masonry foundation of the original wall to support the box frame would minimize ground works.

Disadvantage: the main disadvantage is the increased cost of steelwork. However, the savings in ground works cost and time outweigh the slight increase in steel cost.

So what is better, Box Frame or Goal Posts?

Structural Engineers recommend option 1 for all cases except where the client has already decided to achieve a maximum opening. To achieve the maximum openness, we highly recommend option 3: use of a steel box frame. We have developed a standard method of designing these box frames and provide detailed fabrication drawings that would allow the accurate production and fabrication of the box frame steel. Many steel yards do not have the benefit of an in-house engineer and even if they do, they would charge clients for detailing connections. Our standardized fabrication drawings allow our clients to use any steel yard to procure steel ensuring competitive rates on the steel cost and saving time and cost.

#steel beam#steel beams#timber structure#structure#glulam#box frame#goal posts#portal frame#steel beam connections

2 notes

·

View notes

Text

Mercer Museum. Doylestown, PA.

ISO 1600 | 24mm | f/5.6 | 1/15 sec

Photo © 2023 Brian R. Fitzgerald (brfphoto.

#brfphoto#photography#photographers on tumblr#original photography#lensblr#luxlit#biutifulpics#imiging#clubimiging#telescopical#gray-card#galeriedesartsvisuels#originalphotographers#doylestown#pennsylvania#mercer museum#concrete#steel beams#rust

7 notes

·

View notes

Text

2 notes

·

View notes

Text

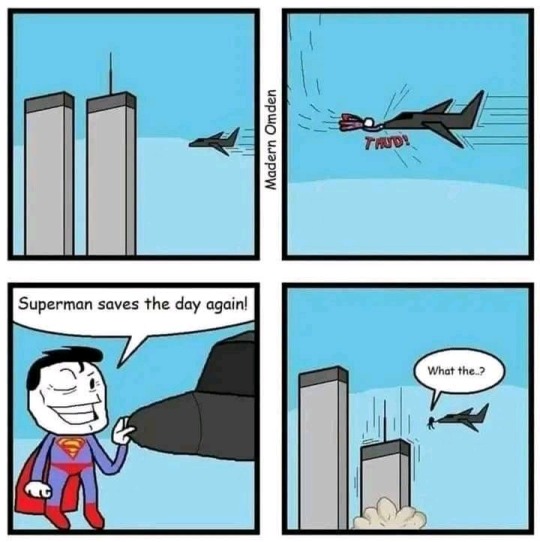

#comics#art#9/11#superman#rick and morty#twin towers#building 7#controlled demolition#george bush#jet fuel#steel beams

6 notes

·

View notes

Text

The division has been established as a part of Mitwalli steel. It provides steel beams from different sources, such as different shapes of steel beams, H- beams, U-channels, I-beams, angles, decorative corners, flat bars, metal sheets, square and twisted steel bars and rebars. This has made us one of the most important suppliers of structural steel. Thus, we guarantee to meet all the needs of our customers from the construction and industrial sector with products of high quality.

#steel beams for construction#steel beams for residential construction#metal beams#iron beam for commercial use#steel beams#iron beams#steel beam manufacturers#steel beam suppliers

2 notes

·

View notes

Text

The Role of Parallel Flange Channel in Structural Engineering and Construction

In the world of structural engineering and construction, the parallel flange channel is a key component that ensures strength and stability. Also known as PFC or C-channel, this steel section is widely used for a variety of structural applications, including beams, supports, and frames.

The unique design of the parallel flange channel—with two parallel flanges and a flat surface—provides excellent load distribution, making it ideal for heavy-duty projects that require high load-bearing capacity. Its strength and stability make it a preferred choice for constructing bridges, buildings, and industrial machinery.

Not only does the parallel flange channel offer impressive durability and load resistance, but it is also resistant to corrosion and can withstand harsh weather conditions, ensuring long-term performance in challenging environments.

For those working on commercial or industrial projects, choosing a parallel flange channel can provide the strength and flexibility needed for a wide range of applications. Make sure to source your PFC from reliable suppliers to guarantee the quality and safety of your structure.

0 notes

Text

The Essential Guide to Bifold Steel Lintels: Strength and Versatility for Modern Construction

In the realm of construction, ensuring structural integrity while maintaining aesthetic appeal is paramount. One of the critical components that contribute to this balance is the lintel. Among the various types of lintels available, bifold steel lintels stand out for their strength, durability, and versatility. This blog delves into what bifold steel lintels are, their benefits, and why they are an excellent choice for modern construction projects.

What Are Bifold Steel Lintels?

A lintel is a horizontal support beam that spans an opening, such as a window or door, and carries the load from the structure above it. Bifold steel lintels are specifically designed with a bifold (or dual) structure, often resembling two steel sections joined together. This design enhances their load-bearing capacity and allows for greater flexibility in various construction applications.

Advantages of Bifold Steel Lintels

1. Superior Strength and Durability

Steel is renowned for its strength and longevity. Bifold steel lintels leverage these properties, offering exceptional support for masonry, brickwork, and other building materials. They are designed to bear heavy loads without deforming or failing, ensuring the structural integrity of buildings over time.

2. Versatility in Application

Bifold steel lintels are suitable for a wide range of applications, from residential homes to commercial buildings. They can be used in load-bearing and non-load-bearing walls, making them a versatile choice for various construction needs. Their design can be adapted to different spans and load requirements, providing a tailored solution for specific projects.

3. Ease of Installation

The bifold design simplifies the installation process. These lintels are prefabricated and often come with pre-drilled holes, reducing the need for on-site modifications. This not only speeds up the construction process but also minimizes labor costs and potential installation errors.

4. Corrosion Resistance

Modern bifold steel lintels are typically treated or coated to resist corrosion. This feature is particularly important in environments exposed to moisture or harsh weather conditions, ensuring the lintels maintain their structural integrity and appearance over time.

5. Aesthetic Appeal

Beyond their functional benefits, bifold steel lintels can also contribute to the aesthetic appeal of a building. Their sleek, modern appearance complements contemporary architectural designs, and they can be painted or coated to match the building’s color scheme.

Applications of Bifold Steel Lintels

1. Residential Buildings

In residential construction, bifold steel lintels are commonly used over doorways, windows, and garage openings. Their ability to support heavy loads while maintaining a slim profile makes them ideal for homes where both strength and aesthetics are important.

2. Commercial Structures

Commercial buildings often require robust materials that can support extensive loads and withstand frequent use. Bifold steel lintels are perfect for such applications, providing reliable support in retail spaces, office buildings, and industrial facilities.

3. Architectural Projects

For architectural projects that demand unique designs and non-standard openings, bifold steel lintels offer the necessary flexibility and support. Their adaptability allows architects to push the boundaries of design without compromising on safety or structural integrity.

Key Considerations When Choosing Bifold Steel Lintels

1. Load-Bearing Requirements

Understanding the specific load-bearing requirements of your project is crucial. Consult with structural engineers to determine the appropriate size, thickness, and type of bifold steel lintel needed to support the expected loads.

2. Compliance with Standards

Ensure that the bifold steel lintels you choose comply with relevant building codes and standards. This includes standards for material quality, load capacity, and corrosion resistance.

3. Supplier Reputation

Select a reputable supplier with a proven track record of providing high-quality bifold steel lintels. A reliable supplier will offer products that meet industry standards and provide necessary certifications and warranties.

4. Installation Expertise

Proper installation is key to the performance of bifold steel lintels. Engage experienced contractors who are familiar with the specific installation requirements of these lintels to ensure they are correctly fitted and secured.

Conclusion

Bifold steel lintels are an excellent choice for modern construction projects, offering unmatched strength, durability, and versatility. Their ease of installation, resistance to corrosion, and aesthetic appeal make them suitable for a wide range of applications, from residential homes to large commercial buildings. By understanding the benefits and key considerations associated with bifold steel lintels, builders and architects can make informed decisions that enhance the structural integrity and visual appeal of their projects.

Ready to enhance your construction project with the reliability and versatility of bifold steel lintels? Consult with industry experts and choose high-quality lintels that meet your specific needs, ensuring a strong, durable, and visually appealing structure

0 notes

Text

Rolled steel sections are considered as the useful materials in steel construction. These are accessible in different forms.

Steel is one of the most vital building materials in construction industry. It has diverse applications.

On the basis of their utilization, various steel members are manufactured in the factories. The continuous casting molds devoid of any joints are used to cast rolled steel sections. Given below, details of various shapes or forms of rolled steel sections.

Types of Rolled Steel Sections: ? Angle sections ? Channel sections ? T- sections ? I-sections ? Round bars ? Square bars Flat bars Corrugated sheets ? Expanded metal ? Plates ? Ribbed bars (HYSD) ? Ribbed bars (mild steel) ? Thermo-mechanically treated bars ? Welded wire fabrics

Read more

0 notes

Text

2,500,000 €

171m² / 1840 ft²

Paris XIe, Ile-de-France, France.

#beautiful french house#beautiful apartment#flat#apartment#loft#glass roof#mezzanine#patio#bay windows#bedroom#kids room#stairs#modern#kitchen#steel beams#parisian#french#paris#11e arrondissement#paris xi#paris 11#ile-de-france#france

1 note

·

View note

Photo

Wet Bar - Rustic Home Bar Example of a mid-sized mountain style single-wall dark wood floor wet bar design with an integrated sink, flat-panel cabinets, distressed cabinets, granite countertops and white countertops

0 notes

Text

Crafting Excellence: A Guide to Choosing the Right Steel Fabrication Suppliers

Steel fabrication is an art that transforms raw steel into structures that shape our cities, industries, and everyday lives. Choosing the right steel fabrication supplier is a pivotal step in ensuring the success of your project. In this blog, we'll explore the key considerations to keep in mind when selecting a steel fabrication partner.

Understanding Your Project Needs

The foundation of any successful collaboration with a steel fabrication supplier is a clear understanding of your project requirements. Identify the specifications, dimensions, and tolerances crucial to your project. Whether you're working on a complex structural framework or intricate components, a detailed understanding of your needs will guide you in finding a supplier with the right capabilities.

Expertise and Specialisation

Steel fabrication is a diverse field that encompasses various techniques and specialities. Some suppliers may specialise in large-scale structural projects, while others excel in precision machining or custom fabrication. Assess the supplier's expertise and past projects to ensure they have experience in your specific industry and can meet the unique challenges of your project.

Quality Assurance and Certifications

Quality is paramount in steel fabrication, and reputable suppliers adhere to industry standards and certifications. Look for suppliers with ISO certifications and those compliant with relevant quality control measures. A commitment to quality assurance ensures that the fabricated steel components meet or exceed your project's specifications.

Technological Capabilities

In the modern era, technology plays a crucial role in steel fabrication. Advanced equipment, such as CNC machines and laser cutting technology, enhances precision and efficiency. Assess the supplier's technological capabilities and the sophistication of their equipment. A supplier investing in cutting-edge technology is likely to deliver high-quality and precisely fabricated components.

Project Management and Communication

Effective project management and communication are vital for seamless collaboration between you and your steel fabrication supplier. Ensure that the supplier has a robust project management system in place, keeping you informed about progress, timelines, and any potential challenges. Clear communication channels contribute to a collaborative and successful partnership.

Flexibility and Customisation

Every project is unique, and a reliable steel fabrication supplier should be able to adapt to your specific requirements. Whether you need custom designs, prototypes, or modifications to existing plans, choose a supplier with the flexibility to accommodate your project's evolving needs. Customisation capabilities set a supplier apart in the competitive steel fabrication landscape.

Conclusion:

Selecting the right steel fabrication supplier is a crucial step in turning your project vision into reality. By understanding your needs, assessing the supplier's expertise, ensuring quality assurance, considering technological capabilities, prioritising effective communication, and valuing flexibility, you'll be well on your way to partnering with a steel fabrication supplier that can bring excellence to your projects. Remember, the right supplier is not just a contractor; they are your partner in crafting success.

0 notes

Text

Sydney Loft-Style Living Room

Huge urban formal and loft-style concrete floor, gray floor and exposed beam living room photo with beige walls and a tv stand

1 note

·

View note

Photo

Front Door Mudroom Denver Example of a huge arts and crafts entryway design

0 notes