#Standard FR4

Explore tagged Tumblr posts

Text

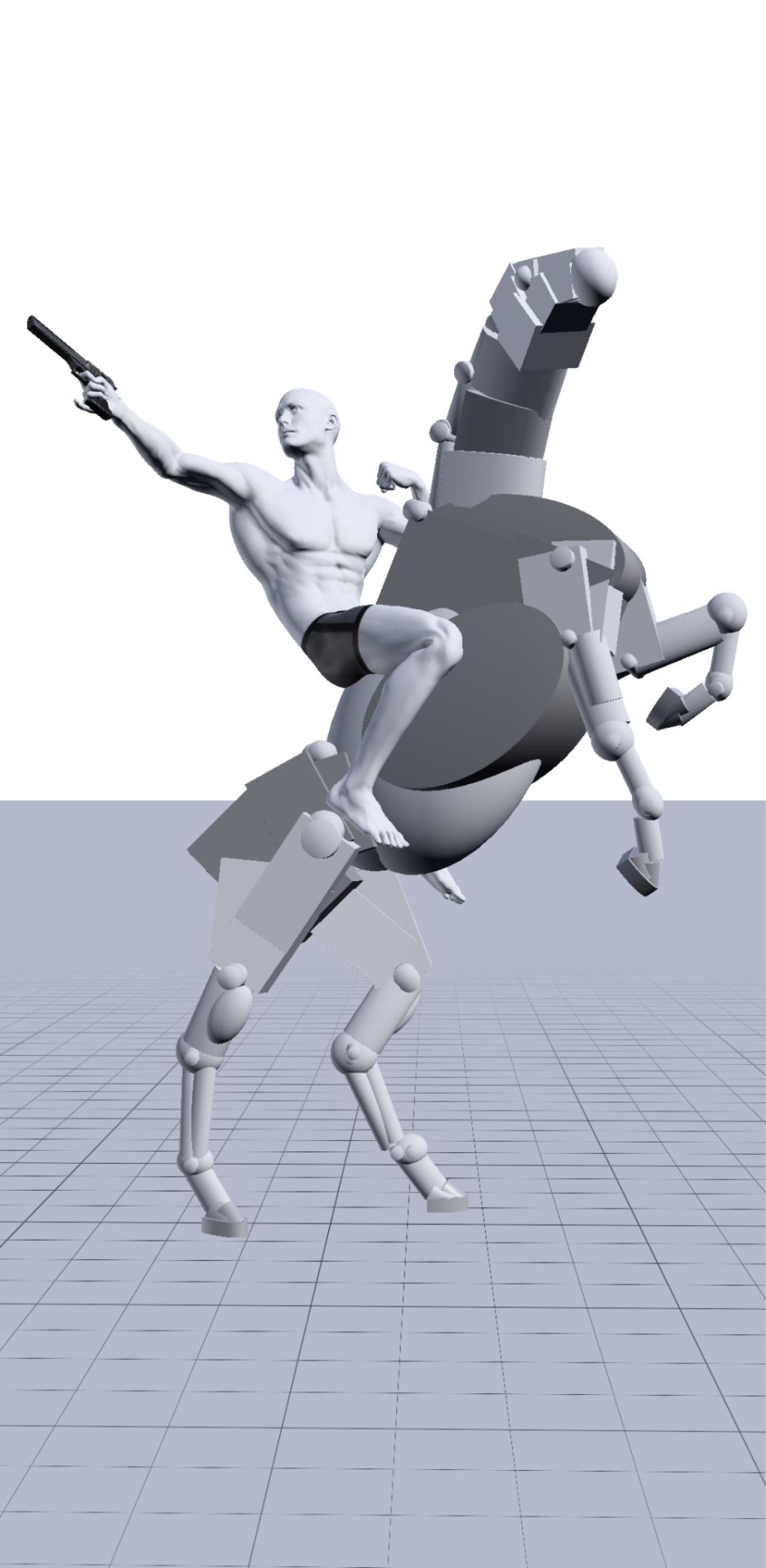

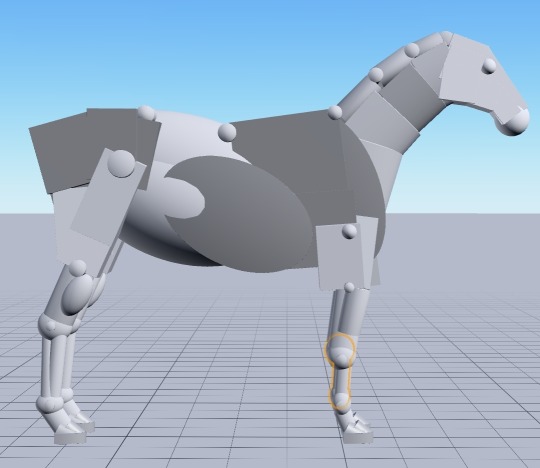

Making custom character/animal/monster models in magic poser:

[example collage]

How detailed you go with the poser is 100% up to you, but keep in mind that the fewer shapes you use the better the app will run. For this tutorial I'm going for the upper end of what I'd recommend attempting, mostly just to prevent the app from dying every time you open the file.

Step 1:

Make a reference image. Ideally you want a good head on front and side view of whatever it is you're making. I'm lazy and need a horse, so for this tutorial I'll be using this stock photo of a horse

Step 2:

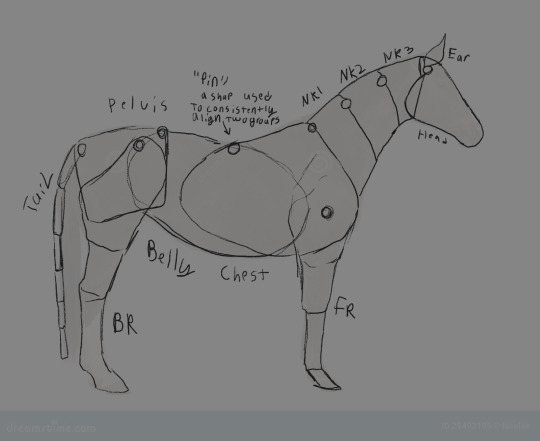

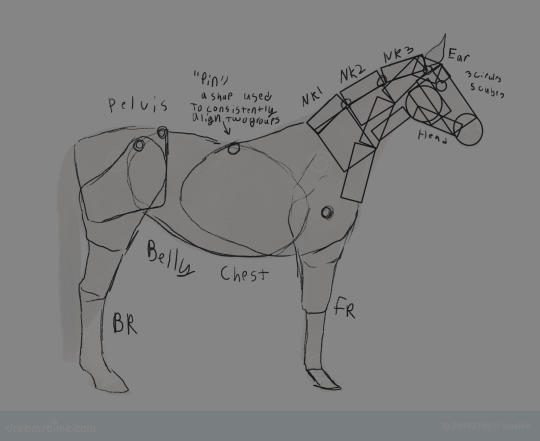

Magic poser lets you group multiple objects together so they can be rotated and moved as a single shape, that is the only reason this method is any kind of doable. This step is technically optional but breaking the form down like this Before you start modeling makes it easier to organize things as you go, and breaks the task up into easier to digest components.

Your goal here is to break the form down into groups you will largely never ungroup. So large forms that will move as a single piece, things like legs and tails will generally be the exception and may be grouped and ungrouped repeatedly during the posing process.

Because I'm going for a fairly high detail end result my groups will be:

Head

Nk1 (neck segment 1), Nk2, Nk3

Chest

Belly

Pelvis

FR1 (Front right shoulder), FR2 (Front right upper arm), FR3 (front right forearm), FR4(front right ankle),FR5 (front right hoof)

FL1, FL2, FL3, FL4, FL5

BL1, BL2, BL3, BL4 BL5

BR1, BR2, BR3, BR4, BR5

Step 2.2:

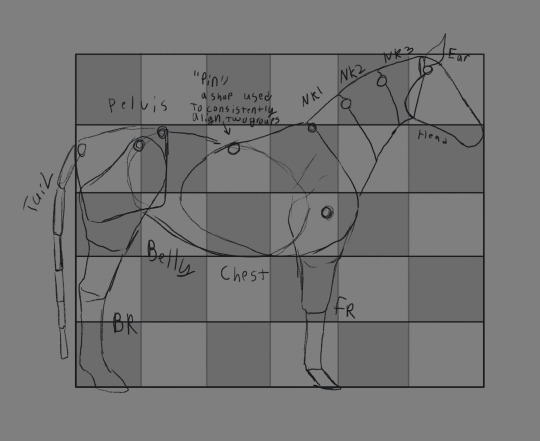

this is completely optional, but if you want to break up the groups into shapes ahead of time, that can make it easier to get everything set up in the file. Alternatively you can just create proportion blocks to give yourself easy reference points during the actual modeling.

Step 3:

If your model is going to interacting with another standard model then it can be helpful to drop the standard into the scene alongside any reference blocks you might have decided on in step 2.2, this is just so you don't have to resize the model every time you use it.

Step 4:

Good luck. (but for real, from here it's up to you to get everything sorted, there's not much specific advice I can give other than reminding you the fewer corners the better. and adding 'pins', a small pair of shapes used to line up two groups, is genuinely going to make your life so much easier. When you're done making a group it can also be helpful to set it to a default position, ungroup it, and then regroup it so it's axis of rotation is in a more convenient place)

Step 5:

Use that grey fucker

24 notes

·

View notes

Text

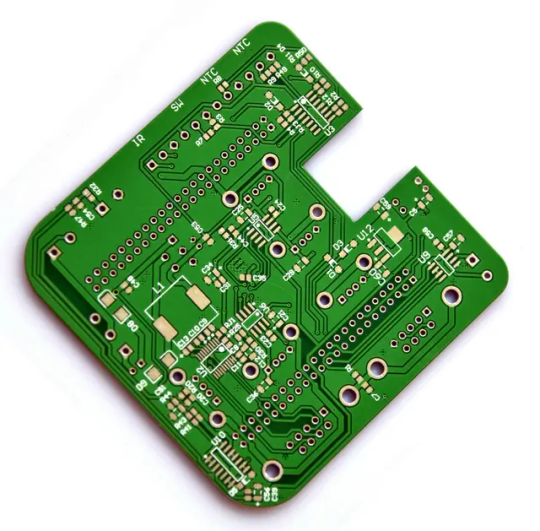

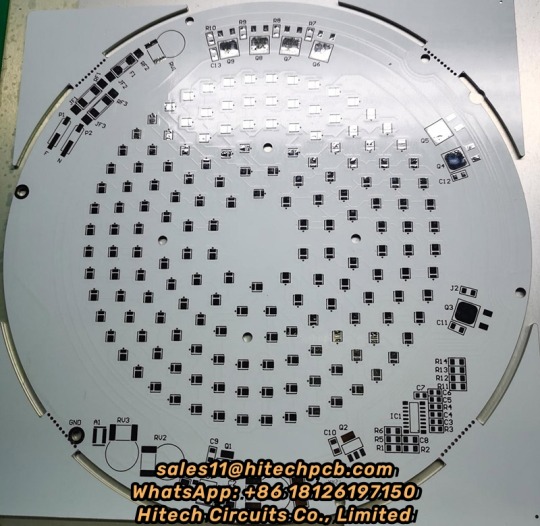

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

Closer Look at 400G QSFP-DD Optical Transceiver Module

Recent years have seen the evolution towards the 5G, Internet of Things (IoT), and cloud computing, increasing pressure on data centers to ramp up both network capacity to 400G and driving providers to search for new solutions to achieve their 400G Data Center Interconnects (DCIs). 400G QSFP-DD optical transceiver module is becoming one of the most popular cutting-edge 400G DCI solutions. This article will provide a basic understanding of QSFP-DD optical transceiver modules.

What is the QSFP-DD Optical Transceiver Module?

Quad small form-factor pluggable-double density (QSFP-DD) is designed with eight lanes that operate at up to 25 Gbps via NRZ modulation or 50 Gbps via PAM4 modulation. It supports data rates of 200 Gbps or 400 Gbps and doubles the density. QSFP-DD is backward compatible with current 40G and 100G QSFPs. It is compliant with IEEE802.3bs and QSFP-DD MSA standards. QSFP-DD is available in single-mode (SM) and multi-mode (MM) fiber optic cables and includes digital diagnostics monitoring (DDM) to monitor parameters such as power, temperature, and voltage.

Types of 400G QSFP-DD Optical Transceiver Module

400G SR8 QSFP-DD

400G SR8 QSFP-DD optical transceiver module is suitable for short-distance interconnection or multi-channel data communication. The transmission rate is up to 425Gbps, and the central wavelength is 850nm. The transmission distance is up to 70m or 100m through multi-mode OM3 and OM4 fiber.

400G DR4 QSFP-DD

400G DR4 QSFP-DD optical transceiver module achieves the transmission over single-mode fiber (SMF) with an MPO-12 connector. It supports a max transmission distance of 500m on SMF.

400G FR4 QSFP-DD

400G FR4 QSFP-DD optical transceiver module supports link lengths of up to 2km SMF with a duplex LC connector. It uses wavelength division multiplexing(CWDM ) technology, eight channels of 53Gbps PAM4 signals on the electrical side, and four channels of 106Gbps PAM4 signals on the optical side, which is twice the rate of the electrical side.

400G LR4 QSFP-DD

400G LR4 QSFP-DD optical transceiver module is designed with a built-in Gearbox chip that multiplexes the two channels' electrical input data into a single-channel outputs signal and then modulates it to the optical receiver end. The digital signal processor (DSP) basis gearbox converts eight channels of 25GBaud PAM4 signals into four channels of 50GBaud (PAM4) over an SMF cable with duplex LC connectors. It supports a transmission distance of up to 10km.

400G LR8 QSFP-DD

The 400GBASE-LR8 optical transceiver module supports link lengths of up to 10km over a standard pair of G.652 SMF with duplex LC connectors.

400G ER8 QSFP-DD

The 400G ER8 QSFP-DD optical transceiver module supports link lengths of up to 40km over a standard pair of G.652 SMF with duplex LC connectors.

400G ER4 QSFP-DD

400G ER4 QSFP-DD optical transceiver module supports link lengths of up to 40km over a standard pair of G.652 SMF with duplex LC connectors. It has only four wavelengths for 4 LAN WDM channels 1295.56/1300.05/1304.58/1309.14nm.

Advantages of 400G QSFP-DD Optical Transceiver Module

Backward compatibility: Allowing the QSFP-DD to support existing QSFP modules (QSFP+, QSFP28, QSFP56, etc.). It provides flexibility for end-users and system designers.

Adopting the 2x1 stacked integrated cage/connector to support the one-high cage connector and two-high stack cage connector system.

SMT connector and 1xN cage design: Enable thermal support of at least 12W per module. The higher thermal reduces the requirement for heat dissipation capabilities of transceivers, thus reducing some unnecessary costs.

ASIC design: Supporting multiple interface rates and fully backward compatible with QSFP+ and QSFP28 modules, thus reducing port and equipment deployment costs.

Applications

400G QSFP-DD optical transceiver module is used in 400G Ethernet, data centers, telecommunications networks, cloud networks, Infiniband interconnects, high-performance computing networks, 5G, 4K video, IoT, etc.

Conclusion

400G QSFP-DD optical transceiver module offers high speed, performance, scalability, and low power in 400G Ethernet. Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if any needs.

2 notes

·

View notes

Text

Aluminum pcb vs fr4 pcb board

FR4 board is a code name for the grade of flame-retardant material. It represents a material specification that the resin material must be able to extinguish by itself after burning. It is not a material name, but a material grade. Therefore, there are many types of FR-4 grade materials used for pcb, but most of them are composite materials made of so-called Tera-Function epoxy resin, Filler and glass fiber.

FR-4 PCB board, according to different uses, industry insider generally call them: FR-4 Epoxy Glass Cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4 , Fiberglass board, fiberglass board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame-retardant insulation board, FR-4 laminated board, epoxy board , FR-4 light board, FR-4 fiberglass board, epoxy glass cloth board, epoxy glass cloth laminate, circuit board drilling pad etc.

Main technical features and applications of FR-4 board: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for high-performance electronic insulation requirements products, such as FPC reinforcement board, PCB drilling pad, glass fiber meson, potentiometer carbon film printed glass fiber board, precision star gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation support spacer, insulation backing plate, transformer insulation plate, motor insulation, grinding gear, electronic switch insulation board, etc.

The aluminum pcb board is a metal-based copper-clad laminate with good heat dissipation function. Generally, a single-sided aluminum PCB is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. For high-end use, it is also designed as a double-sided board, and the structure is circuit layer, insulating layer, aluminum base, insulating layer, and circuit layer. Very few applications are multi-layer boards, which can be formed by bonding ordinary multi-layer boards with insulating layers and aluminum bases.

Compared with traditional FR-4 PCB, aluminum pcb circuit boards have the following advantages:

Good thermal conductivity. The metal layer of the aluminum pcb board can quickly dissipate heat, transfer the heat of the device, minimize the thermal resistance, and have good thermal conductivity.

More environmentally friendly. Aluminum-based pcb boards do not contain substances harmful to human health and the environment, and are more environmentally friendly than FR-4 circuit boards.

High durability. FR-4 pcb may be warped, bent, cracked etc during production and transportation; ceramic substrates are also more fragile. Aluminum pcb circuit boards make up for the shortcomings of FR-4 boards and ceramic substrates, have longer durability, and avoid board cracks caused by production and transportation.

Higher performance. The circuit layer of the aluminum-based PCB board is etched to form the circuit. Compared with the traditional FR-4 pcb board, under the same line width, thickness, etc., the current carried by the aluminum pcb is higher than that of the FR-4 pcb board.

0 notes

Text

Comparison between Rogers PCB and ordinary PCB

Rogers PCBs utilize specialized laminate materials produced by Rogers Corporation, specifically selected to meet the demands of high-frequency and high-performance applications. In contrast, standard PCBs typically use FR4 materials, which are suitable for more general and standardized electronic circuits. To accurately understand the differences between these two types, several key factors must be considered, including the material properties, performance, and applications of each PCB.

Material Differences

There are significant differences between Rogers printed circuit boards and standard PCBs regarding the materials used. Below are some common materials utilized in both types of PCBs:

Rogers PCB Materials

Rogers PCB materials consist of various high-performance laminates designed specifically for high-frequency applications. These materials also exhibit excellent thermal performance. Here are some of the most commonly used materials in Rogers PCB manufacturing:

· RO3000 Series: These materials are known for their low dielectric loss, outstanding thermal management, and stable electrical performance, making them suitable for microwave applications.

· RO4000 Series: This series strikes a good balance between cost and performance, featuring low dielectric constant and high thermal stability.

· RO4350B: This laminate is widely used in RF and microwave applications due to its low dielectric constant and loss tangent, making it particularly suitable for RF applications.

Standard PCB Materials

Most standard PCBs are made using FR4 materials. This common substrate type consists of woven fiberglass and epoxy resin adhesive. FR4 is recognized for its low cost and acceptable performance in standard applications. Its dielectric constant is typically higher than that of Rogers PCBs (about 4.5), which may lead to signal attenuation in high-frequency applications. While FR4 materials perform well in low to mid-frequency ranges, they struggle to maintain good signal integrity and thermal stability in more challenging environments.

Dielectric Properties

The dielectric performance of the materials used in PCBs is crucial, especially for high-frequency applications. Dielectric performance directly affects the board's ability to transmit signals with minimal loss and interference.

Rogers Printed Circuit Boards

· Dielectric Constant: Rogers PCB materials have a low and stable dielectric constant, typically ranging from 2.2 to 3.5. A lower dielectric constant indicates that the material can support faster signal transmission with less delay, which is critical for high-frequency and high-speed applications.

· Dissipation Factor: Rogers laminates have a low dissipation factor, as low as 0.002 units. This stability of the dielectric constant across varying temperatures makes them highly suitable for applications involving rapid thermal changes, such as those found in aerospace or automotive radar systems.

Standard PCBs (FR4)

· Dielectric Constant: FR4 has a higher dielectric constant, typically around 4.0 to 4.5. This can lead to potential signal delays and more severe signal attenuation, particularly in high-speed and high-frequency applications.

· Dissipation Factor: The dissipation factor of FR4 materials is higher than that of Rogers materials, generally between 0.02 and 0.035 units. This increased dissipation factor results in greater signal loss, especially in high-frequency applications.

Cost Considerations

Cost is an important factor to consider in PCB manufacturing. Distinctions can be made between Rogers PCBs and standard PCBs due to their different material compositions.

Rogers Printed Circuit Boards

Rogers PCBs are typically more expensive due to their unique material properties and higher performance. The manufacturing process for Rogers laminates is more complex than for standard FR4 materials, aimed at achieving better signal integrity and thermal performance.

· Higher Material Costs: The superior material characteristics of Rogers laminates, such as their low dielectric constant and excellent thermal conductivity, contribute to increased PCB costs.

· Specialized Manufacturing Process: The manufacturing process for Rogers PCBs is more intricate due to the need for precise control over electrical and thermal performance, significantly increasing overall costs.

Standard PCBs

FR4 PCBs are more cost-effective compared to Rogers PCBs, making them the preferred choice for general applications. The lower material costs also translate to relatively lower manufacturing costs for standard PCBs.

· Reduced Material Costs: FR4 is generally readily available and much cheaper compared to Rogers laminates. Its affordability and quick availability make FR4 PCBs the go-to choice for consumer electronics and other cost-sensitive applications.

· Simpler Manufacturing: The production of FR4 boards does not require the precision needed for Rogers boards, greatly reducing production costs.

Applications

Rogers PCB Applications

Rogers PCBs are frequently used in applications requiring high-frequency performance, excellent signal integrity, and high thermal stability. Here are some common applications for Rogers PCBs:

· RF and Microwave Circuits: Rogers PCBs are widely employed in devices that require significant RF and microwave signal usage, such as mobile base stations, radar systems, and satellite communications.

· High-Speed Digital Circuits: Rogers PCB materials consistently support high-speed data transmission while minimizing signal loss.

· Aerospace and Military Applications: Their durability and thermal stability make Rogers laminates ideal for PCB applications in aerospace and military environments, where signal integrity is crucial.

Standard PCB Applications

FR4 is one of the commonly used materials in everyday electronics, primarily due to its low cost and good performance in most standard applications. It is utilized in:

· Consumer Electronics: Everyday devices such as smartphones, computers, and household appliances primarily rely on FR4 printed circuit boards because they are simple and inexpensive to manufacture.

· Industrial Electronics: Similar to consumer electronics, industrial electronic devices also utilize standard PCBs, where high-frequency performance is not a critical requirement.

Hitech has rich experience in Rogers PCB manufacturing. We have adequate stock for common Rogers material. If you have the requirements for such PCB products, feel free to let us know. https://www.hitechpcba.com/rogers-pcb

0 notes

Text

What are Rigid Circuits? : Rigid Circuits

Rigid circuits, also known as rigid printed circuit boards (PCBs), are made from non-flexible materials that provide a solid foundation for electronic components. Unlike flexible circuits, which can bend and conform to various shapes, rigid circuits maintain their shape and rigidity throughout their lifecycle. They are used in applications where mechanical stability and structural integrity are crucial.

Types of Rigid Circuits : Rigid Circuits

Single-Sided PCBs: These have a single layer of conductive material and are often used in simple electronic devices. They are cost-effective and straightforward to manufacture.

Double-Sided PCBs: These circuits have conductive layers on both sides of the board, allowing for more complex designs and higher component density. They are used in applications requiring more advanced functionality.

Multi-Layer PCBs: These consist of multiple layers of conductive material separated by insulating layers. Multi-layer PCBs can accommodate complex circuit designs and high-density interconnections, making them suitable for advanced electronics such as computers and telecommunications equipment.

Key Features of Rigid Circuits : Rigid Circuits

Mechanical Strength: Rigid circuits provide structural support for electronic components, ensuring they remain securely in place and are protected from mechanical stress.

Thermal Stability: They offer good thermal stability, which helps dissipate heat generated by electronic components and prevents overheating.

Electrical Performance: Rigid circuits provide reliable electrical connections and signal transmission, ensuring consistent performance of electronic devices.

Cost-Effectiveness: They are generally less expensive to produce than flexible circuits, making them a popular choice for a wide range of applications.

Applications of Rigid Circuits : Rigid Circuits

Consumer Electronics: Rigid circuits are widely used in devices such as smartphones, tablets, laptops, and televisions. They provide the necessary support and connectivity for various electronic components.

Automotive Electronics: In the automotive industry, rigid circuits are used in control systems, infotainment systems, and safety features. Their durability and reliability are essential for vehicle performance and safety.

Industrial Equipment: Rigid circuits are employed in industrial machinery, control systems, and automation equipment. Their robustness ensures reliable operation in demanding environments.

Medical Devices: In medical technology, rigid circuits are used in diagnostic equipment, monitoring devices, and other healthcare applications. Their accuracy and reliability are crucial for patient safety and effective treatment.

Manufacturing Process : Rigid Circuits

The manufacturing of rigid circuits involves several steps:

Material Preparation: The process begins with the preparation of laminate sheets, which consist of a base material (such as FR4) and a copper layer. The laminate is coated with a photoresist material that will be used to define the circuit pattern.

Patterning: The circuit design is transferred to the laminate using photolithography. The photoresist material is exposed to light through a mask, which creates a pattern on the copper layer.

Etching: The unexposed copper is removed using an etching solution, leaving behind the desired circuit pattern.

Drilling and Plating: Holes are drilled into the board for component placement, and the holes are plated with a conductive material to create electrical connections between different layers of the circuit.

Assembly and Testing: Electronic components are soldered onto the circuit board, and the assembled boards undergo rigorous testing to ensure they meet performance and reliability standards.

Conclusion : Rigid CircuitsRigid circuits are a vital component of modern electronics, providing the mechanical support and electrical connectivity needed for a wide range of applications. Their durability, thermal stability, and cost-effectiveness make them an essential choice for manufacturers and designers. As technology continues to evolve, rigid circuits remain a foundational element in the development of advanced electronic devices and systems.

0 notes

Text

PCB Assembly Solutions for High-Reliability Applications: What to Look For

In industries where safety and performance are paramount—such as aerospace, medical devices, automotive, and military—reliable and robust electronic systems are crucial. The quality and reliability of these systems largely depend on the precision and effectiveness of the PCB (Printed Circuit Board) assembly process. Selecting the right PCB assembly solution is therefore a critical decision that can impact the overall success and safety of the end product. Here’s what you need to consider when choosing a PCB assembly solution for high-reliability applications.

1. Certification and Compliance

The first and foremost factor to consider is whether the PCB assembly provider adheres to industry-specific standards and certifications. In high-reliability industries, compliance with stringent regulations is non-negotiable. For example:

Aerospace and Defense: Look for PCB assembly providers that are AS9100 certified, which ensures they meet the rigorous quality management standards required in the aerospace industry.

Medical Devices: Providers should comply with ISO 13485, which specifies the requirements for a quality management system that demonstrates the ability to provide medical devices that consistently meet customer and regulatory requirements.

Automotive: IATF 16949 certification is crucial for PCB assembly solutions in the automotive sector, ensuring adherence to the specific needs of the automotive industry.

Certification and compliance indicate that the provider has established processes to meet the high standards required for reliable and safe PCB assemblies.

2. Material Quality

The reliability of a PCB assembly is heavily influenced by the materials used. In high-reliability applications, the choice of materials must be meticulously considered. Key factors include:

Substrate Material: High-temperature laminates like FR4, polyimide, or ceramic substrates are often required to withstand extreme environments and ensure thermal stability.

Solder Materials: The selection of solder is crucial for reliability, especially in environments subject to thermal cycling and vibration. Lead-free solders, while environmentally friendly, need to be carefully chosen to avoid issues like tin whiskers. High-reliability applications often require advanced alloys that provide better resistance to thermal fatigue.

Component Quality: Using high-quality components from reputable suppliers is essential. Counterfeit or substandard components can lead to catastrophic failures, particularly in critical applications.

3. Advanced Testing and Inspection

For PCB assemblies in high-reliability applications, thorough testing and inspection are not just recommended��they are essential. The assembly process should include multiple stages of testing to ensure that the final product meets the required standards.

In-Circuit Testing (ICT): ICT checks for manufacturing defects like shorts, opens, and incorrect component placements. It’s a critical step in identifying issues before the PCB assembly reaches the functional testing stage.

X-Ray Inspection: This non-destructive testing method is particularly useful for inspecting solder joints and connections in complex or high-density PCB assemblies, where visual inspection is not feasible.

Functional Testing: This involves testing the PCB assembly under operational conditions to ensure that it functions as intended in its final application. For high-reliability sectors, functional testing may be conducted in harsh environments to simulate real-world conditions.

4. Process Control and Traceability

High-reliability applications demand a high level of process control and traceability throughout the PCB assembly process. This includes:

Process Monitoring: The use of real-time monitoring tools to track every step of the assembly process ensures consistency and quality. Process control systems should be in place to detect and correct deviations immediately.

Traceability: Full traceability of materials, components, and assembly processes is essential. This allows for quick identification and correction of any issues that arise, and it is particularly important in sectors like aerospace and medical devices where any failure could have serious consequences.

5. Experience and Expertise

Finally, the experience and expertise of the PCB assembly provider cannot be overlooked. High-reliability applications require more than just technical capability—they demand deep industry knowledge and experience in handling complex, mission-critical projects. Look for a provider with a proven track record in your specific industry, as well as a team of engineers and technicians who understand the unique challenges associated with high-reliability PCB assemblies.

Conclusion

Selecting the right PCB assembly solution for high-reliability applications is a crucial step in ensuring the safety, performance, and longevity of your electronic systems. By focusing on factors such as certification and compliance, material quality, advanced testing, process control, and the provider’s experience, you can mitigate risks and achieve the level of reliability required for critical applications. In sectors where failure is not an option, choosing a PCB assembly provider that meets these stringent criteria is an investment in the success and safety of your products.

0 notes

Text

Understanding Rigid-Flex PCBs: The Future of Electronics

In the ever-evolving world of electronics, the quest for more efficient, compact, and reliable devices has led to significant advancements in printed circuit board (PCB) technology. Among these innovations, rigid-flex PCBs have emerged as a game-changer, combining the best features of rigid and flexible circuit boards. In this blog, we delve into the intricacies of rigid-flex PCBs, exploring their construction, advantages, applications, and future prospects.

What Are Rigid-Flex PCBs?

Rigid-flex PCBs are a hybrid solution that integrates both rigid and flexible circuit board technologies. A rigid-flex PCB consists of multiple layers of flexible circuit substrates attached to one or more rigid boards. The flexible layers allow for dynamic bending and folding, while the rigid sections provide structural support and facilitate component mounting.

This combination offers a unique set of properties that neither rigid nor flexible PCBs can achieve alone. The design typically involves a combination of flexible layers laminated together with rigid layers, allowing for a three-dimensional configuration that can fit into complex and constrained spaces.

Construction of Rigid-Flex PCBs

The construction process of rigid-flex PCBs is more complex than that of traditional PCBs. It involves several key steps:

Design and Layout: The design phase requires careful planning to ensure that the flexible and rigid sections are correctly positioned. Advanced CAD tools are used to create the layout, ensuring optimal performance and reliability.

Material Selection: The choice of materials is crucial for the performance of rigid-flex PCBs. Polyimide is commonly used for the flexible layers due to its excellent thermal stability and flexibility. The rigid sections are typically made from FR4 or similar materials.

Lamination: The flexible and rigid layers are laminated together using heat and pressure. This step requires precision to ensure that the layers bond correctly without causing damage.

Drilling and Plating: Holes are drilled through the PCB for vias, which are then plated to create electrical connections between the layers.

Assembly: Components are mounted on the rigid sections of the PCB. The flexible sections allow the board to be folded or bent into the desired shape.

Advantages of Rigid-Flex PCBs

The unique construction of rigid-flex PCBs offers several advantages:

Space and Weight Savings: Rigid-flex PCBs can be designed to fit into tight spaces and reduce the overall weight of the device. This is particularly beneficial in applications such as aerospace, medical devices, and wearable technology.

Improved Reliability: The integration of rigid and flexible sections reduces the number of interconnects and connectors, which are common points of failure in traditional PCBs. This enhances the overall reliability of the device.

Enhanced Durability: The flexible sections can withstand dynamic bending and flexing, making rigid-flex PCBs ideal for applications with moving parts or where the board needs to be folded during assembly.

Design Flexibility: Rigid-flex PCBs offer greater design flexibility, allowing for innovative and complex configurations that would be challenging to achieve with standard rigid or flexible PCBs alone.

Applications of Rigid-Flex PCBs

Rigid-flex PCBs are used in a wide range of applications, including:

Consumer Electronics: Smartphones, tablets, and wearable devices benefit from the compact and lightweight nature of rigid-flex PCBs.

Medical Devices: Medical implants, diagnostic equipment, and portable devices utilize rigid-flex PCBs for their reliability and space-saving properties.

Aerospace and Defense: The demanding environments in aerospace and defense applications require the robustness and durability of rigid-flex PCBs.

Automotive Industry: Modern vehicles rely on rigid-flex PCBs for various electronic systems, including infotainment, safety, and navigation systems.

Future Prospects

The future of rigid-flex PCBs looks promising, driven by the growing demand for miniaturization, increased functionality, and improved reliability in electronic devices. Advances in materials and manufacturing processes will continue to enhance the performance and versatility of rigid-flex PCBs, opening up new possibilities for innovation.

In conclusion, rigid-flex PCBs represent a significant advancement in PCB technology, offering a unique combination of flexibility, durability, and reliability. As electronic devices become more compact and complex, rigid-flex PCBs will play an increasingly important role in meeting the demands of modern technology. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Advantages of FR4 PCB Table Fabric in Great-Speed Digital Designs

The frequency of higher-speed electronic styles in contemporary electronic digital products demands substrates that may accommodate quick transmission transitions, minimize indicate distortion, and sustain signal reliability. FR4 PCB board material, using its excellent power qualities and mechanical dependability, provides several advantages in promoting the functionality and longevity of high-velocity computerized circuits. Here, we explore the advantages of FR4 PCB board materials in substantial-pace computerized models, highlighting its position in enabling powerful and consistent functioning in digital electronic digital solutions.

One of the major features of FR4 PCB board material in great-velocity electronic digital patterns is its constant and reputable power qualities, which contribute to preserving indicate sincerity and decreasing signal distortion. The reduced dissipation aspect, steady dielectric continual, and high electric powered efficiency of FR4 enable it to support rapid indicate propagation, decrease crosstalk, and protect transmission good quality in substantial-pace computerized circuits. These electric powered attributes are basic for reaching minimal indicate damage and reduced jitter, important for trustworthy and exact computerized sign transmitting.

The mechanised robustness and dimensional stability of fr4 pcb board are key advantages that increase the trustworthiness and gratifaction of substantial-velocity computerized designs. The material's high flexural strength, effectiveness against warping and delamination, and very low dampness absorption give rise to the technical reliability of electronic circuits, decreasing the risk of technical problems or sign irregularities because of table deformation or ecological elements. The dimensional stability of FR4 substrates assures regular electric overall performance and impedance management throughout the board, helping reputable higher-speed indicate transmitting.

An additional benefit of FR4 PCB table material in high-pace digital styles is its compatibility with common manufacturing operations and set up methods, facilitating efficient generation and developing produce. FR4 substrates may be readily packaged using business-standard PCB production approaches, for example etching, plating, soldering, and assembly, making them handy for suppliers to do business with and combine inside their generation workflows. This compatibility contributes to productive and cost-successful creation of high-velocity electronic digital circuits, minimizing production problems and maximizing all round product trustworthiness.

The flames-retardant qualities of FR4 PCB fabric are useful for high-pace electronic models, particularly in apps exactly where security and regulatory concurrence are essential. The material's potential to deal with flammability, reduced light up emission, and self-extinguishing features contribute to the safety and reliability of electronic items, especially in sectors for example aerospace, transportation, and commercial manage systems, in which fireplace safety factors are a vital consideration.

In conclusion, the advantages of FR4 PCB table substance in higher-pace electronic digital designs stem from its constant electrical attributes, mechanized trustworthiness, developing compatibility, and flame-retardant attributes. By leveraging the built in attributes of FR4 substrates, designers and designers can produce higher-speed electronic digital circuits that show strong and trustworthy performance, adding to the continuing development of digital digital solutions across various market industries.

related articles:

Refining Excellent-Regularity PCB Design with FR4 Substrates

Being familiar with FR4 PCB Board Material: Components and Software

Perfecting Higher-Volume PCB Design with FR4 Substrates: Factors and finest Techniques

0 notes

Text

When designing your flex circuit board with reinforcement,there are several items to keep in mind. What reinforcement material is used and what is the thickness?Stiffener material and thickness:

Standard FR4=0.008"-0.08";Standard Polyimide=0.001"-0.008";Standard SUS=0.004"-0.024"

#pcb#flex pcb#rigid-flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#fpcway#fpcway.com#www.fpcway.com#today on tumblr

0 notes

Text

Exploring the Robust World of Glass Epoxy Components at Hason Industries

At Hason Industries, we pride ourselves on delivering top-tier Glass Epoxy Components designed for both electrical and mechanical applications. Known for their exceptional electrical insulation and mechanical strength, our Glass Epoxy Slot Wedges and Spacers are integral to the functionality of a variety of devices, from aerospace components to household electronics.

Why Choose Glass Epoxy?

Glass epoxy is celebrated for its outstanding electrical insulation properties, making it ideal for circuit boards and other electrical infrastructures. Not only does it provide strong insulation, but it also boasts high thermal stability and chemical resistance, ensuring performance in diverse environments.

Mechanical and Structural Integrity

Our components are engineered to endure. Whether it's in the high-demand sectors of aerospace or vehicle manufacturing, our products resist wear and tear under stress and maintain their integrity in high-temperature and chemically intensive conditions.

Sustainability and Cost-Effectiveness

In addition to their durability, glass epoxy components from Hason Industries offer an economically advantageous solution. They are light, easy to install, and require minimal maintenance, making them a cost-effective choice for many industrial applications.

Custom Solutions for Critical Applications

At Hason Industries, we understand that each project has unique requirements. That's why we offer custom-made solutions tailored to meet the specific needs of your critical applications. From G11 Glass Epoxy Components to FR4 Glass Epoxy Slot Wedges, our extensive range ensures you have the exact specifications needed for your project.

Here's a set of FAQs based on the information about Glass Epoxy Components from Hason Industries:

What are glass epoxy components used for?

Glass epoxy components are primarily used in electrical systems for their excellent insulation properties. They are ideal for circuit boards and protective gear in electrical and mechanical applications due to their high thermal stability and chemical resistance.

What are the advantages of using glass epoxy components?

Glass epoxy components offer high mechanical strength, superior electrical insulation, thermal stability, and chemical resistance, making them suitable for harsh environments. They are also cost-effective due to their durability and low maintenance needs.

Can Hason Industries customize glass epoxy components?

Yes, Hason Industries specializes in providing custom-made glass epoxy components to meet specific project requirements. Whether it’s for aerospace, automotive, or consumer electronics, they can tailor products to suit precise specifications.

What types of glass epoxy components does Hason Industries offer?

Hason Industries offers a variety of glass epoxy components, including G11 and FR4 Glass Epoxy Slot Wedges and Spacers. Each type is designed to meet different levels of thermal and electrical insulation needs.

How do I order glass epoxy components from Hason Industries?

You can order directly through their website or contact their sales team for more information on specifications and pricing. Custom orders can also be discussed with their engineers to ensure that the components meet your exact needs.

Conclusion:

In conclusion, Hason Industries' Glass Epoxy Components not only elevate the standard for electrical insulation and mechanical strength but also offer the versatility and reliability needed in critical industrial applications. From aerospace to everyday electronics, these components ensure safety, efficiency, and performance. By choosing Hason Industries, you gain access to innovative products tailored to your specific requirements, backed by expert engineering and exceptional customer service. Explore our range today and discover the ideal solution for your project needs. Visit our website to get started and to find out more about how our products can be integrated into your next project.

0 notes

Text

Einführung in Keramikleiterplatten

Keramikleiterplatten sind eine spezielle Art von Leiterplatten (PCBs), die aus keramischen Materialien wie Aluminiumoxid (Al2O3), Aluminiumoxid (AlN) oder Siliziumkarbid (SiC) hergestellt werden. Diese Materialien bieten eine hervorragende Wärmeleitfähigkeit, hohe elektrische Isolation und ausgezeichnete mechanische Festigkeit, was sie ideal für Anwendungen in extremen Umgebungen macht.

Vorteile von Keramikleiterplatten

Hervorragende Wärmeleitfähigkeit: Keramikmaterialien leiten Wärme viel effektiver ab als herkömmliche FR4-Leiterplatten, was sie ideal für Hochleistungsanwendungen macht.

Hohe elektrische Isolation: Die isolierenden Eigenschaften von Keramik verhindern Kurzschlüsse und verbessern die elektrische Leistung.

Mechanische Festigkeit: Keramikleiterplatten sind widerstandsfähiger gegen mechanische Beanspruchungen, was ihre Zuverlässigkeit und Lebensdauer erhöht.

Stabilität bei hohen Temperaturen: Diese Leiterplatten behalten ihre strukturelle Integrität und Leistungsfähigkeit auch bei extremen Temperaturen bei, was sie ideal für Anwendungen in der Luft- und Raumfahrt, Automobilindustrie und industriellen Hochleistungsanlagen macht.

Anwendungen von Keramikleiterplatten

Keramikleiterplatten finden in einer Vielzahl von Anwendungen Verwendung, darunter:

Leistungselektronik: Aufgrund ihrer hohen Wärmeleitfähigkeit und elektrischen Isolation sind sie perfekt für Leistungselektronik geeignet.

LED-Technologie: In LED-Anwendungen helfen sie, die Wärme effektiv abzuleiten und die Lebensdauer der LEDs zu verlängern.

Medizintechnik: Ihre Zuverlässigkeit und Beständigkeit gegen chemische Einflüsse machen sie ideal für medizinische Geräte.

Automobilindustrie: Sie werden in Sensoren, Steuergeräten und anderen Hochleistungsanwendungen eingesetzt.

Hitech Circuits ist Ihr zuverlässiger Partner für hochwertige Keramikleiterplatten. Wir bieten umfassende Dienstleistungen von der Herstellung bis zur Bestückung an, um Ihre spezifischen Anforderungen zu erfüllen. Unsere Expertise und fortschrittlichen Fertigungstechnologien gewährleisten Produkte von höchster Qualität.

Unsere Dienstleistungen umfassen:

Keramikleiterplattenfertigung: Hochleistungsfähige Keramik-PCBs für verschiedenste Anwendungen.

Komponentenbeschaffung und PCB-Bestückung: Ein umfassender Service, der Ihnen Zeit und Ressourcen spart.

Qualitätskontrolle und Tests: Strenge Prüfverfahren, um sicherzustellen, dass jede Leiterplatte Ihren hohen Standards entspricht.

Besuchen Sie unsere Website Hitech Circuits für weitere Informationen und kontaktieren Sie uns, um Ihre speziellen Bedürfnisse zu besprechen. Vertrauen Sie Hitech Circuits für erstklassige PCB-Lösungen, die Ihre Erwartungen übertreffen.

0 notes

Text

Aluminium PCB

1. What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Aluminum LED PCB with White Solder Mask

The retail price of Aluminum LED lights has dropped dramatically in recent years, while the energy efficiency and brightness of LED lights have improved. These technological advances have led some to predict annual growth of 45% over the next five years. With the development of the LED industry, the demand for LED PCBS and solder masks is also increasing. Solder shield is a protective coating applied to exposed printed circuit boards. The exposed PCB board is covered with a mask to prevent accidental solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green, and are expected to withstand the high temperatures that occur in reflow soldering, as different colors such as blue, red, or black will occasionally appear. Increased production of Hitch Aluminum LED PCB requires increased whiteness and color stability of the mask. Aluminum LED PCB commonly used LPI welding color is white and black, of which white welding color is the most commonly used to achieve high brightness and perfect light reflection. White Aluminum LED PCB ensures no darkening and will not affect the color temperature of LED smd. At the same time, it also helps to increase the life of LED applications. Looking for reliable Aluminum LED PCB suppliers, Hitech is a good choice.

6. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

7. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

8. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

9. Technical requirements for Aluminum LED PCB

The main technical requirements are:

1. Dimensional requirements: including panel size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delimitation, aluminum oxide film, etc.

2. Performance requirements, including peel strength, surface resistively, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

10. Special test method for Aluminum-based copper clad plates

One is the measurement method of dielectric constant and dielectric loss factor. It is the series resonance method with variable Q value. The sample and tuned capacitor are connected to the high-frequency circuit in series to measure the Q value of the series circuit.

The other is the measurement method of thermal resistance, which is calculated by the ratio of temperature difference and heat conduction between different temperature measurement points.

11. The Aluminum LED PCB manufacturing process in Hitechpcba

(1)Substrate cutting

a. cutting process: material → cutting

b. Note: ① Check the size of the first piece; ② Pay attention to Aluminum surface scratching and copper surface scratching; ③ Pay attention to the layering of the board edge and the tip.

(2)Plate drilling

a, drilling process: pin → drilling → inspection plate

b, matters needing attention: ① check the number of drilling holes, the size of the empty chestnut chain; ② Check the plate burr, hole deviation; ③ Avoid scratching the substrate; ④ Check and replace the drill nozzle.

(3) Imaging transfer

a, graphic imaging process: grinding plate → film → exposure → development

b, precautions: ① Check whether there is an open circuit after development; ② Pay attention to the poor line caused by the board wipe; ③ There can be no air residual exposure to prevent poor exposure; ④ Whether there is deviation in developing counterpoint; ⑤ After exposure, the development should be done at rest for more than 15 minutes.

(4)Solder mask and Silkscreen process

a, kill row silk printing resistance welding, character process: screen printing → pre-baking → exposure → development → character

b, matters needing attention: ① Check whether there is foreign body on the board; ② Pay attention to the cleaning of the net board; ③ Pre-bake for more than 30 minutes after screen printing, to avoid bubbles in the line; ④ Pay attention to the thickness and uniformity of screen printing; ⑤ After the pre-baked plate to completely mutual cooling, avoid touching film or damage to the ink surface gloss.

(5)E-test or flying probe test

a, test process: line test → withstand voltage test

b, precautions: ① How to distinguish after the test how to store qualified and unqualified products.

(6)FQC, FQA, packaging, shipping

a. Process: FQC→FQA→ Packaging → shipping

b. Note: ① FQC should pay attention to the confirmation of the appearance of the finished Aluminum LED PCB in the process of eye inspection and make a reasonable distinction; ② FQA does spot check and verify the inspection standards of FQC; ③ We should confirm the number of packages to avoid mixed plates, wrong plates and package

12. Application of Aluminum LED PCB

1. Audio devices: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier.

2. Power Supply: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

3. Communication electronic equipment: high frequency amplifier, filter, transmitter circuit

4. Office automation equipment: motor drive, etc

5. Automobile: electronic regulator, ignition device, power controller, etc.

6. Computer :CPU board, floppy disk drive, power equipment, etc.

7. Power module: converter, solid relay, rectifier bridge, etc

8. Lamps and lighting: A variety of colorful LED energy-saving lamps are well received by the market, and Aluminum LED PCB used in LED lights has also begun to be applied on a large scale.

13. Aluminum LED PCB Storage Conditions

Aluminum LED PCB are generally stored in a dark and dry environment. Most Aluminum LED tube lighting metal core pcb are prone to dampness, yellowing, and blackening. Generally, they should be used within 48 hours after opening the vacuum package.

14. Specification for the manufacture of Aluminum LED PCB

a. Aluminum LED PCB is often used in power devices, power density is high, so the copper foil is thicker. If copper foils over 3oz are used, the etching of thick copper foils requires engineered line width compensation, otherwise the line width will be out of tolerance after etching.

b. The aluminum base surface of aluminum substrate must be protected by protective film in advance during PCB processing, otherwise, some chemicals will etch the aluminum base surface, resulting in appearance damage. And the protective film is easy to be hurt, resulting in gaps, which requires the whole PCB processing process must be inserted.

c. The hardness of the milling cutter used by the glass fiber board gong board is relatively small, and the hardness of the milling cutter used by the aluminum substrate is large. In the process of manufacturing glass fiber board milling cutter speed, while the production of aluminum substrate is at least two thirds slower.

d, computer milling glass fiber board is just the use of the machine's own cooling system, but the processing of aluminum substrate must be in addition to alcohol heat dissipation for the gong head.

15. Aluminum LED PCB circuit fabrication

(1) Mechanical processing: Drilling of aluminum substrate can be done, but no burr is allowed on the edge of the inner hole after drilling, which will affect the pressure test. Milling the shape is very difficult. And punching shape, need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After shape punching, the edge should be very neat, without any burr, and do not hurt the welding resistance layer on the edge of the plate. Usually the use of soldier die, hole from the line, shape from the aluminum surface, circuit board punching force is cut down, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

(2) The whole production process is not allowed to wipe the aluminum base surface: aluminum base touch, or by a certain chemical will produce surface discoloration, blackening, which is absolutely unacceptable, re-polishing aluminum base some customers do not receive, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base plate. Some enterprises use passivation process, some in hot air leveling (spray tin) before and after each pasted protective film.

(3) Over-high voltage test: the aluminum base board of the communication power supply shall be tested at 100% high voltage. Some customers require direct current or alternating current. The voltage shall be 1500V or 1600V, and the time shall be 5 seconds or 10 seconds. Dirt on the board, holes and aluminum edge burr, line saw tooth, damage to any little insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board stratification, foaming, are rejected.

1 note

·

View note

Text

Double-Sided PCB Manufacturing in India - Shree Ram Electronics

Double-sided PCB manufacturing in India demands precision and expertise, and Shree Ram Electronics excels in fulfilling this need. As a specialized producer of high-quality circuit boards, we cater to diverse requirements, including single and double-sided PCBs, multi-layer boards, blind hole buried FR4, aluminum base boards, soft boards, and hard and soft combination plates. With a focus on high technology content and stringent quality standards, we stand as a trusted name for both domestic and international clients seeking top-tier PCB solutions.

0 notes

Text

8 MAIN FACTORS AFFECTING PCB FABRICATION COST

Several factors can influence the cost of PCB fabrication. By identifying the stages in production and processing where costs may increase allows you to make reasonable, cost-effective decisions that ensure the quality of your products while minimizing costs.

Board Material Choice

The materials used in a circuit board will invariably affect its cost. Standard PCBs are laminated with FR4 material, but this will not suffice for boards manufactured for high-intensity uses, such as those common in the aerospace and fuel industries. As a rule of thumb, operations that involve higher frequencies require materials of a higher grade than standard FR4. As such, the materials used in a microwave PCB could be 10 times more costly than the materials used for the board in a calculator or other handheld device.

PCB Size

The size and shape of your PCB can impact its costs as they increase. Expanding the PCB’s size will require more materials and time to manufacture the final product, leading to rising costs. PCB price will increase in proportion to the board’s surface area, which you can use to calculate how much extra your product will cost as you expand beyond the standard sizing.

Layer Count

Like the size and material usage, you can expect the price to rise as you add more layers to your PCB. Costs increase for additional layers for many reasons. When you add more layers, you will need more materials for each layer, and it will take longer to produce with extra etching and bonding steps.

Effective Utilization of Materials

Effective utilization of materials correlates closely to size and spacing. When you choose a PCB with a smaller size, you will use fewer materials, making it a more cost-effective option. However, even if you elect to use a larger size, you can cut costs on materials by effectively using your available space to minimize waste and only use what you need. Finding an arrangement that optimizes your space and size can help ensure you are using only what you need.

Surface Finishes

Depending on the surface finish you choose for your PCB, costs can fluctuate. You can find standard and basic finishes, like OSP and HASL, which are more cost-effective and still offer decent solderability. However, some other finishes can lead to increases in price. LF HASL, Imm Ag, Imm SN and ENIG each vary in terms of price, with LF HASL being the most cost-effective and ENIG being the most expensive. Further, prices will change depending on how many layers you need for each material. Choosing a more cost-effective surface finish option can help you cut costs for your PCB fabrication.

Complexity

The further your PCB strays from standard and conventional board technology, the higher your costs. More complex configurations and designs will require more time to assemble with extra steps.

Copper Foil Weights

The weight of your copper foils relates closely to using materials effectively. Thicker copper is more expensive and comes with additional challenges and costs. You will likely need to use more prepreg in your processing steps to fill gaps between copper. Since thicker copper is heavier, you might also experience higher transportation costs.

Customer's quality acceptance criteria

Common acceptance standards for PCB include IPC2, IPC3, enterprise standards, military standards, etc. The higher the standard, the stricter the quality control will be. The level of customer requirements directly impacts the yield rates for PCB manufacturers. For instance, if an FPC is produced per IPC-A-6013 Class 1 standards requiring a 98% pass rate, the cost would be higher than for Class 3 with only a 90% pass rate.

Understanding all of these factors can help you further understand how cost affects price. Then, you can ultimately balance the cost and functionality of your PCB. Hitech can be your ideal PCB supplier, we are committed to providing cost-effective prices and good quality with fast delivery time. If you have any needs for PCB, please feel free to contact us. Any questions, please email [email protected]. For more PCB information, please visit https://hitechcircuits.com/

0 notes

Text

Innovative Applications: the New Role of FR4 Epoxy Fiberglass Boards in Smart Homes

With the continuous advancement of technology and the improvement of people’s living standards, smart homes are gradually becoming the new favorite of modern life. FR4 epoxy fiberglass board, as a substrate material widely used in the electronics industry, has also shown its unique new role in the smart home field in recent years. This article will discuss the innovative application of FR4 epoxy…

View On WordPress

0 notes