#Stainless Steel 316H Buttweld Fittings Suppliers in India

Explore tagged Tumblr posts

Text

Article on : Stainless Steel 316H Buttweld Fittings Manufacturers in India

Stainless Steel 316H Buttweld Fittings are designed to provide superior performance in high-temperature and high-pressure environments. The "H" in 316H stands for "high carbon," indicating a higher carbon content compared to 316 and 316L, which enhances its strength at elevated temperatures. This article explores the properties, applications, and benefits of Stainless Steel 316H Buttweld Fittings in industrial settings.

Characteristics and Properties

Stainless Steel 316H, known as UNS S31609, is an austenitic stainless steel that contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, with a higher carbon content (0.04-0.10%). Key properties of Stainless Steel 316H include:

High-Temperature Strength: The increased carbon content provides higher creep, stress-to-rupture, and tensile strength at elevated temperatures, making it suitable for high-temperature applications.

Corrosion Resistance: The alloy offers excellent resistance to pitting and crevice corrosion, especially in chloride environments, due to the presence of molybdenum.

Oxidation Resistance: Stainless Steel 316H exhibits good oxidation resistance in intermittent service up to 870°C (1600°F) and in continuous service up to 925°C (1700°F).

Weldability: Despite the higher carbon content, 316H maintains good weldability, ensuring robust and reliable joints.

Applications of Stainless Steel 316H Buttweld Fittings

Stainless Steel 316H Buttweld Fittings are used in a variety of high-temperature and high-stress environments across different industries:

Petrochemical and Refining Industries: These fittings are employed in reformers, catalytic crackers, and other high-temperature processing equipment, where their strength and resistance to oxidation and corrosion are essential.

Power Generation: The power industry utilizes 316H fittings in boilers, superheaters, and heat exchangers, where high-temperature strength and resistance to thermal fatigue are critical for maintaining operational efficiency.

Chemical Processing: In chemical plants, 316H fittings are used in high-temperature reactors, heat exchangers, and other processing equipment that handle corrosive substances.

Industrial Heating Equipment: Stainless Steel 316H Buttweld Fittings are ideal for use in furnaces, kilns, and incinerators due to their ability to maintain structural integrity at high temperatures.

Aerospace Industry: The aerospace sector employs these fittings in various high-temperature applications, including engine components and exhaust systems, where their strength and oxidation resistance are vital.

Benefits of Using Buttweld Fittings

Buttweld fittings, particularly those made from Stainless Steel 316H, offer numerous advantages:

Leak-Proof Connections: The seamless design ensures leak-proof connections, essential for maintaining system integrity under high pressure and temperature.

Structural Integrity: Welded joints enhance the strength and durability of the piping system, reducing the likelihood of leaks and failures.

Versatility: Available in various shapes and sizes, including elbows, tees, reducers, and caps, these fittings can be customized to fit different piping configurations.

Efficiency: The smooth interior surface of buttweld fittings minimizes pressure drops and flow restrictions, improving the efficiency of fluid and gas transport systems.

Conclusion

Stainless Steel 316H Buttweld Fittings are crucial components for industries requiring high-temperature strength and superior corrosion resistance. Their unique properties make them suitable for a wide range of demanding applications, from petrochemical processing and power generation to chemical processing and aerospace.

#Stainless Steel 316H Buttweld Fittings Manufacturers#Stainless Steel 316H Buttweld Fittings Suppliers#Stainless Steel 316H Buttweld Fittings Stockists#Stainless Steel 316H Buttweld Fittings Exporters#Stainless Steel 316H Buttweld Fittings Manufacturers in India#Stainless Steel 316H Buttweld Fittings Suppliers in India#Stainless Steel 316H Buttweld Fittings Stockists in India#Stainless Steel 316H Buttweld Fittings Exporters in India

0 notes

Text

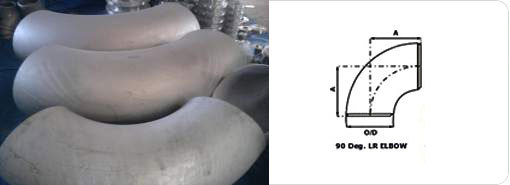

Elbow 90 Manufacturers

Elbow 90 Degree Buttweld Pipe Fittings, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers, Elbow 90 Degree Buttweld Pipe Fittings Suppliers, Elbow 90 Degree Buttweld Pipe Fittings Exporters, Elbow 90 Degree Buttweld Pipe Fittings Stockists.

Elbow 90 Degree Buttweld Pipe Fittings in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Exporters in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Stockists in Mumbai.

Elbow 90 Degree Buttweld Pipe Fittings in India, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in India, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in India, Elbow 90 Degree Buttweld Pipe Fittings Exporters in India, Elbow 90 Degree Buttweld Pipe Fittings Stockists in India.

90° ELBOW

We have earned presumed name in making of Elbow (90°) which is developed with the best of the materials accessible in the business sector. Stainless steel, composite steel and carbon steel and so forth are utilized for manufacturing this elbow. We give these funnel fittings at business sector driving ratesSPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type:

Seamless

ERW

Welded

Fabricated.

Material Type:

Stainless Steel

Alloy Steel

Carbon Steel

Nickel Alloys

Duplex

Grades :

Nickel Alloy: ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel: ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel : ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Alloy Steel : ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Carbon Steel: ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

0 notes

Text

C276 suppliers in India

C276 Round Suppliers in India

C276 Round Suppliers in India (by and large called Branch Connection Fittings or Outlet Fittings) which give an outlet from a more prominent funnel to a humbler one (or one of a near size).

C276 Round Suppliers in India are fanning fittings made by biggest producers of metal fittings like us. C276 Round Suppliers in India offer a substitute technique for interfacing into the essential run and don't require fortress or fortification. Krishna Steel & Alloys are pre-formed to the twist of the run pipe. Level based weldolets are open for interfacing with pipe tops and vessel heads.

The chief channel onto which the branch association is welded is generally called the Run or Header measure gauge. The funnel to which the branch alliance or affiliation gives a channel is known as the Branch or Outlet measure. Branch associations are in all sizes, sorts, types, bores, and classes, in an expansive arrangement of treated steel, chrome-molly, and particular amalgams mixes.

C276 Round Suppliers in India are for the most part used for stretching on high weight and high temperature applications. Most extreme acceptable weight of a fitting is same concerning associated straight steady or consistent run channel of proportionate material.

C276 Round Suppliers in India uses Materials and Grades (Weldolets, Threadolets, Sockolets)

1) Stainless Steel Olet Fittings - ASTM/ASME SA 182F GR. 304, 304L, 304H, 304N, 304LN, 316, 316L, 316H, 316N, 316LN, 309L, 310, 317, 317L, 321, 321H, 347, 347H AND UNS 31254 (254SMO)

2) Carbon Steel Olet Fittings - ASTM/ASME A105/A350 LF2, ASME SA105, A694 - F42, F46, F52, F60, F65, F70, A36, A516 GR. 70, 60

3) Alloy Steel Fittings - ASTM/ASME A182 GR. F1/F5/F9/F11/F22/F91

4) Duplex Steel Fittings - ASTM/ASME SA 182F GR. F44, F45, F51, F53, F55, F60, F61.WERKSTOFF NO. 1.4462

5) Nickel Alloy Steel FittFlangeings - ASTM/ASME SB 256 GR. NICKEL ALLOY 200, NICKEL ALLOY 20, MONEL ALLOY 400, INCONEL ALLOY 600, INCONEL ALLOY 625, INCOLOY ALLOY 800, INCOLOY ALLOY 800H, INCOLOY ALLOY 800HT, INCONEL ALLOY 825, ALLOY 20, HASTELLOY C-276, HASTELLOY C-4, HASTELLOY C-22, ALLOY 6XN

6) Low Temperature Pipe Fittings- A/SA 350 LF2, LF3

C276 Round Suppliers in India is Fittings are likewise accessible in other metal like titanium, aluminum, bronze, Lead, tantalum, zinc, metal and so on.

Application or Uses of Krishna steel & Alloys are are utilized in wide scope of businesses. Some of them are :

· Force Plants

· Water Pipelines

· Treatment facilities

· Nourishment and Beverages

· Pharmaceuticals

· Materials

· Railroads

· Petrochemicals

· Atomic Plants

· Sugar factories

Types of our Products:

1) Brazolet - Brazolet is utilized for the most part and for the most part to interface or partner the continued fittings. Brazolet is same like a weldolet, and is a marvelous fitting for metal channels, copper tubing and iron funnels pipes with metal.

2) Coupolet - Coupolet fittings are gotten ready for use in fire/fire assurance sprinkler structures and other low weight diverting applications.

3) Elbolet - Elbolet is utilized on 90° Long Radius Elbows (can be conveyed for Short Radius Elbows) for thermo well and instrumentation affiliations

4) Flexolet - Flexolets take after weldolets with a minor refinement for example flexolet has straight bore while weldolet has lessened bore.

5) Insert Weldolet - Insert Weldolet is the most extensively seen of all branch affiliations, and is welded onto the outlet pipe.

6) Latrolet - Latrolets are a variety of weldolets. You have to relate it in same manner, anyway these Latrolets make a 45-degree relationship with the standard channel as opposed to a 90 degree.

7) Nipolet - Nipolets is only a blend of olets with pipe areolas. These olets work like the weldolets or threadolets, yet are with areola.

8) Sockolet - Sockolets are in a general sense like weldolets and threadolets; close to the course that in Sockolets there is unique association fit welding.

9) Sweepolet - Sweepolet is a framed, essentially continued; butt-weld branch relationship with a low pressure elevating part for low loads and long consumption or depletion life.

10) Threadolet - Threadolets look like various olets; the essential contrast is that this olet is equipped with female strung affiliation.

11) Weldolet - Weldolets or welding olets or welding branch affiliation fittings are the most comprehended among all the olets. These are for the most used and organized as buttweld fittings, as these are welded into the branch pipe.

Assembling Standards

ASTM A182 - ASME SA182 - Standard Specification

ASME B16.11 - Forged Fittings Socket - Welding and Threaded

1 note

·

View note

Text

Barred Tee Stockists

Omaa Metal Sources, ought to recognize the open method to present as an essential Stainless Steel Barred Tee producer in India. ASME B16.9 Barred Tee are stacked or open in the going with degree of materials and sizes for the oil, gas, petrochemical and joined undertakings. Lines with Barred Tee can be accumulated and devastated with no issue. SS Barred Tee can be made or plate. Many Alloy Steel Buttweld Barred Tee maker in India produce these Carbon Steel Barred Tee from made materials and have machined surfaces. Consider our cost from Barred Tee makers in India or China you will discover best rate from our affiliation.

Barred Tee,Barred Tee Manufacturers, Barred Tee Exporters, Barred Tee Suppliers, Barred Tee Stockists,Barred Tee Buttweld Fittings Manufacturers, Barred Tee Buttweld Fittings Exporters, Barred Tee Buttweld Fitting Suppliers, Barred Tee Buttweld Fitting Stockists. ASME B16.9 Monel 400/K500 Buttweld Barred Tee, ANSI B16.9 Buttweld Barred Tee Pipe Fittings, Nickel 200/201 Buttweld Barred Tee, Inconel 600/601/625 Barred Tee. SS ASTM A403 316/316L/316H Barred Tee, ANSI B16.9 ASTM A403 SS 309/309S Buttweld Barred Tee, SS 321 Buttweld Barred Tee, Alloy Steel ASTM A234 WP1 Barred Tee, Alloy Steel A234 WP9 Barred Tee, Alloy Steel WP11 Barred Tee.

#Barred Tee Manufacturers#Barred Tee Exporters#Barred Tee Suppliers#Barred Tee Buttweld Fittings Exporters#Barred Tee Stockists

0 notes