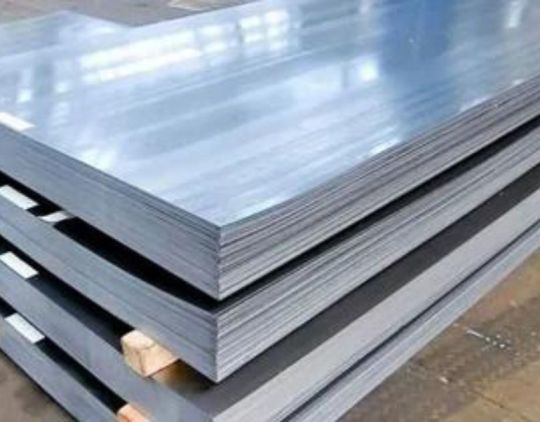

#Stainless Steel 304 Plates Suppliers in India

Text

Stainless Steel 304 Plates Exporters

Shree Venktesh Wires and Steels Pvt Ltd, is a Certified Company, stockholder, supplier, and exporter of Stainless Steel 304 plates. We provide stainless steel 304 plates in various sizes and dimensions. To meet our client's requirements in the right manner. We work together with Jindal Stainless Limited to manufacture Stainless Steel 304 plates as well as other Stainless Steel grades. Our experts can source many hard-to-find grades and or non-standard sizes to meet the special requirements of our customers. All stainless steel hot rolled 304 jindal ss plates can be cut to size with the help of our extensive expertise in processing steel plate products.

Characteristics of 304 Stainless Steel Plates

Corrosion resistance superior to other steels in various Steel

Excellent low-temperature performances

Good welding characteristics

Post-weld annealing is not normally required

Heat resistant performances

Hot workability such as punching or bending

The material used in this stainless steel does not harden during the heat treatment (non-magnetic, uses temperatures -196°C and 800°C)

Specification/Grades of 304 Stainless Steel Plates

Specifications: ASTM A240 / ASME SA240

Thickness: 4mm-100mmWidth 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sand blast, Brush, etching, etc

Finish: Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Form: Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered plates, strips, Flats, Blank (Circle), Ring (Flange) etc.

#Stainless Steel 304 Plates Manufacturers in India#Stainless Steel 304 Plates Suppliers in India#Stainless Steel 304 Plates Stockists in India#Stainless Steel 304 Plates Exporters in India

0 notes

Text

Hastelloy C276 Round Bars Supplier & Exporter | Reliable Overseas

Hastelloy C276 is a versatile and highly corrosion-resistant nickel-molybdenum-chromium alloy with the addition of tungsten, known for its exceptional performance in severe environments. This makes it a favored option across multiple industries. Reliable Overseas is a leading supplier and exporter of Hastelloy C276 round bars, providing top-quality materials to meet diverse industrial needs.

#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Hastelloy C276 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates#stainless steel 446 tubes manufacturers#Super Duplex Steel UNS S32760 Round Bars Manufacturer in Mumbai#Monel 400 Round Bars supplier#Monel 400 Round Bars exporter#Monel 400 Round Bars Manufacturer in India#Inconel 600 Round Bars Supplier#Inconel 600 Round Bars Exporter#Inconel 600 Round Bars Manufacturer

0 notes

Text

#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Hastelloy C276 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates#stainless steel 446 tubes manufacturers#Super Duplex Steel UNS S32760 Round Bars Manufacturer in Mumbai#Monel 400 Round Bars supplier#Monel 400 Round Bars exporter#Monel 400 Round Bars Manufacturer in India#Inconel 600 Round Bars Supplier#Inconel 600 Round Bars Exporter#Inconel 600 Round Bars Manufacturer

0 notes

Text

Supplier of Stainless Steel Sheets in West Bengal

Arisa Impex is a leading Supplier of Stainless Steel Sheets in West Bengal.

Arisa Impex Manufacturing Unit is in Ahmedabad, Gujarat, India.

We are a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel.

Stainless Steel Sheets are flat pieces of stainless steel that are produced by rolling stainless steel into thin, flat pieces.

They are known for their durability, corrosion resistance, and aesthetic appeal, making them suitable for a wide range of applications.

Why Choose Our Stainless Steel Sheets?

High Quality: We source our stainless steel sheets from reputable manufacturers, ensuring top-notch quality and performance.

Custom Sizes: We offer a range of thicknesses and dimensions, allowing for tailored solutions to meet your specific needs.

Expert Support: Our knowledgeable team is here to assist you with product selection, cutting, and fabrication advice.

Specification:

Stainless steel Sheet Grades: TP 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

Size: 1250mm X 2500mm, 1500mm X 3000mm to 6000mm, 4' X 8', 1000 mm X 2000mm, 1220mm X 2440mm, 2000mm X 4000mm to 6000mm, 1250mm X 5000mm

Length: 300 mm ~ 6000 mm

Specifications: ASTM A240 / ASME SA240

Testing: Tensile Test, Hardness Test, Magnetic Particle Test, Ultrasonic Test, Spectrometer Analysis Test.

Value Added Service: Customized Plate Cutting, Laser Cutting

Finish: Hot Rolled Plate (HR), Cold Rolled Sheet (CR), 2B, 2D, BA NO.8 (Mirror),

NO.4 (Satin/Met with Plastic Coated), PVD Coating (Gold/Rose Gold/Black).

Usage in

Construction and Architecture

Manufacturing and Industrial

Marine and Coastal Environments

Energy and Power

Arisa Impex is a leading Supplier of Stainless Steel Sheets in West Bengal including locations like Kolkata, Siliguri, Durgapur, Bardhaman, Malda, Baharampur, Habra, Kharagpur, Shantipur, Dankuni, Dhulian, Ranaghat, Haldia, Raiganj, Krishnanagar, Nabadwip, Medinipur, Jalpaiguri, Balurghat, Basirhat, Bankura, Chakdaha, Darjeeling, Alipurduar, Purulia, Jangipur, Bolpur, Bangaon.

Feel free to contact us for more information and inquiries.

View Product: Click Here

Read the full article

0 notes

Text

Nitronic 50 Sheets & Plates Manufacturers In India

Nitronic 50, also known as XM-19, is a highly versatile austenitic stainless steel that offers a combination of strength, corrosion resistance, and durability. This material is widely used across various industries, including marine, petrochemical, and food processing, due to its superior performance in challenging environments. For those seeking reliable and high-quality Nitronic 50 sheets and plates in India, Padmavati Steel & Engg.Co. stands out as a premier manufacturer and supplier.

About Padmavati Steel & Engg.Co.

Padmavati Steel & Engg.Co. has established itself as a leading name in the stainless steel industry in India. With years of experience and a commitment to excellence, the company has earned a reputation for delivering high-quality products that meet stringent international standards. Their expertise in manufacturing and supplying a wide range of stainless steel products, including Nitronic 50 sheets and plates, has made them a trusted partner for businesses across the globe.

Why Choose Nitronic 50?

Nitronic 50 offers a unique combination of properties that make it an ideal choice for demanding applications:

High Strength: Nitronic 50 provides nearly twice the yield strength of 304 and 316 stainless steels, making it suitable for applications requiring high strength and durability.

Corrosion Resistance: This material exhibits excellent resistance to both general and localized corrosion, even in harsh environments such as marine and chemical processing settings.

Wear and Galling Resistance: Nitronic 50 is known for its superior resistance to wear and galling, which extends the service life of components made from this alloy.

Cryogenic Properties: It retains its toughness and strength even at cryogenic temperatures, making it useful in low-temperature applications.

Nitronic 50 Sheet Plate Specifications

SpecificationsASTM A240 / ASME SA240

StandardASTM, ASME and APIThickness4.0mm – 100mm

SpecializePlate, Coil, Shim Sheet, Designer Sheet, B. Q. Profile.

FormCoils, Foils, Rolls, Plain Sheet, Shim Sheet, Designer Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange)

FinishHot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Conclusion

For industries requiring high-performance materials like Nitronic 50, Padmavati Steel & Engg.Co. is the go-to manufacturer in India. With their commitment to quality, innovation, and customer satisfaction, they continue to set the standard in the stainless steel industry. Whether you need sheets or plates for critical applications, you can trust Padmavati Steel & Engg.Co. to deliver products that exceed your expectations.

For More Information:

Visit: https://www.padmavatisteel.com/

Contact: +91-9930388308

Email-id: [email protected]

0 notes

Text

Unveiling the Excellence of Indian Pipe Manufacturers:

Pipe production has advanced dramatically over the years, with Indian firms leading the way. The varied selection of pipes produced in India meets a variety of industrial applications while maintaining quality and dependability. This article investigates the vast range of Indian pipe producers, focusing on essential items and their uses.

Seamless metallic pipe manufacturers in India

Seamless metal pipes are vital for sectors that demand strong and lengthy-lasting pipeline solutions. India’s seamless metal pipe producers are famous for developing high-quality pipes that shape global necessities. The absence of seams in these pipes increases their energy and strain resistance, making them top-notch for disturbing programs within the oil and gasoline, petrochemical, and strength-producing industries.

Stainless Steel Pipe: Versatile and Strong

Steel sheet channels are vital in businesses that require erosion and electricity. The Indian manufacturer offers a wide range of steel plates, steel 304, and steel pipe 316. This form of pipe is generally used within the meals, pharmaceutical, and pharmaceutical industries due to its potential to resist harsh situations and excessive temperatures Furthermore, SS 317L pipe is known to withstand chemical assault, making it perfect for regions with heavy particles.

Carbon steel pipes are used due to the fact they’re both long-lasting and value-effective. Carbon steel pipe producers in India make excellent pipes, together with API 5L Grade B Pipe and ASTM A53 Grade B, to fulfill traumatic industry standards. Because of their exceptional tensile strength and dependability, these pipes are used in infrastructure tasks, water transportation, and construction.

Alloy metal pipe manufacturers offer excessive-performance solutions.

Alloy metal pipes, with their superior mechanical qualities, are crucial for excessive-pressure environments. Indian alloy metallic pipe manufacturers create pipes including ASTM A335 P11 and ASTM A335 P22, which can be mentioned for their potential to resist harsh situations. These pipes are extensively utilized in strength vegetation, refineries, and petrochemical sectors that require wonderful temperature and pressure resistance.

Specialized products include heat exchanger tubes and duplex pipes.

Heat exchanger tubes are important for powerful warmness transmission in quite a few sectors. Indian producers provide chrome steel heat exchanger tubes with excessive thermal conductivity and corrosion resistance. Furthermore, Duplex Pipe Suppliers in India provide excessive-electricity duplex and notable duplex pipes. These pipes are extremely protective against strain corrosion cracking and are widely used inside the oil and gasoline region due to their lengthy-time period overall performance and value effectiveness.

Advanced grades include A106 Grade B, API 5L X52, and API 5L X65 PSL2.

The A106 Grade B Pipe is wanted for high-stress programs including boilers and warmth exchangers. Indian producers guarantee that these pipes meet high-quality requirements, making them suitable for essential applications. Similarly, API 5L X52 Pipe and API 5L X65 PSL2 are endorsed due to their power and appropriateness for excessive-strain settings inclusive of the herbal gasoline and petroleum sectors. These pipes are intended to endure extreme environments, ensuring operating safety and efficiency.

ASTM Standards and Specialised Piping Solutions.

Pipes that meet ASTM necessities, which include ASTM A333 Grade 6, are crucial for programs that want durability at low temperatures. Indian manufacturers specialize in generating low-temperature carbon steel pipes, which are vital for sectors working at sub-0 temperatures. The varied preference of chrome steel pipes to be had from Indian producers, along with Stainless Steel 304 Pipe and Stainless Steel 316 Pipe, demonstrates their adaptability and electricity.

The Indian pipe manufacturing commercial enterprise is prominent because of its creativity, best, and adherence to global requirements. From consistent and carbon steel channels to cutting-edge amalgam and duplex arrangements, Indian makers meet a wide run of mechanical necessities. Their dedication to perfection guarantees that businesses worldwide rely on Indian pipes for vital applications. As the sector advances, Indian pipe makers’ contributions remain critical to the global supply chain, cementing their position as industry leaders.

0 notes

Text

Stainless Steel Sheets in Madhya Pradesh

Company Overview:

Meghmani Metal Industries is a Manufaturer and Supplier of Stainless Steel Sheets in Madhya Pradesh, India.

SS sheets are flat, thin pieces of stainless steel that come in various grades and finishes.

These sheets are known for their high tensile strength, resistance to corrosion and staining, and ability to withstand extreme temperatures.

Common grades include 304, 316, and 430, each offering unique properties tailored to specific applications.

Technical Specifications:

Material: High-grade stainless steel (grades such as SS 304, SS 316, etc.)

Thickness: Available in a wide range of thicknesses, from thin sheets to heavy plates

Finish: Various finishes including polished, brushed, and matte

Sizes: Customizable dimensions to fit specific project requirements

Standards: Conforms to international standards and specifications for quality and performance

Benefits:

Durability: Engineered to last, providing reliable performance over time.

Corrosion Resistance: Maintains integrity and appearance even in challenging environments.

Aesthetic Versatility: The polished and smooth finish enhances the visual quality of your projects.

Customization: Flexible options to meet specific project needs and preferences.

Meghmani Metal Industries is Stainless Steel Sheets in Madhya Pradesh, India Including Agar, Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Indore, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Ujjain, Umaria, Vidisha, West Nimar.

Please feel free to contact us with any questions or for information.

View Product: Click Here

Read the full article

0 notes

Text

Stainless Steel Flanges: Essential Components for Modern Industry

Riddhi Siddhi Metal Impex is a renowned stainless steel flanges manufacturer in India. The SS flanges have been rigorously designed in accordance with national and international industrial standards, utilising high-quality raw materials and cutting edge technology. Our high-quality stainless steel flanges and other goods are thoroughly tested before being packaged. A stainless steel flanges supplier in India provides stainless steel flanges in various sizes and forms to satisfy our customers' needs. These flanges are vital interior components that support mechanical parts or systems. They can also be used as blind flanges, which operate as plates to cover or seal the end of pipes.

What Are Stainless Steel Flanges?

Stainless steel flanges are components used to connect pipes, valves, pumps, and other equipment in a piping system. They come in various shapes and sizes, each designed to meet specific needs and requirements. The basic function of a flange is to provide a secure, leak-proof connection between two elements, allowing for easy assembly, disassembly, and maintenance.

Types of Stainless Steel Flanges

There are several types of stainless steel flanges, each serving a unique purpose:

Weld Neck Flanges: Known for their strength, these flanges are welded to the pipe, providing a secure and durable connection.

Slip-On Flanges: Easier to install, these flanges slip over the pipe and are then welded in place.

Blind Flanges: Used to close off the end of a piping system, preventing flow.

Threaded Flanges: Feature threads that allow them to be screwed onto the pipe without welding.

Socket Weld Flanges: Ideal for small-diameter, high-pressure pipes, these flanges are welded on the outside.

Benefits of Using Stainless Steel Flanges

Durability

Stainless steel flanges are incredibly durable. They can withstand high pressures and extreme temperatures, making them suitable for various demanding applications.

Corrosion Resistance

One of the most significant advantages of stainless steel is its resistance to corrosion. This makes stainless steel flanges ideal for use in environments where they are exposed to moisture, chemicals, and other corrosive elements.

Strength and Versatility

Stainless steel flanges offer excellent strength, ensuring a long lifespan and reliable performance. They are also versatile, available in various grades and styles to suit different applications.

We are Stainless Steel Flanges Supplier In:

SS Flange Supplier in Mumbai

SS Flange Supplier in Chennai

SS Flange Supplier in Ahmedabad

SS Flange Supplier in Coimbatore

SS Flange Supplier in Firozabad

Applications of Stainless Steel Flanges

In Industrial Piping Systems

Stainless steel flanges are widely used in industrial piping systems due to their strength and reliability. They ensure secure connections and easy maintenance.

In Water Treatment Plants

The corrosion resistance of stainless steel flanges makes them ideal for use in water treatment plants, where they are exposed to moisture and chemicals.

In Oil and Gas Industries

In the oil and gas industry, stainless steel flanges are essential for handling high-pressure and high-temperature applications.

In Chemical Processing Plants

Chemical processing plants require materials that can withstand corrosive environments. Stainless steel flanges are perfect for these conditions, ensuring safety and durability.

Material Grades and Standards

Stainless steel flanges are available in various grades, each with specific properties suited to different applications. Common grades include 304, 316, and 321 stainless steel. These materials meet international standards and certifications, ensuring quality and reliability.

Installation and Maintenance

Installation Tips

Proper installation of stainless steel flanges is crucial for ensuring their performance and longevity. It involves aligning the flanges correctly, using appropriate gaskets, and tightening the bolts to the recommended torque.

Maintenance Best Practices

Regular maintenance is essential to keep stainless steel flanges in good condition. This includes periodic inspections, cleaning to remove any buildup, and checking for signs of wear or damage.

Environmental Impact

Recyclability of Stainless Steel

Stainless steel is highly recyclable, making stainless steel flanges an environmentally friendly choice. They can be recycled without losing their properties, reducing the need for new raw materials.

Sustainability in Industrial Use

Using stainless steel flanges contributes to sustainability in industrial applications by reducing waste and promoting the use of recyclable materials.

Common Challenges and Solutions

Addressing Installation Issues

Proper training and adherence to installation guidelines can prevent common issues such as misalignment and improper sealing.

Dealing with Corrosion

While stainless steel is resistant to corrosion, it is not immune. Regular maintenance and selecting the appropriate grade for the environment can mitigate corrosion issues.

Stainless Steel Flanges Manufacturer in India

Stainless steel flanges are machined from solid forgings. We have become India's premier stockholder, manufacturer, supplier, importer, and exporter due to its performance and dependability. Our SS Flanges Manufacturer are renowned and well-known over the world for their dependability and quality. We regard our customers like partners by offering them our products and services. We are also recognized as one of the largest Pipe Fittings Manufacturers in India.

#stainless steel flanges manufacturer in India#SS Flanges Manufacturer#stainless steel flanges supplier in India

0 notes

Text

#Stainless Steel 446 Sheets and Plates#Stainless Steel 446 Sheets and Plates Suppliers#Stainless Steel 446 Sheets and Plates Exporters#Stainless Steel 446 Tubes#Stainless Steel 446 Tubes Manufacturers#Stainless Steel 446 Tubes Suppliers#Stainless Steel 446 Round Bars#Stainless Steel 446 Round Bars Suppliers#Stainless Steel 446 Round Bars Exporter#Stainless Steel Round Bars Suppliers in india#Stainless Steel 316L Round Bars#Stainless Steel 316L Round Bars Suppliers#Stainless Steel 304 Round Bars#Stainless Steel 304 Round Bars Suppliers#Stainless Steel 304 Round Bars Exporter

0 notes

Text

Crafting Precision: Exploring the World of Stainless Steel Round Bars

Introduction to Stainless Steel Round Bars

Among the numerous kinds of industrial materials currently in the market, stainless steel round bars are particularly outstanding due to their versatility and capacity for strength and corrosion. Hans Metal India these characteristics make them important in a wide range of industries, including construction, automotive, medical, and maritime applications. An investigation of the characterstics of crafting process shall involve stainless steel bar. carfting is one the best method in which its work very smoothly. concreting process is commonly seen in construction works. Stainless Steel Round Bar Manufacturer in India and Stainless Steel Plate Manufacturer in India.This article mainly go to the detectable way and help to work in easy way and quick.

Uses of Stainless Steel Round Bars

Construction and Architecture

Because of its strength, beauty, and ability to withstand weathering, stainless steel round bars are widely utilised in the construction sector. By using Architecture methods it can be easy to analyze the product. Stainless Steel Sheet Manufacturer in India and Round Bar Suppliers in UAE .Their contribution is vital, in constructing buildings, bridges and various infrastructure projects.

Automotive Industry

It is a automated machinery instruments which work in machinery way. SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India.In the sector various parts, like axles, bolts and engine components are crafted from stainless steel bars. These materials excel in applications that demand reliability and top notch performance due, to their durability and resistance to wear.

Medical Devices

In the field of medicine surgical instruments orthopedic implants and various medical devices are crafted from stainless steel bars. These materials are well suited for critical healthcare uses because of their ability to be sterilized without losing their quality and their compatibility, with the body.

The Crafting Process:

1. Choice of Raw Materials:

In the stage of the process one should opt for quality stainless steel. The specific application will dictate the choice of steel alloy with popular options being 304, 316 and 410 grades. common grades include 304, 316, and 410. Specific qualities like stronger corrosion resistance, better machinability, or higher strength are offered by each grade.

2. Pouring and Pouring Melt:

In an electric arc furnace, the chosen raw materials are melted at extremely high temperatures. This method ensures that the alloy composition remains consistent. The process involves melting steel and shaping it into finished forms, like slabs, billets or blooms.

3. Hot Rolling: The cast steel is put through rolling mills and heated above its recrystallization temperature during the hot rolling process. In this process, the steel is shaped into a rough cylindrical shape and its thickness is decreased.

4.Heat Treatment Process; The rolled bars undergo annealing to enhance their flexibility and reduce their toughness. In this procedure the steel is heated to a temperature. Then slowly cooled down. Moreover annealing helps in relieving stresses in the material.

5. Precision Rolling: To obtain the required diameter and surface finish, the bars are subjected to precision rolling or drawing after annealing. By taking this process, the round bars are guaranteed to meet strict criteria for surface quality and dimensional tolerances.

6. Cutting and Finishing: Depending on the needs of the ultimate use, the lengthy steel rods are cut into predetermined lengths and go through a variety of finishing procedures, including grinding, polishing, or coating. The circular bars get their distinctive glossy, smooth look from this process.

Conclusion

Round stainless steel bars are proof of the strength of expert engineering and fine craftsmanship. From raw material to essential industrial component, they go through a number of carefully regulated procedures, each of which adds to their remarkable qualities. The use of stainless steel round bars in aerospace, automotive, medical, and construction applications is still essential to the advancement of contemporary industry. These extraordinary materials will become even more important and versatile as production methods and technology advance.

0 notes

Text

4 Factors that Affects the Price of SS Plates in India

Stainless steel sheets are unique to various industries, e.g. building and construction, food processing, manufacturing or pharmacy, but these are widespread among all industries. The Indian economy as seen the construction is in full swing with the economy on a growth path and the country moving ahead with its infrastructural development.

Although fluctuations in the market for stainless steel plates occur from time to time depending on market dynamics, businesses should be additionally aware of this. The current article will cover four of the major price-affecting factors in the stainless steel plates in India.

1. Raw Material Costs

The cost of raw materials (main factor) primarily affects the price of stainless steel. Stainless steel is an alloy conglomeration formed using iron, chromium, nickel, and other elements. While in the case of stainless steel plates it is usually raw materials which drive the main cost of the product, among them, the nickel price is the most important factor influencing the total manufacturing cost. Nickel is used in structural metals like grade 304 and 316 stainless steels more than any other metal, and its price volatility directly causes the highest fluctuations in the prices of these plates in the market. As the nickel price rises, so does the price of stainless steel plates that are almost synonymous with metal.

2. Global Market Demand and Supply

The global marketplace and its dynamics regarding demand and supply matters big time when it concerns the pricing of stainless steel plates in India. To the extent that there is a strong global demand for stainless steel, this limits the amount of supplies and triggers fierce competition among producers. Prices go up as a result. With the potential imbalance of international market coprings, frequent monitoring of market conditions improves decision-making when purchasing stainless steel plates.

3. Manufacturing and Processing Costs

The raw material and labour expenses associated with producing stainless steel plates are among the causes of the high price in this industry. For example, energy expenses, labour costs, and shipment charges can all contribute to total production overheads. Breakthroughs in process technologies and those that produce efficiency improvements can lower manufacturing costs, but they could also require considerable upfront expenses. Furthermore, the steel grade comes into the light, such as duplex 2205 plate or super duplex 2507, which may intensify the manufacturing complexity to attain that particular quality, so similar factors could increase the price.

4. Government Policies and Regulations

The policies and laws designed by the government can greatly influence the price of stainless steel plates in India. The duties of imports, customs, and trade agreements may impact commodity prices and the finished goods' prices. Such as a change in tariffs for importing nickel or chromium as basic materials on stainless steel plates will directly impact the price of the stainless steel plates. Nevertheless, government programs to protect the domestic steel sector, such as subsidies or countervailing measures, can greatly affect the market prices of steel. Awareness of state policies is among the most important factors that every business dealing with stainless steel plates in India should consider.

Conclusion

For an organization, understanding the factors influencing the price of an Indian stainless steel plate is the key to sensible purchase. At Nitron Alloys, we are a leading stainless steel 304 plate supplier and stainless steel 316 plate supplier in India; here, we closely monitor the market situations and behaviours in order to offer our customers better pricing and high quality With our industry depth and strong supply chains that we have built we can respond favourably to price fluctuations.

1 note

·

View note

Text

Stainless Steel 304 Sheets & Plates Exporters in India: Spotlight on Padmavati Steel & Engg.Co.

Understanding Stainless Steel 304

Stainless steel 304 is an austenitic chromium-nickel alloy known for its excellent corrosion resistance and formability. Its composition includes:

Chromium (18-20%): Enhances corrosion resistance and durability.

Nickel (8-10.5%): Provides toughness and strength.

Carbon (0.08% max): Ensures high strength and weldability.

Key Properties of Stainless Steel 304

Corrosion Resistance: Stainless steel 304 offers superior resistance to corrosion in various environments, including acidic and chloride environments.

Formability: This grade can be easily formed and welded into different shapes, making it ideal for manufacturing sheets and plates.

Durability: The high chromium and nickel content provide excellent durability and strength.

Hygiene: Stainless steel 304 is easy to clean and maintain, making it suitable for hygienic applications.

Conclusion

The export of stainless steel 304 sheets and plates is a critical aspect of India's industrial growth, and companies like Padmavati Steel & Engg.Co. play a vital role in this sector. With its focus on quality, global reach, and customer satisfaction, Padmavati Steel & Engg.Co. continues to be a leader in exporting high-quality stainless steel products. As industries worldwide seek reliable and versatile materials, the demand for stainless steel 304 sheets and plates is set to rise, and Padmavati Steel & Engg.Co. is well-positioned to meet this demand.

For More Information:

Visit : https://www.padmavatisteel.com/stainless-steel-304-sheet-plate-manufacturers-suppliers-importers-exporters-stockists.html

Contact:+91-9930388308

Email-ID: [email protected]

0 notes

Text

Stainless Steel Pipes in Rajasthan

Meghmani Metal Industries is a Manufaturer and Supplier of Stainless Steel Pipes in Rajasthan, India.

Founded in 2011, Meghmani Metal Industries has steadfastly placed emphasis on customer satisfaction and environmental responsibility across all facets of its operations.

Our comprehensive range includes stainless steel plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats.

Stainless Steel Pipes are hollow tubes made primarily from stainless steel, an alloy composed mainly of iron and varying amounts of chromium.

We craft our stainless steel pipes from various grades including Austenitic (e.g., 304, 316), which offer strong corrosion resistance and are non-magnetic; Ferritic (e.g., 409, 430), which are magnetic and durable; and Duplex (e.g., 2205, 2507).

Stainless steel pipes earn renown for their resistance to corrosion, making them suitable for use in aggressive environments where exposure to moisture, chemicals, or salt is common.

They exhibit excellent mechanical properties, including high tensile strength and toughness, which ensure long-term durability and reliability even under extreme conditions.

Stainless steel pipes are easy to clean and sanitize due to their smooth, non-porous surface. This makes them ideal for applications where cleanliness and hygiene are critical.

Stainless steel pipes maintain their strength and integrity at both high and low temperatures, making them suitable for applications ranging from cryogenic conditions to high-temperature industrial processes.

Meghmani Metal Industries is a Manufaturer and Supplier of Stainless Steel Pipes in Rajasthan and places like Ajmer, Alwar, Amer, Barmer, Beawar, Bharatpur, Bhilwara, Bikaner, Bundi, Chittaurgarh, Churu, Dhaulpur, Dungarpur, Ganganagar, Hanumangarh, Jaipur, Jaisalmer, Jalor, Jhalawar, Jhunjhunu, Jodhpur, Kishangarh, Kota, Merta, Nagaur, Nathdwara, Pali, Phalodi, Pushkar, Sawai Madhopur.

Feel free to reach out for further details and inquiries. We're here to assist you.

Read the full article

0 notes

Text

Stainless Steel 309 Sheet & Plate Suppliers in India

Divine Metal & Alloys Spotless is the overall Manufacture, Supplier, and exporter of the SS 309/309S Sheet Plate. We make these sheets and plates in different surface finishes, end finishes, aspects, shapes, sizes, particulars, and thicknesses. These are given to the clients in cut-to-size details according to their assumptions according to public and global quality guidelines. A portion of the kinds where the sheets and plates are accessible are cleaned plates, hot-moved plates, cold-moved plates, shim sheets, checkered plates, and others.

Stainless Steel 309 is a profoundly alloyed austenitic steel utilised for its exceptional oxidation resistance, high-temperature strength, and creep obstruction. The lower nickel content of SS 309 Plates further develops protection from sulphur assault at high temperatures. SS 309 sheets are intense and malleable and can be promptly created and machined. SS 309 Sheets and Plates have high consumption, obstruction, and strength compared with 304-Stainless steel. Stainless Steel UNS S30900 Plates are hot worked at 1177 degrees C (2150 degrees F), followed by warming at 982 degrees C (1800 degrees F). It tends to be extinguished quickly. Post-work tempering should be possible to reestablish its erosion-resistant property.

Stainless Steel 309S Sheets and Plates are the lower carbon adaptation of grade 309 and have high framing and welding qualities. These SS 309S Plates can undoubtedly be welded utilising any opposition and combination strategies. SS UNS S30900 Sheets are suggested for applications where refinement and ensuing consumption by high-temperature gases or condensates during closure might represent an issue. These SS 309 Sheets and Plates can be utilised for different applications like Kettle baffles, furnace components, oven linings, fire box sheets,other high-temperature compartments, and so on. A portion of the properties that are present in the sheets and plates are extraordinary rigidity, high sturdiness, malleability, solidness, and soundness at the raised temperatures. We furnish different test declarations alongside our items as per EN 10204/3.1B: a 100 percent radiography test report, an outsider test report, a natural substance declaration, and so forth, to guarantee harm-free items are conveyed to our clients.

Specification Stainless Steel 309 Sheet & Plate

DimensionsASTM, ASME and APIStandardASTM A240 / ASME SA240Width1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm,Thickness4mm-100mmStandardJIS, AISI, ASTM, GB, DIN, EN, etcSurfacethe surface and finish of stainless steel 301 sheet: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etcBrand:Indian Origin, European Origin, Japanese Origin, US Origin, Korea Origin, Thailand Origin, Taiwan OriginManufacturer:POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, OutokumpuFinishes2D, 2B, 4Pol, BA, X10, XL, Buff, XL Blend S, SATIN (Met with Plastic Coated), NO(8), Hairline, NO.1, NO.4, Mirror FinishExport toIndia, Indonesia, Malaysia, Singapore, Saudi Arabia, Qatar, UAE, Iran, Iraq, Oman, South Africa, Nigeria, Kenya, Italy, UK, Brazil, Russia , Egypt , Kuwait , Taiwan, Australia

0 notes

Text

Fabricate with Confidence: High-Performance Hastelloy C276 Round Bars

Hastelloy C276 round bars are well-known for their outstanding performance in challenging conditions. Whether in corrosive chemical settings or high-temperature applications, these alloys stand out for their reliability and durability.

Introduction to Hastelloy C276 Round Bars

Hastelloy C276 round bar belongs to a family of nickel-molybdenum-chromium superalloys known for their versatility in harsh conditions. Engineered to withstand extreme temperatures and resist corrosion, these bars are vital components in various industrial sectors.

Properties of Hastelloy C276 Alloy

Corrosion Resistance

Hastelloy C276 shows exceptional resistance against various corrosive substances, including both oxidizing and reducing environments. This property makes it ideal for applications where exposure to acids, salts, and solvents is common.

High-Temperature Performance

Hastelloy C276 retains its mechanical strength even at high temperatures, with a melting point surpassing 1300°C. This attribute ensures stability and reliability in environments where heat endurance is crucial.

Mechanical Strength

The alloy's high mechanical strength enables it to withstand intense pressures and stresses without compromising structural integrity. This makes the Hastelloy C276 round bar suitable for critical load-bearing applications.

Applications of Hastelloy C276 Round Bars

Aerospace Industry

In aerospace engineering, Hastelloy round bars are utilized in structural components and engine parts due to their lightweight nature and superior corrosion resistance.

Chemical Processing

Chemical plants rely on Hastelloy C276 round bar for equipment exposed to corrosive chemicals, ensuring longevity and safety in operations.

Oil and Gas Sector

In the oil and gas industry, where harsh drilling conditions prevail, these round bars are used in downhole tools and pipelines, offering protection against corrosive fluids and gases.

Manufacturing Processes of Hastelloy C276 Round Bars

Alloy Composition

Hastelloy C276 round bar are composed of nickel, molybdenum, and chromium, combined in precise proportions to achieve optimal performance characteristics.

Melting and Casting

The alloy is melted in a controlled environment and cast into billets or ingots, which are subsequently hot worked into round bars of varying diameters.

Hot and Cold Working

Hastelloy C276 round bars undergo hot forging and cold drawing processes to refine their structure and enhance mechanical properties, ensuring uniformity and durability.

Comparison with Other Alloys

Hastelloy C276 vs. Inconel Alloys

Unlike Inconel alloys, Hastelloy C276 offers superior resistance to a broader range of corrosive chemicals, making it preferred in aggressive industrial environments.

Hastelloy C276 vs. Stainless Steel

Compared to stainless steel, Hastelloy C276 provides better performance in highly corrosive conditions and at elevated temperatures, making it a cost-effective choice for critical applications.

Quality Standards and Certifications

ASTM Specifications

Hastelloy C276 round bars adhere to ASTM B574/B575 standards, ensuring consistent quality and performance in various applications.

ISO Certifications

Manufacturers of Hastelloy round bars comply with ISO 9001 standards, demonstrating their commitment to quality management and customer satisfaction.

Factors to Consider When Choosing Hastelloy C276 Round Bars

Environmental Factors

Evaluate the operating environment's temperature, pressure, and chemical exposure to determine if Hastelloy round bars are suitable for the application.

Cost Considerations

While initially more expensive than some alternatives, the Hastelloy C276 round bar offers long-term cost savings due to its durability and minimal maintenance requirements.

Maintenance and Care Tips

Cleaning Procedures

Clean Hastelloy C276 round bar regularly using mild soaps and non-abrasive materials to preserve their corrosion-resistant properties and aesthetic appeal.

Storage Recommendations

Store Hastelloy round bars in a dry, ventilated area away from corrosive substances to prevent surface damage and maintain their integrity over time.

Future Trends in Hastelloy C276 Round Bar

Research and Development

Ongoing research aims to enhance Hastelloy C276's properties further, potentially expanding its applications in emerging industries and challenging environments.

Innovations in Alloy Design

Advancements in alloy design may lead to new formulations of Hastelloy round bars with enhanced mechanical strength and improved resistance to specific chemicals.

Conclusion

In conclusion, Hastelloy C276 round bars are indispensable in industries requiring robust, corrosion-resistant materials capable of withstanding extreme conditions. Their superior performance, coupled with ongoing advancements in alloy technology, ensures they remain at the forefront of engineering solutions.

#Hastelloy C276 Round Bars#Hastelloy C276 Round Bars Supplier#Hastelloy C276 Round Bars Exporter#Hastelloy C276 Round Bars Manufacturer in India#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates

0 notes

Text

Top Quality Steel Plate Manufacturer in India

PipingProjects.in is a top steel plate manufacturer in India. A stainless steel plate is a thin sheet of metal that can be 0.5 to 6 mm thick. Steel plates are thicker than foil, but thinner than stainless steel plates. Steel plate has good corrosion resistant qualities and performs well under a variety of circumstances.

Steel plates are frequently used in the petrochemical industry due to their cost-effectiveness and excellent mechanical properties. In petrochemical applications where corrosion resistance is critical, stainless steel plates are the preferred choice. Corrosive settings often utilize grades 304, 316, 321, and 347. We are a leading steel plate manufacturer in India, and our steel plates are extensively used in petrochemical equipment and buildings due to their increased strength and mechanical qualities.

Explore our Steel Plate Weight Chart in kg. Below is a weight table for steel plates of various diameters and wall thicknesses, given in kilograms per meter (kg/m). It is critical to understand that the weights offered are simply estimates and may vary depending on the kind of steel and production processes used.

For more details:

Product: Steel Plate Supplier in India

#steel plate manufacturer in India#steel plate manufacturer#Steel Plate Weight Chart in kg#Steel Plate Supplier in India

0 notes