#Solvent Naphtha Market Trend

Explore tagged Tumblr posts

Text

C10 Solvent Prices: Current Trends and Market Dynamics

C10 solvents, a group of hydrocarbons derived primarily from petroleum refining, are essential in a variety of industries, including paints and coatings, adhesives, and industrial cleaning. These solvents are valued for their high solvency power, low evaporation rates, and compatibility with many formulations. However, like other petrochemical products, the pricing of C10 solvents is subject to multiple factors, including raw material costs, global supply-demand balances, and market-specific dynamics.

Recent Price Trends

The prices of C10 solvents have seen significant fluctuations over the past year. This volatility is largely tied to crude oil prices, as C10 solvents are derived from petroleum feedstocks. In 2023, the global oil market experienced price surges due to geopolitical tensions, OPEC production cuts, and increased energy demand post-pandemic. These factors directly impacted the cost of petrochemical intermediates, including C10 solvents.

As of the fourth quarter of 2024, C10 solvent prices are stabilizing but remain on the higher end compared to historical averages. This stabilization is attributed to several factors:

Moderating Crude Oil Prices: After peaking earlier in the year, crude oil prices have eased slightly due to improved supply dynamics and slower economic growth in major markets like China and Europe.

Seasonal Demand Variations: Demand for C10 solvents typically fluctuates based on seasonal activity in the coatings and construction sectors. The autumn months often see a dip as these sectors wind down.

Currency Fluctuations: The strengthening of the U.S. dollar in recent months has made imports of petrochemical products more expensive for countries with weaker currencies, impacting global trade flows.

Get Real time Prices for C10 solvent: https://www.chemanalyst.com/Pricing-data/c10-solvent-1466

Supply Chain Dynamics

The global supply chain for C10 solvents has faced disruptions in recent years due to logistical bottlenecks, particularly during the COVID-19 pandemic. While supply chains have largely normalized, occasional disruptions continue to occur, particularly in regions prone to natural disasters or political instability.

Additionally, the global transition towards greener energy and stricter environmental regulations have placed pressure on the petrochemical industry. Producers are increasingly focusing on sustainable practices, which may lead to higher production costs for traditional solvents like C10. Some manufacturers are also exploring bio-based alternatives, which could eventually impact the market share and pricing dynamics of conventional C10 solvents.

Outlook for 2025

Market analysts forecast a steady demand for C10 solvents, particularly in emerging economies where industrial growth remains robust. However, potential challenges include:

Environmental Regulations: Stricter emissions standards and sustainability initiatives could limit the use of traditional solvents, encouraging a shift towards low-VOC or bio-based alternatives.

Raw Material Prices: Crude oil and naphtha prices will continue to play a pivotal role in determining the cost of C10 solvents.

Technological Innovations: Advances in solvent recovery and recycling technologies may reduce overall demand for virgin solvents, impacting market dynamics.

Conclusion

The C10 solvent market remains a critical component of the global petrochemical industry, with its pricing influenced by a complex interplay of macroeconomic factors, raw material availability, and regulatory changes. Stakeholders, including manufacturers, distributors, and end-users, must stay attuned to these dynamics to navigate the market effectively. As the industry evolves, adapting to environmental trends and technological advancements will be crucial for long-term sustainability and profitability.

Get Real time Prices for C10 solvent: https://www.chemanalyst.com/Pricing-data/c10-solvent-1466

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#C10 Solvent#C10 Solvent Price#C10 Solvent Prices#C10 Solvent Pricing#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

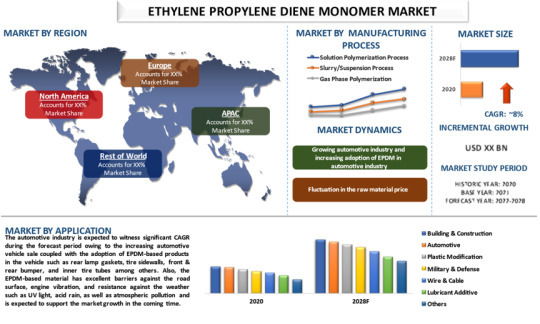

Ethylene Propylene Diene Monomer (EPDM) Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Ethylene Propylene Diene Monomer (EPDM) Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Manufacturing Process (Solution Polymerization Process, Slurry/Suspension Process, and Gas Phase Polymerization); Application (Building & Construction, Automotive, Plastic Modification, Military & Defense, Wire & Cable, Lubricant Additive, and Others); Region/Country.

The Ethylene Propylene Diene Monomer (EPDM) market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Ethylene Propylene Diene Monomer (EPDM) market. The Ethylene Propylene Diene Monomer (EPDM) market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Ethylene Propylene Diene Monomer (EPDM) market at the global and regional levels.

Market Overview

Ethylene Propylene Diene Monomer (EPDM) is a synthetic material obtained from natural gas and thermal cracking petroleum products such as naphtha. EPDM is widely used in low-slope buildings, automotive applications, and construction applications due to their longer durability and superior resistance to environmental factors such as UV, ozone, and other weather condition. In recent times, the EPDM witnessed significant demand due to its increasing demand from the automotive industry, manufacturing & construction industry attributed to its lower cost, higher moldability, and longer durability. Also, the EPDM could be used as an alternative to silicon rubber and could also be incorporated in the hose, O-ring, accumulator bladder, diaphragms, and connectors for wire & cables among many other applications on the account of their higher resistance towards tearing, abrasive, solvent, and temperature.

Factors such as technological advancement coupled with the growing number of industries and manufacturing units along with the new product launches in the market are some of the prominent factors that are positively influencing the market growth globally.

Some of the major players operating in the market include DowDuPont Inc., Exxon Mobil Corporation, Lion Elastomers, Johns Manville, SK Global Chemical Co. Ltd, Lanxess AG, Mitsui Chemical Inc., PetroChina Company Limited, Kumho Polychem, and Versalis S.p.A.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the manufacturing industry along with supply chain disruption, regulatory and policy changes, labor reliance, working capital management, and liquidity & solvency management. The Ethylene Propylene Diene Monomer (EPDM) market has been significantly affected during these times owing to the gap between supply and demand.

The global Ethylene Propylene Diene Monomer (EPDM) market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on application, the market is segmented into building & construction, automotive, plastic modification, military & defense, wire & cable, lubricant additive, and others. The automotive industry is expected to witness significant CAGR during the forecast period owing to the increasing automotive vehicle sale coupled with the adoption of EPDM-based products in the vehicle such as rear lamp gaskets, tire sidewalls, front & rear bumper, and inner tire tubes among others. Also, the EPDM-based material has excellent barriers against the road surface, engine vibration, and resistance against the weather such as UV light, acid rain, as well as atmospheric pollution and is expected to support the market growth in the coming time.

Based on the manufacturing process, the market is segmented into solution polymerization process, slurry/suspension process, and gas phase polymerization. The solution polymerization segment is expected to witness significant growth during the forecast period due to the higher concentration and lower required amount for the optimized performance. Additionally, solution polymerization is used to manufacture both crystalline and amorphous polymer grades and is expected to support market growth.

Ethylene Propylene Diene Monomer (EPDM) Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the rapid industrialization and growing automotive industries along with the electronic & electrical industry, consumer goods industry, and medical sector in the region. Also, the ongoing infrastructural projects and increasing disposable income of the individual are expected to support market growth in the coming time. Furthermore, EPDM has also been used as a substitute for thermoplastic olefins and thermoplastic vulcanizate in the manufacturing industry. Also, the lower cost of the raw material coupled with the lower cost of production associated with the lower labor cost propels the market for the EPDM. Moreover, the growing research & development activities, increasing investment, and technological investment are expected to derive the market in the coming time. For instance, in March 2022, Arlanxeo a Netherland-based firm announced to increase in its production capacity by 15% for its EPDM plant based in Changzhou, China.

The major players targeting the market include:

DowDuPont Inc.

Exxon Mobil Corporation

Lion Elastomers

Johns Manville

SK Global Chemical Co. Ltd

Lanxess AG

Mitsui Chemical Inc.

PetroChina Company Limited

Kumho Polychem

Versalis S.p.A.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Ethylene Propylene Diene Monomer (EPDM) market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are influencing the Ethylene Propylene Diene Monomer (EPDM) market over the forecast period?

• What are the global challenges, threats, and risks in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are propelling and restraining the Ethylene Propylene Diene Monomer (EPDM) market?

• What are the demanding global regions of the Ethylene Propylene Diene Monomer (EPDM) market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Titanium Dioxide Market - SWOT Analysis [2023-2028]

Recycled Carbon Fiber Market - SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Renewable Naphtha Market Key Players Profile Outlook and Forecast Till 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Renewable Naphtha Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Renewable Naphtha Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Renewable Naphtha Market?

The renewable naphtha market size reached US$ 472.4 Million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,104.8 Million by 2032, exhibiting a growth rate (CAGR) of 9.9% during 2024-2032.

What are Renewable Naphtha?

Renewable naphtha is a form of naphtha created from sustainable sources like biomass, algae, or waste products using methods such as pyrolysis, gasification, or fermentation. While chemically akin to conventional naphtha from fossil fuels, it serves as a greener alternative. This renewable naphtha can serve as a raw material for manufacturing different chemicals, including plastics, solvents, and fuels, offering a sustainable and eco-friendly substitute to traditional naphtha sourced from crude oil.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1592

What are the growth prospects and trends in the Renewable Naphtha industry?

The renewable naphtha market growth is driven by various factors. The market for renewable naphtha is experiencing notable growth, fueled by a heightened emphasis on sustainable options within the petrochemical sector. Environmental considerations and regulatory frameworks promoting renewable energy sources are propelling the adoption of renewable naphtha, sourced from biomass, algae, or waste materials. This eco-conscious alternative is increasingly utilized as a raw material for a range of chemicals, including plastics and solvents. Furthermore, advancements in conversion technologies and governmental support for renewable energy are driving further market expansion. Hence, all these factors contribute to renewable naphtha market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Feedstock:

Vegetable Oils

Animal Fats

Algal Biomass

Other Biomass

By Technology:

Hydrotreating

Deoxygenation

Hydrogenation

By Application:

Chemicals & Polymers

Fuels

Others

By End-Use Industry:

Petrochemicals

Transportation

Others

Segmentation By Region:

North America:

United States

Canada

Asia Pacific:

China

India

Japan

South Korea

Australia & New Zealand

Association of Southeast Asian Nations (ASEAN)

Rest of Asia Pacific

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX (Belgium, the Netherlands, Luxembourg)

NORDIC (Norway, Sweden, Finland, Denmark)

Rest of Europe

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

The Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA (Middle East & Africa)

Who are the key players operating in the industry?

The report covers the major market players including:

Neste Corporation

TotalEnergies

Repsol S.A.

Eni S.p.A.

Honeywell UOP

Chevron Corporation

Axens

INEOS Group AG

Preem AB

OMV Aktiengesellschaft

Enerkem Inc.

REG Life Sciences LLC

Clariant AG

Dow Inc.

LyondellBasell Industries N.V.

View Full Report: https://www.reportsandinsights.com/report/Renewable Naphtha-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

IDPE Prices In India

Indian Petrochem sources have announced significant shifts in the pricing dynamics of IDPE in the Delhi market as of May 14, 2024. IDPE, a vital solvent often converted into toluene within naphtha reformers, is experiencing price fluctuations due to factors like raw material costs and market demand.The stability of IDPE, derived from the hydrogenation of benzaldehyde, plays a pivotal role in its pricing trends, acting as a buffer against fluctuations in raw material expenses. Despite challenges related to domestic reliance, the IDPE market exhibits growth potential, driven by increasing demand across industries and its indispensable role in various applications.Recent market reports indicate a slight dip in IDPE prices in the Delhi market. While this decline may reflect short-term fluctuations, industry experts remain optimistic about the future stability of IDPE prices. Stakeholders closely monitor factors such as raw material costs, global market trends, and potential disruptions in the supply chain, IDPE Prices In India, Indian Prices IDPE, Indian Petro Chem.

0 notes

Text

Denatured Alcohol Market to Observe Strong Growth to Generate Massive Revenue in Coming Years

Latest business intelligence report released on Global Denatured Alcohol Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Denatured Alcohol market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are Commercial Alcohols (Canada),Warner Graham Company (United States),Dow Chemical (United States),BASF (Germany),SABIC (Saudi Arabia),Recochem (Canada),ADM (United States),Valero Energy Corporation (United States),Green Plains Renewable Energy (United States),Cargill (United States)

Denatured alcohol is also referred to as is ethanol, ethyl alcohol that is not fit for human consumption as they use to add one or more chemicals (denaturants) to this alcohol. The chemicals that are used are Denaturing which helps in referring to removing a property from the alcohol which is being able to drink it, hence these denatured alcohol contains ordinary ethyl alcohol. These are used in solvent, fuels for different applications such as burners, stoves and many more. It is observed that, in the United States, there is a much greater percentage of Methanol as compared to ethanol. Hence the application of this denatured alcohol in various products is driving nature. Key Market Trends: Acceptance of Methanol as the Main Additive used in the Manufacturing of Denatured Alcohol

Denatured Alcohol Owing to the Eco-Friendly Attributes and its Various Applications in Many Industries Opportunities: Building Commercial and Industrial Spaces has led them for Maintenance and Cleaning purpose, Hence Increasing the Demand for Denatured Alcohol Market

Market Growth Drivers: Rising Demand for Household Applications Coupled with Cosmetic Industry

Cumulating Different Applications as a Solvent and Fuel both Indoor and Outdoor Activities

Challenges: These Alcohols Dries out very Easily and can get Evaporated if not Stored Carefully

Issue related to the Odor and Appearance of these Alcohols that can Make it Difficult for the Consumer to Use

The Global Denatured Alcohol Market segments and Market Data Break Down by Type (Specially Denatured Alcohol (SDA), Completely Denatured Alcohol (CDA)), Application (Cleaning Solvent (Glass/Window Cleaning, Cleaning Paint Brushes (Oil Paint Based), Cleaning of Makeup, Grass Stains and Ink Stains, Cleaning of Metal Parts), Remove mold and Mildew, Woodworking and Restoring Furniture, Fuel, Other), Chemical Additives (Methanol, Isopropyl alcohol, Acetone, Methyl Ethyl Ketone, Denatonium, Methyl isobutyl ketone, Others (Naphtha)

Presented By

AMA Research & Media LLP

0 notes

Text

0 notes

Text

Heavy Aromatic Naphtha Solvent Prices | Pricing | Trend | News | Database | Chart | Forecast

Heavy Aromatic Naphtha Solvent Prices a complex blend of hydrocarbons with a high aromatic content, plays a crucial role in various industrial applications, particularly in the production of high-quality chemicals and as a solvent in different manufacturing processes. Understanding the pricing dynamics of this solvent is essential for businesses involved in its procurement and usage. The cost of Heavy Aromatic Naphtha is influenced by a range of factors, including raw material prices, production costs, and market demand.

In recent years, fluctuations in the price of Heavy Aromatic Naphtha have been notably impacted by changes in crude oil prices. Since Heavy Aromatic Naphtha is derived from crude oil through a refining process, its cost closely tracks the movement of crude oil markets. Periods of high crude oil prices typically lead to increased costs for Heavy Aromatic Naphtha, as refineries pass on their higher production costs to consumers. Conversely, when crude oil prices decline, the cost of Heavy Aromatic Naphtha may also decrease, though this relationship can be influenced by other market dynamics.

Another significant factor affecting Heavy Aromatic Naphtha prices is the level of demand from key industries. Heavy Aromatic Naphtha is widely used in the production of chemicals such as resins, adhesives, and coatings. Therefore, changes in demand from these sectors can drive fluctuations in its price. For instance, a surge in the construction or automotive industry can lead to increased demand for Heavy Aromatic Naphtha, driving prices higher. Similarly, a downturn in these industries can result in lower prices due to reduced demand.

Get Real Time Prices for Heavy Aromatic Naphtha Solvent : https://www.chemanalyst.com/Pricing-data/heavy-aromatic-naphtha-solvent-1177

Supply chain disruptions also play a critical role in shaping the prices of Heavy Aromatic Naphtha. Events such as geopolitical tensions, natural disasters, or logistical issues can impact the production and distribution of this solvent. For example, hurricanes in key oil-producing regions or political instability in major oil-exporting countries can cause significant disruptions in the supply chain, leading to price volatility. Businesses relying on Heavy Aromatic Naphtha must stay informed about such disruptions to manage their procurement strategies effectively.

Regulatory changes and environmental considerations are additional factors that can influence the pricing of Heavy Aromatic Naphtha. Governments around the world are increasingly implementing stricter environmental regulations aimed at reducing emissions and promoting the use of greener alternatives. These regulations can impact the production processes of Heavy Aromatic Naphtha, potentially increasing costs for manufacturers. As the industry adapts to these regulatory changes, businesses may experience shifts in the pricing structure of this solvent.

Technological advancements in refining processes also contribute to the pricing trends of Heavy Aromatic Naphtha. Innovations that improve the efficiency of refining operations or enable the extraction of higher yields of Heavy Aromatic Naphtha from crude oil can influence its market price. Conversely, outdated or less efficient technologies may lead to higher production costs, affecting the final price of the solvent.

Market sentiment and speculative trading can further impact Heavy Aromatic Naphtha prices. Traders and investors in the commodities markets often react to various economic indicators and geopolitical events, which can lead to price swings. For instance, speculation about future oil supply shortages or changes in global economic conditions can lead to increased volatility in the prices of Heavy Aromatic Naphtha.

To navigate the complexities of Heavy Aromatic Naphtha pricing, businesses must adopt strategic approaches to procurement and inventory management. Keeping a close eye on global oil markets, understanding industry-specific demand trends, and staying informed about regulatory developments are crucial for managing costs effectively. Additionally, engaging with reliable suppliers and exploring long-term contracts or hedging strategies can help mitigate the impact of price fluctuations.

In summary, the pricing of Heavy Aromatic Naphtha is influenced by a multifaceted interplay of factors, including crude oil prices, demand from key industries, supply chain disruptions, regulatory changes, technological advancements, and market sentiment. Businesses involved in the use or procurement of this solvent must stay vigilant and adaptable to these dynamics to effectively manage their costs and ensure a steady supply.

Get Real Time Prices for Heavy Aromatic Naphtha Solvent : https://www.chemanalyst.com/Pricing-data/heavy-aromatic-naphtha-solvent-1177

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Heavy Aromatic Naphtha Solvent#Heavy Aromatic Naphtha Solvent Price#Heavy Aromatic Naphtha Solvent Prices#Heavy Aromatic Naphtha Solvent Pricing

0 notes

Text

Solvent Naphtha Market- Drivers, Equipment Suppliers and Price Analysis to 2022

Global Solvent Naphtha Market is segmented on the basis of product types, applications, and region. A flammable liquid distillate containing principally xylenes and higher aromatic hydrocarbons and usually boiling higher than ligroin, obtained especially from coal tar light oils or coke-over-gas light oils or from petroleum cracking, and used chiefly as a solvent and as a raw material for coumarone indene resins.

Naphtha is crude oil refinery’s light product mostly used as either feedstock for petrochemical cracking or gasoline blending and reforming. With the development in technologies, naphtha could also be produced from condensate splitting and gas-to-liquid processing. Naphtha is classified, by type into Heavy Naphtha and Paraffinic Naphtha. Paraffinic naphtha is rich in olefins and best-suited for olefin/polyolefin production. Heavy naphtha is mainly used for gasoline reforming and aromatic production.

View Full Report with TOC @ https://www.millioninsights.com/industry-reports/solvent-naphtha-market

Solvent naphtha is catalytically reformed and desulfurized in certain refineries. Such naphtha is termed as virgin naphtha. The reformation re-structures or re-arranges hydrocarbon molecules in naphtha and also breaks certain molecules into petite ones for producing gasoline’s or petrol’s high-octane component. The other sources of naphtha include shale deposits, wood’s destructive distillation, tar sands, and coal tar. Some petroleum refineries do produce specialty naphthas that find applications in various purification processes.

Solvent Naphtha Market is classified, by product type into Paraffin Solvent, Cyclo Paraffin Solvent, C9 Solvent, and C10 Solvent. Naphtha solvent C9 of good quality is used by the paint, coating and printing industries. Solvent Naphtha Market is classified, by applications into Agrochemicals, Rubber & Resin, Printing Inks, Industrial Cleaning. Solvent Naphtha Market is segmented, geographically into North America, Europe (Eastern Europe, Western Europe), Asia Pacific, Latin America, Middle East and Africa. Solvent Naphtha Market key players are Shell, Exxon Mobil, Total, Chevron Phillips, SK, Calumet, BP, Dow, Citgo, Reliance, KAPCO, Mitsubishi, CEPSA, JX Nippon Oil & Energy, Neste, and CPC Corporation.

Request a Sample Copy of This Report @ https://www.millioninsights.com/industry-reports/solvent-naphtha-market/request-sample

#Solvent Naphtha Market Analysis#Solvent Naphtha Market Trend#solvent naphtha market size#Solvent Naphtha Market Share

0 notes

Text

Renewable Naphtha Market Key Players Profile Outlook and Forecast Till 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Renewable Naphtha Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Renewable Naphtha Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Renewable Naphtha Market?

The renewable naphtha market size reached US$ 472.4 Million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,104.8 Million by 2032, exhibiting a growth rate (CAGR) of 9.9% during 2024-2032.

What are Renewable Naphtha?

Renewable naphtha is a form of naphtha created from sustainable sources like biomass, algae, or waste products using methods such as pyrolysis, gasification, or fermentation. While chemically akin to conventional naphtha from fossil fuels, it serves as a greener alternative. This renewable naphtha can serve as a raw material for manufacturing different chemicals, including plastics, solvents, and fuels, offering a sustainable and eco-friendly substitute to traditional naphtha sourced from crude oil.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1592

What are the growth prospects and trends in the Renewable Naphtha industry?

The renewable naphtha market growth is driven by various factors. The market for renewable naphtha is experiencing notable growth, fueled by a heightened emphasis on sustainable options within the petrochemical sector. Environmental considerations and regulatory frameworks promoting renewable energy sources are propelling the adoption of renewable naphtha, sourced from biomass, algae, or waste materials. This eco-conscious alternative is increasingly utilized as a raw material for a range of chemicals, including plastics and solvents. Furthermore, advancements in conversion technologies and governmental support for renewable energy are driving further market expansion. Hence, all these factors contribute to renewable naphtha market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Feedstock:

Vegetable Oils

Animal Fats

Algal Biomass

Other Biomass

By Technology:

Hydrotreating

Deoxygenation

Hydrogenation

By Application:

Chemicals & Polymers

Fuels

Others

By End-Use Industry:

Petrochemicals

Transportation

Others

Segmentation By Region:

North America:

United States

Canada

Asia Pacific:

China

India

Japan

South Korea

Australia & New Zealand

Association of Southeast Asian Nations (ASEAN)

Rest of Asia Pacific

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX (Belgium, the Netherlands, Luxembourg)

NORDIC (Norway, Sweden, Finland, Denmark)

Rest of Europe

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

The Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA (Middle East & Africa)

Who are the key players operating in the industry?

The report covers the major market players including:

Neste Corporation

TotalEnergies

Repsol S.A.

Eni S.p.A.

Honeywell UOP

Chevron Corporation

Axens

INEOS Group AG

Preem AB

OMV Aktiengesellschaft

Enerkem Inc.

REG Life Sciences LLC

Clariant AG

Dow Inc.

LyondellBasell Industries N.V.

View Full Report: https://www.reportsandinsights.com/report/Renewable Naphtha-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

IDPE Prices In India

Indian Petrochem sources have announced significant shifts in the pricing dynamics of IDPE in the Delhi market as of May 14, 2024. IDPE, a vital solvent often converted into toluene within naphtha reformers, is experiencing price fluctuations due to factors like raw material costs and market demand. The stability of IDPE, derived from the hydrogenation of benzaldehyde, plays a pivotal role in its pricing trends, acting as a buffer against fluctuations in raw material expenses. Despite challenges related to domestic reliance, the IDPE market exhibits growth potential, driven by increasing demand across industries and its indispensable role in various applications. Recent market reports indicate a slight dip in IDPE prices in the Delhi market. While this decline may reflect short-term fluctuations, industry experts remain optimistic about the future stability of IDPE prices. Stakeholders closely monitor factors such as raw material costs, global market trends, and potential disruptions in the supply chain, IDPE Prices In India, Indian Prices IDPE, Indian Petro Chem.

0 notes

Text

Solvent Naphtha Market Analysis to 2022 by Share, Type, Application and Region

Global Solvent Naphtha Market is segmented on the basis of product types, applications, and region. A flammable liquid distillate containing principally xylenes and higher aromatic hydrocarbons and usually boiling higher than ligroin, obtained especially from coal tar light oils or coke-over-gas light oils or from petroleum cracking, and used chiefly as a solvent and as a raw material for coumarone indene resins.

Naphtha is crude oil refinery’s light product mostly used as either feedstock for petrochemical cracking or gasoline blending and reforming. With the development in technologies, naphtha could also be produced from condensate splitting and gas-to-liquid processing. Naphtha is classified, by type into Heavy Naphtha and Paraffinic Naphtha. Paraffinic naphtha is rich in olefins and best-suited for olefin/polyolefin production. Heavy naphtha is mainly used for gasoline reforming and aromatic production.

View Full Report with TOC @ https://www.millioninsights.com/industry-reports/solvent-naphtha-market

Solvent naphtha is catalytically reformed and desulfurized in certain refineries. Such naphtha is termed as virgin naphtha. The reformation re-structures or re-arranges hydrocarbon molecules in naphtha and also breaks certain molecules into petite ones for producing gasoline’s or petrol’s high-octane component. The other sources of naphtha include shale deposits, wood’s destructive distillation, tar sands, and coal tar. Some petroleum refineries do produce specialty naphthas that find applications in various purification processes.

Solvent Naphtha Market is classified, by product type into Paraffin Solvent, Cyclo Paraffin Solvent, C9 Solvent, and C10 Solvent. Naphtha solvent C9 of good quality is used by the paint, coating and printing industries. Solvent Naphtha Market is classified, by applications into Agrochemicals, Rubber & Resin, Printing Inks, Industrial Cleaning. Solvent Naphtha Market is segmented, geographically into North America, Europe (Eastern Europe, Western Europe), Asia Pacific, Latin America, Middle East and Africa. Solvent Naphtha Market key players are Shell, Exxon Mobil, Total, Chevron Phillips, SK, Calumet, BP, Dow, Citgo, Reliance, KAPCO, Mitsubishi, CEPSA, JX Nippon Oil & Energy, Neste, and CPC Corporation.

Request a Sample Copy of This Report @ https://www.millioninsights.com/industry-reports/solvent-naphtha-market/request-sample

#Solvent Naphtha Market Segment#Solvent Naphtha Market Growth#Solvent Naphtha Market Trend#Solvent Naphtha Market Scope

0 notes

Text

0 notes

Text

Biobased Chemicals, Materials, Polymers, Plastics, Paints & Coatings and Fuel Global Market to 2033

New Post has been published on https://petnews2day.com/pet-industry-news/pet-financial-news/biobased-chemicals-materials-polymers-plastics-paints-coatings-and-fuel-global-market-to-2033/

Biobased Chemicals, Materials, Polymers, Plastics, Paints & Coatings and Fuel Global Market to 2033

Company Logo

Dublin, Nov. 09, 2022 (GLOBE NEWSWIRE) — The “The Global Market for Biobased Chemicals, Materials, Polymers, Plastics, Paints & Coatings and Fuels to 2033” report has been added to ResearchAndMarkets.com’s offering.

Biobased materials refer to products that mainly consist of a substance (or substances) derived from living matter (biomass) and either occur naturally or are synthesized, or it may refer to products made by processes that use biomass. Materials from biomass sources include bulk chemicals, platform chemicals, solvents, polymers, and biocomposites.

The many processes to convert biomass components to value-added products and fuels can be classified broadly as biochemical or thermochemical.

In addition, biotechnological processes that rely mainly on plant breeding, fermentation, and conventional enzyme isolation also are used. New bio-based materials that may compete with conventional materials are emerging continually, and the opportunities to use them in existing and novel products are explored in this publication.

There is growing consumer demand and regulatory push for bio-based chemicals, materials, polymers, plastics, paints, coatings and fuels with high performance, good recyclability and biodegradable properties to underpin transition towards more sustainable manufacturing and products.

Contents include:

In-depth market analysis of bio-based chemical feedstocks, biopolymers, bioplastics, natural fibers and lignin, biofuels and bio-based coatings and paints.

Global production capacities, market volumes and trends,current and forecast to 2033.

Analysis of bio-based chemical including 11-Aminoundecanoic acid (11-AA), 1,4-Butanediol (1,4-BDO), Dodecanedioic acid (DDDA), Epichlorohydrin (ECH), Ethylene, Furan derivatives, 5-Chloromethylfurfural (5-CMF), 2,5-Furandicarboxylic acid (2,5-FDCA), Furandicarboxylic methyl ester (FDME), Isosorbide, Itaconic acid, 5 Hydroxymethyl furfural (HMF), Lactic acid (D-LA), Lactic acid – L-lactic acid (L-LA), Lactide, Levoglucosenone, Levulinic acid, Monoethylene glycol (MEG), Monopropylene glycol (MPG), Muconic acid, Naphtha, 1,5-Pentametylenediamine (DN5), 1,3-Propanediol (1,3-PDO), Sebacic acid and Succinic acid.

Analysis of synthetic bio-polymers and bio-plastics market including Polylactic acid (Bio-PLA), Polyethylene terephthalate (Bio-PET), Polytrimethylene terephthalate (Bio-PTT), Polyethylene furanoate (Bio-PEF), Polyamides (Bio-PA), Poly(butylene adipate-co-terephthalate) (Bio-PBAT), Polybutylene succinate (PBS) and copolymers, Polyethylene (Bio-PE), Polypropylene (Bio-PP)

Analysis of naturally produced bio-based polymers including Polyhydroxyalkanoates (PHA), Polysaccharides, Microfibrillated cellulose (MFC), Cellulose nanocrystals, Cellulose nanofibers, Protein-based bioplastics, Algal and fungal.

Analysis of market for biofuels.

Analysis of types of natural fibers including plant fibers, animal fibers including alternative leather, wool, silk fiber and down and polysaccharides.

Markets for natural fibers, including composites, aerospace, automotive, construction & building, sports & leisure, textiles, consumer products and packaging.

Production capacities of lignin producers.

In depth analysis of biorefinery lignin production.

Analysis of the market for bio-based, sustainable paints and coatings.

Analysis of types of bio-coatings and paints market. Including Alkyd coatings, Polyurethane coatings, Epoxy coatings, Acrylate resins, Polylactic acid (Bio-PLA), Polyhydroxyalkanoates (PHA), Cellulose, Rosins, Biobased carbon black, Lignin, Edible coatings, Protein-based biomaterials for coatings, Alginate etc.

Profiles of over 800 companies.

Story continues

Key Topics Covered:

1 EXECUTIVE SUMMARY

2 RESEARCH METHODOLOGY

3 THE GLOBAL PLASTICS MARKET 3.1 Global production 3.2 The importance of plastic 3.3 Issues with plastics use 3.4 Policy and regulations 3.5 The circular economy 3.6 Conventional polymer materials used in packaging 3.6.1 Polyolefins: Polypropylene and polyethylene 3.6.2 PET and other polyester polymers 3.6.3 Renewable and bio-based polymers for packaging 3.7 Comparison of synthetic fossil-based and bio-based polymers 3.8 End-of-life treatment of bioplastics

4 BIO-BASED CHEMICALS 4.1 Types 4.2 Production capacities 4.3 Bio-based adipic acid 4.4 11-Aminoundecanoic acid (11-AA) 4.5 1,4-Butanediol (1,4-BDO) 4.6 Dodecanedioic acid (DDDA) 4.7 Epichlorohydrin (ECH) 4.8 Ethylene 4.9 Furfural 4.10 5-Hydroxymethylfurfural (HMF) 4.11 5-Chloromethylfurfural (5-CMF) 4.12 2,5-Furandicarboxylic acid (2,5-FDCA) 4.13 Furandicarboxylic methyl ester (FDME) 4.14 Isosorbide 4.15 Itaconic acid 4.16 3-Hydroxypropionic acid (3-HP) 4.17 5 Hydroxymethyl furfural (HMF) 4.18 Lactic acid (D-LA) 4.19 Lactic acid – L-lactic acid (L-LA) 4.20 Lactide 4.21 Levoglucosenone 4.22 Levulinic acid 4.23 Monoethylene glycol (MEG) 4.24 Monopropylene glycol (MPG) 4.25 Muconic acid 4.26 Naphtha 4.27 Pentamethylene diisocyanate 4.28 1,3-Propanediol (1,3-PDO) 4.29 Sebacic acid 4.30 Succinic acid (SA)

5 BIOPOLYMERS AND BIOPLASTICS 5.1 Bio-based or renewable plastics 5.1.1 Drop-in bio-based plastics 5.1.2 Novel bio-based plastics 5.2 Biodegradable and compostable plastics 5.2.1 Biodegradability 5.2.2 Compostability 5.3 Advantages and disadvantages 5.4 Types of Bio-based and/or Biodegradable Plastics 5.5 Market leaders by biobased and/or biodegradable plastic types 5.6 Regional/country production capacities, by main types 5.6.1 Bio-based Polyethylene (Bio-PE) production capacities, by country 5.6.2 Bio-based Polyethylene terephthalate (Bio-PET) production capacities, by country 5.6.3 Bio-based polyamides (Bio-PA) production capacities, by country 5.6.4 Bio-based Polypropylene (Bio-PP) production capacities, by country 5.6.5 Bio-based Polytrimethylene terephthalate (Bio-PTT) production capacities, by country 5.6.6 Bio-based Poly(butylene adipate-co-terephthalate) (PBAT) production capacities, by country 5.6.7 Bio-based Polybutylene succinate (PBS) production capacities, by country 5.6.8 Bio-based Polylactic acid (PLA) production capacities, by country 5.6.9 Polyhydroxyalkanoates (PHA) production capacities, by country 5.6.10 Starch blends production capacities, by country 5.7 SYNTHETIC BIO-BASED POLYMERS 5.7.1 Polylactic acid (Bio-PLA) 5.7.1.1 Market analysis 5.7.1.2 Producers 5.7.2 Polyethylene terephthalate (Bio-PET) 5.7.2.1 Market analysis 5.7.2.2 Producers 5.7.3 Polytrimethylene terephthalate (Bio-PTT) 5.7.3.1 Market analysis 5.7.3.2 Producers 5.7.4 Polyethylene furanoate (Bio-PEF) 5.7.4.1 Market analysis 5.7.4.2 Comparative properties to PET 5.7.4.3 Producers 5.7.5 Polyamides (Bio-PA) 5.7.5.1 Market analysis 5.7.5.2 Producers 5.7.6 Poly(butylene adipate-co-terephthalate) (Bio-PBAT) 5.7.6.1 Market analysis 5.7.6.2 Producers 5.7.7 Polybutylene succinate (PBS) and copolymers 5.7.7.1 Market analysis 5.7.7.2 Producers 5.7.8 Polyethylene (Bio-PE) 5.7.8.1 Market analysis 5.7.8.2 Producers 5.7.9 Polypropylene (Bio-PP) 5.7.9.1 Market analysis 5.7.9.2 Producers 5.8 NATURAL BIO-BASED POLYMERS 5.8.1 Polyhydroxyalkanoates (PHA) 5.8.1.1 Types 5.8.1.2 Synthesis and production processes 5.8.1.3 Market analysis 5.8.1.4 Commercially available PHAs 5.8.1.5 Markets for PHAs 5.8.1.6 Producers 5.8.2 Polysaccharides 5.8.2.1 Microfibrillated cellulose (MFC) 5.8.2.2 Cellulose nanocrystals 5.8.2.3 Cellulose nanofibers 5.8.2.4 Bacterial Nanocellulose (BNC) 5.8.3 Protein-based bioplastics 5.8.3.1 Types, applications and producers 5.8.4 Algal and fungal 5.8.4.1 Algal 5.8.4.2 Mycelium 5.8.5 Chitosan 5.8.6 Microplastics alternatives 5.9 PRODUCTION OF BIOBASED AND SUSTAINABLE PLASTICS, BY REGION 5.9.1 North America 5.9.2 Europe 5.9.3 Asia-Pacific 5.9.3.1 China 5.9.3.2 Japan 5.9.3.3 Thailand 5.9.3.4 Indonesia 5.9.4 Latin America 5.10 MARKET SEGMENTATION OF BIOPLASTICS 5.10.1 Packaging 5.10.2 Consumer products 5.10.3 Automotive 5.10.4 Building & construction 5.10.5 Textiles 5.10.6 Electronics 5.10.7 Agriculture and horticulture 5.11 BIO-BASED CHEMICALS, BIOPOLYMERS AND BIOPLASTICS COMPANY PROFILES (325 company profiles)

6 NATURAL FIBERS 6.1 Manufacturing method, matrix materials and applications of natural fibers 6.2 Advantages of natural fibers 6.3 Commercially available next-gen natural fiber products 6.4 Market drivers for next-gen natural fibers 6.5 Challenges 6.6 Plants (cellulose, lignocellulose) 6.6.1 Seed fibers 6.6.1.1 Cotton 6.6.1.2 Kapok 6.6.1.3 Luffa 6.6.2 Bast fibers 6.6.2.1 Jute 6.6.2.2 Hemp 6.6.2.3 Flax 6.6.2.4 Ramie 6.6.2.5 Kenaf 6.6.3 Leaf fibers 6.6.3.1 Sisal 6.6.3.2 Abaca 6.6.4 Fruit fibers 6.6.4.1 Coir 6.6.4.2 Banana 6.6.4.3 Pineapple 6.6.5 Stalk fibers from agricultural residues 6.6.5.1 Rice fiber 6.6.5.2 Corn 6.6.6 Cane, grasses and reed 6.6.6.1 Switch grass 6.6.6.2 Sugarcane (agricultural residues) 6.6.6.3 Bamboo 6.6.6.4 Fresh grass (green biorefinery) 6.6.7 Modified natural polymers 6.6.7.1 Mycelium 6.6.7.2 Chitosan 6.6.7.3 Alginate 6.7 Animal (fibrous protein) 6.7.1 Wool 6.7.1.1 Alternative wool materials 6.7.1.2 Producers 6.7.2 Silk fiber 6.7.2.1 Alternative silk materials 6.7.3 Leather 6.7.3.1 Alternative leather materials 6.7.4 Fur 6.7.4.1 Producers 6.7.5 Down 6.7.5.1 Alternative down materials 6.8 MARKETS FOR NATURAL FIBERS 6.8.1 Composites 6.8.2 Applications 6.8.3 Natural fiber injection moulding compounds 6.8.3.1 Properties 6.8.3.2 Applications 6.8.4 Non-woven natural fiber mat composites 6.8.4.1 Automotive 6.8.4.2 Applications 6.8.5 Aligned natural fiber-reinforced composites 6.8.6 Natural fiber biobased polymer compounds 6.8.7 Natural fiber biobased polymer non-woven mats 6.8.7.1 Flax 6.8.7.2 Kenaf 6.8.8 Natural fiber thermoset bioresin composites 6.8.9 Aerospace 6.8.9.1 Market overview 6.8.10 Automotive 6.8.10.1 Market overview 6.8.10.2 Applications of natural fibers 6.8.11 Building/construction 6.8.11.1 Market overview 6.8.11.2 Applications of natural fibers 6.8.12 Sports and leisure 6.8.12.1 Market overview 6.8.13 Textiles 6.8.13.1 Market overview 6.8.13.2 Consumer apparel 6.8.13.3 Geotextiles 6.8.14 Packaging 6.8.14.1 Market overview 6.9 NATURAL FIBERS GLOBAL PRODUCTION 6.9.1 Overall global fibers market 6.9.2 Plant-based fiber production 6.9.3 Animal-based natural fiber production 6.10 NATURAL FIBER COMPANY PROFILES (178 company profiles)

7 LIGNIN 7.1 INTRODUCTION 7.2 LIGNIN PRODUCTON PROCESSES 7.3 MARKETS FOR LIGNIN 7.4 COMPANY PROFILES (75 company profiles)

8 BIOBASED AND RENEWABLE FUELS 8.1 BIOFUELS 8.2 ELECTROFUELS (E-FUELS) 8.3 GREEN AMMONIA 8.4 COMPANY PROFILES (114 company profiles)

9 BIO-BASED PAINTS AND COATINGS 9.1 The global paints and coatings market 9.2 Bio-based paints and coatings 9.3 Challenges using bio-based paints and coatings 9.4 Types of bio-based coatings and materials 9.5 Market for bio-based paints and coatings 9.6 Company profiles (130 company profiles)

10 REFERENCES

For more information about this report visit https://www.researchandmarkets.com/r/dbzix6

CONTACT: CONTACT: ResearchAndMarkets.com Laura Wood,Senior Press Manager [email protected] For E.S.T Office Hours Call 1-917-300-0470 For U.S./ CAN Toll Free Call 1-800-526-8630 For GMT Office Hours Call +353-1-416-8900

0 notes

Text

Solvent Naphtha Market size, industry outlook and forecast for 2028

The global “Solvent Naphtha Market” report 2022 highlights all of the dynamic elements affecting key growth factors, as well as the most recent trends and developments in the global industry. It gives a complete understanding of key manufacturers’ business development plans, current industry condition, growth areas, and future scope. The Solvent Naphtha market research seeks to give regional development, market driving factors, and sales revenue. With numerous research approaches such as SWOT and PESTLE analysis, it provides extensive research and analysis of key elements and emphasizes current market circumstances. In addition, the study contains valuable information on global players’ future plans and possibilities.

Enquire before purchasing this report

In accordance with the Solvent Naphtha market is set to grow at a CAGR of 3.95% over a forecast period (2022-2028).

#Solvent Naphtha Market Analysis#Solvent Naphtha Market Research#Solvent Naphtha Market Size#Solvent Naphtha Market share

0 notes

Link

0 notes