#Solar Frequency Inverters

Explore tagged Tumblr posts

Text

How To Choose The Right Inverter?

How to choose the right inverter? We believe that many customers do not know this very well. If you are struggling with how to choose the right inverter, then you are in the right place.This article will help you analyze from the following dimensions, so that you can understand how to choose the right inverter.

1. How many types of inverters in the market?

2. How to choose the correct power of the solar inverter?

Next time, please follow us, we will help you how to choose the right solar inverter.

First, let's look at the first question.

1. How many types of inverters in the market?

In the solar market, inverters are generally divided into two types, low frequency inverters and high frequency inverters.

So what is low frequency inverter and high frequency inverter? What is the difference between the them?

1)From the perspective of the transformer.

The low frequency inverter has a large, heavy transformer, which is toroidal and square(EI)transformer respectively. The transformer of the high-frequency inverter is very light.

Therefore, we can also see that when we usually browse the inverter from the shops, we will find that the power is the same, but the weight is very different.

Although square transformers and toroidal transformers are heavy, they have strong impact resistance and stable performance, and can carry more impact loads, such as motors that often need to be started. It is also because of this that the stability of the low frequency inverter is far superior to the high frequency, and the lifespan is longer. Generally speaking, the lifespan of low frequency inverter is about 5-7 years,even can be used longer if it is properly maintained; while the stability of high-frequency one is poor, and its lifespan is generally only about 3-5 years.

2)From the perspective of efficiency.

The inverter efficiency of the high-frequency is higher than low frequency inverter. Generally, the inverter efficiency of low frequency is more than 85%, while the high-frequency can reach more than 95%.

In addition, the mains charging current of the high-frequency inverter is much larger than low frequency machine.

In the market, the mains charging current of low frequency inverter can only reach maximum of about 40A, while the high-frequency can reach 80A. That is to say, the high-frequency inverter can fully charge the battery quickly, and the time spent is more than half that of the low frequency inverter. Therefore, the high-frequency inverter is also very suitable for those residents who live in short supply and unstable electricity.

3)In terms of price.

High frequency machines are cheaper than low frequency machines.

4)From the perspective of development history

Low frequency inverters appeared earlier than high-frequency inverters, have a longer history, and are more mature and stable in technology; most of the high-frequency inverters currently on the market still exist lots of technical issues, which also take more time to develop.

The above is the mainly point of different between low frequency inverter and high frequency inverter.

But here comes the problem, which type should I choose?

Well, the following are some recommendations based on our experience in the industry and from the perspective of consumers:

Firstly, if you want to find better quality and more durable inverter, then the low frequency inverter is the first choice;

Secondly, if you have a lot of inductive loads and high-power loads, such as motors, air conditioners, etc., then the low frequency inverter is the first choice.

Thirdly, if you live in an area with unstable mains, and the average power supply time is only 3-4 hours a day, you can choose high-frequency inverter. As mentioned above, the mains charging current of the high-frequency machine is very big, and it can quickly full charge the battery in a short time.

Finally,if your budget is limited, you can choose high-frequency inverter.

The above suggestions are for reference only, and you need to combine your own various requirements.

After understanding the types of inverters, the next step is the most important.

There are many power for the solar inverter, so how to choose the one that suits you? Following this question and then you will get it.

2. How to choose the correct power of the solar inverter?

Before answering this question, we need to bring up a concept here,inductive load.

What is Inductive load?

Well, When the load current lags behind the load voltage by phase difference compared with the power supply, the load is inductive. The popular understanding is that the machine will shake the load when it is started.

The inductive loads that we often use in our daily life are:

Electric, pumps (water pumps, heat pumps, etc.), air conditioners, refrigerators, washing machines, microwave ovens, electric fans, etc.

When choosing the power of the inverter, we need to abide by a rule: the power of the inverter must be greater than the total power of all loads;

Generally speaking, the instantaneous power of an inductive load at startup will be more than three times the rated power. Therefore, when calculating the power of an inductive load, we need to consider the instantaneous power at startup, which is usually calculated as three times the rated power.

For loads other than inductive loads, usually only their rated power needs to be considered.

Here is a simple example to help you understand:

Load situation:

1pcs air conditioner 1.5HP=1125WKW

1pcs refrigerator 200W

1pcs electric fan 60W

1pcs rice cooker 500W

4pcs bulbs 35W

As be said above, air conditioners, refrigerators and electric fans are all inductive loads. So, First, when considering to start all of these inductive loads at the same time,

The total power of the inductive load is:

(1125+200+60)*3=4155W

Other loads: 500+35=535W

Total load power:

4155+535=4690W

Therefore, the power of the inverter needs to be greater than 4690W, and it is recommended to choose 5KW.

Secondly, when the inductive loads are not started at the same time, such as when only the air conditioner is started.

The total power load is:

1125*3+200+60+500+35=4170W, optional 4.5KW

From this example, we can see that the power of the inverter depends not only on the power of the loads we use, but also on how to use these loads. It is a more cost-effective way to use peak shifting, because some loads we do not used often, such as a washing machine.

From the above, have you get the idea how to choose the right solar inverter?

If you still have some question, just feel free to contact us!

0 notes

Text

A massive power outage hit Spain, Portugal, France and Belgium, triggered by the abrupt failure of solar facilities in Spain—where renewables supply 75% of electricity. The collapse exposed systemic grid vulnerabilities tied to unreliable solar and wind energy.

The outage began when two Spanish solar plants disconnected simultaneously, causing a rapid drop in renewable output (from 66% to 20% capacity). Gas and coal backups were insufficient, leading to 60% power loss in Spain and disruptions across Europe.

Solar and wind lack "synchrophasor inertia," a stabilizing feature of traditional power sources. During the crisis, solar inverters shut off as grid frequency neared collapse (49.85 Hz, just 0.15 Hz above the threshold for total blackout), worsening the imbalance.

Experts criticized aggressive green mandates for ignoring reliability risks. Europe’s nuclear phaseouts (e.g., Germany closing reactors) left grids dependent on unstable renewables. Calls grew for nuclear power as a stable, low-carbon baseload alternative.

The outage underscored the dangers of rapid decarbonization without backup systems. Policymakers must prioritize grid modernization, energy storage and diversified sources (including nuclear and fossil fuels) to prevent future crises.

10 notes

·

View notes

Text

From Smartphones to EVs: How the Capacitors Market Is Powering Innovation

Introduction:

The global capacitors market is undergoing a fundamental transformation, driven by the rise of intelligent electronic systems, energy-efficient solutions, and widespread electrification across industrial sectors. As of 2024, the capacitors market is demonstrating consistent and aggressive growth, with forecasts projecting it will exceed USD 47.3 billion by 2032, propelled by a compound annual growth rate (CAGR) of 6.7%. This momentum is attributed to exponential demand in electric vehicles (EVs), renewable energy, consumer electronics, and industrial automation.

Capacitors have become indispensable across sectors, evolving from simple energy storage components to sophisticated modules that ensure voltage stability, signal integrity, and energy efficiency. Emerging economies are fueling demand through infrastructure modernization and industrial digitization, while developed markets are prioritizing high-performance capacitor solutions aligned with environmental regulations and decarbonization goals.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40592-capacitors-market-analysis

Evolution in Capacitor Types: Ceramic and Supercapacitors Leading Innovation

Ceramic Capacitors Dominating Market Penetration

With their compact size, cost-efficiency, and high-frequency performance, ceramic capacitors are expected to retain the lion’s share of the capacitors market—projected at over 36.4% by 2032. Multi-layer ceramic capacitors (MLCCs) are increasingly favored due to their ability to offer high capacitance in a miniaturized format, especially relevant for 5G devices, IoT modules, and advanced driver-assistance systems (ADAS).

Supercapacitors Revolutionizing Energy Storage

Electric double-layer capacitors (EDLCs) and hybrid supercapacitors are transforming grid storage and transport electrification. Offering ultra-fast charge/discharge cycles and durability far beyond lithium-ion counterparts, supercapacitors are finding increasing use in regenerative braking systems, portable medical devices, and smart grids.

Film capacitors remain essential in high-frequency, high-voltage environments, particularly within renewable inverters and EV drivetrains, whereas electrolytic capacitors retain their stronghold in power supplies, audio systems, and consumer-grade electronics.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40592-capacitors-market-analysis

Material Trends: Inorganic Dielectrics Setting Industry Standards

Capacitor performance is intricately tied to dielectric material innovations. Inorganic dielectrics, such as ceramic, mica, and glass, are poised to dominate due to their thermal resilience, chemical stability, and dielectric strength. By 2032, these materials are expected to constitute 43.7% of the market share.

Organic dielectrics continue to be relevant for applications where low cost and moderate thermal tolerance are acceptable, particularly in consumer-grade circuits and compact electronic boards.

Voltage Segmentation: High Voltage Capacitors Fueling Renewable and Industrial Adoption

The high voltage capacitor segment is experiencing the fastest expansion, with a forecasted CAGR of 6.9%. These components are essential in:

HVDC transmission systems

Wind and solar inverters

EV powertrains and fast-charging stations

Grid stabilization and harmonic filtering

This growth is reinforced by global investments in clean energy, modernization of transmission infrastructure, and decarbonization initiatives requiring scalable and resilient capacitor technologies.

Strategic Industry Applications

Consumer Electronics: Miniaturization and Efficiency

Capacitors in smartphones, wearables, AR/VR devices, and smart appliances demand compactness, reliability, and precision. Increasing integration of AI and 5G in devices is accelerating the need for MLCCs that provide high capacitance in tight form factors.

Automotive: Electrification Demands Capacitor Innovation

As EV sales climb globally, capacitors are integral to battery management systems, onboard chargers, and regenerative braking units. High-temperature, vibration-resistant capacitors are critical for vehicle reliability and performance.

Renewable Energy: Enabling Grid-Level Storage

Capacitors stabilize power output and ensure energy smoothing in solar PV arrays and wind farms. Their role in microgrids and hybrid storage systems is pivotal to managing energy intermittency and supporting real-time load balancing.

Industrial and Power Infrastructure

Capacitors are fundamental in automation, robotics, smart factories, and industrial-grade UPS systems, where precise voltage regulation and high reliability are critical.

Regional Insights: Capacitors Market Dynamics by Geography

Asia-Pacific: The Global Growth Engine

Asia-Pacific commands over 42% of the global market, led by manufacturing powerhouses such as China, Japan, South Korea, and Taiwan. Government subsidies for EVs, robust semiconductor ecosystems, and infrastructure investments in countries like India are fortifying the region's dominance.

North America and Europe: Technological Leadership

These regions are driving demand for automotive-grade capacitors, military-spec devices, and green energy solutions. Strong emphasis on compliance, performance, and sustainability makes them vital markets for high-value, specialized capacitor products.

Latin America, Middle East & Africa: Emerging Opportunities

While infrastructure challenges persist, increasing adoption of smart grid technologies, consumer electronics, and industrial automation present untapped growth opportunities in these regions.

Competitive Landscape: Strategic Consolidation and Innovation

Major capacitors market players are aggressively pursuing mergers, acquisitions, and partnerships to consolidate market share and expand technological capabilities. Key developments include:

Murata Manufacturing expanding into high-performance capacitor segments via acquisition.

TDK Corporation investing in automotive-grade high-voltage ceramic capacitors for EV systems.

Samsung Electro-Mechanics focusing on ultra-miniaturized MLCCs for smartphones and wearables.

KEMET innovating in tantalum and polymer hybrid capacitors with high ripple current ratings.

Strategic Focus Areas for Market Leaders:

Advanced dielectric material research

AI-enabled quality assurance systems

Vertical integration in capacitor manufacturing

Eco-friendly manufacturing practices

Expansion of production capacity in emerging regions

Capacitors Market Challenges and Mitigation Strategies:

Regulatory Compliance and Environmental Standards

Stricter regulations on lead content, PCB emissions, and end-of-life recycling are pushing manufacturers to adopt sustainable materials and green production processes.

Counterfeit Products and Quality Assurance

Rising counterfeit capacitor components threaten OEMs. Implementing blockchain-based traceability, laser etching authentication, and AI-driven quality inspection are essential measures to preserve supply chain integrity.

Supply Chain and Raw Material Volatility

Disruptions in rare earth supply chains, especially tantalum and nickel, can jeopardize production timelines. Strategic sourcing, stockpiling, and alternative material development are key hedging strategies.

Future Outlook: Capacitors market Beyond 2030

The capacitors market is set to evolve into a cornerstone of the next-generation digital and green economy. Key transformational trends include:

Quantum computing and edge AI demanding ultra-high frequency capacitors

Flexible electronics integrating printed capacitors on wearable textiles

Energy harvesting systems using micro-supercapacitors in IoT nodes

Next-gen EV platforms requiring ultracompact, ultra-stable capacitors for fast switching

The convergence of miniaturization, sustainability, and electrification will continue to redefine product innovation and market dynamics well into the next decade.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40592-capacitors-market-analysis

Conclusion

Capacitors are no longer passive components—they are strategic enablers of technological evolution across energy, mobility, and digital infrastructure. Companies that prioritize innovation, scalability, and regulatory readiness will emerge as market leaders in an industry poised for transformational growth. By aligning product development with global megatrends, the capacitors market will continue its upward trajectory and deliver solutions that power the intelligent, electrified, and sustainable world of tomorrow.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

We have pointed out in the past that distributed generation leaves a power grid vulnerable to a variety of disruptions that are much less of a problem in central-station systems. But sophisticated networked inverters on home solar systems, required to allow the central authority to curtail inflow in case of overvoltage in the local substation, frequency imbalance, or other disturbance conditions, introduce even further new vulnerabilities.

2 notes

·

View notes

Text

🌟 🪷 New Moon Cancer🪷🌟

✨️Sirius Solar Alignment✨️

🌟Sirius is the brightest star in our night sky. Its appearance and alignment in early July of each year marks the beginning of the Galactic New Year and also connection to our spiritual sun. There are many Sirian star seeds on this Earth, as Sirius is one of the ancient star systems that is closest to us. They, like Pleaides and Andromeda, are like our spiritual older siblings. Their systems have gone through the collective shifts and spiritual awakening already. They are cheering us on from their Golden Ages as we progress towards ours.

☀️Use the sun portal during this time to clear and communicate with our highly evolved extended galactic family. The suns codes are extremely powerful and clear during this alignment.

🪷Breathe in and out from your heart portal and imagine that your heart is a direct link to the sun which is directly linked to the galactic center. The galactic center holds the information and upgrade frequency from all surrounding star systems.

🪷As we link our hearts with the sun, we activate and spin our merkaba. This radiates and enlightens our aura so we can see with more clarity. Once we can clearly see what is in and around our field, we can initiate proper transmutation. We can clear our subconscious and unite light with dark. We can unite and clear ourselves back into whole beings.

🌟With our spinning Merkaba, we lift up and off the false inverted grid imposed upon us by those who wish to harvest our energy. We become a self generated power source, and rebuild an ascended grid with self sufficient energy.🌟

The more of us that unplug from the inverted grid - the weaker the system gets and the more we get our power back. The inverted system collapses and we rebuild a new system with our collective power.

5 notes

·

View notes

Text

It doesn't even necessarily increase the frequency but it makes it very unstable since the inverters on home solar panels are not nearly as accurate or reliable as a large installation or a power plant -- they might not even have their own timing, they might try to sync to the signal from the grid -- over a large area this adds up and can be disastrous

73K notes

·

View notes

Text

How much electricity does a laundry machine use?

A standard washing machine typically uses between 0.3 to 2 kilowatt-hours (kWh) per load, depending on the model, water temperature, and cycle type. In Aussie terms, that’s roughly 10 to 60 cents per wash, based on an average electricity rate of 30c/kWh.

But the real energy hog? Hot water.

Heating the water can account for up to 90% of a washing machine’s total energy usage. Switching to cold or eco-mode washes slashes electricity use dramatically. If you’re using a front-loader with cold water, you’re likely consuming just 0.3–0.5kWh per cycle—barely enough to toast a few slices of bread.

Is an older washing machine more expensive to run?

Absolutely. Older top-loaders (especially those pre-2000) can chew through up to twice as much energy and water as newer front-loaders. These machines often lack energy-efficient motors and advanced cycle control, meaning longer, hotter washes.

On the flip side, modern front-loaders with high energy star ratings are designed to be stingy with both power and water. Brands now boast about “half-wash” modes, fuzzy logic sensors, and inverter motors that save energy without skimping on clean.

If your machine sounds like a jet taking off, it might be time for an upgrade—or at least a power audit.

Does load size or frequency affect electricity use?

Short answer: yes. But the details matter.

Overloading the drum strains the motor and leads to longer wash times or inefficient rinses.

Underloading means you’re running a full cycle for half the laundry—wasting power.

Frequent small washes (hello, gym gear and baby clothes) can add up, even if each load feels “tiny.”

A good rule of thumb? Wash full loads on eco or cold cycles whenever possible. And don’t forget: your dryer uses 2–3 times more electricity than your washer. Air-drying isn’t just quaint—it’s economically brilliant.

How does laundry machine rental affect energy costs?

This one’s a bit of a curveball—but it’s catching on, especially in urban Australia.

Renting a laundry machine, rather than buying outright, often means getting access to newer, more efficient models without the upfront cost. These machines usually come with top-tier energy ratings, smart sensors, and modern load-balancing tech.

You won’t just save on electricity—there’s a water savings bonus, too. And because rental companies regularly maintain their units, you’re far less likely to suffer through inefficient cycles caused by worn-out parts or dodgy settings.

We’ve even seen cases where families saved up to $150 a year in energy costs simply by switching to a newer rented unit instead of running their old top-loader into the ground.

How can you reduce your washing machine’s electricity use?

Here are a few real-world strategies that don’t require a lifestyle overhaul:

Wash in cold water (unless you’ve got heavy stains or illness concerns)

Use eco modes – they take longer, but use far less energy

Run full loads to maximise energy per kilo of laundry

Clean your machine (especially the lint filter and drum) to keep it running efficiently

Use shorter cycles when clothes aren’t heavily soiled

And if you're using solar panels, consider setting your machine to run mid-morning when solar production peaks.

Are there other costs tied to energy use?

Yep—it's not just about kilowatt-hours. Laundry machines that run inefficiently may also:

Increase water heating bills, if using a shared hot water system

Accelerate wear and tear on electrical circuits in older homes

Raise cooling costs in summer if the dryer’s pushing hot air into the space

So the machine you use—and how you use it—can have ripple effects well beyond your laundry room.

FAQ

Q: Do dryers use more power than washers? Yes. Most dryers use 2–4kWh per load, which can cost 60 cents to over $1.20 each time—double or triple the average washer.

Q: Is cold water as effective for cleaning? In most cases, yes. Modern detergents are designed for cold water. Unless you're dealing with oily stains or illness, cold washes are more energy-efficient and easier on fabrics.

Q: Can I run a washer on solar power? If you’ve got solar panels, absolutely. Run your wash during the day (ideally between 10am–2pm) to take full advantage of solar production and minimise grid usage.

There’s a quiet satisfaction in knowing your laundry isn’t stealthily blowing up your power bill. Most people overestimate the cost per wash and underestimate the impact of small, savvy changes. For many, switching to a rented, energy-efficient unit is the missing link between convenience and cost-saving.

One good example of this approach comes from this deep dive into laundry machine rental—which outlines how smart renters are side-stepping high upfront costs while keeping their energy bills in check.

Who knew clean socks could feel this strategic?

0 notes

Text

What Are Optocouplers, and How Can They Elevate Your Electronics Design?

Introduction to Optocouplers: The Essential Isolation Component

Optocouplers, commonly known as opto-isolators, are ingenious electronic devices designed to safely transfer signals between isolated circuits using light. These components protect sensitive electronic systems from high voltage, noise interference, and potential circuit failures, significantly improving reliability and performance.

Optocouplers primarily consist of:

Infrared LED (Emitter): Converts electrical signals into light.

Photodetector (Receiver): Converts received light back into electrical signals.

By providing electrical isolation, optocouplers safeguard delicate circuits, ensuring stable and safe operation.

How Do Optocouplers Function in Electronic Systems?

Understanding the working principle of optocouplers is crucial for their effective implementation. Their operation follows these simple steps:

An electrical input signal activates the internal LED.

The LED emits infrared light proportional to the input current.

The photodetector receives this infrared signal.

The detector converts the optical signal back into electrical output.

This method ensures that circuits on either side remain electrically isolated, reducing the risk of damage from voltage spikes and interference.

Why Use Optocouplers in Electronic Designs?

Optocouplers offer substantial benefits that enhance the performance, safety, and efficiency of electronic systems. Key reasons to choose optocouplers include:

High Voltage Protection: Optocouplers prevent voltage surges from reaching sensitive circuit components.

Noise Reduction: They effectively minimize electromagnetic interference, preserving signal integrity.

Safety Assurance: Provide critical isolation to protect equipment and operators from electrical hazards.

Increased Reliability: Ensure stable and consistent signal transmission under varying operating conditions.

Different Types of Optocouplers Available Today

Multiple varieties of optocouplers exist to cater to specific electronic applications. Familiarizing yourself with these categories can simplify the selection process:

Transistor Optocouplers:

Commonly used in general-purpose isolation applications.

Ideal for moderate-speed signal transmissions.

Darlington Optocouplers:

Utilize a Darlington transistor configuration for higher sensitivity.

Suitable for applications needing higher current gain and lower input current.

Triac Optocouplers:

Primarily used for switching and controlling AC loads.

Common in motor control, lighting dimmers, and AC-powered circuits.

High-Speed Optocouplers:

Engineered for rapid communication and digital interfacing.

Critical for high-frequency data transmissions and real-time control systems.

Practical Applications: Where Optocouplers Shine

Optocouplers are versatile devices extensively employed across diverse industries. Some prominent applications include:

Industrial Automation:

Programmable Logic Controllers (PLCs)

Robotic arms and automated machinery

Motor drives and motion controllers

Power Electronics:

Power supplies and battery chargers

High-voltage DC/AC converters

Solar inverters and renewable energy systems

Telecommunications and Networking:

Modems and routers

Telephone line isolation

Ethernet communication equipment

Medical Equipment:

Patient monitoring devices

Diagnostic imaging equipment

Laboratory instrumentation

Selecting the Best Optocoupler for Your Electronics Project

Picking the appropriate optocoupler can significantly impact your circuit’s reliability and efficiency. Essential considerations include:

Isolation Voltage: Choose devices with isolation ratings higher than the expected peak voltage.

Current Transfer Ratio (CTR): Opt for higher CTR values for better sensitivity and signal reliability.

Propagation Delay: Critical in digital communication; select fast optocouplers for high-speed data transmission.

Temperature Ratings: Ensure devices can withstand your application's thermal environment.

Best Practices for Effective Optocoupler Implementation

Proper use and installation of optocouplers can maximize their effectiveness. Here’s how you can optimize their performance:

Precisely regulate LED currents to ensure optimal light emission without excessive power dissipation.

Avoid excessive loads on photodetectors, ensuring consistent and stable operation.

Maintain short and isolated signal paths to minimize signal loss and interference.

Conduct periodic performance assessments, especially isolation resistance checks, to maintain reliability.

Current Innovations Shaping Optocoupler Technology

Continuous technological advancements enhance the performance and application potential of optocouplers. Notable trends include:

Ultra-Compact Designs: Optocouplers are increasingly miniaturized, fitting smaller, modern electronic devices.

Enhanced Speed and Bandwidth: Innovations focus on high-speed optocouplers for rapid data transmission and communication.

Energy Efficiency: New-generation optocouplers emphasize reduced power consumption, essential for battery-operated devices.

Integration in IoT and Smart Technologies: Optocouplers are integral to smart home devices, connected appliances, and IoT-based systems for reliable communication.

Overcoming Common Optocoupler Challenges

While optocouplers offer extensive benefits, users can occasionally face challenges. Here’s how to address common issues:

Signal Attenuation: Select devices with higher CTR and carefully design circuits to maintain signal integrity.

Temperature Variations: Opt for optocouplers with broad operating temperature ranges and use thermal management techniques.

Cost and Performance Balance: Analyze device specifications and choose options providing optimal balance between performance and budget.

Tips for Enhancing the Lifespan of Optocouplers

Maintaining optocouplers ensures their longevity and reliability in your electronic projects. Follow these maintenance guidelines:

Regularly inspect circuits for signs of overheating, wear, or abnormal signal behaviors.

Replace worn or damaged optocouplers promptly to avoid system downtime or circuit failures.

Adhere strictly to manufacturer recommendations regarding voltage and current limits to avoid premature degradation.

Conclusion: Why Optocouplers are Indispensable in Electronics

Optocouplers play a critical role in ensuring safe, efficient, and reliable electronic circuit operation. Their exceptional ability to isolate signals, reduce interference, and enhance circuit safety makes them indispensable across industrial, commercial, and consumer electronic applications. By carefully selecting appropriate optocouplers, adhering to implementation best practices, and keeping pace with technological advancements, you can significantly elevate your electronics designs, guaranteeing optimal performance, safety, and efficiency in your projects.

0 notes

Text

The Complete Guide to Pool Pumps and Heat Pumps in Dubai

Owning a swimming pool in Dubai is a dream for many, but maintaining one is a responsibility. Whether it’s draining excess water after a heavy rain or keeping the pool water at a pleasant temperature year-round, having the right equipment is crucial. A reliable submersible pump for pool draining, an efficient swimming pool heat pump, and a well-functioning swimming pool pump dubai are essential tools every pool owner must invest in.

In this guide, we’ll explore how to choose the right pool pumps, compare options, discuss their importance, and provide insights into the current water pump price dubai to help you make informed decisions for your pool with support from Aquasplash.

Why Pool Pumps Matter for Efficient Pool Management

A swimming pool pump dubai is the heart of your pool system. It keeps the water clean and circulating, ensuring chemicals are evenly distributed, debris is filtered out, and the water stays safe for swimmers.

There are generally two types of pumps pool owners should be aware of:

Filtration Pump (Main Pool Pump)

Submersible Pump (Drainage Pump)

While filtration pumps run daily as part of regular maintenance, a submersible pump for pool draining is used when there’s a need to remove excess water due to cleaning, draining for repairs, or during rainy seasons in Dubai.

Choosing the Right Submersible Pump for Pool Draining

A submersible pump for pool draining is designed to be submerged directly into the water. It is ideal for:

Quickly removing water from the pool

Handling accidental overflows

Draining pools during maintenance

When selecting a submersible pump, consider the following factors:

Pump capacity (liters per minute/hour)

Power source (electric, battery)

Durability in chlorinated water

Float switch (automatic shut-off)

At Aquasplash, you’ll find a wide range of submersible pumps suited to different pool sizes and budgets. These pumps are compact, lightweight, and easy to store—making them a practical tool for every pool owner.

Understanding Swimming Pool Heat Pumps in Dubai

In Dubai’s cooler months, pool water can drop below comfortable levels. That’s where a swimming pool heat pump comes in. Unlike gas or electric resistance heaters, swimming pool heat pumps use the ambient air to heat the water, making them energy-efficient and ideal for the region’s climate.

Benefits of using a swimming pool heat pump:

Energy Efficiency: Uses less power by transferring heat from the air.

Environmentally Friendly: Emits fewer greenhouse gases.

Long-Term Savings: Though the upfront cost is higher, monthly operating costs are significantly lower.

Quiet Operation: Modern units run with minimal noise.

Aquasplash offers models designed to suit villas, residential complexes, and commercial properties. These units can operate even in Dubai’s fluctuating winter temperatures.

How to Choose Between Swimming Pool Heat Pumps

There are several types of swimming pool heat pumps available, such as:

Air-source heat pumps

Inverter heat pumps (energy-saving, smart control)

Hybrid systems (integrated with solar)

When choosing the right one, consider:

Pool volume

Desired temperature range

Usage frequency

Energy efficiency ratings

Warranty and after-sales service

At Aquasplash, experts guide clients through model selection, installation, and regular servicing to ensure optimal performance.

Comparing Water Pump Price in Dubai

The water pump price dubai depends on several factors:

Pump Type: Submersible, centrifugal, or booster.

Brand: Reputed international brands cost more but last longer.

Capacity: Higher capacity means higher price.

Material: Stainless steel pumps cost more but resist corrosion better.

On average:

A basic submersible pump for pool draining ranges from AED 300–700.

Standard swimming pool pump dubai prices range between AED 900–2,500.

A high-performance swimming pool heat pump can range from AED 4,500 to over AED 12,000 depending on specifications.

Aquasplash ensures competitive prices with genuine manufacturer warranties, local support, and expert installation—all of which help clients avoid hidden costs and frequent replacements.

Maintenance Tips for Long-Term Efficiency

Whether you own a swimming pool heat pump or use a submersible pump for pool draining, proper maintenance is key. Here are a few tips:

For Pool Heat Pumps:

Clean air filters regularly.

Ensure the area around the unit is free from obstructions.

Schedule yearly inspections with Aquasplash experts.

For Submersible Pumps:

Rinse and dry after every use to prevent mineral buildup.

Store in a cool, dry place.

Periodically check the impeller and wiring for wear.

These practices will extend the life of your investment and prevent unexpected breakdowns.

Why Choose Aquasplash for Your Pool Equipment?

Aquasplash is a trusted name in the UAE’s pool solutions industry. Known for quality products, expert advice, and dedicated service, Aquasplash stands out in the crowded market.

Here’s what makes Aquasplash the preferred choice:

Extensive range of swimming pool pump dubai options.

Competitive water pump price dubai.

Professional installation and post-sale service.

Genuine products with warranty.

Technicians trained for every pool type—residential or commercial.

Whether you need a heavy-duty submersible pump for pool draining or a high-end swimming pool heat pump, Aquasplash has a solution tailored to your pool and budget.

Make the Smart Move for Your Pool’s Performance

A clean, warm, and well-maintained pool enhances your comfort, your property value, and your lifestyle. With the right equipment—from a swimming pool pump dubai to a powerful swimming pool heat pump—you’ll save time, energy, and money.

For those facing seasonal challenges or simply wanting hassle-free pool care, investing in the best equipment makes a real difference. Aquasplash makes this easier with a reliable range of pool pumps, expert support, and competitive water pump price dubai options.

Ready to upgrade your pool experience? Contact Aquasplash today for the best selection of pumps and personalized support across the UAE.

#swimming pool pump#swimming pool pump uae#swimming pool pump dubai#swimming pool pump online#swimming pool pumps

0 notes

Text

Soft Ferrite Material Market Growth

According to latest market research, the global Soft Ferrite Material market was valued at US$ 1996.94 million in 2023 and is projected to reach US$ 2,408.99 million by 2030, growing at a Compound Annual Growth Rate (CAGR) of 2.93% during the forecast period (2024-2030). The market growth is driven by increasing demand from consumer electronics, automotive, and renewable energy sectors.

Get Full Report Here: Soft Ferrite Material Market - Detailed Research Report

What are Soft Ferrite Materials?

Soft ferrite materials are ceramic magnetic compounds composed primarily of iron oxide blended with metal oxides like manganese, nickel, or zinc. Their key advantage lies in the low coercivity that allows easy magnetization and demagnetization with minimal energy loss. These properties make them ideal for high-frequency applications in transformers, inductors, and electromagnetic interference filters across multiple industries.

Key Market Drivers

1. Expansion of 5G and IoT Infrastructure

The global rollout of 5G networks has significantly boosted demand for soft ferrite cores in base stations and communication equipment. Industry reports indicate that 5G infrastructure investments will grow at 65% CAGR through 2025, directly impacting ferrite material consumption. Additionally, the proliferation of IoT devices – projected to exceed 29 billion by 2030 – requires compact ferrite components for signal processing and power management.

2. Electric Vehicle Revolution

EV manufacturers are increasingly adopting soft ferrites for power conversion systems and charging infrastructure. With global EV sales expected to reach 45 million units annually by 2030, ferrite demand in automotive applications could grow 4-5 times current levels. Leading automakers are specifically seeking high-temperature resistant ferrite formulations for next-generation powertrains.

Market Challenges

While prospects appear strong, the industry faces raw material price volatility, particularly for manganese and zinc which have seen 20-30% price swings in recent quarters. Additionally, technical limitations in high-frequency performance (above 1MHz) are pushing some manufacturers toward alternative materials like powdered iron cores. Environmental regulations in major producing nations like China are also adding compliance costs estimated at 8-12% of production expenses.

Emerging Opportunities

The renewable energy sector presents significant growth potential, particularly for grid-scale energy storage systems and solar inverters. Market analysis suggests that ferrite demand from renewable applications could grow at 7.8% CAGR through 2030. Another promising area is medical electronics, where miniaturized ferrite components are enabling advances in diagnostic imaging and therapeutic devices.

Regional Market Insights

Asia-Pacific dominates production and consumption, accounting for 62% of global demand in 2023. China's established supply chain and growing domestic electronics industry continue to drive this regional leadership.

North America shows strong growth in high-value applications, particularly for EV components and military/aerospace systems where performance specifications justify premium pricing.

Europe leads in technical innovation, with companies like FERROXCUBE developing advanced low-loss formulations for industrial automation and smart grid applications.

Competitive Landscape

TDK Corporation maintains market leadership through its extensive portfolio of Mn-Zn and Ni-Zn ferrites for automotive and industrial applications.

DMEGC and KaiYuan Magnetism have gained share through cost-competitive manufacturing and rapid prototyping services for consumer electronics clients.

Strategic acquisitions are reshaping the sector, highlighted by FERROXCUBE's 2023 purchase of several European specialty ferrite producers.

Market Segmentation

By Type:

Manganese-Zinc Ferrite Core

Nickel-Zinc Ferrite Core

Magnesium-Zinc Ferrite Core

Others

By Application:

Communication

Consumer Electronics

Household Appliances

Automotive

New Energy Industry

Others

Report Scope & Offerings

This comprehensive analysis provides:

Market size projections through 2030 with COVID-19 impact analysis

Competitive intelligence on 20+ key players and their market strategies

Technology deep dives into emerging ferrite formulations and applications

SWOT analysis of market drivers, restraints, and opportunities

Get Full Report Here: Soft Ferrite Material Market - Detailed Research Report

Download FREE Sample Report: Soft Ferrite Material Market Sample Report

visit more reports :

About Intel Market Research

Intel Market Research delivers actionable insights in technology and infrastructure markets. Our data-driven analysis leverages:

Real-time infrastructure monitoring

Techno-economic feasibility studies

Competitive intelligence across 100+ countries Trusted by Fortune 500 firms, we empower strategic decisions with precision. International: +1(332) 2424 294 | Asia: +91 9169164321

Website: https://www.intelmarketresearch.com

Follow us on LinkedIn: https://www.linkedin.com/company/intel-market-research

0 notes

Text

How To Choose Inverter For Solar Energy System?

Now more and more people need to buy solar energy system, because solar energy resource can be used locally, and solar energy resource can be collected anywhere, there is no need for long-distance power transmission, and at the same time avoid high energy loss during transmission. Inverter for solar energy systems are also divided into low frequency inverter and high frequency inverter. Today we will share with you how to choose inverter for solar system.

First of all, we need to know what our electrical equipment is and whether there is inductive load. For inductive loads we need to multiply it power by 3 times, while resistive loads do not. Inductive load: induction cooker, electric fan, air conditioner, washing machine, refrigerator, printer, etc. Resistive loads: incandescent lamps, electric ovens, disinfection cabinets, TV sets, lighting lamps, hair dryers, etc.

To sum up, if there are many inductive loads connected to the solar system, we suggest that the inverter choose low frequency inverter. On the contrary, if the electrical equipment connected to the solar system has more resistive loads, we suggest that the inverter choose high-frequency inverter. Of course, if you still don't understand, please contact us to customize the solar system for you.

0 notes

Text

How to Design Solar and On-off-grid Energy Storage Systems?

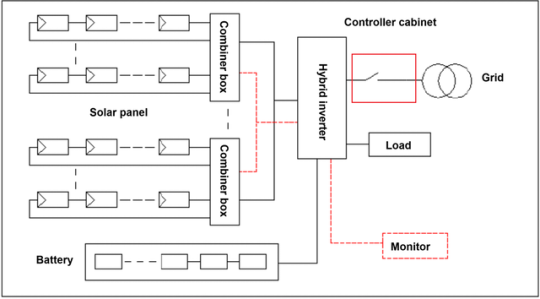

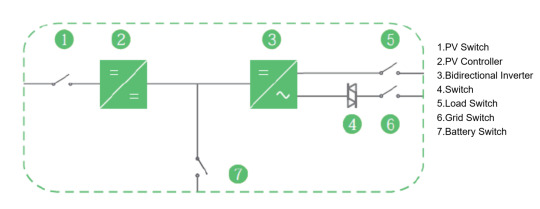

Solar on- off-grid energy storage systems are widely used in factories, commercial facilities and other places with large peak-valley price differences or frequent power outages. The system is composed of photovoltaic arrays made up of solar panels, combiner boxes, hybrid inverters, solar batteries, loads, power grids, etc. PV array converts solar energy into electrical energy under the condition of sunlight, supplies power to the load through a hybrid inverter, and charges the battery pack at the same time. The excess electricity can also be fed into the power grid. When there is no light, the load is powered by the power grid. When the power grid is out of power, the battery supplies power to the load through the hybrid inverter.Visit more

I. Main Components of the System

1.1 Solar panels

It is the main component of the solar power supply system and also the most valuable part in it. Its function is to convert the radiant energy of the sun into direct current electrical energy.

1.2 Hybrid inverter

The main functions are divided into two parts: the MPPT solar controller and the bidirectional DC/AC converter. Their role is to regulate and control the electrical energy generated by the solar panels charge the battery, and provide overcharge protection and overdischarge protection for the battery. At the same time, the direct current from the components and the battery is converted into alternating current for use by AC loads. When appropriate, the power grid can also charge the battery.

1.3 Solar batteries: Its main task is to store energy to ensure the power supply for the load when the power grid is cut off.

2. Main Components

2.1 Solar panels

Solar panels are solar power generation devices that directly convert solar energy into direct current electrical energy. According to the different requirements of users for power and voltage, solar panels can be made for individual use, or several solar panels can be connected in series (to meet voltage requirements) and parallel (to meet current requirements) to form a power supply array to provide greater electrical power. The power generation of solar cells increases proportionally with the increase of sunlight intensity. It slightly decreases as the surface temperature of the component rises. As the temperature changes, the current, voltage and power of the battery components will also change. When designing the components in series, the negative temperature coefficient of the voltage must be taken into consideration.

2.2 Hybrid Inverters

Three-phase solar hybrid inverter integrated machine, adopting the new generation of all-digital control technology, pure sine wave output; The solar controller and inverter are integrated into one, making it convenient to use. It is suitable for areas with power shortages and unstable power grids, providing an economical power supply solution. The product has the following advantages:

(1) Control hybrid inverter: Integrated solar controller and inverter, simple connection, convenient to use;

(2) High efficiency, with an efficiency of over 95%, maximizing the utilization of solar energy.

(3) High reliability: The inverter adopts power frequency design, has strong overload capacity, and is suitable for impact loads such as air conditioners.

(4) Comprehensive protection functions: Battery overcharge and overdischarge protection and advanced battery management functions extend the battery life. Overload protection, short-circuit protection and other functions ensure the safe and reliable operation of equipment and loads.

(5) The LCD liquid crystal screen provides intuitive display: monitoring of multiple working operation status parameters such as photovoltaic input voltage/current, AC output voltage/current, and battery capacity.

(6) The energy storage system is compatible with both lead-acid batteries and lithium batteries, providing users with multiple options.

(7) Various charging methods such as PV charging, mains (generator) charging, and hybrid charging, as well as multiple power supply methods including battery power supply and mains power supply.

(8) It supports multiple inverters running in parallel, making power expansion convenient.

2.3 Solar Batteries

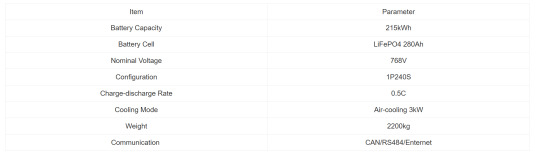

Solar batteries and related devices are an indispensable part of solar generation systems. They are mainly used to store electricity generated by solar energy and provide continuous power to loads at night, when there is insufficient sunlight or in emergencies. Common solar battery technologies include lead-acid batteries, alkaline batteries, supercapacitors and lithium batteries, each with different application ranges. Currently, the most widely used are lithium-ion batteries, especially lithium iron phosphate batteries (LFP), which perform well in solar systems due to their high safety, long life and excellent cycle performance. Since the advent of lithium battery technology in the 1980s, a variety of types have been developed, including ternary lithium, lithium iron phosphate, lithium titanate, etc.In this solution, we choose Brovolt 215 kWh lithium-ion battery cabinet.

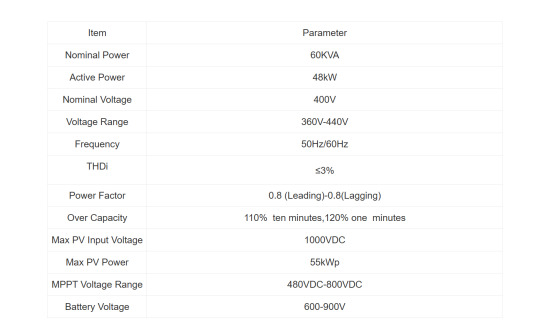

3.Solution design

Solar : monocrystalline 550W, quantity 100 pieces, 20 series and 1 parallel, total power 55kW.

Hybrid inverter: power 48KW

Lithium-ion battery cabinet: 215kWh.

0 notes

Text

Top Practices for Application and Approval in Meeting AEMO GPS Requirements

Australia continues to expand its solar energy capacity, making Generation Performance Standards (GPS) compliance increasingly important. In fact, the Australian Energy Market Operator (AEMO) expects developers to submit technically sound and well-documented GPS applications. However, many proposals face delays or rejections due to incomplete documentation, unclear dynamic modelling, or a lack of early engagement with AEMO.

Fortunately, partnering with specialised engineering firms can help you navigate technical requirements more efficiently and improve the quality of your submission.

The Scope of AEMO GPS Applications

When preparing your GPS application, define the technical performance standards your generating system should meet. If you're developing a solar farm, these include requirements for fault ride-through, frequency response, voltage control, and ramp rates which are specific to inverter-based technologies.

AEMO reviews these standards to confirm that your solar power facility can operate consistently and reliably under varying system conditions. You should also formally register these performance standards as part of the grid connection process.

Engage Early with AEMO and NSPs

It's recommended that you initiate early discussions with AEMO and the relevant network service provider. This early engagement gives you a clear understanding of site-specific technical expectations, grid constraints, and modelling requirements. By addressing issues up front, you can avoid costly redesigns later and improve alignment between stakeholders.

In fact, engineering firms often support these early conversations by providing technical context and translating regulatory language into actionable steps for your team.

Prepare High-Quality Technical Submissions

AEMO places significant importance on the quality and clarity of your technical document. That said, consider submitting validated dynamic models using approved simulation platforms such as PSSE or PSCAD. Also, include system control philosophies and supporting documents that accurately reflect how your asset will behave in the grid.

By working closely with a trusted engineering company, it allows you to avoid inconsistencies in your submission and ensure that all documentation reflects current project specifications.

Address DMAT Requirements

Your simulation models should be proven to represent real-world behaviour accurately. Through Dynamic Model Acceptance Testing (DMAT), you demonstrate that your models perform reliably across various grid conditions. This process is particularly relevant for inverter-based assets like solar farms and battery energy storage systems (BESS).

Typically, engineering firms perform benchmark simulations and use historical data to strengthen the credibility of your model. With a well-executed DMAT, it validates your modelling and provides AEMO with confidence that your asset will contribute to system stability under normal and disturbed operating conditions.

Conduct Thorough GPS Compliance Testing

Once your other generating system is operational, you're required to demonstrate that it performs according to the registered GPS. This includes testing fault ride-through capability, reactive power delivery, frequency control, and voltage support.

That said, you need to plan these tests carefully, using accurate instrumentation and following a documented process that reflects your agreed-upon performance standards. Compliance testing can also help secure final acceptance and market registration.

Manage GPS Updates and Re-Registrations

If you make changes to your system’s design, control settings, or operational approach, you may need to update your registered GPS. This process involves submitting revised modelling, updated system studies, and technical justifications for the modifications.

By maintaining clear version control and timely communication with AEMO, it ensures that your project remains compliant throughout its lifecycle. Partnering with an experienced electrical engineering consultant can help you manage these updates effectively and prepare accurate documentation that aligns with AEMO’s expectations.

Securing Approval Through NER 5.3.10 Negotiations

Under clause 5.3.10 of the National Electricity Rules, you should negotiate the final agreed performance standards with AEMO and the NSP. If your project cannot meet the automatic access standards, you're required to propose negotiated standards supported by technical evidence.

You should come prepared with clear modelling results, system studies, and supporting rationale. With experienced engineering firms, they can assist you in presenting your case effectively, increasing the likelihood of a favourable outcome.

Perform Connection Point Reviews for BESS

Evaluate how battery energy storage systems and other inverter-based technologies in renewable energy projects perform at the connection point. This includes assessing its fault current contribution, interaction with nearby generation, and impact on system strength.

With accurate modelling of connection point behaviour, it helps AEMO assess whether your system will maintain grid stability under various conditions. This step is particularly relevant when using alternative control philosophies such as grid-forming inverters.

Address Metering and Protection Requirements

Your project should meet AEMO’s specifications for metering and protection to ensure operational safety and compliance with market requirements. This includes the installation of approved interval meters, SCADA integration, and protection schemes that coordinate with the broader network.

Clear documentation of your metering setup and protection logic allows AEMO to verify that your system will respond appropriately to disturbances or dispatch instructions.

Identify Runback and Curtailment Scenarios

Anticipate scenarios where your project may be curtailed or run back due to system strength limitations, network congestion, or fault conditions. When it comes to simulations, it should demonstrate how your solar farm or storage system will respond to these events and how it will safely resume normal operation.

Proactively identifying these situations helps build confidence in your system’s ability to integrate into the grid without compromising reliability.

Strengthen Your AEMO GPS Strategy with ElectraGlobe

Navigating the AEMO GPS approval process requires a structured, detail-oriented approach. With each stage, including early engagement, compliance testing, and negotiated standards, it demonstrates your system’s ability to operate reliably in the National Electricity Market.

That said, collaborating with qualified engineering firms, like ElectraGlobe, and following these practices improves submission quality, minimises delays, and supports long-term project success. If you want to learn more about AEMO GPS Applications and more, feel free to visit our website today!

0 notes

Text

Solar PV Inverters Market Drivers Push Equipment Demand Amid Infrastructure Boom Worldwide

As global infrastructure initiatives gain momentum, the Solar PV Inverters Market Trends are seeing significant uplift due to powerful market drivers. These catalysts are transforming how solar inverters are designed, integrated, and deployed across energy projects. From utility-scale solar plants to rooftop systems, increased demand for efficient, reliable, and grid-supportive inverters is being observed across both developed and emerging economies.

Infrastructure Boom: The Primary Catalyst

Worldwide, countries are making large-scale investments in infrastructure, particularly in clean energy. Nations like India, China, the United States, and several European Union members are driving major renewable energy projects to meet climate targets. This construction surge has directly influenced the demand for solar PV inverters as they are essential in converting DC power from solar panels into usable AC power for the grid. Governments are emphasizing decarbonization through solar energy, further propelling demand.

Additionally, the rollout of national electrification programs in Africa and Southeast Asia is expanding off-grid and microgrid applications. These setups rely heavily on string and central inverters, contributing to a healthy global demand.

Decentralization and the Rise of Rooftop Installations

Residential and commercial buildings are increasingly adopting rooftop solar solutions. As more prosumers seek energy independence and cost savings, there's a push for decentralized energy models. This shift supports the growth of single-phase and three-phase inverters suited for distributed energy systems. These compact and efficient inverters also offer greater flexibility for integration with battery energy storage systems (BESS).

In developed markets, policies like net metering and tax credits have further incentivized residential and small business owners to invest in solar, increasing the demand for high-efficiency inverters with smart features and grid support capabilities.

Grid Modernization and Smart Inverter Technologies

One of the strongest drivers reshaping the market is the global trend toward grid modernization. Smart grids need smart inverters—devices capable of voltage regulation, frequency control, reactive power compensation, and communication with the grid. These features not only stabilize the grid but also enable renewable penetration to rise without jeopardizing reliability.

Grid-forming inverters are becoming particularly vital in renewable-dominated energy systems. The push for inverters with advanced functionalities stems from their ability to offer grid support, helping utilities transition from traditional synchronous generation to inverter-based resources.

Demand for Energy Resilience and Storage Integration

Natural disasters, power outages, and rising energy prices are prompting industries and governments to improve grid resilience. Solar PV systems integrated with energy storage solutions are now considered essential infrastructure in regions prone to weather disruptions. Inverters that can seamlessly interact with batteries, manage peak loads, and operate during grid failures (islanding mode) are gaining traction.

This trend is especially visible in regions like California and Australia, where frequent blackouts and grid instability have encouraged users to adopt hybrid inverters with robust backup and storage capabilities.

Industrial Growth and Utility-Scale Solar Expansion

Large-scale solar farms are multiplying across sun-rich regions. Utility companies are deploying central inverters with higher wattage capacity to meet megawatt-scale energy production. These industrial-grade inverters offer better thermal management, lower total harmonic distortion, and enhanced MPPT (Maximum Power Point Tracking), ensuring higher yield and longer life cycles.

The growing popularity of solar farms across deserts, abandoned lands, and agricultural settings has stimulated demand for rugged, weather-resistant inverter systems capable of functioning in harsh conditions.

Government Incentives and Green Financing

Policies that provide financial incentives for solar projects—such as feed-in tariffs (FiTs), investment tax credits (ITCs), and accelerated depreciation—continue to drive inverter demand. Green financing options and public-private partnerships are making it easier for residential, commercial, and industrial consumers to access solar energy systems.

Multilateral institutions like the World Bank and the Asian Development Bank are also funding renewable energy initiatives in Africa, Asia-Pacific, and Latin America. These efforts invariably increase the deployment of solar inverters, especially in remote and underserved areas.

Technological Innovation Fuels Further Demand

The Solar PV Inverters Market is experiencing robust innovation. Manufacturers are developing smaller, more efficient inverters with AI-based monitoring, real-time diagnostics, and remote firmware updates. Features such as predictive maintenance and cloud-based analytics are improving reliability and performance, making inverters more appealing to end-users and utility operators alike.

These innovations not only improve user experience but also reduce operational costs over the inverter’s lifetime—an increasingly attractive prospect in cost-sensitive markets.

Conclusion

The solar energy landscape is evolving rapidly, driven by policy support, technological innovation, and infrastructure growth. As the backbone of solar energy systems, inverters are central to this transformation. Their expanding roles—ranging from basic power conversion to advanced grid stabilization—are being recognized across the energy value chain.

The next article will delve into how automation is reshaping construction projects and what it means for the Solar PV Inverters Market Trends, offering a closer look at the role of inverters in supporting digital and autonomous solar deployment strategies.

#SolarPVInverters#CleanEnergy#GridModernization#SmartInverters#RenewableEnergy#InverterTechnology#SolarPower#GreenInfrastructure#EnergyTransition#UtilityScaleSolar

0 notes

Text

Ferrite Cores Market experiencing steady growth driven by 2037

The Ferrite Cores Market is experiencing robust expansion, underpinned by increasing demand across sectors like consumer electronics, automotive, and renewable energy. The global market size was estimated at USD 4.77 billion in 2024 and is forecasted to exceed USD 10.05 billion by 2037, growing at a Compound Annual Growth Rate (CAGR) of 5.9% from 2025 to 2037. This growth reflects a steady rise in electronic component manufacturing, ongoing digital transformation, and the electrification of transport systems worldwide.

Ferrite Cores Industry Demand

The Ferrite Cores Market refers to the global industry focused on the production and application of ferrite materials—ceramic-like compounds composed of iron oxides combined with other metallic elements. These cores are critical in magnetic components such as transformers, inductors, and antennas due to their magnetic permeability and electrical resistivity.

Ferrite cores serve as essential components for electromagnetic interference (EMI) suppression and signal conditioning. Their appeal lies in:

Cost-effectiveness: Ferrite materials are relatively inexpensive to produce, making them ideal for high-volume electronic manufacturing.

High frequency performance: Especially in soft ferrites, they support energy-efficient operation in modern power systems and communication devices.

Durability and longevity: These components maintain magnetic properties over time, offering a long shelf life and reliability across various operating environments.

Rising demand in industries such as electric vehicles (EVs), 5G infrastructure, and renewable energy systems is fueling growth. Moreover, their critical role in EMI shielding has made them indispensable in achieving regulatory compliance in electronic device manufacturing.

Request Sample@ https://www.researchnester.com/sample-request-7641

Ferrite Cores Market: Growth Drivers & Key Restraint

Key Growth Drivers:

Booming Consumer Electronics and IoT Penetration The surge in smartphones, wearable devices, smart home appliances, and IoT networks has led to skyrocketing demand for compact, high-efficiency magnetic components. Ferrite cores, particularly soft ferrites, are integral to miniaturized, energy-efficient electronics that dominate today's connected ecosystem.

Electrification of the Automotive Sector With the global automotive industry shifting toward electric and hybrid vehicles, the need for efficient energy conversion and EMI suppression components is rising. Ferrite cores are used in battery management systems, inverters, and onboard chargers, aligning perfectly with this growing demand.

Expansion of Renewable Energy and Power Infrastructure Renewable energy generation—particularly wind and solar—requires reliable energy conversion and grid synchronization. Ferrite cores play a key role in power transformers and inverters, making them vital in the global transition to sustainable energy systems.

Major Restraint:

Raw Material Volatility and Performance Limitations The performance of ferrite cores can be influenced by temperature and frequency extremes, limiting their usage in certain high-stress environments. Additionally, price fluctuations in raw materials like manganese and zinc impact production costs, especially in developing economies where manufacturers operate under thin margins.

Ferrite Cores Market: Segment Analysis

By Type:

Soft Ferrite Cores: These dominate the market due to their suitability for high-frequency applications. Their low coercivity and high magnetic permeability make them ideal for switching power supplies, telecommunications, and computing systems. Demand continues to grow as industries focus on energy efficiency and signal clarity.

Hard Ferrite Cores: Used primarily in permanent magnet applications, hard ferrite cores offer high coercivity and are more resistant to demagnetization. Though smaller in market share, they are widely used in motors, sensors, and certain types of loudspeakers and security devices.

By Material:

Manganese-Zinc (Mn-Zn) Ferrite Cores: These are preferred for power and high-frequency applications due to their higher magnetic permeability and lower electrical resistance. They are extensively used in transformers and power inductors, making them a staple in both industrial and consumer electronics.

Nickel-Zinc (Ni-Zn) Ferrite Cores: Ni-Zn ferrites are better suited for high-frequency EMI suppression, especially in signal and communication devices. Their higher electrical resistivity allows them to perform efficiently in RF circuits, antennas, and filters.

By End Use:

Consumer Electronics: This segment drives a significant portion of the market, with ferrite cores found in smartphones, TVs, power adapters, and routers. The growing consumer base and device complexity create a steady need for magnetic components.

Automotive: With rising adoption of electric drivetrains, ADAS (Advanced Driver Assistance Systems), and infotainment systems, ferrite cores are becoming increasingly crucial. They help ensure EMI compliance and efficient power usage across vehicle systems.

Power Generation and Distribution: Ferrite cores are integral in transformers, inverters, and energy meters. The demand is rising in tandem with smart grid projects and renewable energy expansion.

Healthcare: Ferrite cores provide precision and EMI shielding in imaging, diagnostics, and medical sensors, with growth driven by portable and wearable healthcare tech.

Others: Industrial automation, aerospace, and telecommunications also contribute to demand, particularly where signal integrity and compact power solutions are vital.

Ferrite Cores Market: Regional Insights

North America’s market is driven by rapid technological advancements, especially in consumer electronics, aerospace, and medical devices. The presence of leading manufacturers and a robust R&D environment encourages innovation in material and product design. Additionally, the electrification of transport and investments in clean energy projects sustain regional demand.

Europe:

Europe focuses heavily on sustainability and regulatory compliance, which supports the adoption of high-efficiency ferrite cores in electric vehicles and renewable energy systems. Countries such as Germany, France, and the UK are investing in green infrastructure, while automotive manufacturers are increasingly incorporating ferrite components in hybrid and electric vehicles.

Asia-Pacific (APAC):

APAC leads the global market in both production and consumption, with countries like China, Japan, South Korea, and India hosting major electronic manufacturing hubs. The region benefits from economies of scale, strong domestic demand, and export-oriented industries. Increasing 5G rollout, EV adoption, and consumer electronics penetration further accelerate growth.

Top Players in the Ferrite Cores Market

Prominent companies driving the Ferrite Cores Market include MAGNETICS, SAMSUNG ELECTRO-MECHANICS, Fair-Rite Products Corp., COSMO FERRITES LIMITED, Bourns, Inc., VACUUMSCHMELZE GmbH & Co. KG, Delta Manufacturing Limited, and GuangDong FengHua Advanced Technology Holding Co. Ltd. These players are engaged in expanding production capabilities, advancing material science, and pursuing global strategic partnerships to strengthen their positions in a highly competitive and innovation-driven market.

Access Detailed Report@ https://www.researchnester.com/reports/ferrite-cores-market/7641

Contact for more Info:

AJ Daniel

Email: [email protected]

0 notes