#Single Use Bioreactors Market Research

Explore tagged Tumblr posts

Text

#Single Use Bioreactors Market#Single Use Bioreactors Market Trends#Single Use Bioreactors Market Growth#Single Use Bioreactors Market Industry#Single Use Bioreactors Market Research#Single Use Bioreactors Market Report

0 notes

Text

The Future of CDMOs: Key Trends Shaping the Biopharma Outsourcing Industry in 2024

In the fast-paced world of pharmaceuticals, the demand for speed, efficiency, and expertise has given rise to the prominence of Contract Manufacturing Organizations (CMOs). These organizations play a critical role in bringing innovative drugs to market while allowing pharmaceutical companies to focus on research, development, and innovation.

In this blog, we explore the evolving role of CMOs, the benefits they offer, and the latest trends shaping this dynamic industry.

What Are CMOs and Why Are They Essential?

A Contract Manufacturing Organization (CMO) is a company that provides manufacturing services to pharmaceutical and biotechnology firms. CMOs handle everything from small-scale development to large-scale commercial production. By outsourcing manufacturing to CMOs, pharmaceutical companies can save costs, enhance flexibility, and scale their operations without investing heavily in infrastructure.

Key Benefits of CMOs for Pharmaceutical Companies

Cost EfficiencySetting up and maintaining manufacturing facilities can be prohibitively expensive. CMOs offer a cost-effective solution, as pharmaceutical companies can avoid capital investment in equipment, facilities, and regulatory compliance processes.

Access to Specialized ExpertiseCMOs often possess expertise in areas like high-potency API (HPAPI) production, biologics, and sterile manufacturing that many pharmaceutical companies lack in-house.

Faster Time to MarketCMOs help accelerate production timelines, enabling quicker delivery of life-saving drugs to patients. Their established infrastructure and streamlined processes make it easier to scale production.

Regulatory CompliancePharmaceutical manufacturing requires adherence to stringent regulatory standards. CMOs invest heavily in maintaining compliance with FDA, EMA, and other global regulatory authorities, reducing the compliance burden for their clients.

Focus on Core CompetenciesBy outsourcing manufacturing, pharmaceutical companies can focus on their core strengths—such as drug discovery, R&D, and marketing—without getting bogged down by production challenges.

Emerging Trends in the Pharmaceutical CMO Industry

The pharmaceutical CMO landscape is evolving rapidly, driven by technological advancements, changing regulations, and market demands. Here are the key trends to watch:

1. Growth in Biologics Manufacturing

With the rise of biologics and biosimilars, CMOs are expanding their capabilities in areas like monoclonal antibodies, cell therapies, and gene therapies. Advanced manufacturing technologies, such as single-use bioreactors, are transforming biologics production.

2. Digital Transformation

CMOs are adopting cutting-edge technologies like Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) for process optimization, predictive maintenance, and enhanced quality control.

3. Flexible Manufacturing

The need for agile production systems is growing. CMOs are investing in modular and continuous manufacturing solutions to meet diverse client needs and improve cost-effectiveness.

4. Focus on Sustainability

Eco-friendly practices are becoming a priority, with CMOs adopting green chemistry, reducing carbon footprints, and using sustainable raw materials. This aligns with the global push toward Environmental, Social, and Governance (ESG) goals.

5. Expansion of Global Manufacturing Hubs

To ensure resilience and reduce supply chain disruptions, CMOs are setting up manufacturing facilities in emerging markets, particularly in Asia-Pacific, Eastern Europe, and Latin America.

How to Choose the Right CMO Partner

Selecting the right CMO partner is critical for a pharmaceutical company’s success. Here are some factors to consider:

Experience and Track Record: Evaluate the CMO’s experience with similar projects and their history of meeting client expectations.

Technical Expertise: Ensure the CMO has the technical capabilities to handle your product’s specific requirements.

Regulatory Compliance: Verify the CMO’s adherence to international regulatory standards.

Capacity and Scalability: Choose a partner that can scale production to meet your needs, whether for clinical trials or commercial-scale manufacturing.

Communication and Transparency: Strong communication ensures smoother collaboration and quicker resolution of issues.

Future of CMOs in the Pharmaceutical Industry

The pharmaceutical industry is evolving at an unprecedented pace, and CMOs are at the heart of this transformation. From developing advanced therapies to ensuring supply chain resilience, CMOs are becoming strategic partners rather than mere service providers. As outsourcing becomes more integral to the pharmaceutical value chain, CMOs will continue to innovate and adapt to meet the industry's demands.

Conclusion

Contract Manufacturing Organizations are not just manufacturers; they are enablers of innovation and efficiency in the pharmaceutical industry. Whether you are a pharmaceutical company seeking to optimize operations or an industry professional exploring the latest trends, understanding the role of CMOs is essential for navigating the future of healthcare.

0 notes

Text

The Global Small-Scale Bioreactors Market size is USD 1.30 billion and is expected to reach USD 2.32 billion by 2030, growing at a CAGR of 8.6% from 2024 to 2030. The market growth can be attributed to factors such as increasing demand for biopharmaceuticals, rising adoption of single-use technologies, and the need for cost-effective research and development.

0 notes

Text

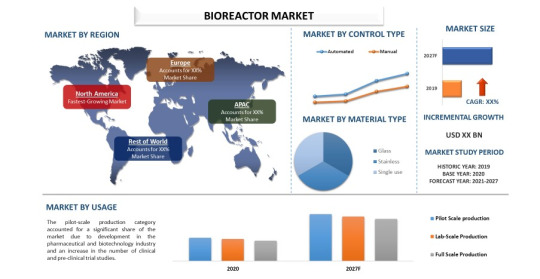

Bioreactors Market - Forecast(2024 - 2030)

Bioreactors Market Overview

Bioreactors Market size is estimated to reach 2.1Bn, growing at a CAGR of 6.91% during the forecast period 2020-2025. Bioreactors are devices used to develop biological processes by closely monitoring controlled environment. It is a closed system used for bioprocessing, that supports the growth of cells or tissues and organisms (yeast, bacteria, or animal cells) under controlled conditions. Bioreactors are used in industrial processes to produce vaccines, antibodies and others. It converts raw materials into useful byproducts in the bioconversion of corn into ethanol. These are commonly cylindrical, ranging in size from liters to cubic meters, and are often made of stainless steel. Single-use material is widely used in the field of mammalian cell culture and is now rapidly replacing conventional bioreactors owing towards increase the quality of the end product by reducing automation complexity.

Report Coverage

The report: “Bioreactors Market – Forecast (2020-2025)”, by IndustryARC covers an in-depth analysis of the following segments of the Bioreactors Market.

By Type: Continuous Stirred Tank Bioreactors, Bubble Column Bioreactors, Airlift Bioreactors, Fluidized Bed Bioreactors, Packed Bed Bioreactors and Photo-Bioreactors.

By Control Type: Manual Control and Automated Control.

By Application: Lab-Scale Production, Pilot-Scale Production and Full-Scale Production.

By Material: Glass, Stainless Steel and Single-Use Plastic Polymer.

By End User: Research & Development, Biopharmaceutics and Others.

By Geography: North America, Europe, Asia-Pacific and Rest of the World.

Request Sample

Key Takeaways

The increase in the number of personalized medicines coupled with rising number of FDA approved orphan drugs has increased bio production, accelerating the bioreactors demand over the forecast years.

Rising chronic diseases and favorable government initiatives to improve healthcare infrastructure is likely to be the major driving factor for the market’s growth.

Asia-Pacific region is projected to record the fastest growth rate during the forecast period 2020-2025

By Type - Segment Analysis

In 2019, Continuous Stirred Tank Bioreactors segment dominated the Bioreactors Market in terms of revenue is estimated to grow at a CAGR of 5.91% owing towards rising production of monoclonal antibodies (MAb) therapeutics and other biological using animal cell cultures. The continuous stirred-tank reactors are the equipped with an impeller for homogenizing culture media and a sparger for delivering oxygen to the cells. It has increased surface area for oxygen transfer, so there is an increased yield of products. These are mostly used in processing of industries, in homogeneous liquid-phase flow reactions, where constant agitation is required and which further is used in pharmaceutical industries abetting towards the growth of the market.

Inquiry Before Buying

Geography - Segment Analysis

In 2019, the North America region dominated Bioreactors Market in terms of revenue with a market share of 41.8% owing towards rising public & private funding for R&D in this region. In U.S., National Institute of Health (NIH) collaborated with 11 biopharmaceutical companies to launch the “Partnership for Accelerating Cancer Therapies (PACT)”, public-private research collaboration. The aim of the collaboration is to develop immunotherapy for cancers with total investment of $215m aids to the market’s growth. Government has taken initiatives to promote technological advancements and initiatives to escalate the drug development process are key factors in the growth of the Bioreactors market. Asia Pacific is set to record the fastest growth rate during the forecast period 2020-2025.

Schedule a Call

Drivers – Bioreactors Market

Rapid Growth Of Single Use Bioreactors In Biopharmaceutical Industries

The increasing adoption of single use bioreactors by biopharmaceutical companies and various research institutions is driving the growth of the market. Single use bioreactors are more feasible than traditional bioreactors for small-scale research and lab-scale applications as they are more economical and flexible. The use of SUBs for the production of biopharmaceutical companies are increasing, as it tends to be more cost-effective for small-scale operations are driving the markets growth.

Challenges – Bioreactors Market

Major Regulatory Concerns

Regulatory concerns regarding usage of bioreactors and growing stringent government policy and regulation toward market growth is restraining growth of the market. Lack of sufficient storage facilities, vulnerability to leaching and transportation is hindering the market’s growth. Also, large-scale disposal of plastic derivatives is a growing environmental concern restraining the business growth over the forecast years.

Buy Now

Bioreactors Industry Outlook

Product Launches was the key strategy of the players in the Bioreactors Industry. Bioreactors top 10 companies include Danaher Corporation, Sartorius AG, Eppendorf AG, ZETA Holding GmbH, Applikon Biotechnology B.V., Solaris Biotechnology srl, Pierre Guerin Technologies, Thermo Fisher Scientific Inc., Finesse Solutions, Inc. and Merck KGaA.

Acquisitions/Product Launches

In May 2019, Sartorius AG, a leading international partner of the biopharmaceutical industry launched ambr® 15 cell culture automated microbioreactor system. It offers increased flexibility and expanded capability for clone selection, media and feed optimization and early process development work.

In March 2020, Thermo Fisher Scientific Inc. to acquire QIAGEN, a leading provider of life science and molecular diagnostic solutions. This acquisition provided opportunity to leverage the industry-leading capabilities and R&D expertise to accelerate innovation and address emerging healthcare needs.

In March 2020, Danaher Corporation acquired Biopharma business from General Electric Company's (NYSE: GE) Life Sciences division. This acquisition helped company by driving its growth across multiple categories and in reaching more consumers.

#Bioreactors Market#Bioreactors Market Share#Bioreactors Market Size#Bioreactors Market Forecast#Bioreactors Market Report#Bioreactors Market Growth

0 notes

Text

Meticulous Research® Unveils Comprehensive Report on Biopharmaceutical Processing Equipment and Consumables Market

August 7, 2024 - Meticulous Research®, a premier global market research firm, has released an in-depth report titled "Biopharmaceutical Processing Equipment and Consumables Market Size, Share, Forecast, & Trends Analysis by Product Type (Filtration, Chromatography, Bioreactors, Cell Culture Media, Shakers, Services), Application (Vaccine, mAb, R&D) - Global Forecast to 2031."

According to the latest findings by Meticulous Research, the global biopharmaceutical processing equipment and consumables market is projected to grow at a CAGR of 9.5%, reaching an estimated $83.39 billion by 2031. Key factors driving this market expansion include initiatives promoting biopharmaceutical adoption, capacity expansions in biopharmaceutical manufacturing plants, and the increasing use of single-use technologies in commercial bioproduction.

Download Sample Report Here : https://www.meticulousresearch.com/download-sample-report/cp_id=4200

Key Market Players

Prominent players in the global biopharmaceutical processing equipment and consumables market include:

3M Company (U.S.)

Thermo Fisher Scientific, Inc. (U.S.)

Bio-Rad Laboratories, Inc. (U.S.)

Danaher Corporation (U.S.)

Agilent Technologies, Inc. (U.S.)

Repligen Corporation (U.S.)

Sartorius AG (Germany)

Merck KGaA (Germany)

Eppendorf AG (Germany)

Solaris Biotechnology Srl (Italy)

Market Segmentation and Future Outlook

The global biopharmaceutical processing equipment and consumables market is segmented by product type, application, and end user:

Product Type: Filtration Systems, Chromatography Equipment and Consumables, Bioreactors, Cell Culture Products, Mixing Systems, Bioprocessing Containers, Sterilizers, Centrifuges, Incubators, Shakers, Biosafety Cabinets, and Other Consumables and Accessories.

Application: Commercial Bioproduction (including Vaccine Manufacturing, mAb Production, Recombinant Protein Production, and Cell and Gene Therapy Production) and Research Bioproduction.

End User: Pharmaceutical and Biopharmaceutical Companies, Contract Development and Manufacturing Organizations (CDMOs), and Academic and Research Institutes.

Quick Buy: https://www.meticulousresearch.com/Checkout/87973509

Key Findings

Filtration Systems: In 2024, filtration systems are expected to dominate the market, holding a 22.3% share. This is attributed to the recurring use of filtration at every production step, technological advancements, and the growing need for single-use bioprocessing systems.

Commercial Bioproduction: This segment is anticipated to hold a 77.5% share in 2024, driven by the increasing number of biopharmaceuticals in clinical development and the rising demand for monoclonal antibodies to treat chronic diseases such as cancer, autoimmune diseases, and diabetes.

End Users: Pharmaceutical and biopharmaceutical companies are expected to dominate the market due to the high demand for biological products, favorable research initiatives, and high volumes of biopharmaceutical production globally.

Geographic Insights

The report provides a detailed geographic analysis, covering North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Europe is projected to lead the market in 2024 with a 33.2% share, with Germany being the largest market within the region, driven by substantial pharmaceutical exports, government grants, and expanding capacities for biologics-based drugs.

Access Request Sample Report : https://www.meticulousresearch.com/request-sample-report/cp_id=4200

Key Questions Addressed

Which are the high-growth market segments by product type, application, end user, and regions/countries?

What were the historical market trends for biopharmaceutical processing equipment and consumables globally?

What are the market forecasts and estimates for 2024–2031?

What are the major drivers, restraints, challenges, opportunities, and trends in the market?

Who are the major players and what is the competitive landscape?

What recent developments have occurred in the market?

What strategies are adopted by key players?

What are the geographical trends and high-growth regions/countries?

Contact Us

Meticulous Research® Email: [email protected] Contact Sales: +1-646-781-8004 Connect with us on LinkedInMeticulous Research® Unveils Comprehensive Report on Biopharmaceutical Processing Equipment and Consumables Market

0 notes

Text

Cell Culture Market to Reach US$19,198.0 Million by 2024 Owing to Growing R&D Investments in Pharmaceutical Industry

The cell culture market has emerged as an important subject area in the fields of biotechnology and pharmaceutical industry. Cell culture involves growing eukaryotic or prokaryotic cells in an artificial controlled environment with a special growth medium. These cells can be derived from plants or animals and are allowed to grow, interact, and divide. Cell culture provides an ideal platform for understanding various aspects of cell physiology outside the body and helps in drug development processes. The Global cell culture market is estimated to be valued at US$ 19,198.0 Mn in 2024 and is expected to exhibit a CAGR of 7.2% over the forecast period 2023 to 2030. Key Takeaways Key players operating in the cell culture market are Corning Incorporated, Merck KGaA, Sartorius AG, BioSpherix, Ltd., Cell Culture Company, LLC, Thermo Fisher Scientific Inc., VWR International LLC, and Lonza. These players are focusing on new product launches and expansions to strengthen their market position. For instance, in 2021, Merck launched new cell culture media to support cell therapy research and developments. The demand for cell culture products is driven by the increasing investments in pharmaceutical and biotech research and rising prevalence of chronic diseases worldwide. Biopharmaceutical companies are engaged in developing novel biologic drugs for the treatment of diseases like cancer, cardiovascular, and infectious diseases which requires extensive cell-based research. Technological advancements like automated cell culture systems, serum-free media, and animal component-free solutions are helping researchers to gain insights faster. Developments in 3D cell culture techniques that can better mimic in vivo environments are further expected to provide a boost to the market. Market Trends Single-use bioreactors : Single-use bioreactors that minimize the risks of contamination and reduce production timelines are being increasingly adopted by biopharma players for monoclonal antibody production and viral vaccine manufacturing. Stem cell banking: Established companies are entering stem cell banking to facilitate clinical research in regenerative medicine. Increasing stem cell therapy treatments will drive the demand for reliable stem cell banking solutions. Market Opportunities Personalized medicine: Advancements in genomic sequencing technologies are enabling the development of novel personalized therapy approaches. This will open opportunities for developing patient-specific induced pluripotent stem (iPS) cell lines. Developing markets: Emerging economies in Asia Pacific and Latin America are witnessing significant growth in biotech industry. Leading players can expand their presence in these regions to tap into the opportunity.

0 notes

Text

Bioreactors Market Dynamics: Global Growth and Trends (2023-2032)

The Bioreactors Market is projected to grow from USD 16,543 million in 2024 to USD 34,624.2 million by 2032, with a compound annual growth rate (CAGR) of 10.50%.

Bioreactors are integral to modern bioprocessing and biotechnology, serving as vessels that provide a controlled environment for the cultivation of microorganisms, cells, or biochemical reactions. These systems are crucial in the production of a wide range of products, including pharmaceuticals, vaccines, biofuels, and industrial enzymes. Bioreactors can vary in design, ranging from simple stirred-tank models to complex, automated systems with advanced monitoring and control capabilities. The primary function of a bioreactor is to maintain optimal conditions for biological activity, including temperature, pH, dissolved oxygen, and nutrient supply. This is achieved through precise engineering and the integration of sensors and actuators that allow for real-time adjustments to the culture conditions.

The pharmaceutical industry heavily relies on bioreactors for the production of monoclonal antibodies, recombinant proteins, and other therapeutic agents. These bioreactors must meet stringent regulatory standards to ensure product safety and efficacy. Single-use bioreactors, made from disposable materials, are becoming increasingly popular due to their flexibility, reduced risk of contamination, and lower capital investment compared to traditional stainless steel systems. This shift towards single-use technologies is particularly advantageous for small-scale production and clinical trials, where rapid changeovers and scalability are essential.

The bioreactors market is influenced by various dynamic factors that shape its growth, trends, and competitive landscape. Here are the key dynamics affecting the bioreactors market:

Market Drivers

Rising Demand for Biopharmaceuticals: The increasing prevalence of chronic diseases and the demand for personalized medicine are driving the growth of biopharmaceuticals, which in turn boosts the demand for bioreactors. Monoclonal antibodies, vaccines, and recombinant proteins are some of the key biopharmaceutical products that require bioreactors for production.

Advancements in Bioreactor Technology: Technological innovations, such as the development of single-use bioreactors, continuous bioprocessing, and improved control systems, are enhancing the efficiency and scalability of bioreactors. These advancements are making bioreactors more adaptable to various production needs, from small-scale research to large-scale manufacturing.

Expansion of the Biotechnology Industry: The growing biotechnology sector, supported by increased funding and research initiatives, is a significant driver for the bioreactors market. The rise in biotech startups and expansion of research and development activities are fueling the demand for bioreactors.

Increasing Adoption of Single-Use Bioreactors: Single-use bioreactors (SUBs) offer several advantages, including reduced contamination risk, lower capital investment, and greater flexibility. Their adoption is particularly high in biopharmaceutical manufacturing and small-scale production, driving market growth.

Growth in Cell and Gene Therapy: The rapid advancements in cell and gene therapy are creating a need for specialized bioreactors capable of supporting cell cultures and genetic modifications. This emerging field is contributing to the expansion of the bioreactors market.

Market Restraints

High Capital Investment: The initial investment required for setting up bioreactor systems, especially for large-scale production, can be substantial. This high capital cost can be a barrier for small and medium-sized enterprises (SMEs) and research institutions with limited budgets.

Operational Complexity: The operation and maintenance of bioreactors require skilled personnel and strict adherence to protocols to ensure optimal performance and sterility. The complexity of bioreactor systems can pose challenges, particularly for smaller organizations lacking technical expertise.

Regulatory Challenges: Bioreactors used in pharmaceutical and biopharmaceutical production must comply with stringent regulatory standards. Navigating these regulations can be challenging and time-consuming, potentially delaying product development and market entry.

Market Opportunities

Emerging Markets: Developing regions, such as Asia-Pacific, Latin America, and the Middle East, offer significant growth opportunities due to their expanding biopharmaceutical and biotechnology industries. Increasing healthcare expenditure, supportive government policies, and growing investments in research and development are driving market growth in these regions.

Customization and Personalization: The trend towards personalized medicine and customized therapies is creating a demand for flexible and scalable bioreactor solutions. Companies that can offer tailored bioreactor systems to meet specific production needs are likely to gain a competitive advantage.

Integration of Digital Technologies: The incorporation of digital technologies, such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT), is transforming bioreactor operations. These technologies enable real-time monitoring, predictive maintenance, and process optimization, enhancing overall efficiency and productivity.

Competitive Landscape

Key Players and Strategies: Major players in the bioreactors market include companies like Thermo Fisher Scientific, Sartorius AG, Merck KGaA, GE Healthcare, and Danaher Corporation. These companies are focusing on strategies such as mergers and acquisitions, partnerships, and product innovations to strengthen their market positions.

Innovation and Product Development: Continuous innovation and the development of new bioreactor models are critical for maintaining competitiveness. Companies are investing in research and development to introduce advanced bioreactors with improved performance, scalability, and user-friendliness.

Key Player Analysis

Sartorius AG (Germany)

Thermo Fisher Scientific, Inc. (U.S.)

Merck KGaA (Germany)

GE Healthcare (A subsidiary of General Electric Company) (U.S.)

Danaher Corporation (U.S)

Eppendorf AG (Germany)

Amec Foster Wheeler plc (U.K.)

Fluor Corporation (U.S.)

Jacobs Engineering Group Inc. (U.S.)

M+W Group (Germany)

More About Report- https://www.credenceresearch.com/report/bioreactors-market

The bioreactors market exhibits varying dynamics across different regions, driven by local demand, industrial applications, technological adoption, and regulatory environments. Here are the regional insights for the bioreactors market:

North America

Market Size and Growth: North America is one of the largest markets for bioreactors, driven by a robust biopharmaceutical industry, significant investments in biotechnology, and strong research and development activities. The United States, in particular, is a major contributor to market growth due to its advanced healthcare infrastructure and numerous biotech companies.

Key Drivers: High demand for biologics and biosimilars, substantial R&D funding, and a favorable regulatory environment.

Challenges: High capital investment and operational costs, stringent regulatory requirements.

Key Players: Thermo Fisher Scientific, GE Healthcare, and Danaher Corporation.

Europe

Market Size and Growth: Europe is a significant market for bioreactors, with countries like Germany, France, and the UK leading the way. The region benefits from a strong focus on biopharmaceutical production, innovative research, and supportive government policies.

Key Drivers: Growing biopharmaceutical industry, increasing adoption of single-use technologies, and strong focus on sustainability and innovation.

Challenges: Regulatory complexity and high production costs.

Key Players: Sartorius AG, Merck KGaA, and Eppendorf AG.

Asia-Pacific

Market Size and Growth: The Asia-Pacific region is experiencing the fastest growth in the bioreactors market, driven by expanding biopharmaceutical manufacturing capabilities, rising healthcare expenditures, and growing investments in biotechnology. Countries such as China, India, Japan, and South Korea are at the forefront of this growth.

Key Drivers: Large population base, increasing demand for biologics and vaccines, supportive government initiatives, and cost-effective manufacturing.

Challenges: Variability in regulatory standards and need for skilled workforce.

Key Players: Thermo Fisher Scientific, Sartorius AG, and local manufacturers such as Esco Aster.

Latin America

Market Size and Growth: The bioreactors market in Latin America is growing steadily, with Brazil and Mexico being key contributors. The market is supported by increasing investments in biotechnology and healthcare infrastructure improvements.

Key Drivers: Growing biopharmaceutical sector, increasing healthcare access, and favorable government policies.

Challenges: Economic instability, supply chain issues, and regulatory compliance.

Key Players: GE Healthcare, Sartorius AG, and local companies.

Middle East and Africa

Market Size and Growth: The Middle East and Africa region is developing as a potential market for bioreactors, driven by improving economic conditions, increasing healthcare investments, and a growing focus on biotechnology.

Key Drivers: Expanding healthcare infrastructure, rising demand for biopharmaceuticals, and government initiatives to boost local production.

Challenges: Political instability, limited local production capacity, and regulatory challenges.

Key Players: International companies like Thermo Fisher Scientific and Sartorius AG, with emerging local manufacturers.

Regional Highlights

North America and Europe: These regions are characterized by mature markets with a focus on innovation, high regulatory standards, and significant investments in research and development.

Asia-Pacific: This region is marked by rapid industrialization, increasing investments in biotechnology, and a large consumer base driving market growth.

Latin America and Middle East & Africa: Emerging markets with significant growth potential, driven by economic development, urbanization, and increasing demand for biopharmaceuticals.

Future Outlook

Technological Advancements: Ongoing innovations in bioreactor technology, such as the development of single-use systems and continuous bioprocessing, are expected to drive market growth across all regions.

Sustainability Focus: Increasing emphasis on sustainable production practices and the use of environmentally friendly materials is influencing market dynamics, particularly in developed regions.

Market Expansion: Emerging markets in Asia-Pacific, Latin America, and the Middle East & Africa offer significant opportunities for market expansion, driven by economic growth and industrial development.

Segments:

Based on End-Users

R&D Departments

R&D Institutes

CROs (Contract Research Organizations)

Biopharmaceutical Companies

Biopharmaceutical Manufacturers

CMOs (Contract Manufacturing Organizations)

Biopharmaceutical Companies

Based on Usage

Lab-Scale Production

Pilot-Scale Production

Full-Scale Production

Based on Scale (In Liters)

5L-20L

20L-200L

200L-1500L

Above 1500L

Browse the full report – https://www.credenceresearch.com/report/bioreactors-market

Browse Our Blog: https://www.linkedin.com/pulse/bioreactors-market-analysis-global-industry-trends-a8l4f

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Factors Influencing Antibody Production Market Size

The Antibody Production Market size was estimated at USD 18.45 billion in 2023 and is expected to reach USD 43.22 billion by 2031 at a CAGR of 12.93% during the forecast period of 2024-2031.The antibody production market is experiencing robust growth, driven by the escalating demand for targeted therapeutics in chronic diseases and cancer treatment. Technological advancements in monoclonal antibody production and increasing investments in biopharmaceutical research are propelling the market forward. The rise in prevalence of infectious diseases and the growing focus on personalized medicine further enhance market prospects. Key players are expanding their production capabilities and engaging in strategic collaborations to enhance their market presence. With the continuous innovation in biotechnology and a supportive regulatory environment, the antibody production market is poised for significant expansion, offering promising opportunities for new and established companies alike.

Get Sample Of The Report @ https://www.snsinsider.com/sample-request/3716

Market Scope & Overview

A competitive analysis, company market shares, and profiles of major revenue-generating companies are all included in the market research report. The Antibody Production Market research report offers a thorough and insightful analysis of the commercial activities of all market leaders in this industry. It also includes a history of market development and a thorough analysis of the market's current state, taking into account the most recent news and media sources.

The market research on Antibody Production Market aims to give readers both a broad overview and a thorough breakdown of the market's segments. Using research, market dynamics at the local and federal levels are examined during the market analysis. A thorough analysis of the market is provided by the market research, with an emphasis on global market trends.

Market Segmentation Analysis

By Product

Instruments

Bioreactors

Multi-use Bioreactors

Single-use Bioreactors

Chromatography Systems

Filtration systems

Consumables

Media

Buffers and Reagents

Chromatography Resins and Columns

Filtration Consumables and Accessories

Others

Software

By Process

Upstream Processing

Downstream Processing

By Type

Monoclonal Antibody

Polyclonal Antibody

By End User

Pharmaceutical and Biotechnology Companies

Research Laboratories

CROs and CDMOs

COVID-19 Pandemic Impact Analysis

The COVID-19 epidemic had a significant impact on the Antibody Production Market. Additionally, new projects have been postponed internationally, effectively ending the sector. The COVID-19 pandemic forced the development of new strategies for managing potential future challenges while maintaining growth rates.

Regional Outlook

Reports on industry research help to identify and visualize new market participants and portfolios so that decision-making skills can be improved and counterstrategies can be created that have a competitive advantage. The regional markets studied in-depth in the Antibody Production Market research report are North America, Latin America, Asia Pacific, Europe, and the Middle East and Africa.

Competitive Analysis

At various points along the value chain, industry actors keep an eye on how the value chain interacts with commercial activities. In-depth details on anticipated financial performance, company portfolios, and market leaders who are enhancing supply chain logistics, extending their global reach, and gaining a competitive edge are provided in the Antibody Production Market research report. To gain a competitive advantage, businesses employ a variety of growth and expansion strategies.

Key Reasons to Purchase Antibody Production Market Report

The market research includes crucial market trends, opportunities for the top players in the industry, and crucial market data.

The analysis considers the current state of the industry group as well as anticipated future developments that may forecast market growth over the forecast period.

Conclusion

The Antibody Production Market research report will be a priceless tool for market players looking to comprehend market trends and create business plans to prosper in a cutthroat sector.

Read Full Report @ https://www.snsinsider.com/reports/antibody-production-market-3716

About Us

SNS Insider is a market research and insights firm that has won several awards and earned a solid reputation for service and strategy. We are a strategic partner who can assist you in reframing issues and generating answers to the trickiest business difficulties. For greater consumer insight and client experiences, we leverage the power of experience and people.

When you employ our services, you will collaborate with qualified and experienced staff. We believe it is crucial to collaborate with our clients to ensure that each project is customized to meet their demands. Nobody knows your customers or community better than you do. Therefore, our team needs to ask the correct questions that appeal to your audience in order to collect the best information.

Related Reports

BOTOX Market Growth

Botulinum Toxin Market Growth

Bovine Mastitis Market Growth

Brain Tumor Drugs Market Growth

Breast Cancer Therapeutics Market Growth

0 notes

Text

Pioneering Precision Medicine: The Role of Monoclonal Antibody Companies in Modern Healthcare

The Science Behind Monoclonal Antibodies

Monoclonal antibodies are laboratory-produced molecules engineered to serve as substitute antibodies that can restore, enhance, or mimic the immune system's attack on diseased cells. Each monoclonal antibody is designed to bind to a specific target, such as a protein on the surface of a cancer cell. This precision allows for highly targeted therapies that minimize damage to healthy cells, a significant advantage over traditional treatments like chemotherapy and radiation.

Development and Manufacturing

The journey of a monoclonal antibody from concept to patient involves a complex and meticulous process. It begins with the identification of a suitable target antigen, followed by the creation of hybridoma cells, which are fused from a specific type of white blood cell and a cancer cell, enabling the continuous production of the desired antibody. Monoclonal Antibody Company These hybridoma cells are then cultivated in bioreactors, large-scale devices that provide the ideal environment for cell growth and antibody production.

One of the key challenges in this process is ensuring the consistency and purity of the monoclonal antibodies produced. Companies invest heavily in state-of-the-art manufacturing facilities and rigorous quality control systems to meet stringent regulatory standards. Advanced technologies, such as single-use systems and continuous manufacturing, are increasingly being adopted to enhance efficiency and scalability.

Clinical Trials and Regulatory Approval

Before reaching patients, monoclonal antibodies undergo extensive preclinical and clinical testing to demonstrate their safety and efficacy. This involves multiple phases of clinical trials, beginning with small groups of patients to assess safety (Phase I), followed by larger groups to evaluate efficacy and side effects (Phase II), and finally, extensive testing in a broad patient population to confirm effectiveness and monitor adverse reactions (Phase III).

Obtaining regulatory approval is a rigorous process. Agencies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) review the clinical trial data and inspect manufacturing facilities to ensure compliance with Good Manufacturing Practices (GMP). Monoclonal antibody companies often collaborate closely with these regulatory bodies to navigate the complex approval landscape.

Market Impact and Future Prospects

Monoclonal antibody therapies have significantly impacted the pharmaceutical market. The global market for monoclonal antibodies is projected to grow rapidly, driven by increasing prevalence of chronic diseases, advancements in biotechnology, and the rising demand for personalized medicine. Leading companies in this sector, such as Genentech, Amgen, and AbbVie, continue to invest in research and development to expand their portfolios and address unmet medical needs.

Moreover, monoclonal antibodies are being explored for new applications beyond oncology and autoimmune diseases, including infectious diseases, neurological disorders, and cardiovascular diseases. Innovations in antibody engineering, Antibody Affinity Measurement such as bispecific antibodies and antibody-drug conjugates, hold promise for even more targeted and effective treatments.

0 notes

Text

The Booming Bioreactors Market: Key Trends and Growth Drivers

The bioreactors market has witnessed significant growth over the past few years, driven by advancements in biopharmaceutical production, increasing research activities in biotechnology, and the rising demand for personalized medicine. Bioreactors, essential for cultivating cells or tissues in a controlled environment, are crucial in various applications, including pharmaceuticals, food and beverage production, and waste management. As the bioreactors market continues to expand, it is poised to revolutionize several industries by enhancing productivity and efficiency in bioprocesses.

Market Drivers and Technological Advancements

One of the primary drivers of the bioreactors market is the burgeoning biopharmaceutical industry. With the global population's aging and the rise in chronic diseases, there is a growing demand for advanced therapeutics, including monoclonal antibodies, vaccines, and cell and gene therapies. Bioreactors play a pivotal role in the large-scale production of these biopharmaceuticals, ensuring high yield and consistent quality. The shift towards biologics, which are more complex and sensitive than traditional small-molecule drugs, necessitates sophisticated bioreactor systems capable of maintaining precise environmental conditions.

Technological advancements have significantly influenced the bioreactors market. Innovations such as single-use bioreactors (SUBs) have gained immense popularity due to their cost-effectiveness, reduced risk of contamination, and operational flexibility. Unlike traditional stainless-steel bioreactors, SUBs do not require extensive cleaning and sterilization processes, making them ideal for small-scale production and research purposes. Moreover, advancements in automation and digitalization have enabled real-time monitoring and control of bioprocesses, enhancing efficiency and reducing human error.

For a comprehensive analysis of the market drivers https://univdatos.com/report/bioreactors-market/

Market Segmentation and Applications

The bioreactors market can be segmented based on type, usage, scale, and end-user. Types of bioreactors include single-use bioreactors and stainless-steel bioreactors. Single-use bioreactors are witnessing higher adoption rates due to their advantages in terms of cost, scalability, and reduced contamination risk. However, stainless-steel bioreactors remain prevalent in large-scale commercial production due to their durability and suitability for high-volume manufacturing.

Usage segmentation includes microbial and cell culture bioreactors. Microbial bioreactors are primarily used for the production of antibiotics, enzymes, and other microbial products, while cell culture bioreactors are crucial for producing biopharmaceuticals, vaccines, and therapeutic proteins. The growing focus on cell and gene therapies has further fueled the demand for cell culture bioreactors, as these therapies require precise and controlled culturing environments.

In terms of scale, bioreactors are categorized into lab-scale, pilot-scale, and industrial-scale. Lab-scale bioreactors are essential for research and development activities, pilot-scale bioreactors for process development and optimization, and industrial-scale bioreactors for large-scale production. The increasing investment in R&D by biopharmaceutical companies and research institutions is driving the demand for lab-scale and pilot-scale bioreactors.

End-users of bioreactors include biopharmaceutical companies, academic and research institutions, and contract research and manufacturing organizations (CROs and CMOs). Biopharmaceutical companies hold the largest market share due to their extensive use of bioreactors in drug development and production. CROs and CMOs are also significant contributors to the market, offering bioreactor-based services to various industries.

Regional Insights and Growth Opportunities

Geographically, the bioreactors market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. North America dominates the market, driven by the presence of major biopharmaceutical companies, advanced healthcare infrastructure, and significant R&D investments. Europe follows closely, with a strong focus on biotechnology and pharmaceutical research.

The Asia-Pacific region is expected to witness the highest growth rate during the forecast period. Factors such as increasing healthcare expenditure, a growing biopharmaceutical industry, and favorable government initiatives to promote biotechnology research contribute to this growth. Countries like China and India are emerging as key markets due to their expanding biotechnological capabilities and large patient populations.

For a sample report, visit https://univdatos.com/get-a-free-sample-form-php/?product_id=22012

Challenges and Future Outlook

Despite the promising growth prospects, the bioreactors market faces several challenges. High initial investment costs, the complexity of bioprocessing, and stringent regulatory requirements can impede market growth. Additionally, the ongoing COVID-19 pandemic has disrupted supply chains and delayed clinical trials, impacting the bioreactors market.

However, the long-term outlook for the bioreactors market remains positive. Continuous advancements in bioprocessing technologies, increasing adoption of single-use systems, and the growing focus on personalized medicine and biologics are expected to drive market growth. As industries adapt to evolving healthcare needs and technological innovations, the bioreactors market will continue to expand, offering enhanced solutions for biopharmaceutical production and other applications.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411x

Website -www.univdatos.com

0 notes

Text

0 notes

Text

The Global Small-Scale Bioreactors Market size is USD 1.30 billion and is expected to reach USD 2.32 billion by 2030, growing at a CAGR of 8.6% from 2024 to 2030. The market growth can be attributed to factors such as increasing demand for biopharmaceuticals, rising adoption of single-use technologies, and the need for cost-effective research and development.

0 notes

Text

Global Top 5 Companies Accounted for 73% of total SUS (Single Use System) for Biopharma Process market (QYResearch, 2022)

Single-use systems (SUS) refers to biopharmaceutical manufacturing (bioprocessing) equipment designed to be used once (or for a single manufacturing campaign) and then discarded.

This report focuses on devices and consumables, mainly including single-use bioreactors, disposable sterile bags, and disposable filtration systems.

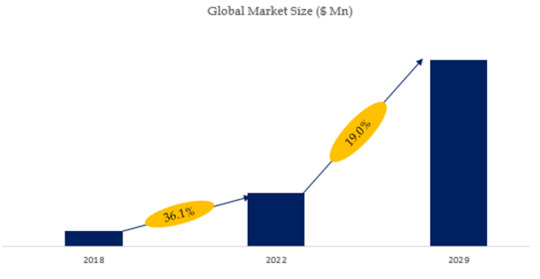

According to the new market research report “Global SUS (Single Use System) for Biopharma Process Market Report 2023-2029”, published by QYResearch, the global SUS (Single Use System) for Biopharma Process market size is projected to reach USD 15.47 billion by 2029, at a CAGR of 19.0% during the forecast period.

Figure. Global SUS (Single Use System) for Biopharma Process Market Size (US$ Million), 2018-2029

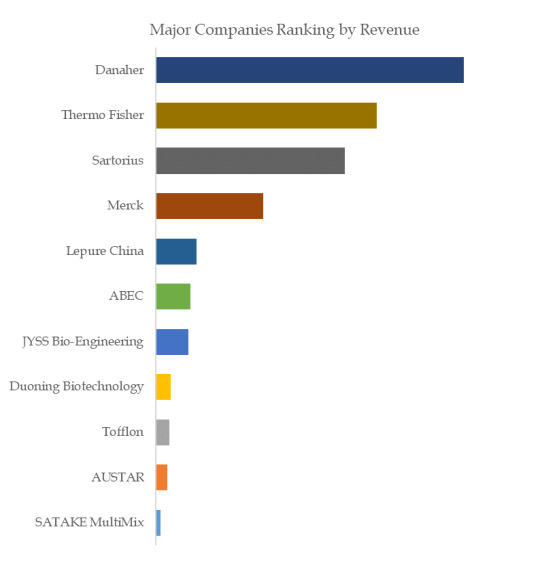

Figure. Global SUS (Single Use System) for Biopharma Process Top 11 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of SUS (Single Use System) for Biopharma Process include Danaher, Thermo Fisher, Sartorius, Merck, Lepure China, ABEC, JYSS Bio-Engineering, Duoning Biotechnology, Tofflon, AUSTAR, etc. In 2022, the global top five players had a share approximately 73.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Meticulous Research® Unveils Comprehensive Report on Biopharmaceutical Processing Equipment and Consumables Market

August 7, 2024 - Meticulous Research®, a premier global market research firm, has released an in-depth report titled "Biopharmaceutical Processing Equipment and Consumables Market Size, Share, Forecast, & Trends Analysis by Product Type (Filtration, Chromatography, Bioreactors, Cell Culture Media, Shakers, Services), Application (Vaccine, mAb, R&D) - Global Forecast to 2031."

According to the latest findings by Meticulous Research, the global biopharmaceutical processing equipment and consumables market is projected to grow at a CAGR of 9.5%, reaching an estimated $83.39 billion by 2031. Key factors driving this market expansion include initiatives promoting biopharmaceutical adoption, capacity expansions in biopharmaceutical manufacturing plants, and the increasing use of single-use technologies in commercial bioproduction.

Download Sample Report Here : https://www.meticulousresearch.com/download-sample-report/cp_id=4200

Key Market Players

Prominent players in the global biopharmaceutical processing equipment and consumables market include:

3M Company (U.S.)

Thermo Fisher Scientific, Inc. (U.S.)

Bio-Rad Laboratories, Inc. (U.S.)

Danaher Corporation (U.S.)

Agilent Technologies, Inc. (U.S.)

Repligen Corporation (U.S.)

Sartorius AG (Germany)

Merck KGaA (Germany)

Eppendorf AG (Germany)

Solaris Biotechnology Srl (Italy)

Market Segmentation and Future Outlook

The global biopharmaceutical processing equipment and consumables market is segmented by product type, application, and end user:

Product Type: Filtration Systems, Chromatography Equipment and Consumables, Bioreactors, Cell Culture Products, Mixing Systems, Bioprocessing Containers, Sterilizers, Centrifuges, Incubators, Shakers, Biosafety Cabinets, and Other Consumables and Accessories.

Application: Commercial Bioproduction (including Vaccine Manufacturing, mAb Production, Recombinant Protein Production, and Cell and Gene Therapy Production) and Research Bioproduction.

End User: Pharmaceutical and Biopharmaceutical Companies, Contract Development and Manufacturing Organizations (CDMOs), and Academic and Research Institutes.

Quick Buy: https://www.meticulousresearch.com/Checkout/87973509

Key Findings

Filtration Systems: In 2024, filtration systems are expected to dominate the market, holding a 22.3% share. This is attributed to the recurring use of filtration at every production step, technological advancements, and the growing need for single-use bioprocessing systems.

Commercial Bioproduction: This segment is anticipated to hold a 77.5% share in 2024, driven by the increasing number of biopharmaceuticals in clinical development and the rising demand for monoclonal antibodies to treat chronic diseases such as cancer, autoimmune diseases, and diabetes.

End Users: Pharmaceutical and biopharmaceutical companies are expected to dominate the market due to the high demand for biological products, favorable research initiatives, and high volumes of biopharmaceutical production globally.

Geographic Insights

The report provides a detailed geographic analysis, covering North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Europe is projected to lead the market in 2024 with a 33.2% share, with Germany being the largest market within the region, driven by substantial pharmaceutical exports, government grants, and expanding capacities for biologics-based drugs.

Access Request Sample Report : https://www.meticulousresearch.com/request-sample-report/cp_id=4200

Key Questions Addressed

Which are the high-growth market segments by product type, application, end user, and regions/countries?

What were the historical market trends for biopharmaceutical processing equipment and consumables globally?

What are the market forecasts and estimates for 2024–2031?

What are the major drivers, restraints, challenges, opportunities, and trends in the market?

Who are the major players and what is the competitive landscape?

What recent developments have occurred in the market?

What strategies are adopted by key players?

What are the geographical trends and high-growth regions/countries?

Contact Us

Meticulous Research® Email: [email protected] Contact Sales: +1-646-781-8004 Connect with us on LinkedIn

0 notes

Text

Insights into Demand Drivers: Bioreactors and Fermenters Market Forecast

Overview and Scope Bioreactors and fermenters are specialized systems used in biotechnology and industrial processes for the cultivation and growth of microorganisms, cells, or tissues by providing a controlled environment. These are used in the development and optimization of bioprocesses for the production of bio-based products. A bioreactor is a vessel developed for growing microorganisms or cells under controlled conditions for biotechnological processes, while a fermenter is a type of bioreactor specifically designed for microbial fermentation and used to produce enzymes, antibiotics, and biofuels. Sizing and Forecast The bioreactors and fermenters market size has grown rapidly in recent years. It will grow from $3.60 billion in 2023 to $ 4.12 billion in 2024 at a compound annual growth rate (CAGR) of 14.3%. The bioreactors and fermenters market size is expected to see rapid growth in the next few years. It will grow to $7.06 billion in 2028 at a compound annual growth rate (CAGR) of 14.5%. To access more details regarding this report, visit the link: https://www.thebusinessresearchcompany.com/report/bioreactors-and-fermenters-global-market-report Segmentation & Regional Insights The bioreactors and fermenters market covered in this report is segmented – 1) By Type: Single Use Bioreactors, Multiple Use Bioreactors 2) By Process: Fed Batch, Continuous, Batch 3) By End User: Biopharmaceutical Companies, Beverage Companies, Contract Research Organization (CRO), Academic And Research Institutions North America was the largest region in the bioreactors and fermenters market in 2023. Europe is expected to be the fastest-growing region in the forecast period. The regions covered in the bioreactors and fermenters market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa. Intrigued to explore the contents? Secure your hands-on sample copy of the report: https://www.thebusinessresearchcompany.com/sample.aspx?id=14654&type=smp Major Driver Impacting Market Growth Increasing biotechnology investment is expected to propel the growth of the bioreactors and fermenters market going forward. Biotechnology investment refers to allocating financial resources, such as capital or funding, into companies, projects, or ventures within the biotechnology industry. Investments in biotechnology are increasing due to the growing demand for innovative healthcare solutions and advancements in genetic engineering. Key Industry Players Major companies operating in the bioreactors and fermenters market are Merck & Co. Inc., Thermo Fisher Scientific Inc., Danaher Corporation, GE Healthcare, Sartorius AG, Getinge AB, Eppendorf AG, ZETA Holding, Pierre Guerin SAS, Parr Instrument Company, Bionet Inc., PBS Biotech. The bioreactors and fermenters market report table of contents includes: 1. Executive Summary 2. Market Characteristics 3. Market Trends And Strategies 4. Impact Of COVID-19 5. Market Size And Growth 6. Segmentation 7. Regional And Country Analysis . . . 27. Competitive Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected] Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Detailed Report on Upstream Bioprocessing Market | BIS Research

Upstream bioprocessing is a crucial stage in the production of biopharmaceuticals and other bioproducts.

The Global Bioprocessing Market was valued at $250.1 million in 2023 and is expected to reach $1,639.1 million by 2033, growing at a CAGR of 20.68% between 2023 and 2033.

Upstream Bioprocessing Overview

Upstream bioprocessing forms the foundational phase in the production of biopharmaceuticals, encompassing a series of interconnected steps that initiate with the selection of host organisms and culminate in the production of viable cell cultures or microbial systems.

Grab the free sample page click here

Key Elements for Upstream Bioprocessing

Host Organism Selection

Cell Culture and Development

Gene Cloning and Vector Design

Cell Expansion and Bioreactor Cultivation

Market Drivers and Trends for Upstream Bioprocessing Market

Market drivers are as follows

Growing demand for Biopharmaceuticals

Expanding Biopharmaceuticals Pipelines

Advancements in Genetic Engineering

Rapid Technological Advancements

Market trends are as follows

Single use bioprocessing systems

Digitalization and Data Analytics

Focus on Sustainability

Cell and Gene Therapy Manufacturing

These trends reflect the dynamic and evolving nature of the upstream bioprocessing industry, driven by technological innovation, market demand, regulatory dynamics, and sustainability considerations.

Applications for Upstream Bioprocessing Market

Biopharmaceutical Production

Industrial Enzyme Production

Food and Beverages Ingredients

Speciality Chemicals and Biopolymers

These applications highlight the versatility and importance of upstream bioprocessing across various industries, driving innovation, sustainability, and economic growth through the production of biologically derived products and materials.

Recent Developments in the Bioprocessing Market

• Waters and Sartorius expanded their partnership to develop integrated analytical tools for downstream biomanufacturing following their successful collaboration in upstream processes. • Sartorius and Repligen Corporation launched an integrated system with Biostat STR and XCell ATF for upstream process intensification.

Visit our Life Sciences and Biopharma Vertical page for better understanding

Key Players in the market

• 3M • Bio-Rad Laboratories, Inc. • Thermo Fisher Scientific, Inc. • Merck KGaA • Sartorius AG • Danaher Corporation

Key Questions Answered

Q What is the estimated global market size for the Upstream Bioprocessing Market ?

Q What future trends are expected in the Upstream Bioprocessing Market ?

Q What does the supply chain of the Upstream Bioprocessing Market look like?

QWhat does the value chain of the Upstream Bioprocessing Market look like?

Q What is the regulatory framework within the Upstream Bioprocessing Market ?

Q What is the patent analysis trend based on country and year in the Upstream Bioprocessing Market ?

Q How has the COVID-19 outbreak affected the future trajectory of the Upstream Bioprocessing Market ?

Q What are the next frontiers in the Upstream Bioprocessing Market ?

Conclusion

In conclusion, Upstream Bioprocessing plays a pivotal role in the production of biopharmaceuticals and various bio-based products. Through this study, we have explored the diverse methodologies, technologies, and strategies employed in upstream processes, highlighting their significance in optimizing productivity, quality, and scalability. From cell culture techniques to fermentation processes, the advancement of upstream bioprocessing continues to drive innovation in biotechnology, offering promising solutions to meet the growing demands of the industry.

0 notes