#Single Slide Injection Molding

Explore tagged Tumblr posts

Text

Get Well Soon john price x f!reader word count: 4.3k tw: MDNI, NSFW, jealous price, possessiveness, oral sex, fingering, dirty talk, just a bit nasty ngl

Jealousy was a disease, and John was its desired host that it ravaged with an unfurling blaze of smoldering flames that scorched through the bloodstream like injected venom. It simmered at the bones and left him scathed, dissipating into bitter ash that filled the air around him with the pungent scent of his own distaste.

In other words, John really fucking hated seeing you wrapped around Soap like a damn boa constricter ready to sink your fangs into him like a feast.

The whiskey he’d been sipping on with tedious sips was now thrown back into his throat, sliding down to his stomach and leaving him with an acidic aftertaste. The alcohol only coaxed the fire into an uproar, the tips of the flames flicking its red-hot tongue in the flesh of his skin and scalding him with third degree burns from the inside and out.

He tried focusing on the emptiness that stared back at him from the bottom of his glass, fingers coated in the icy condensation where he gripped around it with vice. It prickled his fingertips, the force of his grasp causing his knuckles to go white and veins to flex uncomfortably in the back of his hand.

But the grim sight of melting ice wasn’t nearly as intriguing as the sight of you, the woman who’s been gnawing your way through his skin and bone for the past however-the-fuck-long that John’s been tongue-tied over you, smiling like a cheshire while Soap maneuvered you around on the dance floor of the dimly lit club, dipping his fingertips in the fat of your hips.

Your hips swayed in earnest, Soap and you sharing a laugh as he tried to replicate your pace and ended up stumbling around like a damn fool. The spark of amusement that shimmered in your irises was so bright, John could see it from where he sat at the bar. It blinded him, like a flashbang being hurled his way without a single ounce of warning, causing his ears to ring and his eyes to blink away the dryness that dusted his retinas.

He shouldn’t be mad, really. You weren’t his, and he wasn’t yours.

Soap was simply livening the mood after a grueling mission was deemed a success. John was the one that offered to take you out, allowing you a night free of suffocating peril, yet here he was, moping like a child who’d just gotten his video games taken away.

He wasn’t a jealous man. He’d never taken an interest in a woman long enough for it to tread into that type of territory, and his work occupied him like a slave to commitment – commitment to the job, and never to a pretty woman deserving of much more than him.

Yet, you had somehow begun worming your way into his brain, molding it to the shape of you. Your smile, your laugh, the way you chewed your lip when deep in thought, the plush skin reddening under its abuse and clashing with the tone of your skin. Everything about you was hardwired into his brain, filed away and hidden in the depths of his thoughts.

It was selfish of him, he knew.

You were his subordinate – if he could call you that, really. You worked with Laswell, which meant you worked with him. A package deal, one he had no choice but to accept when it came down to it.

He was playing a dangerous game, allowing the churlish spur of envy to grab him by the throat and choke him into submission. It darkened his vision with spots of red rage, lighting with a flicker of flames that illuminated in the reflection of his pupils.

But John was a fond lover of games, given his track record of coaxing enemy intel out of the lips of grotty men through the bite of his threatening words and the sting of his knife into their mangy skin. He knew how to play to get what he wanted, what he needed, but you were a puzzle with thousands of pieces that he just couldn’t figure out how to complete.

He clung to you like a moth to a flame. A dog to its bone. A bullet to a wound.

You were his ecstasy that he could no longer deny, and he was slowly succumbing to the addiction. He got high off of the very being of you, injecting you into his veins with guilty pleasure.

And John didn't know how much longer he could starve himself from his fix.

Unable to watch the way Soap embraced you with a feverish warmth that had your expression melted into content gratification, he stood from the bar stool with a lick of virulent hostility, the legs scraping against the floor like nails to a chalkboard. Gaz spared him a worrying look, and when he went to open his mouth to ask if he was okay, John sent him a dismissive wave of his hand, muttering a gravelly ‘smoke break’ before taking off.

The chill of the night air smothered him with a relieving shiver down his spine, nipping his cheeks that were warmed from a mix of club smog and alcohol firing in his bloodstream. He was far from drunk, far from tipsy, but the burning desire he harbored for you made him feel the buzz of a high that hazed over all thoughts of calm serenities.

Leaning against the old brick of the club, he sifted a hand through the pocket of his jacket, fishing out a cigarette. Cigars were much more his taste, but unenjoyable when having to shove them in the bowels of a cramped pocket.

Lighting it up and taking a thick puff, the burn of smoke did nothing to calm the hideous monster that dared to rear its head against the fabrics of his heart. It was hungry, vengeful, baring its teeth in hopes of sinking them into flesh and bone, tearing its victim apart limb by measly limb.

The music boomed faintly from the closed door of the club, pounding vexing notes through his eardrums and tainting them with a distasteful noise.

John continued his routine of inhale and exhale, dipping into the dance of wispy smoke that surrounded him and basked his aura in musk and pungency. It swallowed him whole, enough so that he didn’t hear the whisk of the club door opening from beside him, and a familiar voice sparking fireworks in his mind.

“Sir!” you exclaimed, and John felt his shoulders tense with wavering remembrance of the way Soap wrapped his tattered arms around you, his lips leaned in close to your ear to speak with you over the loudness of the music, the way he was the reason you were giggling like schoolgirl off her rocker. “I didn’t see you at the bar. You feeling okay, Captain?”

The name left a tangy taste in his mouth. Bittersweet, souring.

“Thought I told you to call me John,” he grumbled with a ghost of a smile, tight and forced. It was more a grimace than a smile, as of course you would notice. Of course.

Keen eye, you had. It was one of the many traits John found himself falling into.

“John,” you corrected with a smile so bright, it practically laid out all of the stars in the sky in a shimmering blanket of wondrous light. “Why are you out here and not inside with the others?”

John had to hold back a lingering scoff that threatened to claw its way out of purgatory and fill the air with bitter irk.

“Got a bit stuffy in there, don’t you think?” he offered in place of spiteful words, but even at his attempt, the words came out clipped if your frown was anything to come by. “Needed a break.”

“You seemed bothered, Cap– John.”

“Mm.”

Your frown deepened and it only burdened him further. He didn’t want to be the reason for your upset, but that green little gremlin that coaxed him into anguished jealousy didn’t give two shits. It settled into his bones with enervating annoyance, paining him with ache.

“Don’t let me stop you from your fun with Soap,” he muttered dryly, uttering the words before he could stop himself.

Your eyebrows raised and you stared at him for a long moment, taking him in. His tense shoulders, tight lips pulled into a thin line, his firm grip on his cigarette that would’ve snapped it in half if he used an ounce more of strength.

“Something’s bothering you, sir,” you noted, and he gave you a taut smile.

“Look at that. Quite the brain on you.”

“No need to be rude about it, John.”

“Not being rude.”

“You are.”

John sucked in a sharp breath, nostrils flaring when he deeply exhaled. His eyes bore into yours like frigid icicles ready to pierce into you. It was chilling to the bone, sending an unsettling shiver down your spine. John noticed.

“It’d be best if you head on inside,” he hummed, his tone quipped with a hint of warning.

“Really?” you asked in disbelief and he snorted.

“Really.”

John knew he was being unfair. His envy was eating at him from the inside, bubbling its way out in molten poison that burned in his mouth.

“Something is clearly bothering you, Captain. Is it a crime to check on you?” Your tone began matching his own sour one, biting into him like a feral dog with its hackles raised.

“What’s a crime is you saddlin’ up with Soap like he’s your bloody suitor,” he hissed, and there it was, the bitter taste of frothing temper seeping out of his lips like red-hot lava. It scalded him, leaving him with third degree burns on his tongue. “Lettin’ him have at you like a fuckin’ dove for the takin’.”

“What?” you breathed, eyebrows knitting together in bafflement. “What are you trying to say?”

“What I’m tryin’ t’say, what I’ve been wantin’ t’say, is that I don’t like the way he was touchin’ you,” he declared in earnest. He stood straight from where he was leaned against the wall, glowering down at you with a look that could’ve pinned you to the gravel beneath your foot. “I’ve been patient. I’ve kept my distance. But enough’s a fuckin’ ‘nough.”

You didn’t cower under his looming glare, nor did you take a step back like you should’ve. You remained firmly rooted in your spot next to him, eyes flickering between the scowl on his mouth to the fiery eyes that threatened to burst into explosion any second.

“You’re jealous, Captain,” you stated, quite obviously. It tickled the little monster that was nearly bursting out of his skin.

“Rightfully so,” he muttered. “I don’t like people touchin’ what’s mine.”

“I wasn’t aware that I was yours to begin with, Captain.”

“John,” he reminded you. “I’d be happy to make you aware of it. Print it in that pretty head of yours so you won’t forget it.”

Warmth blossomed under your skin, spreading from head to toe and curling you into his burning embers. The words struck you like lightning, quick and sudden, leaving you dazed.

You could smell the faint cigarette smoke and whiskey in the fan of his breath as it settled over your face. You took it in, breathing through your nostrils and letting it settle to the core. It was musky and fragrant, stirring your brain into goopy mush.

“How’s that sound, sweetheart?” he mused, nearly sending you into an early grave. Fuck, you’d dig it yourself if it meant hearing those words on repeat.

“I–” You swallowed, mouth suddenly parched.

John stepped closer to you, a dangerous and brooding step. His frame towered over yours, head tilted down to ensure eye contact remained secured. He wouldn’t allow you to look away, wouldn’t allow you the chance to catch your breath. He knew what he was doing, knew what you were feeling.

“Just say the word,” he breathed, tickling your nose with his piquant scent. “Say the word and I’ll make it happen, sweetheart.”

“Yes,” you managed, voice less confident than it had been before when you let your frustration get the better of you. Submissive, willing.

John’s lips perked into a pleased smile, eyes brimming with amusement and risk. He was taking the leap off of a daunting cliff, diving headfirst in a pool of unknown and uncertainty. But oh, he was certain of this.

You tasted the poignant flavors that melted from his tongue on to yours when he sealed his offer with a kiss. It was demanding, stern, his mouth molding into yours in the shape of a promise.

He traveled the shape of your jaw, rough hand entangling itself in the feathers of your hair. Tugging, wrapping it in his grasp, luring you into him with a burning desire to mark what was his. It was fire mixing with gasoline, burning scriptures in your skin, burning his name.

John swallowed every gasp and groan, eager and greedy. He captured your bottom lip with teeth, sinking in with a grueling bite, carving his indents into the plush flesh. He barely allowed you to gather air in your lungs, and it left you feeling dizzy, untrusting of your own legs to keep you steady.

“Do me a favor, love,” he grunted in the midst of your kiss, pulling back only to get a glimpse of the glossy look in your eyes. “Go on and tell the boys you aren’t feelin’ well and I’m takin’ you home. Had too much to drink, so I’m gettin’ you to bed, hm? Can you do that f’me?”

Your breath was shaky when you released a sigh, and nodded in tenacity, practically scrambling back into the club like a dog with its tail between its legs.

John stayed true to his promise of taking you home and tucking you into bed – just not in the way the boys were told.

He was like a predator pouncing on its prey the moment you arrived at your humble abode. His hands explored every expanse of your body, shedding you until you were bare with a trail of clothes leading to your bedroom in its wake.

He was famished, like a man starved for weeks on end, and the only thing that would satiate him was ravishing you to the bone.

You thought after agreeing that you were John’s and he was yours, it would feed his burning anger warranted from jealousy. If anything, it was the opposite.

He was firm and demanding, determined to etch every part of him into the plains of your skin. His hands were skilled in the way he practically shoved you into the mattress, lips remaining locked into place on your own.

He was a man on a mission, and you knew John to be one to never fail to complete it.

“M’gonna show you exactly what’s botherin me,” he mumbled into your mouth. His voice was raspy and guttural, laced with an undeniable wisp of arousal. “Been botherin’ me for ages.”

True to his word, his lips, chapped with a sheen of your mixed saliva moistening them, trailed down the column of your neck. They were neither rough or soft kisses, but rather balanced and precise. Teeth nicked the sensitive skin, taking it between tender bites and nursing the hissing stings with the point of his tongue.

Marking his territory, just as promised.

“You never said anything,” you acknowledged through a breathy sigh, lips parted and hazy eyes pointed at the ceiling as he worked wonders on your jawline.

“Didn’t have the gall to, ‘til I saw you cozied up with Mactavish,” he grunted, and as if the thought passing by in remembrance settled into his brain, he bit down a bit harder on the spot where your neck and shoulder met.

John peppered his kisses down from your clavicle, creating a trail to your sternum. It tingled with a feverish burn, spotting your skin with a faint flush. One of his calloused hands slid up your side, prompting a shiver along the way, until it grasped the mounds on your chest in a possessive hold.

His tongue darted out to circle a perked nipple, teasing, mocking. You couldn’t hold back the pathetic whine, and the rumble of his smug chuckle vibrated your whole body. Offering mercy, he enveloped the entirety of your nipple in his mouth, grazing his teeth along the sensitive bud and causing you to hiss in a mix of pain and pleasure – perfectly balanced, because John was a calculated man, and he never left a job unsatisfactory.

Your thighs rested limply on each side of his waist, and when he gave a particularly hard suck, they tightened around him, knees knocking into the thick of his ribcage. Instantaneously, his other hand that wasn’t occupied with holding your breast came to grab hold of your knee, carefully peeling it away from where it rested on the warmth of his skin, tugging you apart until you were spread and vulnerable.

That same hand slowly slipped down your knee, sweeping along your inner thigh and worshiping the smooth skin with a swipe of his fingertips. They were rough against your skin in comparison, and the sensation made you jolt.

They continued their downward exploration until you felt the subtle touch of a finger experimentally slide along your slit. You wanted to feel embarrassed by how wet you were from nothing more than kissing and him ravishing your breasts like he was feasting on a meal, but you couldn’t.

Judging from his muffled groan, he didn’t seem to mind it either.

“Fuckin’ soaked and I haven’t even touched you,” he observed, rearing his head back from your chest so he could gleam down at the sight of you spread out for him, glistening in the dim light of the room, forming a sheen over the tips of his fingers.

An embarrassed noise sounded in the back of your throat and you tilted your head to the side to avoid his smoldering gaze. He tutted, grabbing hold of you by the chin to force you to look back at him. His eyes were lit up with the same fire as before, yet this time, it burned brightly, illuminating his thirst for salvation.

“Don’t do that,” he said, tone dripping with the command of the leader he was and had always been. “You’re goin’ to look at me while I take you. Had no problem lookin’ at Soap when you danced with him, so you should have no problem lookin’ at me when I make you come on my tongue.”

You had to close your eyes to compose yourself, sucking in a sharp breath that pierced your lungs and filled your chest with an ache only he could soothe. They sent shocks through your body, lighting up like fireworks.

When John seemed satisfied that you’d listen, that you’d digested every word and command that slipped off his tongue, he let go of your chin, pleased to see you kept your promise of keeping your eyes on him.

He returned his attention to your silky cunt, dipping a finger in the slick that seemed never ending. His mouth was practically watering at the visual, and he was desperate for a taste.

John wasted no time in stooping down to be leveled with your cunt, breath fanning over it and causing you to squirm. He sent you a warning glare before poking out his tongue, gliding it over the sensitive nub before fully engulfing his mouth around it.

The sound you released was near inhuman, strangled and choked in surprise. His mouth was warm and inviting as he began devouring you, humming greedily at the tangy taste that smoothed over his tongue and filled his mouth.

It was intoxicating, addicting, surging through his bloodstream like a high he’d never come down from. Hazy, clouded. It disoriented him, smoothing over his mind with nothing but thoughts of consuming you until you were a puddled mess.

Your hand found its way in his hair, tangling in the mess of strands and tugging. Possessive in the way you pushed him deeper into your core, his nose digging into you as he inhaled the sweetness of your scent. The smell of you attracted him like hummingbirds to nectar, and he couldn’t get enough.

“Fuck,” he breathed into you, and the gust of air mixed with warmth and a slight chill all at the same time had you whining. “Look at you. Such a pretty little thing, aren’t you?”

He didn’t bother to wait for your answer before diving right back into you. He didn’t want to hear words, he didn’t want to hear smugness. All he wanted was to hear those sweet sounds filter out of you, like a soothing song playing on repeat.

He became more possessive in the way he took you, the subtle tenderness he was showing before melting into filth. Your slick soaked into the coarse hairs of his beard, chin dripping with evidence of your arousal that only became more pungent the more he sucked and prodded.

“John,” you whimpered helplessly, and he rumbled with a satisfied noise, so you repeated his name. It became pleading, desperate, voice turning into a shaky mess that only sent his mouth into overdrive.

The ghost of a fingertip brushed along the rim of your entrance, and when you took a breath, he seized the opportunity to sink it into you, all the way to the knuckle. It curled into you, before pulling out then pumping back in. It became a dance, the way his finger fucked into you with curious ambition, and it had you pooling into a moaning mess, writhing from stimulation.

His eyes fluttered up to meet yours with his mouth still wrapped around your clit, and you nearly gushed just from the look of him alone – beads of sweat already dotting on his hairline, brows furrowed in concentration, eyes dark and sultry with intentions of ruining you. They locked on to yours and never left for a single moment, not even when he stretched you open with a second finger, then a third.

It was all so fucking much. You could barely think with him filling you, curving right into that sweet spot of serenity that had stars bursting in your vision. Your body moved on its own accord, and to keep you still, he placed a thick arm over the plains of your stomach, holding you down while keeping the other occupied in the tightness of your cunt.

Too much, so much, all at once. It had your mind in the skies, floating on clouds of euphoria.

John seemed to map out your body language just from one taste of you on his tongue along, because when your stomach began to tighten and flex, legs trembling and quivering, he pulled his mouth away from you, fucking you with his fingers with a quickened pace.

“You goin’ to come, sweetheart? Hm?” he asked, and it felt as if he was teasing you. Mocking you, filled with overwhelmed smugness. “Goin’ to come from my mouth like I told you?”

You nodded vigorously, shameless in your own desperation. The squelch of his fingers dripping into your cunt with every shallow thrust was enough to leave you breathless. They filled you with a frantic need, shooing away the emptiness you once felt and submerging you in a febrile warmth.

“Good fuckin’ girl,” he praised, and it had you keening.

You attempted to lift your hips, pushing them in the direction of his mouth. He released a hearty chuckle, eyes crinkling from his bashful smile before he gave in to what you wanted, Mouth returning to your cunt, sinking into you like a feral animal, quenching his thirst and hunger.

You cried out, hand tightening in his hair. It was almost instant that you felt the coil of string ready to snap at any moment, tearing and tearing, bordering you on the edge of breaking apart.

His tongue flattened over your clit before circling his lips and giving it a hard suck, all while curling his fingers once more. That was enough to send you over the edge, your climax hitting you like a collapsing building, smothering you in its aftermath.

Your entire body shook, wetness gushing around his fingers as you clenched on them for dear life. You ground your hips subconsciously, fucking yourself on his fingers and riding out the seamless paradise and basking in the warm light. All thoughts blanked into nothing but your own ecstasy, and you selfishly drowned yourself in waves of rapture.

You were in heaven, you were one with the angels, singing godly praises with a halo over your head and a fluorescent glow that accumulated around you. This was what peace on Earth felt like, this was what it felt like to die and be reborn.

John’s voice was the gospel, embracing you with clarity and purpose, guiding you to the pearly gates to seek pursuit of happiness.

When John pulled away from you and carefully slipped his fingers out of you, he brought them up to your view, flaunting them with pride. His chin was soaked, glistening with sinful beauty, mangling itself in the hairs of his beard.

If you weren’t so high off of pleasure, you might’ve thought that John was God himself, smiling down at you from the clouds and showering you with loving conviction.

“See that, sweetheart?” he asked, referring to the sticky strings that stuck together when he parted his fingers. “That’s from me. And nobody’s goin’ to get a chance to taste you like I have. We clear on that?”

It was a silly thing for him to even state, given he had just taken you to oblivion, but you nodded anyway, going as far to even hum in dazed satisfaction when he brought his slick-covered fingers to your lips and you wiped them clean.

Jealousy was a disease, and you were the only thing that could cure John of the simmering rage that came with it. Now that he’d made it clear who you belonged to, the ugly monster returned to hibernation, and the sickening green that tainted his insides melted into worlds of color that only you could paint.

wrote this for my girly @ebodebo because i've been deprived of john and needed to write something for him asap, so i hope this met your needs (I need this man so badly it's unhealthy) <3

if you see any writing mistakes, mind you it’s 3am and i woke up to write this so no u didn’t

#cod#call of duty#cod mw3#cod x reader#cod mwii#cod fanfic#cod oneshot#captain john price x reader#john price x reader#captain john price#john price#captain price#i'm gonna eat him#cod smut#john price smut

870 notes

·

View notes

Text

Old-School Shave

“My shaving razor’s cold and it stings.” Lyrics from Daydream Believer by The Monkees, 1968

Trends evade me. What the cool kids, or cool oldsters, were wearing blips my radar long after Hot Topic or L. L. Bean phase it out. So my dive into the past casting about for an old-school razor ended in surprise. Wet shaving is a thing! Again.

My generation saw double-edged safety razors as grandpa’s archaic shave. The trend that would culminate in the cartridge razor was already growing when hair sprouted on my face. Blade companies sold single-edged blade dispensers. The dispensers had a key that fit into the razor’s head. Pushing a slider forced a new blade into the razor while sliding the used blade out. The dispenser had a second compartment to hold the used blades. It was the paragon of convenience. (See photo below.)

But more was afoot. Gillette introduced twin blades with the Trac II. TV commercials dramatized the first blade lifting and cutting a hair. Then, with the first blade still holding the hair, the second blade neatly trims it at skin level. But if the Trac II could really do that, it was too late. Around that time a French company, Bic, developed a disposable razor for their home market. And Gillette, reading the writing on the wall, dropped its Good News disposable razor on the American market. The Good News was the Trac II revamped as a throwaway shaver. And this is where it went off the rails. "The width of a human hair" is famously used to express how small something is, or how tight its tolerances must be. Chintzy blades injection molded into a holder can’t reach the needed TV commercial tolerances. Not at 99¢ each. There was no way for both blades to act on a single hair. But we bought them anyway.

The race was on. Disposable razors became disposable cartridges. Twin blades became triplets became quadruplets. Became quintuplets. Along came moisturizing strips. Along came swivel heads. And 99¢ was no longer a speck in the rearview mirror. All this without shaving being one iota better.

In the lost years of the pandemic I started going to a barber shop. Not a new stylist. Not another Super Cuts or Great Clips. A barber. The plan was to get a good old fashioned #2-and-up men's haircut. And on a regular schedule. I needed to start treating myself like I cared about how I looked. So that's what I did. In the luck of the draw the first barber I tried was a master. Her attention to detail was phenomenal. And the hot-shaving-cream, straight-razor trim of my hairline was to die for. I started wondering what else I had been missing.

Turns out it was shaving. The feel of the barber's straight razor tripped a neural circuit. Taking a straight razor to my own face was unimaginable though. Especially one I had honed and stropped myself. But images from the Demon Barber of Fleet Street helped me recall that somewhere in a lost corner of grandpa’s medicine cabinet was a safety razor. A double-edged safety razor. When Father's Day rolled around I knew what to ask for.

As with all trends, wet shaving has its hype. It's cheaper. It keeps plastic out of the environment. It's a better shave than a cartridge razor. The list goes on. Are any of those things true? Blade cartridges are not recyclable. So the environment part is true. A dozen shaves from double-edged blades is far and away cheaper than an equal number from cartridge blades. But… You have to start with a high quality razor. And various other accoutrements. All that needs amortized before any savings kick in. Shave quality? That’s a tricky one. Admittedly, there is no faster way to scrap hair from your face or legs than a cartridge razor. But a quality safety razor—with the proper blade and a little care—will do what the Gillette Fusion 5 cannot. Even at $3.16 each.

But I'm not sure any of that matters. There is really only one compelling reason to wet shave: It's personal.

Every face is different. I'm sure every set of legs is as well. So shouldn't shaving be personal? With wet shaving it's not just the blades. It's not just the razor. It's not just your shaving soap. It's not just your brush, your balm, your lotion. These things are part of a set to be tweaked toward your personal result. Manufacturing engineers or chemists at Gillette, Mennen, Schick, Bic or Harry no longer decide how your shave comes out. You decide. Does this blade changed every day work better? Or that blade changed once a week? Do you like heavy razors with long handles? Or does lighter or shorter suit your style? Do you like the look of polished stainless? Or is jaunty anodized aluminum your speed? Should the razor expose a blade edge that is more aggressive? Or does just a hair's breadth work? Is a shaving brush of silvertip badger hair a luxury or a necessity? Should its knot be large, medium or small? Does a shave soap heavy with tallow suit your skin well? Or are duck fat or botanicals a better choice? Do you want to slap on an astringent aftershave? Or is rubbing in a balm more to your liking? How much time would you like to take? How little? What fragrance families—if any—do you enjoy?

You see what I mean? But there's more. It’s not only about wet shaving’s decidedly individual choices; it’s the care and technique involved. By comparison, cartridge shaving has all the romance of taking out the garbage. Plus, a well-made safety razor has the feel of permanence. All the plastic from Bic and Schick is headed for a landfill. Your Henson AL-13 might well be passed down. Your high-end Muhle or Merkur is definitely worthy of inheritance.

Maybe that was what I wanted to recapture in the lost years of the pandemic. It’s turmoil, it’s upheaval, it’s shortages, it’s endless propagandizing, all created a yearning for permanence. A little extra self-care became soothing. It was a little surprising to find it in a wet shave.

When King Camp Gillette, in 1902, developed a safety razor with cheap replaceable blades it improved shaving. Other options were straight razors. Or safety razors with removable blades that had to be honed and stropped. But let’s not kid ourselves. Gillette’s goal wasn’t improvement; it was about selling something over and over again. The Fusion 5 is just the inevitable result of that march. But your shaving razor doesn’t need to be cold and sting. You can go a short distance back in time for a warm luxurious shave.

2 notes

·

View notes

Link

Check out this listing I just added to my Poshmark closet: UGG Men's Slide Sandal Slippers.

0 notes

Text

Canon Pokedex Entries (That Belong To Beta Designs)

One interesting thing about Pokemon’s development history is that in the early gens, the ‘dex tended to be written early on, but then would never be updated after the designs were finalized. This means that a lot of Pokedex entries in the games apply to designs that we never got. I couldn’t find any collections of these “contradictory” entries, so I wanted to list them out here.

(Note that this strictly applies to Pokedex entries only. If you guys would be interested in seeing a list of similar non-Pokedex things, like typing or design elements held from the beta, let me know.)

Umbreon--Gold

When agitated, this Pokémon protects itself by spraying poisonous sweat from its pores.

We’ll start with an easy, well known one: Umbreon’s Gold entry mentions it spraying poison because it was originally meant to be a poison-type according to Gen 2′s Spaceworld beta.

Dragonair--FireRed

It is said to live in seas and lakes. Even though it has no wings, it has been seen flying occasionally.

Dragonair’s beta design was named “White Dragon”, and as you can see from the image above, it had no wings--hence why Dragonair’s FireRed entry claims that it flies without wings despite it very clearly having wings.

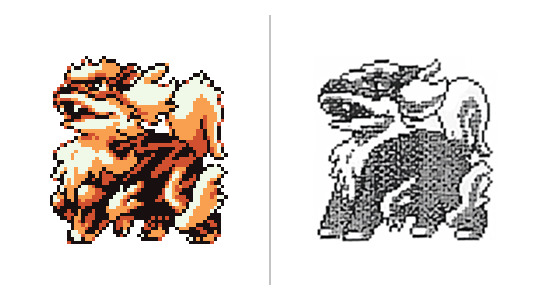

Arcanine--Blue/Red and Stadium

A Pokémon that has been admired since the past for its beauty. It runs agilely as if on wings.

A Pokémon whose beauty is legendary in China. It is said to run gracefully and lightly, as if it were flying.

Ignoring that the IRL location of China no longer exists in Pokemon, these entries mention it running “as if” it had wings or was flying. This is because Arcanine’s beta design, called “Wing”, had wings on its heels (which is also why Arcanine’s final design has clumps of fur around the legs).

Celebi--Gold

When Celebi disappears deep in a forest, it is said to leave behind an egg it brought from the future.

A very obscure and weird one. Celebi’s original design was based off of Kokopelli, a fertility deity worshipped by many indigenous cultures, such as the Hopi. Kokopelli is said to carry children on his back to give to women, hence this very weird Celebi entry that states that it brings eggs from the future. (Side note: this is also probably the biggest single improvement over the beta Gamefreak has ever done because seriously, what were they thinking).

Latias--Ruby

Latias is highly sensitive to the emotions of people. If it senses any hostility, this Pokémon ruffles the feathers all over its body and cries shrilly to intimidate the foe.

Latias appears to be fairly smooth in its final art, with not much implying it’s supposed to be feathery, and certainly not much implying it has enough long feathers to ruffle. This is because Latias and Blaziken were once one Pokemon; one that clearly had a lot more feathers than the final design does.

Shuckle--Gold, Crystal, and Black

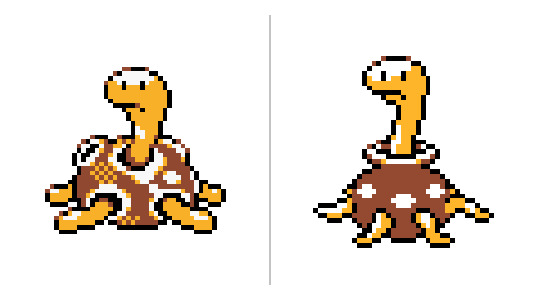

The Berries it stores in its vase-like shell decompose and become a gooey liquid.

The fluid secreted by its toes carves holes in rocks for nesting and can be mixed with Berries to make a drink.

It stores berries in its shell. The berries eventually ferment to become delicious juices.

Another weird one. Based on Shuckle’s original design and its original Rock/Ground typing, Shuckle is either based off of snake wine of all things, or the act of fermenting alcohol in a jug or piece of pottery. This is why it has the category of “mold Pokemon” (”fermentation Pokemon” in the original Japanese) and why there’s an emphasis on it making fermented juices (alcohol) in the ‘dex.

Gligar--Gold and Ruby

It flies straight at its target's face then clamps down on the startled victim to inject poison.

Gligar glides through the air without a sound as if it were sliding. This Pokémon hangs on to the face of its foe using its clawed hind legs and the large pincers on its forelegs, then injects the prey with its poison barb.

It’s still somewhat there in the final design, but Gligar appears to be based off a facehugger, judging by the beta. It’s even possible that this is where the English name comes from (as in, H. R. Giger).

#pokemon#pkmn#beta pokemon#umbreon#dragonair#arcanine#celebi#latias#shuckles#gligar#outdesign posts things#was debating on including vulpix's entry about it being born with one tail because it originally had a pre evo with only three tails#but that's not a direct contradiction and it has to do with a pre evo rather than just an old beta design for vulpix itself

136 notes

·

View notes

Text

Cravings (Albert Wesker x Excella Gionne)

Warnings: smut, angst.

Prompt: Excella goes to Wesker’s room to give him his medicine but it takes an interesting turn of events.

This was requested by @renlaufeysonwesker. Hope you like it.

Ko-fi

Excella’s heels clicked on the metal floor as she walked towards Wesker’s room. Missions and tasks completed with perfection granted her many benefits, but none of them was greater than having his trust. She proved herself worthy. Under his guidance she gained control over Tricell, and thus he became her mentor. But they weren’t were like this. Excella wasn’t a fool herself, she wouldn’t blindly trust a man. It was because of his reputation that she accepted the meeting in the first place and she wasn’t disappointed by either his appearance or by his offer. Excella’s eyes shinned in greed when she saw the variety of viruses laying on her table. G-virus, T-virus, Mold, Las Plagas, all of them worth million of dollars if in good hands. Wesker also offered his service in exchange of proper equipment to develop a stronger virus and Excella happily agreed.

The next events were just crossing her mind in a chaotic order. She was so young and she never realised that Albert was slowly taking control over her as well. Now she was all alone, all of them long gone. The people she knew and worked over the years were replaced with those braindead majinis. They could barely speak and they smelled awful, but they were easily controlled by him. In fact, this is what Albert truly brought, death. His new virus was a failure that killed everyone. Not a single soul survived and Excella had her doubts Albert could survive too. Was his true goal the extinction of humanity? Was he despising them so much. She followed him blindly.

She was so lost in her thoughts that when she came back to reality she was standing in front of his door. How long has she been staying there? She had one task that was mandatory: give Wesker his dose of serum and leave. Now that she was the only one, the pressure of the immense failure was heavy on her shoulders. With shaky hands she knocked at the mad man’s door waiting for an answer.

“Give him the shot and leave.” She took deep breaths. The waiting was agonizing.

“Come in.”

He seemed displeased. Was he ever happy? She tried to remember. Even when she succeeded in her tasks he still was still disgusted. He had a violent reaction every time she tried to touch him too. She never touched another man, or let anyone touch her, and never knew what was like to receive back. She was saving herself for the false god.

“Do i have to repeat myself?”

He was impatient. Every minute past the limited term for his injection was another minute of agony. The virus would start to take over and destroy him.

Excella pressed the access card near the metal panel from his door and the light turned green. Inside it was even darker than in the corridors. She took a step forward and the door automatically closed behind her.

Her vision started to accommodate with the darkness and she was able to see her surroundings. The room was a mess. On the floor there were documents and reports scattered around as well as broken test tubes with god knows what substance leaked on the floor. She slowly headed forward trying not to knock things down or bump accidentally into Wesker. When her vision fully accommodated she saw Wesker, sitting on a chair, with his back at the door and held his head in his hands. He didn’t bother to look at her, he instead just rolled up his sleeve and stretched his arm. Somehow she was grateful he was sitting. In this atmosphere the only thing she wanted to see were his red eyes looking down at her.

She quickly approached his arm and ran a few fingers over his skin, feeling his prominent veins and hot skin, before injecting the serum into his body. Even if she didn’t look at him she could feel his intense stare on her skin.

After emptying the syringe, she quickly got up but Albert grabbed her forearm. His grip was so tight that her skin began to burn.

“Why?” He said between his teeth. This tone wasn’t the tone of a god, but the tone of a desperate man on the verge of dying.

“Why what?” Excella tried to free herself but the more she struggled the tighter the grip was.

“Why did you fail me?”

Excella was speechless, and Wesker waited for a response. Seeing he doesn’t get any he stands up at inhuman speed, without loosening the grip, and stares at her with his red glowing eyes. The look on his face is one of anger and disappointment. His grimace lost his humanity and it frightened Excella. She tried to speak but the words would get stuck in her throat. The air was now enough to fill her lungs. She froze in place without knowing what to do.

“I gave you everything and yet you fail me. Everyone fails me.”“I will not fail you, please” she said between sobs. Crying was her only reaction in response to the fear she felt. It didn’t characterised her, and she knew Wesker wasn’t looking for this type of reaction as well, that’s why she suddenly felt like suffocating and die. “I want you help you, please, i can help you.” Wesker wanted to see that self-assured woman she met a few years ago, but what was now in front of him was just a crying mess. The pain started to slowly leave his body, but not as fast as it used to be, that’s why he is putting so much pressure on the human in front of him. He could feel his morality approaching and he needs a solution fast.

With his mind a little clearer, he realised frightening her would not provide any results. She’ll just end up like the rest, and he needed her to live a little longer so, he loosened the grip around her wrist.

When she felt a little freedom around her wrist she let out a deep exhale and her body became less tensed. She couldn’t see much, but she felt Wesker relaxing too. He eventually let go of her, but didn’t turn around as if he was expecting something, a word, some reassurance. He knew what he wanted, but he let Excella to make the decision.

Excella took this opportunity and raised her hand to cares his face, examining under her fingers his defined features. She couldn’t see much, but she felt his lips turning into a smirk. This is the most intimate gesture they ever shared and it did not ended in a painful rejection. Wesker moved his hands on the sides of her body griping at the flesh. His body still ached because of the slow effect of the serum, but he still found pleasure in the moment. After all, Excella was pleasant to the eye, and he tried to make her cling to him as much as possible. When her fingers found his lips he started to place small kisses on them.

In this moment her desires were almost becoming reality. Wesker pulled her closer to his body so now they were pressing and slowly rubbing on each other. Excella wasn’t wearing a bra on purpose, and he could feel her had nipples rubbing against the thin material of his shirt. Seeing everything was in her favour, she leaned closer to his face until she could feels his hot breath over he cheeks. The shy kisses didn’t last long before Albert took the lead and parted his lips so his tongue could slide into hers.

At this point Excella turned into jelly and she was unsure of what to do next. This is what Albert was doing to her, when she was near him her reasoning would leave her mind. Seeing this Wesker took the lead again and removed her dress, then he cupped her boobs into his enormous hands. He ran his thumbs over her hardening nipples a few times then he pressed his hot mouth over one, sucking and biting it. Excella was struggling to remove his shirt too, as her hands were too weak. Pleasure overcome her senses. With his mouth still pleasuring her nipples, Wesker ran a hand and unzipped his shirt. Then, Excella didn’t hesitate to press her palms over the hot skin of his abdomen, squeezing his pecs and tracing every curve of his muscles with her fingers. He did trespass a little when he felt her touch because he is not used to this due to his disgust to human race. Before the virus he was more indulgent with others and often engaged in sexual activities, but after he started to see the world with different eyes. He changed his goals and he perceived every human need as a weakness.

These eager touches eventually led to Excella finally putting her hands inside his pants. She had a hard fight with his belt but she did it and now she was tracing the contour of his erection through his boxers with her fingers. She gasped when she felt how thick he was and she was afraid to think how long too. By the time Excella moved to his pants, Wesker was at her neck biting various portions of her skin.

“You want it?” He asked between kisses.

“Y-yes.”

A deep growl came from his throat before leading Excella to his bed. He positioned himself between her legs and pulled the fabric of her panties aside, revealing her pink cunt.

“Have you done this before?”

Excella remained silent. Wesker used two fingers to spread her lips apart and traced with a finger a line from her clit to her hole.

“It’s your first time, huh? I couldn’t guess, you don’t seem the type.” He began to thrust a finger inside her slowly.

“Relax, you’re not the first virgin in this world.” He inserted a second finger already filling her up.

“Excella dear, how are you going to be able to take my cock like this?” Wesker was making scissor motions trying to stretch her a little more. Excella was a moaning mess and wasn’t able to form words anymore. He made her feel so good and he didn’t even started yet.

Her heart started to bump rapidly when she heard the zipper. In a few fluid motions Wesker discarded his pants and now he was sitting close to her cunt with his erection exposed. She tried to get up but she was shortly pinned back down by Wesker, who bent over her.

“Breath, you’re going to be fine.” He kept whispering in her ear while slowly entering her. He felt his wet tip and her entrance, waiting for her approval. When she nodded Wesker began to push slowly. His tip didn’t enter properly and she started to feel the burn. By the time he was half deep she started whimpering and squirming underneath him. She felt so full.

“Shh, you’re with me. Come on, relax.” He kept caressing her face and placing small kisses on her cheeks. Their hands tangled and she dug her nails so hard that it almost drained blood.

He was moving at a slow pace until Excella told him to go deeper. The pain faded and pleasure started to take over her. Wesker began to move at his usual pace. He wished he could quickly go and turn the lights one, so he could see those beautiful breasts bouncing on his cock, but he felt her walls contracting meaning she was close. He pressed his thumb over her puffy clit and stroked rapidly. Excella nails were scratching his back but he couldn’t care less, he actually enjoyed a little pain.

“Albert, I- i think i need to pee.”

“No you’re not. Let it go Excella, cum for me.”

A few more thrusts and her legs started to shake, being completely dazed by her climax. Wesker pumped a few times before reaching his orgasm too, releasing his load into her.

She needed a moment, or maybe two, to come back to reality. Cuddling was not part of his schedule, so now that his pain was gone and that the effects of orgasm faded away, he got up and started to dress.

“Can you please stay a little more.” Excella grabbed a blanket to cover herself because she started to feel cold.

“I don’t want to waste anymore time.”

After all that’s what she was for him, a waste of time. Everyone around him was a waste of time. She was a fool to think she could get more affection from him. He left the room without even looking back at her. There was a short moment where light invaded the room and she could see him properly. He had a pleased look on his face but he was already distant and lost in his own thoughts. The door closed behind him and Excella was drowned in darkness again. Hot tears started to stream down her cheeks as she realized he will never have feelings for her no matter what and that she is just a toy he’ll eventually dispose off.

60 notes

·

View notes

Text

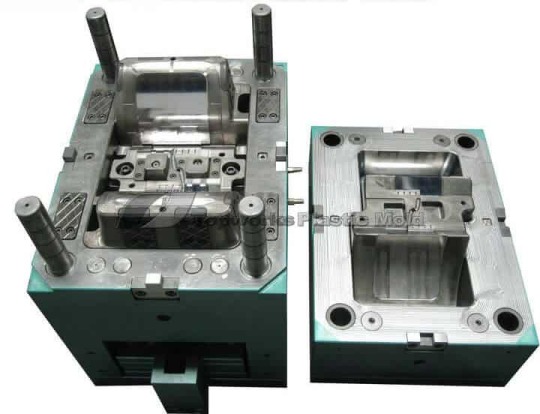

The mold design task book is proposed by the plastic parts craftsman according

According to the specific requirements and functions of the whole product of plastic products, which kind of external quality and specific size are determined: plastic products with higher appearance quality requirements and lower dimensional accuracy, such as toys; functional plastic products, size requirements Strict; plastic products that require strict appearance and size, such as cameras. If these problems are solved, the structural form of the mold will naturally be solved.04 is 0. The draft angle is directly related to the release and quality of the plastic products, that is, whether the injection can be carried out smoothly during the injection process: the draft angle is sufficient; the slope should be in the form of the part or the part of the molded part of the plastic product. The amount of plastic products produced is far beyond the reach of other molding methods. The number of cavities and their arrangement are determined according to the geometrical features of the plastic parts, the dimensional accuracy requirements, the batch size, the difficulty in mold manufacturing, and the cost of the mold.

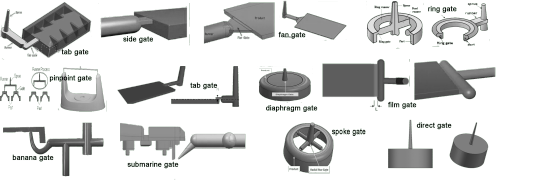

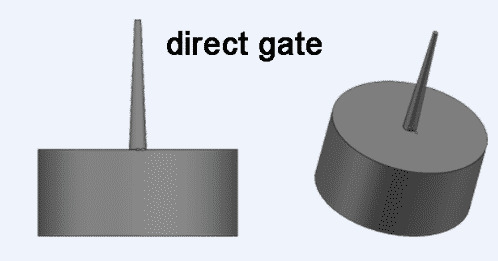

Under a small injection pressure, a shorter molding time, a better product than the general injection molding system is injected. When using the gate, To ensure the shedding of the runner, attention should also be paid to the design of the degasser and the nine-gate mechanism of the demister. The economic requirement of production is to make the cost of plastic parts low, the production efficiency is high, the mold can work continuously, the service life is long, and labor is saved. Stamping die - computer panel D. Smooth inflow; 4 gate position should be opened at the thickest part of the plastic part; 5 to avoid the plastic straight into the cavity wall, core or insert when flowing down the cavity, so that the plastic can flow into the cavity as soon as possible, and avoid The core or insert is deformed; 6 try to avoid causing the product to have weld marks, or make the weld mark appear in the unimportant part of the product; 7 the gate position and the plastic inflow direction should be such that the plastic can flow along the cavity when flowing into the cavity The parallel flow of the cavity in a uniform direction facilitates the discharge of gas in the cavity; 8 the gate should be placed on the most easily removed part of the product without affecting the appearance of the product as much as possible. Generally, it depends on the product requirements.

The design is exquisite, diverse, easy to use, and stable and reliable. 2. Compression molding die - Bakelite switch, scientific porcelain dishes D. The hot runner system, also known as the hot runner system, is mainly composed of a hot sprue bush, a hot runner plate, and a temperature-controlled electric box. Thermoforming mold - transparent molded packaging shell G. For example, ABS 0. When continuing to increase the weight of plastic parts, multi-cavity molds are rarely used. Low, so more people use the large nozzle system to work. This system is also called the waterless mouth system, which can save raw materials, is suitable for the case where the raw materials are expensive and the product requirements are high, the design and processing are difficult, and the mold cost is high. Determine whether the molding method uses direct pressure method, casting pressure method or injection method.02 mm or less. The mold design personnel design the mold based on the molded plastic parts task book and the mold design task book. For example, for the injection machine, the following should be understood in terms of specifications: injection capacity, mold clamping pressure, injection pressure, mold mounting size, ejection device and size, nozzle hole diameter and nozzle spherical radius, gate sleeve positioning ring size, The maximum thickness and minimum thickness of the mold, the stroke of the template, etc. Blowing mold - beverage bottle C. General definition of mold: In industrial production, various kinds of presses and special tools mounted on the press are used to produce metal or non-metal materials by pressure to produce parts or products of the desired shape. The shape, position, and mounting location of the heating element of the cooling, heating, and heating cooling grooves are determined. It consists of several sets of parts with a molded cavity. For example, what are the requirements for the appearance, color transparency, and performance of plastic parts, whether the geometrical structure, slope, inserts, etc. (2) Thermal radiation is difficult to control. Die-casting mold - super alloy, cylinder block (2) plastic mold is divided into different according to the production process and production products: A. The choice of gate location should follow the following principles: 1 The gate location should be selected on the parting surface to facilitate the processing and use of the gate. Determine the parting surface. The mouth is directly on the product, so the flow channel does not need to be demoulded. Adaptation; whether it will affect the accuracy of the appearance and wall thickness; whether it will affect the strength of a certain part of the plastic product. proposed in the process task book, whether it can be implemented. The depth of the venting groove varies depending on the plastic, and is basically determined by the maximum allowable gap in which the plastic does not generate a flash. Injection molding process description: Plastic mold is a tool for producing plastic products. (2) Sluice nozzle: The runner and gate are not on the parting line, generally directly on the product, so it is necessary to design a set of nozzle parting lines. Tools are collectively referred to as molds. Our common hot runner systems are available in single-point hot gates and multi-point hot gates. 4.

During injection molding, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and is processing of plastic products factory cooled and shaped in the cavity, and then the upper and lower molds are separated, and the product is ejected from the cavity from the cavity through the ejection system, and finally the mold is closed. Wait. The hot runner temperature is equal to the temperature of the injection molding machine nozzle, which avoids the surface condensation of the raw material in the runner and the injection pressure loss is small. (2) The pressure loss is small. Digestion process data, analysis of the requirements of the molding method, equipment model, material specifications, mold structure type, etc. Sluice system. A. The hot runner is re-entered into the cavity, which is suitable for single-cavity multi-point feeding or multi-cavity molds.. (3) Hot runner mold: This type of mold structure is basically the same as the fine water nozzle. (4) The cost of mold manufacturing is increased, and the price of standard accessories for hot runner systems is high, which affects the popularity of hot runner molds. Rotating Molding - Soft Plastic Doll Toys ◆ Injection molding is the most commonly used method in plastic processing. The arrangement of the cooling system and the specific form of the cooling system; the specific location and size of the cooling system; the cooling of key parts such as moving molds or inserts; the cooling of side slides and side cores; the design and cooling standards of cooling components Selection of components; sealing structure design. Digest the plastic parts drawing, understand the use of the parts, analyze the technical requirements of the plastic parts, dimensional accuracy and other technical requirements

1 note

·

View note

Text

Magpul QD Sling Stud Bipod Announced

Magpul has just announced their new Sling Stud QD Bipod. the Magpul Bipod | QD Sling Stud works with traditional Uncle Mike’s QD sling studs and shows that Magpul isn’t just thinking tactical!

Magpul QD Sling Stud Bipod pictures

Read the Magpul Press release below:

The Magpul Bipod | QD Sling Stud is the next offering in the Magpul bipod line. Able to mount on the Uncle Mike’s® Sling Swivel Stud that’s common to nearly every sporting rifle made, the Magpul Bipod – Sling Stud QD is the strongest, most fully featured bipod available with direct sling stud mounting.

With its rapid-attach sling stud mounting system, the Sling Stud QD bipod takes the effort out of aligning and tightening that comes with traditional sling stud-mount bipods. The stainless-steel mounting system self-locates and aligns perfectly every time, and an ergonomic thumbwheel allows for excellent grip to ensure easy tightening. Additionally, two sizes of non-marring, high-durometer rubber mounting gaskets are provided to ensure optimized fit and load distribution on narrow sporter-contour or wider target-style forends. The ability to mount a sling with standard locking sling swivels on the forend is maintained with a low-profile sling stud on the rear of the Sling Stud QD mount, which also provides for a quick detachment when it’s needed.

Magpul QD Sling Stud Bipod Pics

Magpul QD Sling Stud Bipod Extended

FDE Magpul QD Sling Stud Bipod

Magpul QD Sling Stud Bipod Image

Providing the same premium features available in the existing line of Magpul bipods, the Magpul Bipod | QD Sling Stud brings you the high performance associated with higher-priced bipods at a significantly more affordable price. Spring-tensioned, Mil-Spec hard anodized 6061-T6 aluminum and injection-molded, reinforced polymer legs stow neatly forward and snap down and lock into place with one hand. Leg extensions slide and lock securely with the push of a button on any of the seven locking detents extending from 6.6” to 10.0”. An industry-exclusive 50° of total tilt are controlled by a glove-friendly, knurled, tool-less, bipod locking knob located between the extended legs, allowing easy adjustment between shots. A soft rubber bipod locking knob cap is attached to the locking knob, giving users a steady, non-marring forward rest while the bipod is folded. Additionally, its staggered soft rubber feet hold fast on a variety of shooting surfaces and are easily removed with a roll pin punch. Should users choose to change feet, the Sling Stud QD’s legs accept most Atlas-pattern bipod replaceable feet. The streamlined housing and legs fit neatly under the barrel and are just under 2.5” deep and 3.3” wide when folded.

New Magpul QD Sling Stud Bipod

Magpul QD Sling Stud Bipods

Magpul Bipod | QD Sling Stud Features:

Rapid-attach, self-locating stainless-steel mounting system attaches to Uncle Mike’s Sling Studs on narrow or wide forends, while also providing a quick detachment capability

High strength reinforced injection-molded polymer, Steel and Mil-Spec hard anodized 6061 T-6 aluminum construction

(+/-) 25 degrees of tilt about the longitudinal axis of weapon for a total of 50 degrees

Uncle Mike’s-style sling stud on rear of mounting body

Rapid leg deployment with efficient single-handed adjustability

Quiet and positive leg deployment, adjustment and stowage

Adjustable friction knob for setting tilt and ease of movement

Individually adjustable leg lengths in 0.5” increments for a total of seven positions

Removable rubberized feet are compatible with B&T Industries Atlas pattern replaceable feet

Magpul QD Sling Stud Bipod images

Magpul QD Sling Stud Bipod review

Magpul Bipod | QD Sling Stud Compatibility:

Wide or narrow forends or M1913/M-LOK® adapters using the Uncle Mike’s pattern QD sling stud

Magpul Bipod | QD Sling Stud Colors:

BLK and FDE

MSRP Price:

$129.95

Purchase From Magpul here we will be adding them to our www.mtgtactical.com store soon as well.

Magpul QD Sling Stud Bipod Announced

Magpul QD Sling Stud Bipod Details

Magpul QD Sling Stud Bipod Announced Magpul QD Sling Stud Bipod Announced Magpul has just announced their new Sling Stud QD Bipod. the Magpul Bipod | QD Sling Stud works with traditional Uncle Mike's QD sling studs and shows that Magpul isn't just thinking tactical!

2 notes

·

View notes

Text

Cheap Injection Mould Intended for Safety Seat

Cheap Injection Mould Intended for Safety Seat

A safety seat can be a common item this requires a plastic injection mold. The theory of this mildew is complex. It must make it possible for molten plastic to be able to flow smoothly on the mold's cavities along with solidify the part with no difficulty. Some molds could possibly have additional parts pertaining to complicated features within the part. In inclusion, most devices slide in the part's cavity through a side-action or go. It's imperative how the mould design become precise and suitable for the part's pattern and manufacturing process.

Safety seat plastic moulds are widely-used to manufacture little one seats. These protection seats are recognised by several names including child restraint system, infant security seat, restraining motor vehicle seat, and little one restraint system. These seats are designed to protect children during an accident and are generally installed in magnetic generator vehicles. A seat belt putting your unit together helps adjust the kid restraint system to fit correctly. This safety seat is normally made of naff and metal areas.

The plastic injection mould to get a safety seat may be extensively tested throughout production. Its structure is reasonable but it produces plastic elements that meet design requirements. It also lessens post-production work as the parts have the best finish upon ejection. It can furthermore plastic injection mould for safety seat Manufacturer contain fillers this reduce plastic density whilst in the moulding process. Those fillers also can add strength towards finished part. These safety seats may also be very easy to repair if required.

Another important section of a safety seat is the headrest cover cheap part. This plastic component has undercuts in addition to lug structures as well as an inner recess produced by a square pit that passes via it. The mold includes a small structural area, but a very stable operation. It also improves design creativeness. With this software, manufacturers can without difficulty design and manufacture child car seats.

The mold has two halves that must be fixed to your large platen interior an injection molding machine. One half is fixed to a stationary platen, along with the other half is fixed to your movable platen. The ejector bar is attached to the rear half belonging to the mold base. One time the mold cavity provides cooled, the ejection process pulls out the solidified part in the rear half.

Another component to the mold will be gating system. The gating product is closely related into the layout of that cavities. This mold can be either one or two cavities. The internal dimensions of the mold are important factors, as is this injection molding machine's treatment capacity. A core-pulling shape makes the form convenient to create. The mould also can have a single-point latent entrance gating system regarding mass production.

The basic structure on this mold is three-plates. The theory of the pattern is illustrated inside Figure 5. The fixed mold foundation plate 1 translates into the opening push. The wedge TWENTY TWO is pushed away from the fixed mould slider 25 with a spring 43. A mechanical movement rod first reset mechanism is built to ensure a clean clamping process. While the main structure on the mold is essentially like that of your safety seat, the structural accessory holder needs to be flexible to bend about the anchoring pole.

The Plastics Sector Association's Machinery Safe practices Standards Committee has revised the conventional for injection molding. It isn't really surprising that the 2 organizations are lifetime improve their standards for plastic injection moulds. Those involved inside the safety seat industry should notice this new progression. Once approved, these new standards can be the standard for everyone safety seat moulds.

The idea became widespread and affordable, making it a indispensable tool intended for manufacturers to produce lots of consumer products. The leading advantage of injection molding is the fact it allows complicated shapes to get mass-produced. There is not any other manufacturing process which is so efficient plus versatile.

0 notes

Link

Check out this listing I just added to my Poshmark closet: NWT adidas Duramo Black & White Slide Sandals.

0 notes

Text

Rotary Seal Ring then add a small amount of magnesium oxide

According to metal powder supplier, silicon nitride is currently used as a horizontal continuous casting separation ring using excellent materials.The second method is first nitride silicon powder into silicon nitride powder, Rotary Seal Ring then add a small amount of magnesium oxide, placed in the mold, at a high temperature of 1700-1800 hot pressing.mhcmp.07mm. Molding method can use casting method, compression molding, hot pressing injection method or isostatic compaction methods. Then at 1350-1400 nitriding for a long time, through the reaction of nitrogen and silicon powder, the original network structure silicon nitride continue to develop, dense.

Silicon nitride ceramics used silicon powder as the raw material, used reaction sintering and hot press two kinds of process methods. for zinc refining furnace, is a widely used, great potential for developing high-temperature structural and refractory products. One method is nitrided at 1250 for a certain time, make the silicon powder surface form an interleaved ±- silicon nitride single crystal, fills the pores between the silicon particles, the green body has a certain strength. Furnace should be sealed tight, to ensure the vacuum and used safety. However, if the temperature quickly rises above the silicon melting point, then base will collapse because the silicon melting. Do second nitriding, fine grinding, for hot products. After the semifinished products through preliminary nitriding repair and processing, then placed in a high temperature of 1350-1450 for the second nitride, thereby producing silicon nitride ceramic.

The ceramic device produced by this method has a characteristic, not shrink, high precision. The specific method is nitriding silicon powder in the nitriding furnace, pulverized after obtain the silicon nitride, as the hot-press material. Also can be used as a crucible, conveying liquid metal pipes, pumps, valves, thermocouple protection tube, slide gate, high temperature products, ceramic firing batts, roller kiln rollers, and high-temperature ceramic bearings, ceramic turbine leaves, etc. Then purify raw materials, ingredients made into adobe. Another method is after keep warm and nitrided at 1250 for a certain time, nitriding at 1450, then silica melt into a liquid, the reaction rate is fast, the resulting silicon nitride are hardness, high density particles, dispersed within the generated network-like silicon nitride which formed in low temperature.

0 notes

Text

The Most Complete Guide On Fitness Yoga Socks

Some people feel that it is not necessary to wear fitness yoga socks, but when I practiced on a yoga mat for an hour or less without wearing socks, I found that my feet were always slipping and even starting to get cold. So, awesome sports custom socks for yoga is not missed, you can find them in this article.

What is fitness yoga socks?

Yoga socks are socks designed according to the needs of yoga practitioners. Its function is to protect yoga practitioners, reduce the probability of slipping during training, and also effectively maintain personal hygiene.

What do yoga socks look like?

You may have hurriedly placed an order when you only saw a picture of the homepage on the Internet. When you receive the package and happily open the express, you may be disappointed;

There is a little "bubble" on the bottom of the socks, which can make yoga socks have anti-slip silicone anti-slip particles, and they feel smooth and even.

Types of yoga socks

They are wide types of awesome sports custom socks for yoga on the market.

Backrest yoga socks

The first feeling of putting on the backrest yoga socks is that the mouth of the socks is a little tight and the ankles are tightened. The heel is wrapped just right, and basically fits the skin. Because of the mesh design of the instep, the ventilation is not bad, and the feet will not be too stuffy.

When you step on the flat ground, you will obviously feel that the anti-slip particles at the bottom of the socks have good support and will not collapse due to human weight;

When stepping on the yoga mat, the soles of the feet feel very comfortable. The anti-slip particles and elastic yoga mats just form a rigid and soft shape, which is indeed a bit like massaging the soles of the feet.

Five toe yoga socks

I personally feel that the breathability of the five-toed yoga socks on the feet is average, because the toes are tightly wrapped, and the feet feel very hot and stuffy inside, as if they are wrapped in a thick cotton cloth, unless it is really cold in winter. Otherwise, there is no need to choose this style.

There are also non-slip particles under each toe, so you can press the flesh under the toes and feel quite comfortable when you pad your toes.

Open toe yoga socks

The biggest feeling of the open-toe model is that the toe part is not smooth enough to put on and take off. You need to align your toes one by one through or pull them out. Because there is a cloth space between the toes, I feel a little uncomfortable between the toes. The heel of the socks is also relatively shallow. Compared with the previous two models, the wrapping is not good. In addition to these, the air permeability is very good.

Are yoga socks worth it?

Water absorbing, quick-drying and durable

Most of the anti-skid socks for yoga are finely woven with absorbent materials, and some products are made of new quick-drying materials, so the durability of absorbent and quick-drying is greatly improved.

Damping

The bottom of traditional yoga socks adopts a special terry structure to provide cushioning and shock absorption for the feet during exercise;

Anti-slip, protect your safety

Yoga socks are provided with point-like plastic point anti-slip particles on the back, which can effectively prevent yoga practitioners from slipping their feet when doing movements, and effectively protect the safety of yoga practitioners.

Keep warm

After the sweat flows, a person may become cold and even have menstruation after a period of time. Wearing them, there will be massage particles at the bottom of the yoga socks, which will allow the body to get a better massage, promote blood flow, and keep your feet warm.

Health

In the yoga studio, you and many practitioners step on the ground with bare feet, a mixture of various bacteria and ground dust. In addition, if someone has some problems with their feet, you need to pay more attention to hygiene. Wearing yoga socks can effectively reduce bacterial exposure.

Questions you may be interested in

Are grip socks good for yoga?

Yes, they can effectively help you maintain your balance and maintain your posture without worrying about your feet moving due to non-slip resistance.

How do I choose best fitness yoga socks?

Prevent feet confine

Breathable and skin-friendly.

Correct your deformational toes.

Support versus hammertoes, bunions, claw toes, and also other toes deformity.

Maintain your feets warm and comfortable when cold.

Springy and also elastic.

Ensure relief from feet ache.

Filled with soft non-skid bits on the soles for certain ground

Non-slippery as well as conveniently fitted.

Ensures independence of motion and flexibility being barefoot.

Should reduce irritation in between your feet.

How to clean yoga socks?

The method of cleaning yoga socks has a great influence on their service life. Do not use fabric softener to avoid breaking down the fibers.

Open Toe and Heel Socks

They can be washed on a 40 ° C setup. Once more, you need to stay away from ironing or bleaching the socks. If you want the doing yoga belts to final a lot longer, are sure you leave them to dry out normally, rather than in the dryer.

Grasp Socks

Prior to washing your grasp doing yoga socks, make certain to turn all of them completely. Use a gentle pattern as you do not would like to prevent the textile or component. For the best outcomes, put the socks level to dry normally or utilize a low-heat in the clothing dryer. Stay away from ironing or even utilizing bleach.

Can I wear ordinary socks for yoga?

Yes, but for safety reasons, choose barefoot or yoga socks. They can improve friction. Wearing ordinary socks has poor friction.

Can I wear compression socks for yoga?

Compression socks are more suitable for running, medical treatment, ball games or mountaineering. View custom compression socks nursing.

All in all, the use of fitness yoga socks has great benefits. They mainly keep my feet warm, stop slipping in warm weather, or protect my feet from the dirty gym floor.

Pick it!

Fitness yoga socks wholesale in our company, you can find perfect one from us, and there are other yoga socks for different purpose, if you are taking part in dance class, you can also find women yoga gym dance sport exercise cotton non slip massage fitness yoga socks. Any interests, welcome to contact us.

If you are interested in the following, you can click them to get more information.

RPET backack Manufacturer

Smart Soft Backpack factory

delonghi bottomless portafilter

single head coffee distributor

china oem display light

Injection molding machine for disposable fork wholesaler

sliding door window lock exporter

IEEE 1138 cable

IEC 60794-1-2

MIL-C 28830

0 notes

Text

How to choose windows suitable for home decoration?

In the whole process of home decoration, windows do not seem to be the focus, but they play an important role in daily life. There are still different windows such as sliding windows, casement windows, internal windows and external windows. Today, I would like to share with you the advantages and disadvantages of different window opening methods.

Sliding window

The sliding window uses the external force acting on the window frame to drive the slide rail to realize the opening and closing of the window frame. According to the number of blades, the sliding door is divided into single sliding door, double sliding door and multi sliding door.

Advantages: the sliding window fan has large width and high luminous rate.

Vertical hinged window

The hinges of doors and windows are installed on the sides of doors and windows. Windows open inward or outward for better sealing. Generally, double-layer and three-layer insulating glass can be installed.

Advantages: large open area, flexible mode, good ventilation and daylighting performance. Good sealing performance, good sound insulation and convenient window replacement.

Disadvantages: the inner window will occupy the indoor space, which is easy to bump, and the curtain is inconvenient to use. It's easy to seep when it rains.

Flip window

Flip window is to install the hinge or hinge under the window and push or pull the handle to open the window.

Advantages: because the hinged window has hinges, people can't come in from the outside, which is very safe for residents. It is suitable for places with limited installation positions such as kitchen and bathroom

Disadvantages: due to the small gap that can be opened, the ventilation is not very good.

Next, I would like to tell you some precautions for installing windows.

Precautions for installing windows:

Before installation, check whether the size of the window is the same as the opening size of the balcony.

When fixing the support with expansion bolt, the bolt shall be 10cm long. Before hitting the ball, hit the wall around the window frame with your hand. If the wall is empty, you need to hit it deeper.

After installing the window sash and all spare parts, seal evenly around the window frame to prevent rainwater from penetrating into the room from the gap between the window and the wall.

After reading this blog, do you know more about the different types of windows? Our sliding window handle exporters have professional sliding window handles. Any interests, welcome to contact us!

Tel: 0086-13929118702 Email: [email protected] sponsorship:51mm coffee tamper distributor

wholesale freezer light

custom bowling socks

Injection molding machine for petri dish exporter

0 notes

Text

Done To A Tee: Nigel Petrie’s immaculate R nineT chopper

Nigel Petrie is a bike builder who deserves way more attention than he gets. Despite his next-level fabrication skills and Born Free show invites, he tends to fly under the radar outside his native Australia. Which is a shame, because he doesn’t only build kickass bikes—he also builds incredible cars too, such as the Toyota Hilux ‘Drift Ute.’

Motorcycles have fascinated Nigel since his childhood days, growing up on the outskirts of a tiny rural town, some 200 kilometers away from Melbourne. Being outside mainstream life maybe explains why there’s nothing conventional about his builds.

Nigel has already turned a KTM 350 SX-F into a salt flat racer, and he’s now turned a BMW R nineT into a slim, elegant chopper with a 21st century vibe.

A boxer-powered BMW is not the first platform one usually thinks of when building a chopper. And Nigel already has a vintage Harley in his garage. So how did this strange business start?