#Single Skin Insulated Construction

Explore tagged Tumblr posts

Text

||COUNTDOWN ||SEASON 7 EPISODE 05 || SINGAPORE ||

#83daysofoutlander☆

She pressed her back against the tunnel wall, hands flat on the rough rock, and thought. That’s where they’d gone, then. It made no difference, but she closed her eyes to improve her concentration and summoned up the pages of the massive binder—presently on the seat of the vanished truck—that contained the structural and engineering details of all the hydroelectric stations under her purview.She’d looked at the diagrams for this one last night and again, hastily, while brushing her teeth this morning. The tunnel led to the dam, and had obviously been used in the construction of the lower levels of that dam. How low? If the tunnel joined at the level of the turbine chamber itself, it would have been walled off. But if it joined at the level of the servicing chamber above—a huge room equipped with the multi-ton ceiling cranes needed to lift the turbines from their nests—then there would still be a door; there would have been no need to seal it off, with no water on the other side.Try as she might, she couldn’t bring the diagrams to mind in sufficient detail to be sure there was an opening into the dam at the far end of the tunnel—but it would be simple enough to find out.

SHE’D SEEN THE TRAIN, in that brief moment before the doors closed; it didn’t take much fumbling round to get into the open cab of the tiny engine. Now, had those clowns taken the key to the engine, too? Ha. There was no key; it worked by a switch on the console. She flipped it, and a red button glowed with sudden triumph as she felt the hum of electricity run through the track beneath.The train couldn’t have been simpler to run. It had a single lever, which you pushed forward or back, depending on which direction you meant to go. She shoved it gently forward, and felt air move past her face as the train moved silently off into the bowels of the earth.She had to go slowly. The tiny red button shed a comforting glow over her hands, but did nothing to pierce the darkness ahead, and she had no idea where or how much the track curved. Neither did she want to hit the end of the track at a high rate of speed and derail the engine. It felt as though she was inching through the dark, but it was much better than walking, feeling her way over a mile of tunnel lined with high-voltage cables.It hit her in the dark.

For a split second, she thought someone had laid a live cable on the track. In the next instant, a sound that wasn’t a sound thrummed through her, plucking every nerve in her body, making her vision go white. And then her hand brushed rock and she realized that she had fallen across the console, was hanging halfway out of the tiny, trundling engine, was about to fall out into darkness.Head spinning, she managed to grab the edge of the console and pull herself back into the cab. Flipped the switch with one shaking hand and half-fell to the floor, where she curled up, gripping her knees, her breath a whimpering in the dark.

“Holy God,” she whispered. “Oh, Blessed Mother. Oh, Jesus.”

She could feel it out there. Still feel it. It didn’t make a sound now, but she felt its nearness and couldn’t stop trembling.She sat still for a long time, head on her knees, until rational thought began to come back.She couldn’t be mistaken. She’d passed through time twice, and knew the feeling. But this hadn’t been nearly so shocking. Her skin still prickled and her nerves jumped and her inner ears rang as though she’d thrust her head into a hive of hornets—but she felt solid. She felt as though a red-hot wire had sliced her in two, but she hadn’t had the horrible sense of being disassembled, turned physically inside out.

A terrible thought sent her surging to her feet, clinging to the console.

Had she jumped? Was she somewhere—somewhen—else?

But the metal console was cool and solid under her hands, the smell of damp rock and cable insulation unchanged.“No,” she whispered, and flicked the power light for reassurance. It came on, and the train, still in gear, gave a sudden lurch. Hastily, she throttled back the speed to less than a crawl.She couldn’t have jumped into the past.

Small objects in direct contact with a traveler’s person seemed to move with them, but an entire train and its track was surely pushing it. “Besides,” she said out loud, “if you’d gone more than twenty-five years or so into the past, the tunnel wouldn’t be here. You’d be inside… solid rock.” Her gorge rose suddenly, and she threw up.The sense of… it… was receding, though. It—whatever it was—was behind her. Well, that settled it, she thought, wiping her mouth with the back of her hand. There bloody well had to be a door at the far end, because there was no way she was going back the way she’d come.

There was a door. A plain, ordinary, industrial metal door. And a padlock, unlocked, hanging from an open hasp. She could smell WD-40; someone had oiled the hinges, very recently, and the door swung open easily when she turned the knob. She felt suddenly like Alice, after falling down the White Rabbit’s hole. A really mad Alice.A steep flight of steps lay on the other side of the door, dimly lit—and at the top was another metal door, edged with light. She could hear the rumble and the metallic whine of a ceiling crane in operation.Her breath was coming fast, and not from the effort of climbing the stairs. What would she find on the other side? It was the servicing chamber inside the dam; she knew that much. But would she find Thursday on the other side? The same Thursday she’d had when the tunnel doors had closed behind her?She gritted her teeth and opened the door. Rob Cameron was waiting, lounging back against the wall, lit cigarette in hand. He broke into an enormous grin at sight of her, dropped the butt, and stepped on it.

“Knew ye’d make it, hen,” he said. Across the room, Andy and Craig turned from their work and applauded.“Buy ye a pint after work, then, lass,” Andy called.“Two!” shouted Craig.She could still taste bile at the back of her throat. She gave Rob Cameron the sort of look she’d given Mr. Campbell.

“Don’t,” she said evenly, “call me hen.”

His good-looking face twitched and he tugged at his forelock with mock subservience.“Anything you say, boss,” he said.

Tunnel Tigers ~ An Echo in the Bone

#the frasers#outlander#outlander series#outlanderedit#outlander fanart#outlander starz#outlander book#outlander books#sophie skelton#brianna fraser#brianna mackenzie#outlander season 7#outlander 7x05

29 notes

·

View notes

Text

Working Hands (A poem for my dad)

Split, scabbed knuckles and

Grease under fingernails, tracing

Every fissure and whorl, an inky sheen

Perfumed by exhaust.

You sit down at the dinner table in a shirt my mother says should have been thrown out years ago,

Constellations of paint and oil and sweat and moth-holes.

A single bead of saline sweat rolls off the tip of your nose

Falls through the air

And lands in your glass of Coca Cola.

The ice cubes hiss.

I spent this summer, too, reddening my shoulders

Under midday sun

Rivulets of water pouring down my face, salting flushed cheeks,

Tasting salt as my muscles ache with effort.

Back at school in the studio

The grease and industrial solvents remind me of you.

The litho ink seeps into my palms, a dusky glow,

Tacky and fragrant like the Sunday paper.

Remember when we used to get the paper?

In orange plastic bags to protect it from the rain. You’d unfurl the pages, reclined on the couch, leafing through while you sipped your coffee.

That orange plastic waterproofed my broken arm, ballooned around my fist in the bathtub.

I think I was born to work with my hands

Or maybe I learned it from you.

I remember sitting in the basement, dust motes catching the evening light,

Begging you to draw things for me with your bulky construction pencil.

And you’d come home from a hard day’s work smelling of sawdust,

Of metal and sweat,

Glittering with specks of insulation,

Eggshell white or periwinkle blue spattered on your work boots.

I wonder, one day,

If I’ll be walking through the doorway,

Flushed and sparkling,

A bead of saline dripping from the end of my nose.

Will my callused, stained hands,

Sore from a day of work,

Reach down to hold the tiny pink hands of another?

Grime and paint and sweat are no deterrent to reaching arms,

Sunburned skin and tight muscles are no excuse

Not to sweep us up into an embrace.

The mold of me is made with your fingerprints.

In the valleys and clefts

I find oily residue,

perfumed like gasoline,

Old hurts echoed into the present by touch.

Some inks never dry.

But that doesn’t mean what’s stained is ruined,

Or what’s written is written in stone.

Let out each drop, til rivulets form, til

The things you can’t say spill off the end of your nose.

I’ll wait, hands cupped,

To catch you,

Until my palms run dry again.

5 notes

·

View notes

Text

Flat Roofs Contractors: Solutions for Common Flat Roof Issues

Flat roofs are a popular choice for commercial and residential properties in the UK due to their modern aesthetic, cost-effectiveness, and ability to maximise usable space. However, they come with unique challenges that require professional expertise to address. Flat roofs contractors specialise in installing, repairing, and maintaining these systems, offering tailored solutions to common issues like ponding water, leaks, and material degradation. In this article, we explore the most frequent flat roof problems, expert solutions, and why hiring a reputable contractor is essential for long-term durability.

Why Choose Flat Roofs?

Flat roofs, despite their name, have a slight pitch (up to 10°) to facilitate drainage. They are widely used for extensions, garages, commercial buildings, and modern homes because they are:

Cost-effective: Cheaper to install than pitched roofs due to simpler construction.

Space-efficient: Ideal for rooftop terraces, solar panel installations, or green roofs.

Aesthetically versatile: Complement contemporary architectural designs.

However, their low slope makes them prone to specific issues, which is where professional flat roofs contractors come in. Below, we dive into the most common problems and how skilled contractors resolve them, drawing on insights from leading UK roofing specialists.

Common Flat Roof Issues and Expert Solutions

1. Ponding Water

Problem: Flat roofs often struggle with water drainage, leading to ponding or pooling water that lingers for over 48 hours. This can degrade roofing materials, cause leaks, and weaken the structure over time. Poor installation or blocked drains are common culprits.

Solution: Experienced contractors ensure proper drainage during installation by incorporating a slight slope (typically 1:80) and installing efficient drainage systems like internal outlets or scuppers. Regular maintenance, such as clearing debris from drains and gutters, prevents blockages. For existing roofs, contractors may recommend tapered insulation to redirect water or liquid-applied membranes to seal low spots. Proactive Flat Roofing, a UK-based specialist, emphasises the importance of addressing ponding promptly to protect waterproofing integrity.

2. Leaks and Water Infiltration

Problem: Leaks are among the most common flat roof issues, often caused by cracked membranes, poor flashing, or degraded seals around penetrations (e.g., skylights or vents). Water infiltration can damage insulation, decking, and interior spaces, leading to costly repairs.

Solution: Contractors use advanced diagnostic tools like thermal imaging cameras to pinpoint leaks, as demonstrated by London Flat Roofing’s success in identifying and fixing leaks on the spot. Repairs may involve patching damaged areas with compatible materials (e.g., EPDM patches for rubber roofs) or applying liquid coatings for seamless waterproofing. For severe cases, a full replacement with high-quality materials like EPDM or single-ply membranes ensures long-term protection. Contractors also reinforce flashing and joints to prevent future leaks.

3. Blistering and Alligatoring

Problem: Blistering occurs when air or moisture gets trapped under the roofing membrane, forming bubbles that expand in heat. Alligatoring, resembling cracked alligator skin, results from prolonged exposure to UV rays or water damage. Both compromise the roof’s integrity.

Solution: Professional contractors address blistering by cutting away affected areas and applying a new membrane with a 6-inch overlap for a robust seal, as advised by Proactive Flat Roofing. For alligatoring, they clean the surface, apply a primer, and coat it with a reflective liquid membrane to restore flexibility and UV resistance. Using durable materials like EPDM or TPO during installation minimises these issues, as they are less prone to cracking.

4. Thermal Movement and Membrane Buckling

Problem: Temperature fluctuations cause flat roof materials to expand and contract, leading to membrane buckling or flashing detachment. Over time, this weakens the roof and creates entry points for water.

Solution: Contractors mitigate thermal movement by selecting flexible, high-quality materials like EPDM or single-ply PVC, which accommodate expansion and contraction. Proper installation techniques, such as securing membranes with adhesives or mechanical fasteners, prevent buckling. Regular inspections, especially after extreme weather, help identify and fix early signs of movement. Roofline Replacement UK recommends using robust materials and skilled installers to reduce thermal stress.

5. Punctures and Tears

Problem: Falling debris, foot traffic, or extreme weather can puncture or tear flat roof membranes, allowing water to seep through. Even small openings can lead to significant damage if not addressed quickly.

Solution: Contractors repair punctures with material-specific patches (e.g., EPDM tapes for rubber roofs) or liquid-applied coatings for seamless coverage. For high-traffic areas, they may install protective walkways or reinforce membranes with fibreglass. A. L. King Roofing advises using durable membranes and scheduling regular inspections to catch tears early. For commercial roofs with complex features like skylights, liquid systems like Kemper are ideal for waterproofing intricate details.

6. Poor Installation and Maintenance

Problem: Many flat roof issues stem from improper installation or neglected maintenance. Substandard workmanship, such as inadequate sealing or incorrect material application, leads to premature failure. Lack of upkeep exacerbates problems like blocked drains or membrane degradation.

Solution: Hiring accredited contractors registered with bodies like the National Federation of Roofing Contractors (NFRC) ensures high standards. Aspect, a UK roofing specialist, offers a 10-year installation guarantee and 12-month workmanship warranty for repairs, highlighting the value of professional expertise. Contractors also provide maintenance plans, including biannual inspections and debris clearance, to extend roof lifespan. Stuart & Moffat Roofing stresses that correct installation by experienced roofers prevents most issues.

Why Hire Professional Flat Roofs Contractors?

Choosing a reputable flat roofs contractor is critical for addressing and preventing these issues. Here’s why:

Expertise and Certification: Skilled contractors are trained to handle various materials (EPDM, felt, fibreglass, single-ply) and are certified by manufacturers, ensuring compliance with industry standards.

Quality Materials: Professionals use premium, durable materials with long lifespans (e.g., EPDM’s 50+ years) and offer warranties for peace of mind.

Advanced Techniques: From thermal imaging to liquid-applied systems, contractors employ cutting-edge methods for accurate diagnostics and lasting repairs.

Safety and Insurance: Accredited contractors are fully insured, protecting you from liability during repairs or installations. They also adhere to safety protocols, crucial for working at height.

Tailored Solutions: Contractors assess your property’s unique needs, recommending the best materials and systems for your budget and climate.

Choosing the Right Flat Roofs Contractor in the UK

To ensure quality service, consider the following when selecting a contractor:

Check Credentials: Verify NFRC registration, manufacturer certifications, and insurance coverage.

Read Reviews: Platforms like TrustATrader and Checkatrade provide customer feedback on local specialists.

Request Quotes: Obtain detailed, written quotes outlining materials, labour, and warranties. Avoid the cheapest option, as it may compromise quality.

Ask for References: Reputable contractors, like Fix All Roofing, provide case studies or client testimonials showcasing their work.

Ensure Guarantees: Look for insurance-backed guarantees and workmanship warranties, as offered by Flat Roofing Specialists UK.

Preventative Maintenance Tips

To maximise your flat roof’s lifespan, follow these tips from UK roofing experts:

Regular Inspections: Schedule professional inspections every 1–2 years to catch issues early.

Clear Debris: Remove leaves, dirt, and debris from drains and surfaces to prevent ponding.

Monitor Weather Impact: Check for damage after storms or heavy rain.

Invest in Quality: Opt for durable materials like EPDM or single-ply membranes during installation or replacement.

Conclusion

Flat roofs offer practical and aesthetic benefits, but their maintenance requires professional expertise to tackle common issues like ponding, leaks, and blistering. By hiring experienced flat roofs contractors, UK property owners can ensure durable, high-quality solutions that stand the test of time. From advanced diagnostics to premium materials, reputable contractors deliver peace of mind and long-term protection. For reliable service, contact a certified contractor today and safeguard your flat roof against the elements.

FAQs

Q1: How long does a flat roof last? A: A well-installed flat roof can last 20–50 years, depending on the material. EPDM and single-ply membranes often exceed 50 years, while felt and asphalt typically last 20–30 years with proper maintenance.

Q2: What is the best material for a flat roof? A: EPDM rubber is highly recommended for its durability, low maintenance, and 50+ year lifespan. Single-ply PVC and fibreglass are also excellent for specific applications, depending on your property’s needs.

Q3: How can I prevent ponding water on my flat roof? A: Ensure proper drainage with a slight slope, clear debris from drains regularly, and schedule professional inspections. Tapered insulation or liquid membranes can address existing pooling issues.

Q4: Are flat roof repairs expensive? A: Costs vary based on damage extent and materials. Minor repairs (e.g., patching) are cost-effective, while replacements are pricier. Professional surveys provide accurate estimates tailored to your roof.

Q5: Can I repair a flat roof myself? A: DIY repairs are risky due to working at height and the need for specialised knowledge. Hiring a professional ensures safety, quality, and warranties. For simple tasks, consult a contractor for guidance.

Learn more:

Roof Repairs Contractors Reveal Top Maintenance Tips for UK Homeowners

0 notes

Text

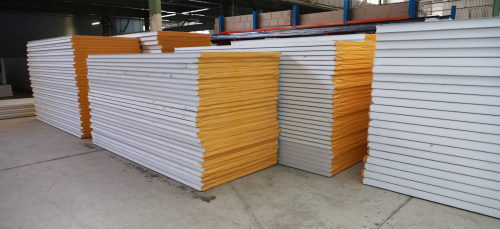

Modular Clean Room Manufacturers in India | PUF Panel & Sandwich Partition Experts

AUM Industries – Turnkey Clean Room & Modular OT Solutions in India

🌐 Website: www.aumindustriesmfg.com

📍 Based in: Ahmedabad & Vadodara, Gujarat | Since: 2019

About AUM Industries

Established in 2019, AUM Industries is a leading Indian manufacturer of cleanroom systems and modular medical environments. From concept to commissioning, we deliver custom-built turnkey cleanroom solutions that meet global standards and serve critical industries like pharmaceuticals, healthcare, food, electronics, and more.

🏭 Industries We Serve

Pharmaceutical Manufacturing Units

Hospitals & Modular Operation Theatres

ICUs, Diagnostic Labs & IVF Setups

Food & Beverage Processing

Electronics & Semiconductor Clean Zones

Chemical, Cosmetic & Engineering Industries

🔧 Our Products & Services

Clean Room Partitions: PUF / Rockwool Sandwich Panels, Pre-coated GI, SS, HPL

Modular OTs & ICUs: Class 100 environments with HEPA filters, positive pressure

Flush Doors: SS, GI, Aluminium doors with cleanroom-grade hardware

Air Handling Units (AHU): 500–100,000 CFM, single/double skin, CFC-free insulation

Aluminium Coving: 3-way welded, wall-to-wall and ceiling-to-wall

Fabricated Ducting: GI, SS, Aluminium, insulated and custom-designed

Laminar Air Flow (LAF): Ceiling-suspended, vertical/horizontal

Vinyl Flooring: Dissipative, waterproof, durable

Epoxy Flooring: Antimicrobial, hygienic, low maintenance

Pass Boxes: Static & Dynamic

HEPA Filters: 0.3 micron

IVF Lab Setups: Custom-built clean environments

Lighting Fixtures: Cleanroom-compliant

Turnkey Project Execution: Design to commissioning

Pan-India Technical Support: Engineering, installation & maintenance

🧱 Clean Room Partition Specifications

Panel Thickness: 50mm / 80mm / 100mm

Insulation: Polyurethane (PUF 40kg/m³), Rockwool

Ceiling Panels: Walkable/Non-walkable, Single/Double Skin

Advantages: Removable, relocatable, corrosion-resistant, fast installation

🏥 Modular OT & ICU Features

Noise level: <62 dB

Class 100 HEPA-protected environment

Positive pressure airflow, seamless construction

Materials: SS, GI, HPL – steam-cleanable and anti-microbial

🌬️ Air Handling Units (AHU)

Mounting: Floor, ceiling suspended, vertical

Capacity: 500 to 100,000 CFM

Construction: GI, Aluminium; single/double skin

Advantages: Vibration-free, corrosion-resistant, thermal break design

🚪 Flush Doors

Frame: 50mm / 80mm | Shutter: 40mm

Sizes: Height up to 2400mm | Width up to 1200mm

Materials: SS, GI, Aluminium

Cleanroom hardware: Interlocking, pin-type hinges, SS kick/push plates

🧼 Flooring & Finishing

Vinyl Flooring

Two-layer dissipative vinyl with conductive backing

Waterproof, elastic, abrasion-resistant

Epoxy Flooring

Antimicrobial, hygienic, seamless

Easy to clean and maintain

💡 Why Choose AUM Industries?

✔️ Complete Turnkey Solutions – Concept to commissioning

✔️ Custom Designs – Tailored to each project

✔️ Advanced Manufacturing Facility – Precision-built components

✔️ WHO, GMP, USFDA, NABH, MHRA Compliant

✔️ Skilled Pan-India Support Team

✔️ Timely Delivery with Competitive Pricing

🏅 Certifications & Regulatory Compliance

ISO 9001:2015

GMP (Good Manufacturing Practice)

USFDA (United States Food & Drug Administration)

WHO (World Health Organization)

NABH (National Accreditation Board for Hospitals)

MHRA (UK Medicines and Healthcare Products Regulatory Agency)

📍 Our Locations

Corporate Office: World Trade Tower – A-617, SG Highway, Makarba, Ahmedabad, Gujarat 380051

Manufacturing Facility: Plot No. 3, 4, B/h Shah Industrial Park – 2, Lamdapura Road, At Post Manjusar, Savli, Vadodara – 391775, Gujarat

📞 Contact Us

+91-9664808777

+91-9722549868

+91-9978629339

Email: [email protected]

Website: www.aumindustriesmfg.com

📣 Final Thoughts

At AUM Industries, we’re not just supplying components—we’re helping organizations build hygienic, compliant, and future-ready environments. Whether you’re constructing a hospital OT or a pharmaceutical production unit, trust AUM for quality, expertise, and peace of mind.

Let’s build something extraordinary together.

#CleanroomManufacturersIndia#TurnkeyCleanroomSolutions#ModularOT#CleanroomDesign#HospitalOTSetup#EpoxyFlooringIndia#USFDAComplianceIndia#PharmaInfrastructure#HealthcareInfrastructureIndia#MadeInIndiaCleanroom#AUMIndustries#PUFPanelPartitions

0 notes

Text

Fortifying Your Fortress: Unveiling the Security Secrets of Insulated Garage Doors

We all cherish the feeling of safety and security within our homes, that comforting sense of being protected from the outside world. While we often focus on the obvious security measures like front door locks and alarm systems, there’s a significant entry point that can sometimes be overlooked: the humble garage door.

A standard, uninsulated garage door, often constructed from a single layer of relatively thin metal, can unfortunately represent a point of vulnerability. However, by choosing an insulated garage door, you’re not just investing in temperature control and noise reduction; you’re also significantly bolstering your home’s security in ways you might not have even considered. Let’s delve into the often-unsung security advantages that these robust doors offer.

The Steel Shield Within: Strength Beyond Insulation

The fundamental upgrade that an insulated garage door provides in terms of security stems directly from its enhanced construction. Unlike their single-skin counterparts, insulated garage doors are engineered with multiple layers. Typically, this involves a dense core of insulating material, such as polyurethane or polystyrene foam, firmly bonded between two layers of steel or another resilient material like aluminium. This sandwich-like construction creates a far more substantial and rigid barrier than a single sheet of metal.

The insulation itself contributes significantly to the door’s structural integrity, acting like a reinforcing element that resists bending, warping, and impact. This inherent strength forms the foundation of the increased security that these doors offer, making them a far less appealing target for anyone looking to gain unauthorised access.

Thwarting the Uninvited Guest: Resistance to Forced Entry

The robust nature of an insulated garage door makes it considerably more difficult to force open. Opportunistic intruders often rely on speed and minimal resistance to gain entry. A flimsy, uninsulated door can be relatively easy to pry open with a crowbar or even kick in with sufficient force. The multi-layered construction of an insulated door, however, presents a much tougher challenge. The bonded layers and the density of the insulation provide significant resistance against such attempts. The door is less likely to buckle or give way under pressure, forcing potential intruders to expend more time and effort, increasing their risk of being detected.

This inherent resistance can be a crucial deterrent, often prompting them to seek out a less fortified property. Imagine the difference between trying to bend a thin piece of cardboard versus trying to bend a thick, reinforced panel — that’s the level of increased resistance an insulated garage door offers.

A Visual Pledge of Protection: Projecting an Image of Security

Beyond the tangible physical strength, the very appearance of an insulated garage door can contribute to your home’s security. These doors often have a more substantial and well-built look compared to their thinner, uninsulated counterparts. This visual solidity can subconsciously signal to potential burglars that your property is well-maintained and that gaining entry might be more challenging.

A well-kept home with visible security features, even subtle ones like a robust-looking garage door, can often be enough to make an opportunistic thief think twice and move on to an easier target. It’s about projecting an image of security that discourages unwanted attention in the first place.

Locking Down Your Belongings: Enhanced Mechanisms for Added Defence

The increased security of insulated garage doors isn’t solely reliant on their robust construction. Many manufacturers also equip these doors with upgraded and more sophisticated locking mechanisms. While a standard garage door might feature a simple slide bolt or a basic T-handle lock, insulated models often incorporate multi-point locking systems that secure the door at several points along its width. Some even include internal deadbolt mechanisms that provide an extra layer of security, similar to the deadbolts on your front and back doors.

Furthermore, the solid construction of an insulated door provides a more stable platform for these advanced locking systems to function effectively, ensuring they can withstand greater force. Increasingly, insulated garage doors are also being designed to integrate with smart home security systems, allowing for remote monitoring and control of the door’s locking status, further enhancing security.

Beyond Break-ins: Enduring Resilience Against Damage

The inherent strength of an insulated garage door also translates to increased resilience against accidental damage and even vandalism. Whether it’s a stray football, a minor bump from a vehicle, or an attempted act of vandalism, an insulated door is far less likely to dent, bend, or suffer significant damage compared to a thinner, uninsulated door. This durability not only keeps your garage door looking better for longer but also contributes to its long-term security.

A damaged garage door can be a security vulnerability, potentially making it easier for someone to gain access. The robust construction of an insulated door helps to mitigate this risk, ensuring your garage remains a secure part of your property for years to come.

Peace of Mind: Investing in Your Sense of Security

Ultimately, the enhanced security features of an insulated garage door offer a priceless benefit: peace of mind. Knowing that your garage, a significant entry point to your home, is more secure can provide a profound sense of comfort and safety for you and your family. This is particularly true if your garage is directly connected to your living spaces, as a breach in the garage could easily provide access to the rest of your home.

By investing in an insulated garage door, you’re not just upgrading your home’s functionality and energy efficiency; you’re also making a tangible investment in its security and the well-being of your loved ones. That feeling of enhanced security, of knowing you’ve taken an extra step to protect your home, is a benefit that truly has no price tag.

Think your garage door is just for parking the car? Think again. Discover the surprising security secrets hidden within insulated garage doors. Beyond keeping your garage warmer in winter and cooler in summer, these robust doors offer a significant and often overlooked layer of protection against intruders.

Learn how their reinforced construction, upgraded locking systems, and even their solid appearance can fortify your home and provide you with invaluable peace of mind. It’s time to upgrade to a garage door that not only insulates but also actively safeguards your property.

0 notes

Text

Benefits Of Solar Window Glazing For Residential And Commercial Spaces

Homeowners and business owners are always looking for solutions to maximize energy usage while providing cozy, productive spaces in the modern era, when sustainability and energy efficiency are crucial. An efficient alternative is solar window glazing, which blends cutting-edge window coatings with solar control elements. In addition to improving a building’s overall efficiency, it has several other advantages besides shielding interior spaces from intense sunlight. Energy savings, UV protection, increased comfort, and lower heating and cooling expenses are just a few of the many benefits that solar window glazing offers, whether in residential or commercial settings.

Cost reduction

Significant savings on heating and cooling expenses result from solar window glazing’s capacity to maintain constant interior temperatures. The absence of insulation in traditional windows, especially single-pane ones, results in energy loss and increased electricity costs. Solar window glazing reduces the need for air cooling, one of the largest energy costs, in warmer areas by blocking a significant portion of solar heat gain. Solar window glazing reduces the demand for continuous heating in colder climates by retaining heat. Over time, this saves a significant amount of money by lowering heating and cooling expenses. Even though solar window glazing may cost more to install initially than conventional windows, the long-term energy savings can yield a significant return on investment, making it a cost-effective choice for the owners.

Energy savings

Because solar window glazing can conserve energy and lower overall energy usage, it has become a popular alternative. Solar window glazing uses unique coatings to control the amount of light and heat that enters windows, saving energy. The stable internal temperature is ensured by solar window glazing, which serves as a barrier against excessive heat during hot weather and aids in retaining warmth during colder months. This implies less dependence on heating and cooling systems, which lowers energy use and, in turn, energy costs. By lessening the load on HVAC systems, solar window glazing also helps them last longer, which eventually ensures more economical and sustainable operation.

UV protection

Solar window glazing not only controls temperature but also offers excellent UV protection, as the sun’s harmful rays can cause fading fabrics, warping wood, and deterioration of artwork, putting valuable items like carpets and curtains at risk in residential spaces and causing inventory, artwork, and other materials that are susceptible to sunlight to deteriorate in commercial settings. Solar window glazing helps block a significant percentage of UV rays, protecting both people and property, especially in homes with valuable furnishings or businesses that deal with sensitive goods. Reducing UV radiation indoors also lowers the risk of skin cancer and helps prevent premature ageing, ensuring both health and property are safeguarded.

Environmental impact

In addition to offering economical advantages, solar window glazing promotes environmental sustainability. Buildings with solar window glass use less electricity because their heating and cooling systems require less energy, which lowers the carbon footprint overall. By reducing energy usage, less non-renewable energy is used, which lowers carbon emissions. Solar window glazing is a great option for people who want to earn sustainability certifications like LEED (Leadership in Energy and Environmental Design) because it also promotes green construction projects. Solar window glazing is the ideal option for people who want to lessen their environmental effect while simultaneously taking advantage of energy savings because of its energy-efficient qualities, which are in line with green building regulations.

Privacy and security

Solar window glazing increases security and privacy for homes and businesses. Reflective coatings increase privacy without compromising natural light by giving the exterior a mirror-like appearance that makes it harder for outsiders to look inside. Additionally, by increasing windows’ resistance to impact, solar window glazing can improve security. Some varieties of solar glazing are made to last longer, providing an additional degree of security against accidents and break-ins. For property owners wishing to improve the usability and security of their areas, this privacy and security combination is a huge benefit.

Enhanced comfort

Solar window glazing regulates the amount of heat and sunlight that enters a place, improving indoor comfort. This is especially advantageous for places that receive direct sunlight all day long or extremely high or low temperatures. Solar window glazing makes homes and workplaces more comfortable by lowering the glare that sunshine causes. Glare can interfere with everyday tasks including computer work, TV watching, and reading. By dispersing sunshine, solar window glazing avoids discomfort. Furthermore, unlike ordinary windows that could result in hot spots or cold drafts, solar window glazing guarantees a constant internal temperature. This consistency helps create a cozy living or working environment. Reduced glare and better temperature control have a direct effect on worker productivity in commercial environments, making the workplace more comfortable.

Aesthetic and value enhancement

Buildings with solar window glass are more aesthetically pleasing and useful. Property owners can select the style that best complements the appearance of their building, thanks to the wide range of finishes available, which include clear, tinted and reflective alternatives. Reflective glazing gives windows a sleek, contemporary appearance, while tinted windows offer a sophisticated, muted appearance. This can enhance curb appeal in residential areas and provide a more appealing and modern feel in business settings. Additionally, adding solar window glass can raise the value of a property when it comes time to sell. When it comes time to sell or lease their property, owners can take advantage of a better market value as energy-efficient buildings and residences gain popularity.

There are numerous advantages to solar window glazing for both commercial and residential settings. The benefits of this cutting-edge technology are numerous. Solar window glazing offers both immediate and long-term benefits that make it a wise decision for enhancing the comfort and efficiency of your building, no matter whether it is a residential property or a commercial one. You can rely on Southmen for superior solar window glazing in Jayanagar to improve your space’s sustainability, comfort, and energy efficiency. For both residential and commercial premises, Southmen provides professional installation and high-quality solar window glazing solutions, guaranteeing improved energy efficiency, UV protection, and visual appeal. Southmen’s dedication to quality and client satisfaction makes them the best option for sustainable building solutions.

Resource: Read more

0 notes

Text

What are pre-engineered buildings? What are their functions?

Pre-engineered buildings (PEBs) are structures made from prefabricated components that are designed, manufactured, and assembled in a factory, then transported to the construction site for final assembly. These buildings offer numerous advantages and serve various functions:

Key Functions of Pre-Engineered Buildings:

Versatility: PEBs can be used across a broad spectrum of applications, from warehouses and industrial facilities to commercial spaces, sports arenas, and even residential buildings.

Efficiency: The manufacturing process of PEB components is highly automated, which allows for precise planning. Parts are pre-cut, pre-welded, and pre-painted, reducing on-site labor and time. Additionally, the lack of curing periods speeds up the construction process compared to conventional methods.

Design Flexibility: The design process for PEBs is streamlined with specialized software, allowing for efficient and accurate planning. The use of built-up members in the primary load-bearing structure allows for tailored solutions, such as tapered beams and columns, to meet specific design and functional needs. This results in highly optimized and customizable structures, often surpassing traditional buildings in efficiency.

Cost Effectiveness: The optimized design, combined with the automated manufacturing process, reduces waste and construction time, which leads to significant cost savings compared to traditional building methods.

Durability: PEBs are built to last, often using materials like steel or aluminum that are resistant to environmental factors. With proper maintenance, these buildings offer long-term durability and minimal upkeep.

Sustainability: Many PEB components are recyclable, and the design process can incorporate energy-efficient features such as skylights and ventilation systems. Additionally, the reduced waste during construction further supports the sustainability of PEBs.

Components of Pre-Engineered Buildings:

Primary Frames: These structural elements provide overall stability and support the entire framework of the building, ensuring stability in the transverse direction.

Secondary Members: Positioned on the roof and walls, these members support the sheeting panels and framed openings.

Sheeting Panels and Accessories: The panels, which may be single or double-skin with insulation, are supported by secondary members. These also accommodate accessories such as skylights, roof vents, louvers, gutters, and downspouts.

Bracing: Bracings provide stability in the longitudinal direction, reinforcing the overall structural integrity.

Connections and Anchor Bolts: Depending on the design, the connections between components may be fixed or pinned.

Pre-engineered buildings offer an efficient, cost-effective, and adaptable solution for a wide range of construction needs, balancing speed, economy, and flexibility.

0 notes

Text

15 Most Underrated Skills That'll Make You A Rockstar In The Roofers Industry

Benefits of shingle roofing versus metal roofing in Wilmington NC - Aesthetic Appeal in Residential Settings.

Wilmington, NC homeowners often prefer shingle roofing not only for its traditional aesthetic but also due to the wide variety of styles and colors available. Shingles are often designed to look like higher-end materials such as slate or cedar shakes. This gives them an upscale appearance without the price tag. Shingle roofs are a great choice for residential areas that place a high priority on aesthetics. Metal roofing, while versatile in design, tends to lend itself more to modern or industrial looks which may not fit as well within certain residential landscapes.

5 Bad Habits That People In The Abc Roofing Industry Need To Quit

Installing and Repairing Your Appliances at a Cost-Effective Price

Installing shingle roofs is typically cheaper than installing metal roofs. Because shingles are cheaper, and many roofers have experience with shingle installations, labor costs are also lower. This cost-effectiveness also extends to repairs. Finding a contractor who is skilled in repairing shingles can be easier and less expensive than specialized metal repair. For homeowners in Wilmington mindful of their budget both at initial installation and over the life of the roof, this can be a significant advantage.

Insulation and Energy Efficiency

While metal roofing excels at reflecting solar heat metal roofing companies away from a home, thereby reducing cooling costs in hot climates like Wilmington's summers, it's important to note the insulation benefits of shingle roofing. Shingles are a little more insulating, which can help keep homes warm during cooler months. However, technological advancements such as reflective coatings on metal roofs have narrowed this gap significantly.

Will Monarch Roofing Wilmington Ever Rule The World?

Noise Considerations

Metal roofing has sometimes been criticized for being noisier during rainstorms or hail when compared to its shingle counterparts. It is possible to reduce the noise level by using proper insulation and designing attic spaces, but it will require extra considerations during installation. If you value quietness in bad weather, you might choose shingles because of their sound dampening properties.

Durability and Longevity

To put it short, while both types of roofing materials offer durability against Wilmington's coastal weather patterns--resisting wind, rain, and even salty air--metal roofs generally boast longer lifespans than asphalt shingles. Metal roofs can last up to 50 years with the right maintenance, compared to asphalt shingles' average lifespan of 20 years. This increased longevity comes with an upfront price premium that may not be justified by every homeowner based on their property plans.

10 Best Facebook Pages Of All Time About Roofing Company Wilmington Nc

This means that homeowners in Wilmington NC must weigh the initial costs against the potential savings over time when choosing between metal or shingle roofs. Roofing contractors versed in both materials can provide valuable insight tailored to specific homes' needs taking into account local climate conditions, house style preferences, noise sensitivity concerns, energy efficiency requirements as well as financial considerations.

Historical facts about roofer

Roofers are skilled workers who specialize in the installation, repair and construction of roofs. Roofers can use a wide range of materials, from traditional shingles to modern single-ply membranes and even eco-friendly green roofs. The history of roofing is as old as human structures themselves, with evidence of roofing going back thousands of years.

Roofing has always been a vital part of construction, as it protects against the elements. Early humans used natural materials like leaves, straw and animal skins as coverings for their homes. As civilizations developed, so did roofing techniques and materials.

In ancient Mesopotamia, one of the earliest known waterproof roofing materials was bitumen--a natural tar-like substance--used to seal terraces and baths against water leakage. Clay tiles were used in ancient Greek and Roman architectures because of their durability and ease-of-production.

During the Middle Ages in Europe, thatched roofs made from bundles of reeds or straw were common among rural populations because these materials were readily available. Fire hazards forced urban areas to use clay tiles similar to the ones used by Romans.

Slate was a popular roofing product during the Industrial Revolution because of its durability and fire-resistance. It was during this time that metal also began being used for roofing because it is lightweight and resistant to severe weather conditions.

The profession of a roofer has evolved over centuries from simple methods to sophisticated techniques involving advanced materials science. In medieval times, roof building was usually done by carpenters. This changed when specialization began to occur within the building trades.

With industrialization came changes in work safety regulations. Roofers are considered hazardous in many countries, including the United States. This is due to the risks of falling from heights and being exposed to extreme weather conditions.

Modern roofers must be knowledgeable about different types of roofing systems (e.g., pitched vs. flat), various materials (from asphalt shingles to solar tiles), local building codes, safety regulations, sustainable practices like rainwater harvesting systems on vegetative roofs, etc.

Training for roofers often involves apprenticeships where they learn both theoretical knowledge about construction principles along with practical skills like measuring angles or cutting materials precisely according to project specifications.

Roofers are increasingly using green technologies, such as photovoltaics or rooftop gardens. These not only have ecological benefits, but can also save energy for property owners.

The future outlook for roofers suggests moderate growth in employment opportunities primarily driven by the need for repairs on aging infrastructures as well as new installations that meet contemporary energy efficiency standards or aesthetic designs preferred by homeowners or commercial clients seeking unique architectural features.

youtube

0 notes

Text

What materials are used in Christian Blankets, and are they comfortable?

Christian blankets are a popular way to express faith and provide warmth and comfort. They come in a variety of materials, each with its own unique benefits. Popular Materials for Christian Blankets Here are some of the most common materials used in Christian blankets: Flannel: Flannel is a soft, warm, and comfortable fabric that is often used for blankets. It is made from cotton or wool that has been brushed to create a fuzzy surface.Flannel is a good choice for people who want a blanket that is both cozy and durable. Microfiber: Microfiber is a synthetic fabric that is known for its softness and durability. It is also very lightweight and breathable, making it a good choice for people who live in warm climates. Microfiber blankets are often used for their ability to resist wrinkles and fading. Polyester: Polyester is another synthetic fabric that is often used in blankets. It is a very durable fabric that is resistant to wrinkles and fading. Polyester blankets are also very easy to care for and can be machine washed and dried. Cotton: Cotton is a natural fiber that is known for its softness and breathability. It is also hypoallergenic, making it a good choice for people with sensitive skin. However, cotton can be prone to wrinkles and shrinkage, so it is important to choose a high-quality cotton blanket. Wool: Wool is a natural fiber that is known for its warmth and durability. It is also a good insulator, which means it can help to keep you warm even in cold weather. Wool blankets are often used for their ability to absorb moisture and regulate temperature. Fleece: Fleece is a synthetic fabric that is known for its softness and warmth. It is also very lightweight and breathable, making it a good choice for people who want a blanket that is both cozy and easy to care for. Fleece blankets are often used for their ability to resist pilling and shrinking. Comfort and Quality The comfort of a Christian blanket is largely dependent on the material used, the weight of the blanket, and the overall construction. When choosing a Christian blanket, it is important to consider your personal preferences. Weight: Christian blankets come in a variety of weights, from lightweight to heavy. The weight of the blanket will affect its warmth and how comfortable it feels. Lighter blankets are typically more comfortable for warmer climates, while heavier blankets are better suited for colder climates. Construction: The construction of a Christian blanket will also affect its comfort. Some blankets are made with a single layer of fabric, while others are made with multiple layers. Multi-layered blankets are often warmer and more comfortable than single-layer blankets. Christian Blanket Designs Christian blankets often feature religious designs or imagery. Some popular designs include: Crosses: Crosses are a common symbol of Christianity and are often featured on Christian blankets. Bible verses: Many Christian blankets feature Bible verses, such as the Lord's Prayer or verses about hope and faith. Angels: Angels are another common symbol of Christianity and are often featured on Christian blankets. Floral patterns: Floral patterns are often used to represent the beauty and wonder of God's creation. Choosing the Right Christian Blanket Here are some tips for choosing the right Christian blanket for your needs: Consider your personal preferences. What kind of fabric do you prefer? What weight of blanket is best for you? Think about the purpose of the blanket. Will you be using it for warmth, comfort, or decoration? Choose a blanket that is made from quality materials. This will help to ensure that the blanket is durable and comfortable. Look for a blanket with a design that you love. There are many different designs available, so you're sure to find one that speaks to you. Ultimately, the best Christian blanket is the one that you find most comfortable and meaningful. https://lowpricetee.com/collections/christian-blankets/

1 note

·

View note

Text

Customization Options for Fire Rated Roller Shutters

When it comes to fire rated roller shutters, there are numerous customization options available to ensure they meet the specific needs and requirements of your building. From size and material to color and finish, fire shutters can be tailored to suit your unique preferences while prioritizing safety and compliance. Let's explore some of the key customization options for fire rated roller shutters:

Size and Dimensions

Fire rated roller shutters are available in a wide range of sizes to accommodate various openings. Whether you need a compact shutter for a smaller space or a large industrial shutter spanning up to 12 meters wide, there are options to suit your requirements. The maximum height can reach 8000 mm, with a maximum area of 96 square meters.

Material and Finish

Fire rated roller shutters are typically constructed from high-quality, fire-resistant materials such as steel. Single skin shutters use 76mm curved steel for an affordable, straightforward fire protection solution. Twin skin shutters offer superior fire and sound insulation, reducing radiant heat transfer and providing 20dB sound reduction.The material finish can also be customized to match your building's aesthetics. Standard options include galvanized steel for the box, guides, and bottom rail. Powder coating is available in any BS or RAL color to suit your preferences.

Insulation and Thermal Properties

For areas like kitchens that are adjacent to spaces requiring a cooler environment, such as meeting rooms or exhibition spaces, twin skin roller shutters offer an ideal solution. These shutters provide exceptional fire protection while also offering thermal insulation to prevent heat transfer.

Automation and Control Options

Fire rated roller shutters are designed to automatically close in the event of a fire, either through a fusible link that melts at 67°C or direct integration with a fire alarm system. This ensures prompt closure to contain the spread of fire and smoke.Various control options are available to enhance safety and convenience, such as audio-visual panels, emergency release switches, and single or three-phase inline industrial motors for seamless operation.

Compliance and Certification

It's crucial to ensure that your fire rated roller shutters comply with the relevant legislation and certification standards. As of November 2019, all new fire shutters in the UK must be CE marked and comply with BS EN 16034, replacing the previous BS 476 part 22 (1987) standard.Look for shutters that have been independently tested and certified by a notified body, such as Exova, to ensure they meet the required fire resistance levels and structural integrity.By considering these customization options, you can select fire rated roller shutters that not only provide reliable fire protection but also complement your building's design and meet your specific requirements. Remember, investing in high-quality, customized fire shutters is an essential step in ensuring the safety of your property and occupants.

0 notes

Text

She pressed her back against the tunnel wall, hands flat on the rough rock, and thought. That’s where they’d gone, then. It made no difference, but she closed her eyes to improve her concentration and summoned up the pages of the massive binder—presently on the seat of the vanished truck—that contained the structural and engineering details of all the hydroelectric stations under her purview.She’d looked at the diagrams for this one last night and again, hastily, while brushing her teeth this morning. The tunnel led to the dam, and had obviously been used in the construction of the lower levels of that dam. How low? If the tunnel joined at the level of the turbine chamber itself, it would have been walled off. But if it joined at the level of the servicing chamber above—a huge room equipped with the multi-ton ceiling cranes needed to lift the turbines from their nests—then there would still be a door; there would have been no need to seal it off, with no water on the other side.Try as she might, she couldn’t bring the diagrams to mind in sufficient detail to be sure there was an opening into the dam at the far end of the tunnel—but it would be simple enough to find out.

SHE’D SEEN THE TRAIN, in that brief moment before the doors closed; it didn’t take much fumbling round to get into the open cab of the tiny engine. Now, had those clowns taken the key to the engine, too? Ha. There was no key; it worked by a switch on the console. She flipped it, and a red button glowed with sudden triumph as she felt the hum of electricity run through the track beneath.The train couldn’t have been simpler to run. It had a single lever, which you pushed forward or back, depending on which direction you meant to go. She shoved it gently forward, and felt air move past her face as the train moved silently off into the bowels of the earth.She had to go slowly. The tiny red button shed a comforting glow over her hands, but did nothing to pierce the darkness ahead, and she had no idea where or how much the track curved. Neither did she want to hit the end of the track at a high rate of speed and derail the engine. It felt as though she was inching through the dark, but it was much better than walking, feeling her way over a mile of tunnel lined with high-voltage cables.It hit her in the dark.

For a split second, she thought someone had laid a live cable on the track. In the next instant, a sound that wasn’t a sound thrummed through her, plucking every nerve in her body, making her vision go white. And then her hand brushed rock and she realized that she had fallen across the console, was hanging halfway out of the tiny, trundling engine, was about to fall out into darkness.Head spinning, she managed to grab the edge of the console and pull herself back into the cab. Flipped the switch with one shaking hand and half-fell to the floor, where she curled up, gripping her knees, her breath a whimpering in the dark.

“Holy God,” she whispered. “Oh, Blessed Mother. Oh, Jesus.”

She could feel it out there. Still feel it. It didn’t make a sound now, but she felt its nearness and couldn’t stop trembling.She sat still for a long time, head on her knees, until rational thought began to come back.She couldn’t be mistaken. She’d passed through time twice, and knew the feeling. But this hadn’t been nearly so shocking. Her skin still prickled and her nerves jumped and her inner ears rang as though she’d thrust her head into a hive of hornets—but she felt solid. She felt as though a red-hot wire had sliced her in two, but she hadn’t had the horrible sense of being disassembled, turned physically inside out.

A terrible thought sent her surging to her feet, clinging to the console.

Had she jumped? Was she somewhere—somewhen—else?

But the metal console was cool and solid under her hands, the smell of damp rock and cable insulation unchanged.“No,” she whispered, and flicked the power light for reassurance. It came on, and the train, still in gear, gave a sudden lurch. Hastily, she throttled back the speed to less than a crawl.She couldn’t have jumped into the past.

Small objects in direct contact with a traveler’s person seemed to move with them, but an entire train and its track was surely pushing it. “Besides,” she said out loud, “if you’d gone more than twenty-five years or so into the past, the tunnel wouldn’t be here. You’d be inside… solid rock.” Her gorge rose suddenly, and she threw up.The sense of… it… was receding, though. It—whatever it was—was behind her. Well, that settled it, she thought, wiping her mouth with the back of her hand. There bloody well had to be a door at the far end, because there was no way she was going back the way she’d come.

There was a door. A plain, ordinary, industrial metal door. And a padlock, unlocked, hanging from an open hasp. She could smell WD-40; someone had oiled the hinges, very recently, and the door swung open easily when she turned the knob. She felt suddenly like Alice, after falling down the White Rabbit’s hole. A really mad Alice.A steep flight of steps lay on the other side of the door, dimly lit—and at the top was another metal door, edged with light. She could hear the rumble and the metallic whine of a ceiling crane in operation.Her breath was coming fast, and not from the effort of climbing the stairs. What would she find on the other side? It was the servicing chamber inside the dam; she knew that much. But would she find Thursday on the other side? The same Thursday she’d had when the tunnel doors had closed behind her?She gritted her teeth and opened the door. Rob Cameron was waiting, lounging back against the wall, lit cigarette in hand. He broke into an enormous grin at sight of her, dropped the butt, and stepped on it.

“Knew ye’d make it, hen,” he said. Across the room, Andy and Craig turned from their work and applauded.“Buy ye a pint after work, then, lass,” Andy called.“Two!” shouted Craig.She could still taste bile at the back of her throat. She gave Rob Cameron the sort of look she’d given Mr. Campbell.

“Don’t,” she said evenly, “call me hen.”

His good-looking face twitched and he tugged at his forelock with mock subservience.“Anything you say, boss,” he said.

Tunnel Tigers ~ An Echo in the Bone

#outlander#outlanderedit#the frasers#outlander starz#outlander series#outlander fanart#outlander books#outlander book#outlander season 7#outlander 7x05#sophie skelton#brianna mackenzie#brianna fraser

22 notes

·

View notes

Text

Optimizing Energy Efficiency in Power Transformers: Techniques and Technologies

Power transformers are essential components of the electrical grid, responsible for stepping up or stepping down voltage levels to facilitate the efficient transmission and distribution of electricity. Given their critical role, optimizing the energy efficiency of power transformer is not only important for reducing operational costs but also for minimizing energy losses and improving the overall sustainability of the power grid. This article explores the key techniques and technologies that are being employed to enhance the energy efficiency of power transformers.

The Importance of Energy Efficiency in Power Transformers

Power transformers operate continuously, and even small improvements in their efficiency can lead to significant energy savings over time. Inefficient transformers contribute to energy losses in the form of heat, which not only wastes electricity but also requires additional cooling, further increasing energy consumption. Therefore, enhancing the efficiency of power transformers is crucial for both economic and environmental reasons. It reduces operating costs for utilities and industries while also helping to lower carbon emissions associated with electricity generation.

Key Techniques for Enhancing Transformer Efficiency

Use of High-Efficiency Core Materials

The core of a power transformer is one of the primary areas where energy losses occur, particularly through hysteresis and eddy currents. Traditional transformers use silicon steel as the core material, which, while effective, has inherent limitations in terms of energy losses. To overcome this, modern transformers are increasingly using high-efficiency core materials such as amorphous steel.

Amorphous steel, also known as metallic glass, has a disordered atomic structure that significantly reduces hysteresis losses compared to conventional silicon steel. This material also exhibits lower eddy current losses due to its higher electrical resistance. By incorporating amorphous steel into transformer cores, manufacturers can achieve substantial reductions in core losses, leading to higher overall efficiency.

Advanced Core Design

In addition to using high-efficiency materials, optimizing the design of the transformer core itself can further enhance efficiency. Modern transformers are often designed with a stepped-lap core construction, which minimizes air gaps and reduces magnetic flux leakage. This design approach helps to concentrate the magnetic field within the core, reducing energy losses and improving the transformer's efficiency.

Another innovative design technique is the use of distributed gap cores, where small gaps are evenly distributed throughout the core rather than concentrated in a single location. This design reduces the intensity of the magnetic field at any one point, which in turn reduces core losses.

Improved Winding Techniques

The windings in a power transformer are another area where energy losses can occur, primarily through resistive heating (I²R losses). To minimize these losses, manufacturers are employing advanced winding techniques and materials.

One such technique is the use of continuously transposed conductors (CTC) in transformer windings. CTC consists of multiple insulated strands of copper or aluminum that are transposed at regular intervals. This configuration reduces the skin effect and proximity effect, which are responsible for increasing resistive losses in conventional windings. By using CTC, transformers can achieve lower resistive losses and higher energy efficiency.

Optimized Cooling Systems

Effective cooling is essential for maintaining transformer efficiency, as excessive heat can lead to higher losses and reduce the lifespan of the transformer. Traditional cooling systems rely on natural or forced air and oil circulation, but modern transformers are incorporating more advanced cooling technologies to enhance efficiency.

One such technology is directed oil flow, where the cooling oil is precisely directed to the areas of the transformer that generate the most heat, such as the windings and core. This targeted cooling approach ensures that these critical components remain at optimal temperatures, reducing the risk of overheating and improving the transformer's efficiency.

Another innovative cooling method is the use of synthetic ester fluids, which have better thermal properties and higher fire points compared to traditional mineral oils. These fluids not only improve cooling efficiency but also enhance the safety and environmental performance of the transformer.

Smart Monitoring and Control Technologies

In addition to physical design and materials improvements, the integration of smart monitoring and control technologies is playing an increasingly important role in optimizing transformer efficiency.

Real-Time Monitoring

Sensors embedded in modern transformers can continuously monitor key parameters such as temperature, load levels, and insulation health. By collecting and analyzing this data in real-time, operators can identify potential inefficiencies or issues before they lead to significant energy losses or failures. This proactive approach allows for more efficient operation and maintenance, ensuring that transformers run at optimal efficiency throughout their lifespan.

Predictive Maintenance

Predictive maintenance technologies use advanced analytics and machine learning algorithms to predict when a transformer is likely to experience a fault or efficiency drop. By anticipating these issues, operators can perform maintenance at the most effective times, avoiding unnecessary energy losses and extending the operational life of the transformer.

Conclusion

Optimizing energy efficiency in power transformers is crucial for reducing operational costs, minimizing energy losses, and contributing to a more sustainable power grid. Through the use of high-efficiency core materials, advanced design techniques, improved winding methods, optimized cooling systems, and smart monitoring technologies, manufacturers and operators can significantly enhance the efficiency of power transformers. As the demand for electricity continues to grow and environmental concerns intensify, these innovations will play a key role in ensuring that power transformers remain efficient, reliable, and environmentally friendly components of the global energy infrastructure.

0 notes

Text

Understanding PIR Panels | For Your Home

Sandwich panels are unique thermal components that are primarily used for walls and roofs; these are made of two thin metal sheets and one thick core material. These core materials play an important role in the properties of the panels; types include PIR/PUR, EPS, Rockwool, Glass, Wool, Hollow glass magnesium, among others. Let us try and decode the ones that are most commonly known and used, i.e. PIR panels, EPS wall panels, rock wool and glass wool.

PIR Panels

PIR sandwich panels are regarded to be the best when it comes to insulation material and can be used under varied joint applications depending on how or where you want to use them. Their general characteristics include optimal fire resistance, insulation, extensive strength, waterproofing propensity, and easy installation features.

EPS Wall Panels

EPS sandwich panels are well known for their lightweight design, easy installation, and especially for their competitive pricing range. These can be found in concealed and overlap joint ways depending on whether or not you want the screws to be visible upon installation or not.

Others:

Rockwool panels:

These panels are known for their optimal fireproof material, along with the propensity of exhibiting soundproof performance. They also display immense strength, insulation, waterproofing and are made out of pure material.

Glass Wool panels:

Panels with this core material are lightweight, fire-resistant and soundproof as well. However, this is not the ideal option for those with regard to the environment since they are not made of eco-friendly materials.

Which Is The Right Fit For You?

In order to decide which of the panels are the right choice for your insulation requirements, based on their core materials, let us understand key features and the application of each of these. This will help make decision making easier.

EPS wall panels are lightweight budget solutions and are ideally used to make temporary buildings, steel sheds, container houses, mobile homes, or partition walls.

PIR panels are the ideal thermal material partnered with high tensile strength; these are most frequently used in the curation of cold areas, cold storage projects, and buildings that require increased insulation propensity. Food preserve areas, meat storage units, and other refrigeration projects fall under the purview of these panels.

When it comes to rock wool and glass wool, these are most commonly optimised at commercial or civil structures that require high fire resistance and noise proofing features.

Reasons To Use Sandwich Panels:

uction process also doesn't demand any wet processes or fixed and controlled approximate humidity levels.

If one were to compare these to single skin panels or traditional walls or roofs, the time of construction optimised by these panels is negligible. Further, there is no waiting time between construction for the structure shell to lose any excess moisture.

The pointers, as mentioned above, throw light on the various types of insulated sandwich panels along with their respective characteristics and features; consider these and make the optimal choice to meet your construction requirements suitably.

0 notes

Text

From Classic to Cutting-Edge: The Evolution of Water Bottles

Introduction:

Water bottles have been used for centuries to carry water for drinking and other purposes. They were originally made from animal skins, gourds, and clay. Over time, they evolved to include glass, metal, and now plastic. Plastic bottles are the most common today, but there's growing concern about their environmental impact, leading to a resurgence of reusable bottles made from sustainable materials.

Types of Water Bottles.

Thermosteel: These bottles have a double-walled stainless steel construction with a vacuum between the layers, providing excellent insulation for hot or cold liquids.

Unisteel: Similar to thermosteel, unisteel bottles also use stainless steel but may have a single-wall construction or a different vacuum insulation method.

Benefits of Water Bottles:

Stay Hydrated: Water bottles help you remember to drink water throughout the day, keeping you hydrated.

Save Money: Using reusable water bottles can save you money by avoiding buying bottled water.

Reduce Waste: Reusable water bottles help reduce plastic waste from single-use bottles.

Good for the Environment: Using reusable bottles helps protect the environment by reducing pollution.

Convenient: Water bottles are easy to carry and use, making it convenient to stay hydrated on the go.

Uses of Water Bottles.

Camping and Hiking:

Imagine you're on a camping trip in the mountains. It's a cold morning, and you're craving a warm cup of coffee. Your thermosteel water bottle is the perfect solution. You pour in your hot coffee, seal it, and by the time you reach your campsite, your coffee is still steaming hot.

Similarly, on a hot summer hike, you want to stay hydrated. You fill your thermos-teel water bottle with ice-cold water. Even after hours of hiking under the scorching sun, your water remains refreshingly cold.

So, thermosteel water bottles are ideal for outdoor activities like camping and hiking because they can keep your drinks at the desired temperature for extended periods, making your adventure more enjoyable.

Work:

Imagine you're sitting at your desk, ready to start your workday. You pour a fresh cup of coffee into your thermo-steel water bottle. As you work throughout the morning, your coffee stays hot and flavorful.

During the afternoon, you might switch to cold water for hydration. Your thermosteel water bottle keeps your water chilled, providing a refreshing drink even on the hottest days.

So, thermosteel water bottles are great for work because they help you maintain the desired temperature of your drinks, whether it's hot coffee or cold water, throughout your workday.

School:

Imagine you're a student sitting in class, trying to focus on your studies. Dehydration can make it difficult to concentrate. A thermo-steel water bottle can help you stay hydrated throughout the day.

You can fill it with your favorite drink, whether it's water, juice, or a sports drink. The insulation will keep it at the desired temperature, ensuring you have a refreshing beverage whenever you need it.

So, thermosteel water bottles are a great choice for students because they help you stay hydrated and focused, making it easier to learn and perform well in school.

Picnics:

Imagine you're having a picnic in the park on a sunny day. You've packed sandwiches, snacks, and, of course, drinks. A thermosteel water bottle is essential to keep your beverages at the perfect temperature.

If you're bringing hot tea or coffee, your thermo-steel bottle will keep it warm and cozy throughout the day. If you prefer cold drinks like soda or juice, the insulation will keep them chilled and refreshing.

So, thermosteel water bottles are ideal for picnics because they ensure your drinks stay at the desired temperature, no matter how long your picnic lasts.

The Science Behind Bottle Design and Manufacturing

The design and manufacturing of bottles involve a complex interplay of science, engineering, and materials science. Key factors include:

Materials Science

Material Selection: The choice of material depends on factors like the product's contents, durability, cost, and environmental impact. Common materials include glass, plastic (e.g., PET, HDPE, LDPE), aluminum, and steel.

Material Properties: The material's properties, such as strength, flexibility, and chemical resistance, are crucial for ensuring the bottle's integrity and safety.

Engineering

Structural Design: Engineers calculate the required thickness and shape of the bottle to withstand pressure, impact, and other stresses.

Closure Design: The design of the bottle's cap or lid must ensure a tight seal to prevent leakage and contamination.

Manufacturing Processes: Engineers select appropriate manufacturing methods, such as blow molding, injection molding, or extrusion, based on the material and desired shape.

Science

Fluid Dynamics: Understanding fluid flow helps in designing bottles that minimize turbulence and prevent the buildup of contaminants.

Chemistry: Chemical analysis ensures that the bottle material does not interact with the contents, causing contamination or degradation.

Microbiology: Preventing microbial growth within the bottle is essential for food and beverage safety.

Omichef: Your Affordable Hydration Solution

Omichef offers a range of high-quality water bottles at unbeatable prices. Our bottles are designed to keep your drinks cold or hot for hours, perfect for work, school, or outdoor adventures. With durable materials and stylish designs, Omichef bottles are the perfect choice for anyone looking to stay hydrated without breaking the bank.

Conclusion

Water bottles are essential for staying hydrated and reducing waste. Whether you choose a reusable or single-use option, there's a bottle out there to suit your needs. From durable stainless steel bottles to lightweight plastic bottles, the variety of options is vast.

Omichef is more than just a brand of water bottles. We're committed to providing high-quality, affordable products that enhance your everyday life. From our durable water bottles to our innovative kitchenware like Triply-cookware and Pressure cookers, Omichef offers a range of products designed to make your life easier and more enjoyable. Choose Omichef and experience the difference.

Source: Omichef ( If you want to purchase a designed and premium water bottle at an affordable price. You should try the Omichef brand.)

0 notes

Text

Black Mold on Windows: Causes Removal and Prevention